Abstract

In this paper, a methodology for depositing wear- and corrosion-resistant layers of geometrically more complex tracks on metal substrates is presented. The corresponding mathematical model includes the temperature field produced by the laser beam, the field of residual mechanical stresses, and the efficiency of utilization of the delivered powder material. The computations are realized using the finite element method, with a substantial improvement in processing the time-variable geometry of the investigated system being found, based on the introduction of two specific matrices that characterize both the surface on which the tracks are cladded as well as the track itself. The proposed technique is illustrated by cladding an angled helix on a metal surface. Selected results are successfully verified by experiments.

1. Introduction

Additive technologies are highly advanced processes which are used in many industries. One of these processes is the cladding of thin layers of a special metallic powder onto a metal substrate [1]. This process is usually carried out to improve the functional requirements of surfaces machinery and components to increase their resistance to mechanical wear (abrasion, erosion, adhesion, cavitation, fatigue wear), to increase their corrosion resistance, or for the refurbishment and repair of worn components (e.g., metal casting moulds). In the case of steels, it is often necessary to increase the hardness of the surface. After laser heating, the exposed area cools rapidly, thus fulfilling the most important prerequisite for the formation of the necessary martensitic structure. Cladding is also commonly used in railway construction for repairing the tops of rails in urban railways.

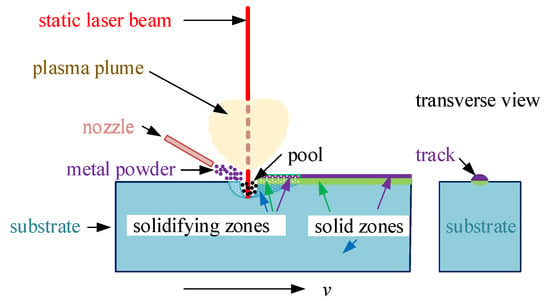

From a physical point of view, the cladding of thin layers onto a metal substrate is a very complex task. Figure 1 represents this process, which is often realised in a protective (gaseous) atmosphere.

Figure 1.

Basic scheme of the process.

The substrate moves in the direction indicated at a velocity . The laser head is placed above the substrate, which heats its surface with its beam, and a suitable metallic powder is injected into the heated area with a nozzle. In the irradiated area, both the surface layer of the substrate and the supplied powder are simultaneously heated and then melted. The heat-affected zone is not too large, but a pool containing the flowing melt of the substrate material and powder is formed within it. Together with a capillary through which the evaporated particles of metal penetrate the surroundings, a plasma plume forms above the pool. Its presence may reduce the power delivered by the laser beam to the irradiated area, as a part of it is reflected and another part is absorbed. As the substrate shifts, the molten layers begin to solidify. The bottommost layer of melt (light blue) contains mainly substrate material. Above it, the middle layer (light green) is a mixture of substrate and powder material, and the top layer (purple) consists mainly of powder material. In this way, a track is formed. A series of tracks next to each other forms a continuous surface layer.

The deposition of thin layers on the surfaces of metallic bodies with the aim to enhance their physical properties began to be investigated in the 1980s. In practice, this technology was introduced only at the very end of the 20th century, and its development was based mainly on experiments [2,3,4,5,6,7,8]. The cladding process is physically very complex and involves not only the heating and melting of metals and metal powder (and, to a lesser extent, even their evaporation), but also metallurgical and chemical changes and possibly elastic or elastic-plastic deformations.

For these reasons, mathematical modelling for the process has only started to develop in the last fifteen to twenty years. References [9,10,11] deal with the modelling of the temperature field generated by laser beam as well as the field of mechanical stresses and the resulting structure of deposited layers. References [12,13] present studies concerning the distribution of the powder added by the nozzle and its utilization efficiency during the process. Further research works [14,15] investigate the influence of the mutual positioning of the laser beam and nozzle on the temperature field. The behaviour of the liquid in the pool (its flow and temperature) has also been studied [16,17], with consequences concerning the metallurgical properties of the deposited layer (structure, morphology, etc.). Other works [18,19] concern the mechanical properties (such as thermal stresses, residual stresses, or hardness) of tracks. However, the list of the above papers is far from exhaustive.

Despite the considerable progress made in this area, there still exists a number of unresolved issues, such as:

- Choosing an appropriate powder material for the given application;

- Achieving the required coating quality;

- The accuracy of individual patterns;

- Problems with the discretization of the examined area, where the coated substrate continuously changes its phase and geometry;

- The inclusion of various stochastic phenomena (not all powder material is used during the process, the defocusing of the laser beam, and the reduction in its power due to plasma plume formation above the irradiated area);

- The significant amount of time (usually many hours) needed for the computation of one variant of the task.

At present, based on theoretical research, several professional codes are available that allow solving the task numerically (even in 3D). However, these always have some simplifications. We refer to, for example, COMSOL Multiphysics and ANSYS. Both codes provide acceptable results when working with correct input data. However, issues arising from the long computational times are mostly connected with the algorithms used for processing geometry. The geometry of the system continuously varies together with the pool position, which results in time-dependent boundaries between the solid and liquid phases.

The time-varying shape of the track is here modelled mostly using the method of geometry deformation (GD) [20] combined with the finite element method (FEM) [21]. The flow field is modelled by the finite element method or in ANSYS by the finite volume method (FVM) [22], which proves to be more efficient in many cases.

The authors present an optional algorithm that describes the time-varying geometry of the track using two specific matrices (described in more detail in the following section). This algorithm, written in MATLAB, proves to be substantially faster than algorithms built using the above GD method. In combination with COMSOL Multiphysics, this method is used to solve the numerical model of 3D cladding of an angled helix.

2. Mathematical Model

The cladding process generally represents a multiphysics problem in which the primary temperature field induced by the laser beam gives rise to other physical fields. These include melt motion, metallurgical, and possibly chemical changes, as well as fields of thermoelastic or elastic-plastic deformations and corresponding mechanical stresses. These fields interact with each other, and this interaction is characterized by a high degree of nonlinearity. This is a consequence of the nonlinear dependencies of material properties on temperature, particularly when above melting temperature. For alloys, these characteristics are often not well known.

2.1. Temperature Field

The heat source is a laser beam that delivers power to the surface of the substrate and simultaneously heats the particles of the supplied metal powder. Since there is no heat generated by internal sources, the power delivered must be included in the boundary condition. In this case, the heat transfer equation has the formula [23]:

where is the thermal conductivity, denotes the temperature, stands for the specific mass, represents the specific heat capacity at a constant pressure, is the time, and denotes the vector of speed. The corresponding boundary condition reads:

Here, is the surface temperature, denotes the outward normal, is the coefficient of convection, stands for the temperature of environment, represents the Stefan-Boltzmann constant, denotes the emissivity, and is the temperature of the medium on which the thermal radiation is reflected. Finally, denotes the heat flux delivered via laser beam that is assumed to satisfy the normal distribution.

Although the solution to this equation is seemingly simple, problems can arise in correctly determining the convection coefficient and emissivity at the point of irradiation. However, these errors do not have a decisive influence on the results, as the area irradiated by the laser beam is small.

2.2. Field of Flow

At the point irradiated by the laser beam, both the substrate and the powdered material are heated very quickly, creating a pool of molten metal with a capillary in its centre. The molten material starts to flow here due to gravitational, buoyancy, and inertia forces, and this flow is turbulent. In doing so, some particles of metallic material evaporate and escape through the capillary and into the surrounding space. The interaction between the temperature field and the flow field is very strong here, and must be solved for in the hard-coupled formulation [24,25].

The flow-field equation uses the Reynolds-averaged approach and the Navier-Stokes model of the turbulence considering a weakly compressible flow. This may be written in a simplified form:

with the supplementary condition.

Here, is the velocity of the flow, denotes the pressure, represents the unit matrix, stands for the dynamic viscosity, and is the vector of volumetric internal forces. The mentioned simplification consists of neglecting the Marangoni effect and Darcy damping force [26].

However, this simplification causes complications in determining boundary conditions, based on the assumption that the flow velocity on the pool walls is zero. For this reason, a dynamic viscosity is introduced in the form of and , where is the temperature of melting. The interface between the solid and liquid phases is then at the boundary along which . The diameter and depth of the capillary are determined from the magnitude of the partial pressure acting there.

The issue of molten metal flow is also closely related to the evaporation of its ionized particles and the formation of a plasma cloud over the irradiated area. The plasma state is usually described by electron density and temperature . The plasma plume causes a loss in power in the laser beam, as one part is absorbed and another part, which can be neglected, is reflected back. The absorption coefficient (if we consider this process to be linear) is given as [27]:

where is the ionic valence, denotes the Boltzmann constant, represents the ion density, stands for the Coulomb logarithm, is the laser angular frequency, stands for the light speed, denotes the permittivity of the vacuum, denotes the electron mass, and is the angular frequency of plasma oscillations. If the power of the laser beam is , then the power delivered onto the heated surface is:

with being the thickness of the plasma plume.

2.3. Field of Mechanical Stresses

To determine the mechanical stresses of formed tracks, knowledge of the time evolution of their temperature and material parameters such as Young’s modulus, Poisson’s ratio and yield strength is essential. The total strain at any point of the processed body is given by a sum of the particular strains in the form:

Here, denotes the elastic strain; is the plastic strain; represents the thermal strain; and stands for the strain due to the phase transformation—in other words, due to different changes in volume between the two phases. The model is relatively complicated and must incorporate material nonlinearities, complex geometry, and the theory of large deformations (based mostly on Green-Lagrange strain equations). More particulars can be found in references [28,29].

2.4. Numerical Solution

The numerical solution of the model is still a challenge due to the continuously changing geometry of the substrate with the track. Initially, this problem was solved by reshaping the domain at each time step. However, this was only viable for 2D regions., In the case of 3D objects, this approach already led to unacceptably long computation times. One of the reasons for this limitation was the fact that the amount of effectively used powder could only be estimated.

Later, a geometry deformation method was proposed, which has been implemented in some professional programs such as COMSOL Multiphysics 5.5 (Burlington, MA, USA). This method has been proven to be faster, but several parameters had to be calibrated on an experimental basis, and these parameters vary for different materials.

Due to the complexity of the additive model calculations and the necessity of regenerating the geometry and thus the mesh around the heat-affected zone, our efforts were focused on making the computational elements in the area of pattern formation as simple as possible. Thus, the mesh is divided into very small cubic elements in the area above the substrate surface in the welding region, whose dimensions in the substrate area are described by the area matrix m × n, where m and n are the numbers of elements in both directions. If, for example, we choose these elements with a volume of 1 mm3, then the dimensions m and n correspond to the surface area of the weld in millimeters. In the same way, using the square matrix j × j, we divide the area of the irradiated spot into small elements whose third dimension (basically the height of the pattern) is calculated from the temperature of the spot, the powder rate, and the speed of the laser movement. Thus, the pattern is created in the model by moving this spot across the surface of the pattern and overwriting 0 with 1 in the affected elements of the volume grid, thus defining the change in the material from air to metal. We are continuously improving the methodology, in particular the functions for sophisticated calculation of the height of the track, where we use optimization techniques and experiments to calibrate it. Since a grid with cubic elements is used, the calculation is very fast in contrast to free deformation. It is necessary to note that this model still has some shortcomings, such as the “swelling” shape of the track (which expands upwards) or the somewhat collapsed shape in the case of overheating. However, since in the end our algorithm is supposed to eliminate such shapes, this neglect is acceptable. The principal advantages of this methodology are:

- The area matrix itself is mathematically much easier and faster to work with than the deformed geometry;

- It is possible to define an arbitrary shape of the spot of the pattern, therefore it is possible that the final shape of the deposited track will be closer to the real shape;

- The mesh is always generated without problems and faster using such a geometry, which also reduces the overall simulation computation time;

- Any overlapping of the deposited tracks can be performed;

- The amount of material deposited can be easily calculated;

- It can be found that the height of the track is also dependent on the welding speed and the flow rate of the powder.

3. Illustrative Example

As a demonstration of the results achieved, below is an example of cladding three layers of a square spiral onto a steel plate.

3.1. Input Data

The plate representing the substrate is made of steel S355 and its dimensions are mm3. The make of the powder is H13. The situation and principal dimensions of the track are depicted in Figure 2.

Figure 2.

Track to be deposited on the substrate (all dimensions given in mm).

The power supplied to the laser head was 1.4 kW and the part delivered by the laser beam to the surface of the substrate was about 360 W. The power loss is very difficult to determine, as it consists of the power absorbed or reflected by the plasma plume above the irradiated area and power loss caused by the scattering of energy on powder particles. The defocusing of the laser beam by particles of material in the evaporated layer also has some effect. Therefore, the ratio of the power delivered to the substrate surface to the power delivered to the laser head has been verified experimentally and is used in a series of calculations and models for the substrate material with very good agreement in subsequent measurements.

The optics used for cladding provide a circular beam profile with a radius of 2 mm. The velocity of the laser head was 8.5 mm/s. The injected powder was delivered at a rate of 10 g/min. The ambient (initial) temperature was 25 °C and the generalized coefficient of convection (taking into account the radiation) was taken as

W·m−2·K−1. Even this value was very difficult to determine. Similarity theory is practically inapplicable in the case of an irradiated spot of small dimensions, and a more accurate answer could perhaps be provided using a complex CFD model, but this would lead to unacceptably long calculation times. In general, however, the air in the vicinity of the irradiated site is flowing, but its temperature is relatively high, meaning that it cools rather inefficiently. The value reported here was therefore chosen by averaging numerical modelling and experimentation performed on arrangements with similar topologies.

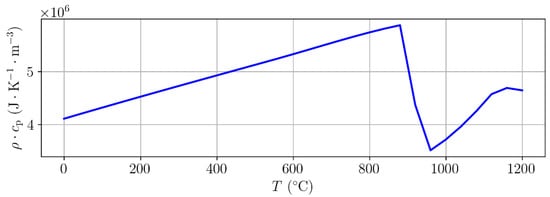

Substrate: Steel S355 is a standard construction material made from specific grades of steel and formed in a range of industry-standard cross-sectional shapes. Its chemical composition and mechanical properties correspond to a variety of applications and can be found in various databases and datasheets, such as [30,31]. For illustration, Figure 3 shows the temperature dependence of its specific heat .

Figure 3.

Temperature dependence of specific heat (steel S355).

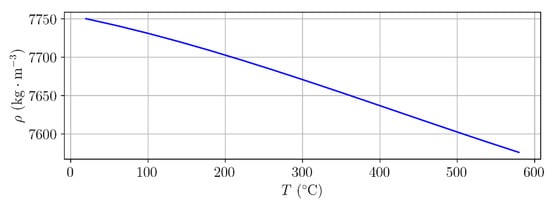

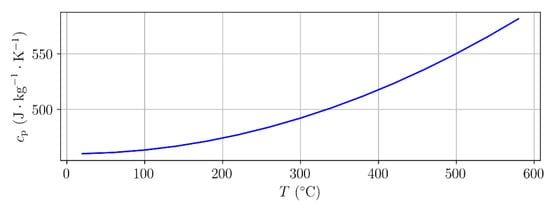

Powder: MetcoAdd™ H13 is a martensitic, iron-chromium, air-hardening steel powder designed for processing in laser powder bed fusion. For some particulars, see [32]. Figure 4, Figure 5 and Figure 6 show, in turn, the temperature dependencies of its specific mass, specific heat, and thermal conductivity.

Figure 4.

Temperature dependence of specific mass (powder H13).

Figure 5.

Temperature dependence of specific heat capacity (powder H13).

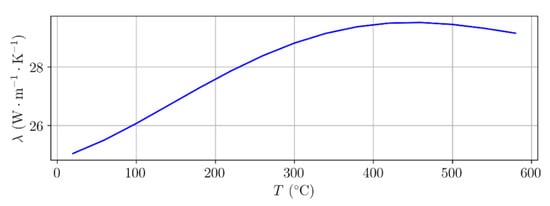

Figure 6.

Temperature dependence of thermal conductivity (powder H13).

3.2. Computations

The HTCondor computational cluster was used to calculate the simulation of the cladding of a three-layer square spiral. During the computation, 32 computational threads were loaded and a memory of 256 GB of RAM was allocated. The computation took approximately 11 h. The convergence of the solution with respect to the shape and fineness of the mesh was carried out and preliminarily tested. However, describing its parameters is very complicated due to the incommensurable geometry of the heat-affected zone involving the pool, its close surroundings, and the total volume of substrate and track. In general, a strong mesh refinement towards the heat-affected zone is used (inside it, the dimensions of the individual elements are at the level of tenths of mm), and the total number of degrees of freedom during the calculations is in the order of hundreds of thousands to millions just for the common calculation of the temperature and flow fields.

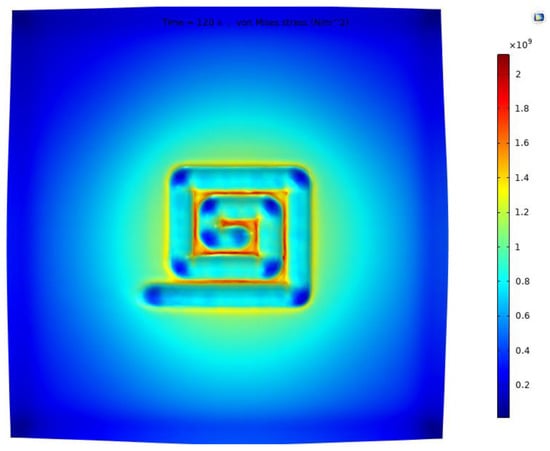

The computations were carried out using a combination of COMSOL Multiphysics and MATLAB. Particular physical fields were calculated by the FEM, as COMSOL does not make it possible to use FVM implemented in computational fluid dynamics codes. The simulation results of the cladding are shown in the following figures. Figure 7 shows the temperature field at a time point of 120 s, at which point the spiral is already finished and cooling. The total volume of powder material used in the simulation was 1923 mm3. Since the spiral was cladded from the outside towards the center, the highest temperature is in the center of the spiral.

Figure 7.

Distribution of temperature (in °C) after 120 s (track is finished and system is cooled).

Figure 8 shows the field of von Mises stress, also after 120 s of time, and additionally shows the deformation at a magnified scale. If the user only needs to calculate the temperature field, the calculation of the deformation can be turned off. The calculation time needed for only the temperature field would be approximately half the time, and of course the resulting volume of stored data with results would be smaller.

Figure 8.

Distribution of von Mises stress (in N/m2) after 120 s (track is finished and system is being cooled). Deformations are also depicted.

3.3. Experiment

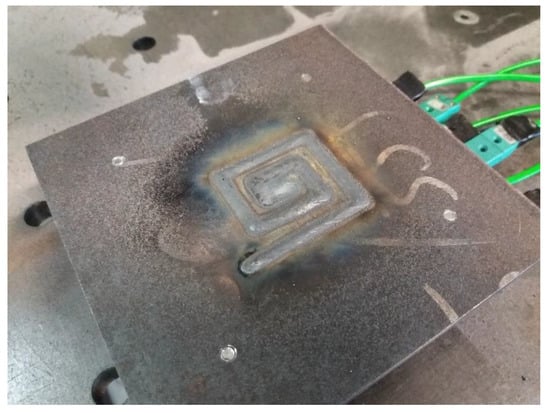

The numerical models used in the software had to be calibrated. Therefore, experiments were carried out and the correct parameters for the fit were set using model adaptation. Figure 9 shows the resulting deposited three-layer square spiral.

Figure 9.

Experiment: cladding of a three-layer square spiral at RAPTECH.

During the experiment, the temperature was sensed and recorded using six K-type thermocouples placed in drilled holes on the underside of the plate, as well as a thermocamera. The holes were drilled so that each thermocouple was 2 mm below the surface to be cladded. The positions of the thermocouples in the plate are shown in Figure 10.

Figure 10.

Positions of thermocouples in the plate: top view of the cladded side.

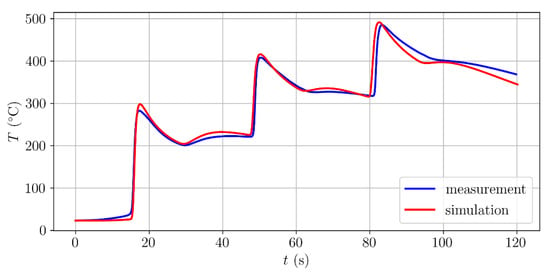

Figure 11 is shown to illustrate the comparison of temperatures from the experiment and simulation. It shows the temperature history calculated by simulation at the location of thermocouple 6, which has a position of mm, mm. The comparison of the temperature waveforms from the simulation and experiment shows great agreement. The maximum difference (for ) does not exceed about 5%.

Figure 11.

Time evolution of temperature at thermocouple no. 6.

We have not yet compared the exact dimensions of the modelled and real tracks. However, we are comparing the amounts of powder deposited, which is about 95% in both model and experiment. However, as the experimentally deposited track is not completely uniform in proportions and even homogeneous, the comparison of these dimensions is still under development within the model and what we can compare at this moment is the volume of the track.

4. Conclusions

Although cladding and additive technologies in general represent a rather difficult problem from the point of view of mathematical modelling, many important results can already be obtained with an acceptable accuracy and in a reasonable computational time.

For defined combinations of substrate and track material, we are able to provide a model-based insight into the thermal behaviour of the system with a very good agreement and thus control the quality of the design with respect to shape, hardness, and detection of dangerous stresses in the tracks. By using FEM and advanced optimization techniques, we are able to replace the expensive experimental development phase in a number of aspects (variation in cladding speed, laser power, and powder quantity rate) and provide very valuable information from the numerical simulation. The optional method used for discretizing the area around the heat-affected zone significantly accelerated the computations.

Nevertheless, the calculations will still have to be accelerated, especially if the whole process has to be optimized. One of the options considered for the physical process is the creation of a digital twin [33] applied to a suitable surrogate or neural network-based model that would extract data directly from the physical process—i.e., from real measured quantities.

The solution team is currently preparing a database of the most commonly used materials for cladding for the simulation scripts already developed. The user will therefore also have the ability to easily select the material when entering input data for the cladding simulation via the web interface. At the same time, scripts for variational calculations are being prepared to improve the quality of the cladding process.

Author Contributions

Conceptualization, writing and supervision, I.D.; Project administration, preparation of data, computations and evaluation of results, V.K.; Writing of software and computations and evaluation of results, R.H.; Processing of data and computations, K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been supported by the Technological Agency of the Czech Republic, project No. TH03020130.

Data Availability Statement

Data presented in this article are available at request from Václav Kotlan and Roman Hamar.

Conflicts of Interest

The authors declare no conflict of interest.

References

- von Starck, A.; Mühlbauer, A.; Kramer, C. Handbook of Thermoprocessing Technologies: Fundamentals, Processes, Components, Safety; Vulkan: Essen, Germany, 2005. [Google Scholar]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and Development Status of Laser Cladding on Magnesium Alloys: A Review. Opt. Lasers Eng. 2015, 93, 195–210. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, W. Laser surface cladding: The state of the art and challenges. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 224, 1041–1060. [Google Scholar] [CrossRef]

- Birger, E.M.; Moskvitin, G.V.; Polyakov, A.N.; Arkhipov, V.E. Industrial laser cladding: Current state and future. Weld. Int. 2011, 25, 234–243. [Google Scholar] [CrossRef]

- Lu, P.; Lewis, S.R.; Fretwell-Smith, S.; Engelberg, D.L.; Fletcher, D.I.; Lewis, R. Laser Cladding of Rail: The Effects of Depositing Material on Lower Rail Grades. Wear 2019, 438–439. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.; Jiao, H. Microstructure and properties of 6FeNiCoSiCrAlTi high-entropy alloy coating prepared by laser cladding. Appl. Surf. Sci. 2011, 257, 2259–2263. [Google Scholar] [CrossRef]

- Vilar, R.; Santos, E.C.; Ferreira, P.N.; Franco, N.; da Silva, R.C. Structure of NiCrAlY coatings deposited on single-crystal alloy turbine blade material by laser cladding. Acta Mater. 2009, 57, 5292–5302. [Google Scholar] [CrossRef]

- Yi, P.; Liu, Y.; Fan, C.; Zhan, X.; Xu, P.; Liu, T. Impact analysis of the thermal mechanical coupling characteristics of graphite morphologies during laser cladding of gray cast iron. Opt. Laser Technol. 2017, 90, 52–64. [Google Scholar]

- Javid, Y.; Ghoreishi, M. Thermo-mechanical analysis in pulsed laser cladding of WC powder on Inconel 718. Int. J. Adv. Manuf. Technol. 2017, 92, 69–79. [Google Scholar] [CrossRef]

- Zhang, Z.; Farahmand, P.; Kovacevic, R. Laser cladding of 420 stainless steel with molybdenum on mild steel A36 by a high power direct diode laser. Mater. Des. 2016, 109, 686–699. [Google Scholar] [CrossRef] [Green Version]

- Wen, S.; Shin, Y. Modeling of transport phenomena during the coaxial laser direct deposition process. J. Appl. Phys. 2010, 108, 044908. [Google Scholar]

- Kovaleva, I.; Kovalev, O.; Zaitsev, A.; Smurov, I. Numerical Simulation and Comparison of Powder Jet Profiles for Different Types of Coaxial Nozzles in Direct Material Deposition. Phys. Procedia 2013, 41, 870–872. [Google Scholar] [CrossRef] [Green Version]

- Yang, N. Concentration model based on movement model of powder flow in coaxial laser cladding. Opt. Laser Technol. 2009, 41, 94–98. [Google Scholar] [CrossRef]

- Huang, Y.; Khamesee, M.B.; Toyserkani, E. A Comprehensive Analytical Model for Laser Powder-fed Additive Manufacturing. Addit. Manuf. 2016, 12, 90–99. [Google Scholar] [CrossRef]

- Lee, Y.; Farson, D.F. Simulation of transport phenomena and melt pool shape for multiple layer additive manufacturing. J. Laser Appl. 2016, 28, 012006. [Google Scholar]

- Li, C.; Liu, C.; Li, S.; Zhang, Z.; Zeng, M.; Wang, F.; Wang, J.; Guo, Y. Numerical Simulation of Thermal Evolution and Solidification Behavior of Laser Cladding AlSiTiNi Composite Coatings. Coatings 2019, 9, 391. [Google Scholar] [CrossRef] [Green Version]

- Ghorashi, M.S.; Farrahi, G.H.; Movahhedy, M.R. Considering Cyclic Plasticity to Predict Residual Stresses in Laser Cladding of Inconel 718 Multi Bead Samples. J. Manuf. Processes 2019, 42, 149–158. [Google Scholar] [CrossRef]

- Nazemi, N.; Urbanic, J. An Experimental and Simulation Study for Powder Injection Multitrack Laser Cladding of P420 Stainless Steel on AISI 1018 Steel for Selected Mechanical Properties. J. Manuf. Sci. Eng. 2017, 140, 011009. [Google Scholar]

- Diez, M.; Campana, E.F.; Stern, F. Design-space Dimensionality Reduction in Shape Optimization by Karhunen–Loève Expansion. Comput. Methods Appl. Mech. Eng. 2015, 283, 1525–1544. [Google Scholar] [CrossRef]

- Solin, P.; Segeth, K.; Dolezel, I. Higher-Order Finite Element Methods; Chapman and Hall/CRC: Boca Raton, FL, USA, 2003. [Google Scholar]

- Ibarra-Medina, J.; Vogel, M.; Pinkerton, A.J. A CFD Model of Laser Cladding: From Deposition Head to Melt Pool Dynamics. In Proceedings of the Proc. ICALEO 2011, Orlando, FL, USA, 23–27 October 2011. [Google Scholar]

- Holman, J.P. Heat Transfer; McGraw-Hill: New York, NY, USA, 2009. [Google Scholar]

- Panek, D.; Kotlan, V.; Hamar, R.; Dolezel, I. Novel Algorithm for Modeling Combined Laser and Induction Welding Respecting Keyhole Effect. Appl. Math. Comput. 2018, 319, 254–263. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; le Mason, P.; Gaied, S.; Balabane, M. A Complete Model of Keyhole and Melt Pool Dynamics to Analyze Instabilities and Collapse during Laser Welding. J. Laser Appl. 2014, 26, 042001. [Google Scholar] [CrossRef] [Green Version]

- Tan, C.; Zhao, L.; Chen, M.; Cheng, J.; Wu, C.; Liu, Q.; Yang, H.; Yin, Z.; Liao, W. Experimental and theoretical investigation of localized CO2 laser interaction with fused silica during the process of surface damage mitigation. Results Phys. 2020, 16, 102936. [Google Scholar]

- Xu, J.; Luo, Y.; Zhu, L.; Han, J.; Zhang, C.; Chen, D. Effect of shielding gas on the plasma plume in pulsed laser welding. Measurement 2018, 134, 25–32. [Google Scholar]

- Zhang, Z.; Kovacevic, R. A thermo-mechanical model for simulating the temperature and stress distribution during laser cladding process. Int. J. Adv. Manuf. Technol. 2019, 102, 457–472. [Google Scholar] [CrossRef]

- Elmesalamy, A.S.; Abdolvand, H.; Walsh, J.N.; Francis, J.A.; Suder, W.; Williams, S.; Li, L. Measurement and modelling of the residual stresses in autogenous and narrow gap laser welded AISI grade 316L stainless steel plates. Int. J. Press. Vessel. Pip. 2016, 147, 64–78. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Khurshid, M.; Barsoum, Z. Accuracy of computational welding mechanics methods for estimation of angular distortion and residual stresses. Weld. World 2019, 63, 1391–1405. [Google Scholar]

- Dzioba, I.; Lipiec, S. Fracture Mechanisms of S355 Steel—Experimental Research, FEM Simulation and SEM Observation. Materials 2019, 12, 23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Narvan, M.; Al-Rubaie, K.S.; Elbestawi, M. Process-Structure-Property Relationships of AISI H13 Tool Steel Processed with Selective Laser Melting. Materials 2019, 12, 2284. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gunasegaram, D.R.; Murphy, A.B.; Barnard, A.; DebRoy, T.; Mathews, M.J.; Ladani, L.; Gu, D. Towards Developing Multiscale-Multiphysics Models and their Surrogates for Digital Twins of Metal Additive Manufacturing. Addit. Manuf. 2021, 46, 102089. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).