Effect of Sputter Deposition on the Adhesion and Failure Behavior between Cu Film and Glassy Calcium Aluminosilicate: A Molecular Dynamics Study

Abstract

:1. Introduction

2. Computational Methods

2.1. Materials and Building of CAS Substrate

2.2. Simulation of the Film Growth by PVD

2.3. SMD Simulation and Adhesion Calculation

3. Results and Discussion

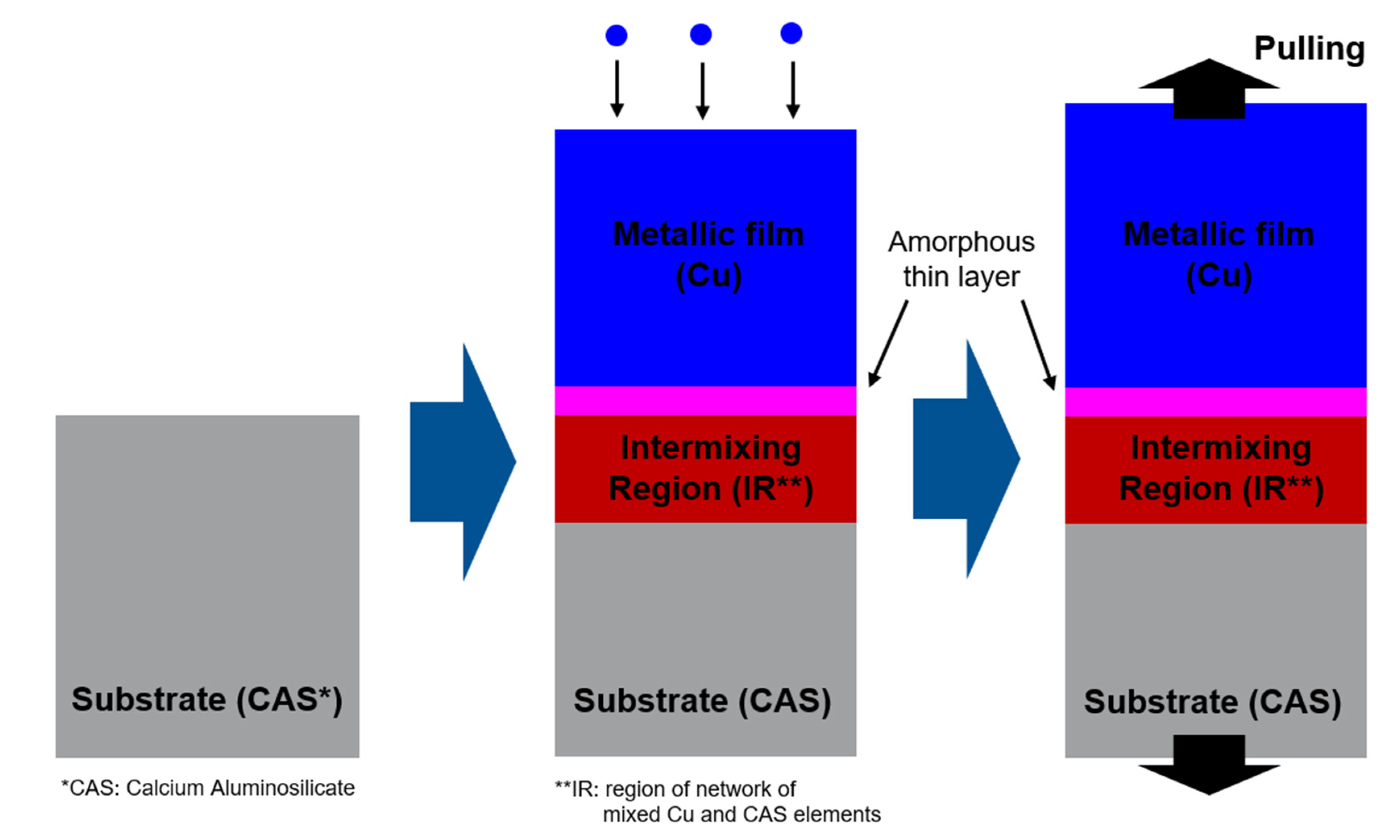

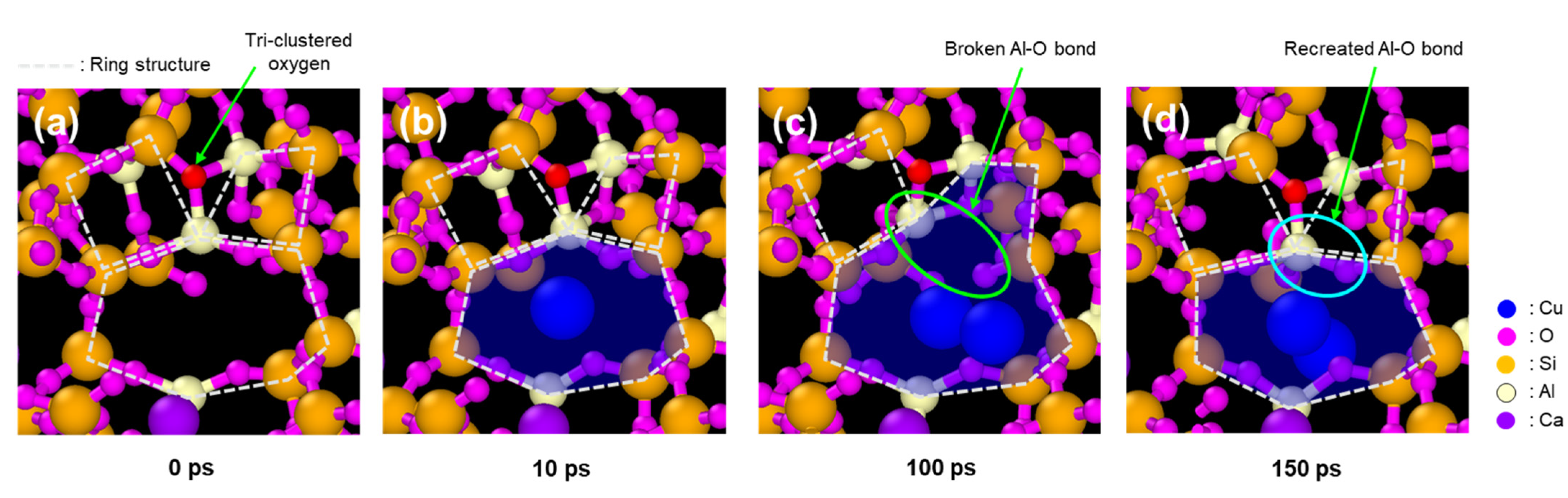

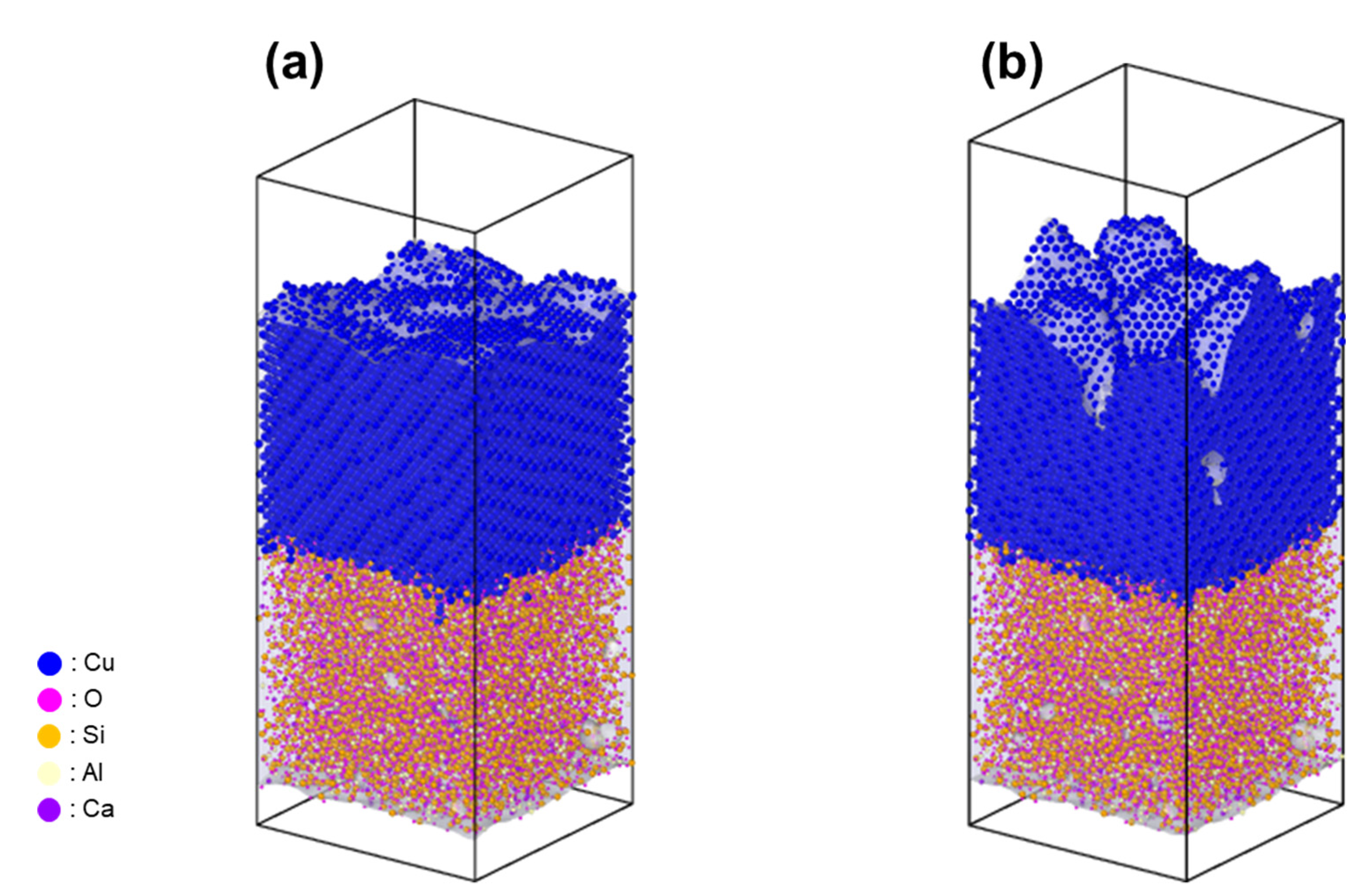

3.1. Formation of Intermixing Region (IR)

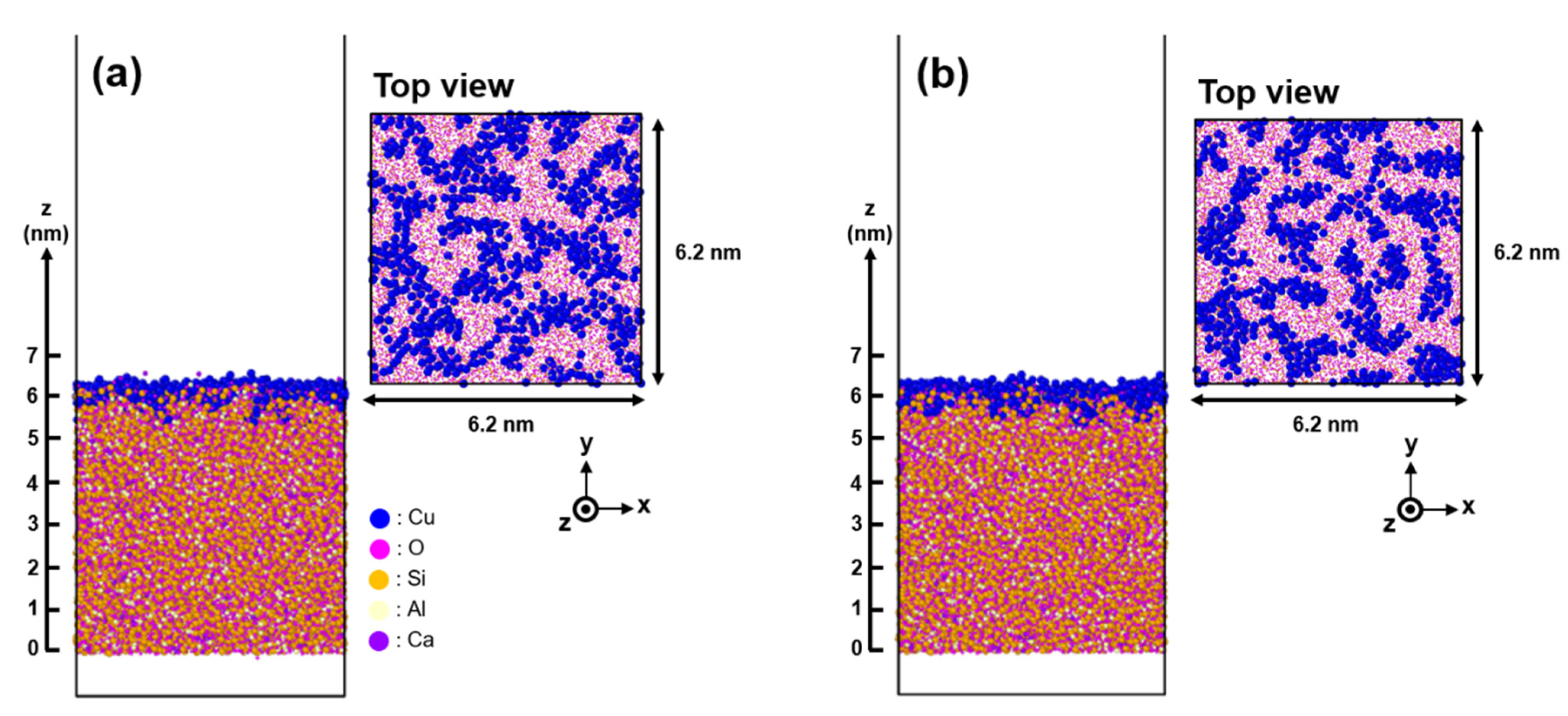

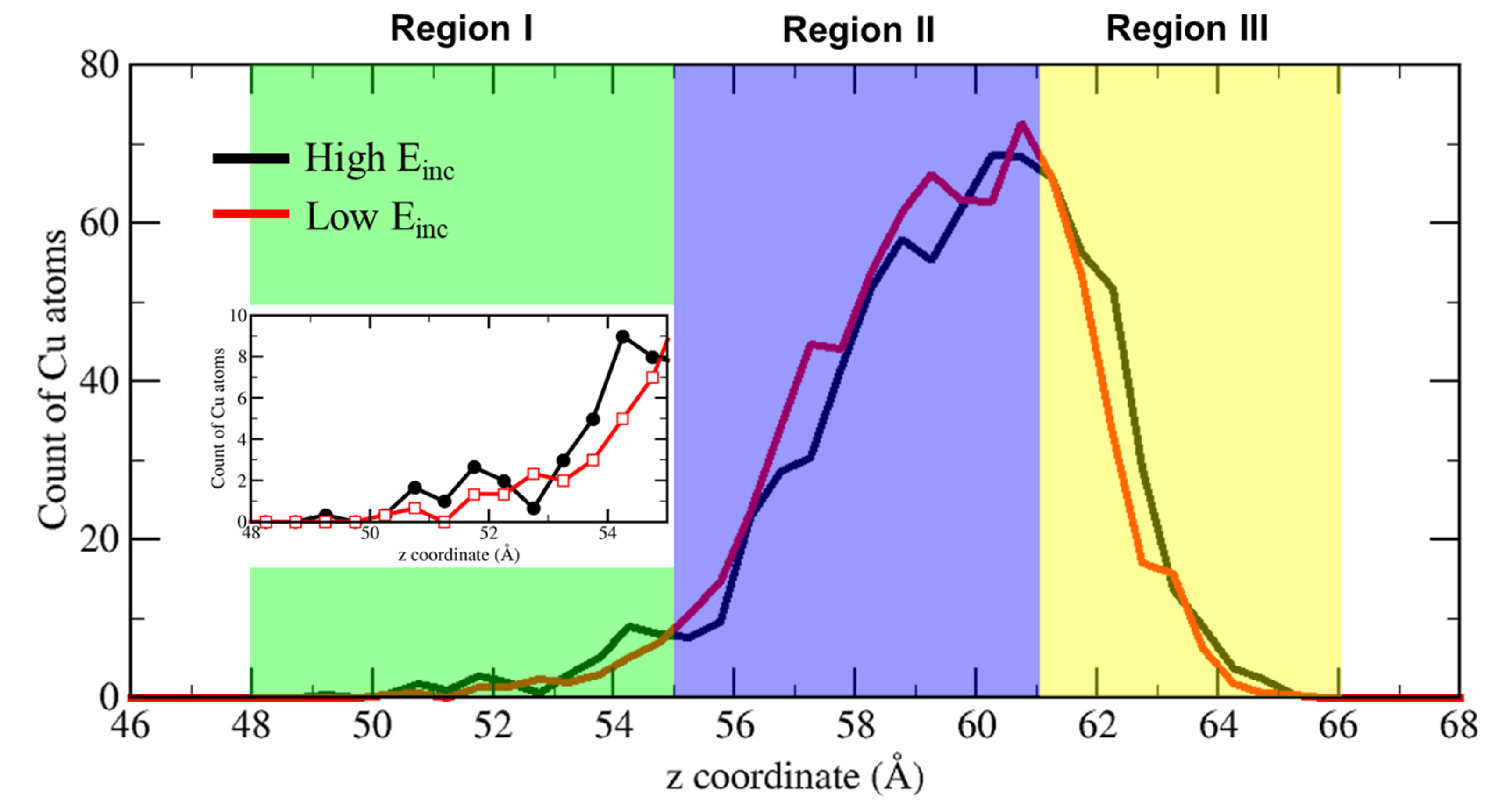

3.2. Cu Film Growth on IR

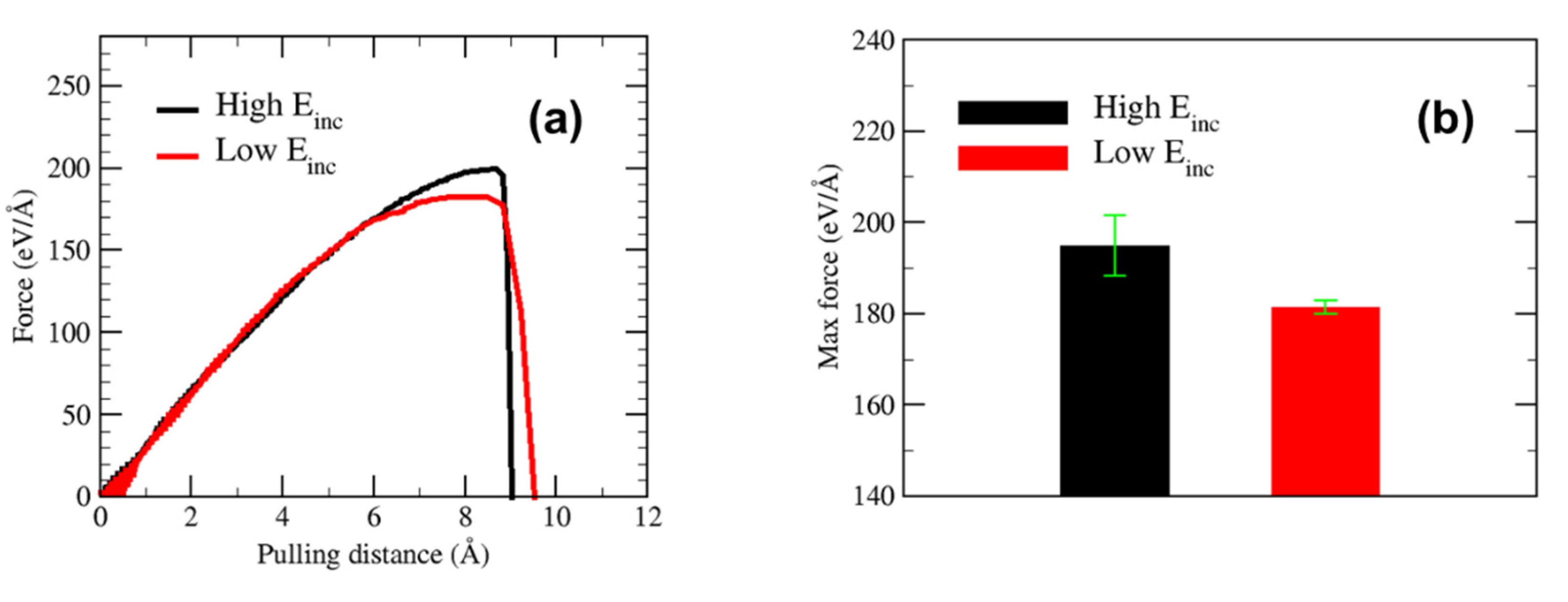

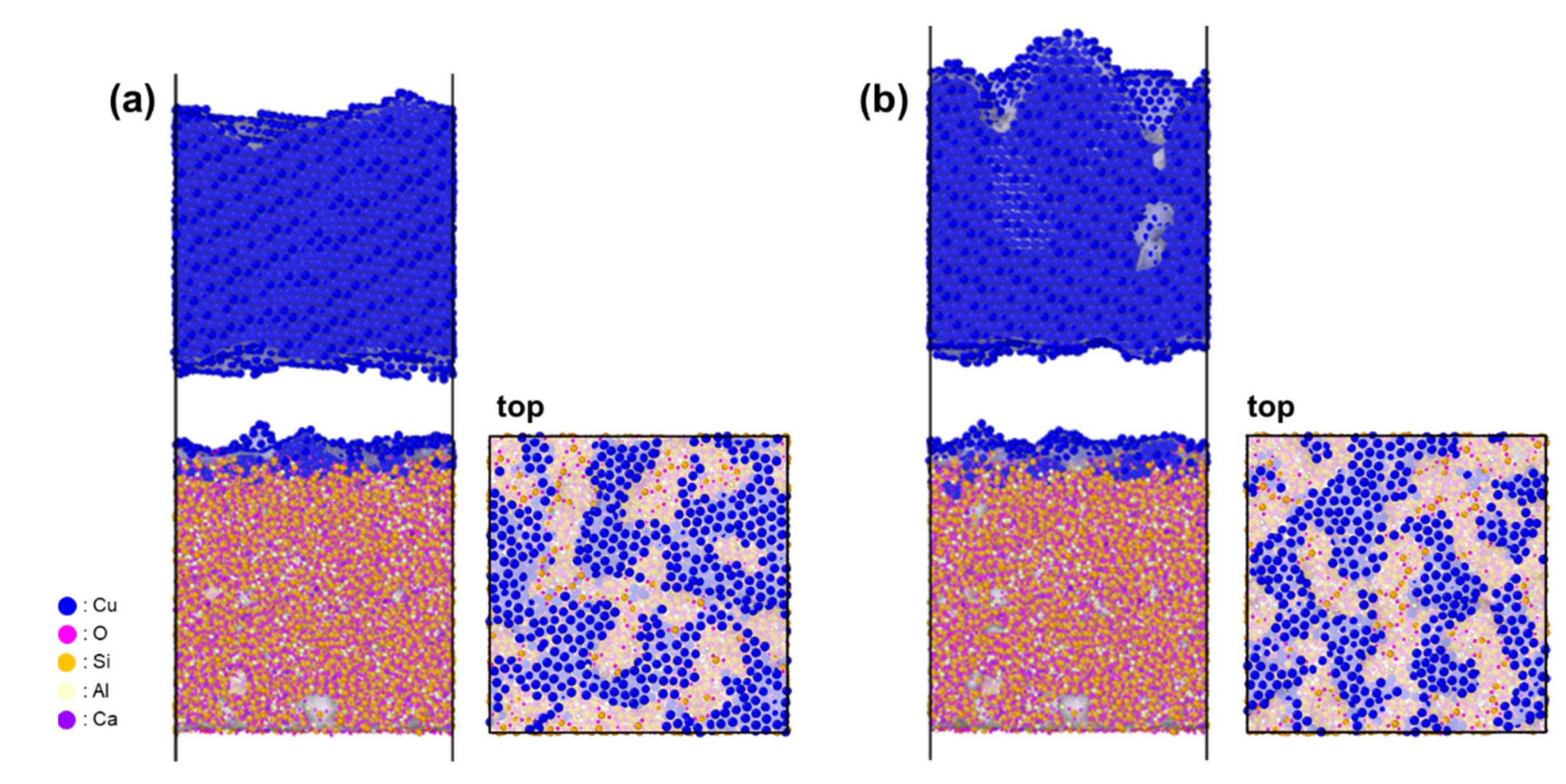

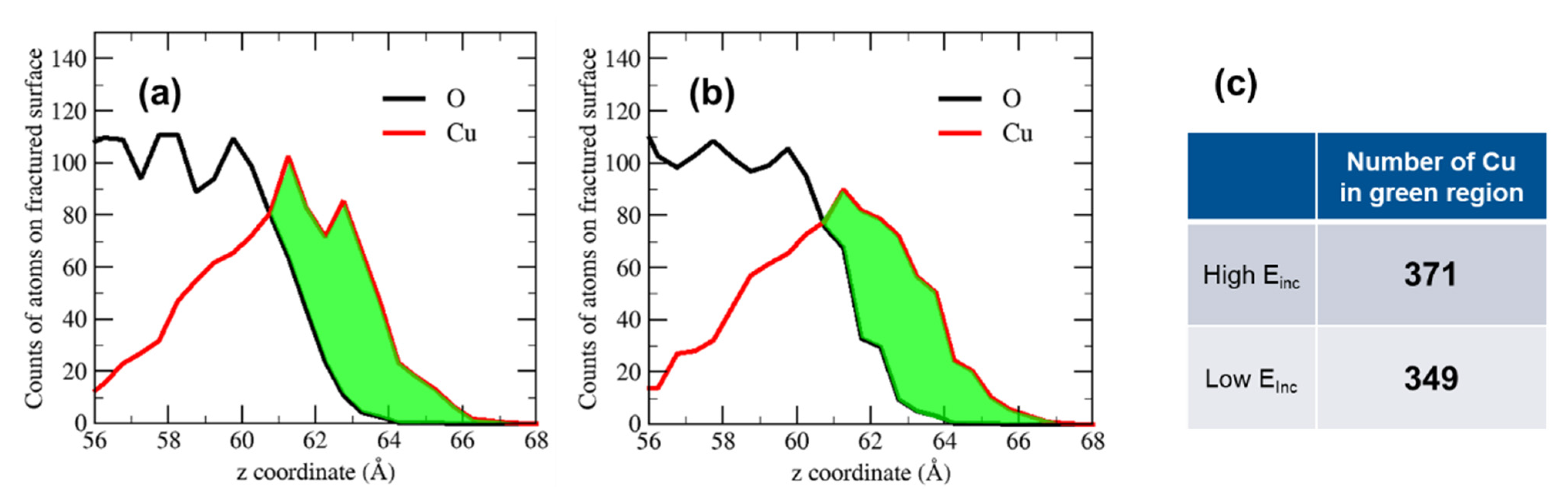

3.3. Deformation and Failure of Cu-CAS Bilayer

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tilli, M.; Mottoka, T.; Airaksinen, V.-M.; Fransilla, S.; Paulasto-Krockel, M.; Lindroos, V. Handbook of Silicon Based MEMS Materials and Technologies, 2nd ed.; Elsevier: London, UK, 2015. [Google Scholar]

- Lu, D.; Wong, C.P. Materials for Advanced Packaging; Springer: New York, NY, USA, 2008. [Google Scholar]

- Datta, M. Microelectronic Packaging Trends and the Role of Nanotechnology; Springer: New York, NY, USA, 2010. [Google Scholar]

- Ohno, T. Thin-Film PVD: Materials, Processes, and Equipment. In Flat Panel Display Manufacturing; Souk, J.M.S., Luo, F.-C., Bita, I., Eds.; John Wiley and Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Mittal, K.L. Adhesion Measurement of Films and Coatings, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014; Volume 1. [Google Scholar]

- Teraoka, A.; Watanabe, M.; Nabetani, Y.; Kondoh, E. Room-Temperature Formation of a ZnO-Based Adhesion Layer for Nanoprecision Cu/Glass Metallization. Jpn. J. Appl. Phys. 2013, 52, 05FB04. [Google Scholar] [CrossRef]

- Benjamin, P.; Weaver, C. The Adhesion of Evaporated Metal Films on Glass. Proc. R. Soc. Lond. A 1962, 261, 516–531. [Google Scholar]

- Mingos, D.M.P.; Day, P.; Dahl, J.P. Molecular Electronic Structures of Transition Metal Complexes; Springer: Heidelberg, Germany, 2012. [Google Scholar]

- Haynes, W.M. CTC Handbook of Chemistry and Physics, 95th ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Lee, L.H. Fundamentals of Adhesion; Plenum Press: New York, NY, USA, 1991. [Google Scholar]

- Paunovic, M.; Schlesinger, M. Fundamentals of Electrochemical Deposition, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Wasa, K.; Kanno, I.; Kotera, H. Handbook of Sputter Deposition Technology: Fundamentals and Applications for Functional Thin Films, Nanomaterials, and MEMS, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology; Marcel Dekker Inc.: New York, NY, USA, 2003. [Google Scholar]

- Piggot, M. Why Interface Testing by Single-fiber Methods can be Misleading. Compos. Sci. Technol. 1997, 57, 965–974. [Google Scholar] [CrossRef]

- Favre, J.P.; Desarmot, G.; Sudre, O.; Vassel, A. Were McGarry or Shiriajeva Right to Measure Glass. Compos. Interfaces 1997, 4, 313–326. [Google Scholar] [CrossRef]

- Hampe, A.; Marotzke, C. The Energy Release Rate of the Fiber/polymer Matrix Interface: Measurement. J. Reinf. Plast. Compos. 1997, 16, 341–352. [Google Scholar] [CrossRef]

- Marks, N.A.; McKenzie, D.R.; Pailthorpe, B.A. Molecular-dynamics Study of Compressive Stress Generation. Phys. Rev. B. 1996, 53, 4117–4124. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.W.; Wadley, N.G. Atomistic Simulations of the Vapor Deposition of Ni/Cu/Ni Multilayers: The Effects of Adatom Incident Energy. J. Appl. Phys. 1998, 84, 3201–3215. [Google Scholar] [CrossRef] [Green Version]

- Houska, J. Pathway for a Low-temperature Deposition of α-Al2O3: A Molecular Dynamics Study. Surf. Coat. Technol. 2013, 235, 333–341. [Google Scholar] [CrossRef]

- Hong, Z.-H.; Fang, T.-H.; Hwang, S.-F. Atomic-level Stress and Induced Growth of Wurtzite Zinc Oxide Using Molecular Dynamics Simulation. J. Phys. D Appl. Phys. 2011, 44, 505301. [Google Scholar] [CrossRef]

- Georgieva, V.; Saraiva, M.; Jehanathan, N.; Levelev, O.I.; Depla, D.; Bogaerts, A. Sputter-deposited Mg-Al-O Thin Films: Linking Molecular Dynamics Simulations to Experiments. J. Phys. D Appl. Phys. 2009, 42, 065107. [Google Scholar] [CrossRef] [Green Version]

- Min, K.; Kim, Y.; Goyal, S.; Lee, S.H.; McKenzie, M.E.; Park, H.; Savoy, E.; Rammohan, A.R.; Mauro, J.C.; Kim, H. Interfacial Adhesion Behavior of Polyimides on Silica Glass: A Molecular Dynamics Study. Polymer 2016, 98, 1–10. [Google Scholar] [CrossRef]

- Davis, D.A.; Hamilton, A.; Yang, J.; Cremar, L.D.; Van Gough, D.; Potisek, S.L.; Ong, M.T.; Braun, P.V.; Martinez, T.J.; White, S.R.; et al. Force-Induced Activation of Covalent Bonds in Mechano-Responsive Polymeric Materials. Nature 2009, 459, 68–72. [Google Scholar] [CrossRef]

- Varshneya, A.K. Fundamentals of Inorganic Glasses, 2nd ed.; Society of Glass Technology: Sheffield, UK, 2013; Volume 1. [Google Scholar]

- Musgraves, J.D.; Hu, J.; Calves, L. Springer Handbook of Glass; Springer Nature: Sheffield, UK, 2019. [Google Scholar]

- Pedone, A. Properties Calculations of Silica-Based Glasses by Atomistic Simulations Techniques: A Review. J. Phys. Chem. C 2009, 113, 20773–20784. [Google Scholar] [CrossRef]

- Pedone, A.; Malavasi, G.; Menziani, M.C.; Segre, U.; Cormack, A.N. Molecular Dynamics Studies of Stress-Strain Behavior of Silica Glass under a Tensile Load. Chem. Mater. 2008, 20, 4356–4366. [Google Scholar] [CrossRef]

- Pedone, A.; Malavasi, G.; Cormack, A.N.; Segre, U.; Menziani, M.C. Insight into Elastic Properties of Binary Alkali Silicate Glasses; Prediction and Interpretation through Atomistic Simulation Techniques. Chem. Mater. 2007, 19, 3144–3154. [Google Scholar] [CrossRef]

- Bansal, N.P.; Doremus, R.H. Handbook of Glass Properties; Academic Press: Orlando, FL, USA, 1986. [Google Scholar]

- Xie, L.; Brault, P.; Bauchire, J.-M.; Thomann, A.-L.; Bedra, L. Molecular Dynamics Simulations of Clusters and Thin Film Growth in the Context of Plasma Sputtering Deposition. J. Phys. D Appl. Phys. 2014, 47, 224004. [Google Scholar] [CrossRef]

- Wadley, H.N.G.; Zou, W.; Zhou, X.W.; Groves, J.F. Multiscale Simulations of the RF Diode Sputtering of Copper. Mat. Res. Soc. Symp. Proc. 1999, 536, 323–328. [Google Scholar] [CrossRef] [Green Version]

- Plimpton, S. Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Sheng, H.W.; Kramer, M.J.; Cadien, A.; Fujita, T.; Chen, M.W. Highly Optimized EAM Potentials for 14 fcc Metals. Phys. Rev. B 2011, 83, 134118. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.-T.; Li, C.-M.; Yan, H.; Evans, D.G.; Duan, X. Density Functional Theory Study on the Metal-Support Interaction between Ru Cluster and Anatase TiO2(101) Surface. J. Phys. Chem. C 2014, 118, 3514–3522. [Google Scholar] [CrossRef]

- Goyal, S.; Park, H.-H.; Lee, S.H.; Savoy, E.; McKenzie, M.E.; Rammohan, A.R.; Mauro, J.C.; Kim, H.; Min, K.; Cho, E. Characterizing the Fundamental Adhesion of Polyimide Monomers on Crystalline and Glassy Silica Surfaces: A Molecular Dynamics Study. J. Phys. Chem. C 2016, 120, 23631–23639. [Google Scholar] [CrossRef]

- Lee, S.H.; Stewart, R.J.; Park, H.; Goyal, S.; Botu, V.; Kim, H.; Min, K.; Cho, E.; Rammohan, A.R.; Mauro, J.C. Effect of Nanoscale Roughness on Adhesion between Glassy Silica and Polyimides: A Molecular Dynamics Study. J. Phys. Chem. C 2017, 121, 24648–24656. [Google Scholar] [CrossRef]

- Min, K.; Rammohan, A.R.; Lee, H.S.; Shin, J.; Lee, S.H.; Goyal, S.; Park, H.; Mauro, J.C.; Stewart, R.; Botu, V.; et al. Computational Approaches for Investigating Interfacial Adhesion Phenomena of Polyimide on Silica Glass. Sci. Rep. 2017, 7, 10475. [Google Scholar] [CrossRef] [Green Version]

- Min, K.; Rammohan, A.R.; Lee, S.H.; Goyal, S.; Park, H.; Stewart, R.; He, X.; Cho, E. Grafting Functional Groups in Polymeric Binder toward Enhancing Structural Integrity of LixSiO2 Anode during Electrochemical Cycling. J. Phys. Chem. C 2018, 122, 17190–17198. [Google Scholar] [CrossRef]

- Chabria, M.; Gertig, S.; Smith, M.L.; Vogel, V. Stretching Fibronectin Fibres Disrupts Binding of Bacterial Adhesins by Physically Destroying an Epitope. Nat. Commun. 2010, 1, 135. [Google Scholar] [CrossRef] [Green Version]

- Jarzynski, C. Nonequilibrium Equality for Free Energy Differences. Phys. Rev. Lett. 1997, 78, 2690. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Schulten, K. Calculating Potentials of Mean Force from Steered Molecular Dynamics Simulations. J. Chem. Phys. 2004, 120, 5946. [Google Scholar] [CrossRef]

- Agnello, G.; Wang, L.; Smith, N.; Manley, R.; Cormack, A. Structure of CAS Glass Surfaces and Eletrostatic Contact Charging Behavior: A Joint Simulation and Experimental Investigation. Int. J. Appl. Glass Sci. 2021, 12, 111–123. [Google Scholar] [CrossRef]

- Herman, M.A.; Richter, W.; Sitter, H. Epitaxy: Physical Principles and Technical Implementation; Springer: Berlin, Germany, 2004. [Google Scholar]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated Identification and Indexing of Dislocations in Crystal Interfaces. Modeling Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Ren, X.; Eckert, J.; Wang, Y.; Zhu, Z.; Gemming, T.; Pauly, S. Amorphous Martensite in β-Ti Alloys. Nat. Commun. 2018, 9, 506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salavati-Niasari, M.; Davar, F. Synthesis of Copper and Copper(I) Oxide Nanoparticles by Thermal Decomposition of a New Precursor. Mater. Lett. 2009, 63, 441–443. [Google Scholar] [CrossRef]

- Windischmann, H. Intrinsic Stress in Sputter-deposited Thin Films. Crit. Rev. Solid State 1992, 17, 547–596. [Google Scholar] [CrossRef]

- Thornton, J.A.; Hoffman, D.W. Stress Related Effects in Thin Films. Thin Solid Film. 1989, 171, 5–31. [Google Scholar] [CrossRef]

| Coordinate | Number of Cu for High Einc Case | Number of Cu for Low Einc Case |

|---|---|---|

| Whole region (48–66 Å) | 769 | 769 |

| Region I (48–55 Å) | 34 | 23 |

| Region II (55–61 Å) | 503 | 552 |

| Region III (61–66 Å) | 232 | 194 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.; Lee, S. Effect of Sputter Deposition on the Adhesion and Failure Behavior between Cu Film and Glassy Calcium Aluminosilicate: A Molecular Dynamics Study. Metals 2021, 11, 1365. https://doi.org/10.3390/met11091365

Park H, Lee S. Effect of Sputter Deposition on the Adhesion and Failure Behavior between Cu Film and Glassy Calcium Aluminosilicate: A Molecular Dynamics Study. Metals. 2021; 11(9):1365. https://doi.org/10.3390/met11091365

Chicago/Turabian StylePark, Hyunhang, and Sunghoon Lee. 2021. "Effect of Sputter Deposition on the Adhesion and Failure Behavior between Cu Film and Glassy Calcium Aluminosilicate: A Molecular Dynamics Study" Metals 11, no. 9: 1365. https://doi.org/10.3390/met11091365

APA StylePark, H., & Lee, S. (2021). Effect of Sputter Deposition on the Adhesion and Failure Behavior between Cu Film and Glassy Calcium Aluminosilicate: A Molecular Dynamics Study. Metals, 11(9), 1365. https://doi.org/10.3390/met11091365