Influence of Tool Wear on Form Deviations in Dry Machining of UNS A97075 Alloy

Abstract

1. Introduction

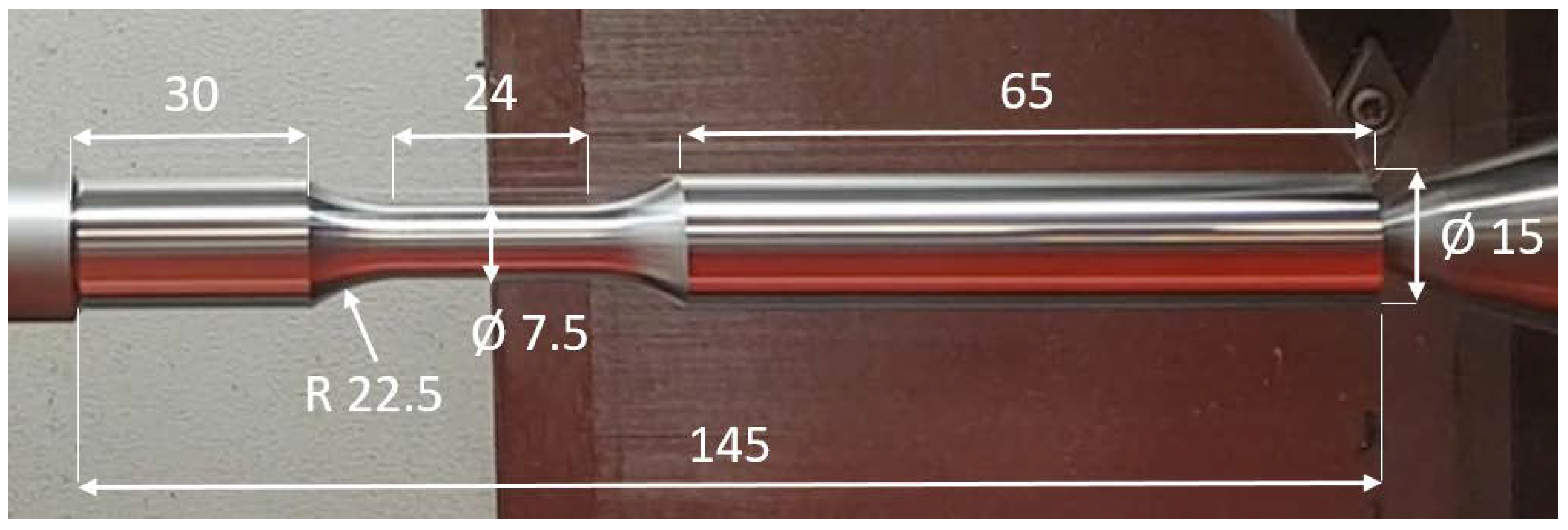

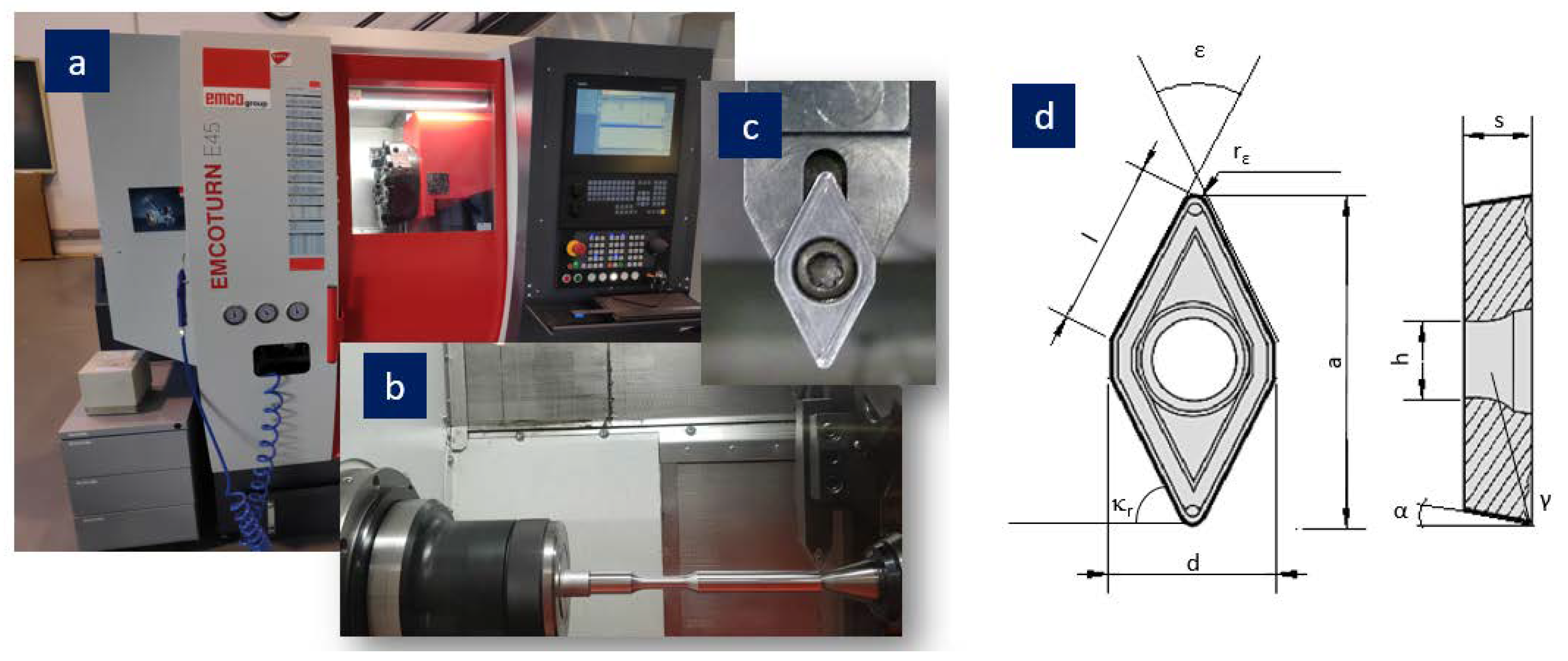

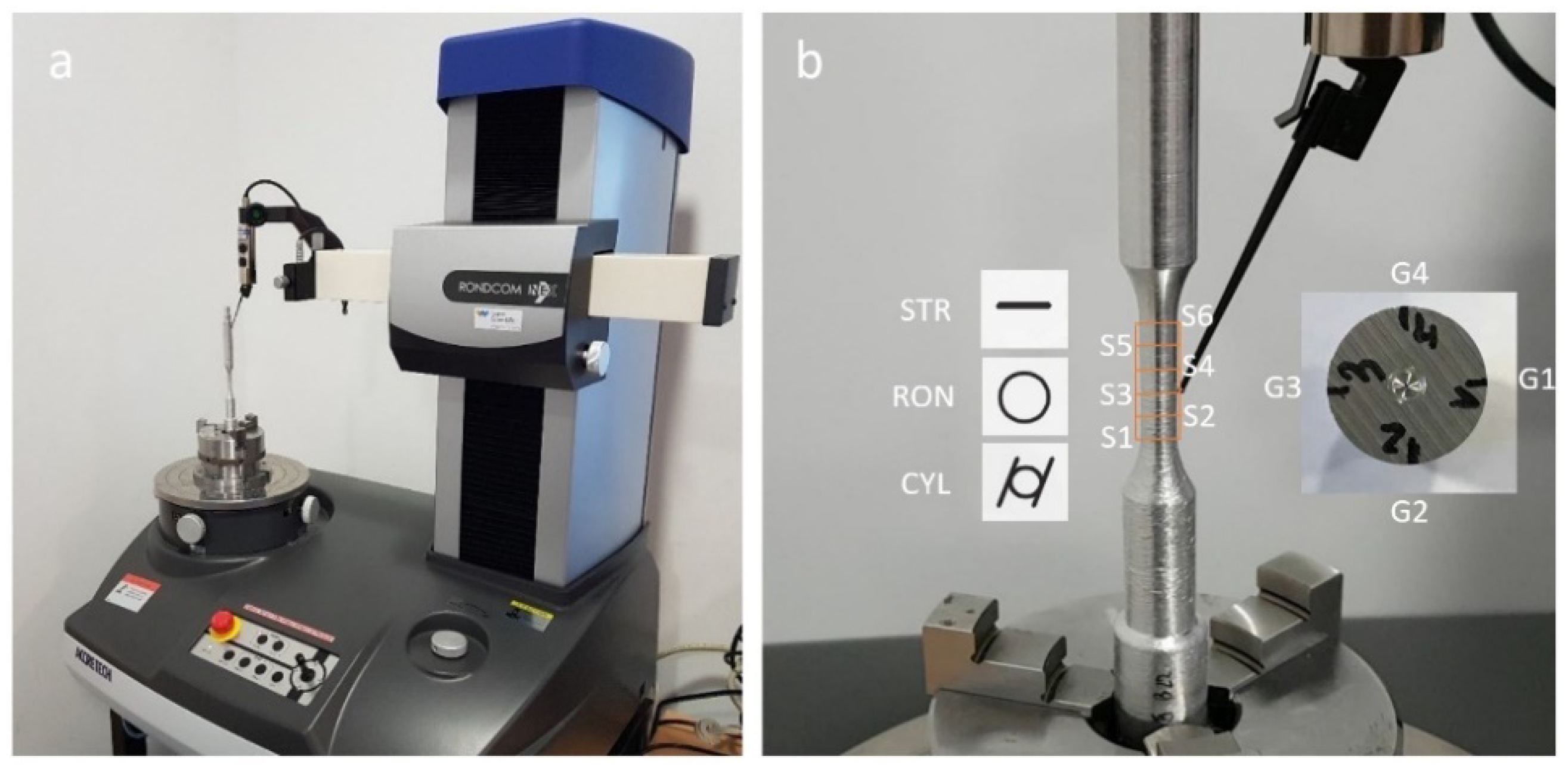

2. Materials and Methods

3. Results and Discussion

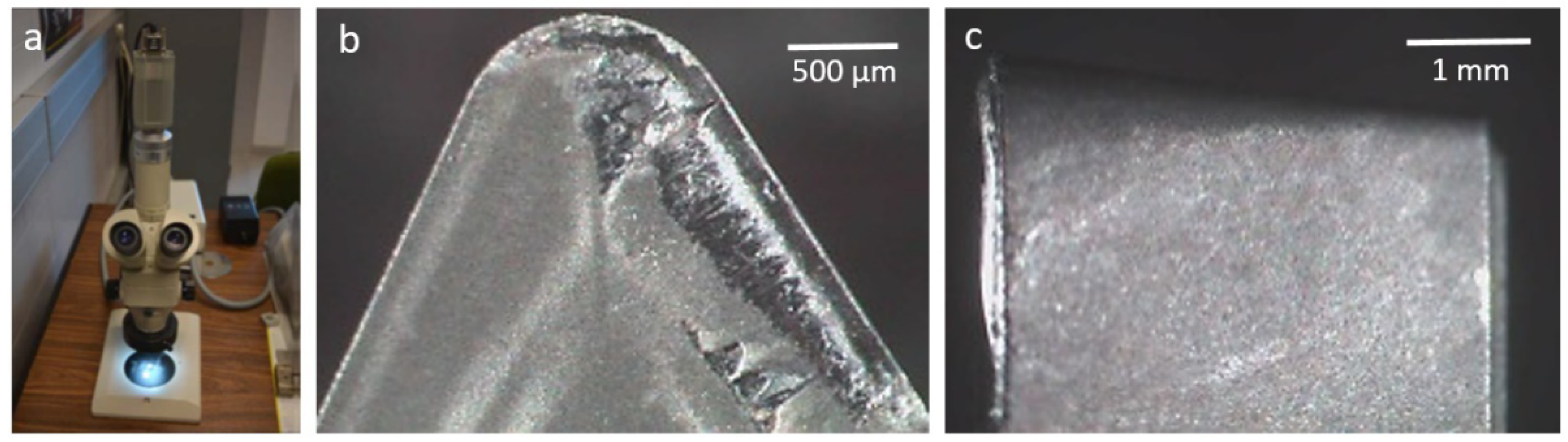

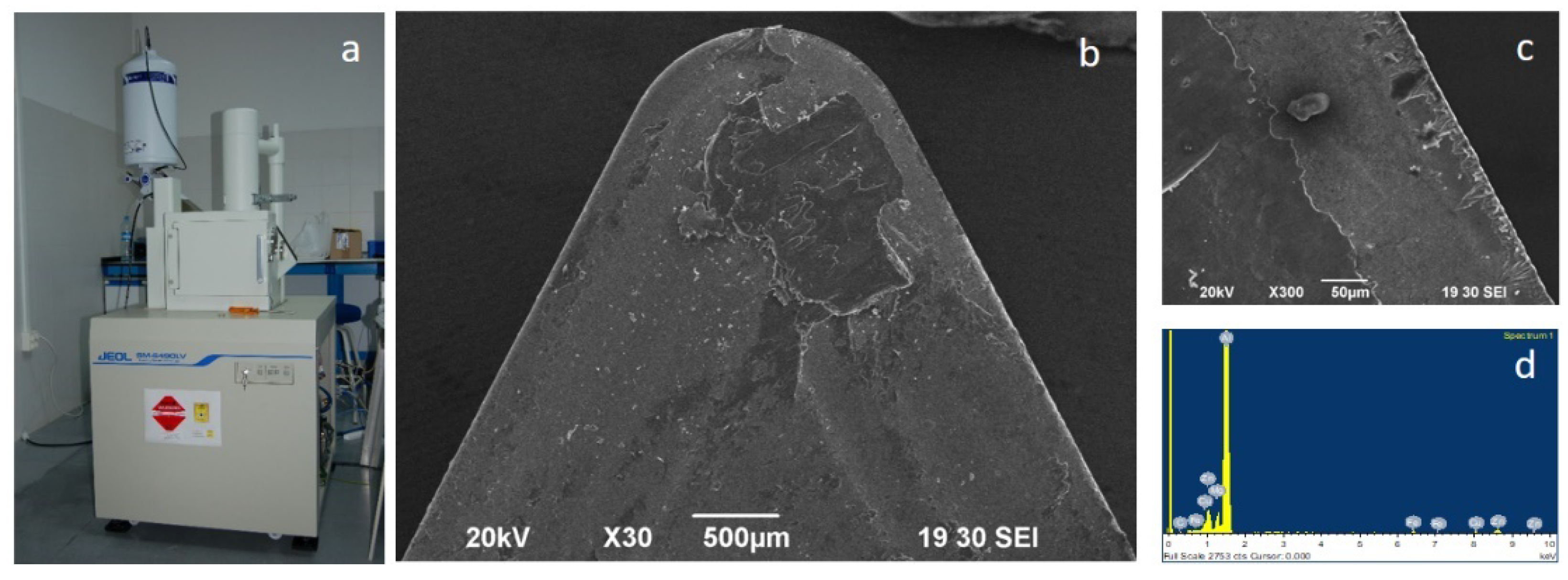

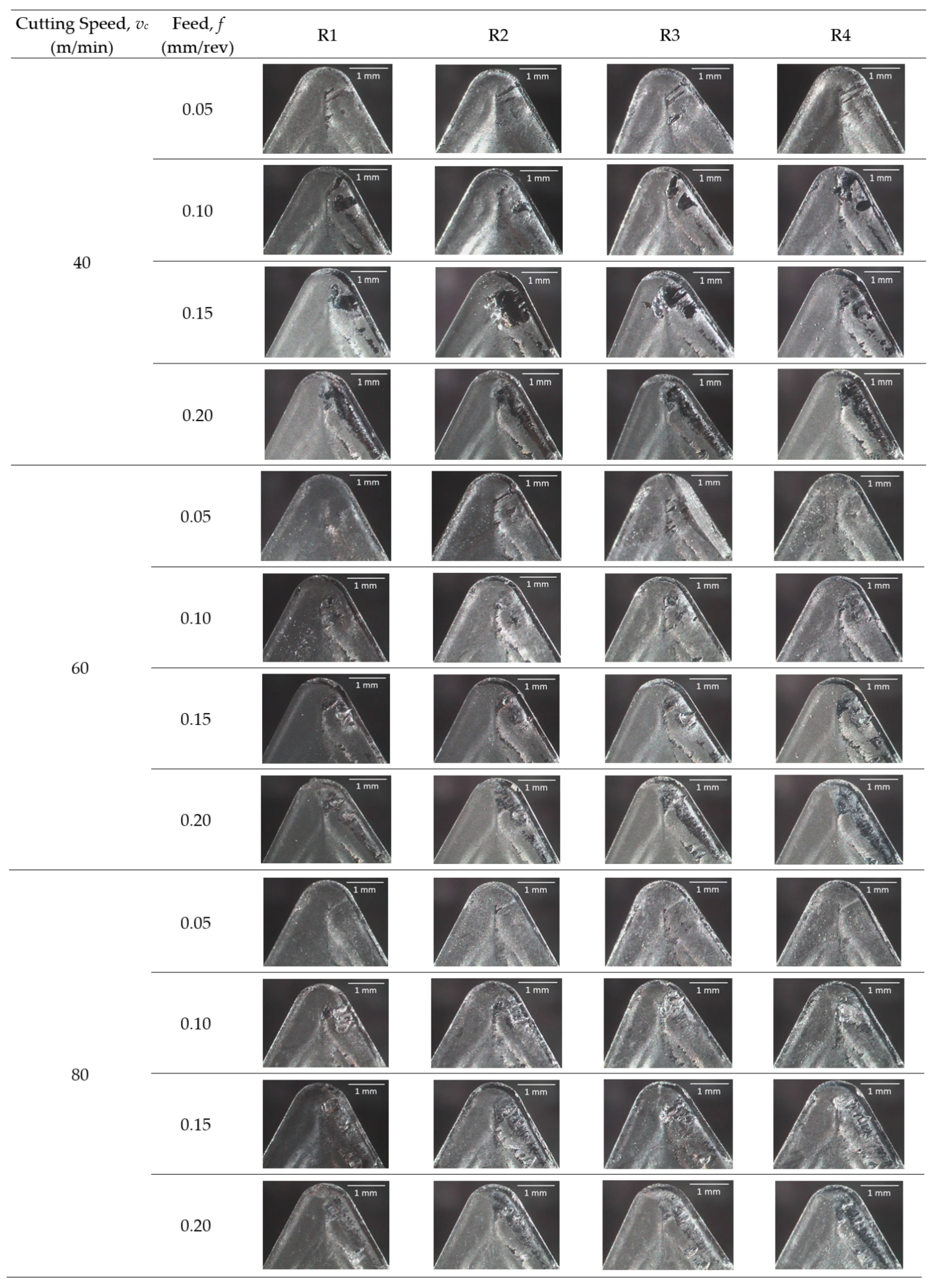

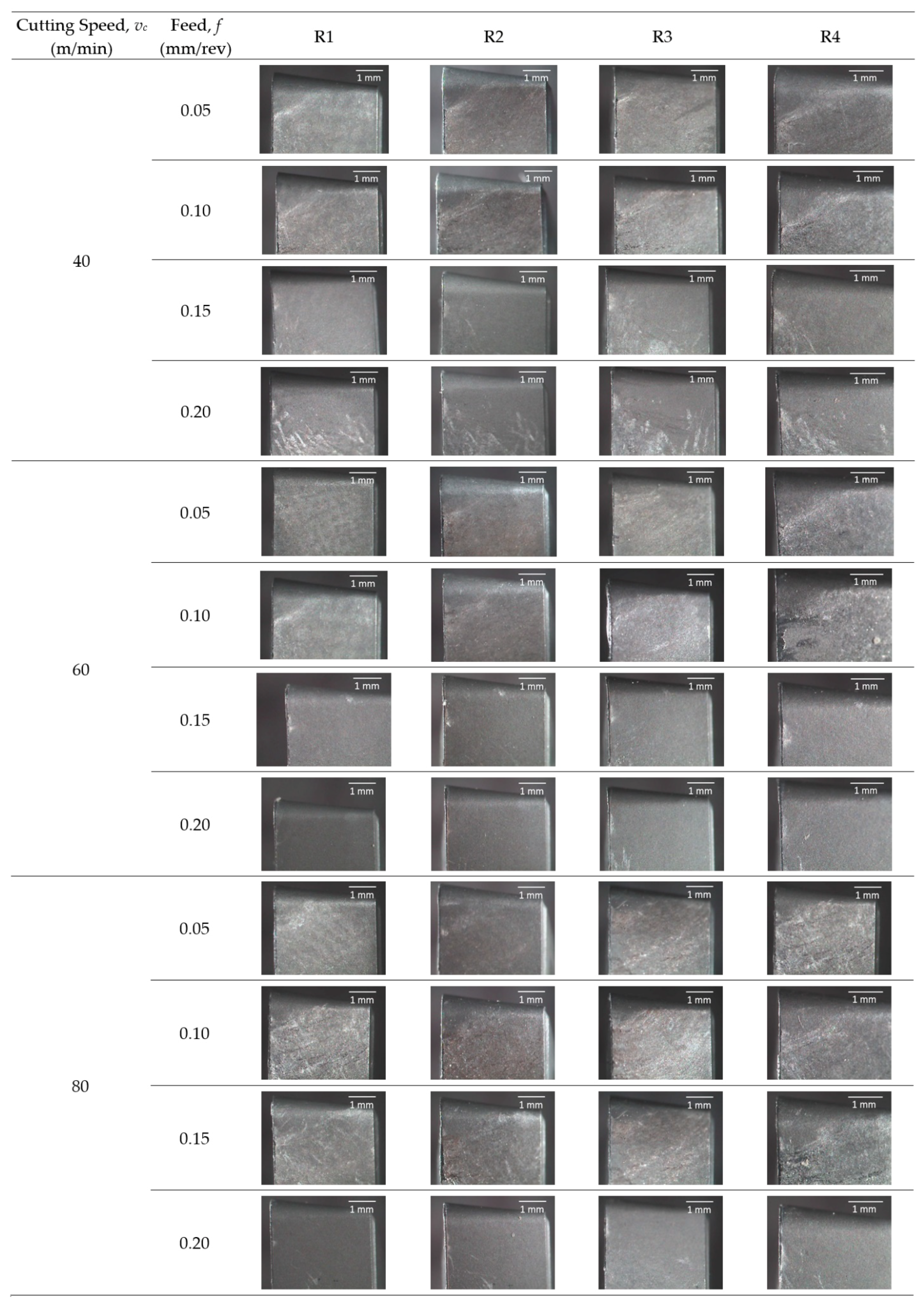

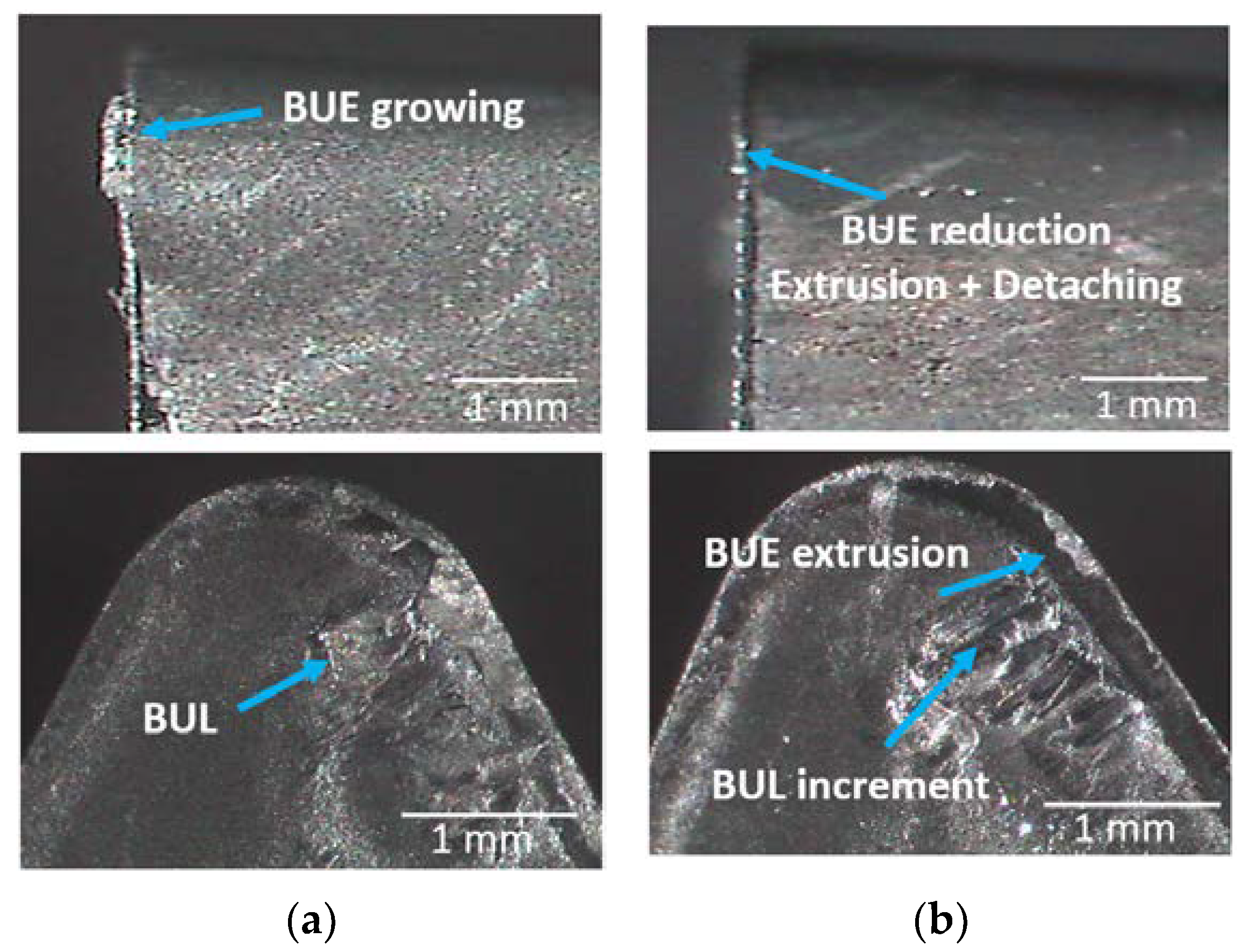

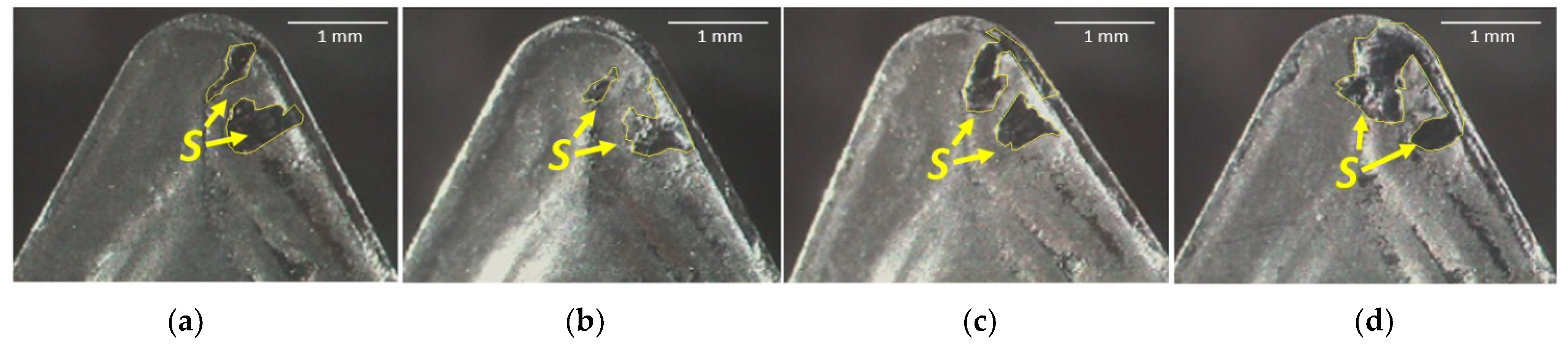

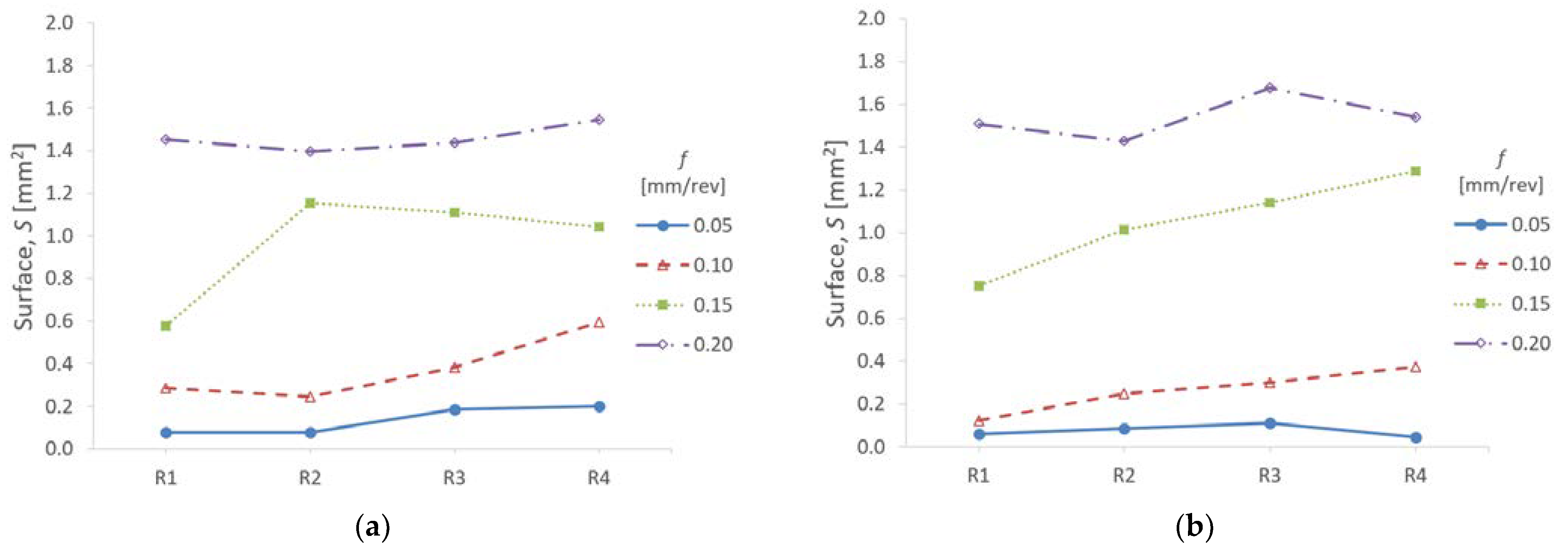

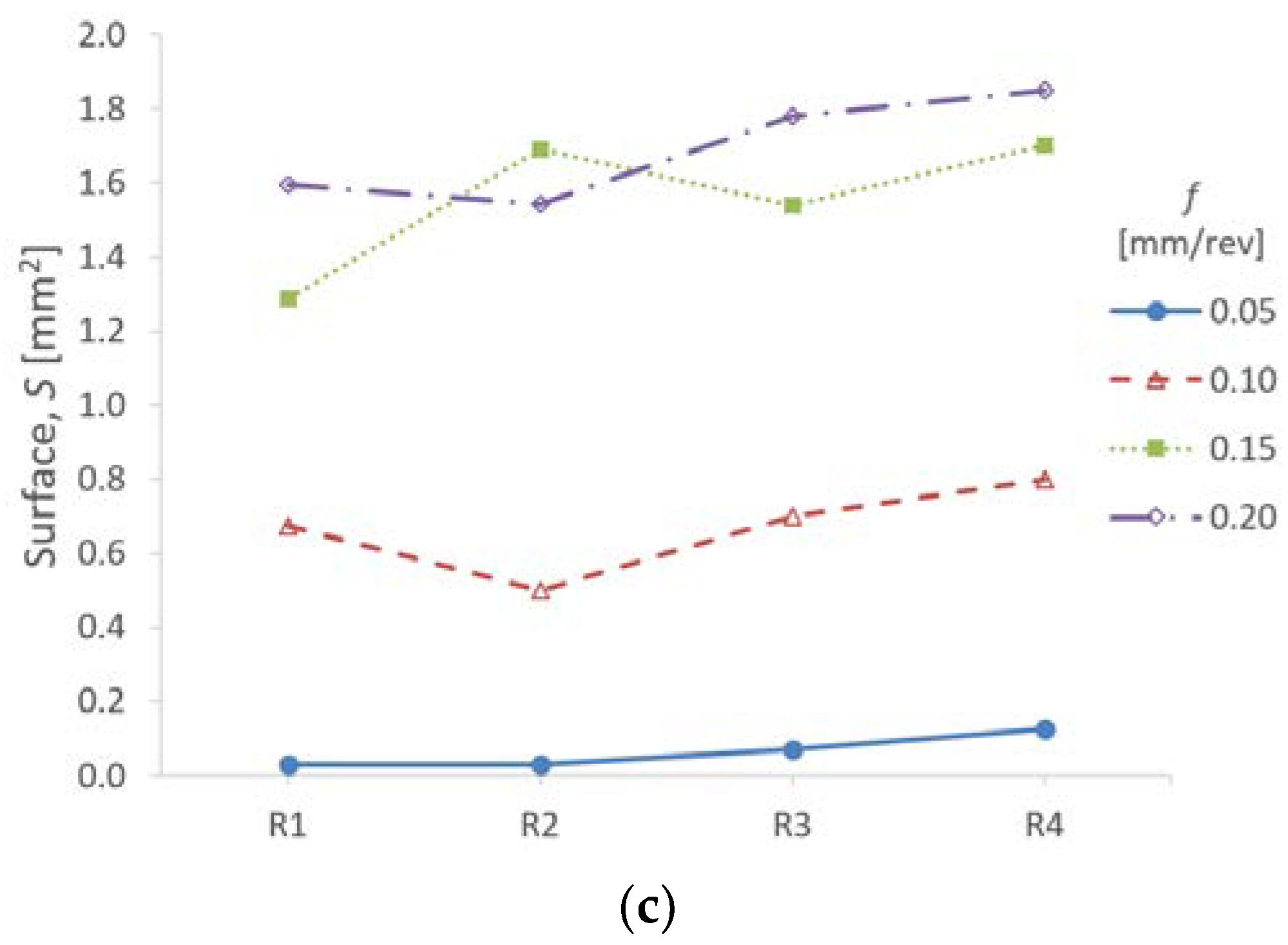

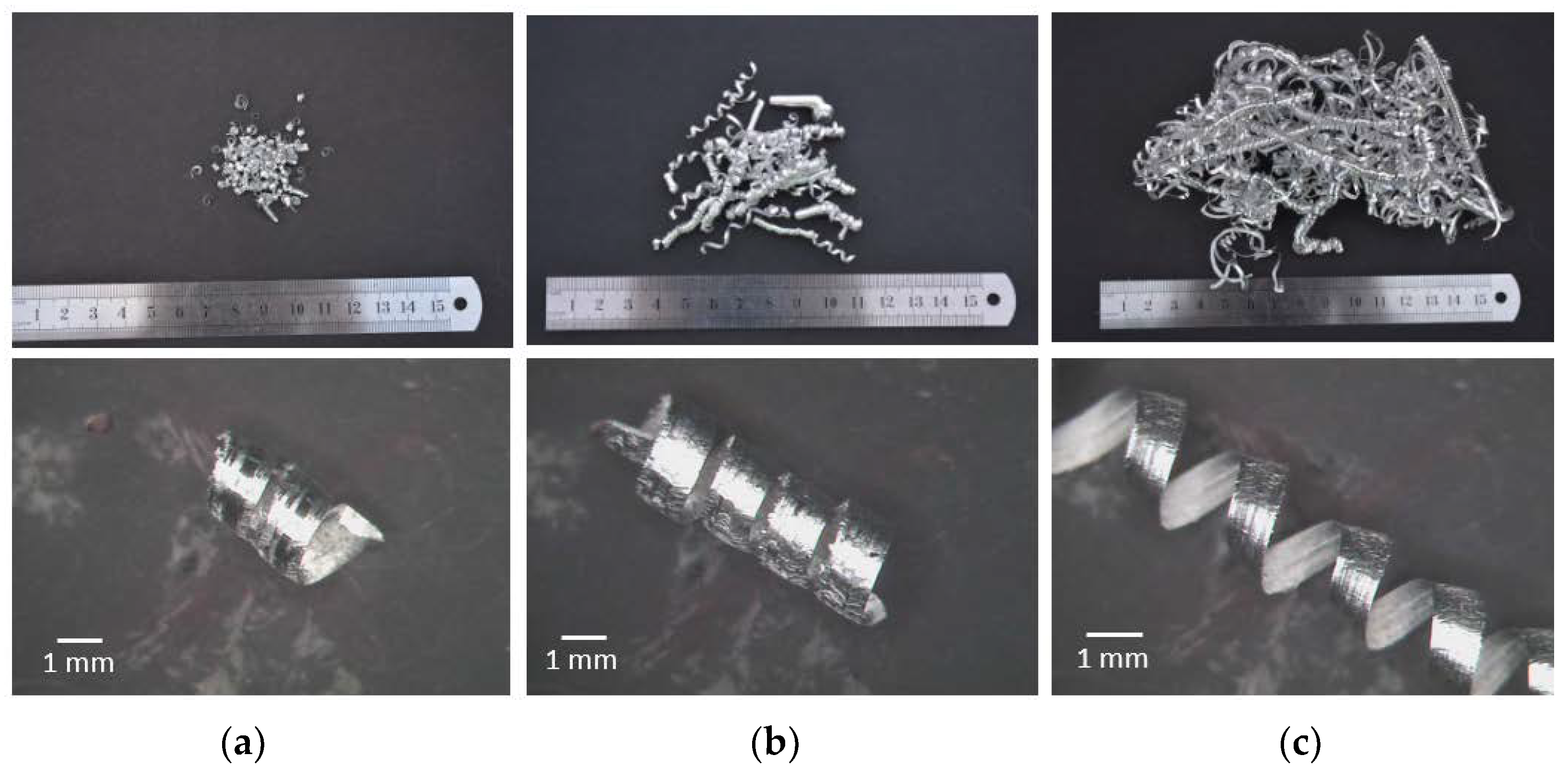

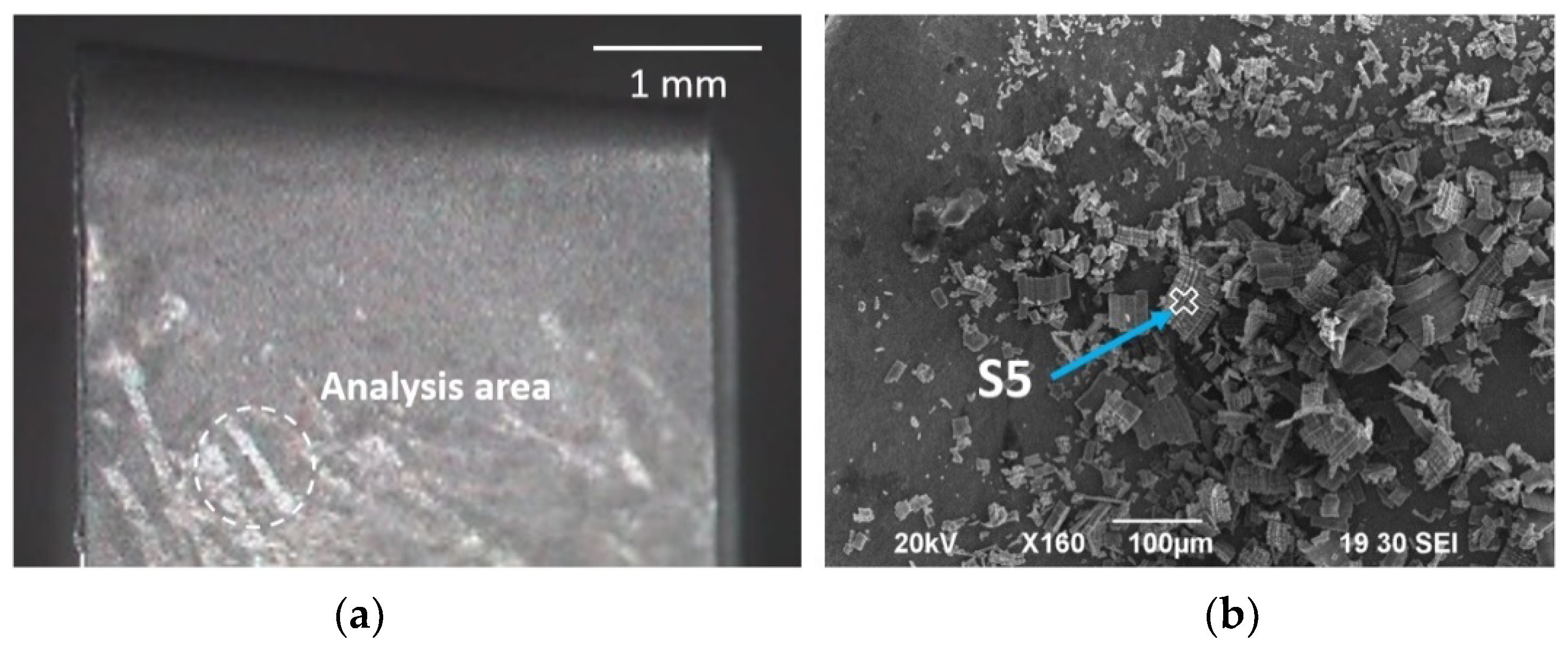

3.1. Tool Wear

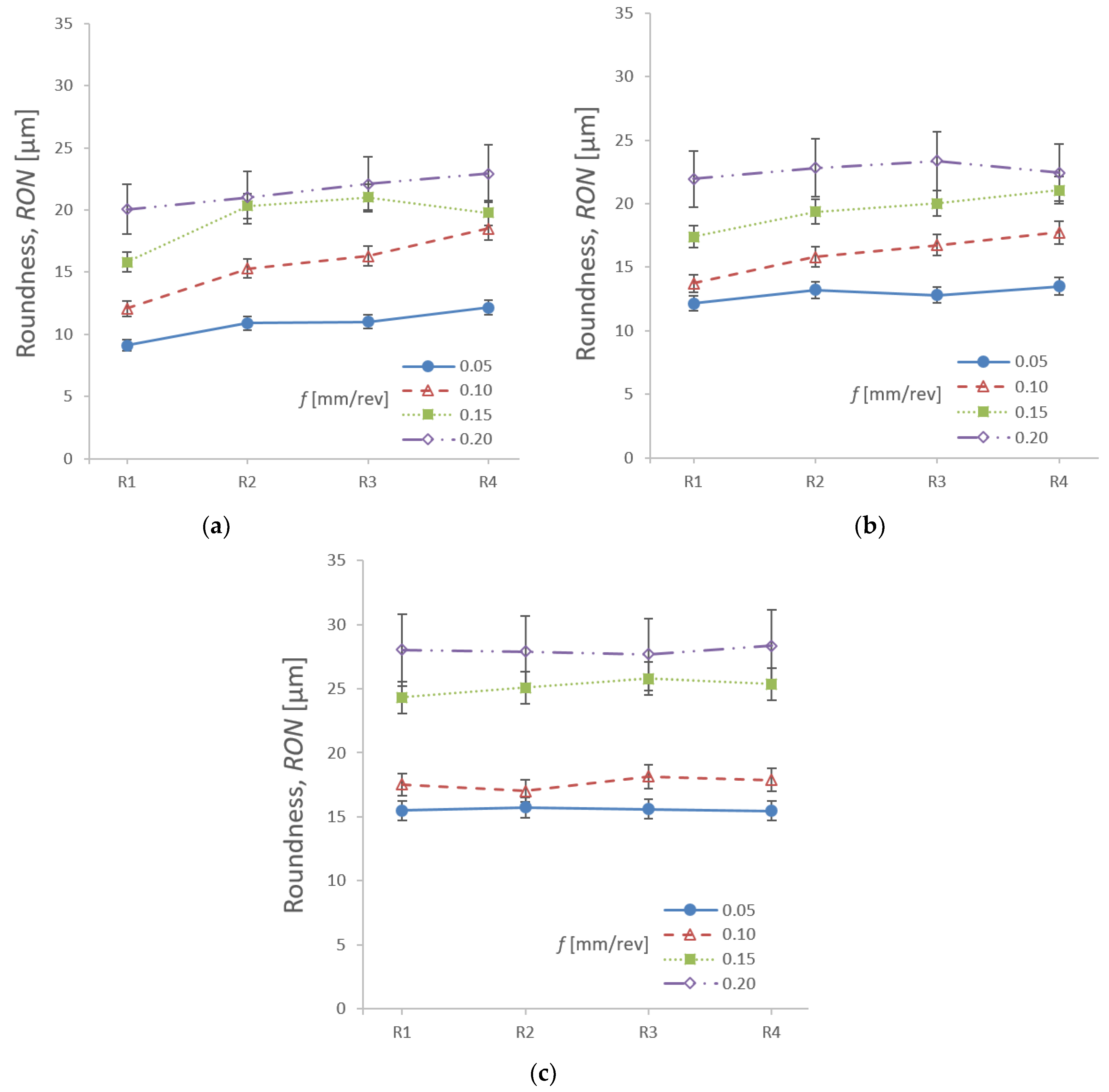

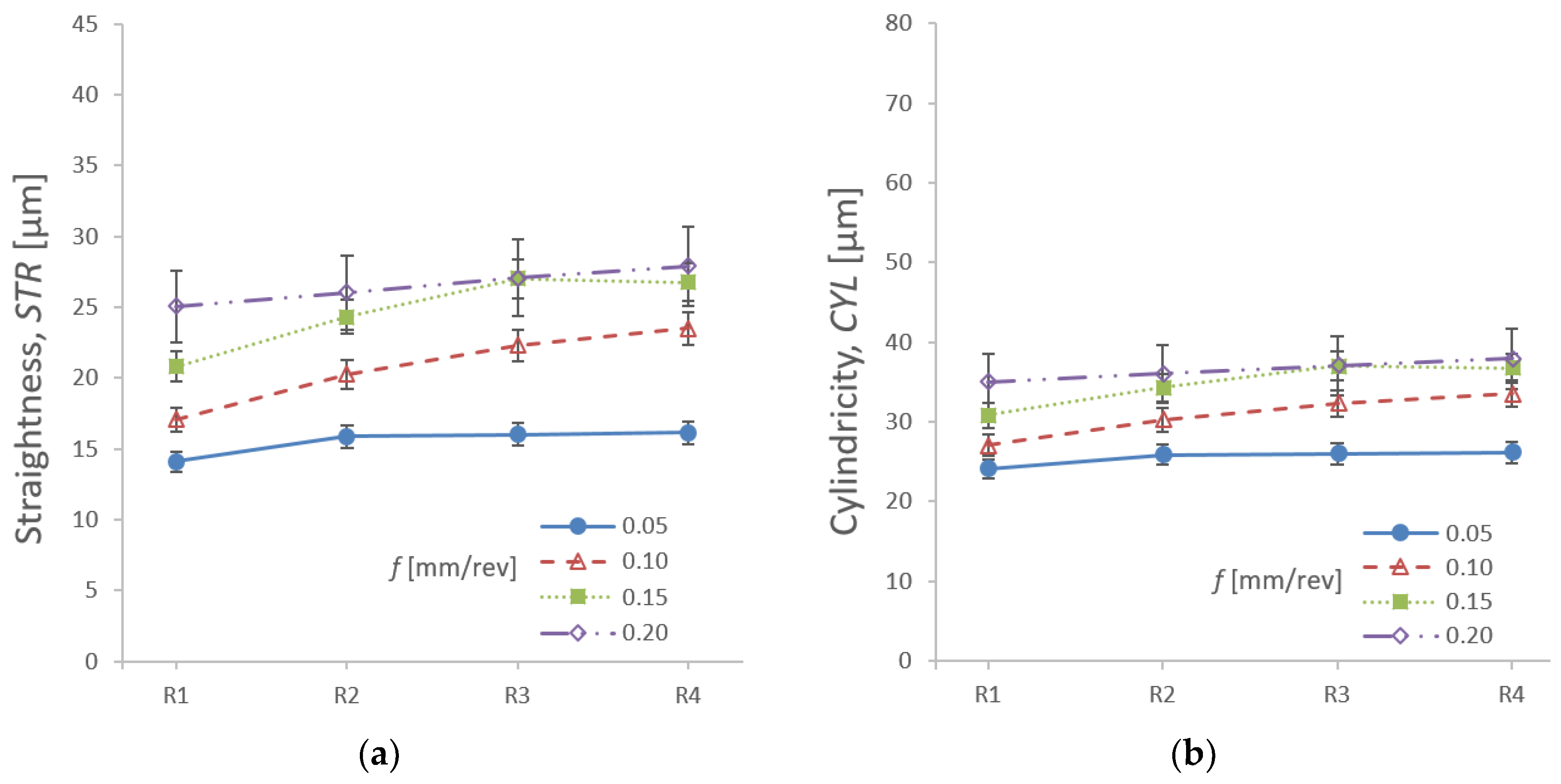

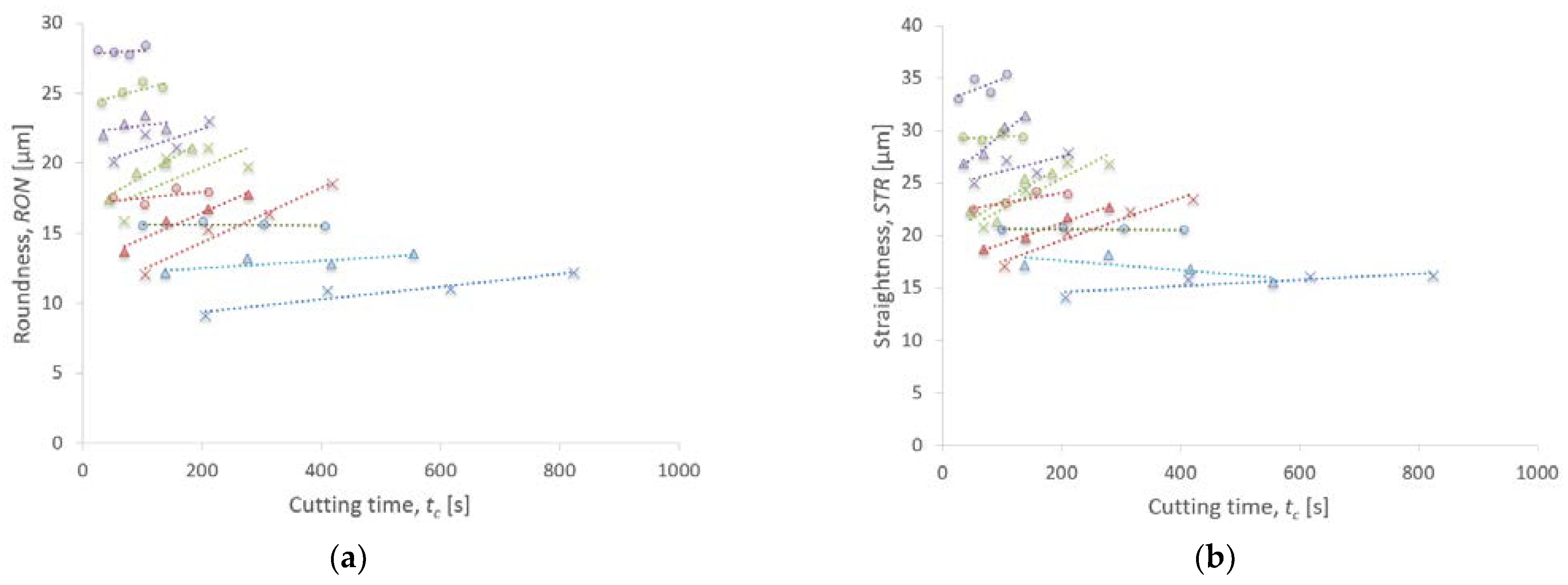

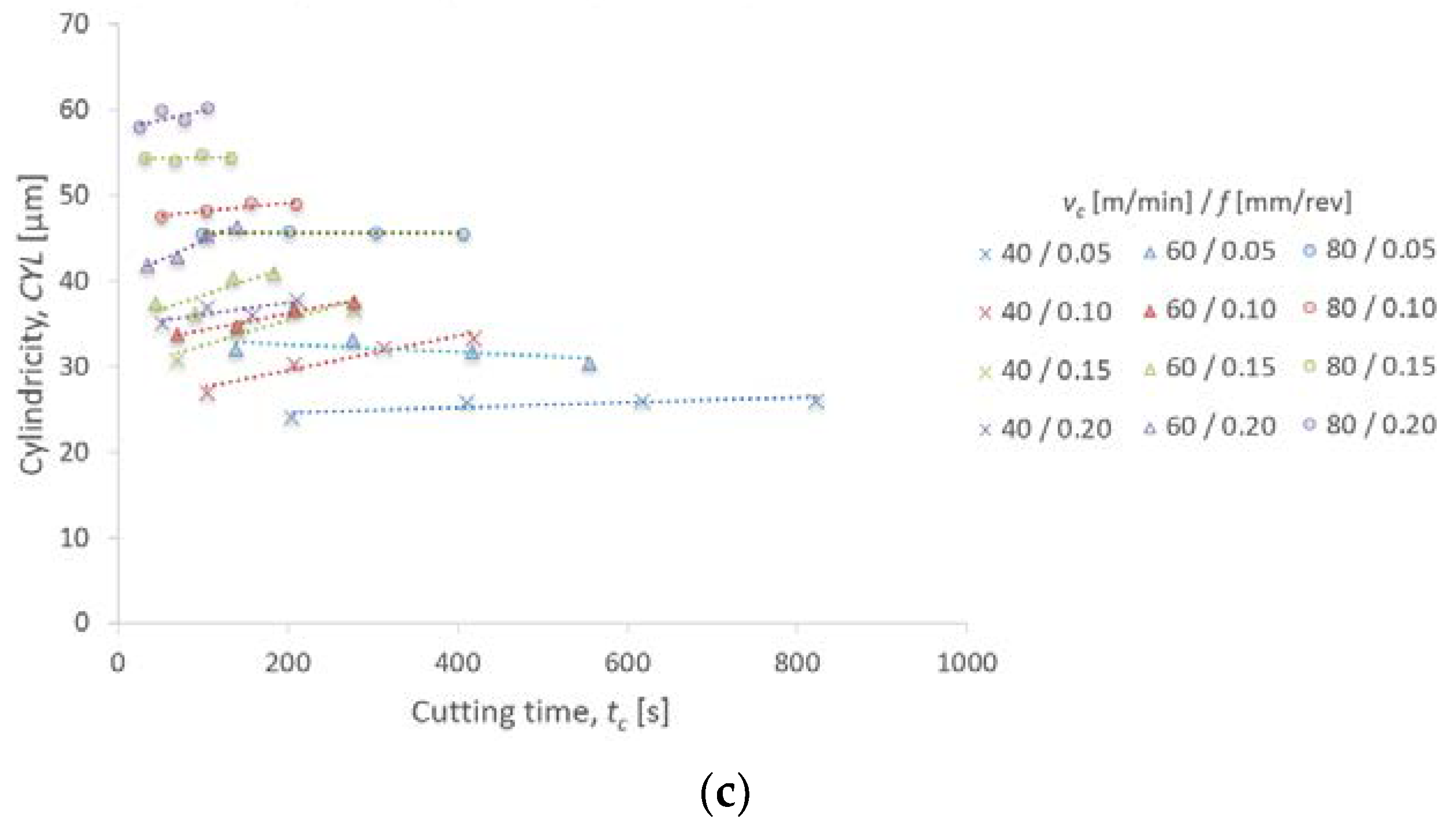

3.2. Form Deviations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BUE | built-up edge |

| BUL | built-up layer |

| CFRP | carbon fiber reinforced polymers |

| CYL | cylindricity |

| EDS | energy dispersive spectroscopy |

| FD | form deviation |

| HCP | high-pressure coolant |

| MQL | minimum quantity of lubrication |

| RON | roundness |

| SEM | scanning electron microscopy |

| SOM | stereoscopic optical microscopy |

| STR | straightness |

| MZC | minimal zone circumscribing |

Nomenclature

| Ra | arithmetical mean roughness |

| Rz | maximum height of the roughness profile |

| vc | cutting speed |

| f | feed |

| ap | cutting depth |

| α | tool clearance angle |

| γ | tool rake angle |

| ε | tool included angle |

| rε | nose radius |

| κr | main cutting edge angle |

| κr’ | secondary cutting edge angle |

| d | tool width |

| l | cutting edge length |

| a | tool length |

| h | tool fixing hole diameter |

| s | tool thickness |

| Ri | test repetition (i = 1 to 4) |

| Si | roundness measurement section (i = 1 to 6) |

| Gi | straightness measurement generatrix (i = 1 to 4) |

| λc | cut off |

| S | adhered material surface to the tool rake face |

| tc | cutting time |

| K | form deviations model constant |

| x | cutting speed coefficient |

| y | feed coefficient |

| z | cutting time coefficient |

| R2 | coefficient of determination |

References

- Wiesner, C.; Künzi, H.U.; Ilschner, B. Characterization of the topography of turned surfaces and its influence on the fatigue life of Al-7075. Mater. Sci. Eng. A 1991, 145, 151–158. [Google Scholar] [CrossRef]

- Clares, J.M.; Vazquez, J.M.; Gomez-Parra, A.; Puerta, F.J.; Marcos, M. Experimental methodology for evaluating workpieces surface integrity in dry turning of aerospace alloys. In Proceedings of the 26th DAAAM International Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 21–24 October 2015; pp. 0849–0855. [Google Scholar]

- ISO 1101:2017. Geometrical Product Specifications (GPS)—Geometrical Tolerancing—Tolerances of Form, Orientation, Location and Run-Out; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Umamaheswara, R.S.; Ramesh, R.; Rohit, K. Development of surface texture evaluation system for highly sparse data-driven machining domains. Int. J. Comput. Integr. Manuf. 2020, 33, 859–868. [Google Scholar] [CrossRef]

- Martín-Béjar, S.; Trujillo, F.J.; Bermudo, C.; Sevilla, L. Fatigue behavior parametric analysis of dry machined UNS A97075 aluminum alloy. Metals 2020, 10, 631. [Google Scholar] [CrossRef]

- ISO ISO 1143:2010. Metallic Materials—Rotating bar Bending Fatigue Testing; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- Sánchez, M.; Marcos, M. On the machinability of aluminium and aluminium alloys. J. Mech. Behav. Mater. 1996, 7, 179–193. [Google Scholar]

- Santos, M.C.; Machado, A.R.; Sales, W.F.; Barrozo, M.A.S.; Ezugwu, E.O. Machining of aluminum alloys: A review. Int. J. Adv. Manuf. Technol. 2016, 86, 3067–3080. [Google Scholar] [CrossRef]

- Khettabi, R.; Nouioua, M.; Djebara, A.; Songmene, V. Effect of MQL and dry processes on the particle emission and part quality during milling of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 2593–2598. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Sugihara, T.; Nishimoto, Y.; Enomoto, T. New production technologies in aerospace industry—5th machining innovations conference (MIC 2014) on-machine tool resharpening for dry machining of aluminum alloys. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 24, pp. 68–73. [Google Scholar]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2021, 62, 179–201. [Google Scholar] [CrossRef]

- Kopac, J.; Krolczyk, G. Cryogenic machining, surface integrity and machining performance. Arch. Mater. Sci. Eng. 2015, 71, 83–93. [Google Scholar]

- Gupta, M.K.; Mia, M.; Singh, G.; Pimenov, D.Y.; Sarikaya, M.; Sharma, V.S. Hybrid cooling-lubrication strategies to improve surface topography and tool wear in sustainable turning of Al 7075-T6 alloy. Int. J. Adv. Manuf. Technol. 2018, 101, 55–69. [Google Scholar] [CrossRef]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining—Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Grzesik, W. 15.2—Dry and semi-dry machining. In Advanced Machining Processes of Metallic Materials; Elsevier: Amsterdam, The Netherlands, 2008; pp. 226–245. ISBN 978-0-08-044534-2. [Google Scholar]

- Hamed, M.; Zedan, Y.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effect of tool quality on the machinability characteristics of Al-Cu and Al-Si cast alloys. Int. J. Adv. Manuf. Technol. 2020, 106, 1317–1326. [Google Scholar] [CrossRef]

- Il, A.; Chatelain, J.F.; Lalonde, J.F.; Balazinski, M.; Rimpault, X. An experimental investigation of the influence of cutting parameters on workpiece internal temperature during Al2024-T3 milling. Int. J. Adv. Manuf. Technol. 2018, 97, 413–426. [Google Scholar] [CrossRef]

- Carrilero, M.S.; Bienvenido, R.; Sánchez, J.M.; Álvarez, M.; González, A.; Marcos, M. A SEM and EDS insight into the BUL and BUE differences in the turning processes of AA2024 Al–Cu alloy. Int. J. Mach. Tools Manuf. 2002, 42, 215–220. [Google Scholar] [CrossRef]

- Batista, M.; Salguero, J.; Gómez, A.; Álvarez, M.; Marcos, M. Image based analysis evaluation of the elements of secondary adhesion wear in dry turning of aluminum alloys. Adv. Mater. Res. 2012, 498, 133–138. [Google Scholar] [CrossRef]

- Batista, M.; Del Sol, I.; Fernandez-Vidal, S.; Salguero, J. Experimental parametric model for adhesion wear measurements in the dry turning of an AA2024 alloy. Materials 2018, 11, 1598. [Google Scholar] [CrossRef] [PubMed]

- Trujillo, F.J.; Sevilla, L.; Marcos, M. Experimental parametric model for indirect adhesion wear measurement in the dry turning of UNS A97075 (Al-Zn) alloy. Materials 2017, 10, 152. [Google Scholar] [CrossRef]

- Gómez-Parra, A.; Álvarez-Alcón, M.; Salguero, J.; Batista, M.; Marcos, M. Analysis of the evolution of the Built-Up Edge and Built-Up Layer formation mechanisms in the dry turning of aeronautical aluminium alloys. Wear 2013, 302, 1209–1218. [Google Scholar] [CrossRef]

- Trujillo, F.J.; Sevilla, L.; Marcos, M. Influence of the axial machining length on microgeometrical deviations of horizontally dry-turned UNS A97075 Al-Zn alloy. Procedia Eng. 2013, 63, 405–412. [Google Scholar] [CrossRef]

- Trujillo, F.J.; Sevilla, L.; Salguero, J.; Batista, M.; Marcos, M. Parametric potential model for determining the micro-geometrical deviations of horizontally dry-turned UNS A97075 (Al-Zn) alloy. Adv. Sci. Lett. 2013, 19, 731–735. [Google Scholar] [CrossRef]

- Salguero, J.; Puerta, F.J.; Gomez-Parra, A.; Trujillo, F.J.; Sevilla, L.; Marcos, M. An analysis of geometrical models for evaluating the influence of feed rate on the roughness of dry turned UNS A92050 (Al-Cu-Li) alloy. Adv. Mater. Process. Technol. 2016, 2, 578–589. [Google Scholar] [CrossRef]

- Salguero, J.; Gómez, A.; Carrilero, M.S.; Batista, M.; Álvarez, M. Roughness prediction models for tangential cutting forces in the dry turning of Al-Cu alloys. In Proceedings of the 14th International Conference on Advances in Material Processing Technologies AMPT, Istambul, Turkey, 13–16 July 2011; Volume 1. [Google Scholar]

- Martín-Béjar, S.; Trujillo Vilches, F.J.; Bermudo Gamboa, C.; Sevilla Hurtado, L. Cutting speed and feed influence on surface microhardness of Dry-Turned UNS A97075-T6 Alloy. Appl. Sci. 2020, 10, 1049. [Google Scholar] [CrossRef]

- Trujillo, F.J.; Sevilla, L.; Martín, F.; Gamboa, C. Analysis of the chip geometry in dry machining of aeronautical aluminum alloys. Appl. Sci. 2017, 7, 132. [Google Scholar] [CrossRef]

- Salguero, J.; Sanchez, J.M.; Sebastian, M.A.; Sanchez-Carrilero, M.; Marcos, M. Cutting speed and feed based model for evaluating parallelism deviations in horizontal dry turning of aluminium alloys. Ann. Daaam Proc. 2010, Volume 1, 719–720. [Google Scholar]

- Sánchez, J.M.; Batista, M.; Salguero, J.; Gómez, A.; Marcos, M. Cutting speed-feed based parametric model for macro-geometrical deviations in the dry turning of UNS A92024 Al-Cu alloys. Key Eng. Mater. 2012, 504–506, 1311–1316. [Google Scholar] [CrossRef]

- Trujillo, F.J.; Sevilla, L.; Marcos, M. Cutting speed-feed coupled experimental model for geometric deviations in the dry turning of UNS A97075 Al-Zn alloys. Adv. Mech. Eng. 2014, 6, 382435. [Google Scholar] [CrossRef]

- Li, B.; Cao, Y.; Ye, X.; Guan, J.; Yang, J. Multi-scale prediction of the geometrical deviations of the surface finished by five-axis ball-end milling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1685–1702. [Google Scholar] [CrossRef]

- Martín-Béjar, S.; Trujillo, F.J.; Bermudo, C.; Sevilla, L. Parametric analysis of macro-geometrical deviations in dry turning of UNS A97075 (Al-Zn) alloy. Metals 2019, 9, 1141. [Google Scholar] [CrossRef]

- Martín-Béjar, S.; Trujillo, F.J.; Bermudo, C.; Sevilla, L. Cutting parameters influence on total run-out of dry machined UNS A97075 alloy parts. Procedia Manuf. 2019, 41, 835–842. [Google Scholar] [CrossRef]

| Zn | Mg | Cu | Cr | Si | Mn | Al |

|---|---|---|---|---|---|---|

| 6.05 | 2.59 | 1.91 | 0.18 | 0.08 | 0.06 | Rest |

| Cutting Speed, vc (m/min) | Feed, f (mm/rev) | Cutting Depth, ap (mm) |

|---|---|---|

| 40 60 80 | 0.05 0.10 0.15 0.20 | 1 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Tool clearance angle, α | 7° | Tool width, d | 9.53 mm |

| Tool rake angle, γ | 17° | Cutting edge length, l | 11.60 mm |

| Tool included angle, ε | 55° | Tool length, a | 18.77 mm |

| Nose radius, rε | 0.80 mm | Tool fixing hole diameter, h | 4.40 mm |

| Main cutting edge angle, κr | 62.5° | Tool thickness, s | 3.97 mm |

| Secondary cutting edge angle, κr’ | 62.5° | - | - |

| - | Co | C | W | O | Zn | Mg | Cu | Cr | Si | Mn | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy | - | - | - | - | 6.05 | 2.59 | 1.91 | 0.18 | 0.08 | 0.06 | 89.13 |

| Spectrum 1 | 6.57 | 4.15 | 23.91 | 2.62 | 1.23 | 0.32 | 0.17 | - | - | - | 61.03 |

| Spectrum 2 | 1.44 | 0.93 | 5.22 | 1.32 | 5.44 | 2.43 | 1.62 | 0.16 | 0.07 | 0.05 | 81.32 |

| Spectrum 3 | 0.82 | 0.38 | 2.80 | 4.25 | 5.62 | 2.38 | 1.47 | 0.14 | 0.06 | 0.04 | 82.04 |

| Spectrum 4 | 17.33 | 11.37 | 67.58 | 3.72 | - | - | - | - | - | - | - |

| Spectrum 5 | 0.90 | 0.54 | 3.10 | 1.13 | 5.78 | 2.19 | 1.83 | 0.17 | 0.07 | 0.05 | 84.24 |

| Form Deviation, FD | K | x | y | z | Multiple R | R2 | Adjusted R2 | Standard Error |

|---|---|---|---|---|---|---|---|---|

| Roundness, RON | 5.50 | 0.47 | 0.55 | 0.10 | 0.95 | 0.91 | 0.90 | 0.0377 |

| Straightness, STR | 9.26 | 0.37 | 0.46 | 0.08 | 0.93 | 0.89 | 0.88 | 0.0339 |

| Cylindricity, CYL | 12.23 | 0.41 | 0.38 | 0.07 | 0.92 | 0.88 | 0.86 | 0.0358 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trujillo Vilches, F.J.; Martín Béjar, S.; Bermudo Gamboa, C.; Herrera Fernández, M.; Sevilla Hurtado, L. Influence of Tool Wear on Form Deviations in Dry Machining of UNS A97075 Alloy. Metals 2021, 11, 958. https://doi.org/10.3390/met11060958

Trujillo Vilches FJ, Martín Béjar S, Bermudo Gamboa C, Herrera Fernández M, Sevilla Hurtado L. Influence of Tool Wear on Form Deviations in Dry Machining of UNS A97075 Alloy. Metals. 2021; 11(6):958. https://doi.org/10.3390/met11060958

Chicago/Turabian StyleTrujillo Vilches, Francisco Javier, Sergio Martín Béjar, Carolina Bermudo Gamboa, Manuel Herrera Fernández, and Lorenzo Sevilla Hurtado. 2021. "Influence of Tool Wear on Form Deviations in Dry Machining of UNS A97075 Alloy" Metals 11, no. 6: 958. https://doi.org/10.3390/met11060958

APA StyleTrujillo Vilches, F. J., Martín Béjar, S., Bermudo Gamboa, C., Herrera Fernández, M., & Sevilla Hurtado, L. (2021). Influence of Tool Wear on Form Deviations in Dry Machining of UNS A97075 Alloy. Metals, 11(6), 958. https://doi.org/10.3390/met11060958