Comparative Studies of Digestion Techniques for the Dissolution of Neodymium-Based Magnets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Demagnetisation and Grinding

2.3. Elemental Analyses

2.4. Leaching

2.4.1. Total Dissolution of the NdFeB Magnets

2.4.2. Leaching Experiments

3. Results and Discussion

3.1. Particle Size Distribution of the Ground Demagnetized NdFeB Magnets

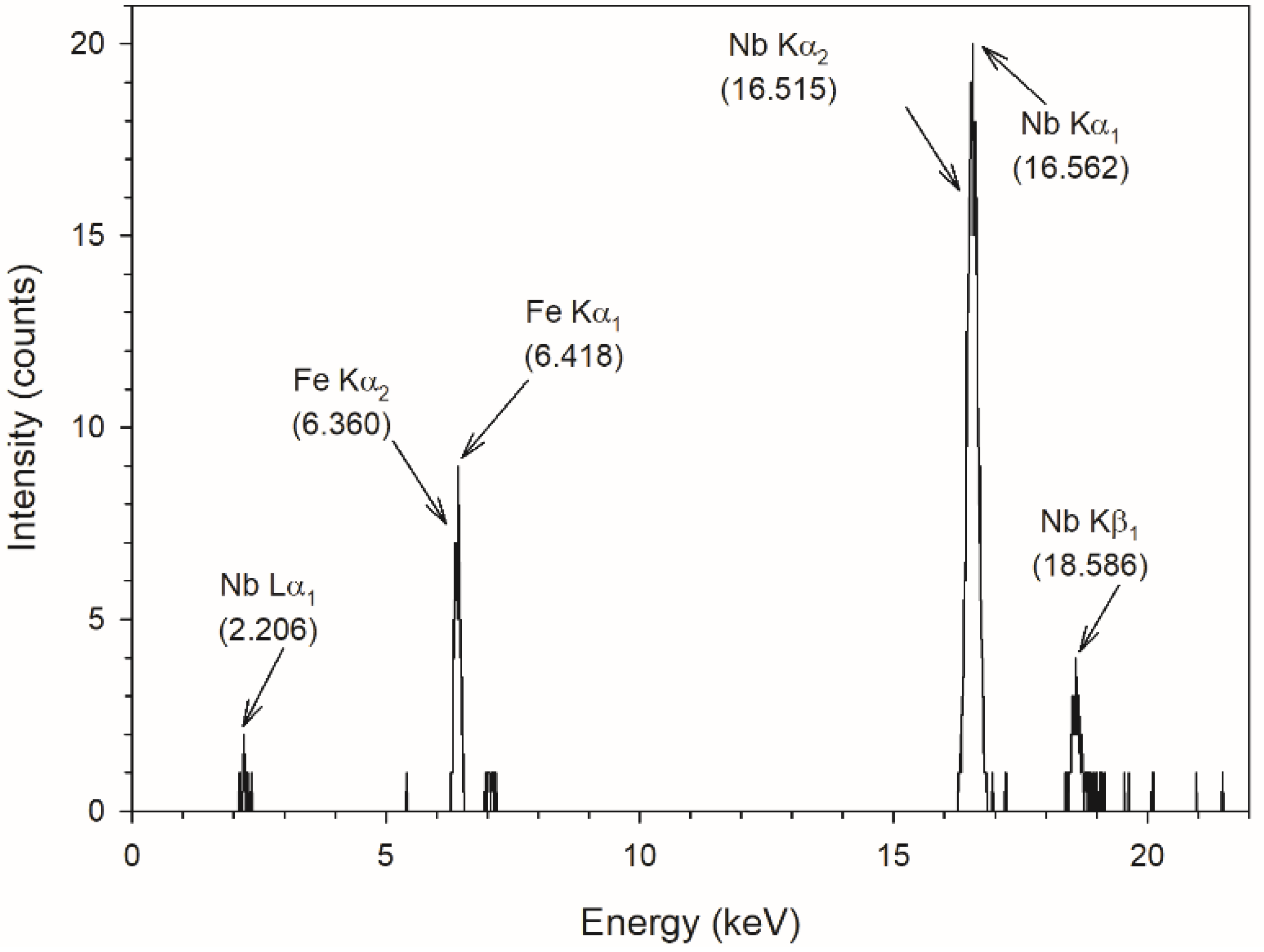

3.2. Elemental Composition of Ground Demagnetized NdFeB Magnets

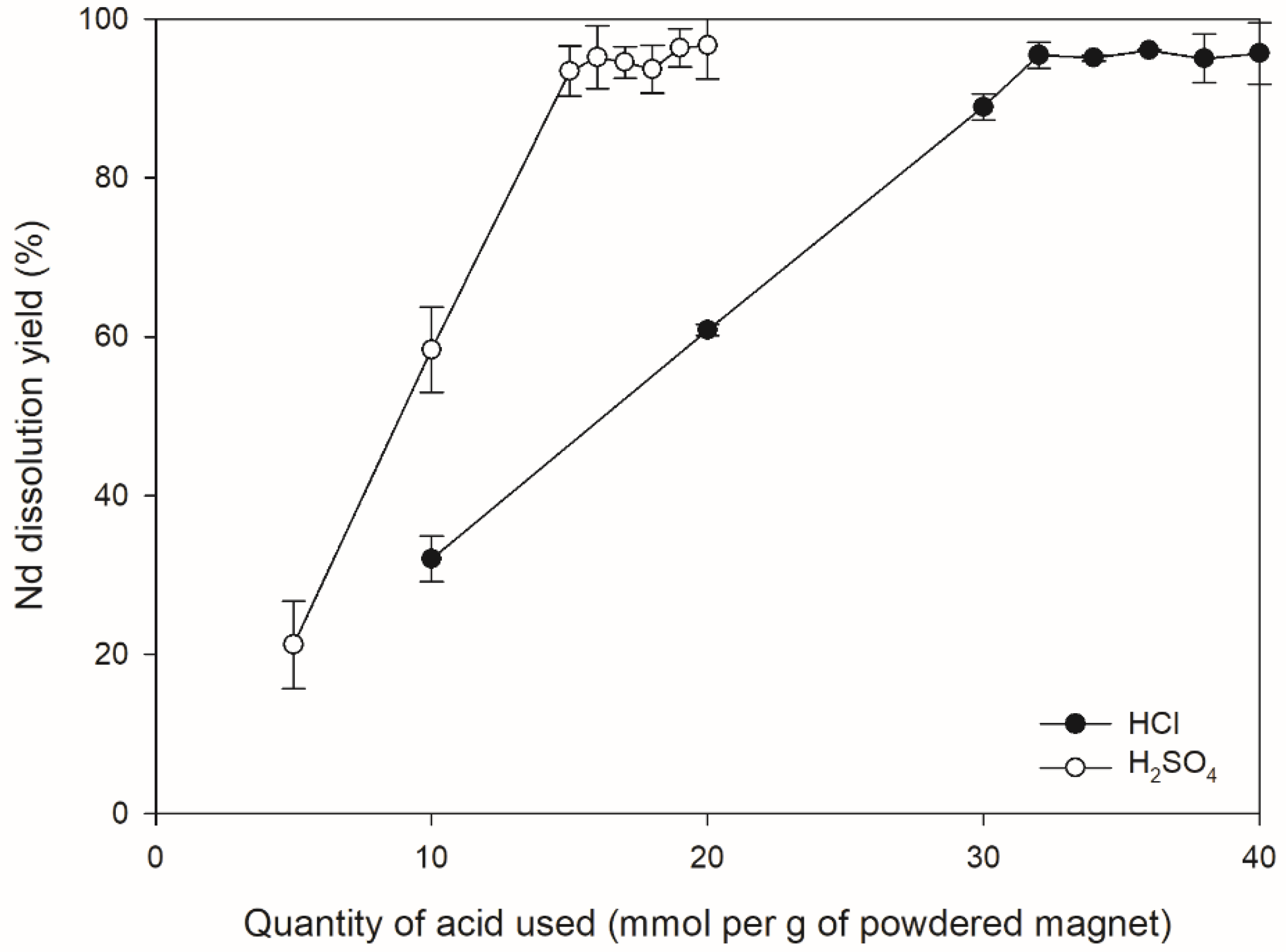

3.3. Leaching of Powdered and Demagnetized Magnets

3.3.1. Design of Experiments

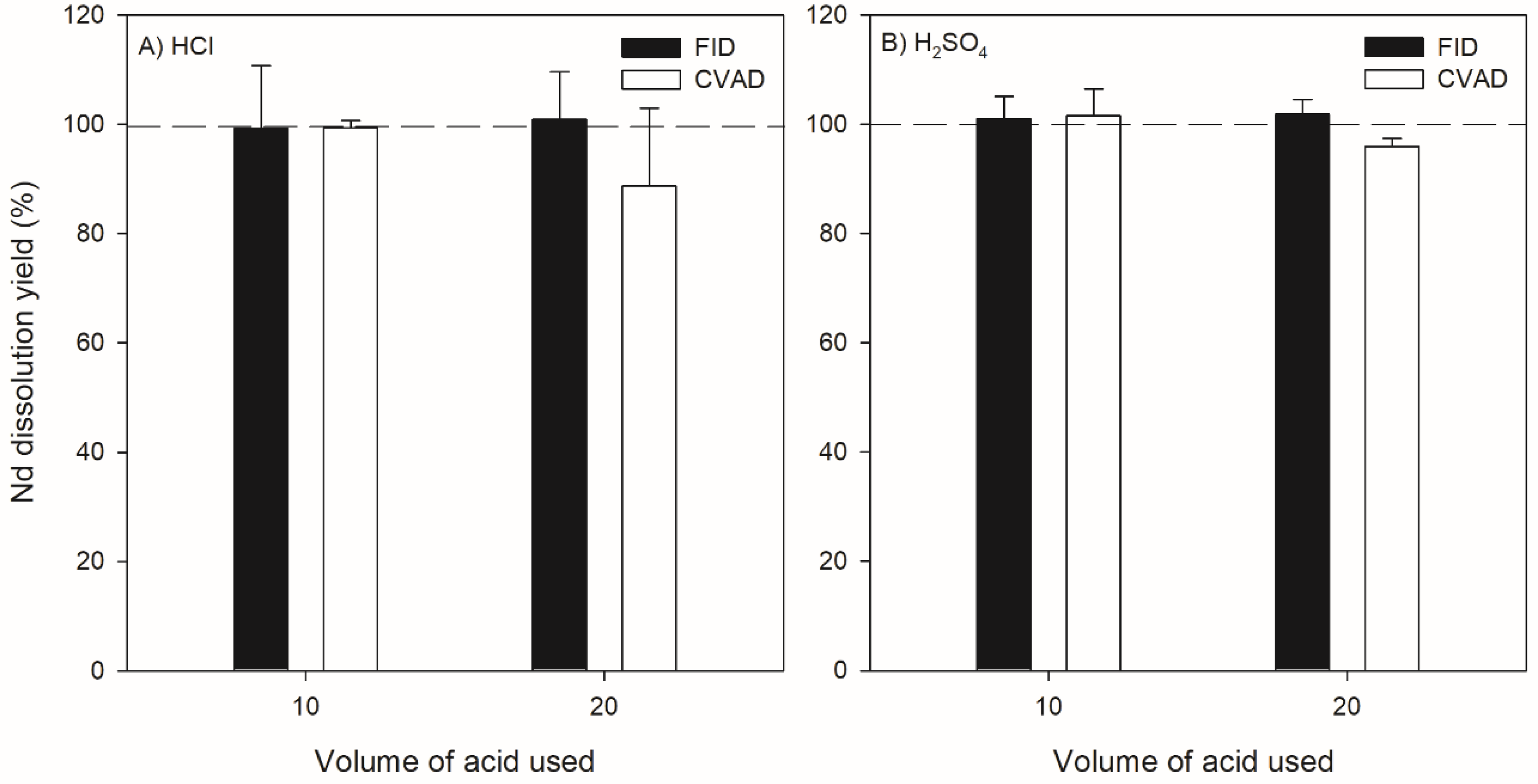

3.3.2. Leaching Performance Comparisons (CVAD, FID)

3.3.3. Magnet Pieces Leaching

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Forti, V.; Cornelis Peter, B.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows, and the Circular Economy Potential; United Nations University (UNU): Bonn, Germany; United Nations Institute for Training and Research (UNITAR): Geneva, Switzerland; International Telecommunication Union: Geneva, Switzerland; International Solid Waste Association: Rotterdam, The Netherlands, 2020; p. 120. [Google Scholar]

- Zeng, X.L.; Mathews, J.A.; Li, J.H. Urban Mining of E-Waste is Becoming More Cost-Effective Than Virgin Mining. Environ. Sci. Technol. 2018, 52, 4835–4841. [Google Scholar] [CrossRef] [PubMed]

- Ferron, C.J.; Henry, P. A review of the recycling of rare earth metals. Can. Metall. Q. 2015, 54, 388–394. [Google Scholar] [CrossRef]

- Lister, T.E.; Wang, P.M.; Anderko, A. Recovery of critical and value metals from mobile electronics enabled by electrochemical processing. Hydrometallurgy 2014, 149, 228–237. [Google Scholar] [CrossRef] [Green Version]

- Lixandru, A.; Venkatesan, P.; Jonsson, C.; Poenaru, I.; Hall, B.; Yang, Y.; Walton, A.; Guth, K.; Gauss, R.; Gutfleisch, O. Identification and recovery of rare-earth permanent magnets from waste electrical and electronic equipment. Waste Manag. 2017, 68, 482–489. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.-M.; Van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Metall. 2016, 3, 122–149. [Google Scholar] [CrossRef]

- Rademaker, J.H.; Kleijn, R.; Yang, Y.X. Recycling as a Strategy against Rare Earth Element Criticality: A Systemic Evaluation of the Potential Yield of NdFeB Magnet Recycling. Environ. Sci. Technol. 2013, 47, 10129–10136. [Google Scholar] [CrossRef]

- Florek, J.; Giret, S.; Juere, E.; Lariviere, D.; Kleitz, F. Functionalization of mesoporous materials for lanthanide and actinide extraction. Dalton Trans 2016, 45, 14832–14854. [Google Scholar] [CrossRef]

- Vander Hoogerstraete, T.; Blanpain, B.; Van Gerven, T.; Binnemans, K. From NdFeB magnets towards the rare-earth oxides: A recycling process consuming only oxalic acid. RSC Adv. 2014, 4, 64099–64111. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.H.; Chen, Y.J.; Liao, C.H.; Popuri, S.; Tsai, S.L.; Hung, C.E. Selective Leaching Process for Neodymium Recovery from Scrap Nd-Fe-B Magnet. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2013, 44A, 5825–5833. [Google Scholar] [CrossRef]

- Helmeczi, E.; Wang, Y.; Brindle, I.D. A novel methodology for rapid digestion of rare earth element ores and determination by microwave plasma-atomic emission spectrometry and dynamic reaction cell-inductively coupled plasma-mass spectrometry. Talanta 2016, 160, 521–527. [Google Scholar] [CrossRef]

- Rabatho, J.P.; Tongamp, W.; Takasaki, Y.; Haga, K.; Shibayama, A. Recovery of Nd and Dy from rare earth magnetic waste sludge by hydrometallurgical process. J. Mater. Cycles Waste Manag. 2013, 15, 171–178. [Google Scholar] [CrossRef]

- Yoon, H.S.; Kim, C.J.; Chung, K.W.; Jeon, S.; Park, I.; Yoo, K.; Jha, M.K. The Effect of Grinding and Roasting Conditions on the Selective Leaching of Nd and Dy from NdFeB Magnet Scraps. Metals 2015, 5, 1306–1314. [Google Scholar] [CrossRef]

- München, D.D.; Bernardes, A.M.; Veit, H.M. Evaluation of Neodymium and Praseodymium Leaching Efficiency from Post-consumer NdFeB Magnets. J. Sustain. Metall. 2018, 4, 288–294. [Google Scholar] [CrossRef]

- Kumari, A.; Sinha, M.K.; Pramanik, S.; Sahu, S.K. Recovery of rare earths from spent NdFeB magnets of wind turbine: Leaching and kinetic aspects. Waste Manag. 2018, 75, 486–498. [Google Scholar] [CrossRef]

- Tanvar, H.; Kumar, S.; Dhawan, N. Microwave Exposure of Discarded Hard Disc Drive Magnets for Recovery of Rare Earth Values. JOM 2019, 71, 2345–2352. [Google Scholar] [CrossRef]

- Erust, C.; Akcil, A.; Tuncuk, A.; Deveci, H.; Yazici, E.Y. A Multi-stage Process for Recovery of Neodymium (Nd) and Dysprosium (Dy) from Spent Hard Disc Drives (HDDs). Miner. Process. Extr. Metall. Rev. 2021, 42, 90–101. [Google Scholar] [CrossRef]

- Ciro, E.; Alzate, A.; López, E.; Serna, C.; Gonzalez, O. Neodymium recovery from scrap magnet using ammonium persulfate. Hydrometallurgy 2019, 186, 226–234. [Google Scholar] [CrossRef]

- Kumari, A.; Jha, M.K.; Pathak, D.D. An innovative environmental process for the treatment of scrap Nd-Fe-B magnets. J. Environ. Manag. 2020, 273, 7. [Google Scholar] [CrossRef]

- Berghof Products + Instruments GMBH. Microwave Digestion of Permanent Magnets; Application Note XT4; Eningen, Germany, 2020; Available online: https://www.berghof-instruments.com/en/application/microwave-digestion-of-permanent-magnets/ (accessed on 14 July 2021).

- Milliard, A.; Durand-Jezequel, M.; Lariviere, D. Sequential automated fusion/extraction chromatography methodology for the dissolution of uranium in environmental samples for mass spectrometric determination. Anal. Chim. Acta 2011, 684, 40–46. [Google Scholar] [CrossRef]

- Yu, L.Q.; Wen, Y.H.; Yan, M. Effects of Dy and Nb on the magnetic properties and corrosion resistance of sintered NdFeB. J. Magn. Magn. Mater. 2004, 283, 353–356. [Google Scholar] [CrossRef]

- Le Breton, J.M.; Teillet, J. Mössbauer and X-ray study of NdFeB type permanent magnets oxidation: Effect of A1 and Nb addition. J. Magn. Magn. Mater. 1991, 101, 347–348. [Google Scholar] [CrossRef]

- Prasad, V.; Baligidad, R.; Gokhale, A. Niobium and Other High Temperature Refractory Metals for Aerospace Applications. Aerosp. Mater. Mater. Technol. 2017, 267–288. [Google Scholar] [CrossRef]

- Habashi, F. Extractive metallurgy of rare earths. Can. Metall. Q. 2013, 52, 224–233. [Google Scholar] [CrossRef]

- Washburn, E.W.; West, C.J.; Dorsey, N.E.; National Research Council; International Research Council; National Academy of Science. International Critical Tables of Numerical Data, Physics, Chemistry and Technology; The National Academies Press: Washington, DC, USA, 1926. [Google Scholar]

| Magnets Source | Studied Elements | Demagnetization | Particles Size | Pre-Treatment | Leaching Method | Solubilization REEs a/Fe (%) | References |

|---|---|---|---|---|---|---|---|

| Magnetic sludge | Nd, Dy, Fe, B | (Not magnetized) | <250 µm | Drying of the sludge | 1 M HNO3 + 0.3 M H2O2, 80 °C, 10 mL/g, 5 min | 98, 81/15 | Rabatho, et al. (2013) [12] |

| Manufacturing waste magnets | Nd, Fe, B | 350 °C, 15 min | <297 μm | - | 3 N H2SO4, 27 °C, 50 mL/g 15 min (ultrasound) | 100/100 | Lee, et al. (2013) [10] |

| Manufacturing waste magnets | Nd, Dy, Fe | (Not magnetized) | not mentioned | Roasting at 400 °C, 2 h | 1 M acetic acid, 90 °C, 100 mL/g, 400 rpm, 3 h | 94, 93/1 | Yoon, et al. (2015) [13] |

| HDD | Nd, Pr | 320 °C, time not mentioned | <250 µm | - | 2 M H2SO4, 70 °C, 20 mL/g, 15 min | 90/not mentioned | München, Bernardes, and Veit (2018) [14] |

| Wind turbine | Nd, Pr, Dy, Fe, B, Al, Co | 310 °C, 60 min | <149 µm | Roasting at 850 °C, 6 h | 0.5 M HCl, 10 mL/g, 500 rpm, 5 h | 98, 97/<1 | Kumari, et al. (2018) [15] |

| HDD | Nd, Dy, Fe | 350 °C, 60 min | <100 µm | 900 W microwave, opened vessels, 5 min | 0.5 M HCl, 70 °C, 25 mL/g, 900 rpm, 2 h | 56/low (not mentioned) | Tanvar, Kumar, and Dhawan (2019) [16] |

| HDD | Nd, Dy, Fe | 350 °C, 30 min | <500 µm | 2 M H2SO4, 27 °C, 20 mL/g, 15 min | 100/100 | Erust, et al. (2019) [17] | |

| HDD | Fe, Nd, Co, Ni | 400 °C, 45 min | <420 µm | - | 1.3 M (NH4)2S2O8, 75 °C, 50 mL/g, 15 min | 99/64 | Ciro, et al. (2019) [18] |

| HDD | Nd, Pr, Dy, Fe | 350 °C, 3 h | ~2 mm | - | 1 M H2SO4, 25 °C, 20 mL/g, 90 min | 100/100 | Kumari, et al. (2020) [19] |

| HDD | Nd, Pr, Dy, Tb, B, Fe, Al, Cu, Ni, Co | 350 °C, 60 min | <250 µm | - | 1.6 N HCl or H2SO4, 20 mL/g, 5 min | 100/100 | Present work |

| HDD | Nd, Pr, Dy, Tb, B, Fe, Al, Cu, Ni, Co | No demagnetization | Coarsely broken | - | 1.6 N HCl or H2SO4, 20 mL/g, ~30 min for 6 × 3 × 2 mm pieces | 100/100 | Present work |

| Instrumental Parameters | iCAP 7000 Series ICP-OES |

|---|---|

| RF Power (W) | 1150 |

| Plasma gas flow (L/min) | 12 |

| Auxiliary gas flow (L/min) | 0.5 |

| Nebulizer gas flow (L/min) | 0.5 |

| Analysis mode | Radial (Fe, Nd), Axial (others) |

| Stabilization Time (s) | 5 |

| Sample flow rate (mL/min) | 1.8 |

| Wavelength (nm) | Al(309.271), B(249.773), Co(228.616), Cu(224.700, 324.754), Dy(353.170), Fe(238.204, 259.940), Nb(309.418), Nd(401.225, 406.109), Ni(216.556, 221.647), Pr(422.535), Tb(350.917) |

| Digestion Technique | CVAD | MWD | FID | AF a |

|---|---|---|---|---|

| Instrument | DigiPrep Jr 12 pos. | Mars 5 | 6 channels ColdBlock | M4 Fluxer |

| Amount of ground magnet used (g) | 0.5 | 0.25 | 1.0 | 0.1 |

| Volume of acid (mL) | 30 mL | 10 mL | 25 mL | 100 mL |

| Nature of the acid used | HCl:HNO3 (8:2) | HCl:HNO3 (8:2) | HCl:HNO3 (8:2) | 3 M HNO3 |

| Digestion procedure | Ramp ca. 30 min, 240 min at 100 °C | Ramp 25 min, hold 15 min, 1600 W at 100% | 15 min at 100% power for both lamps | See Milliard et al. [21] |

| Nominal Variables | Value 1 | Value 2 | |

| Acid type | HCl | H2SO4 | |

| Numerical Variables | Low-Value | Mid-Value | High-Value |

| Acid concentration (N) | 1 | 2 | 3 |

| Acid-to-sample ratio (mL/g) | 10 | 20 | 30 |

| Dissolution time (s) | 300 | 450 | 600 |

| Lamp power (%) | 80 | 90 | 100 |

| Particle Size (µm) | Mass Percentage (%) |

|---|---|

| <53 | 42 |

| 54–150 | 34 |

| 151–250 | 24 |

| Element | Digestion Technique | |||

|---|---|---|---|---|

| Closed-Vessel Acid (n = 6) | Microwave (n = 2) | Focused Infrared (n = 3) | Alkaline Fusion (n = 3) | |

| Fe | 64 ± 1 | 67 ± 2 | 65 ± 2 | 67 ± 3 |

| Nd | 24.5 ± 0.7 | 25.6 ± 0.9 | 26.0 ± 0.6 | 25 ± 2 |

| Pr | 3.4 ± 0.1 | 3.6 ± 0.1 | 3.5 ± 0.2 | 3.3 ± 0.3 |

| Ni | 1.8 ± 0.2 | N.D. | 1.9 ± 0.1 | 1.7 ± 0.3 |

| Dy | 1.57 ± 0.04 | 1.61 ± 0.08 | 1.5 ± 0.2 | 1.5 ± 0.1 |

| B | 1.04 ± 0.02 | 0.93 ± 0.03 | 1.0 ± 0.1 | N.M. |

| Co | 1.02 ± 0.02 | 1.02 ± 0.01 | 1.00 ± 0.07 | 1.0 ± 0.1 |

| Al | 0.43 ± 0.02 | 0.50 ± 0.01 | 0.5 ± 0.1 | 0.49 ± 0.07 |

| Nb | 0.44 ± 0.08 | 0.4 ± 0.1 | 0.223 ± 0.005 | 0.35 ± 0.02 |

| Cu | 0.20 ± 0.02 | N.D. | 0.17 ± 0.03 | 0.16 ± 0.02 |

| Tb | 0.07 ± 0.02 | 0.09 ± 0.05 | 0.09 ± 0.03 | 0.08 ± 0.01 |

| Total | 99 ± 2% | 101 ± 4% | 100 ± 4% | 100 ± 6 |

| Source | Log Worth a for 5 Factors | Log Worth a for 4 Factors b |

|---|---|---|

| Concentration | 1.734 | 3.506 |

| Ratio | 1.724 | 3.484 |

| Concentration * Ratio | 1.567 | 3.142 |

| Acid | 0.448 | 0.706 |

| Intensity * Time | 0.354 | |

| Intensity * Ratio | 0.240 | 0.360 |

| Time * Acid | 0.209 | |

| Time | 0.137 | |

| Concentration * Acid | 0.137 | 0.223 |

| Ratio * Acid | 0.131 | 0.215 |

| Intensity * Acid | 0.130 | 0.189 |

| Intensity * Concentration | 0.091 | 0.145 |

| Intensity | 0.089 | 0.127 |

| Time * Ratio | 0.064 | |

| Time * Concentration | 0.026 |

| Conditions | Relative Dissolved Mass a (%) |

|---|---|

| Room temp., without agitation | 5 ± 2 |

| Room temp., with agitation b | 5 ± 2 |

| CVAD | 34 ± 5 |

| FID | 62 ± 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonin, M.; Fontaine, F.-G.; Larivière, D. Comparative Studies of Digestion Techniques for the Dissolution of Neodymium-Based Magnets. Metals 2021, 11, 1149. https://doi.org/10.3390/met11081149

Bonin M, Fontaine F-G, Larivière D. Comparative Studies of Digestion Techniques for the Dissolution of Neodymium-Based Magnets. Metals. 2021; 11(8):1149. https://doi.org/10.3390/met11081149

Chicago/Turabian StyleBonin, Mélodie, Frédéric-Georges Fontaine, and Dominic Larivière. 2021. "Comparative Studies of Digestion Techniques for the Dissolution of Neodymium-Based Magnets" Metals 11, no. 8: 1149. https://doi.org/10.3390/met11081149

APA StyleBonin, M., Fontaine, F.-G., & Larivière, D. (2021). Comparative Studies of Digestion Techniques for the Dissolution of Neodymium-Based Magnets. Metals, 11(8), 1149. https://doi.org/10.3390/met11081149