Growth and Deformation Simulation of Aluminum Bronze Grains Produced by Electron Beam Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

3. Model Description

4. Results of Simulation and Comparison with Experiment

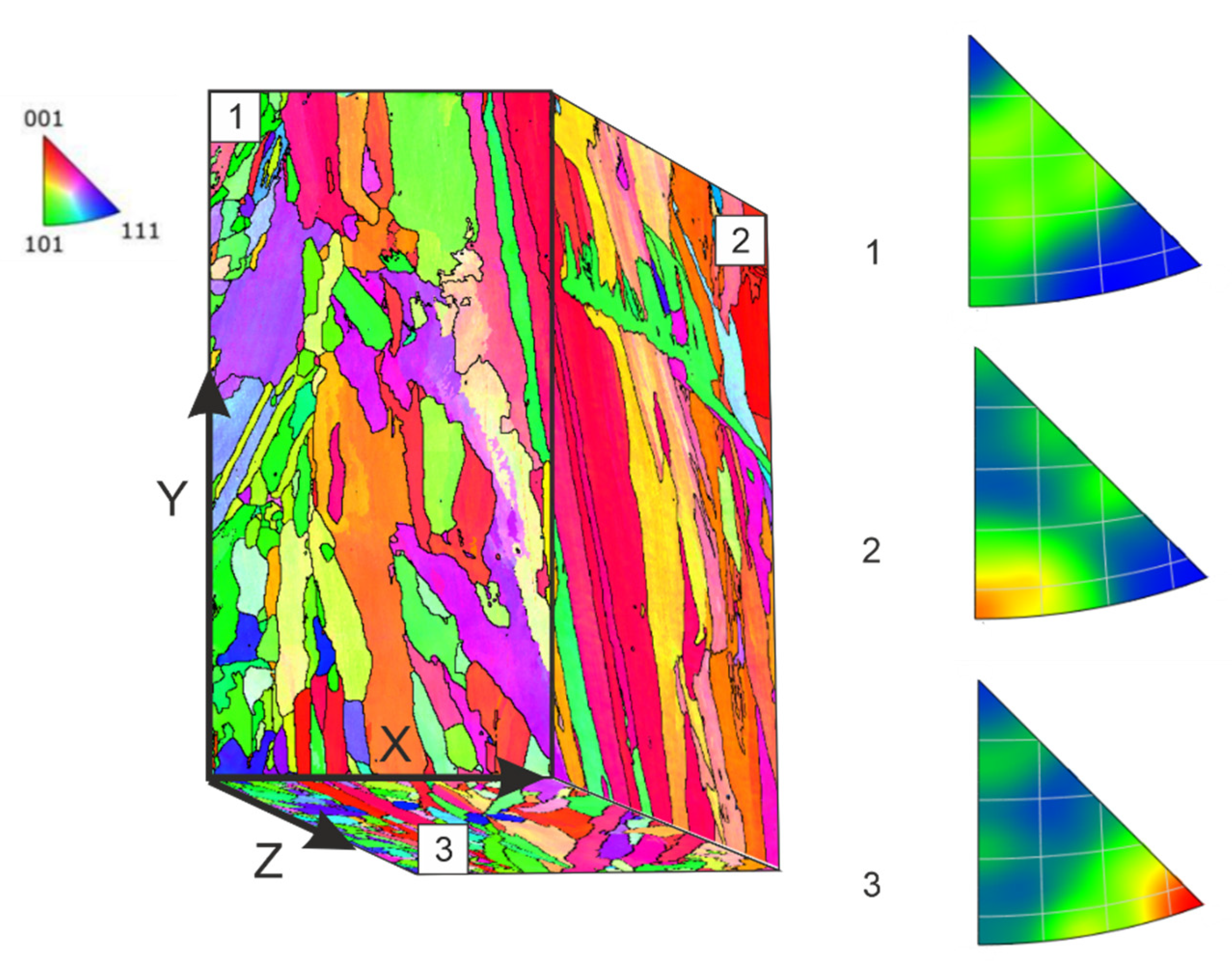

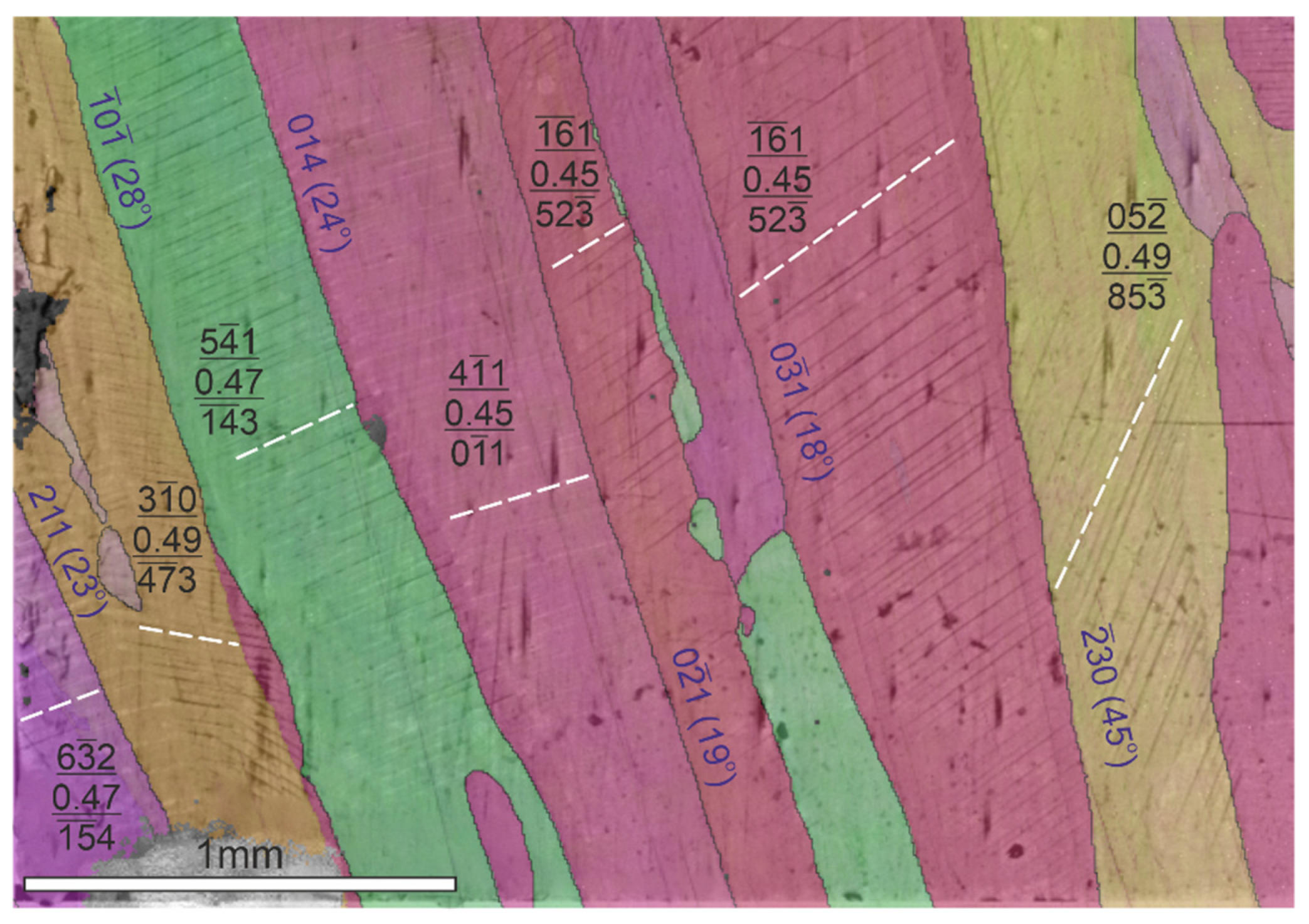

4.1. EBSD Crystallographic Analysis of Grains Obtained by Electron Beam Surfacing

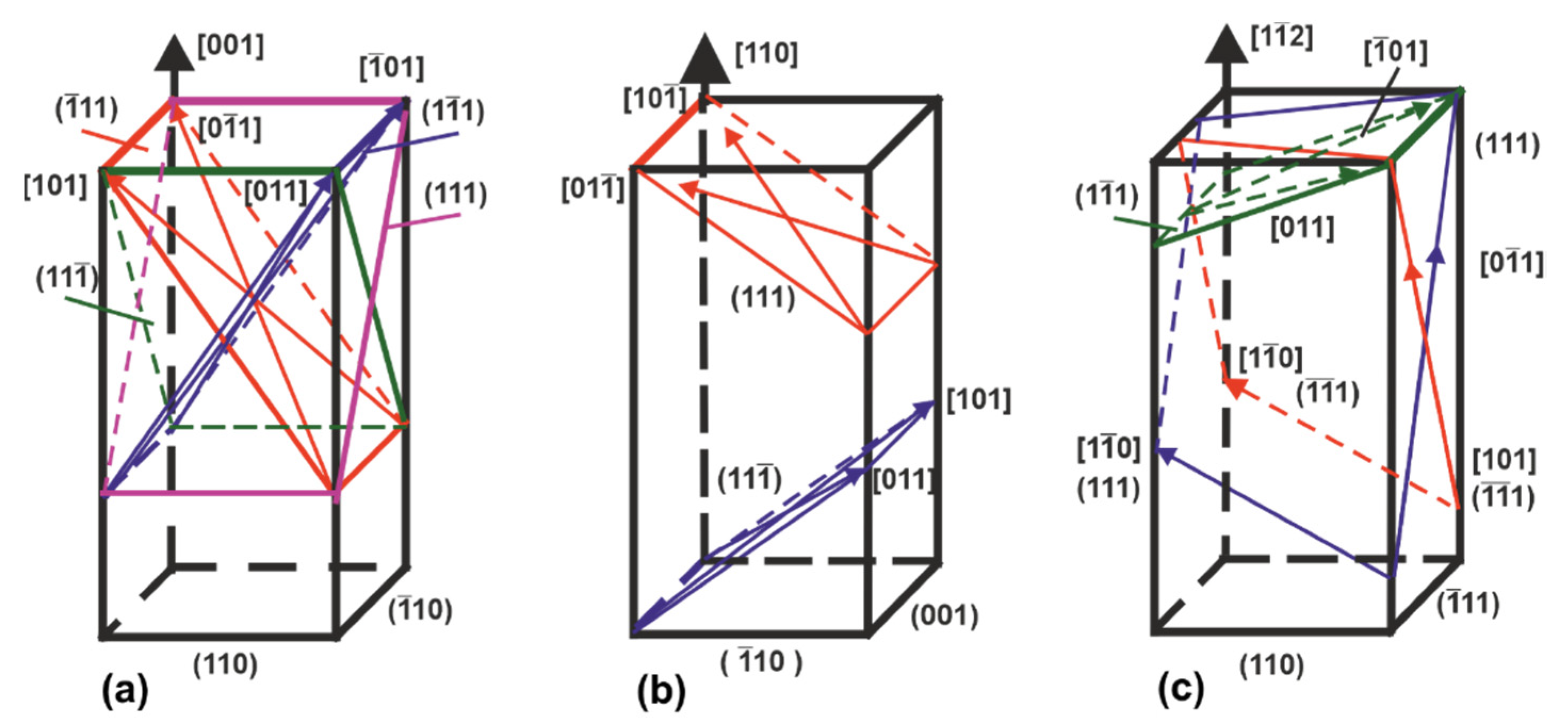

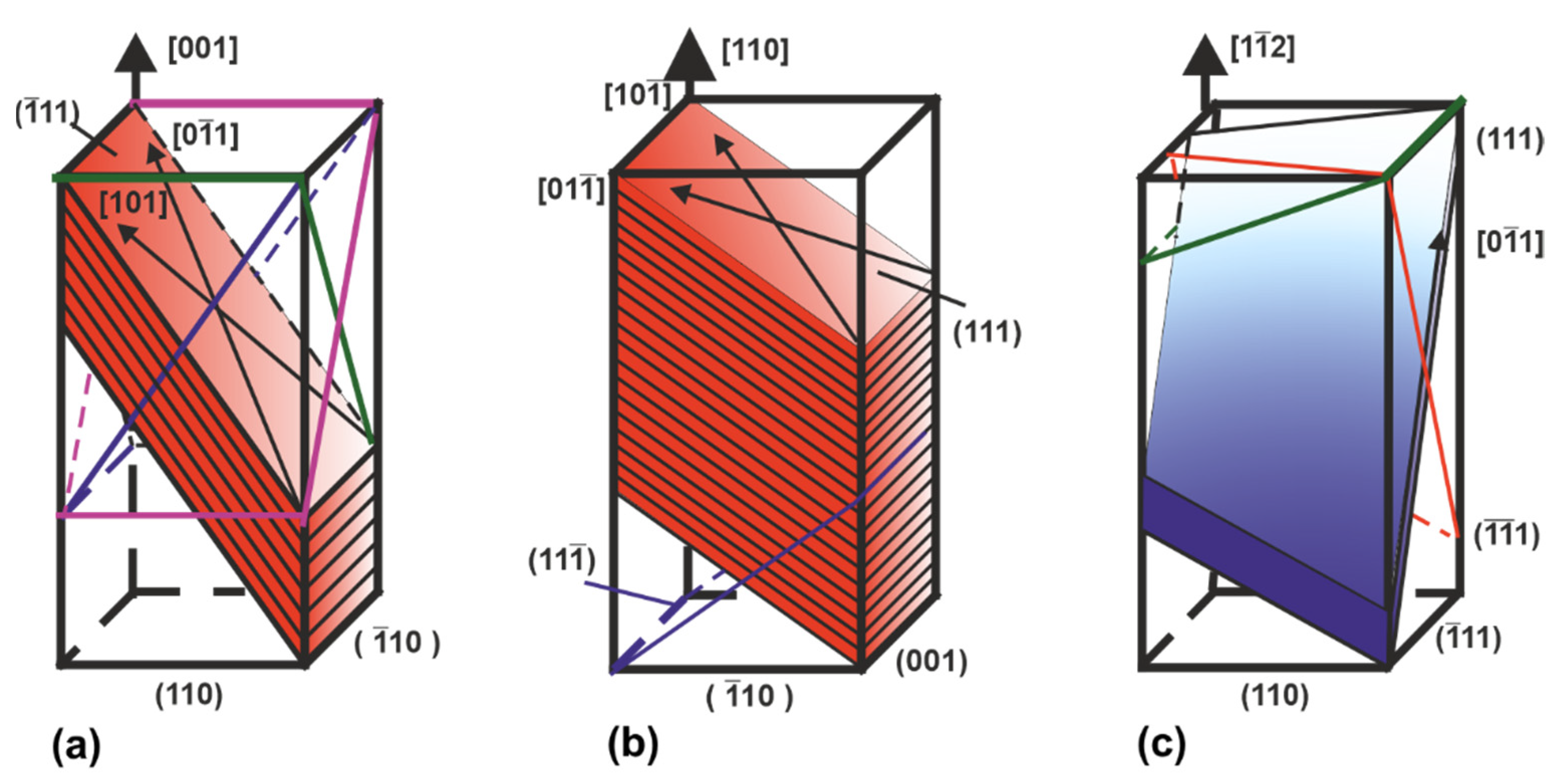

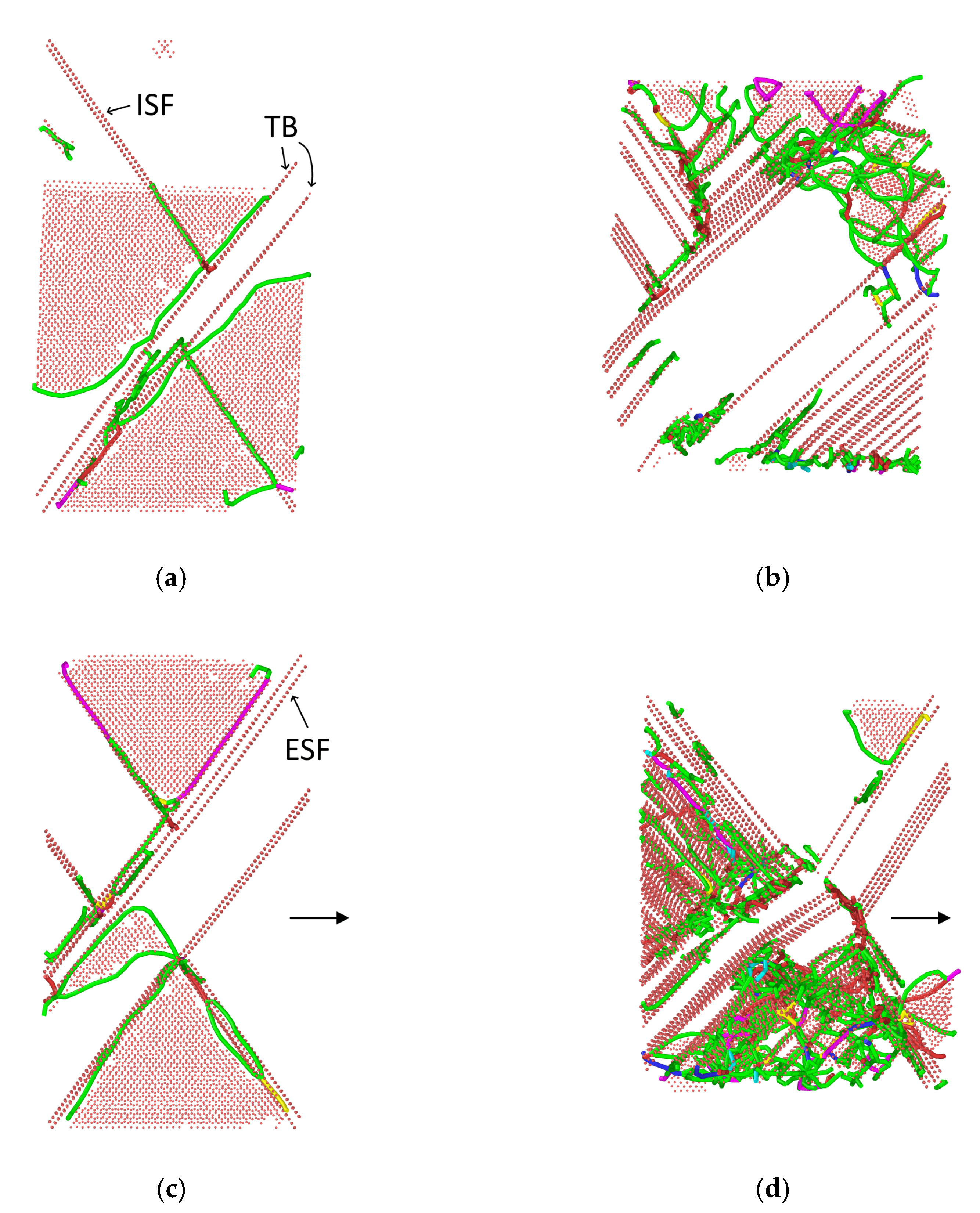

4.2. Slip Schemes

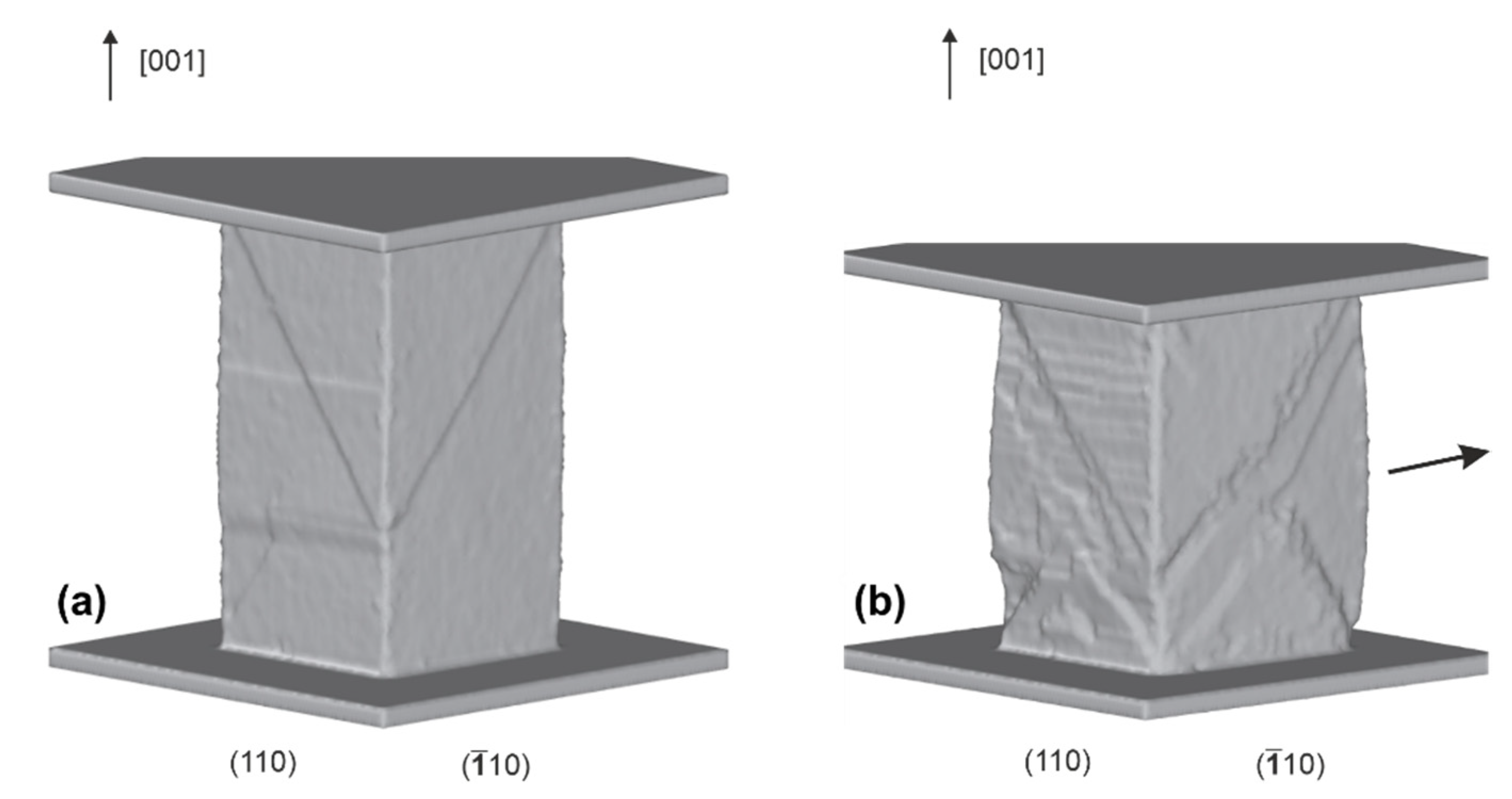

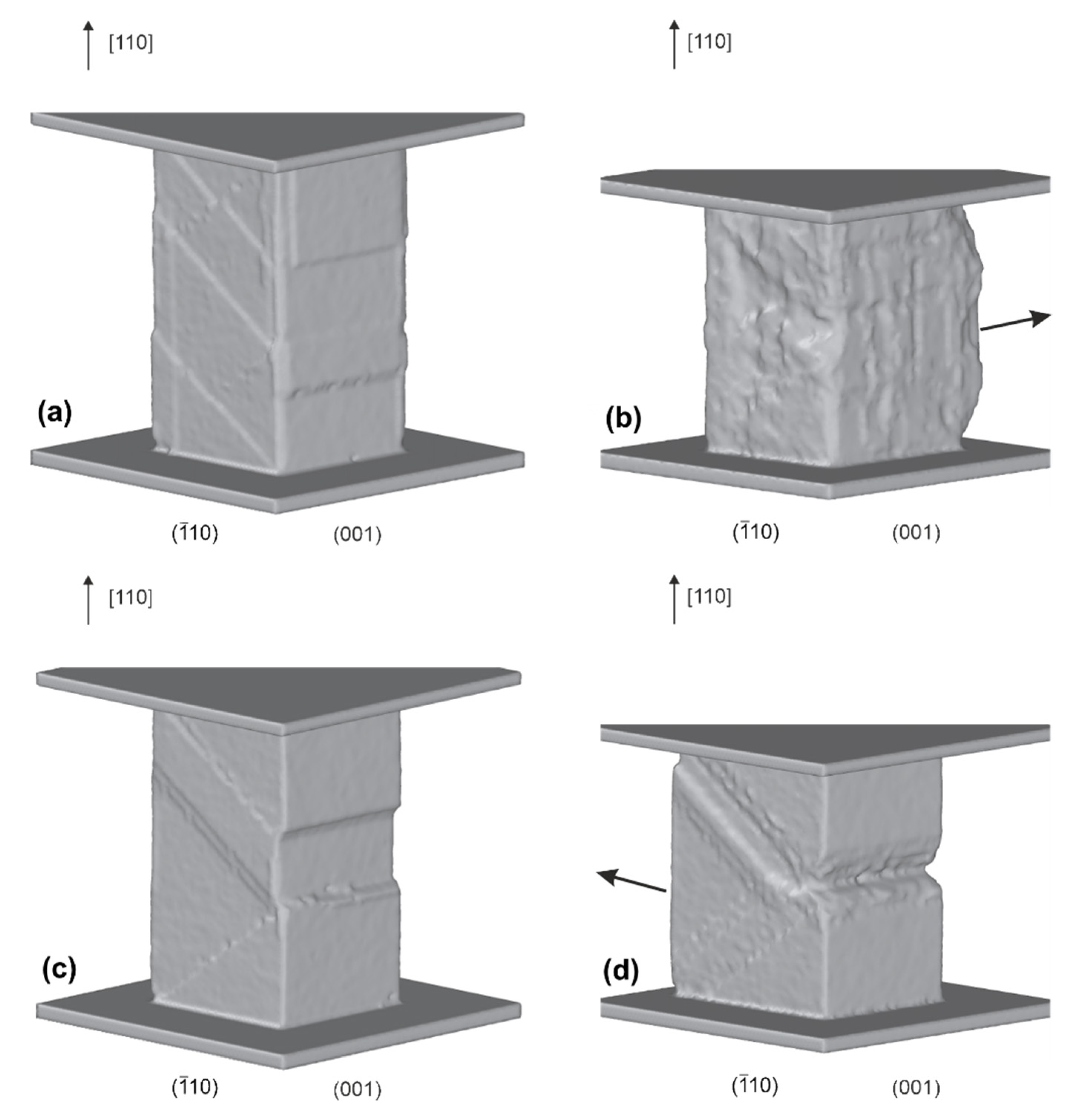

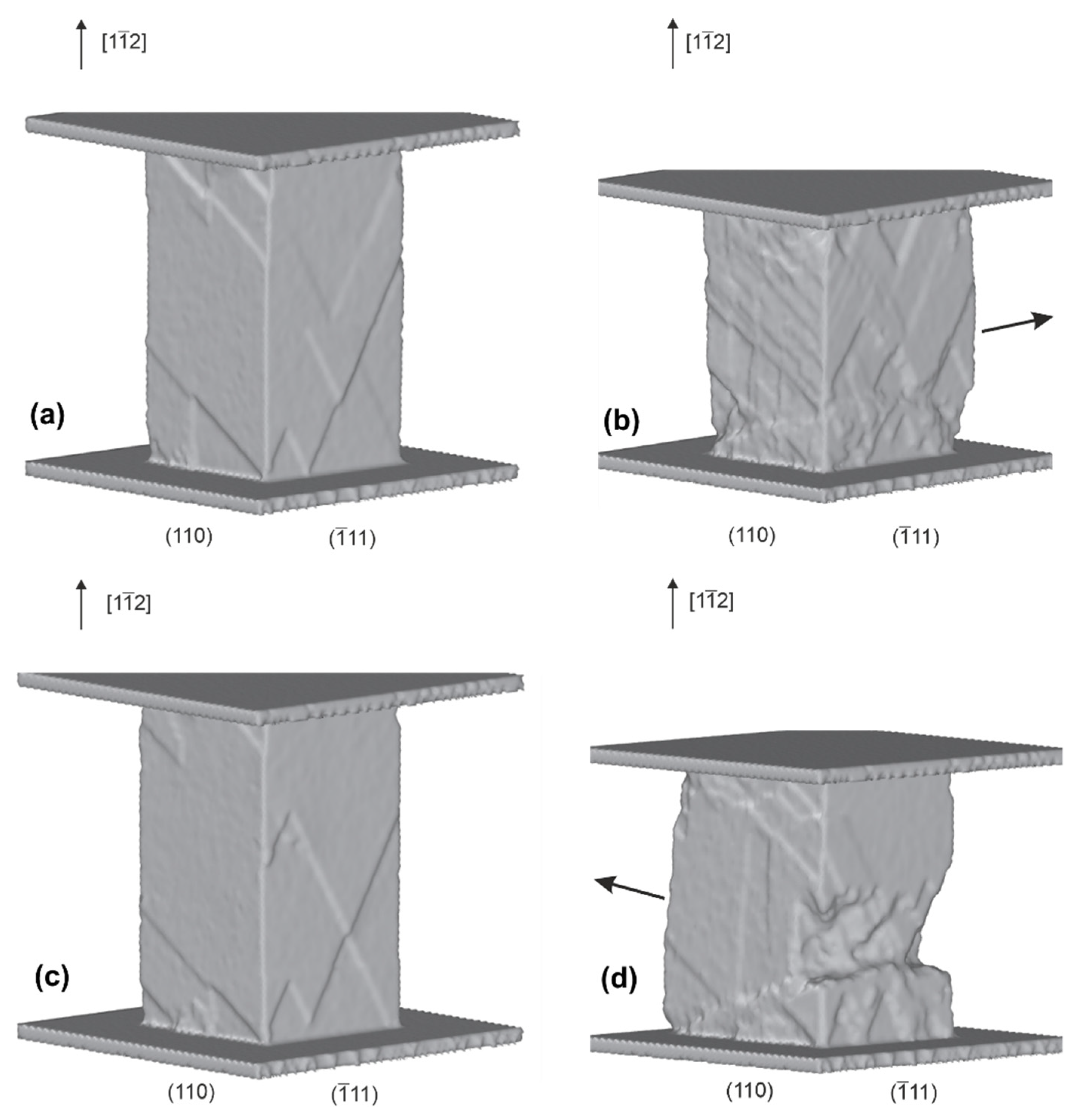

4.3. The Deformation Relief: Simulation of Individual Grain Deformation (The Case of Free Lateral Faces) and Experiment

4.4. The Deformation Relief: Simulation of Individual Grain Deformation (The Constrained Deformation Conditions)

4.5. Analysis of Grains Deformation of Polycrystal Obtained by Electron Beam Melting

5. Discussion

- Strengthening depends not on the number of equally loaded slip systems, but on the possibility of interaction between dislocations of different slip systems. In this case, the relationship between the averaged values of the strain hardening coefficient can be represented by the following ratio .

- Relationship between strain hardening coefficients for free and constrained deformation conditions: .

- depends on the face orientation.

- The stages of the deformation curves do not always appear.

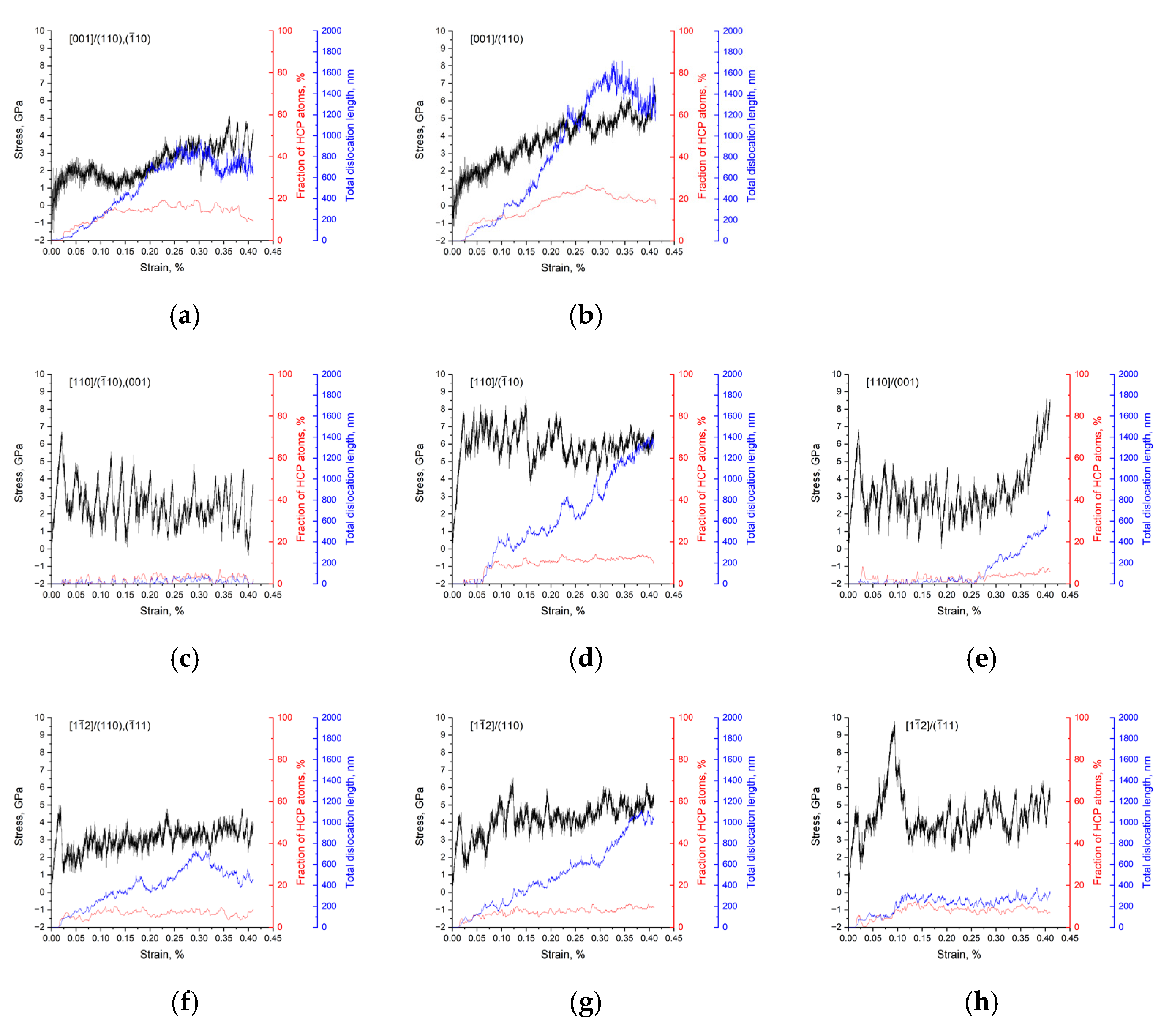

- The fraction of HCP atoms increases at 15% strain for orientations most favorable for the interaction of different slip systems. Further growth is observed only for [001] single crystals deformed under constrained conditions.

- The change in the fraction of HCP dislocations can be approximately compared with the change in stress up to 20% strain.

- An increasing in stress for [001] single crystals with 20% strain correlates with an increasing in the total dislocation length while maintaining the fraction of HCP atoms at the same level for the cases of free and constrained deformation conditions.

- In the case of single crystals [110] and an increasing in the total length of dislocations is not always accompanied by an increasing in the stress. The absence of such correlation is due to the possibility of deformation twinning along with slip.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clare, A.T.; Mishra, R.S.; Merklein, M.; Tan, H.; Todd, I.; Chechik, L.; Li, J.; Bambach, M. Alloy design and adaptation for additive manufacture. J. Mater. Process. Technol. 2022, 299, 117358. [Google Scholar] [CrossRef]

- Gaytan, S.M.; Murr, L.E.; Martinez, E.; Martinez, J.L.; Machado, B.I.; Ramirez, D.A.; Medina, F.; Collins, S.; Wicker, R.B. Comparison of Microstructures and Mechanical Properties for Solid and Mesh Cobalt-Base Alloy Prototypes Fabricated by Electron Beam Melting. Metall. Mater. Trans. A 2010, 41, 3216–3227. [Google Scholar] [CrossRef]

- Muhammad, M.; Nezhadfar, P.D.; Thompson, S.; Saharan, A.; Phan, N.; Shamsaei, N. A comparative investigation on the microstructure and mechanical properties of additively manufactured aluminum alloys. Int. J. Fatigue 2021, 146, 106165. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Lopez-Galilea, I.; Ruttert, B.; He, J.; Hammerschmidt, T.; Drautz, R.; Gault, B.; Theisen, W. Additive manufacturing of CMSX-4 Ni-base superalloy by selective laser melting: Influence of processing parameters and heat treatment. Addit. Manuf. 2019, 30, 100874. [Google Scholar] [CrossRef]

- Buchbender, I.; Hoff, C.; Hermsdorf, J.; Wesling, V.; Kaierle, S. Single-crystal height extension by Laser Metal Deposition of CMSX-4. Procedia CIRP 2020, 94, 304–309. [Google Scholar] [CrossRef]

- Hitzler, L.; Merkel, M.; Hall, W.; Öchsner, A. A Review of Metal Fabricated with Laser- and Powder-Bed Based Additive Manufacturing Techniques: Process, Nomenclature, Materials, Achievable Properties, and its Utilization in the Medical Sector. Adv. Eng. Mater. 2018, 20, 1700658. [Google Scholar] [CrossRef] [Green Version]

- Bailey, N.S.; Katinas, C.; Shin, Y.C. Laser direct deposition of AISI H13 tool steel powder with numerical modeling of solid phase transformation, hardness, and residual stresses. J. Mater. Process. Technol. 2017, 247, 223–233. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Heinl, P.; Rottmair, A.; Körner, C.; Singer, R.F. Cellular Titanium by Selective Electron Beam Melting. Adv. Eng. Mater. 2007, 9, 360–364. [Google Scholar] [CrossRef]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.; Hague, R.; Galea, M.; Dickens, P. Electrical resistivity of pure copper processed by medium-powered laser powder bed fusion additive manufacturing for use in electromagnetic applications. Addit. Manuf. 2019, 29, 100831. [Google Scholar] [CrossRef]

- Khoroshko, E.; Filippov, A.; Tarasov, S.; Shamarin, N.; Moskvichev, E.; Fortuna, S.; Lychagin, D.V.; Kolubaev, E. Strength and Ductility Improvement through Thermomechanical Treatment of Wire-Feed Electron Beam Additive Manufactured Low Stacking Fault Energy (SFE) Aluminum Bronze. Metals 2020, 10, 1568. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, T.; Chen, Y.; Li, L.; Zhang, Y.; Liou, F. Additive manufacturing of copper-stainless steel hybrid components using laser-aided directed energy deposition. J. Mater. Sci. Technol. 2021, 80, 100–116. [Google Scholar] [CrossRef]

- Rappaz, M.; Gandin, C.-A. Probabilistic modelling of microstructure formation in solidification processes. Acta Metall. Mater. 1993, 41, 345–360. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Evolution of microstructure in laser deposited Al–11.28%Si alloy. Surf. Coat. Technol. 2012, 206, 2152–2160. [Google Scholar] [CrossRef]

- Piglione, A.; Dovgyy, B.; Liu, C.; Gourlay, C.M.; Hooper, P.A.; Pham, M.S. Printability and microstructure of the CoCrFeMnNi high-entropy alloy fabricated by laser powder bed fusion. Mater. Lett. 2018, 224, 22–25. [Google Scholar] [CrossRef]

- Pham, M.S.; Dovgyy, B.; Hooper, P.A. Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Texture control during laser deposition of nickel-based superalloy. Scr. Mater. 2012, 67, 503–506. [Google Scholar] [CrossRef]

- Ramsperger, M.; Singer, R.F.; Körner, C. Microstructure of the Nickel-Base Superalloy CMSX-4 Fabricated by Selective Electron Beam Melting. Metall. Mater. Trans. A 2016, 47, 1469–1480. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.-Y.; Tang, H.-B.; Li, Z.; Xu, C.; He, B. Solidification behavior and grain morphology of laser additive manufacturing titanium alloys. J. Alloy. Compd. 2019, 777, 712–716. [Google Scholar] [CrossRef]

- Pham, M.-S.; Dovgyy, B.; Hooper, P.A.; Gourlay, C.M.; Piglione, A. The role of side-branching in microstructure development in laser powder-bed fusion. Nat. Commun. 2020, 11, 749. [Google Scholar] [CrossRef]

- Ramirez, D.A.; Murr, L.E.; Martinez, E.; Hernandez, D.H.; Martinez, J.L.; Machado, B.I.; Medina, F.; Frigola, P.; Wicker, R.B. Novel precipitate–microstructural architecture developed in the fabrication of solid copper components by additive manufacturing using electron beam melting. Acta Mater. 2011, 59, 4088–4099. [Google Scholar] [CrossRef]

- Dharmendra, C.; Gururaj, K.; Pradeep, K.G.; Mohammadi, M. Characterization of κ-precipitates in wire-arc additive manufactured nickel aluminum bronze: A combined transmission Kikuchi diffraction and atom probe tomography study. Addit. Manuf. 2021, 46, 102137. [Google Scholar] [CrossRef]

- Dharmendra, C.; Amirkhiz, B.S.; Lloyd, A.; Ram, G.D.J.; Mohammadi, M. Wire-arc additive manufactured nickel aluminum bronze with enhanced mechanical properties using heat treatments cycles. Addit. Manuf. 2020, 36, 101510. [Google Scholar] [CrossRef]

- Filippov, A.; Shamarin, N.; Moskvichev, E.; Savchenko, N.; Kolubaev, E.; Khoroshko, E.; Tarasov, S. Heat Input Effect on Microstructure and Mechanical Properties of Electron Beam Additive Manufactured (EBAM) Cu-7.5wt.%Al Bronze. Materials 2021, 14, 6948. [Google Scholar] [CrossRef]

- Wei, D.; Anniyaer, A.; Koizumi, Y.; Aoyagi, K.; Nagasako, M.; Kato, H.; Chiba, A. On microstructural homogenization and mechanical properties optimization of biomedical Co-Cr-Mo alloy additively manufactured by using electron beam melting. Addit. Manuf. 2019, 28, 215–227. [Google Scholar] [CrossRef]

- Kurian, S.; Mirzaeifar, R. Selective laser melting of aluminum nano-powder particles, a molecular dynamics study. Addit. Manuf. 2020, 35, 101272. [Google Scholar] [CrossRef]

- Singh, G.; Waas, A.M.; Sundararaghavan, V. Understanding defect structures in nanoscale metal additive manufacturing via molecular dynamics. Comput. Mater. Sci. 2021, 200, 110807. [Google Scholar] [CrossRef]

- Arifin, R.; Astuti, F.; Baqiya, M.A.; Winardi, Y.; Wicaksono, Y.A.; Darminto; Selamat, A. Structural Change of TiAl Alloy under Uniaxial Tension and Compression in the <001>; Direction: A Molecular Dynamics Study. Metals 2021, 11, 1760. [Google Scholar] [CrossRef]

- Lychagin, D.; Dmitriev, A.; Nikonov, A.; Alfyorova, E. Crystallographic and Geometric Factors in the Shear Development in <001> FCC Single Crystals: Molecular Dynamics Simulation and Experimental Study. Crystals 2020, 10, 666. [Google Scholar] [CrossRef]

- Nikonov, A.Y.; Dmitriev, A.I.; Lychagin, D.V.; Lychagina, L.L.; Bibko, A.A.; Novitskaya, O.S. Numerical Study and Experimental Validation of Deformation of <111> FCC CuAl Single Crystal Obtained by Additive Manufacturing. Metals 2021, 11, 582. [Google Scholar] [CrossRef]

- CHANNEL 5, General Introduction, Oxford Instruments HKL. 2007, p. 475. Available online: www.oxinst.com. (accessed on 13 December 2021).

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Mishin, Y.; Farkas, D.; Mehl, M.; Papaconstantopoulos, D. Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys. Rev. B 1999, 59, 3393–3407. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.; Ye, Y.Y. Simple analytical embedded-atom-potential model including a long-range force for fcc metals and their alloys. Phys. Rev. B 1996, 54, 8398–8410. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Lychagin, D.V. Fragmentation of plastically deformed fcc metallic materials. Phys. Mesomech. 2006, 9, 95–105. (In Russian) [Google Scholar]

- Teplyakova, L.A.; Lychagin, D.V.; Bespalova, I.V. Mechanisms of deformation macrolocalization in aluminium single crystals with loading axis orientation [110]. Phys. Mesomech. 2004, 7, 63–78. [Google Scholar]

- Pande, C.S.; Hazzledine, P.M. Dislocation arrays in Cu-Al alloys. II. Philos. Mag. 1971, 24, 1393–1410. [Google Scholar] [CrossRef]

- Fujita, H.; Sumida, N.; Kimura, S.; Takemoto, T. Dislocation Multipoles in Slightly Deformed Cu–10 at%Al Single Crystals. J. Phys. Soc. Jpn. 1982, 51, 577–582. [Google Scholar] [CrossRef]

- Solov’ev, A.N.; Starenchenko, S.V.; Solov’eva, Y.V.; Starenchenko, V.A. Substructural Transformations in Cu–12 at.% Al Single Crystals with [001] Deformation Axis. Russ. Phys. J. 2020, 63, 1233–1237. [Google Scholar] [CrossRef]

- Starenchenko, S.V.; Solov’eva, Y.V.; Starenchenko, V.A.; Solov’ev, A.N. Stress and Strain Effect on Defect Structure Parameters of Single Crystals in Cu–12 at.% Al Alloy. Russ. Phys. J. 2021, 64, 625–631. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikonov, A.Y.; Lychagin, D.V.; Bibko, A.A.; Novitskaya, O.S. Growth and Deformation Simulation of Aluminum Bronze Grains Produced by Electron Beam Additive Manufacturing. Metals 2022, 12, 114. https://doi.org/10.3390/met12010114

Nikonov AY, Lychagin DV, Bibko AA, Novitskaya OS. Growth and Deformation Simulation of Aluminum Bronze Grains Produced by Electron Beam Additive Manufacturing. Metals. 2022; 12(1):114. https://doi.org/10.3390/met12010114

Chicago/Turabian StyleNikonov, Anton Yu., Dmitry V. Lychagin, Artem A. Bibko, and Olga S. Novitskaya. 2022. "Growth and Deformation Simulation of Aluminum Bronze Grains Produced by Electron Beam Additive Manufacturing" Metals 12, no. 1: 114. https://doi.org/10.3390/met12010114

APA StyleNikonov, A. Y., Lychagin, D. V., Bibko, A. A., & Novitskaya, O. S. (2022). Growth and Deformation Simulation of Aluminum Bronze Grains Produced by Electron Beam Additive Manufacturing. Metals, 12(1), 114. https://doi.org/10.3390/met12010114