Hydrogen Effects in Equiatomic CrFeNiMn Alloy Fabricated by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

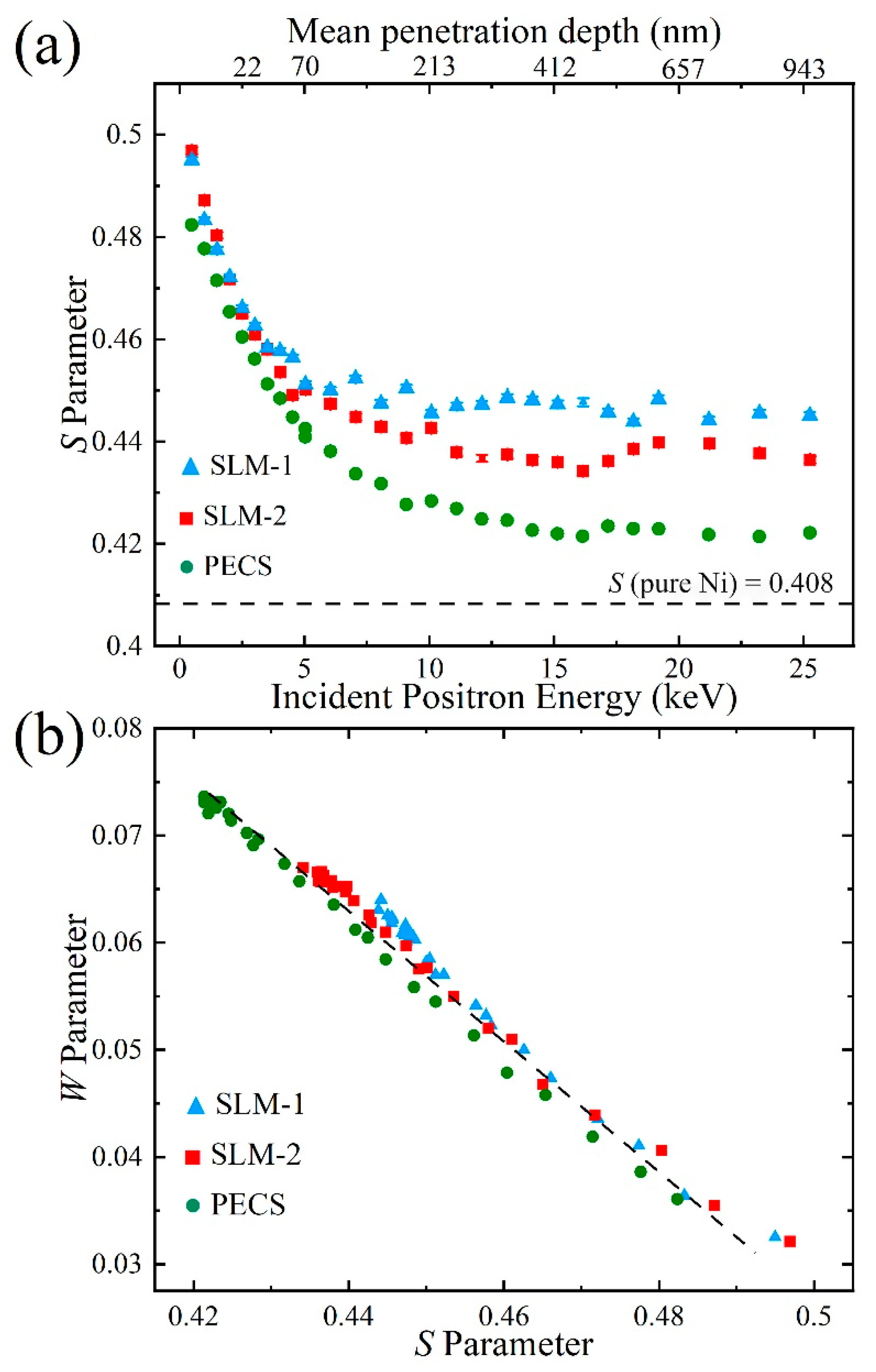

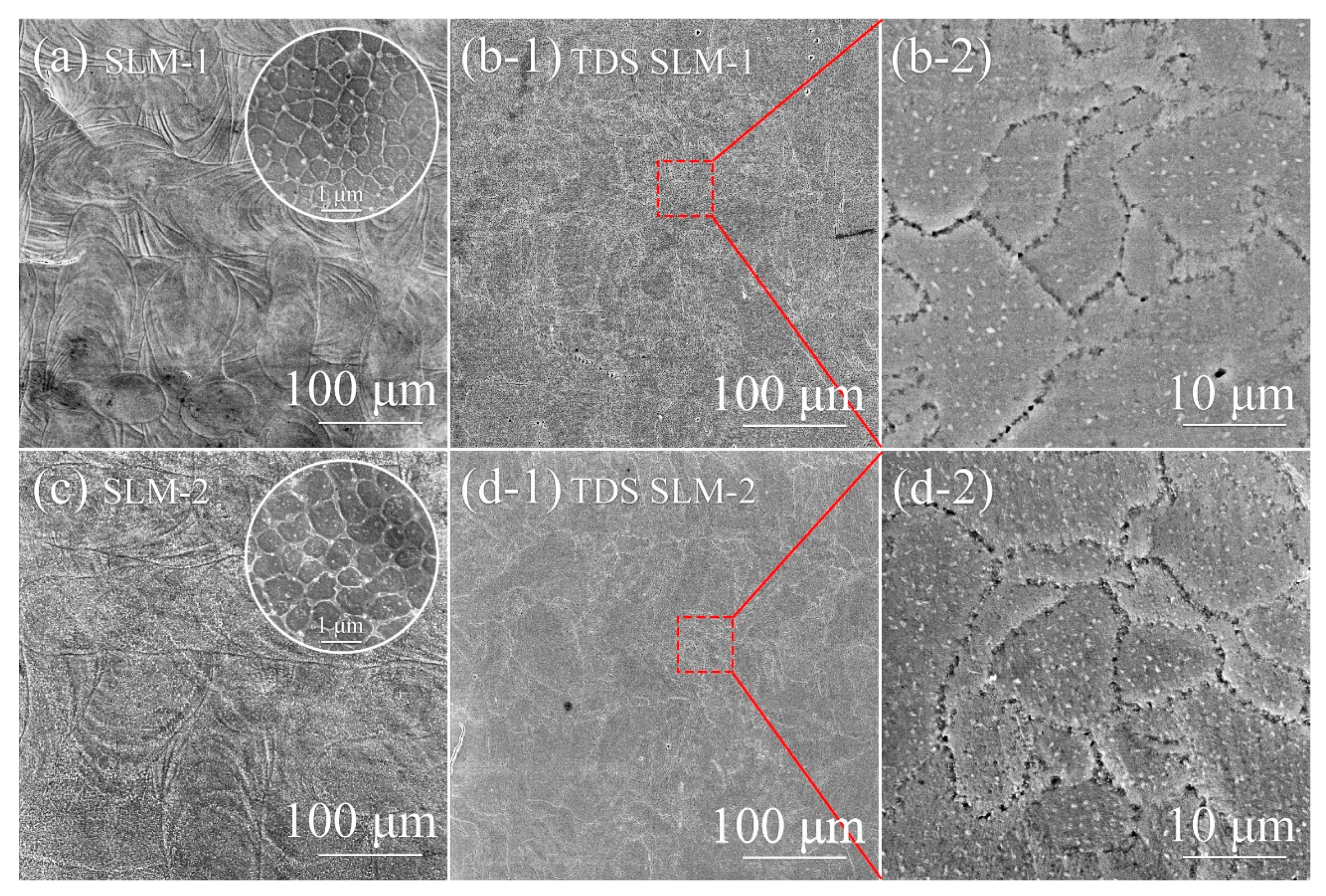

3.1. Defect Structure

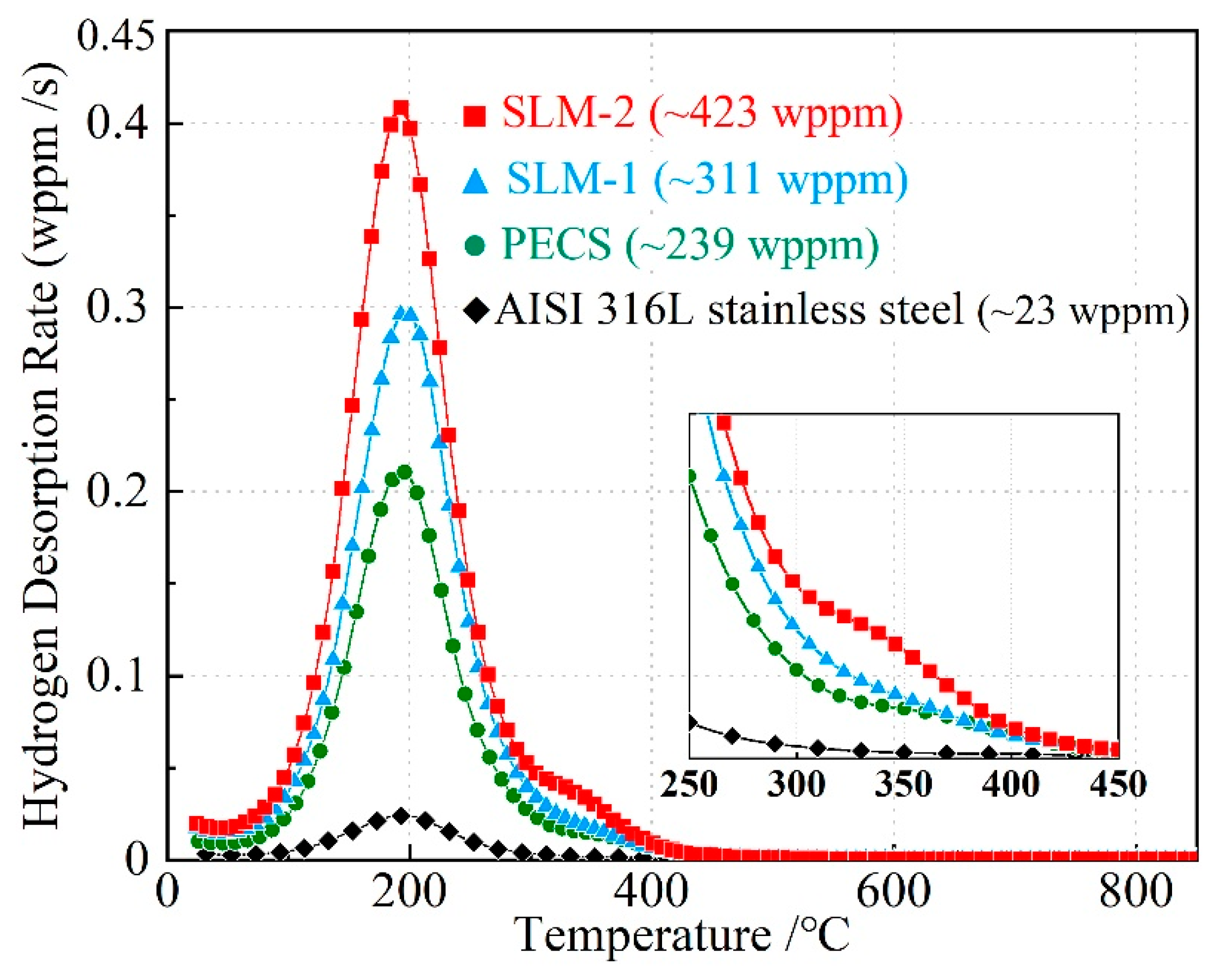

3.2. Hydrogen Uptake Ability

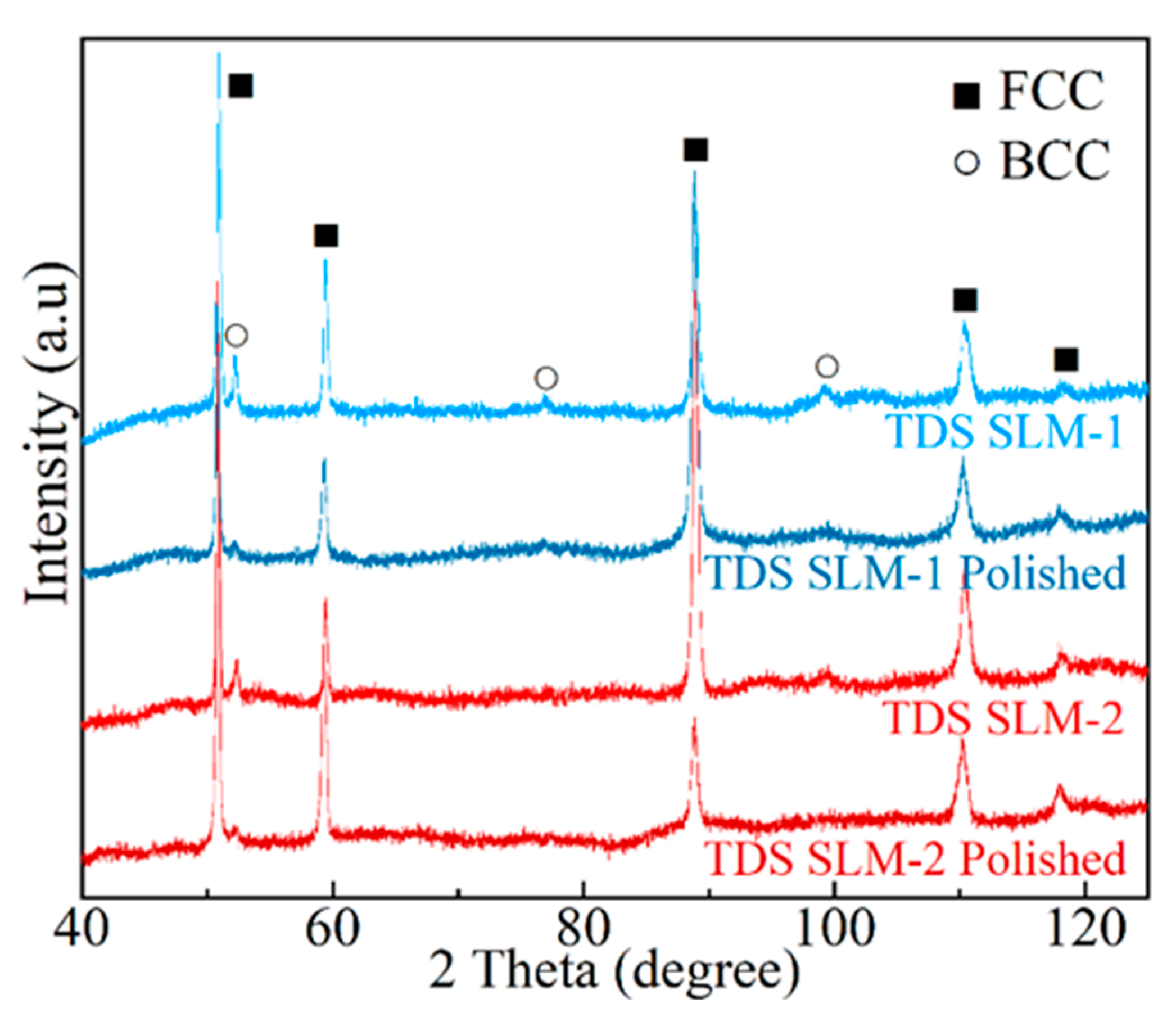

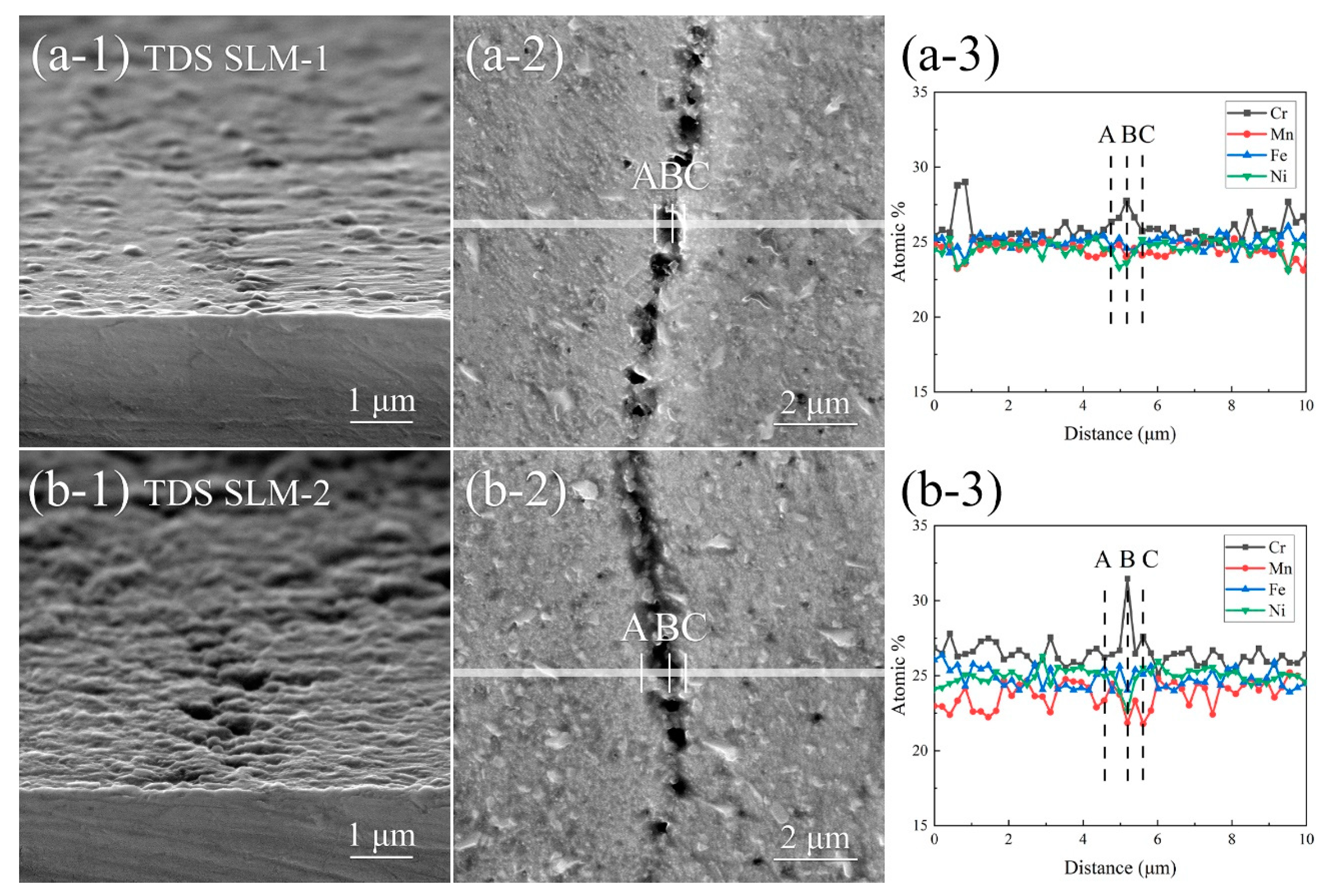

3.3. Analysis of TDS-Tested Specimens

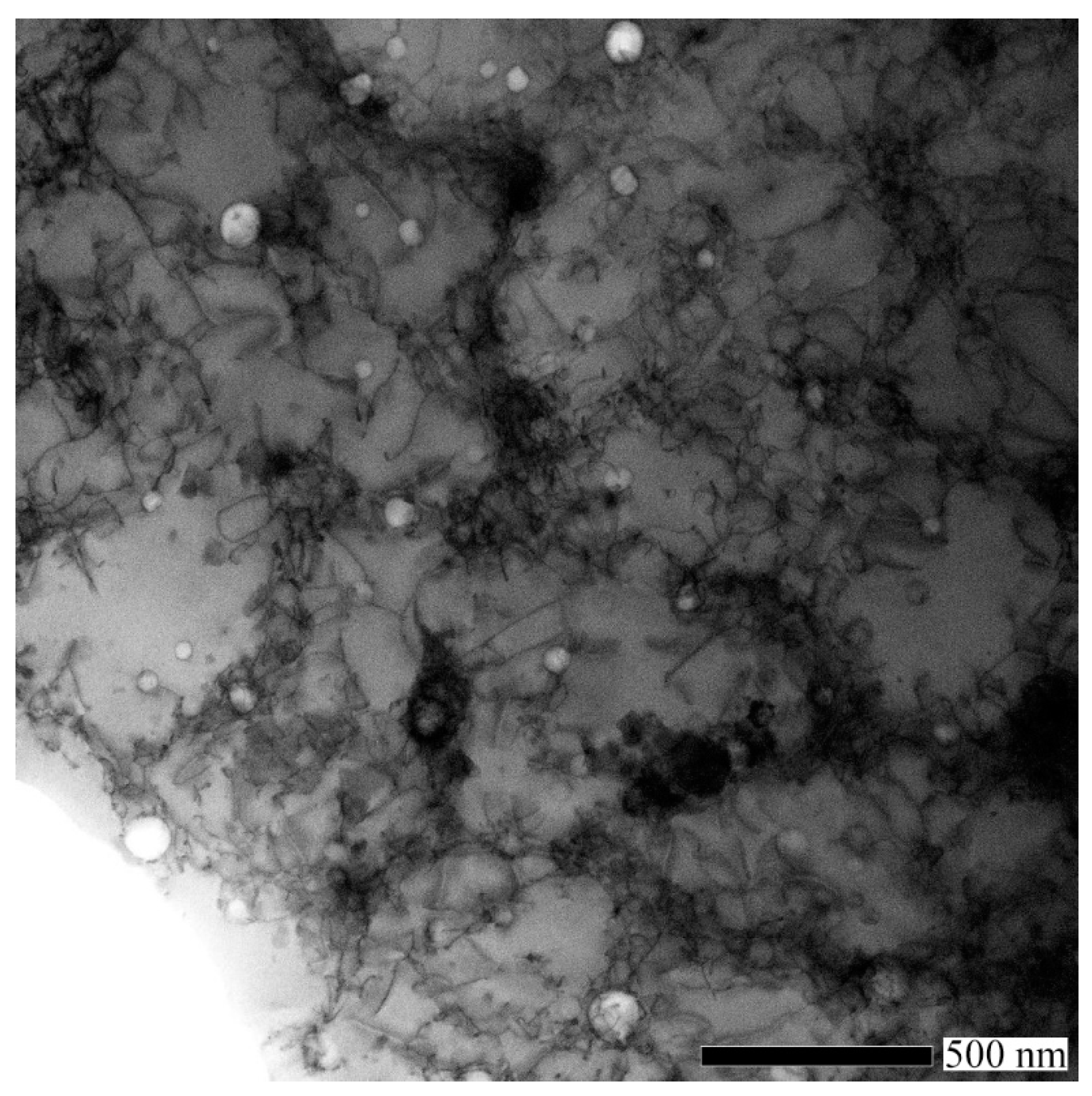

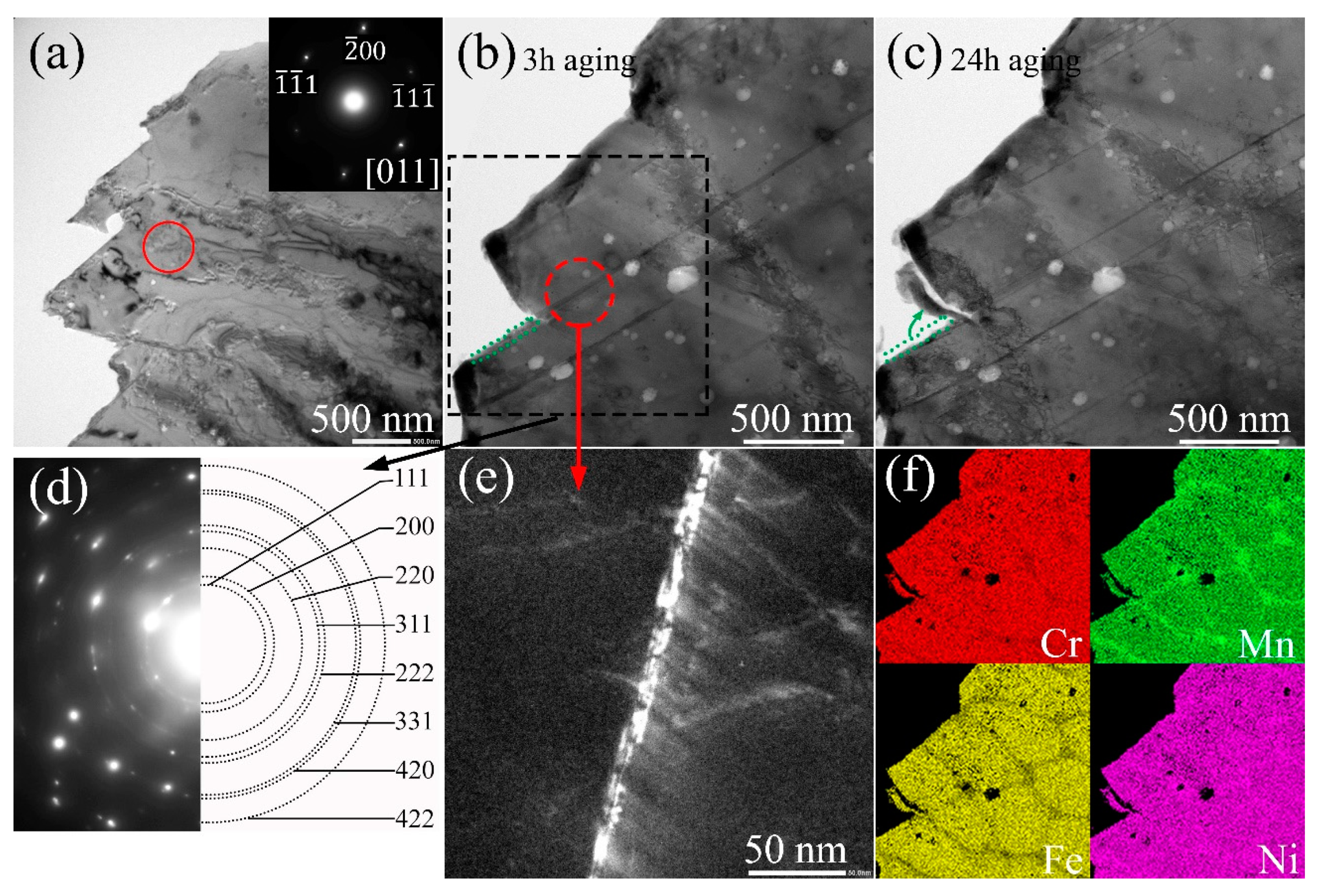

3.4. Analysis of TEM Specimen

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Okamoto, N.L.; Fujimoto, S.; Kambara, Y.; Kawamura, M.; Chen, Z.M.T.; Matsunoshita, H.; Tanaka, K.; Inui, H.; George, E.P. Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. Sci. Rep. 2016, 6, 35863. [Google Scholar] [CrossRef]

- Tasan, C.C.; Deng, Y.; Pradeep, K.G.; Yao, M.J.; Springer, H.; Raabe, D. Composition dependence of phase stability, deformation mechanisms, and mechanical properties of the CoCrFeMnNi High-entropy alloy system. JOM 2014, 66, 1993–2001. [Google Scholar] [CrossRef]

- Wu, H. Excellent mechanical properties of in-situ TiC/FeCrNiCuV0.1 high entropy alloy matrix composites. Mater. Lett. 2019, 4, 257. [Google Scholar] [CrossRef]

- Lu, C.; Niu, L.; Chen, N.; Jin, K.; Yang, T.; Xiu, P.; Zhang, Y.; Gao, F.; Bei, H.; Shi, S.; et al. Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys. Nat. Commun. 2016, 7, 13564. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Bei, H. Microstructures and mechanical properties of compositionally complex Co-free FeNiMnCr18 FCC solid solution alloy. Mater. Sci. Eng. A 2015, 640, 217–224. [Google Scholar] [CrossRef]

- Kumar, N.A.P.K.; Li, C.; Leonard, K.J.; Bei, H.; Zinkle, S.J. Microstructural stability and mechanical behavior of FeNiMnCr high entropy alloy under ion irradiation. Acta Mater. 2016, 113, 230–244. [Google Scholar] [CrossRef]

- Eißmann, N.; Klöden, B.; Weißgärber, T.; Kieback, B. High-entropy alloy CoCrFeMnNi produced by powder metallurgy. Powder Metall. 2017, 60, 184–197. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.-L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Yang, X.; Ge, Y.; Lehtonen, J.; Hannula, S.-P. Hierarchical microstructure of laser powder bed fusion produced face-centered-cubic-structured equiatomic CrFeNiMn multicomponent alloy. Materials 2020, 13, 4498. [Google Scholar] [CrossRef]

- Donik, Č.; Kraner, J.; Paulin, I.; Godec, M. Influence of the energy density for selective laser melting on the microstructure and mechanical properties of stainless steel. Metals 2020, 10, 919. [Google Scholar] [CrossRef]

- Konovalov, S.; Osintsev, K.; Golubeva, A.; Smelov, V.; Ivanov, Y.; Chen, X.; Komissarova, I. Surface modification of Ti-based alloy by selective laser melting of Ni-based superalloy powder. J. Mater. Res. Technol. 2020, 9, 8796–8807. [Google Scholar] [CrossRef]

- Do, D.K.; Li, P. The Effect of laser energy input on the microstructure, physical and mechanical properties of Ti-6Al-4V alloys by selective laser melting. Virtual Phys. Prototyp. 2016, 11, 41–47. [Google Scholar] [CrossRef]

- Chang, K.-C.; Zhao, J.-R.; Hung, F.-Y. Microstructure, mechanical properties, and fatigue fracture characteristics of high-fracture-resistance selective laser melting Al-Ni-Cu alloys. Metals 2021, 11, 87. [Google Scholar] [CrossRef]

- Brif, Y.; Thomas, M.; Todd, I. The use of high-entropy alloys in additive manufacturing. Scr. Mater. 2015, 99, 93–96. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Turnbull, A.; Hutchings, R.B.; Ferriss, D.H. Modelling of thermal desorption of hydrogen from metals. Mater. Sci. Eng. A 1997, 238, 317–328. [Google Scholar] [CrossRef]

- Yagodzinskyy, Y.; Saukkonen, T.; Kilpeläinen, S.; Tuomisto, F.; Hänninen, H. Effect of hydrogen on plastic strain localization in single crystals of austenitic stainless steel. Scr. Mater. 2010, 62, 155–158. [Google Scholar] [CrossRef]

- Luo, H.; Li, Z.; Raabe, D. Hydrogen enhances strength and ductility of an equiatomic high-entropy alloy. Sci. Rep. 2017, 7. [Google Scholar] [CrossRef] [PubMed]

- Nygren, K.E.; Bertsch, K.M.; Wang, S.; Bei, H.; Nagao, A.; Robertson, I.M. Hydrogen embrittlement in compositionally complex FeNiCoCrMn FCC solid solution alloy. Curr. Opin. Solid State Mater. Sci. 2017. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Suh, J.-Y.; Lee, K.-A. Effect of gaseous hydrogen embrittlement on the mechanical properties of additively manufactured CrMnFeCoNi high-entropy alloy strengthened by in-situ formed oxide. Mater. Sci. Eng. A 2020, 796, 140039. [Google Scholar] [CrossRef]

- Lee, D.-H.; Sun, B.; Lee, S.; Ponge, D.; Jägle, E.A.; Raabe, D. Comparative study of hydrogen embrittlement resistance between additively and conventionally manufactured 304L austenitic stainless steels. Mater. Sci. Eng. A 2021, 803, 140499. [Google Scholar] [CrossRef]

- Silverstein, R.; Eliezer, D. Mechanisms of hydrogen trapping in austenitic, duplex, and super martensitic stainless steels. J. Alloys Compd. 2017, 720, 451–459. [Google Scholar] [CrossRef]

- Fukai, Y.; Mizutani, M.; Yokota, S.; Kanazawa, M.; Miura, Y.; Watanabe, T. Superabundant vacancy–hydrogen clusters in electrodeposited Ni and Cu. J. Alloys Compd. 2003, 4, 270–273. [Google Scholar] [CrossRef]

- Tuomisto, F.; Makkonen, I. Defect identification in semiconductors with positron annihilation: Experiment and theory. Rev. Mod. Phys. 2013, 85, 1583–1631. [Google Scholar] [CrossRef]

- Lu, E.; Makkonen, I.; Mizohata, K.; Li, Z.; Räisänen, J.; Tuomisto, F. Effect of interstitial carbon on the evolution of early-stage irradiation damage in equi-atomic FeMnNiCoCr high-entropy alloys. Appl. Phys. 2020, 8. [Google Scholar] [CrossRef]

- Lehtonen, J.; Ge, Y.; Ciftci, N.; Heczko, O.; Uhlenwinkel, V.; Hannula, S.-P. Phase structures of gas atomized equiatomic CrFeNiMn high entropy alloy powder. J. Alloys Compd. 2020, 827, 154142. [Google Scholar] [CrossRef]

- Lu, E.; Cao, X.; Jin, S.; Zhang, P.; Zhang, C.; Yang, J.; Wu, Y.; Guo, L.; Wang, B. Investigation of vacancy-type defects in helium irradiated FeCrNi alloy by slow positron beam. J. Nucl. Mater. 2015, 458, 240–244. [Google Scholar] [CrossRef]

- Morris, M.A.; George, O.; Morris, D.G. Vacancies, vacancy aggregates and hardening in FeAl. Mater. Sci. Eng. A 1998, 258, 99–107. [Google Scholar] [CrossRef]

- Ryu, J.H.; Chun, Y.S.; Lee, C.S.; Bhadeshia, H.K.D.H.; Suh, D.W. Effect of deformation on hydrogen trapping and effusion in TRIP-assisted steel. Acta Mater. 2012, 60, 4085–4092. [Google Scholar] [CrossRef]

- Kirchheim, R.; Pundt, A. Hydrogen in metals. In Physical Metallurgy; Elsevier: Amsterdam, The Netherlands, 2014; pp. 2597–2705. ISBN 978-0-444-53770-6. [Google Scholar]

- Zhao, Y.; Lee, D.-H.; Seok, M.-Y.; Lee, J.-A.; Phaniraj, M.P.; Suh, J.-Y.; Ha, H.-Y.; Kim, J.-Y.; Ramamurty, U.; Jang, J. Resistance of CoCrFeMnNi high-entropy alloy to gaseous hydrogen embrittlement. Scr. Mater. 2017, 135, 54–58. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.-W.; Liaw, P.K.; Zhang, Y. (Eds.) High-Entropy Alloys; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-27011-1. [Google Scholar]

- Zhao, Y.; Park, J.-M.; Lee, D.-H.; Song, E.J.; Suh, J.-Y.; Ramamurty, U.; Jang, J. Influences of hydrogen charging method on the hydrogen distribution and nanomechanical properties of face-centered cubic high-entropy alloy: A comparative study. Scr. Mater. 2019, 168, 76–80. [Google Scholar] [CrossRef]

- Baek, S.-W.; Song, E.J.; Kim, J.H.; Lee, Y.-H.; Ryu, K.S.; Kim, S.-W. Hydrogen susceptibility of nano-sized oxide dispersed austenitic steel for fusion reactor. Fusion Eng. Des. 2017, 121, 105–110. [Google Scholar] [CrossRef]

- Lin, J.; Chen, F.; Liu, F.; Xu, D.; Gao, J.; Tang, X. Hydrogen permeation behavior and hydrogen-induced defects in 316L stainless steels manufactured by additive manufacturing. Mater. Chem. Phys. 2020, 250, 123038. [Google Scholar] [CrossRef]

- Park, J.-M.; Zhao, Y.; Voisin, T.; Lee, D.-H.; Komazaki, S.; Ko, Y.; Kim, D.-I.; Suh, J.-Y.; Han, H.N.; Wang, Y.M.; et al. Hydrogen uptake and its influence in selective laser melted austenitic stainless steel: A nanoindentation study. Scr. Mater. 2021, 194, 113718. [Google Scholar] [CrossRef]

- Macadre, A.; Masumura, T.; Manabe, R.; Tsuchiyama, T.; Takaki, S. Effect of nitrogen-addition on the absorption and diffusivity of hydrogen in a stable austenitic stainless steel. Int. J. Hydrogen Energy 2019, 44, 1263–1271. [Google Scholar] [CrossRef]

- Hoelzel, M.; Rajevac, V.; Danilkin, S.A.; Udovic, T.J.; Wipf, H.; Fuess, H. Lattice dynamics of high-pressure hydrogenated austenitic stainless steels. J. Phys. Condens. Matter 2005, 17, 3537–3546. [Google Scholar] [CrossRef]

- Narita, N.; Altstetter, C.J.; Birnbaum, H.K. Hydrogen-related phase transformations in austenitic stainless steels. Metall. Trans. A 1982, 13, 1355–1365. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Luo, H.; Li, R.; Wang, L.; Man, C.; Li, X. Superior resistance to hydrogen damage for selective laser melted 316L stainless steel in a proton exchange membrane fuel cell environment. Corros. Sci. 2020, 166, 108425. [Google Scholar] [CrossRef]

- Whiteman, M.B.; Troiano, A.R. the influence of hydrogen on the stacking fault energy of an austenitic stainless steel. Phys. Status Solid. B 1964, 7, K109–K110. [Google Scholar] [CrossRef]

- Eliezer, D.; Chakrapani, D.G.; Altstetter, C.J.; Pugh, E.N. The influence of austenite stability on the hydrogen embrittlement and stress- corrosion cracking of stainless steel. Metall. Trans. A 1979, 10, 935–941. [Google Scholar] [CrossRef]

- Rozenak, P.; Eliezer, D. Phase changes related to hydrogen-induced cracking in austenitic stainless steel. Acta Metall. 1987, 35, 2329–2340. [Google Scholar] [CrossRef]

- Zevin, L.S.; Rozenak, P.; Eliezer, D. Quantitative X-ray phase analysis of surface layers. J. Appl. Crystallogr. 1984, 17, 18–21. [Google Scholar] [CrossRef]

- Eliezer, D.; Tal-Gutelmacher, E.; Boellinghaus, T. Hydrogen Embrittlement in Hydride- and Non Hydride-Forming Systens–Microstructural/Phase Changes and Cracking Mechanisms. In Proceedings of the 11th International Conference on Fracture, Turin, Italy, 20–25 March 2005; Available online: http://www.gruppofrattura.it/ocs/index.php/ICF/ICF11/paper/view/10870/10199 (accessed on 19 March 2016).

- Hannula, S.-P. The effect of pre-existing epsilonmartensite on the hydrogen induced fracture of austenitic stainless steel. Scr. Metall. 1983, 17, 509–513. [Google Scholar] [CrossRef]

- Baranowskip, B.; Flanagans, T.B. The volume increase of Fcc metals and alloys due to interstitial hydrogen over a wide range of hydrogen contents. J. Phys. F Met. Phys. 1971, 1, 5. [Google Scholar]

- von Pezold, J.; Lymperakis, L.; Neugebeauer, J. Hydrogen-enhanced local plasticity at dilute bulk H concentrations: The role of H–H interactions and the formation of local hydrides. Acta Mater. 2011, 59, 2969–2980. [Google Scholar] [CrossRef]

- Mine, Y.; Kimoto, T. Hydrogen uptake in austenitic stainless steels by exposure to gaseous hydrogen and its effect on tensile deformation. Corros. Sci. 2011, 53, 2619–2629. [Google Scholar] [CrossRef]

| Sample | Cr | Mn | Fe | Ni | Porosity | Average Cell Size (nm) |

|---|---|---|---|---|---|---|

| SLM-1 | 25.5 | 24.9 | 24.8 | 24.8 | 2.0 | 390 |

| TDS SLM-1 | 25.7 | 24.7 | 25.0 | 24.6 | - | - |

| TDS SLM-1 Polished | 25.1 | 25.0 | 25.2 | 24.7 | - | - |

| SLM-2 | 25.8 | 24.0 | 25.3 | 24.9 | 2.1 | 520 |

| TDS SLM-2 | 26.1 | 23.4 | 25.5 | 25.0 | - | - |

| TDS SLM-2 Polished | 25.3 | 23.9 | 25.6 | 25.2 | - | - |

| PECS | 26.0 | 24.2 | 25.3 | 24.5 | 2.4 | - |

| TDS PECS | 26.4 | 23.6 | 25.0 | 25.0 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Yagodzinskyy, Y.; Ge, Y.; Lu, E.; Lehtonen, J.; Kollo, L.; Hannula, S.-P. Hydrogen Effects in Equiatomic CrFeNiMn Alloy Fabricated by Laser Powder Bed Fusion. Metals 2021, 11, 872. https://doi.org/10.3390/met11060872

Yang X, Yagodzinskyy Y, Ge Y, Lu E, Lehtonen J, Kollo L, Hannula S-P. Hydrogen Effects in Equiatomic CrFeNiMn Alloy Fabricated by Laser Powder Bed Fusion. Metals. 2021; 11(6):872. https://doi.org/10.3390/met11060872

Chicago/Turabian StyleYang, Xuan, Yuriy Yagodzinskyy, Yanling Ge, Eryang Lu, Joonas Lehtonen, Lauri Kollo, and Simo-Pekka Hannula. 2021. "Hydrogen Effects in Equiatomic CrFeNiMn Alloy Fabricated by Laser Powder Bed Fusion" Metals 11, no. 6: 872. https://doi.org/10.3390/met11060872

APA StyleYang, X., Yagodzinskyy, Y., Ge, Y., Lu, E., Lehtonen, J., Kollo, L., & Hannula, S.-P. (2021). Hydrogen Effects in Equiatomic CrFeNiMn Alloy Fabricated by Laser Powder Bed Fusion. Metals, 11(6), 872. https://doi.org/10.3390/met11060872