Progress of Flake Powder Metallurgy Research

Abstract

1. Introduction

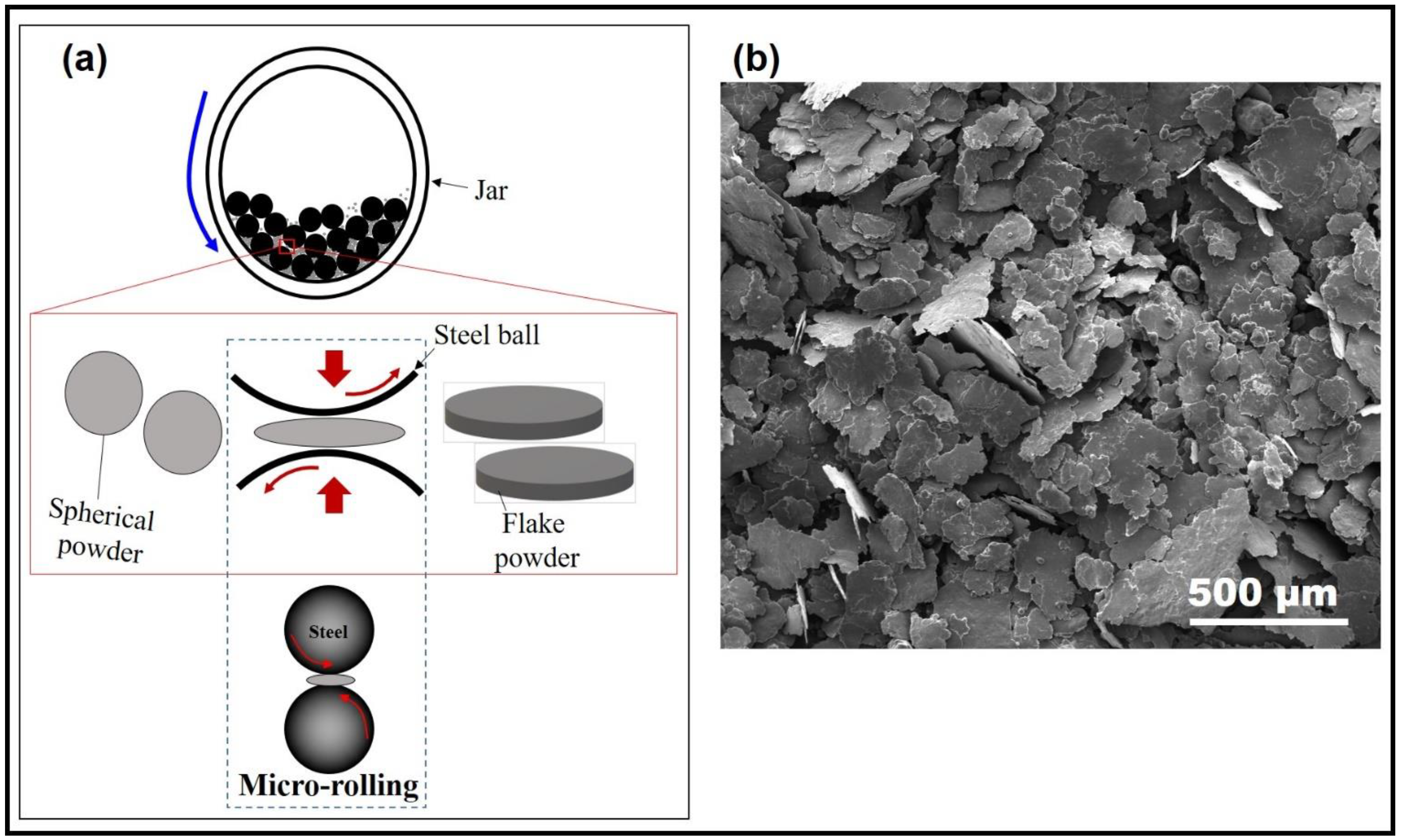

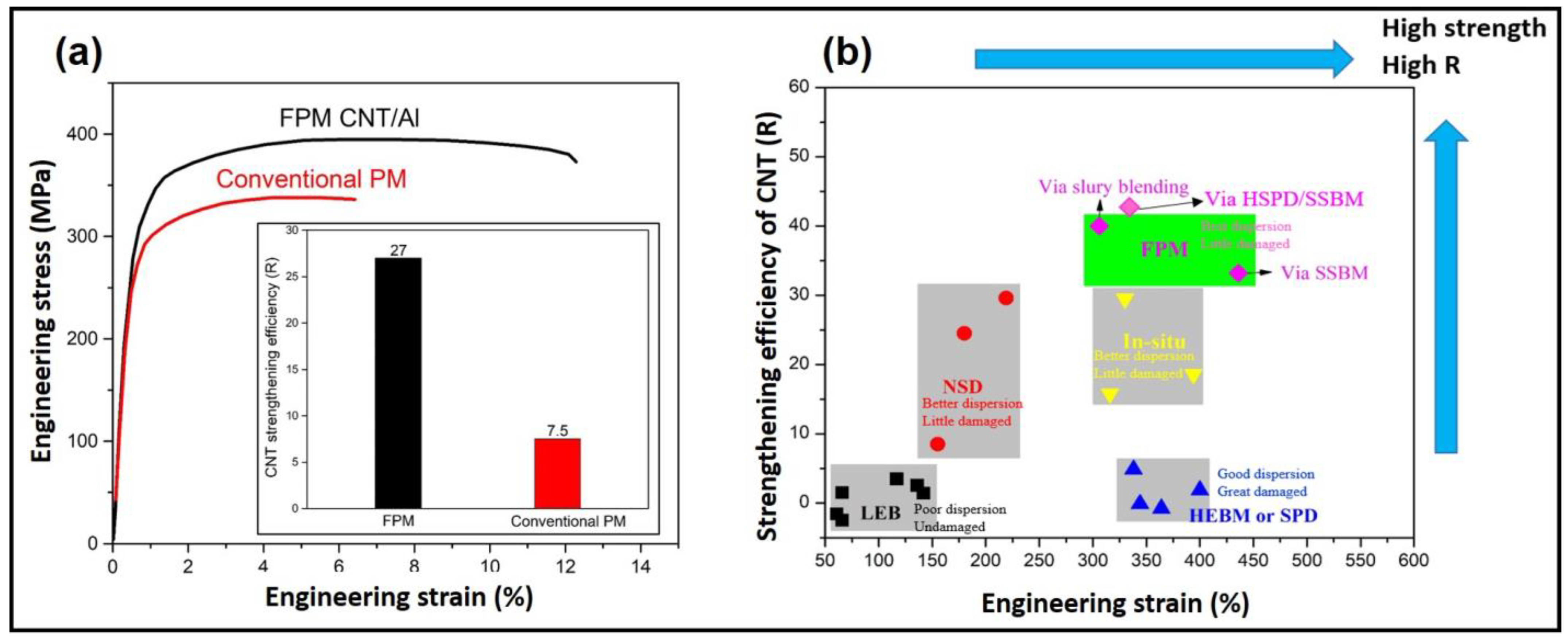

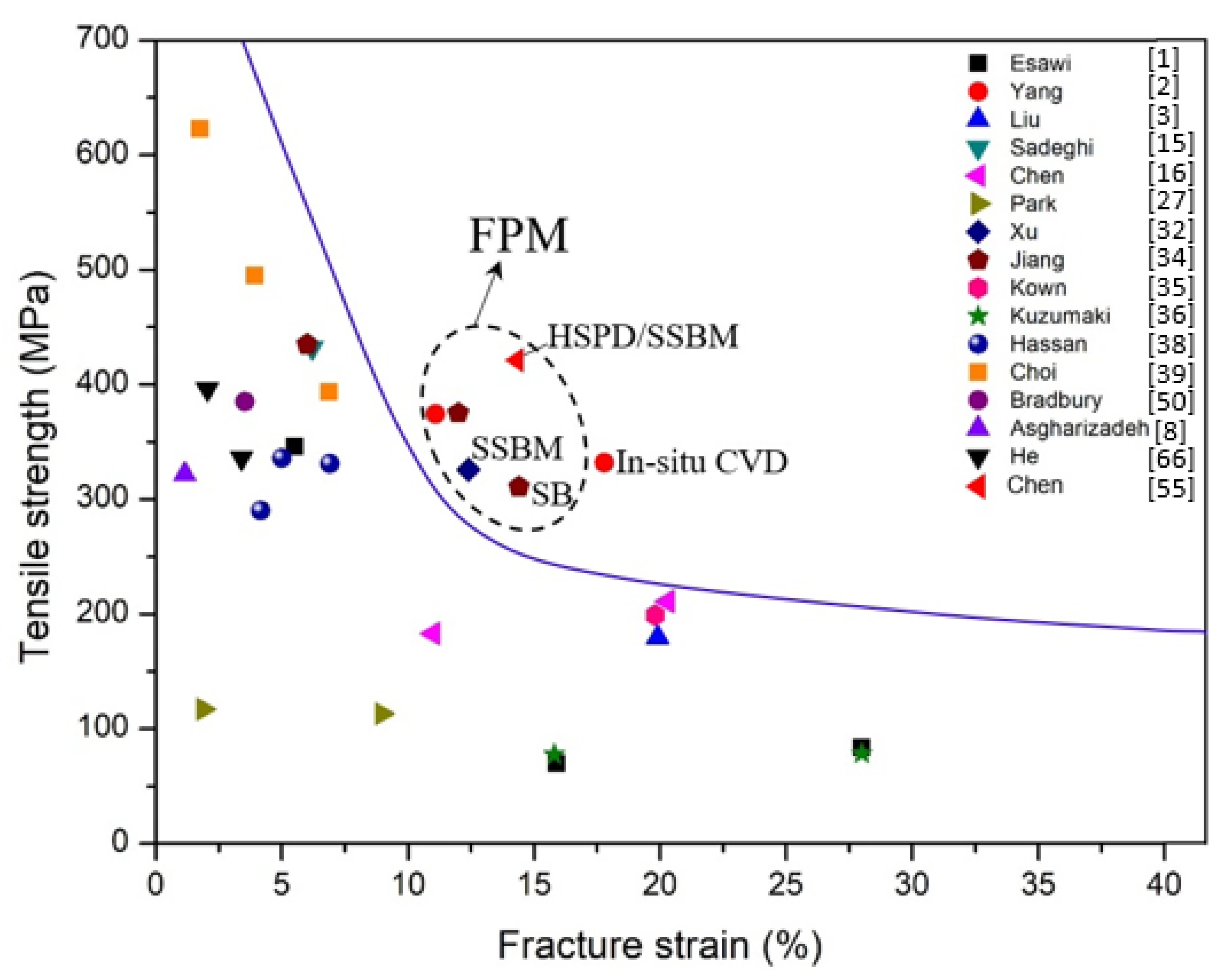

2. Conventional Flake Powder Metallurgy (C-FPM)

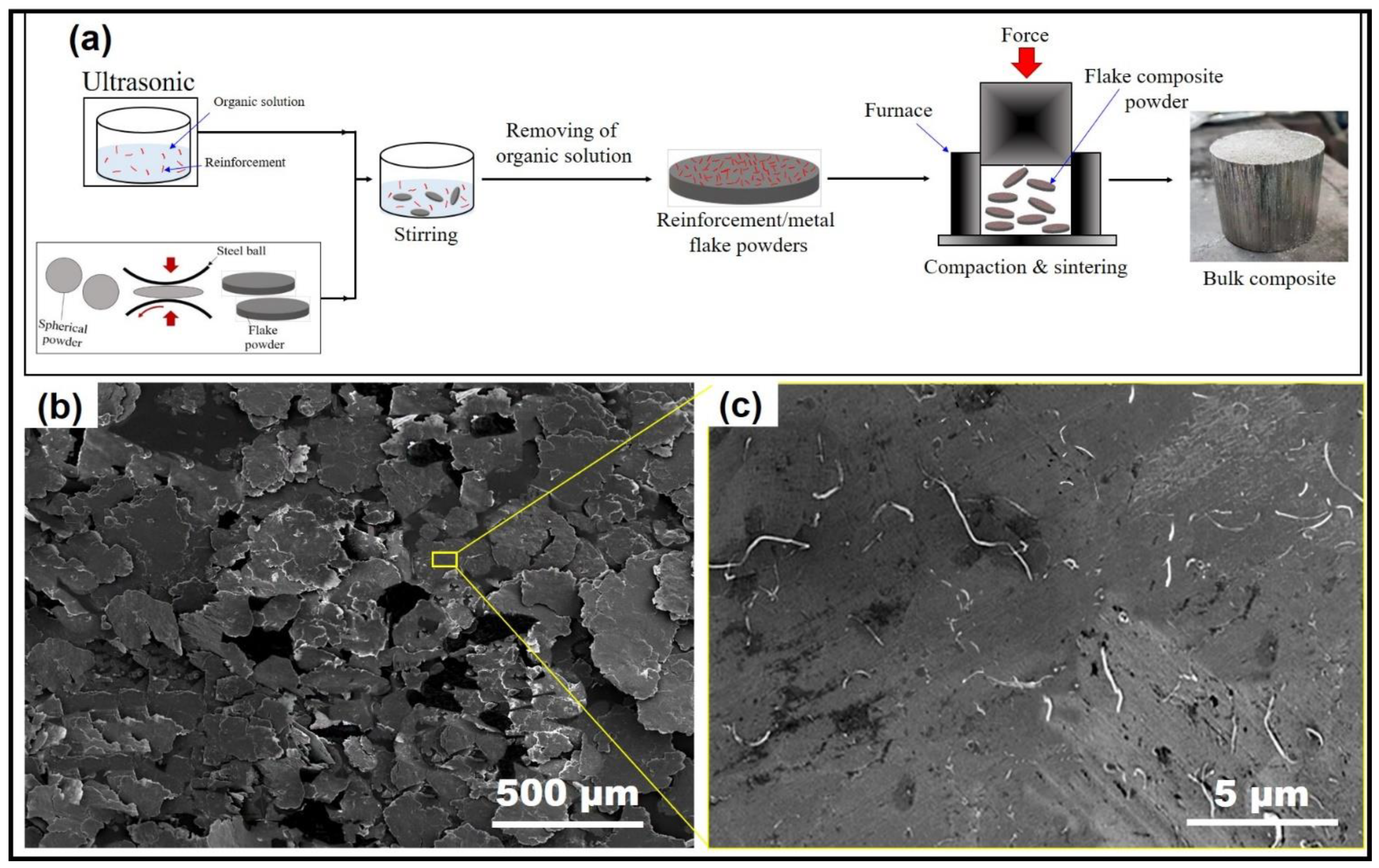

3. Flake Powder Metallurgy via Slurry Blending (FPM-SB)

4. Flake Powder Metallurgy via Shift Speed-Ball Milling (FPM-SSBM)

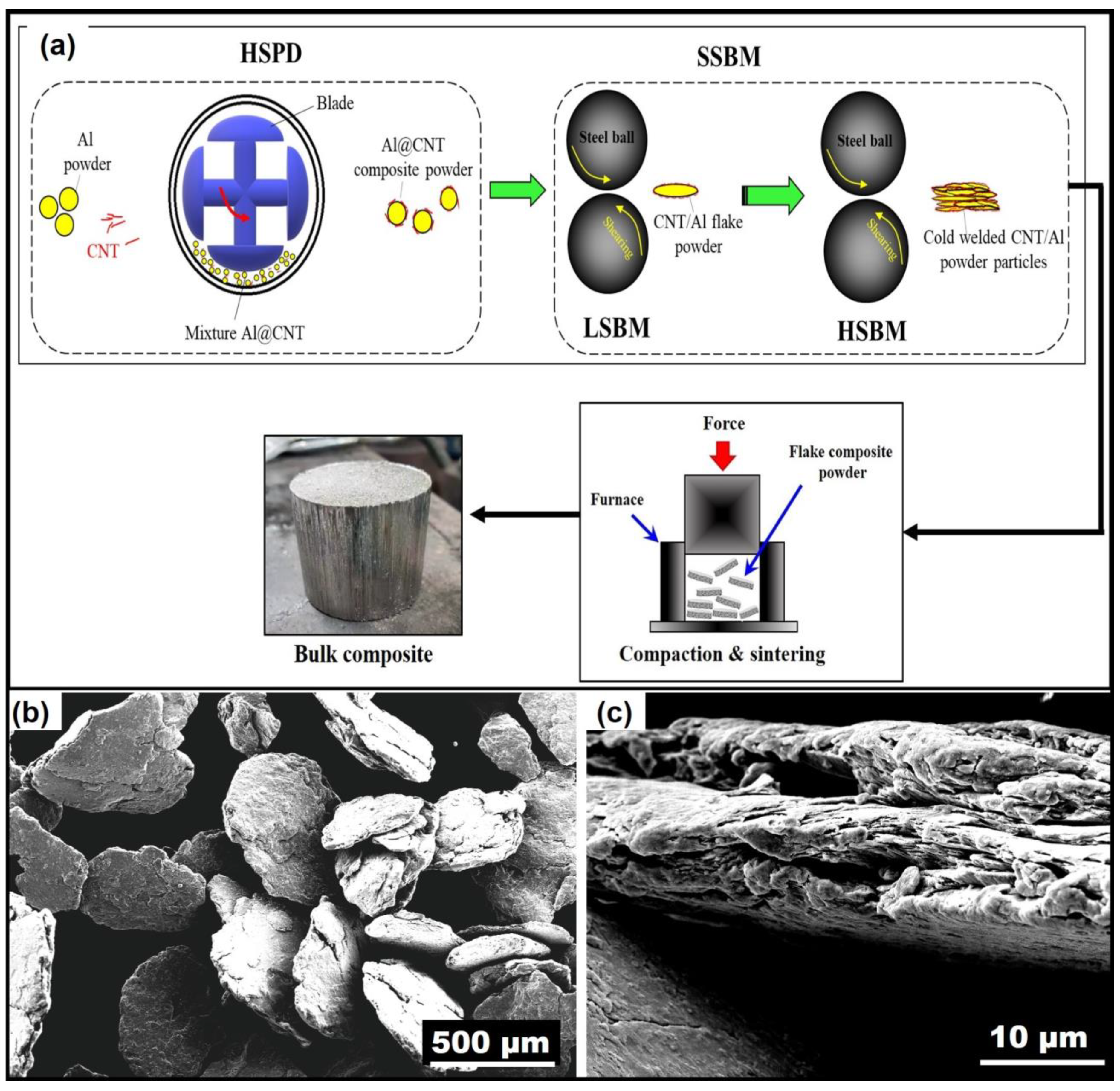

5. Flake Powder Metallurgy High-Shear Pre-Dispersion and SSBM (FPM-HSPD/SSBM)

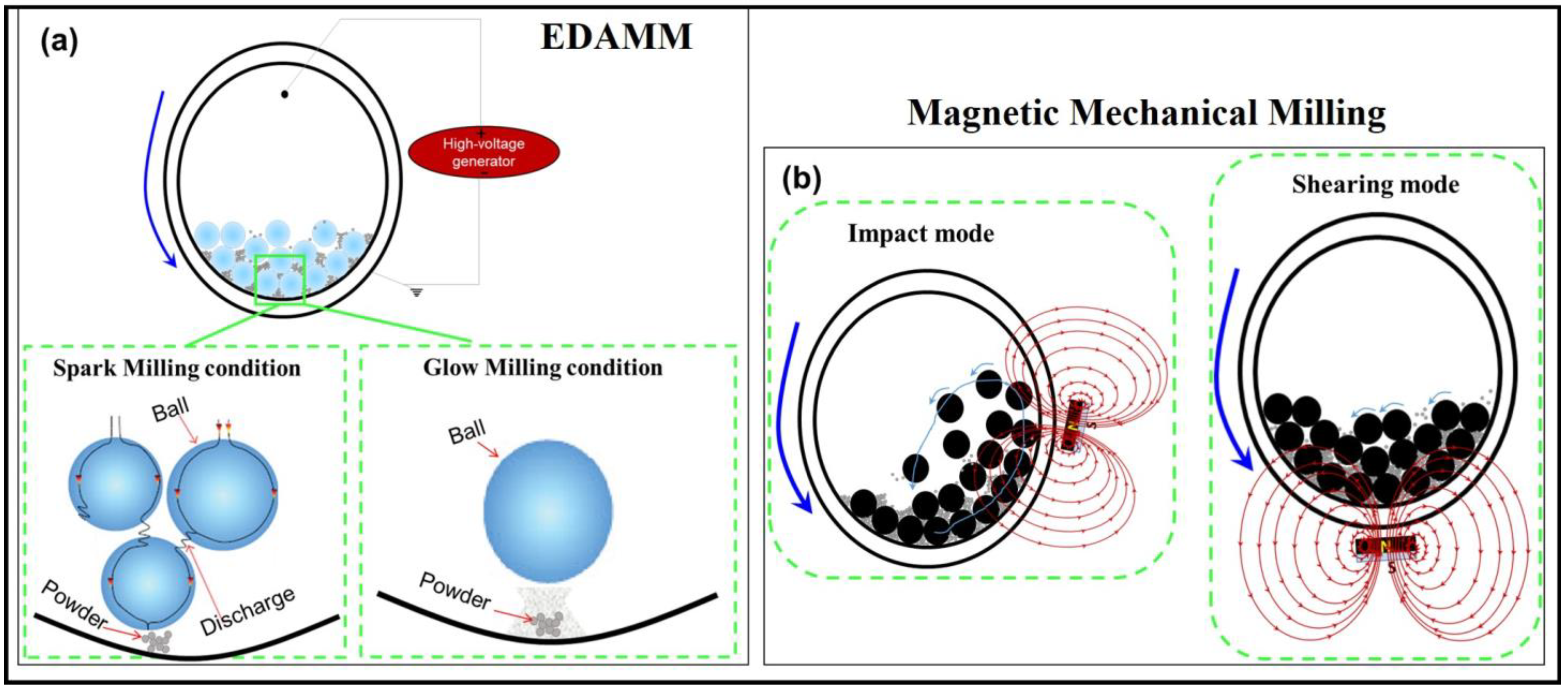

6. Promising BM Techniques

7. Conclusions and Vista

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Choi, H.; Shin, J.; Bae, D. The effect of milling conditions on microstructures and mechanical properties of Al/MWCNT composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1061–1072. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Carbon nanotube reinforced aluminum matrix composites produced by spark plasma sintering. J. Mater. Sci. 2017, 52, 8618–8629. [Google Scholar] [CrossRef]

- Salimi, S.; Izadi, H.; Gerlich, A.P. Fabrication of an aluminum–carbon nanotube metal matrix composite by accumula-tive roll-bonding. J. Mater. Sci. 2010, 46, 409–415. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; Joo, S.-H.; Kim, H.S. Consolidation of carbon nanotube reinforced aluminum matrix composites by high-pressure torsion. Met. Mater. Trans. A 2014, 45, 4129–4137. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Cavaliere, P.; Ashrafizadeh, F. Effect of processing parameters on the microstructural and mechanical properties of aluminum–carbon nanotube composites produced by spark plasma sintering. Int. J. Mater. Res. 2018, 109, 900–909. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Perrone, A. Effect of Al2O3, SiO2 and carbon nanotubes on the microstructural and mechan-ical behavior of spark plasma sintered aluminum based nanocomposites. Part. Sci. Technol. 2018, 38, 7–14. [Google Scholar] [CrossRef]

- Esawi, A.; Morsi, K.; Sayed, A.; Taher, M.; Lanka, S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminium composites. Compos. Sci. Technol. 2010, 70, 2237–2241. [Google Scholar] [CrossRef]

- Noguchi, T.; Magario, A.; Fukazawa, S.; Shimizu, S.; Beppu, J.; Seki, M. Carbon nanotube/aluminium composites with uniform dispersion. Mater. Trans. 2004, 45, 602–604. [Google Scholar] [CrossRef]

- Kwon, H.; Estili, M.; Takagi, K.; Miyazaki, T.; Kawasaki, A. Combination of hot extrusion and spark plasma sintering for producing carbon nanotube reinforced aluminum matrix composites. Carbon 2009, 47, 570–577. [Google Scholar] [CrossRef]

- Yang, X.; Liu, E.; Shi, C.; He, C.; Li, J.; Zhao, N.; Kondoh, K. Fabrication of carbon nanotube reinforced Al composites with well-balanced strength and ductility. J. Alloys Compd. 2013, 563, 216–220. [Google Scholar] [CrossRef]

- Yang, X.; Zou, T.; Shi, C.; Liu, E.; He, C.; Zhao, N. Effect of carbon nanotube (CNT) content on the properties of in-situ synthesis CNT reinforced Al composites. Mater. Sci. Eng. A 2016, 660, 11–18. [Google Scholar] [CrossRef]

- Deng, H.; Yi, J.; Xia, C.; Yi, Y. Improving the mechanical properties of carbon nanotube-reinforced pure copper matrix composites by spark plasma sintering and hot rolling. Mater. Lett. 2018, 210, 177–181. [Google Scholar] [CrossRef]

- Li, Q.Q.; Viereckl, A.; Rottmair, C.A.; Singer, R.F. Improved processing of carbon nanotube/magnesium alloy compo-sites. Compos. Sci. Technol. 2009, 69, 1193–1199. [Google Scholar] [CrossRef]

- Li, X.; Liu, C.; Ma, M.; Liu, R. Microstructures and mechanical properties of AA6061–SiC composites prepared through spark plasma sintering and hot rolling. Mater. Sci. Eng. A 2016, 650, 139–144. [Google Scholar] [CrossRef]

- Guo, B.; Ni, S.; Yi, J.; Shen, R.; Tang, Z.; Du, Y.; Song, M. Microstructures and mechanical properties of carbon nanotubes reinforced pure aluminum composites synthesized by spark plasma sintering and hot rolling. Mater. Sci. Eng. A 2017, 698, 282–288. [Google Scholar] [CrossRef]

- Liu, Z.; Xiao, B.; Wang, W.; Ma, Z. Tensile strength and electrical conductivity of carbon nanotube reinforced alumi-num matrix composites fabricated by powder metallurgy combined with friction stir processing. J. Mater. Sci. Technol. 2014, 30, 649–655. [Google Scholar] [CrossRef]

- Zabihi, M.; Toroghinejad, M.R.; Shafyei, A. Application of powder metallurgy and hot rolling processes for manu-facturing aluminum/alumina composite strips. Mater. Sci. Eng. A 2013, 560, 567–574. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Roeen, G.A.; Nosko, M.; Shamanian, M.; Trembošová, V.; Nagy, Š.; Ebrahimzadeh, N. Hot rolling of MWCNTs reinforced Al matrix composites produced via spark plasma sintering. Adv. Compos. Hybrid Mater. 2019, 2, 549–570. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Gómez-Esparza, C.; Estrada-Guel, I.; Miki-Yoshida, M.; Licea-Jiménez, L.; Pérez-García, S.; Martínez-Sánchez, R. Microstructural and mechanical characterization of Al–MWCNT composites produced by mechanical milling. Mater. Sci. Eng. A 2009, 502, 159–163. [Google Scholar] [CrossRef]

- Choi, H.; Kwon, G.; Lee, G.; Bae, D. Reinforcement with carbon nanotubes in aluminum matrix composites. Scr. Mater. 2008, 59, 360–363. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Liu, Z.; Xiao, B.; Wang, W.; Ma, Z. Modelling of carbon nanotube dispersion and strengthening mechanisms in Al matrix composites prepared by high energy ball milling-powder metallurgy method. Compos. Part A Appl. Sci. Manuf. 2017, 94, 189–198. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Fan, G.; Cao, L.; Zhang, D. The use of flake powder metallurgy to produce carbon nanotube (CNT)/aluminum composites with a homogenous CNT distribution. Carbon 2012, 50, 1993–1998. [Google Scholar] [CrossRef]

- Fan, G.; Jiang, Y.; Tan, Z.; Guo, Q.; Xiong, D.-B.; Su, Y.; Lin, R.; Hu, L.; Li, Z.; Zhang, D. Enhanced interfacial bonding and mechanical properties in CNT/Al composites fabricated by flake powder metallurgy. Carbon 2018, 130, 333–339. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Fan, G.; Cao, L.; Zhang, D. Strong and ductile carbon nanotube/aluminum bulk nanolaminated composites with two-dimensional alignment of carbon nanotubes. Scr. Mater. 2012, 66, 331–334. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Xiong, D.; Fan, G.; Guo, Q.; Zhang, J.; Su, Y.; Li, Z.; Zhang, D. Balanced strength and ductility in CNT/Al composites achieved by flake powder metallurgy via shift-speed ball milling. Compos. Part A Appl. Sci. Manuf. 2017, 96, 57–66. [Google Scholar] [CrossRef]

- Xu, R.; Fan, G.; Tan, Z.; Ji, G.; Chen, C.; Beausir, B.; Xiong, D.-B.; Guo, Q.; Guo, C.; Li, Z.; et al. Back stress in strain hardening of carbon nanotube/aluminum composites. Mater. Res. Lett. 2017, 6, 113–120. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of metal matrix composites by metal injection molding—A review. J. Mater. Process. Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef]

- Burmeister, C.F.; Kwade, A. Process engineering with planetary ball mills. Chem. Soc. Rev. 2013, 42, 7660–7667. [Google Scholar] [CrossRef] [PubMed]

- Witkin, D.; Lavernia, E. Synthesis and mechanical behavior of nanostructured materials via cryomilling. Prog. Mater. Sci. 2006, 51, 1–60. [Google Scholar] [CrossRef]

- Zhang, Y.; Sabbaghianrad, S.; Yang, H.; Topping, T.D.; Langdon, T.G.; Lavernia, E.J.; Schoenung, J.M.; Nutt, S.R. Two-Step SPD processing of a trimodal al-based nano-composite. Met. Mater. Trans. A 2015, 46, 5877–5886. [Google Scholar] [CrossRef]

- Ma, K.K.; Wen, H.M.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical be-havior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Fan, G.; Xu, R.; Tan, Z.; Zhang, D.; Li, Z. Development of Flake Powder Metallurgy in Fabricating Metal Matrix Composites: A Review. Acta Met. Sin. Engl. Lett. 2014, 27, 806–815. [Google Scholar] [CrossRef]

- Morsi, K.; Esawi, A. Effect of mechanical alloying time and carbon nanotube (CNT) content on the evolution of alu-minum (Al)–CNT composite powders. J. Mater. Sci. 2007, 42, 4954–4959. [Google Scholar] [CrossRef]

- Zan, Y.; Zhou, Y.; Liu, Z.; Ma, G.; Wang, D.; Wang, Q.; Wang, W.; Xiao, B.; Ma, Z. Enhancing strength and ductility synergy through heterogeneous structure design in nanoscale Al2O3 particulate reinforced Al composites. Mater. Des. 2019, 166, 107629. [Google Scholar] [CrossRef]

- Cao, L.; Li, Z.; Fan, G.; Jiang, L.; Zhang, D.; Moon, W.-J.; Kim, Y.-S. The growth of carbon nanotubes in aluminum powders by the catalytic pyrolysis of polyethylene glycol. Carbon 2012, 50, 1057–1062. [Google Scholar] [CrossRef]

- Tang, J.; Fan, G.; Li, Z.; Li, X.; Xu, R.; Li, Y.; Zhang, D.; Moon, W.-J.; Kaloshkin, S.D.; Churyukanova, M. Synthesis of car-bon nanotube/aluminium composite powders by polymer pyrolysis chemical vapor deposition. Carbon 2013, 55, 202–208. [Google Scholar] [CrossRef]

- Jiang, L.; Fan, G.; Li, Z.; Kai, X.; Zhang, D.; Chen, Z.; Humphries, S.; Heness, G.; Yeung, W.Y. An approach to the uniform dispersion of a high volume fraction of carbon nanotubes in aluminum powder. Carbon 2011, 49, 1965–1971. [Google Scholar] [CrossRef]

- Hu, Y.; Yu, Z.; Fan, G.; Tan, Z.; Zhou, J.; Zhang, H.; Li, Z.; Zhang, D. Simultaneous enhancement of strength and ductility with nano dispersoids in nano and ultrafine grain metals: A brief review. Rev. Adv. Mater. Sci. 2020, 59, 352–360. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Fan, G.; Ji, G.; Xiong, D.-B.; Guo, Q.; Su, Y.; Li, Z.; Zhang, D. High-strength CNT/Al-Zn-Mg-Cu composites with improved ductility achieved by flake powder metallurgy via elemental alloying. Compos. Part A Appl. Sci. Manuf. 2018, 111, 1–11. [Google Scholar] [CrossRef]

- Chen, M.; Fan, G.; Tan, Z.; Xiong, D.; Guo, Q.; Su, Y.; Zhang, J.; Li, Z.; Naito, M.; Zhang, D. Design of an efficient flake powder metallurgy route to fabricate CNT/6061Al composites. Mater. Des. 2018, 142, 288–296. [Google Scholar] [CrossRef]

- Fu, X.; Tan, Z.; Min, X.; Li, Z.; Yue, Z.; Fan, G.; Xiong, D.-B.; Li, Z. Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying. Mater. Res. Lett. 2020, 9, 50–57. [Google Scholar]

- Shi, Y.; Lu, Y.; Ni, Z.; Zhao, L.; Li, Z.; Xiong, D.-B.; Zou, J.; Guo, Q. Correlation Between Microstructural Architecture and Mechanical Behavior of Single-Walled Carbon Nanotube-Aluminum Composites. Met. Mater. Trans. A 2019, 51, 545–551. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, L.; Li, Z.; Li, Z.; Xiong, D.-B.; Su, Y.; Osovski, S.; Guo, Q. Strengthening and deformation mechanisms in nanolaminated single-walled carbon nanotube-aluminum composites. Mater. Sci. Eng. A 2019, 764, 138273. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Nosko, M.; Trembošová, V.; Nagy, Š. Hot deformation behaviour of bimodal sized Al 2 O 3/Al nanocomposites fabricated by spark plasma sintering. J. Microsc. 2021, 281, 28–45. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, B.; Shabani, A.; Cavaliere, P. Hot rolling of spark-plasma-sintered pure aluminium. Powder Met. 2018, 61, 285–292. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Agarwal, A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon 2011, 49, 533–544. [Google Scholar] [CrossRef]

- Sadeghi, B.; Fan, G.; Tan, Z.; Li, Z.; Kondo, A.; Naito, M. Smart mechanical powder processing for producing carbon nanotube reinforced aluminum matrix composites. KONA Powder Part. J. 2020, 2022004. [Google Scholar] [CrossRef]

- Li, Z.; Guo, Q.; Li, Z.; Fan, G.; Xiong, D.-B.; Su, Y.; Zhang, J.; Zhang, D. Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioinspired nanolaminated structure. Nano Lett. 2015, 15, 8077–8083. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, R.; Tan, Z.; Ji, G.; Fan, G.; Li, Z.; Xiong, D.-B.; Guo, Q.; Li, Z.; Zhang, D. Interface-induced strain hardening of graphene nanosheet/aluminum composites. Carbon 2019, 146, 17–27. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, D.; Liang, S.; Cao, F.; Zou, J.; Xiao, P. Effect of local alloying on interfacial bonding in laminated cop-per matrix composites reinforced by carbon nanotubes. Mater. Sci. Eng. A 2019, 748, 173–179. [Google Scholar] [CrossRef]

- Yoo, S.J.; Han, S.H.; Kim, W.J. Strength and strain hardening of aluminum matrix composites with randomly dis-persed nanometer-length fragmented carbon nanotubes. Scr. Mater. 2013, 68, 711–714. [Google Scholar] [CrossRef]

- Esawi, A.; Morsi, K.; Sayed, A.; Gawad, A.A.; Borah, P. Fabrication and properties of dispersed carbon nanotube–aluminum composites. Mater. Sci. Eng. A 2009, 508, 167–173. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; Tan, Z.; Zhao, H.; Fan, G.; Xu, Y.; Xiong, D.-B.; Li, Z. Bioinspired hierarchical Al2O3/Al laminated composite fabricated by flake powder metallurgy. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106187. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F.; Cavaliere, P.; Rizzo, A. Influence of Al2O3 nanoparticles on microstructure and strengthening mechanism of al-based nanocomposites produced via spark plasma sintering. J. Mater. Eng. Perform. 2017, 26, 2928–2936. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F. Al-based nanocomposites produced via spark plasma sintering: Effect of processing route and reinforcing phases. In Spark Plasma Sintering of Materials; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2019; pp. 161–190. [Google Scholar]

- Sadeghi, B.; Shamanian, M.; Cavaliere, P.; Ashrafizadeh, F.; Sanayei, M.; Szpunar, J.A. Microstructural and mechanical behavior of bimodal reinforced Al-based composites produced by spark plasma sintering and FSP. Int. J. Adv. Manuf. Technol. 2017, 94, 3903–3916. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Shamanian, M.; Sanayei, M.; Szpunar, J.A.; Nosko, M. Electron backscattered diffraction analysis of friction stir processed nanocomposites produced via spark plasma sintering. J. Microsc. 2018, 271, 145–163. [Google Scholar] [CrossRef]

- Yuan, C.; Tan, Z.; Fan, G.; Chen, M.; Zheng, Q.; Li, Z. Fabrication and mechanical properties of CNT/Al composites via shift-speed ball milling and hot-rolling. J. Mater. Res. 2019, 34, 2609–2619. [Google Scholar] [CrossRef]

- Chen, B.; Li, S.; Imai, H.; Jia, L.; Umeda, J.; Takahashi, M.; Kondoh, K. An approach for homogeneous carbon nanotube dispersion in Al matrix composites. Mater. Des. 2015, 72, 1–8. [Google Scholar] [CrossRef]

- Nam, D.H.; Cha, S.I.; Lim, B.K.; Park, H.M.; Han, D.S.; Hong, S.H. Synergistic strengthening by load transfer mecha-nism and grain refinement of CNT/Al–Cu composites. Carbon 2012, 50, 2417–2423. [Google Scholar] [CrossRef]

- Cha, S.I.; Kim, K.T.; Arshad, S.N.; Mo, C.B.; Hong, S.H. Extraordinary strengthening effect of carbon nanotubes in metal-matrix nanocomposites processed by molecular-level mixing. Adv. Mater. 2005, 17, 1377–1381. [Google Scholar] [CrossRef]

- He, N.Z.C.; Shi, C.; Du, X.; Li, J.; Li, H.; Cui, Q. An approach to obtaining homogeneously dispersed carbon nano-tubes in al powders for preparing reinforced al-matrix composites. Adv. Mater. 2007, 19, 1128–1132. [Google Scholar] [CrossRef]

- Baig, Z.; Mamat, O.; Mustapha, M. Recent progress on the dispersion and the strengthening effect of carbon nanotubes and graphene-reinforced metal nanocomposites: A review. Crit. Rev. Solid State Mater. Sci. 2018, 43, 1–46. [Google Scholar] [CrossRef]

- Basariya, M.R.; Srivastava, V.C.; Mukhopadhyay, N.K. Microstructural characteristics and mechanical prop-erties of carbon nanotube reinforced aluminum alloy composites produced by ball milling. Mater. Des. 2014, 64, 542–549. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xu, S.J.; Xiao, B.L.; Xue, P.; Wang, W.G.; Ma, Z.Y. Effect of ball-milling time on mechanical properties of car-bon nanotubes reinforced aluminum matrix composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2161–2168. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Fan, G.; Zhang, D. A flake powder metallurgy approach to Al2O3/Al biomimetic nanolaminated composites with enhanced ductility. Scr. Mater. 2011, 65, 412–415. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Z.; Jiang, L.; Kai, X.; Dai, X.; Fan, G.; Guo, Q.; Xiong, D.; Su, Y.; Zhang, D. Flake thickness effect of Al2O3/Al biomimetic nanolaminated composites fabricated by flake powder metallurgy. Mater. Sci. Eng. A 2014, 594, 324–329. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for poly-mer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Fan, G.; Ji, G.; Li, Z.; Guo, Q.; Li, Z.; Zhang, D. Microstructure-based modeling on structure-mechanical property relationships in carbon nanotube/aluminum composites. Int. J. Plast. 2019, 120, 278–295. [Google Scholar] [CrossRef]

- Cavaliere, P.; Jahantigh, F.; Shabani, A.; Sadeghi, B. Influence of SiO2 nanoparticles on the microstructure and me-chanical properties of Al matrix nanocomposites fabricated by spark plasma sintering. Compos. Part B Eng. 2018, 146, 60–68. [Google Scholar] [CrossRef]

- Azarniya, A.; Azarniya, A.; Sovizi, S.; Hosseini, H.R.M.; Varol, T.; Kawasaki, A.; Ramakrishna, S. Physicomechanical properties of spark plasma sintered carbon nanotube-reinforced metal matrix nanocomposites. Prog. Mater. Sci. 2017, 90, 276–324. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, N.; He, C. The superior mechanical and physical properties of nanocarbon reinforced bulk compo-sites achieved by architecture design—A review. Prog. Mater. Sci. 2020, 113, 100672. [Google Scholar] [CrossRef]

- Hao, X.-n.; Zhang, H.-p.; Zheng, R.-x.; Zhang, Y.-t.; Ameyama, K.; Ma, C.-l. Effect of mechanical alloying time and rota-tion speed on evolution of CNTs/Al-2024 composite powders. Trans. Nonferrous Met. Soc. China 2014, 24, 2380–2386. [Google Scholar] [CrossRef]

- Wu, Y.; Kim, G.-Y.; Russell, A.M. Mechanical alloying of carbon nanotube and Al6061 powder for metal matrix composites. Mater. Sci. Eng. A 2012, 532, 558–566. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F.; Cavaliere, P.; Valerini, D. Nanoindentation characterization of Al-matrix nanocomposites produced via spark plasma sintering. Int. J. Mater. Res. 2018, 109, 50–62. [Google Scholar] [CrossRef]

- Simoes, S.; Viana, F.; Reis, M.A.L.; Vieira, M.F. Improved dispersion of carbon nanotubes in aluminum nanocompo-sites. Compos. Struct. 2014, 108, 992–1000. [Google Scholar] [CrossRef]

- Deng, K.-K.; Wang, C.-J.; Nie, K.-B.; Wang, X.-J. Recent research on the deformation behavior of particle reinforced magnesium matrix composite: A review. Acta Met. Sin. Engl. Lett. 2019, 32, 413–425. [Google Scholar] [CrossRef]

- Jiang, Y.Y.; Tan, Z.Q.; Xu, R.; Fan, G.L.; Xiong, D.B.; Guo, Q.; Su, Y.S.; Li, Z.Q.; Zhang, D. Tailoring the structure and me-chanical properties of graphene nanosheet/aluminum composites by flake powder metallurgy via shift-speed ball milling. Compos. Part A Appl. Sci. Manuf. 2018, 111, 73–82. [Google Scholar] [CrossRef]

- Tan, Z.; Li, Z.; Fan, G.; Li, W.; Liu, Q.; Zhang, W.; Zhang, D. Two-dimensional distribution of carbon nanotubes in cop-per flake powders. Nanotechnology 2011, 22, 225603. [Google Scholar] [CrossRef]

- Sharma, R.; Setia, G. Mechanical dry particle coating on cohesive pharmaceutical powders for improving flowability—A review. Powder Technol. 2019, 356, 458–479. [Google Scholar] [CrossRef]

- Foppoli, A.A.; Maroni, A.; Cerea, M.; Zema, L.; Gazzaniga, A. Dry coating of solid dosage forms: An overview of pro-cesses and applications. Drug Dev. Ind. Pharm. 2017, 43, 1919–1931. [Google Scholar] [CrossRef] [PubMed]

- Naito, M.; Abe, H.; Kondo, A.; Yokoyama, T.; Huang, C.C. Smart powder processing for advanced Materials. KONA Powder Part. J. 2009, 27, 130–143. [Google Scholar] [CrossRef]

- Ghoroi, C.; Han, X.; To, D.; Jallo, L.; Gurumurthy, L.; Davé, R.N. Dispersion of fine and ultrafine powders through sur-face modification and rapid expansion. Chem. Eng. Sci. 2013, 85, 11–24. [Google Scholar] [CrossRef]

- Chen, M.; Fan, G.; Tan, Z.; Yuan, C.; Xiong, D.; Guo, Q.; Su, Y.; Naito, M.; Li, Z. Tailoring and characterization of carbon nanotube dispersity in CNT/6061Al composites. Mater. Sci. Eng. A 2019, 757, 172–181. [Google Scholar] [CrossRef]

- Calka, A.; Wexler, D. Mechanical milling assisted by electrical discharge—Recent developments. J. Metastable Nanocryst. Mater. 2004, 20–21, 111–117. [Google Scholar] [CrossRef]

- Calka, A.; Radlinski, A.P. Universal high performance ball-milling device and its application for mechanical alloy-ing. Mater. Sci. Eng. A 1991, 134, 1350–1353. [Google Scholar] [CrossRef]

- Calka, A.; Wexler, D. Mechanical milling assisted by electrical discharge. Nat. Cell Biol. 2002, 419, 147–151. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Spark Plasma Sintering: Process Fundamentals. In Spark Plasma Sintering of Materials; Springer: Cham, Switzerland, 2019; pp. 3–20. [Google Scholar]

- Smolira, A.; Szymanska, M.; Jartych, E.; Calka, A.; Michalak, L. Structural transformations in graphite induced by magneto-mechanical-milling in hydrogen atmosphere. J. Alloys Compd. 2005, 402, 256–262. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghi, B.; Cavaliere, P. Progress of Flake Powder Metallurgy Research. Metals 2021, 11, 931. https://doi.org/10.3390/met11060931

Sadeghi B, Cavaliere P. Progress of Flake Powder Metallurgy Research. Metals. 2021; 11(6):931. https://doi.org/10.3390/met11060931

Chicago/Turabian StyleSadeghi, Behzad, and Pasquale Cavaliere. 2021. "Progress of Flake Powder Metallurgy Research" Metals 11, no. 6: 931. https://doi.org/10.3390/met11060931

APA StyleSadeghi, B., & Cavaliere, P. (2021). Progress of Flake Powder Metallurgy Research. Metals, 11(6), 931. https://doi.org/10.3390/met11060931