Study on Ultra-High Temperature Contact Solution Treatment of Al–Zn–Mg–Cu Alloys

Abstract

1. Introduction

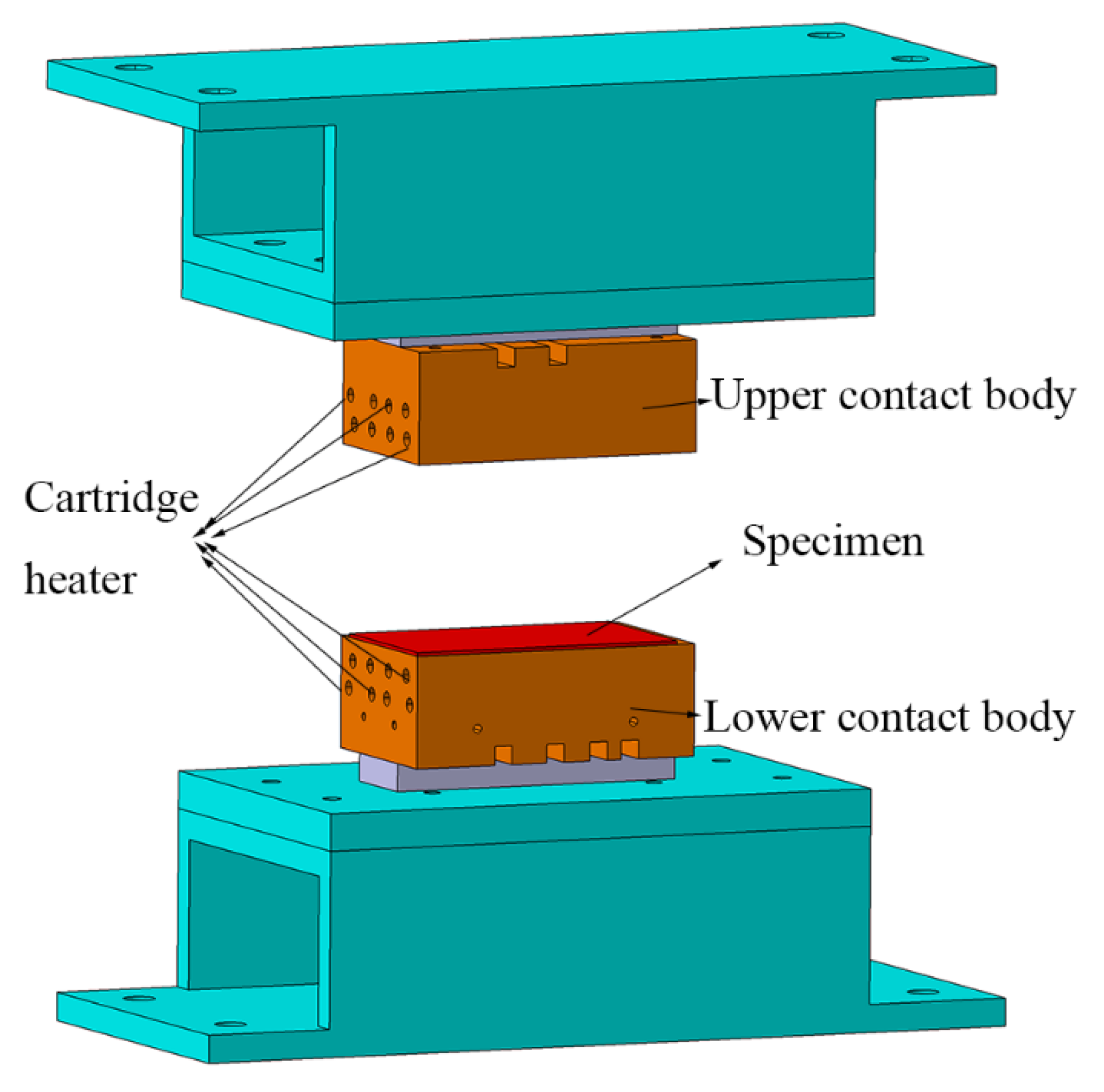

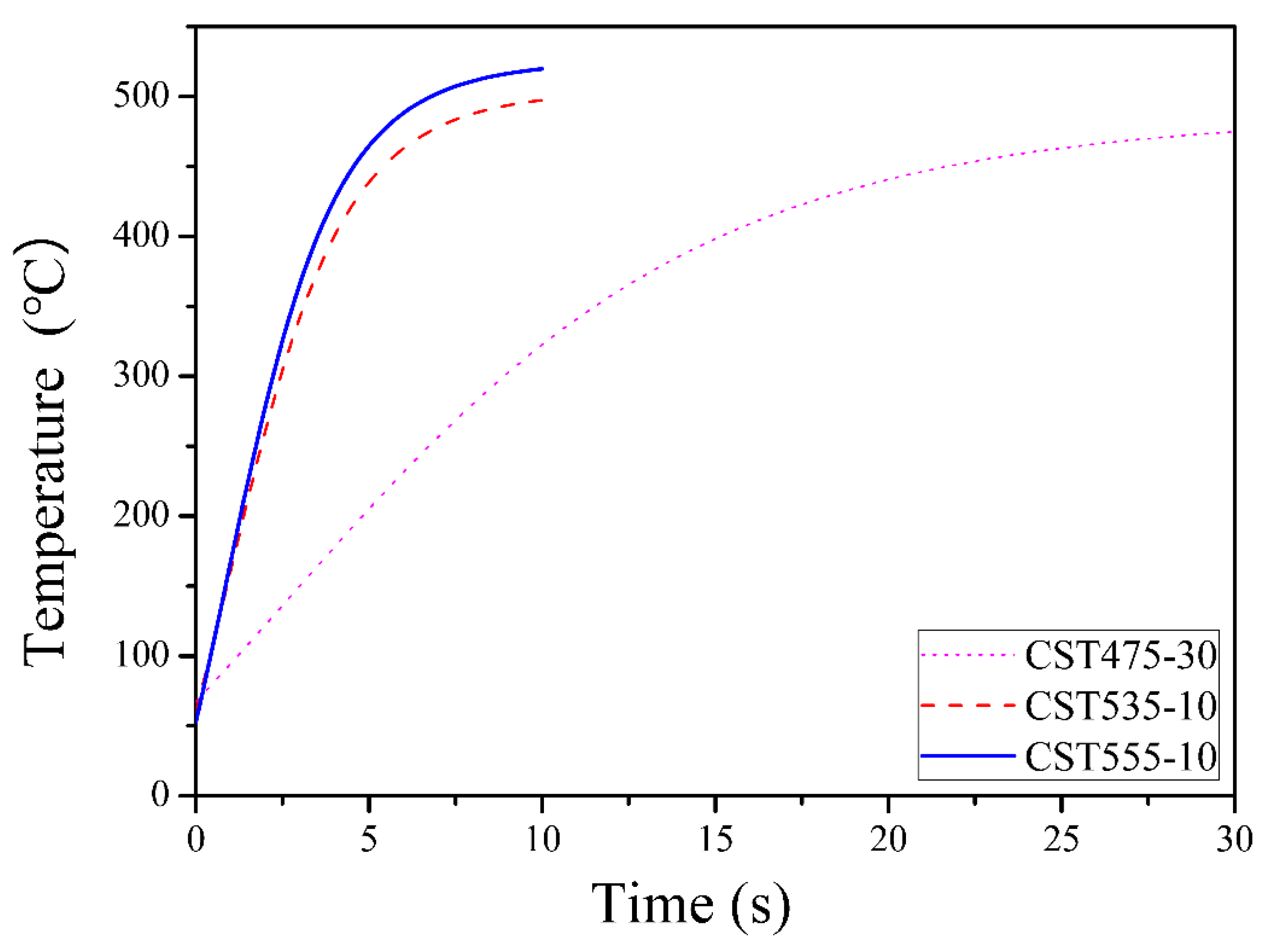

2. Materials and Methods

3. Results and Discussion

3.1. Analysis of Mechanical Properties

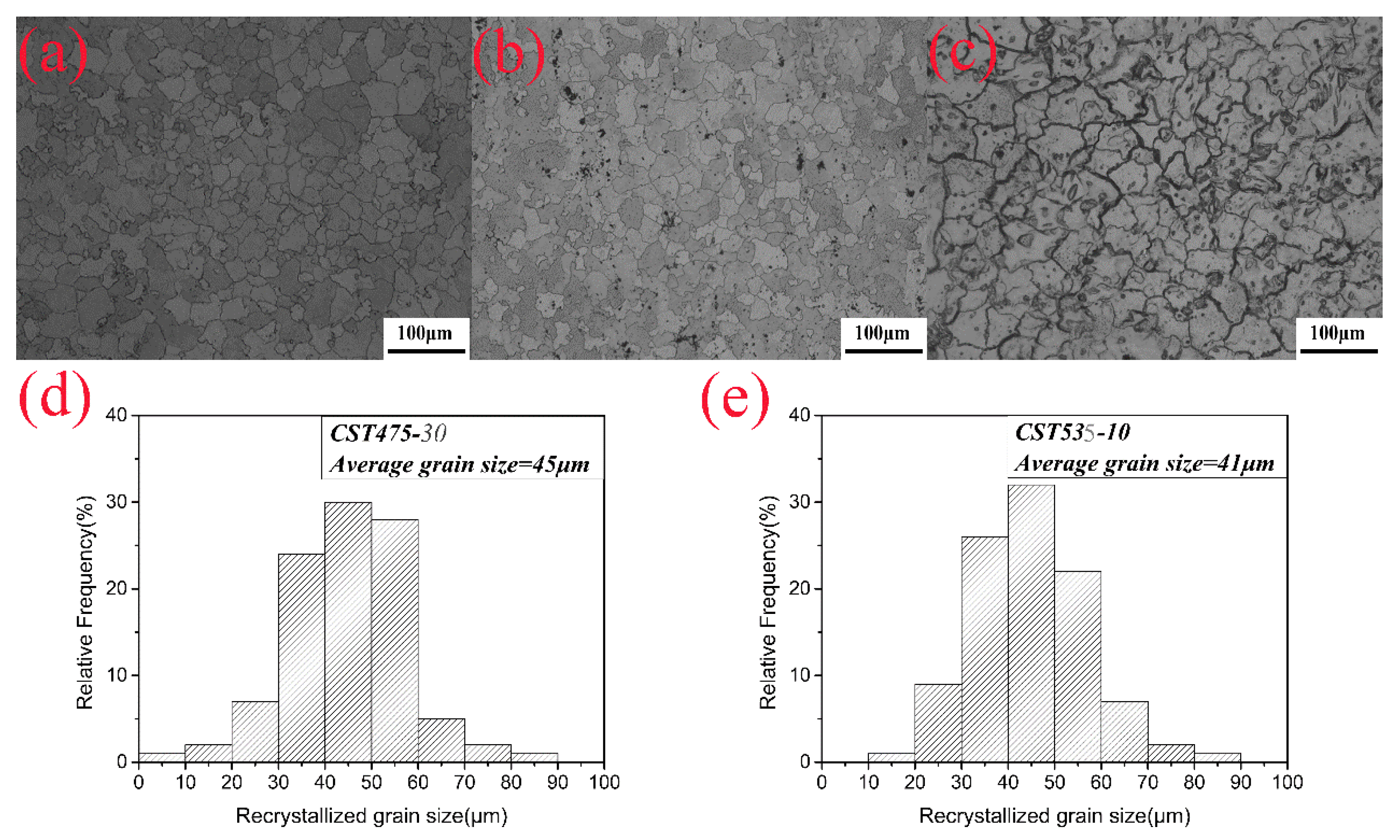

3.2. Grain Morphology Observation

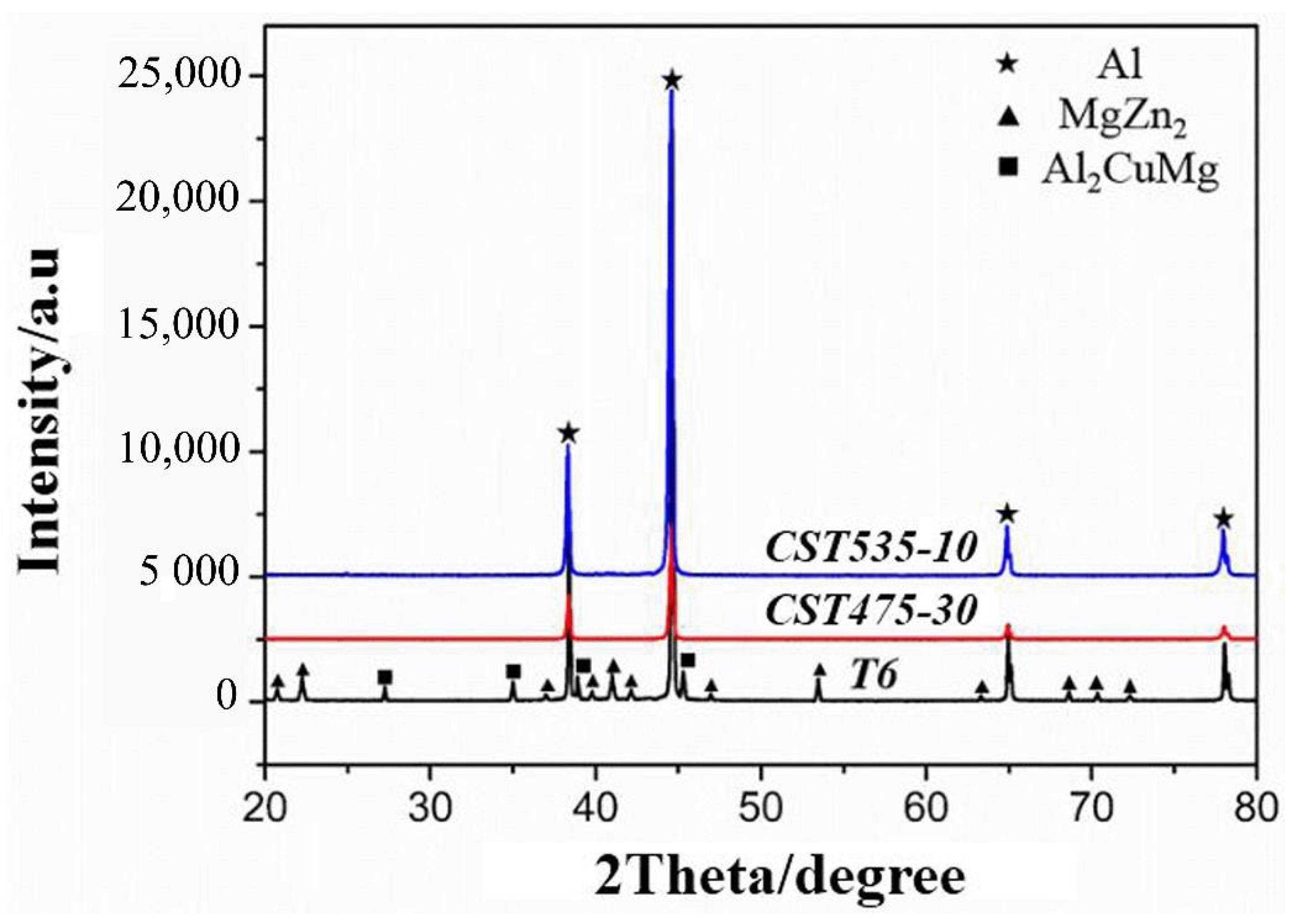

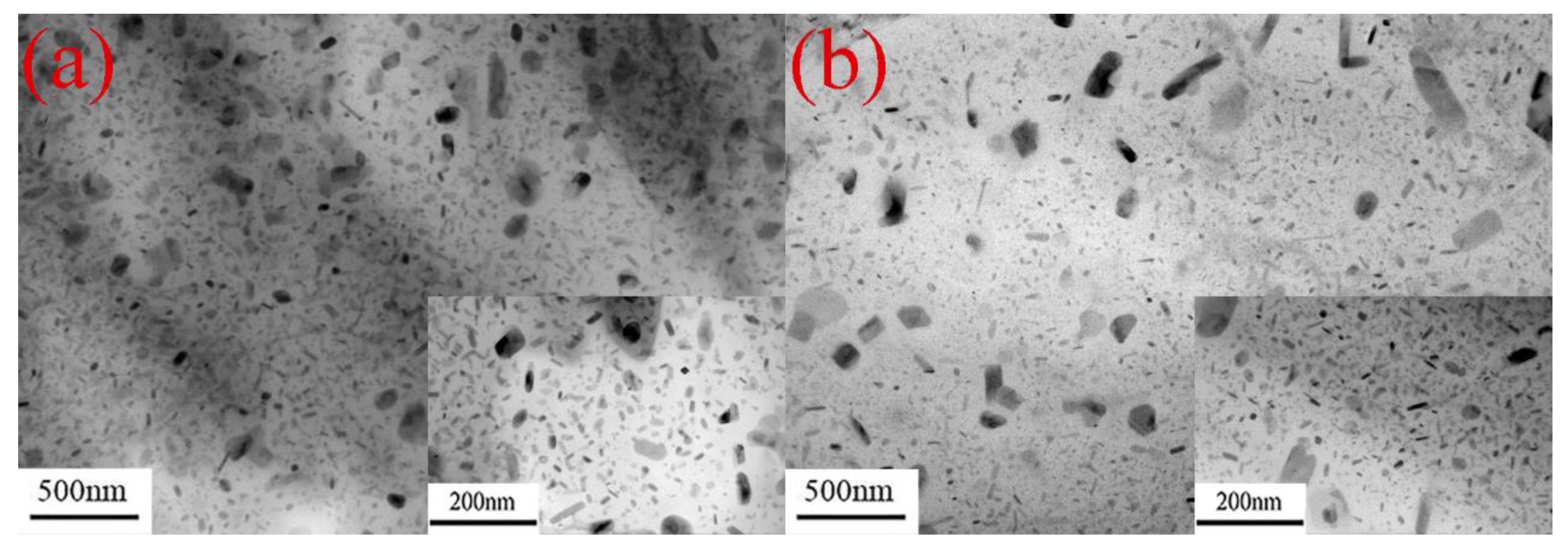

3.3. Analysis of the Second Phases Evolution

4. Conclusions

- (1)

- With the increase of the solution temperature, the temperature rise rate of the specimen increased and the holding time decreased. When the solution temperatures were 475 °C and 535 °C, the mechanical properties of the specimens were similar. However, when the solution temperature increased to 555 °C, the grain boundaries of the specimen showed local over-burning, leading to the decrease in the mechanical properties.

- (2)

- With the contact bodies’ temperature of 535 °C and holding time of 10 s, the dissolution of low-melting MgZn2 phase was fast and the coarsening of the high-melting Al2CuMg phase in the low-temperature range was avoided. The tensile strength of the specimen was 545 MPa after artificial aging, and the contribution of precipitation strengthening was 411 MPa, accounting for about 75.4% of the total strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Strangwood, M.; Balint, D.; Lin, J.; Dean, T.A. Formability and failure mechanisms of AA2024 under hot forming conditions. Mater. Sci. Eng. A 2011, 528, 2648–2656. [Google Scholar] [CrossRef]

- Ko, D.C.; Ko, D.H.; Kim, J.H.; Park, J.H. Development of a partition panel of an Al6061 sheet metal part for the improvement of formability and mechanical properties by hot forming quenching. Adv. Mech. Eng. 2017, 9, 1–15. [Google Scholar] [CrossRef]

- Harrison, N.R.; Luckey, S.G. Hot Stamping of a B-Pillar Outer from High Strength Aluminum Sheet AA7075. SAE Int. J. Mater. Manuf. 2014, 7, 567–573. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, Y.; Ma, B.; Zhang, J.; Zhang, M. Rapid grain refinement of 2024 Al alloy through recrystallization induced by electropulsing. Mater. Sci. Eng. A 2014, 612, 223–226. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, Y.; Wang, X.; Zhang, Y.; Ning, Y. Effect of rapid solid-solution induced by electropulsing on the microstructure and mechanical properties in 7075 Al alloy. Mater. Sci. Eng. A 2016, 654, 278–281. [Google Scholar] [CrossRef]

- Chang, Y.L.; Huang, F.Y.; Lui, T.S. Enhancing the tensile yield strength of A6082 aluminum alloy with rapid heat solutionizing. Mater. Sci. Eng. A 2017, 702, 438–445. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Yu, J.H.; He, D.Y. Influence of contact solid-solution treatment on microstructures and mechanical properties of 7075 aluminum alloy. Mater. Sci. Eng. A 2019, 743, 500–503. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Yu, J.H.; He, D.Y. Effects of contact body temperature and holding time on the microstructure and mechanical properties of 7075 aluminum alloy in contact solid solution treatment. J. Alloys Compd. 2020, 823, 153919. [Google Scholar] [CrossRef]

- Xu, D.K.; Rometsch, P.A.; Birbilis, N. Improved solution treatment for an as-rolled Al−Zn−Mg−Cu alloy. Part Ⅱ. Characterisation of constituent particles and overheating. Mater. Sci. Eng. A 2012, 534, 234–243. [Google Scholar] [CrossRef]

- Mazibuko, N.E.; Curie, U.A. Effect of solution heat treatment time on a rheocast Al-Zn-Mg-Cu Alloy. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 690, pp. 343–346. [Google Scholar]

- Ashrafizadeh, S.M.; Eivani, A.R.; Jafarian, H.R.; Zhou, J. Improvement of mechanical properties of AA6063 aluminum alloy after equal channel angular pressing by applying a two-stage solution treatment. Mater. Sci. Eng. A 2017, 687, 54–62. [Google Scholar] [CrossRef]

- Fan, Y.Q.; Wen, K.; Li, Z.H.; Li, X.W.; Zhang, Y.A.; Xiong, B.Q.; Xie, J.X. Microstructure of as-extruded 7136 aluminum alloy and its evolution during solution treatment. Rare Met. 2017, 36, 256–262. [Google Scholar] [CrossRef]

- He, Y.; Jia, Z.H.; Sanders, R.E.; Liu, Y.Y.; Ding, L.P.; Xing, Y.; Liu, Q. Quantitative study of dissolution of Mg2Si during solution treatment in AA6014 alloy. J. Alloys Compd. 2017, 703, 272–279. [Google Scholar] [CrossRef]

- Pande, C.S.; Cooper, K.P. Nanomechanics of Hall–Petch relationship in nanocrystalline materials. Prog. Mater. Sci. 2009, 54, 689–706. [Google Scholar] [CrossRef]

- Cao, B.; Joshi, S.P.; Ramesh, K.T. Strengthening mechanisms in cryomilled ultrafine-grained aluminum alloy at quasi-static and dynamic rates of loading. Scr. Mater. 2009, 60, 619–622. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Han, B.Q.; Schoenung, J.M. Cryomilled nanostructured materials: Processing and properties. Mater. Sci. Eng. A 2008, 493, 207–214. [Google Scholar] [CrossRef]

- Witkin, D.B.; Lavernia, E.J. Synthesis and mechanical behavior of nanostructured materials via cryomilling. Prog. Mater. Sci. 2006, 51, 1–60. [Google Scholar] [CrossRef]

- Cong, F.; Zhao, G.; Jiang, F.; Tian, N.; Li, R. Effect of homogenization treatment on microstructure and mechanical properties of DC cast 7X50 aluminum alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 1027–1034. [Google Scholar] [CrossRef]

- Rokhlin, L.L.; Dobatkina, T.V.; Bochvar, N.R.; Lysova, E.V. Investigation of phase equilibria in alloys of Al−Zn−Mg−Cu−Zr−Sc system. J. Alloys Compd. 2004, 367, 10–16. [Google Scholar] [CrossRef]

- Chen, S.Y.; Chen, K.H.; Peng, G.S.; Peng, L.J.; Dong, X. Effect of heat treatment on strength, exfoliation corrosion and electrochemical behavior of 7085 aluminum alloy. Mater. Des. 2012, 35, 93–98. [Google Scholar] [CrossRef]

- BjØrnekletta, B.I.; Gronga, Ø.; Myhrb, O.R.; Klukenb, A.O. Additivity and isokinetic behaviour in relation to particle dissolution. Acta Mater. 1998, 46, 6257–6266. [Google Scholar] [CrossRef]

- Todaa, H.; Nishimuraa, T.; Uesugib, K.; Suzukib, Y.; Kobayashia, M. Influence of high-temperature solution treatments on mechanical properties of an Al–Si–Cu aluminum alloy. Acta Mater. 2010, 58, 2014–2025. [Google Scholar] [CrossRef]

- Djurdjevic, M.B.; Kierkus, C.A.; Northwood, D.O.; Sokolowski, J.H. Improvement of 319 aluminum alloy casting durability by high temperature solution treatment. J. Mater. Process. Technol. 2001, 109, 174–180. [Google Scholar]

- Wen, K.; Xiong, B.Q.; Fan, Y.Q.; Zhang, Y.A.; Li, Z.H.; Li, X.W.; Wang, F.; Liu, H.W. Transformation and Dissolution of Second Phases during Solution Treatment of An Al-Zn-Mg-Cu Alloy Containing High Zinc. Rare Met. 2018, 5, 1–5. [Google Scholar] [CrossRef]

- Peng, G.; Chen, K.; Chen, S.; Fang, H. Evolution of The Second Phase Particles during The Heating-Up Process of Solution Treatment of Al–Zn–Mg–Cu Alloy. Mater. Sci. Eng. A 2015, 641, 237–241. [Google Scholar] [CrossRef]

- Mondal, C.; Mukhopadhyay, A.K. On the nature of T (Al2Mg3Zn3) and S (Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater. Sci. Eng. A 2005, 391, 367–376. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Li, D.; Wu, Y. Application of novel physical picture based on artificial neural networks to predict microstructure evolution of Al−Zn−Mg−Cu alloy during solid solution process. Trans. Nonferrous Met. Soc. China 2015, 25, 944–953. [Google Scholar] [CrossRef]

- Deng, Y.L.; Wan, L.; Zhang, Y.; Zhang, X.M. Evolution of microstructures and textures of 7050 Al alloy hot-rolled plate during staged solution heat-treatments. J. Alloys Compd. 2010, 498, 88–94. [Google Scholar] [CrossRef]

- Zou, X.L.; Yan, H.; Chen, X.H. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment. Trans. Nonferrous Met. Soc. China 2017, 27, 2146–2155. [Google Scholar] [CrossRef]

- Roknia, M.R.; Zarei-Hanzakia, A.; Abedib, H.R. Microstructure evolution and mechanical properties of back extruded 7075 aluminum alloy at elevated temperatures. Mater. Sci. Eng. A 2012, 532, 593–600. [Google Scholar] [CrossRef]

- Papazian, J.M. Calorimetric Studies of Precipitation and Dissolution Kinetics in Aluminum Alloys 2219 and 7075. Metall. Trans. A 1982, 13, 761–769. [Google Scholar] [CrossRef]

- Birbilis, N.; Cavanaugh, M.K.; Buchheit, R.G. Electrochemical behavior and localized corrosion associated with Al7Cu2Fe particles in aluminum alloy 7075-T651. Corros. Sci. 2006, 48, 4202–4215. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Booth-Morrison, C.; Dunand, D.C.; Seidman, D.N. Coarsening resistance at 400 °C of precipitation-strengthened Al–Zr–Sc–Er alloys. Acta Mater. 2011, 59, 7029–7042. [Google Scholar] [CrossRef]

| Element | Zn | Mg | Cu | Fe | Si | Mn | Cr | Ti | Other | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| wt% | 5.1~ 6.1 | 2.1~ 2.9 | 1.2~ 2.0 | ≤0.5 | ≤0.4 | ≤0.3 | ≤0.2 | ≤0.2 | 0.15 | Bal |

| Conditions | Contact Body Temperature/°C | Holding Time/s | Holding Pressure/MPa | Temperature of the Specimen/°C |

|---|---|---|---|---|

| CST475-40 | 475 | 30 | 20 | 470 |

| CST535-10 | 535 | 10 | 20 | 500 |

| CST555-10 | 555 | 10 | 20 | 515 |

| Conditions | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| CST475-30 + AA | 465 | 538 | 11.6 |

| CST535-10 + AA | 472 | 545 | 11.2 |

| CST555-10 + AA | 418 | 523 | 9.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, W.; Yu, J.; Zhang, Z.; Jia, H.; Ren, M. Study on Ultra-High Temperature Contact Solution Treatment of Al–Zn–Mg–Cu Alloys. Metals 2021, 11, 842. https://doi.org/10.3390/met11050842

Jin W, Yu J, Zhang Z, Jia H, Ren M. Study on Ultra-High Temperature Contact Solution Treatment of Al–Zn–Mg–Cu Alloys. Metals. 2021; 11(5):842. https://doi.org/10.3390/met11050842

Chicago/Turabian StyleJin, Wenming, Jianhao Yu, Zhiqiang Zhang, Hongjie Jia, and Mingwen Ren. 2021. "Study on Ultra-High Temperature Contact Solution Treatment of Al–Zn–Mg–Cu Alloys" Metals 11, no. 5: 842. https://doi.org/10.3390/met11050842

APA StyleJin, W., Yu, J., Zhang, Z., Jia, H., & Ren, M. (2021). Study on Ultra-High Temperature Contact Solution Treatment of Al–Zn–Mg–Cu Alloys. Metals, 11(5), 842. https://doi.org/10.3390/met11050842