Hot Deformation Behavior and Dynamic Recrystallization of Ultra High Strength Steel

Abstract

:1. Introduction

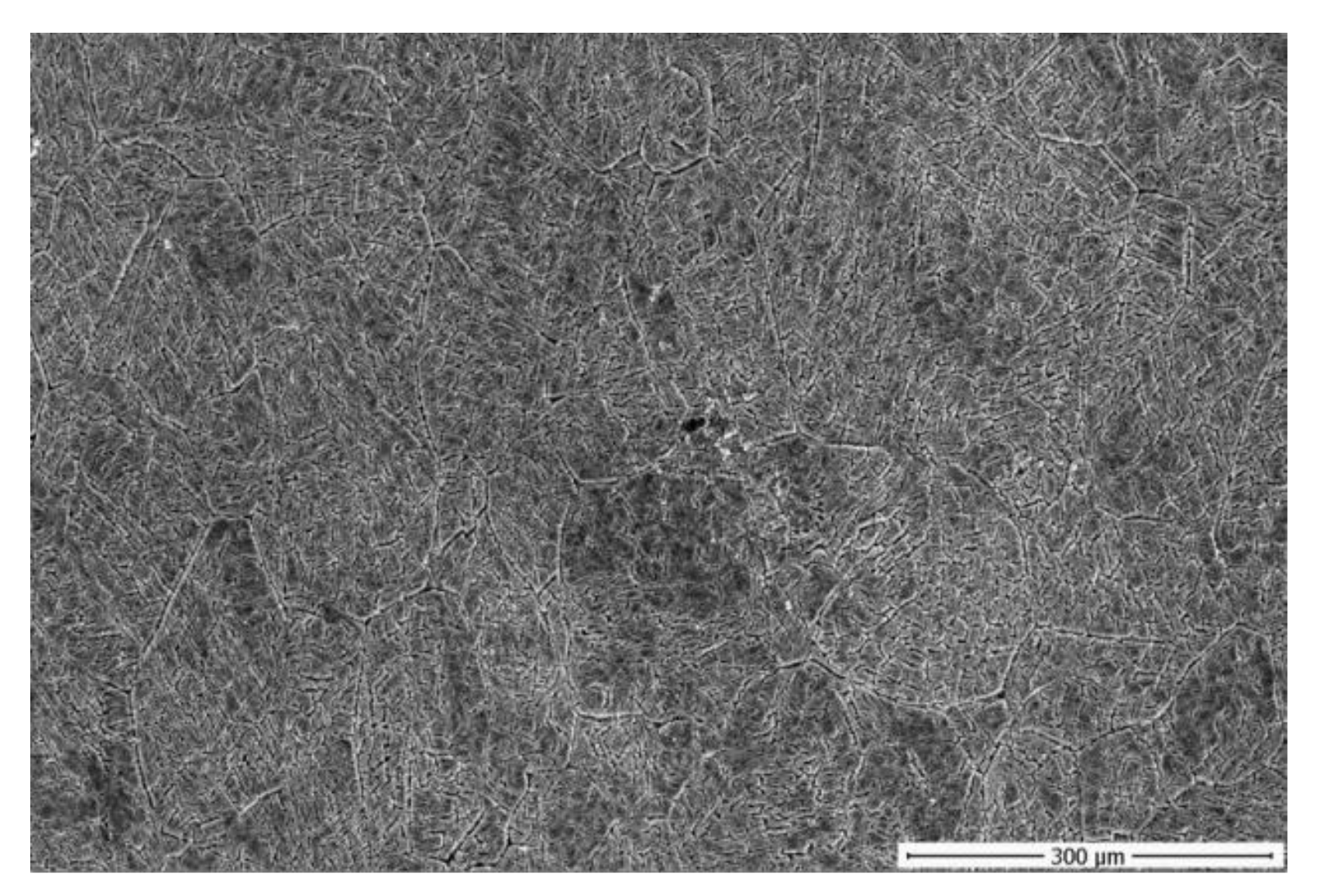

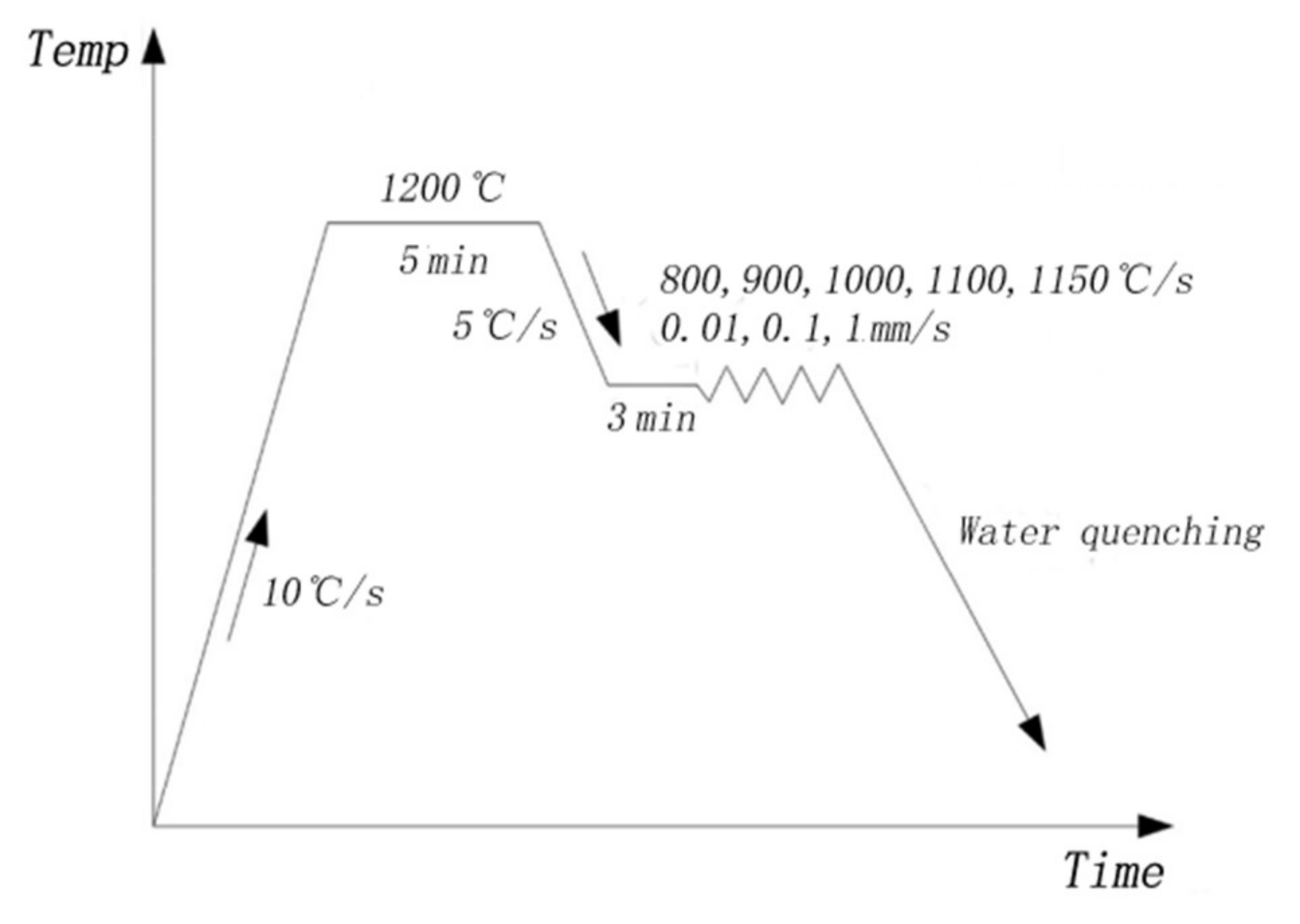

2. Experimental Procedure

3. Results and Discussions

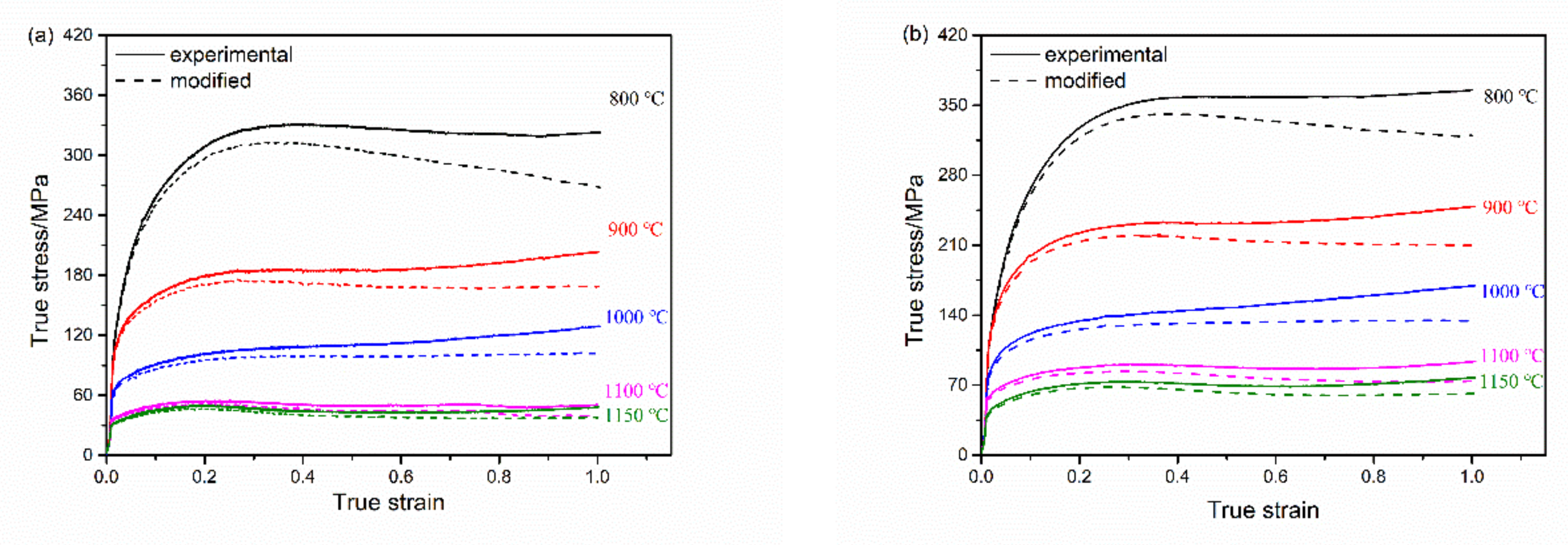

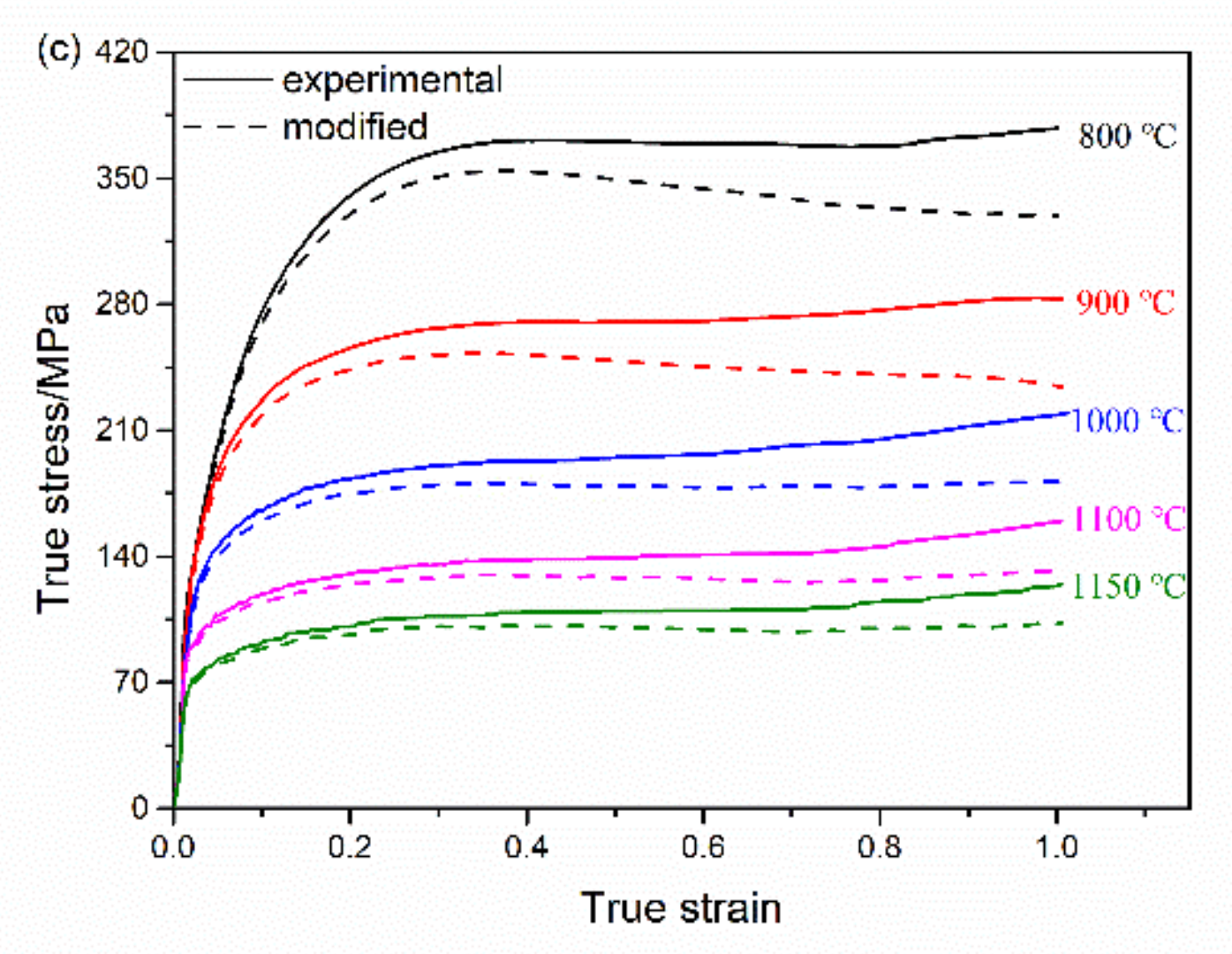

3.1. Discussion on Hot Deformation Behavior

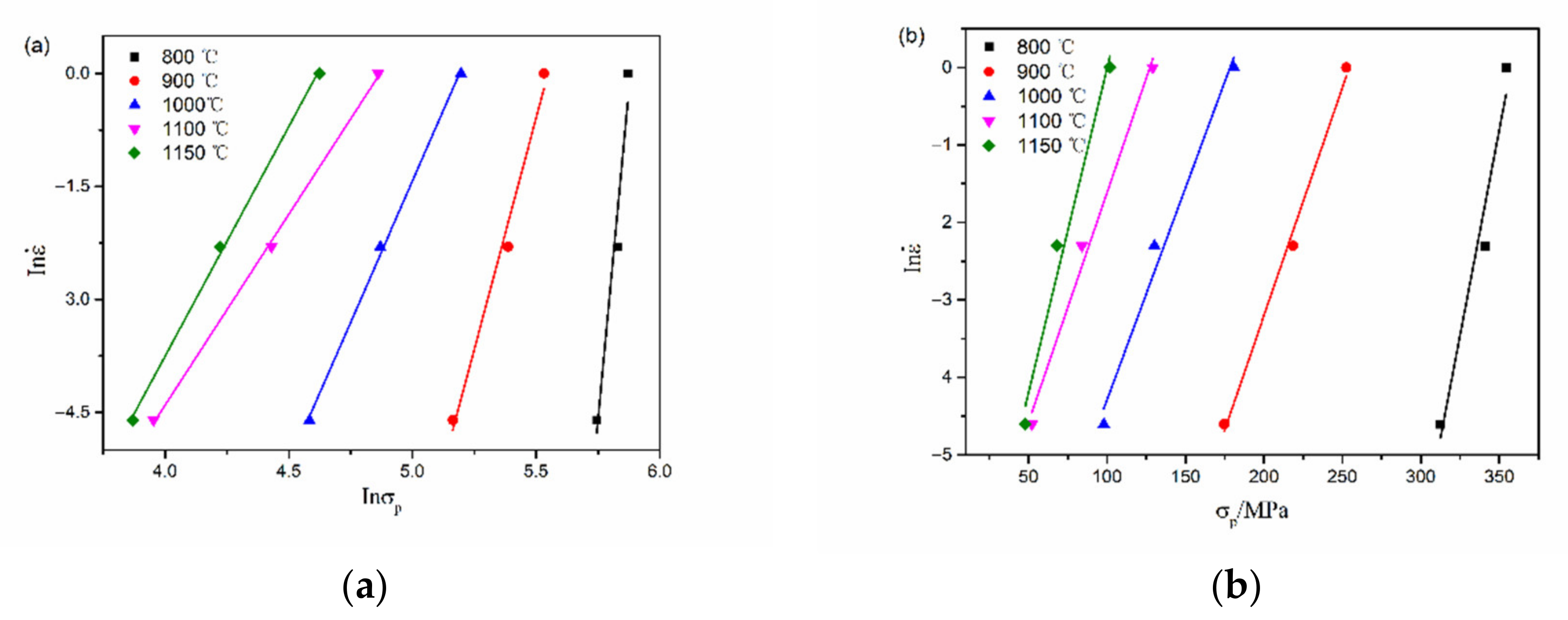

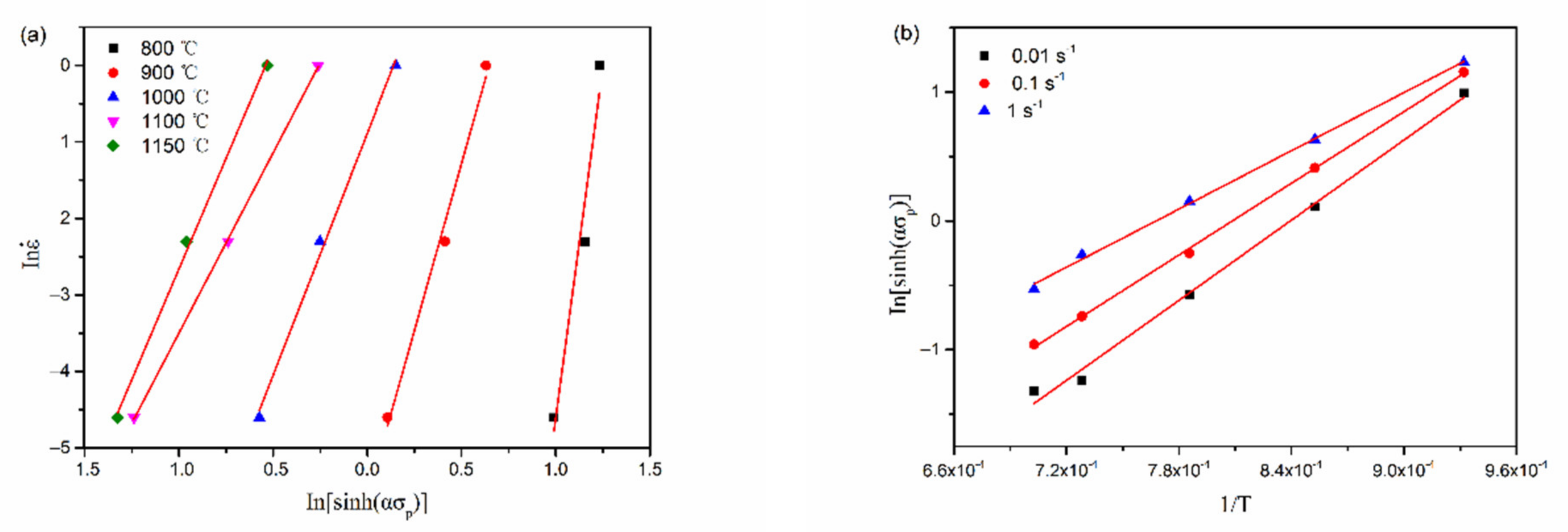

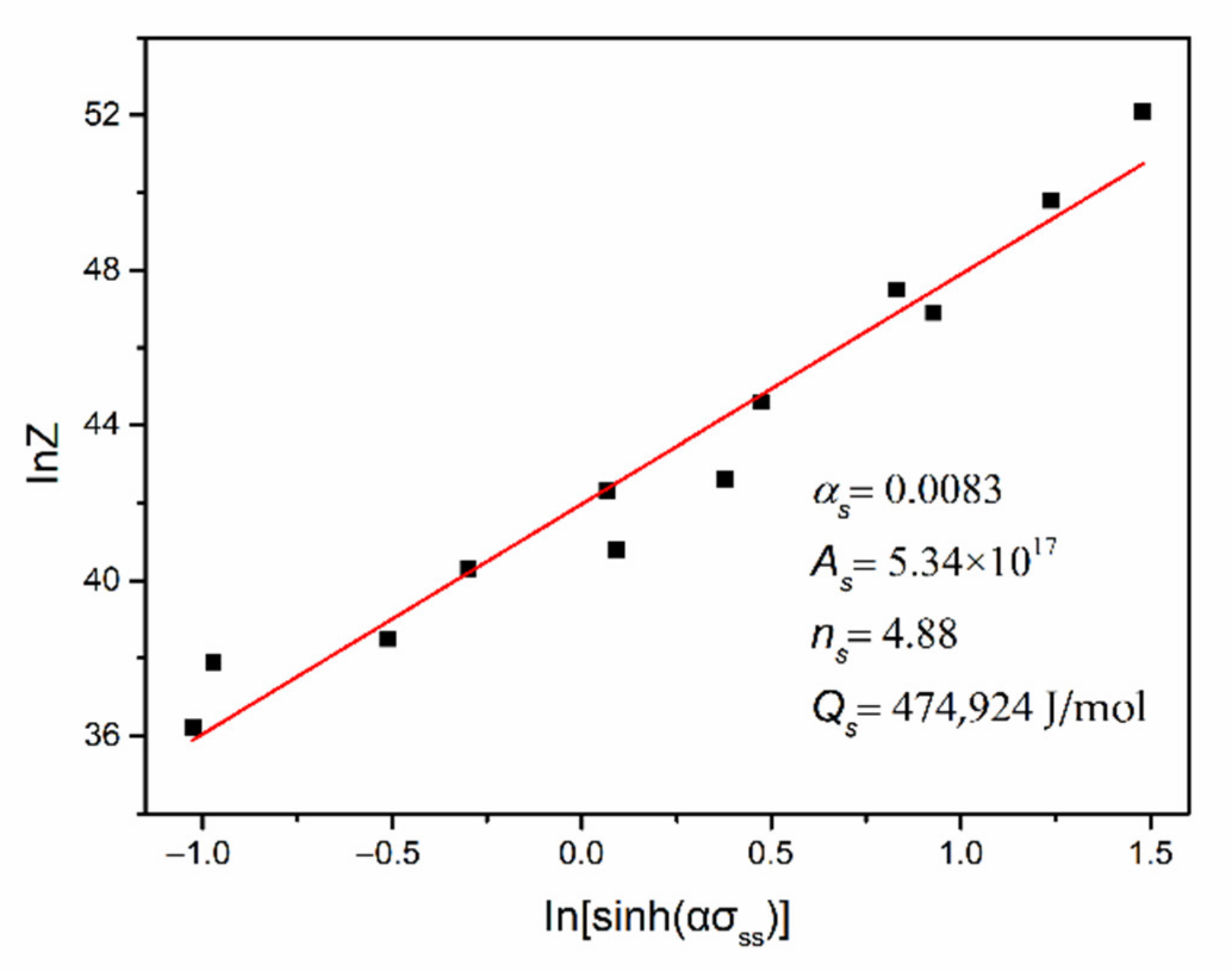

3.2. Establishment of Constitutive Model of Hot Deformation

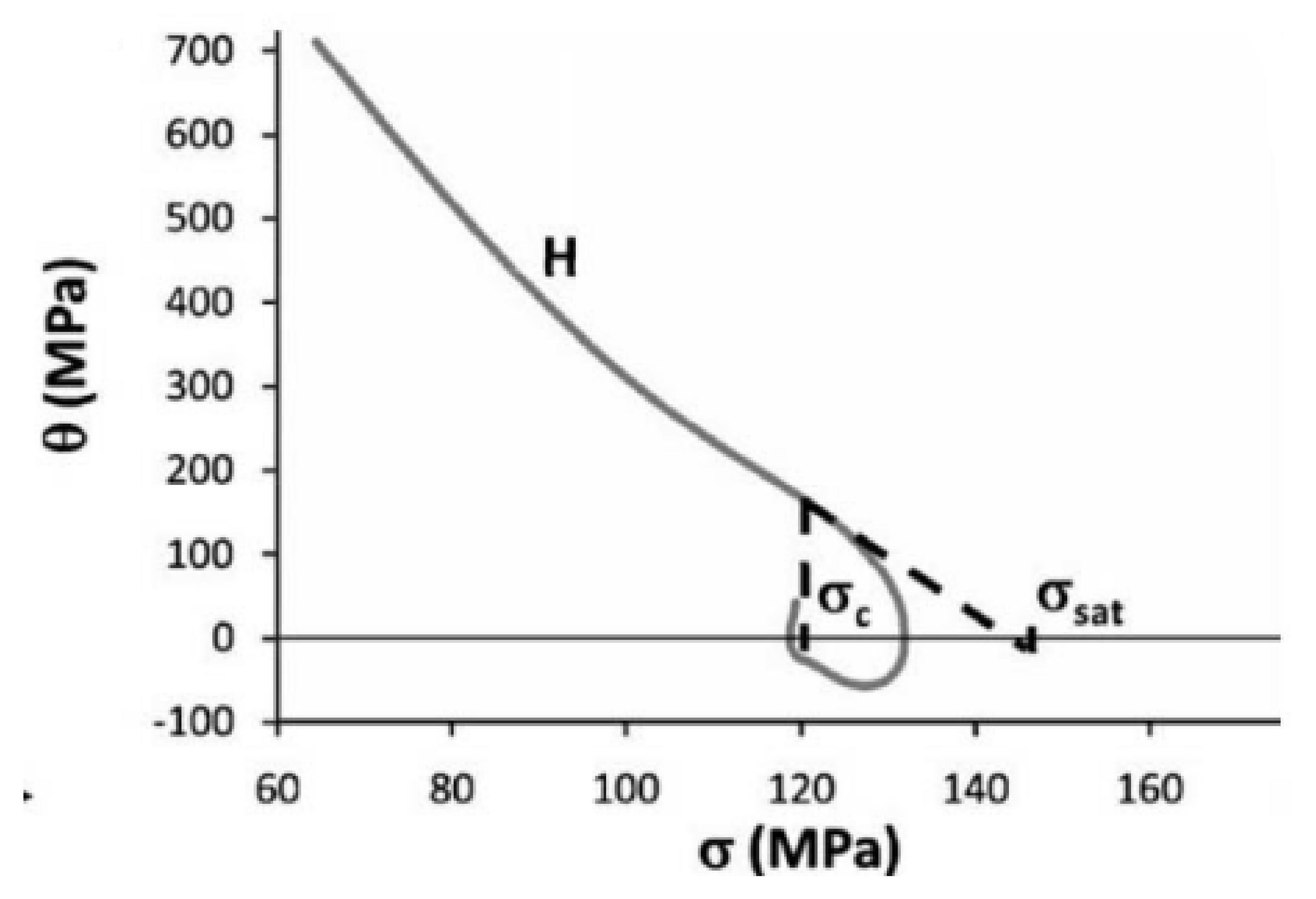

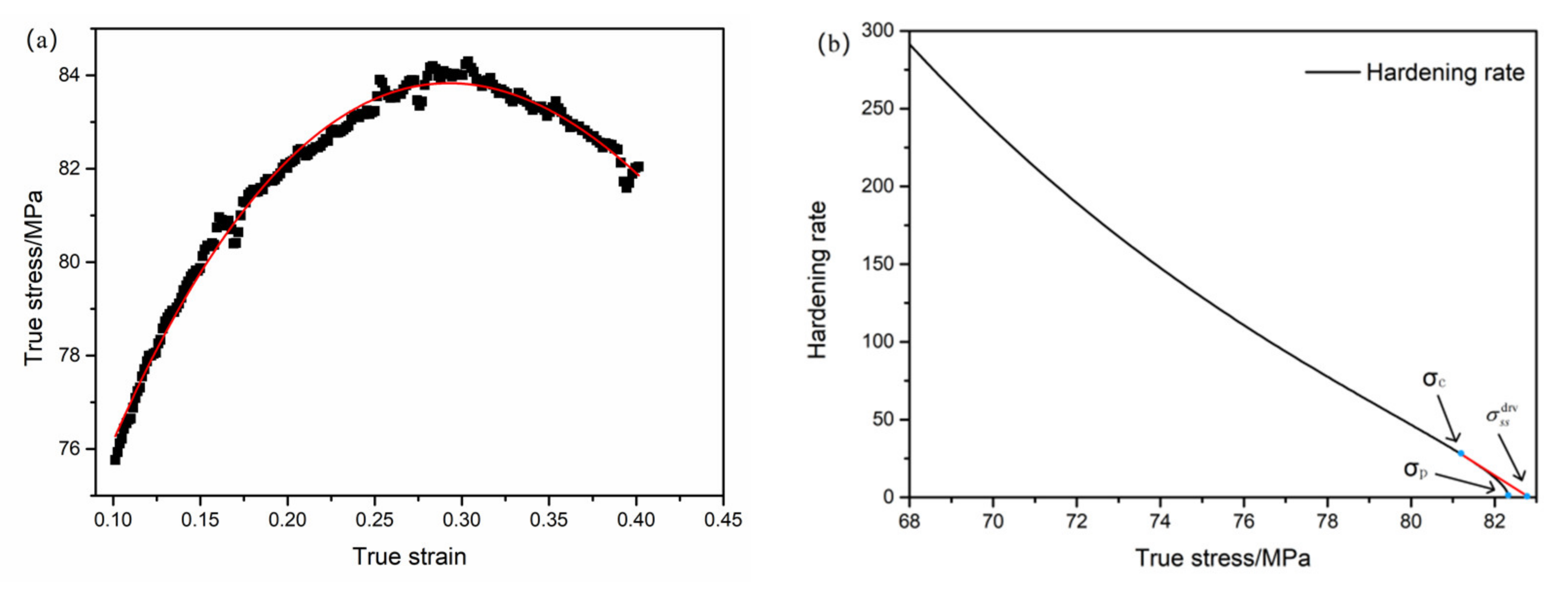

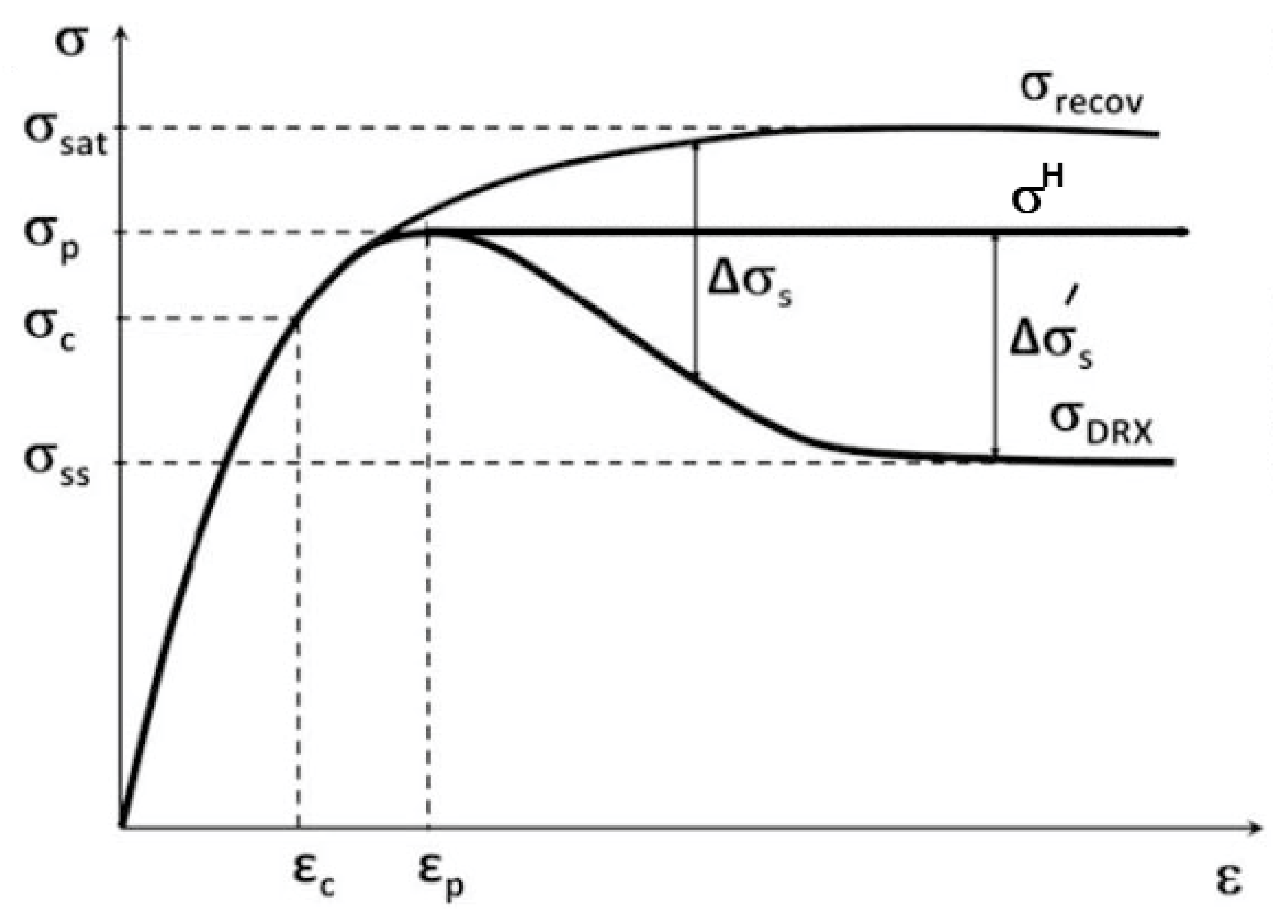

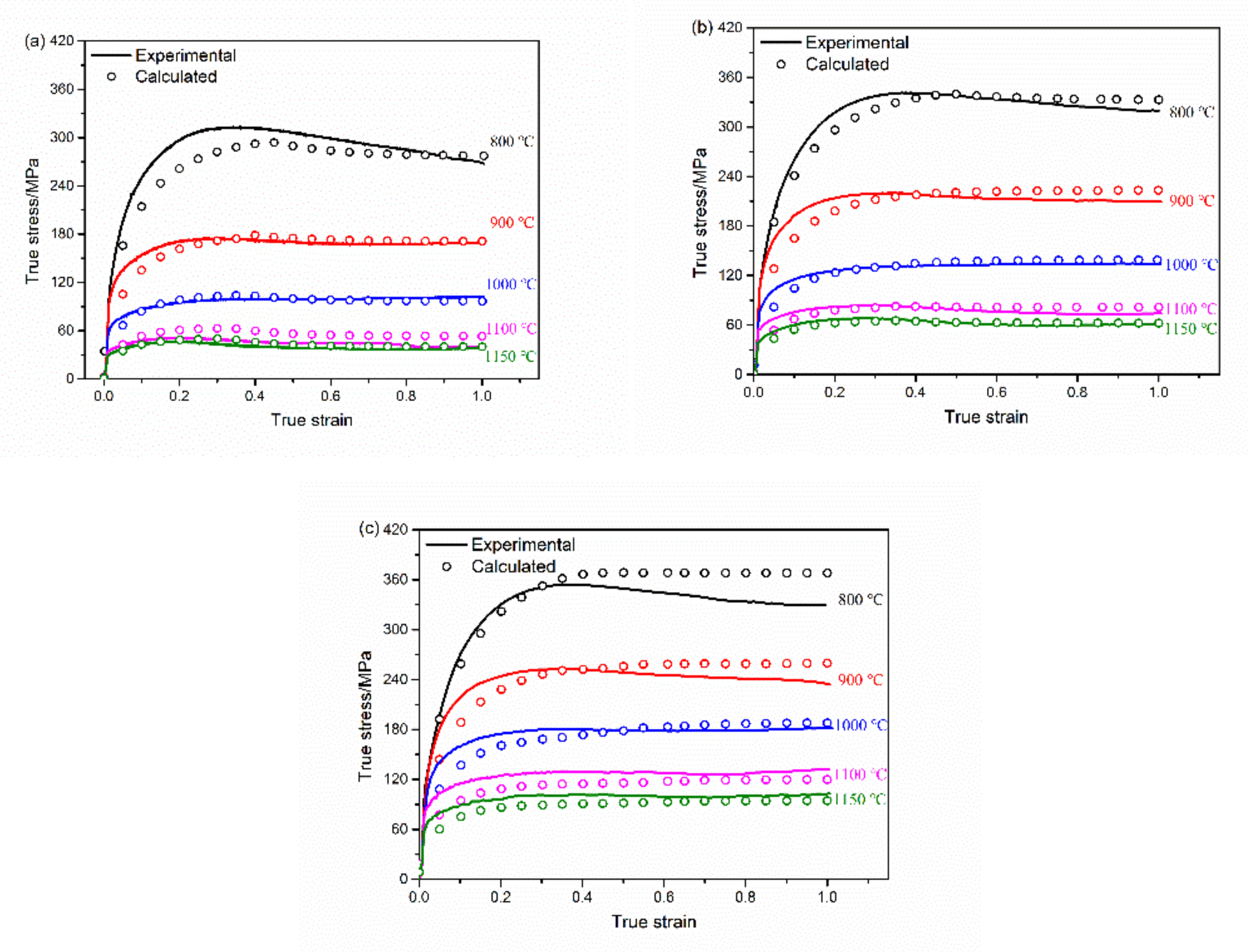

3.3. Constitutive Equation of Hardening Part Considering Dynamic Recrystallization

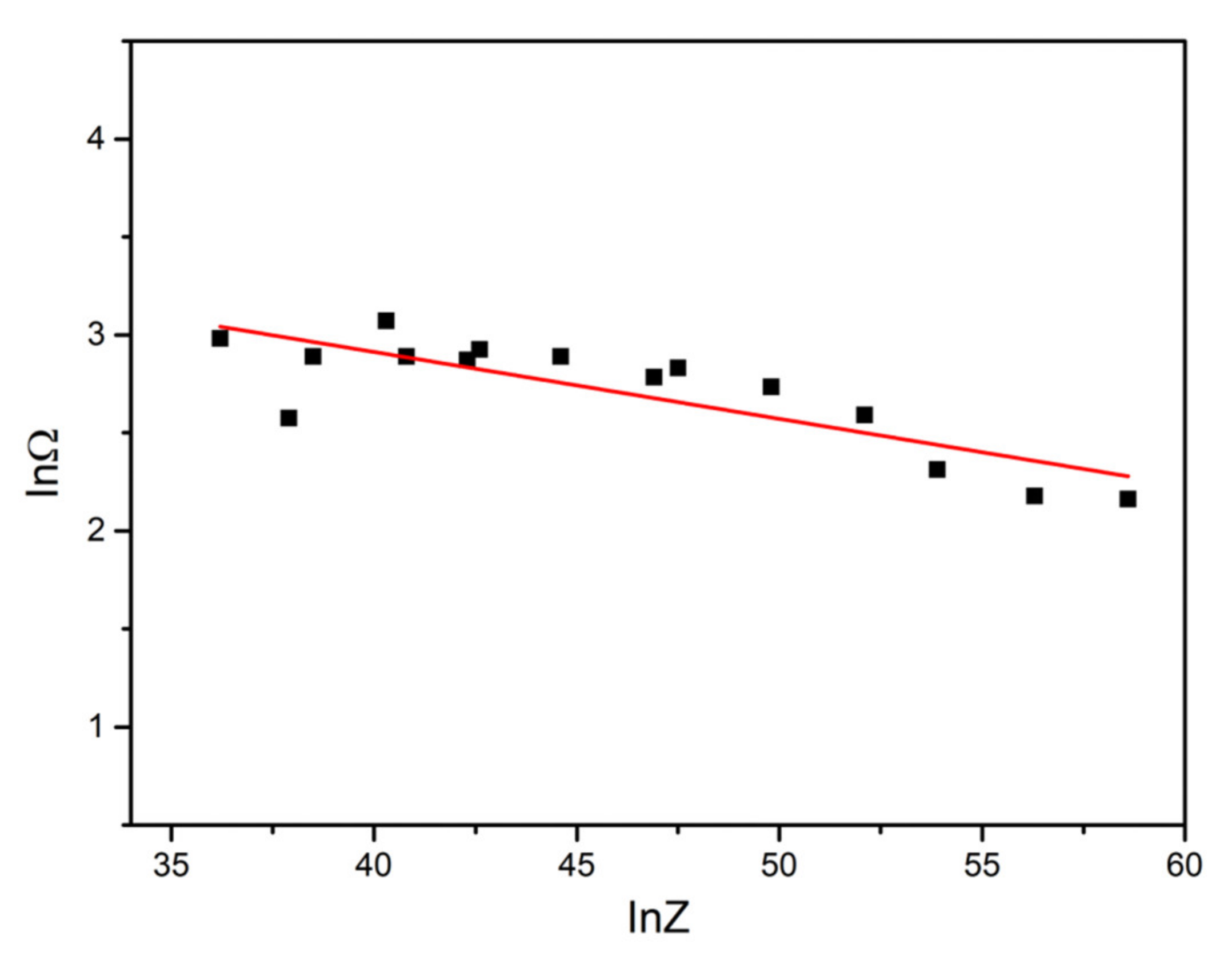

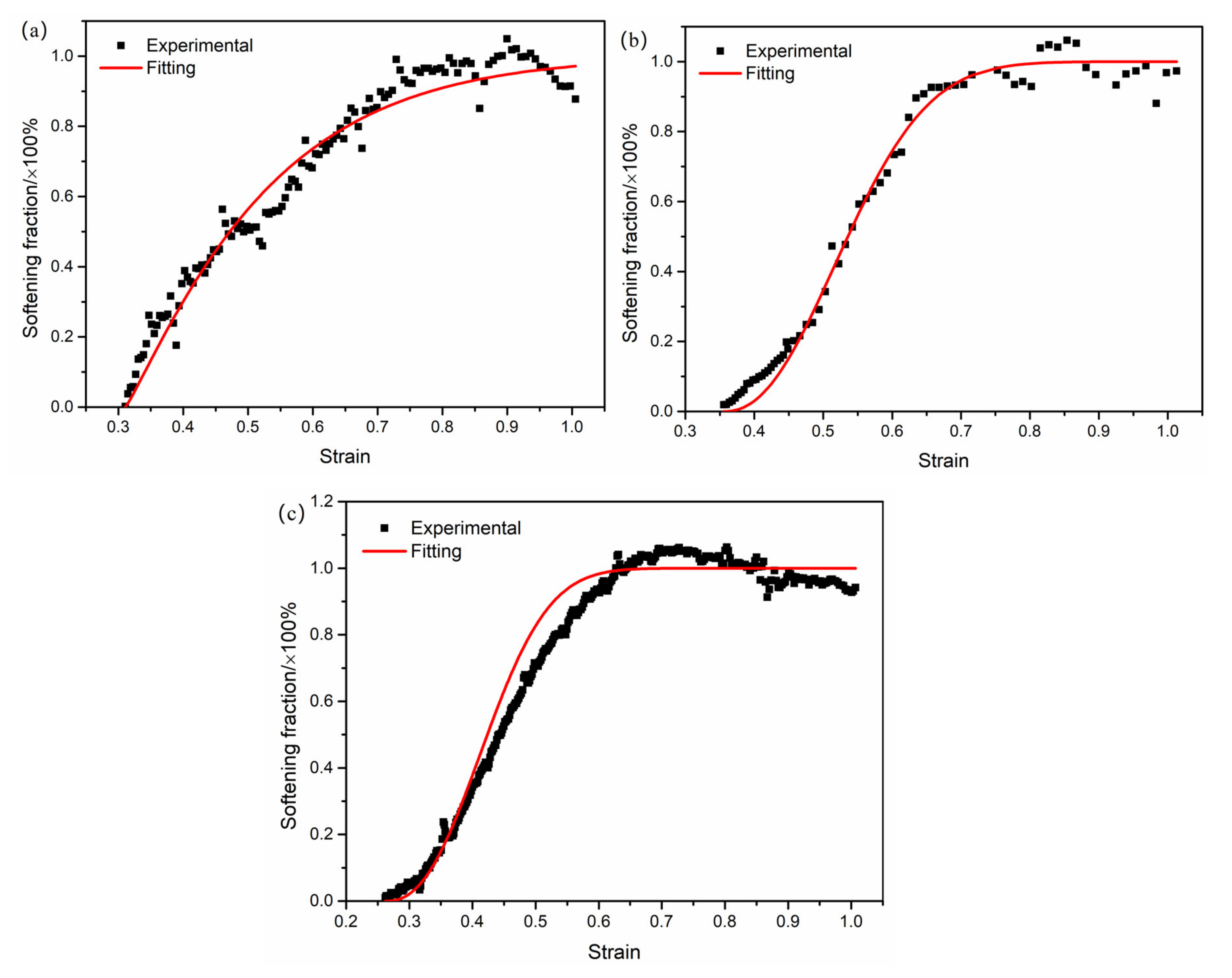

3.4. Constitutive Equation of Softening Part Considering Dynamic Recrystallization

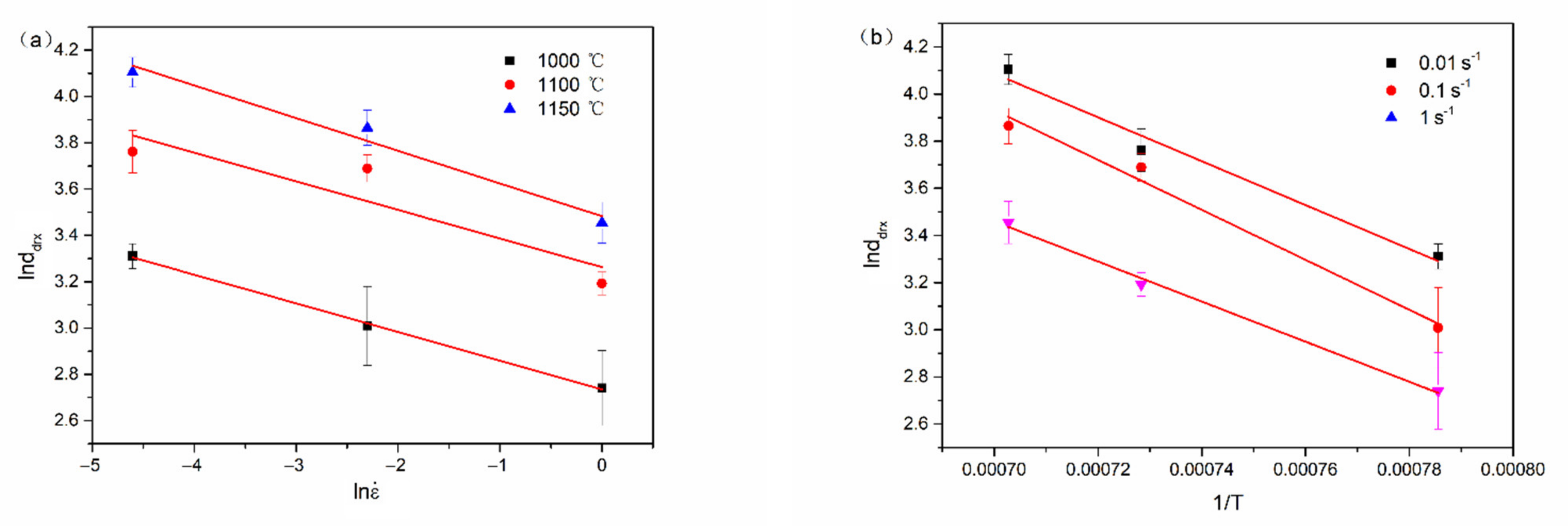

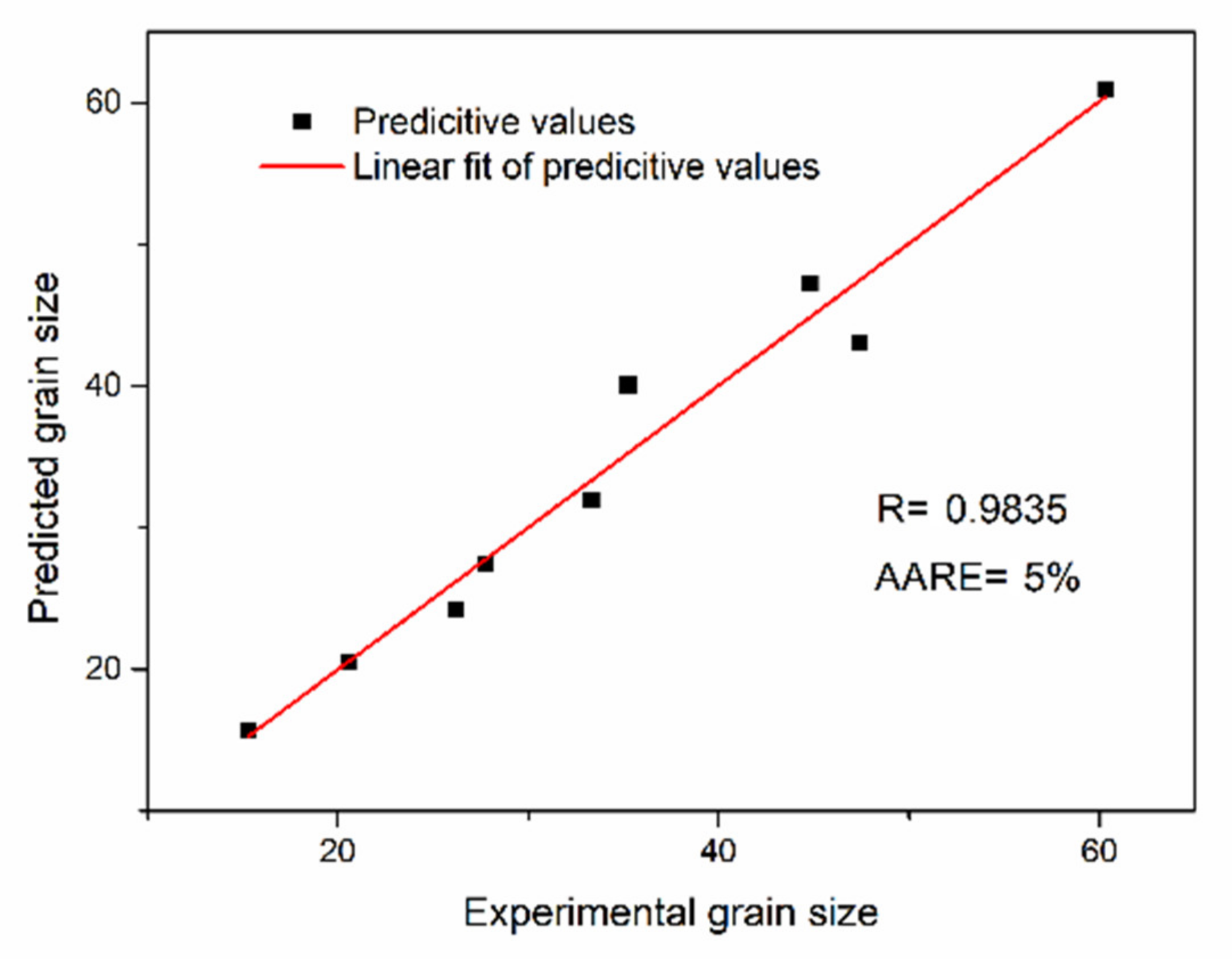

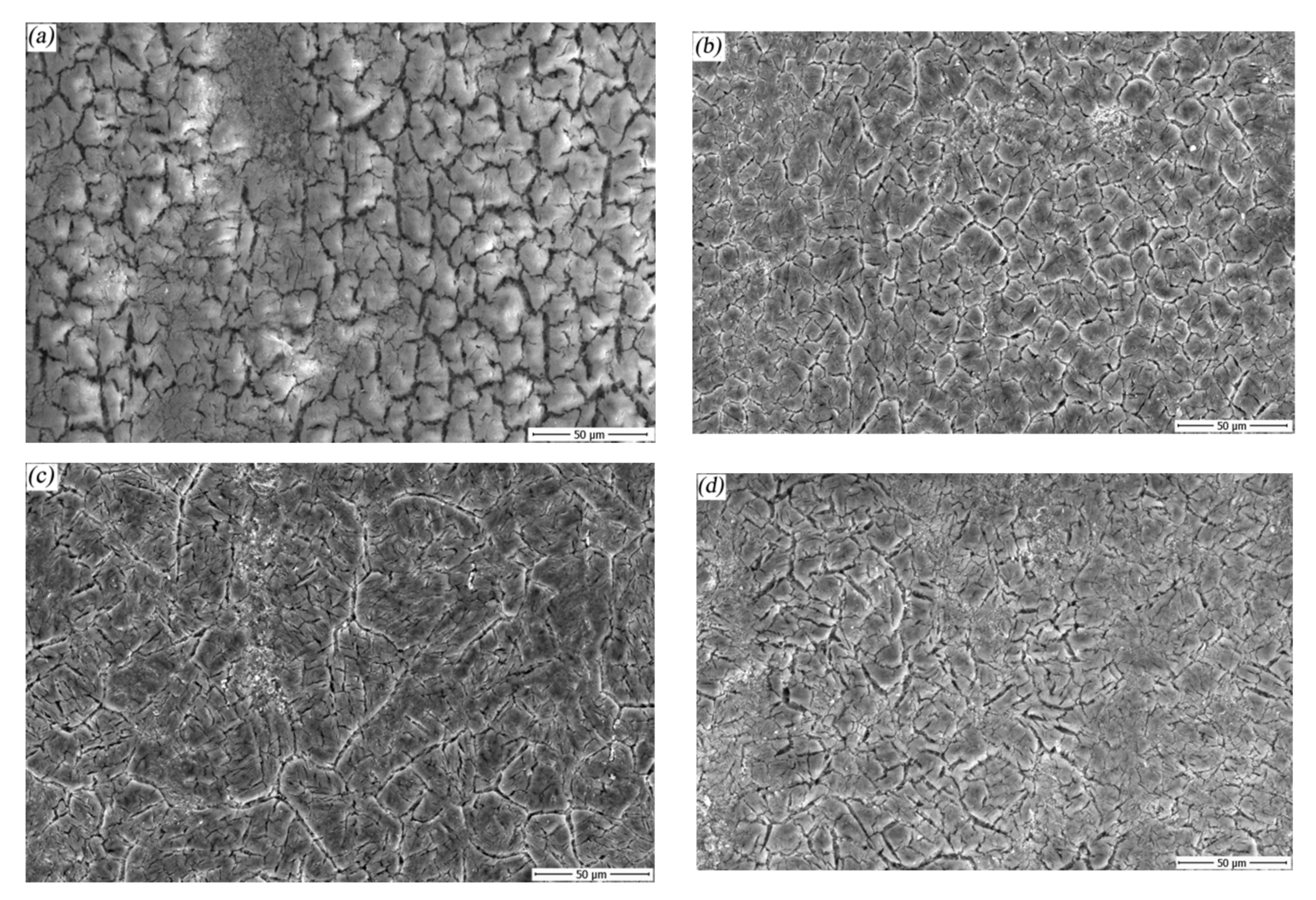

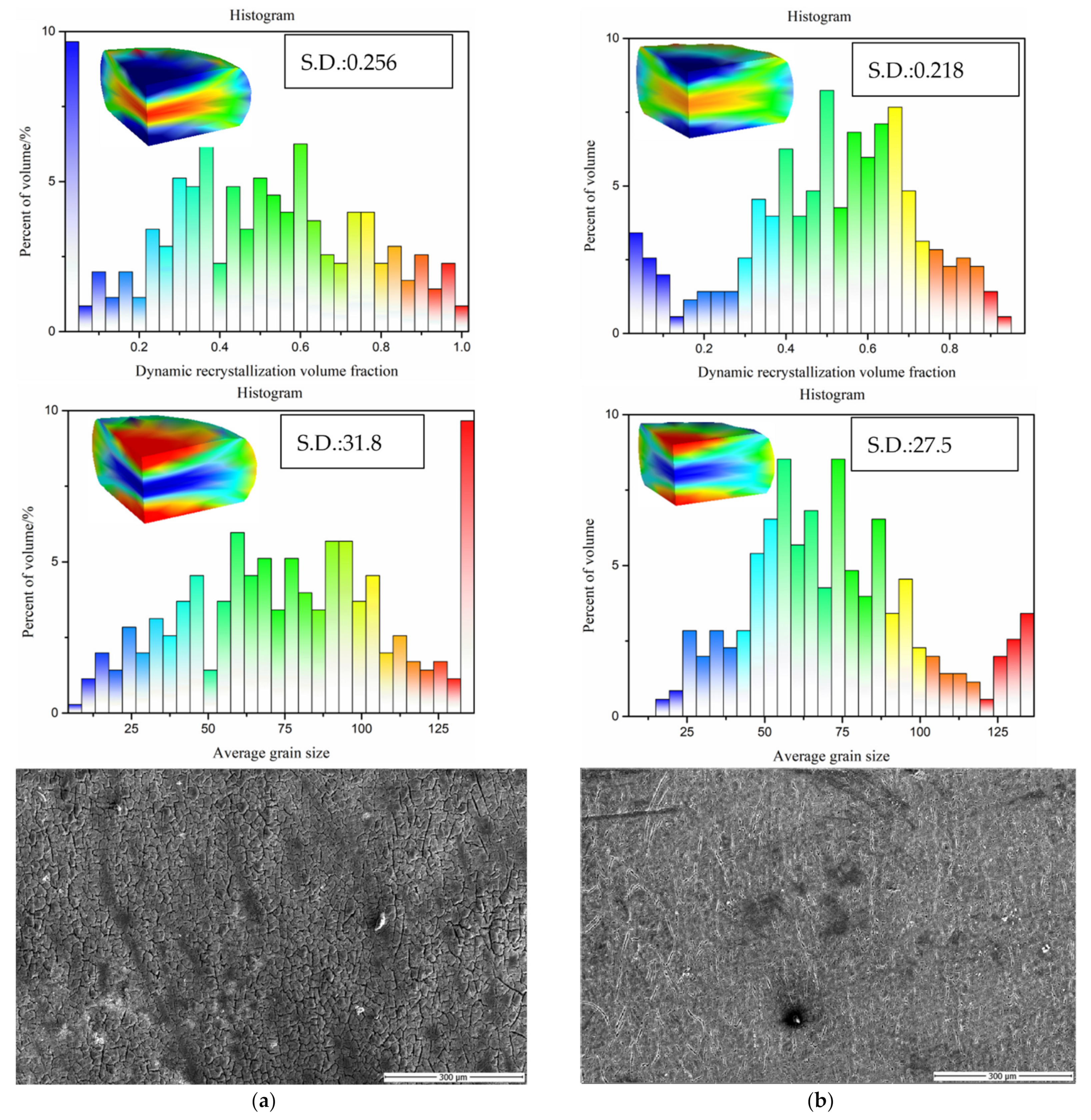

3.5. Grain Size Model of Dynamic Recrystallization

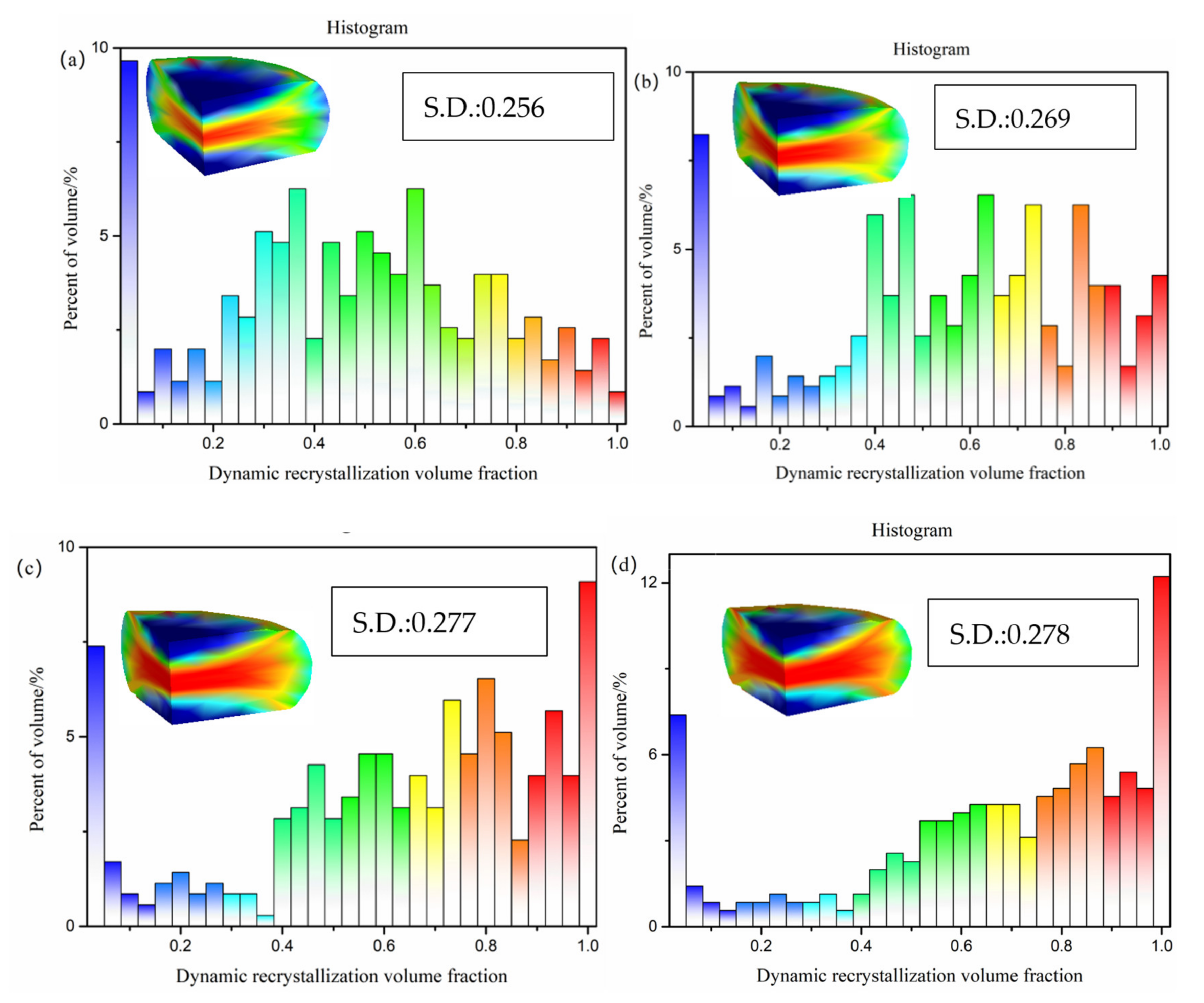

3.6. Simulation and Experimental Results

4. Conclusions

- Amend the flow-stress curve through the friction correction formula to reflect the actual deformation process accurately.

- According to the constitutive equation below, the average relative error of the predicted flow stress and the experiment is 7.46%, which can be used for the finite element analysis of thermal deformation process.

- The following dynamic recrystallization grain size model can predict the change of recrystallization grain size during hot deformation well.

- After the above model is implemented, software can be used to simulate the thermal deformation process of the material. The simulation results are in good agreement with the experimental results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Malakondaiah, G.; Srinivas, M.; Rama Rao, P. Ultrahigh-strength low-alloy steels with enhanced fracture toughness. Prog. Mater. Sci. 1997, 42, 209–242. [Google Scholar] [CrossRef]

- Wu, Z. Ultra-high strength steel. Iron Steel 1986, 21, 71–75. [Google Scholar]

- Wang, B.Y.; Liu, Z.; Shi, W. Application of numerical simulation technology in the heavy forgings production. Heavy Cast. Forg. 1999, 1, 15–20. [Google Scholar]

- Sun, Z.C.; Yang, H.; Li, M.Q. FEM simulation od tube axial compressive precision forming process. Chin. J. Mech. Eng. 2001, 9, 34–38. [Google Scholar] [CrossRef]

- Jong, T.Y.; Chong, S.L.; Jeoung, H.K.; Nho-Kwang, P. Finite-element analysis of microstructure evolution in the cogging of alloy 781 ingot. Mater. Sci. Eng. A 2007, 449, 722–726. [Google Scholar]

- Cho, J.R.; Park, C.Y.; Yang, D.Y. Investigation of the cogging process by three-dimensional thermos-viscoplastic finite element analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1992, 206, 277–286. [Google Scholar] [CrossRef]

- Dembiczak, T.; Knapinski, M.; Garbarz, B. Mathematical modeling of phenomena of dynamic recrystallization during hot plastic deformation in high-carbon bainitic steel. Metalurgija 2017, 56, 107–110. [Google Scholar]

- Knapinski, M.; Dyja, H.; Kawalek, A.; Fraczek, T.; Laber, K. Analysis of the microstructure evolution during thermo-mechanical treatment of the steel plates in grade X80-X100. Mater. Sci. 2013, 52, 239–242. [Google Scholar]

- Wu, M.W.; Zhang, S.J.; Ma, S.B.; Yan, H.J.; Wang, W.; Li, Q. Hot Deformation Behavior of Q345 Steel and Its Application in Rapid Shear Connection. Materials 2019, 12, 2186. [Google Scholar] [CrossRef] [Green Version]

- Ramana, A.V.; Balasundar, I.; Davidson, M.J.; Balamuralikrishnan, R.; Raghu, T. Constitutive Modelling of a New High-Strength Low-Alloy Steel Using Modified Zerilli–Armstrong and Arrhenius Model. Trans. Indian Inst. Met. 2019, 72, 2869–2876. [Google Scholar] [CrossRef]

- Suwaree, C.; Dmitry, G.E.; Chaowalit, L. Constitutive Behavior of an AA4032 Piston Alloy with Cu and Er Additions upon High-Temperature Compressive Deformation. Metall. Mater. Trans. A 2020, 51, 467–481. [Google Scholar]

- Lei, B.W.; Chen, G.Q.; Liu, K.H.; Wang, X.; Jiang, X.M.; Pan, J.L.; Shi, Q.Y. Constitutive analysis on high-temperature flow behavior of 3Cr-1Si-1Ni ultra-high strength steel for modeling of flow stress. Metals 2019, 9, 42. [Google Scholar] [CrossRef] [Green Version]

- Ren, S.J.; Luo, F.; Tian, Y.; Liu, D.B.; Wang, K.L.; Lu, S.Q. Flow stress curve correction and phenomenological constitutive relationship of A100 ultra-high strength steel. J. Mater. Eng. 2019, 47, 144–151. [Google Scholar]

- Cheng, L.; Chang, H.; Tang, B.; Kou, H.C.; Li, J.S. Flow stress prediction of high-Nb TiAl alloys under high temperature deformation. Adv. Mater. Res. 2012, 510, 723–728. [Google Scholar] [CrossRef]

- Ebrahimi, R.; Najafizadeh, A.A. new method for evaluation of friction in bulk metal forming. J. Mater. Pro. Tec. 2004, 152, 136–143. [Google Scholar] [CrossRef]

- Chen, M.M. Study on Surface Metal Flow Behavior and Residual Microstructure of Aluminum Alloy during Hot Extrusion; Shandong University: Jinan, China, 2018. [Google Scholar]

- McQueen, H.; Ryan, N. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Hu, Z.C.; Zhang, D.F.; Huang, T.; Wang, F. Flow Stress Behavior and Dynamic Recrystallization of 3104 Aluminum Alloy. Mater. Mech. Eng. 2005, 29, 6–9. [Google Scholar]

- Li, X.C.; Wu, W.F.; Sun, Q.P. “Study of hot-working steels” thermal-fatigue property prediction based on PLS. J. Mech. Strength 2010, 32, 824–828. [Google Scholar]

- Jonas, J.J.; Quelennec, X.; Jiang, L.; Martin, E. The Avrami kinetics of dynamic recrystallization. Acta Mater. 2009, 57, 2748–2756. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jones, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Mater. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Prediction of 42CrMo steel flow stress at high temperature and strain rate. Mech. Res. Commun. 2008, 35, 142–150. [Google Scholar] [CrossRef]

- Bailey, J.E.; Hirsch, P.B. The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 1960, 5, 485–497. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadeh, A. Extrapolation of flow curves at hot working conditions. Mater. Sci. Eng. A 2010, 527, 1856–1860. [Google Scholar] [CrossRef]

- Cheng, L.; Xue, X.Y.; Tang, B.; Kou, H.C.; Li, J.S. Flow characteristics and constitutive modeling for elevated temperature deformation of a high Nb containing TiAl alloy. Intermetallics 2014, 49, 23–28. [Google Scholar] [CrossRef]

- Sellars, C.M.; Whiteman, J.A. Recrystallization and grain growth in hot rolling. Met. Sci. 1979, 13, 187–194. [Google Scholar] [CrossRef]

- Li, Y.J.; Zhang, Y.; Chen, Z.Y.; Ji, Z.C.; Zhu, H.Y.; Sun, C.F.; Dong, W.P.; Li, X.; Sun, Y.; Yao, S. Hot deformation behavior and dynamic recrystallization of GH690 nickel-based superalloy. J. Alloy. Compd. 2020, 847, 156507. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, F.Z. Fundamentals of Materials Science, 2rd ed.; Dalian University of Technology Press: Dalian, China, 2009; pp. 113–116. [Google Scholar]

| Strain Rates s−1 | Deformation Temperature | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 800 °C | 900 °C | 1000 °C | 1100 °C | 1150 °C | ||||||

| 0.01 | 312.6 | 0.356 | 174.7 | 0.315 | 97.9 | 0.274 | 52.1 | 0.262 | 47.9 | 0.200 |

| 0.1 | 340.8 | 0.367 | 218.6 | 0.334 | 130.2 | 0.308 | 83.9 | 0.271 | 68.1 | 0.250 |

| 1 | 354.2 | 0.368 | 252.6 | 0.355 | 180.7 | 0.311 | 129.1 | 0.274 | 101.8 | 0.253 |

| Strain Rates s−1 | Deformation Temperature | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 800 °C | 900 °C | 1000 °C | 1100 °C | 1150 °C | ||||||

| k | n | k | n | k | n | k | n | k | n | |

| 0.01 | - | - | 2.39 | 2.29 | 1.58 | 1.03 | 0.96 | 0.81 | 1.48 | 1.18 |

| 0.1 | - | - | 0.73 | 1.82 | 1.45 | 1.12 | 0.74 | 2.17 | 2.21 | 2.39 |

| 1 | - | - | 0.71 | 1.45 | 3.15 | 2.22 | 1.77 | 1.81 | 1.23 | 1.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, L.; Wang, B.; Hu, C.; Zhang, J.; Yao, Y. Hot Deformation Behavior and Dynamic Recrystallization of Ultra High Strength Steel. Metals 2021, 11, 1239. https://doi.org/10.3390/met11081239

Zhong L, Wang B, Hu C, Zhang J, Yao Y. Hot Deformation Behavior and Dynamic Recrystallization of Ultra High Strength Steel. Metals. 2021; 11(8):1239. https://doi.org/10.3390/met11081239

Chicago/Turabian StyleZhong, Liping, Bo Wang, Chundong Hu, Jieyu Zhang, and Yu Yao. 2021. "Hot Deformation Behavior and Dynamic Recrystallization of Ultra High Strength Steel" Metals 11, no. 8: 1239. https://doi.org/10.3390/met11081239

APA StyleZhong, L., Wang, B., Hu, C., Zhang, J., & Yao, Y. (2021). Hot Deformation Behavior and Dynamic Recrystallization of Ultra High Strength Steel. Metals, 11(8), 1239. https://doi.org/10.3390/met11081239