Successive Grinding and Polishing Effect on the Retained Austenite in the Surface of 42CrMo4 Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results

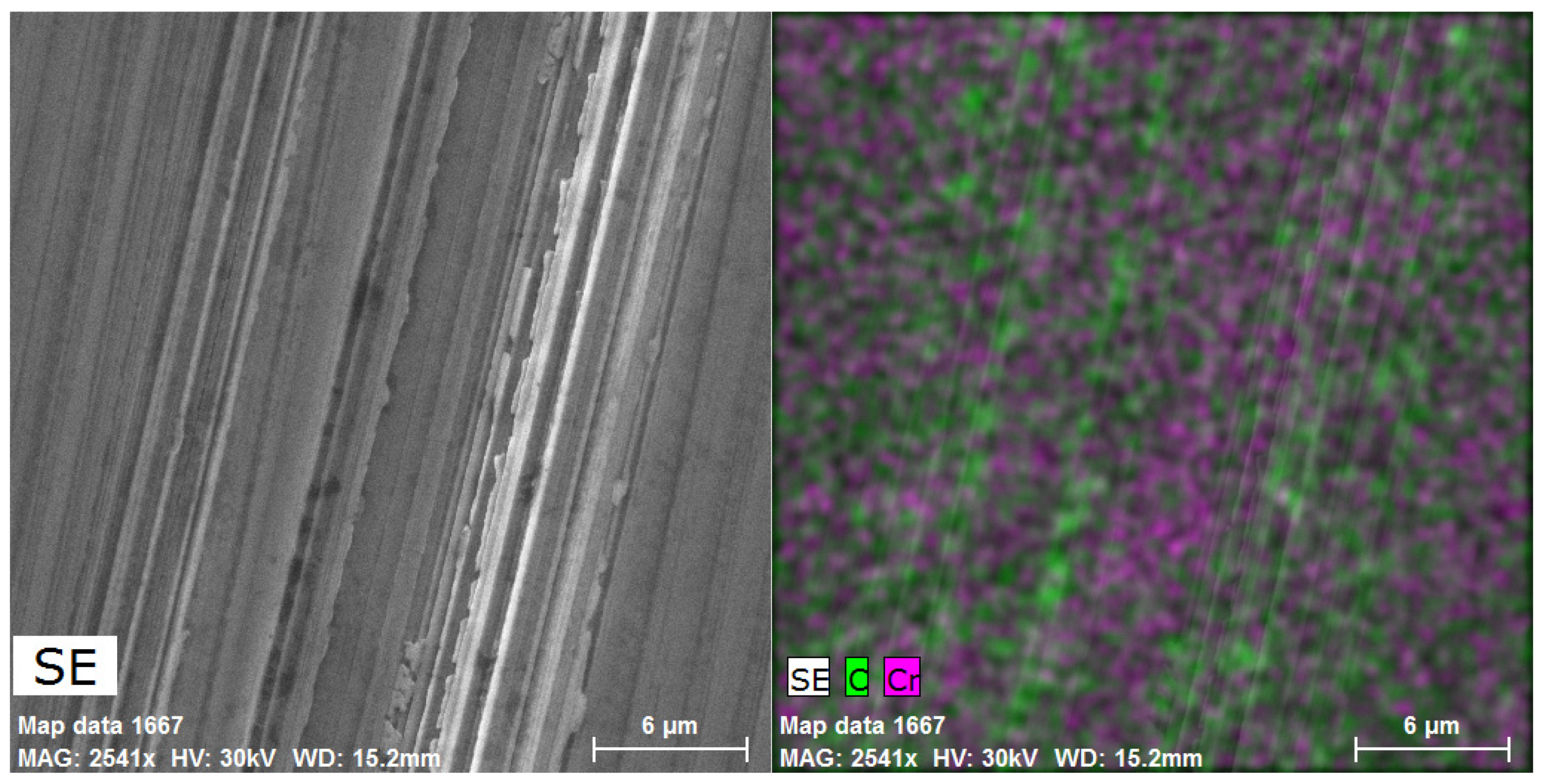

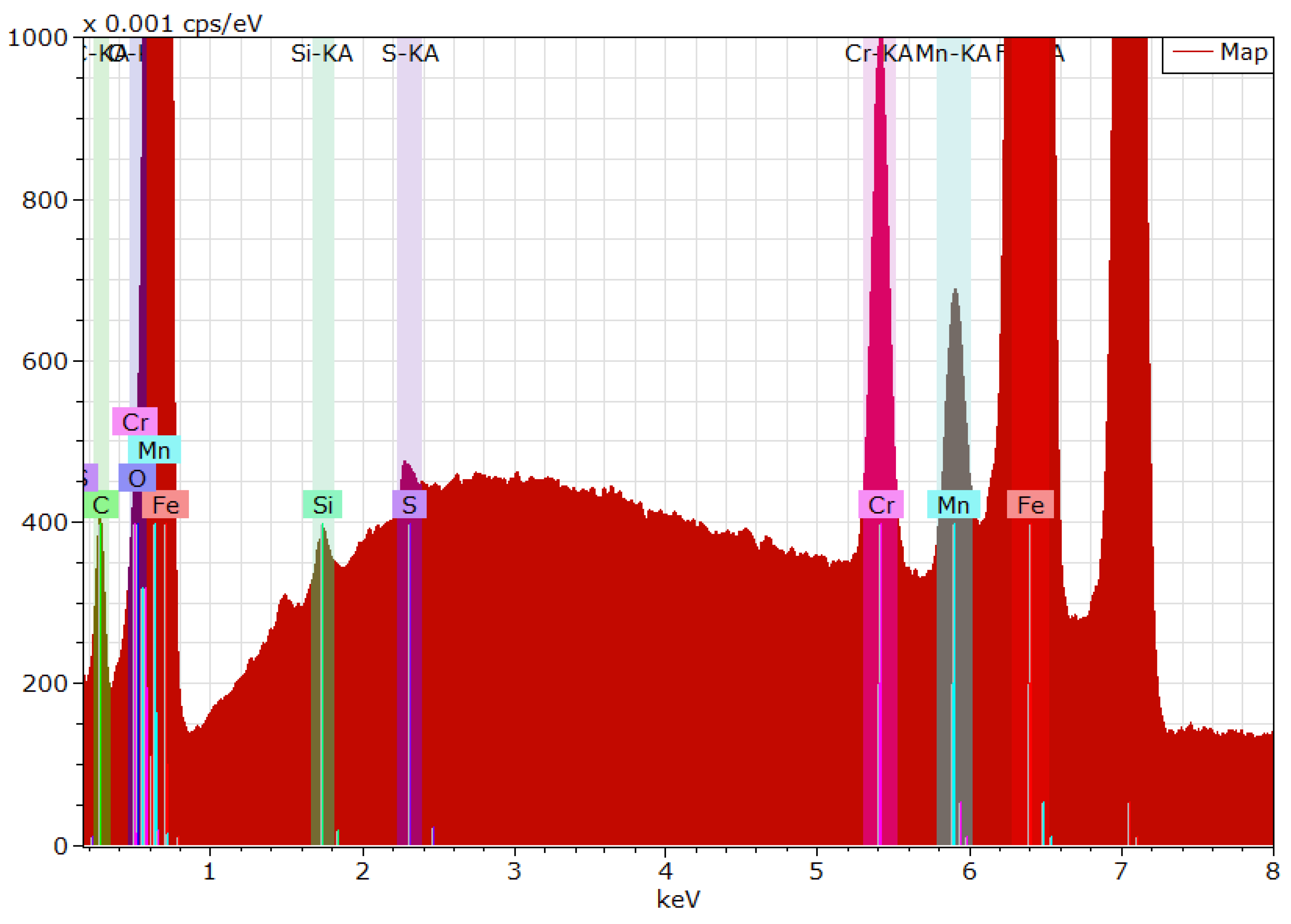

3.1. SEM and EDS Elemental Analysis

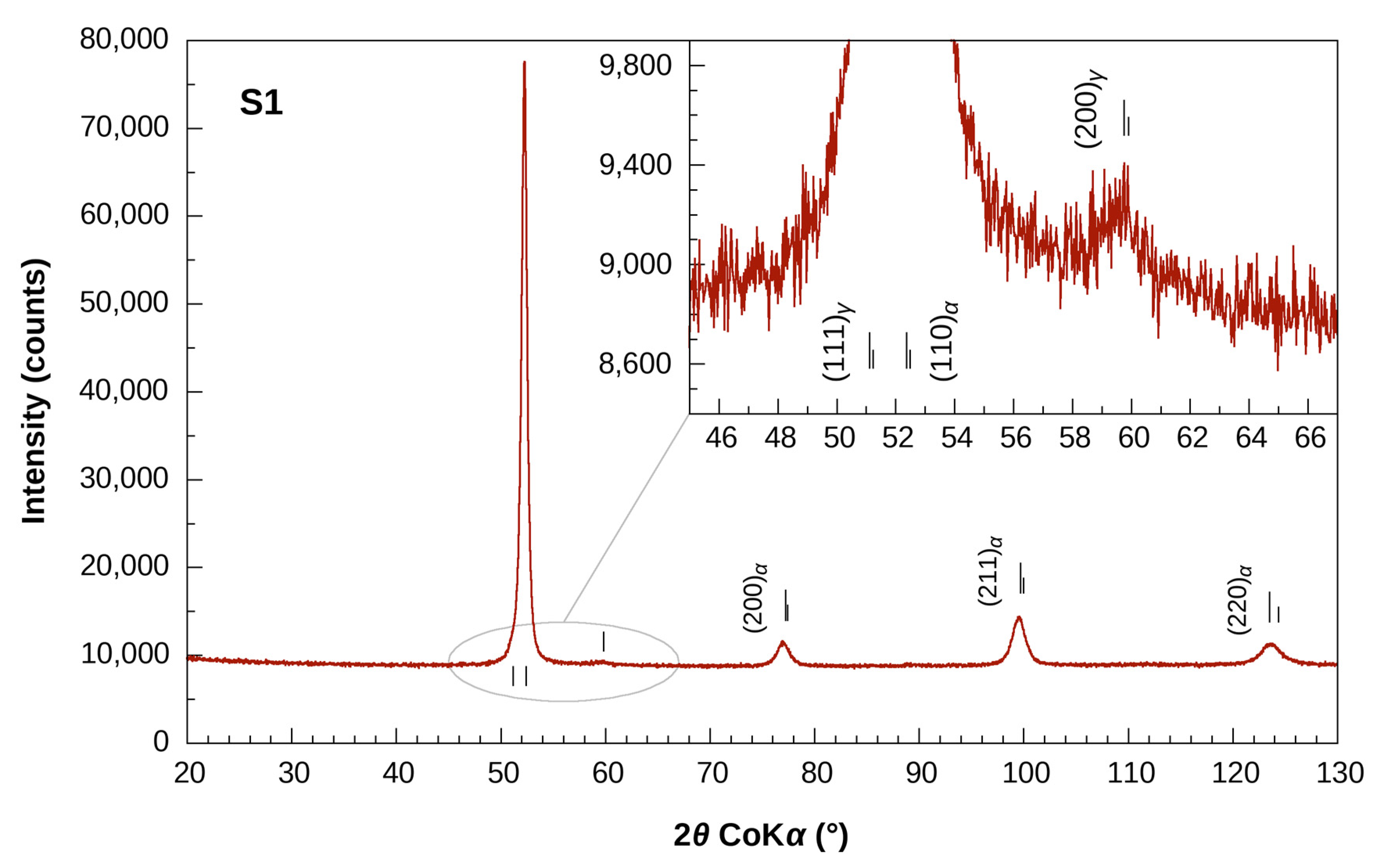

3.2. XRD Analysis

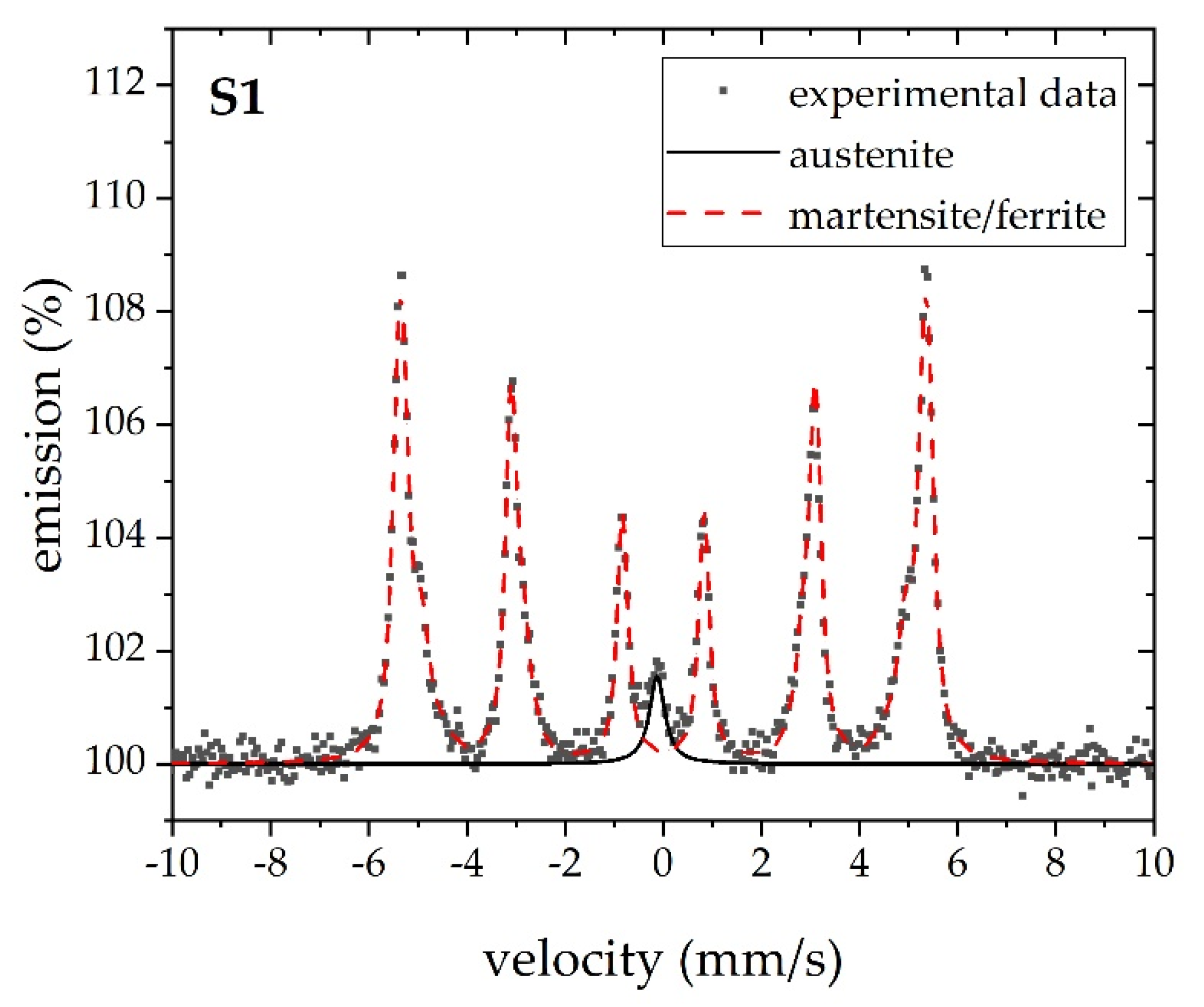

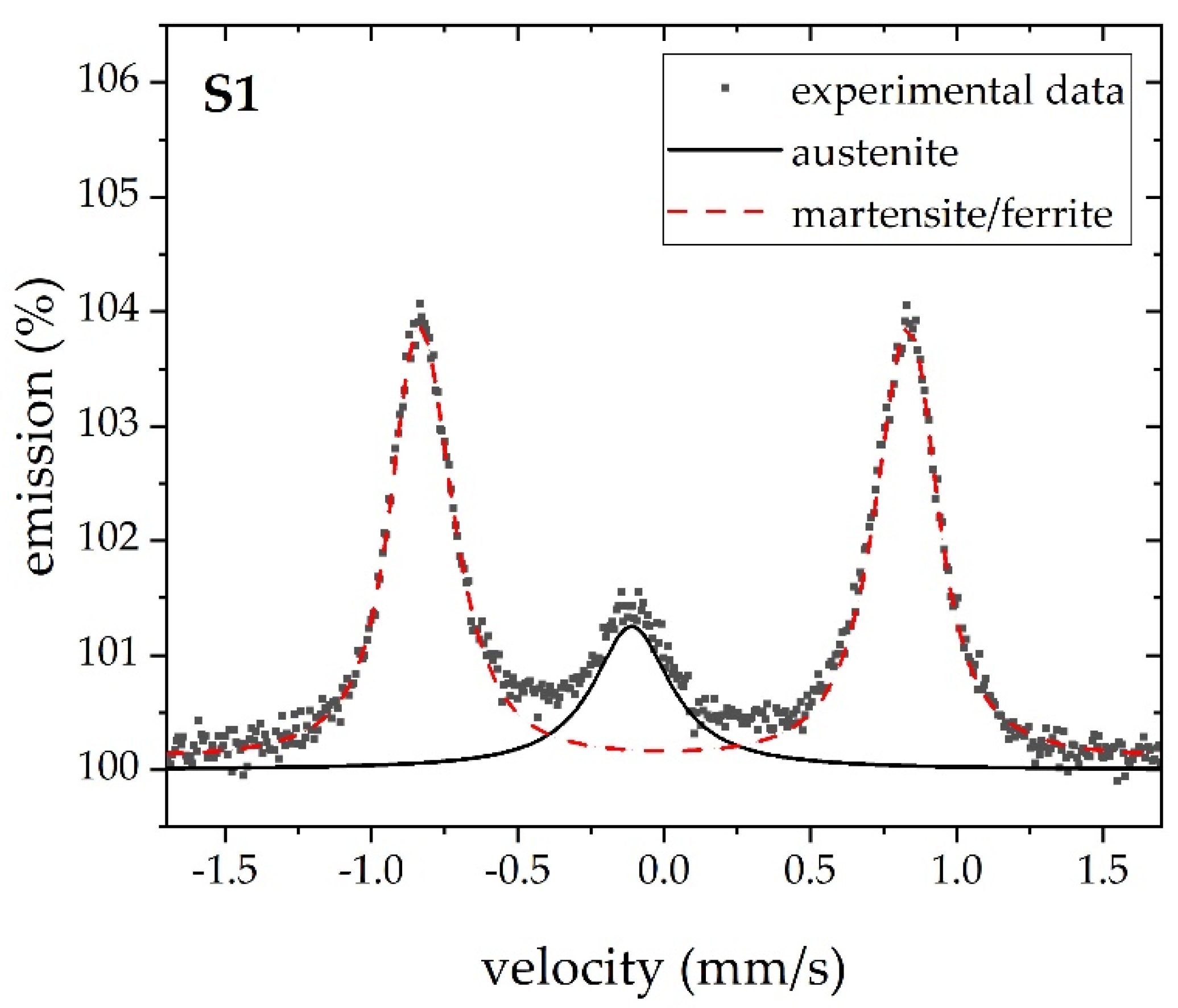

3.3. Conversion X-ray Mössbauer Spectroscopy

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, S.B. Mechanisms of bainite transformation in steels. In Phase Transformations in Steels: Fundamentals and Diffusion-Controlled Transformations, 1st ed.; Pereloma, E., Edmons, D.V., Eds.; Woodhead Publishing: Oxford, UK; Cambridge, UK; Cambridge, UK; Philadelphia, PA, USA; New Delhi, India, 2012; Volume 1, pp. 385–416. [Google Scholar]

- Palombarini, G.; Carbucicchio, M. Materials and surface treatments for tribological applications. Hyperfine Interact 1998, 111, 101–111. [Google Scholar] [CrossRef]

- Kholmetskii, A.L.; Uglov, V.V.; Khodasevich, V.V.; Anishik, V.M.; Ponaryadov, V.V.; Mashlan, M. Application of the Mössbauer effect in some tribological problems. In Mössbauer Spectroscopy in Materials Science, 1st ed.; Miglierini, M., Petridis, D., Eds.; Kluwer Academic Publishers: Dordecht, The Netherlands, 1999; Volume 66, pp. 215–226. [Google Scholar] [CrossRef]

- Yingjie, L.; Xingui, B.; Keqiang, C. A study on the formation of wear debris during abrasion. Tribol. Int. 1985, 18, 107–111. [Google Scholar] [CrossRef]

- Zambrano, A.; Valdés, J.; Rodriguez, L.A.; Reyes, D.; Snoeck, D.; Rodríguez, S.A.; Coronado, J.J. Elucidating the role of κ-carbides in FeMnAlC alloys on abrasion wear. Tribol. Int. 2019, 135, 421–431. [Google Scholar] [CrossRef]

- Changle, Z.; Shouhai, L.; Hanguang, F.; Yinghua, L. Microstructure evolution and wear resistance of high silicon bainitic steel after austempering. J. Mater. Res. Technol. 2020, 9, 4826–4839. [Google Scholar] [CrossRef]

- Schwartzendruber, L.J.; Bennett, L.H.; Schoefer, E.A.; Delong, W.T.; Campbell, H.C. Mössbauer-effect examination of ferrite in stainless steel welds and castings. Weld. Res. Suppl. 1974, 1s–12s. [Google Scholar]

- Wagner, F.E. Applications of Mössbauer scattering techniques. J. De Phys. 1976, 37, C6-673-689. [Google Scholar] [CrossRef]

- Longworth, G. The use of Mössbauer spectroscopy in non-destructive testing. NDT Int. 1977, 10, 241–246. [Google Scholar] [CrossRef]

- Kuzmann, E.; Domonkos, L.; Kocsis, M.; Nagy, S.; Vertes, A.; Mehner, H. Determination of retained austenite in steels alloyed with carbide formers. J. De Phys. 1979, 40, C2-627-629. [Google Scholar] [CrossRef]

- Zemčík, T.; Havlicek, S. Fast Mössbauer austenitometer. In Proceedings of the International Conference on Mössbauer Spectroscopy, Bucharest, Romania, 1st ed.; Barb, D., Tarina, D., Eds.; Central Institute of Physics: Bucharest, Romania, 1977; pp. 405–406. [Google Scholar]

- Pechousek, J.; Kouril, L.; Novak, P.; Kaslik, J.; Navarik, J. Austenitemeter—Spectrometer for rapid determination of residual austenite in steels. Measurement 2019, 131, 671–676. [Google Scholar] [CrossRef]

- Schwartz, L.H. Quantitative Analysis Using Mössbauer Effect Spectroscopy. Int. J. Non-Destr. Test. 1970, 1, 353–359. [Google Scholar]

- Schwartzendruber, L.J.; Bennett, L.H. Retained austenite developed during surface grinding of a carbon steel. Scr. Met. 1972, 6, 737–742. [Google Scholar] [CrossRef]

- Fornal, P.; Stanek, J.; Gawlik, J.; Wantuch, E.; Binczycka, H. Surface modifications of upgraded high-speed tool steel. Hyperfine Interact 1994, 92, 1355–1360. [Google Scholar] [CrossRef]

- Vertes, C.; Vass, G.; Kuzmann, E.; Romhanyi, K.; Lakatos-Varsanyi, M.; Vertes, A. Conversion electron Mössbauer and XPS study on the effect of polishing of a stainless steel sample. J. Radioanal. Nucl. Chem. Lett. 1994, 186, 447–454. [Google Scholar] [CrossRef]

- Jiraskova, Y.; Schneeweiss, O.; Van Hoecket, T.; Segers, D.; Dauwe, C. Investigation of defects and stresses in SiFe steel surfaces. J. Magn. Magn. Mater. 2000, 215–216, 118–120. [Google Scholar] [CrossRef]

- Pašteka, L.; Miglierini, M.; Bujdoš, M. Identification of Magnetic Phases in LC200N Steel by Backscattering Mössbauer Spectrometry. Acta Phys. Pol. A 2017, 131, 1078–1080. [Google Scholar] [CrossRef]

- Pinto, L.A.; Escobar, D.P.; Santos, O.S.H.; Lopes, N.I.A.; Carneiro, J.R.G.; Ribeiro-Andrade, R. Influence of surface preparation method on retained austenite quantification. Mater. Today Commun. 2020, 24, 101226. [Google Scholar] [CrossRef]

- Xiu, S.; Deng, Y.; Kong, X. Effects of stress on phase transformations in grinding by FE modeling and experimental approaches. Materials 2019, 12, 2327. [Google Scholar] [CrossRef] [Green Version]

- Miglierini, M.; Pašteka, L.; Cesnek, M.; Kmječ, T.; Bujdoš, M.; Kohout, J. Influence of surface treatment on microstructure of stainless steels studied by Mössbauer spectrometry. J. Radioanal. Nucl. Chem. 2019, 322, 1495–1503. [Google Scholar] [CrossRef]

- Brnic, J.; Krscanski, S.; Brcic, M. Comparison of the mechanical behavior of materials subjected to specific operating conditions. IOP Conf. Ser. Mater. Sci. Eng. 2018, 378, 012007. [Google Scholar] [CrossRef]

- Bulin, T.; Svabenska, E.; Hapla, M.; Roupcova, P.; Ondrusek, C.; Schneeweiss, O. Magnetic properties of 42CrMo4 steel. IOP Conf. Ser. Mater. Sci. Eng. 2017, 179, 012010. [Google Scholar] [CrossRef] [Green Version]

- Siemiątkowski, Z.; Gzik-Szumiata, M.; Szumiata, T.; Rucki, M.; Martynowski, R. Metallurgical quality evaluation of the wind turbine main shaft 42CrMo4 steel: Microscopic and Mössbauer studies. Nukleonika 2017, 62, 171–176. [Google Scholar] [CrossRef] [Green Version]

- Kouril, L.; Pechousek, J.; Novak, P.; Navarik, J.; Kohout, P. Toroidal proportional gas flow counter for conversion X-ray Mössbauer spectroscopy. Nucl. Inst. Methods Phys. Res. B 2018, 432, 55–59. [Google Scholar] [CrossRef]

- Olina, A.; Píška, M.; Petrenec, M.; Hervoches, C.; Beran, P.; Pechoušek, J.; Král, P. Assessment of retained austenite in fine grained inductive heat treated spring steel. Materials 2019, 12, 4063. [Google Scholar] [CrossRef] [Green Version]

- Klencsár, Z.; Kuzmann, E.; Vértes, A. User-friendly software for Mössbauer spectrum analysis. J. Radioanal. Nuclear Chem. 1996, 210, 105–118. [Google Scholar] [CrossRef]

- –Klencsár, Z.; Kuzmann, E.; Vértes, A. User-Friendly Program for Multifold Evaluation of Mössbauer Spectra. Hyperfine Interact. 1998, 112, 269–274. [Google Scholar] [CrossRef]

- Kuzmann, E.; Bene, E.; Domonkos, L.; Hegedűs, Z.; Nagy, S.; Vértes, A. Structure investigation and phase analysis of Fe-Cr carbides. J. De Physique 1976, 37, C6-409-414. [Google Scholar] [CrossRef]

- Fujita, F.E. Mössbauer Spectroscopy in Physical Metallurgy. In Mössbauer Spectroscopy, 1st ed.; Gonser, U., Ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1975; pp. 201–237. [Google Scholar]

- Suwalski, J.; Kucharski, Z.; Lukasiak, M. Determination of retained austenite in bearing steel. Hyperfine Interact. 1986, 29, 1491–1494. [Google Scholar] [CrossRef]

- Uwakweh, O.N.C.; Bauer, J.P.; Genin, J.M.R. Mössbauer study of the distribution of carbon interstitials in iron alloys and the isochronal kinetics of the aging of martensite: The clustering-ordering synergy. Metall. Trans. A 1990, 21A, 589–602. [Google Scholar] [CrossRef]

- Varga, I.; Kuzmann, E.; Káldor, M.; Vértes, A. Mössbauer study of the kinetic behavior of anomalous austenite formation in Fe-12Cr-4Ni steel. J. Radioanal. Nucl. Chem. 1992, 165, 115–126. [Google Scholar] [CrossRef]

- Wyckoff, R.W.G. Crystal Structures, 2nd ed.; Interscience Publishers: New York, NY, USA, 1963; Volume 1, pp. 7–83. [Google Scholar]

- Cahn, R.W. Physical Metallurgy, 1st ed.; Elsevier: Amsterdam, The Netherlands; London, UK; New York, NY, USA, 1965; pp. 281–381. [Google Scholar]

- Zhang, F.C.; Zheng, Y.Z.; Ruifu, Z.; Tingquan, L. Mössbauer studies on aging of deformed Fe–6Mn–2Cr–1C alloy. Scr. Metall. Mater. 1995, 32, 1477–1481. [Google Scholar] [CrossRef]

- Kuzmann, E.; Varga, I.; Vértes, A. Kinetical behaviour of anomalous austenite formation in turbine blade steel. Nucl. Instrum. Methods Phys. Res. B 1996, 76, 292–294. [Google Scholar] [CrossRef]

- Kuzmann, E.; Jaen, J.; Vértes, A.; Csöme, L.; Tibiássy, B.; Káldor, M. Mössbauer investigation of austenite formation together with Cr depletion in aged turbine blade steels. Hyperfine Interact. 1990, 58, 2593–2598. [Google Scholar] [CrossRef]

- Varga, I.; Kuzmann, E.; Vértes, A. Kinetics of α-γ phase transition of Fe-12Cr-4Ni Alloy aged between 500–650 °C. Hyperfine Interact. 1998, 112, 169–174. [Google Scholar] [CrossRef]

- Kalchenko, V.; Yeroshenko, A.; Boyko, S.; Sira, N. Determination of cutting forces in grinding with crossed axes of tool and workpiece. Acta Mech. Et Autom. 2017, 11, 58–63. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.; Shang, C.; Wang, X.; Wang, X.; Han, G.; Misra, R. Recent progress in third-generation low alloy steels developed under M3 microstructure control. Int. J. Miner. Metall. Mater. 2020, 27, 1–9. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Monshi, A.; Monajatizadeh, H.; Idris, M.H.; Kadir, M.R.A.; Jafari, H. Effect of Multi-Step Tempering on Retained Austenite and Mechanical Properties of Low Alloy Steel. J. Iron Steel Res. Int. 2011, 18, 49–56. [Google Scholar] [CrossRef]

| Sample | Surface Treatment |

|---|---|

| S1 | cutting, 0.5 mm/s |

| S2 | grinding 120 µm + water for 10 min, disc Struers MD-Piano 120 |

| S3 | as S2 and grinding 220 µm + water for 5 min, disc Struers MD-Piano 220 |

| S4 | as S3 and grinding 500 µm + water for 3 min, disc Struers MD-Piano 500 followed by grinding 1200 µm + water for 3 min, disc Struers MD-Piano 1200 |

| S5 | as S4 and polishing 3 µm + alcohol for 5 min, polishing canvas 3 µm Struers MD-MOL and diamond paste Struers P3 |

| S6 | as S5 and polishing 1µm + alcohol for 2 min polishing canvas 1 µm Struers MD-NAP and diamond paste Struers P1 |

| Sample | Surface Treatment |

|---|---|

| S1-P | polishing up to 3 µm |

| S2-P | polishing up to 3 µm |

| S3-P-EP | polishing up to 3 µm, and electrolytic polishing |

| S4-P-EP | polishing up to 3 µm, and electrolytic polishing |

| S5-P | polishing up to 3 µm |

| S6-P | polishing up to 3 µm |

| Sample | δγ (mm/s) ±0.04 mm/s | LWγ (mm/s) ±0.04% | Aγ (%) 1 ±1.0% | δα (mm/s) ±0.04 mm/s | B*hf (T) ±0.3 T | Aα (%) 1 ±1.0% | Mγ (%) 1 ±1.0% |

|---|---|---|---|---|---|---|---|

| S1 | −0.13 | 0.38 | 4.2 | 0.00 | 32.5 | 95.8 | 4.8 |

| S2 | −0.06 | 0.58 2 | 2.3 | 0.00 | 32.6 | 97.7 | 2.6 |

| S3 | −0.17 | 0.50 | 2.3 | 0.00 | 32.5 | 97.7 | 2.6 |

| S4 | −0.12 | 0.41 | 2.8 | 0.00 | 32.5 | 97.2 | 3.3 |

| S5 | −0.17 | 0.38 | 3.7 | 0.00 | 32.5 | 96.3 | 4.3 |

| S6 | −0.10 | 0.24 | 1.9 | 0.00 | 32.5 | 98.1 | 2.3 |

| Sample | δγ (mm/s) ±0.04 mm/s | LWγ (mm/s) ±0.04% | Aγ (%) 1 ±1.0% | δα (mm/s) ±0.04 mm/s | B*hf (T) ±0.3 T | Aα (%) 1 ±1.0% | Mγ (%) 1 ±1.0% |

|---|---|---|---|---|---|---|---|

| S1-P | −0.12 | 0.40 | 4.2 | 0.00 | 32.4 | 95.8 | 4.8 |

| S2-P | −0.12 | 0.41 | 4.2 | 0.00 | 32.5 | 95.8 | 4.9 |

| S3-P-EP | −0.12 | 0.25 | 4.2 | 0.00 | 32.5 | 95.8 | 4.9 |

| S4-P-EP | −0.12 | 0.31 | 4.3 | 0.00 | 32.6 | 95.7 | 5.0 |

| S5-P | −0.10 | 0.45 | 4.5 | 0.00 | 32.5 | 95.5 | 5.2 |

| S6-P | −0.12 | 0.31 | 3.7 | 0.00 | 32.5 | 96.3 | 4.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pechoušek, J.; Kuzmann, E.; Vondrášek, R.; Olina, A.; Vrba, V.; Kouřil, L.; Ingr, T.; Král, P.; Mashlan, M. Successive Grinding and Polishing Effect on the Retained Austenite in the Surface of 42CrMo4 Steel. Metals 2022, 12, 119. https://doi.org/10.3390/met12010119

Pechoušek J, Kuzmann E, Vondrášek R, Olina A, Vrba V, Kouřil L, Ingr T, Král P, Mashlan M. Successive Grinding and Polishing Effect on the Retained Austenite in the Surface of 42CrMo4 Steel. Metals. 2022; 12(1):119. https://doi.org/10.3390/met12010119

Chicago/Turabian StylePechoušek, Jiří, Ernö Kuzmann, René Vondrášek, Anna Olina, Vlastimil Vrba, Lukáš Kouřil, Tomáš Ingr, Petr Král, and Miroslav Mashlan. 2022. "Successive Grinding and Polishing Effect on the Retained Austenite in the Surface of 42CrMo4 Steel" Metals 12, no. 1: 119. https://doi.org/10.3390/met12010119

APA StylePechoušek, J., Kuzmann, E., Vondrášek, R., Olina, A., Vrba, V., Kouřil, L., Ingr, T., Král, P., & Mashlan, M. (2022). Successive Grinding and Polishing Effect on the Retained Austenite in the Surface of 42CrMo4 Steel. Metals, 12(1), 119. https://doi.org/10.3390/met12010119