2. Materials and Methods

The alloy under investigation was vacuum induction melted into an ingot measuring 400 × 460 × 75 mm

3. Hot rolling was performed by heating the ingot to 1260 °C with a total thickness reduction of 73% to produce plates 20 mm thick (Sophisticated Alloys Inc., Butler, PA, USA). The composition of the alloy was 0.26C-0.60Mn-1.0Si-1.0Ni-2.8Cr-0.92Mo-0.1V-balFe (in wt. %) according to optical emission spectroscopy (Element Materials Technology, Daleville, IN, USA) and gas combustion analysis to measure carbon content. It is noted that the alloy contains significant concentrations of carbide stabilizing elements such as vanadium, molybdenum, and chromium. The measured composition was modeled using ThermoCalc 2018a with the TCFE9 database to determine carbide stability of the bulk alloy and the A

1 and A

3 temperatures. Due to the high partitioning coefficient for certain elements the segregation associated with casting was modeled. The composition of the last 15% to solidify was modeled using the Scheil module assuming all elements are slow to diffuse with the exception of carbon. The first 85% to solidify was determined by calculating a mass balance. Paraequilibrium, assuming an equivalent activity in austenite of two compositions (the first 85% and the last 15%) was used to calculate the carbon concentration of the last 15% composition according to Equation (1) as described in previous works by Field et al. [

3] and Athavale et al. [

14]. In this manner the carbon content of the last 15% is determined by the difference in alloy content (e.g., ΔNi) between the first 85% and last 15% in weight percent, and the carbon contained in the first 85% was then calculated by mass balance. The composition of the bulk alloy, and the first 85% and last 15% to solidify are shown in

Table 1. It should be noted that Mo and V have the highest ratio of increase from the bulk to solute rich composition. The Mo increases by 81.5% and the V increases in concentration by 130%. The martensite start temperatures were calculated using Equation (2) from De Cooman and Speer [

15].

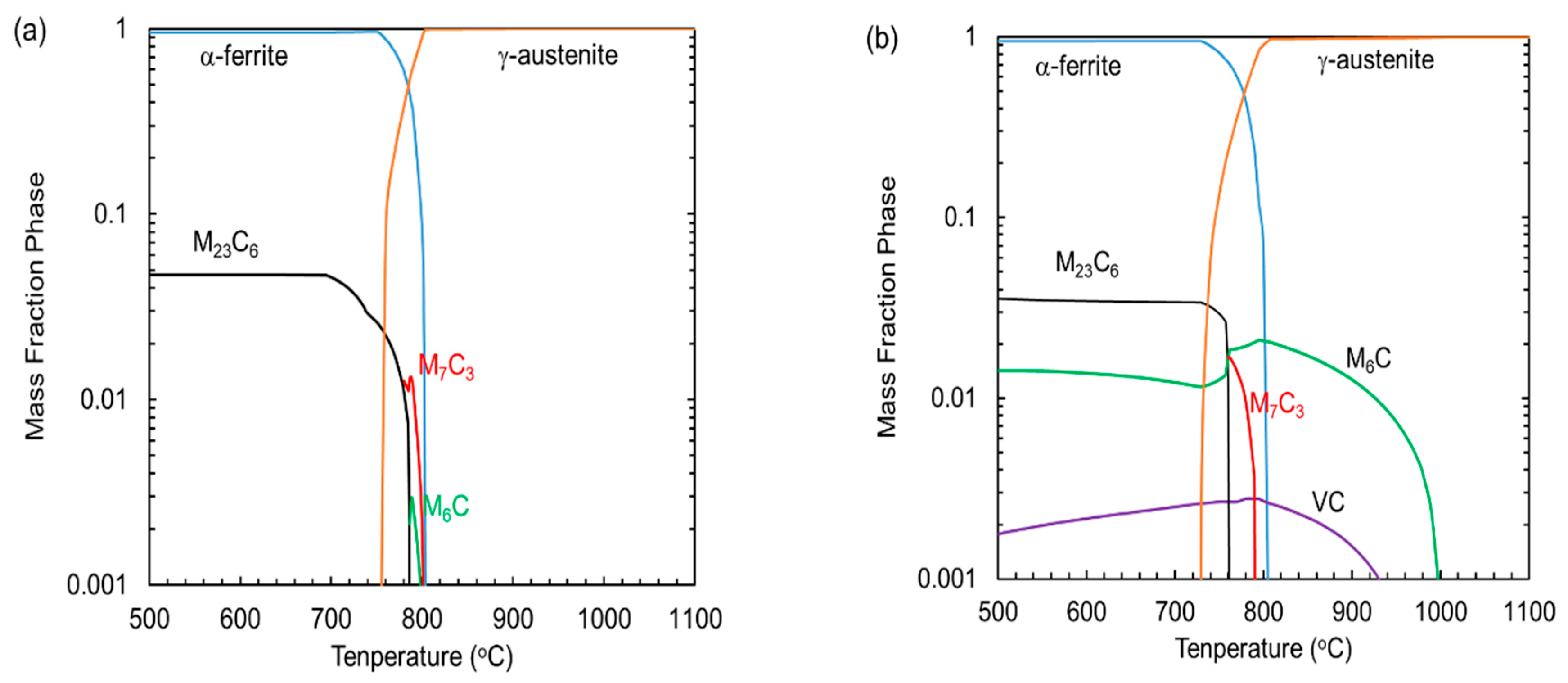

ThermoCalc 2018a energy minimization simulations were performed on both the bulk and solute rich compositions and are shown in

Figure 1. It should be noted that the A

1 and A

3 temperatures are not significantly shifted using the bulk or solute rich composition. The A

1 is decreased in the solute rich region from 750 °C to 730 °C due to the increase in austenite stabilizing elements like Ni and Mn. It is surprising however that the A

3 is not lowered, but increases by 10 °C. In the bulk composition calculations, α-ferrite and all stable carbides are fully dissolved at 800 °C, whereas in the solute rich region the α-ferrite is stabilized up to 810 °C. The increase in concentration of Mo, Si, and Cr appear to stabilize the carbides to higher temperatures. The M

6C, a Mo-Si rich carbide, is stabilized up to 1000 °C from the bulk composition of 800 °C. VC is stable up to 970 °C which is significant to note due to the lack of stability of VC in the bulk alloy entirely.

The wrought steel was subjected to four different heat treatment cycles to elucidate the effects of normalization temperature and austenitizing temperature on mechanical performance. Heat treatments were performed in cycles to both refine the microstructure and reduce elemental segregation. The components of each treatment step used in this study are shown in

Table 2. During heat treatment, samples were placed in 321-type stainless steel bags for oxidation protection. Sample temperature was tracked with secondary thermocouples on the surface of the material and heat treatment times were initiated when the surface temperature reached ±5 °C of the target temperature. For processing steps that required quenching, samples were removed from the stainless bags and quenched to room temperature in agitated room temperature water.

Heat treatments were performed using a sequence of temper normalize—air cool, temper, and concluded with an austenitize and quench. All alloys were finalized with a stage I temper of 204 °C for 4 h. A schematic of the heat treatment temperature is shown in

Figure 2. This 4-step heat treatment was based on the results from the work of Field et al. [

3] that showed both sub-critical temper (T) and a high temperature normalization was of necessity to obtain superior strength and toughness from these types of highly alloyed steels. Two levels of normalizing temperatures and austenitizing temperatures were examined. The lower normalization temperature (N

L) was based on the bulk composition to homogenize the austenite to remove chemical segregation, the higher normalization temperature (N

H) was derived from the segregated composition that showed M6C, and VC to be stable at temperatures exceeding 1000 °C. The lower austenitizing temperature (Q

L) was based on the A

3 + 25 °C of the bulk composition, and the higher austenitizing temperature (Q

H) was derived from the solute rich composition to solubilize the VC before quenching. For simplicity, samples will be labeled using a combination of the normalizing and austenitizing temperatures, excluding the consistent intermediate sub-critical temper steps in the nomenclature for simplicity.

To quantify the microstructure, samples in the longitudinal-short (LS) orientation were mechanically polished to 0.02 μm finish using colloidal silica. Electron backscattered diffraction using orientation image mapping (EBSD-OIM) was performed to measure misorientation and identify prior austenite grain size. EBSD was carried out using an FEI NovaNanolab 600i (Thermo Fisher Scientific, Waltham, MA, USA) dual beam Focused Ion beam microscope (FIB) at an accelerating voltage of 20 kV, emission current of 2.7 nA and a working distance of 7–8 mm.

EBSD data was used to reconstruct the parent austenite microstructure for samples having undergone each processing scheme. Reconstructions were performed in MATLAB (Mathworks, Natick, MA, USA) using the method as outlined in [

11]. Grouping of martensite laths into their parent austenite grains was accomplished via a seed-growth type clustering algorithm that checks for neighboring laths that could have come from the same parent grain. The Kurdjumov–Sachs (KS) orientation relationship was assumed for all samples in this study. Additionally, the relationship between reconstructed austenite grains was used to identify the possibility of partial austenitization in some samples.

Secondary electron imaging was also performed on samples following etching using a modified Marbles Reagent comprised of 50 vol. % Marbles Reagent and 50 vol. % glycerin. Fracture surfaces were analyzed with a Phenom XL (Thermo Fisher Scientific, Waltham, MA, USA) operating at 15 kV in backscatter mode. Tensile testing was performed with the loading axis parallel to the rolling direction according to ASTM E8 [

16] using a sub-sized flat tensile bar with gauge width of 6.0 mm, and gauge length of 25.0 mm and a strain rate of 10

-4 s

-1. The toughness of the alloy was determined through Charpy V-notch (CVN) impact testing using standard full-sized V-notch samples according to ASTM E23 [

17]. Testing temperatures ranged from −40 °C to ambient (measured to be 25 °C) in increments of 20 °C. CVN bars were in the transverse-longitudinal (T-L) orientation, with the notch direction parallel to the rolling direction.

3. Results and Discussion

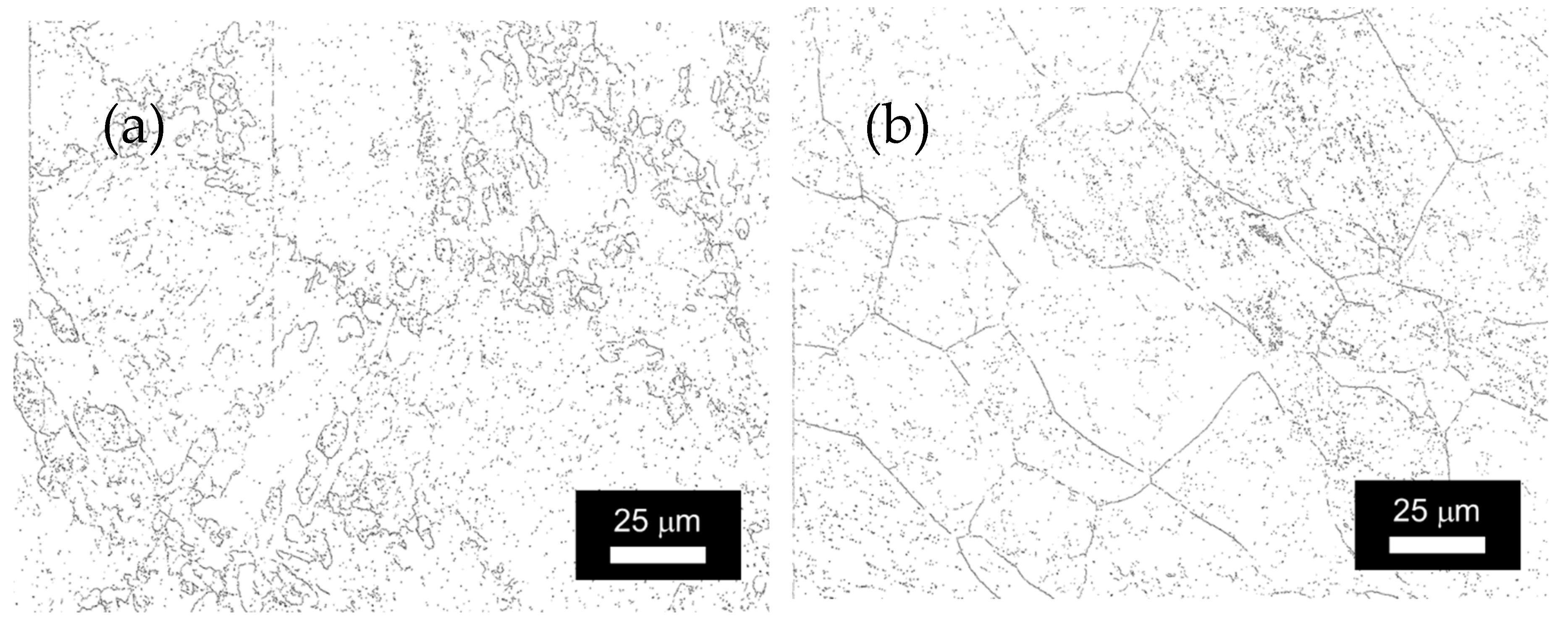

Representative EBSD-OIM micrographs of the heat-treated samples are shown in Figure 4. Misorientation angles between 15 and 45° are highlighted in yellow to identify the prior austenite grain size as has been shown from the work of Sinha et al. [

18]. It is noted that in the N

HQ

L (

Figure 3a) and N

LQ

L (

Figure 3b) there is a high volume of the 15–45° boundaries and the prior austenite grain shape is highly irregular. This is further observed by the reconstructions of the parent austenite grains depicted in

Figure 4. There are instances where austenite grains are formed within larger parent austenite grains. These microstructures would imply that the Q

L step at 825 °C was insufficient to fully austenitize the alloy. The A

3 temperature for the bulk composition is calculated to be 800 °C according to

Figure 1a. The Q

L temperature was 825 °C which provides an excess 25 °C to be fully in the austenite phase field. Using a Kernal Average Misorientation (KAM) map for the Q

L processed steels regions of highly recrystallized α-ferrite with extremely low internal misorientation are identified as shown in

Figure 5. This implies that during Q

L step, at 825 °C, the microstructure was a mixture of undissolved α-ferrite and fresh austenite. This implication is further supported by the reconstructed prior austenite regions for the samples that underwent the Q

L step.

Figure 4a identifies several small prior austenite grains that are contained within a single larger austenite region. Each small austenite region shares a KS variant with the surrounding region (within a tolerance of 5° misorientation). This suggests that the small austenite regions nucleated from existing martensite/ferrite laths and did not grow sufficiently to fully erase the austenite grains in place after normalization.

The N

HQ

H (

Figure 4c) and N

LQ

H (

Figure 4d) both exhibit typical equiaxed prior austenite grains in the range of 70 to 50 μm and is consistent with previous work [

3] on these alloys. The N

HQ

H microstructure appears to have slightly larger prior austenite grain size compared to the N

LQ

H and is rationalized by the higher normalizing temperature which would have led to grain growth. In addition to the prior austenite reconstructions, a map of the 15–45° boundaries is shown in

Figure 6 for N

LQ

L and N

LQ

H and it can be seen both in

Figure 4b and

Figure 6a that within the N

LQ

L condition there is a large dispersion of fine grains surrounding a set of larger grains. Some of the fine grain regions are depicted in black in

Figure 4b, where they were unable to be reconstructed due to an insufficient number of martensite variants to back-calculate a parent austenite orientation. Some of these fine grain regions were only comprised of a single martensite or ferrite variant. It is further noted that these finer grains all contain a radius of curvature pointing to the interior of said grains implying that during the austenitizing heat treatment the grains were being devoured by the larger surrounding grains. In both

Figure 4b and

Figure 6b the N

LQ

H exhibits a uniform equiaxed grain structure.

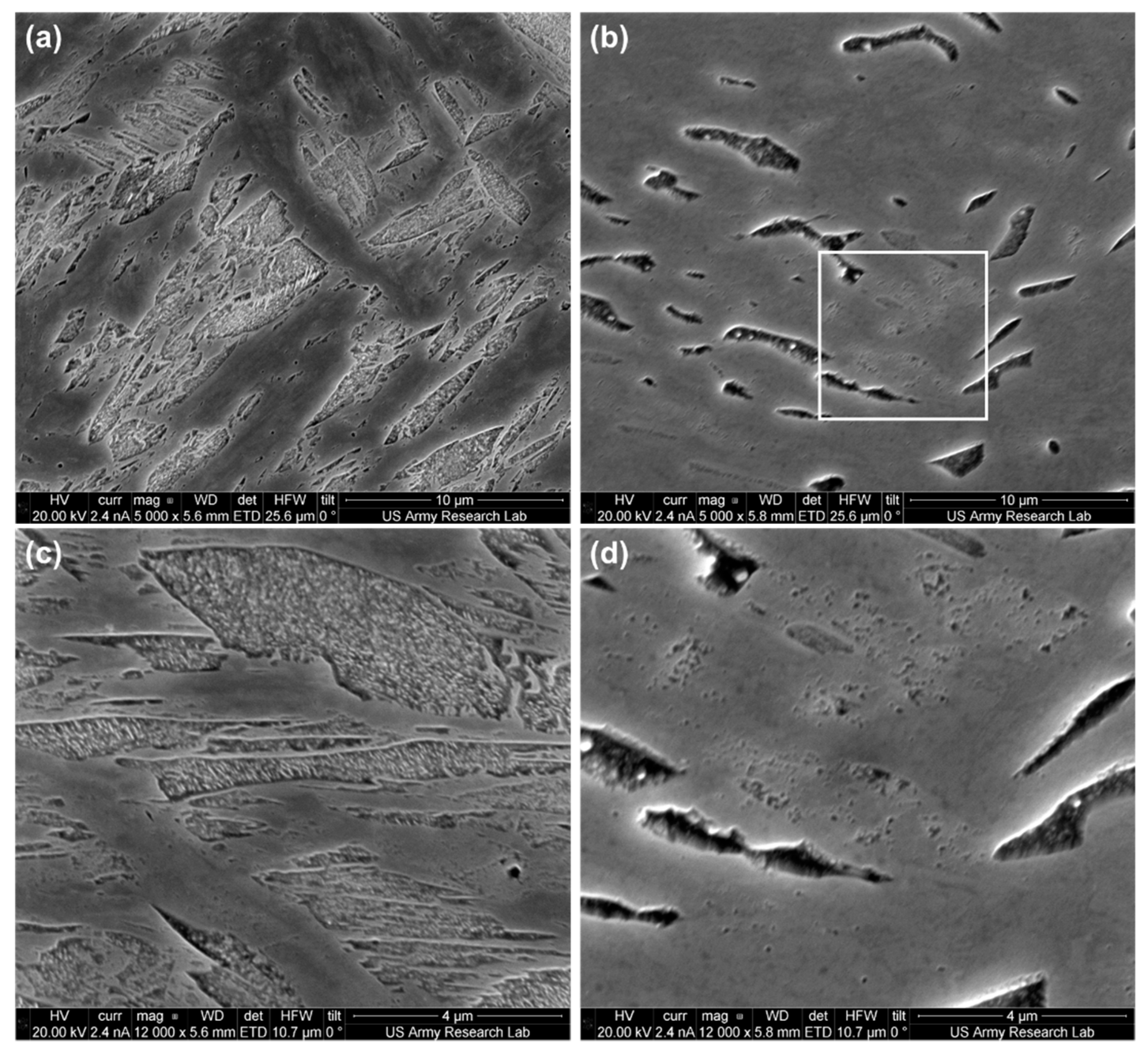

The structure of the alloy is shown

Figure 7 after etching. The N

HQ

H and N

HQ

L etched micrographs appear to corroborate the effect of incomplete austenitization. In

Figure 7a,c the N

HQ

H structure clearly reveals a fine carbidic structure within the martensite laths as would be expected from a Stage I tempered martensitic steel. In

Figure 7b,d however, the N

HQ

L a very different structure is revealed. Firstly, there is a poor etching region which according to

Figure 3a and

Figure 5 is identified as a highly recovered ferrite. Secondly, it is noted at higher magnification (denoted by the white box) that there lacks a distinctive carbidic structure of tempered martensite. This effect is anticipated to be from a lack of supersaturated carbon during the austenitization quench-hardening process within those highly recovered grains. During austenitization of the low temperature austenitized samples (N

H/

LQ

L) a dual-phase structure of austenite and ferrite is created. Carbon, being a small interstitial element is able to quickly diffuse into the austenite and is locked in place during quenching. The retained ferrite is denuded of carbon and dislocations; upon tempering the ferrite does not precipitate any carbides. Coarse carbides are however noted within the martensite between the ferrite crystals and they are significantly coarser compared to the N

HQ

H condition.

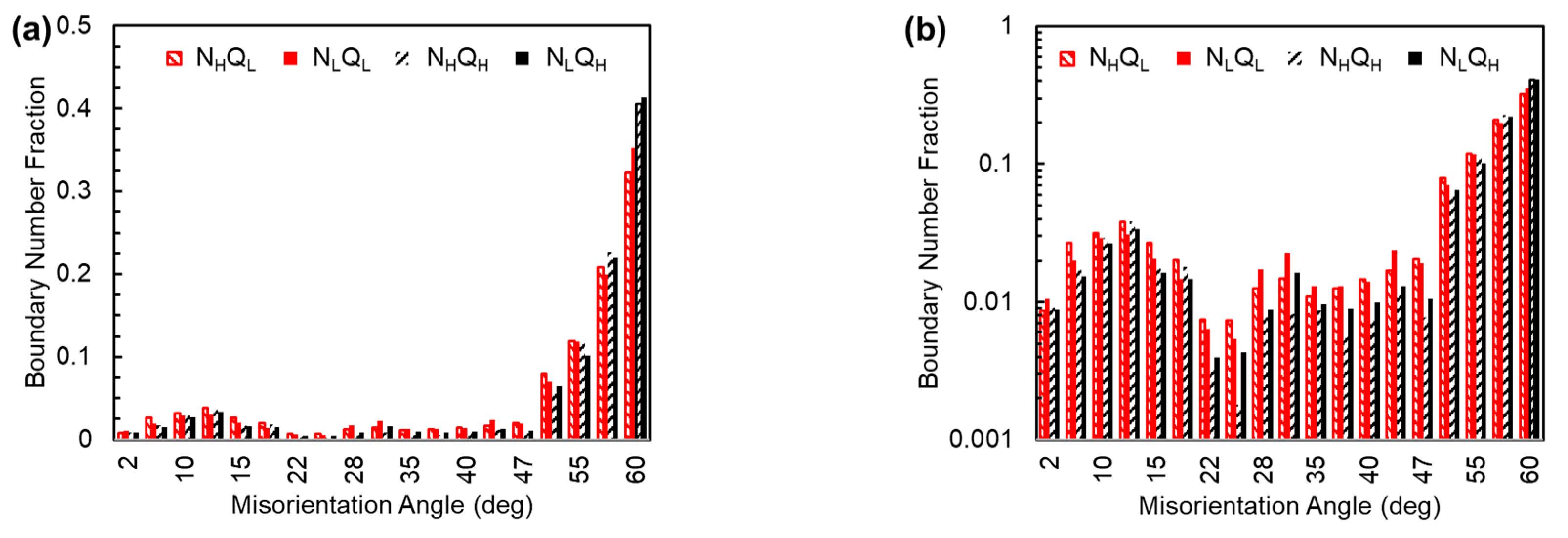

Many authors [

3,

4,

5,

19] have investigated the effect of martensite misorientation on mechanical properties, and it has been shown that misorientations >45° are representative of the internal misorientation of the martensite. This misorientation is considered of significant utility to improve mechanical properties. From EBSD-OIM mapping the misorientation number fractions are shown for the four different heat treatment conditions in

Figure 8. It is noted that the Q

H alloys exhibit significantly more misorientations greater than 50° as compared to the Q

L condition.

Figure 8b is included using a log10 scale to highlight the increased misorientation of 15–45° within the Q

L condition. As noted by previous authors [

3,

18] this would imply a higher density of prior austenite grain boundaries and was previously confirmed within this work (see

Figure 6). A tabulated sum of misorientations is also provided in

Table 3. The Q

H conditions have the highest sum of angles >46°. From previously reported works, this implies that the Q

H should have superior properties compared to the Q

L heat treated alloys.

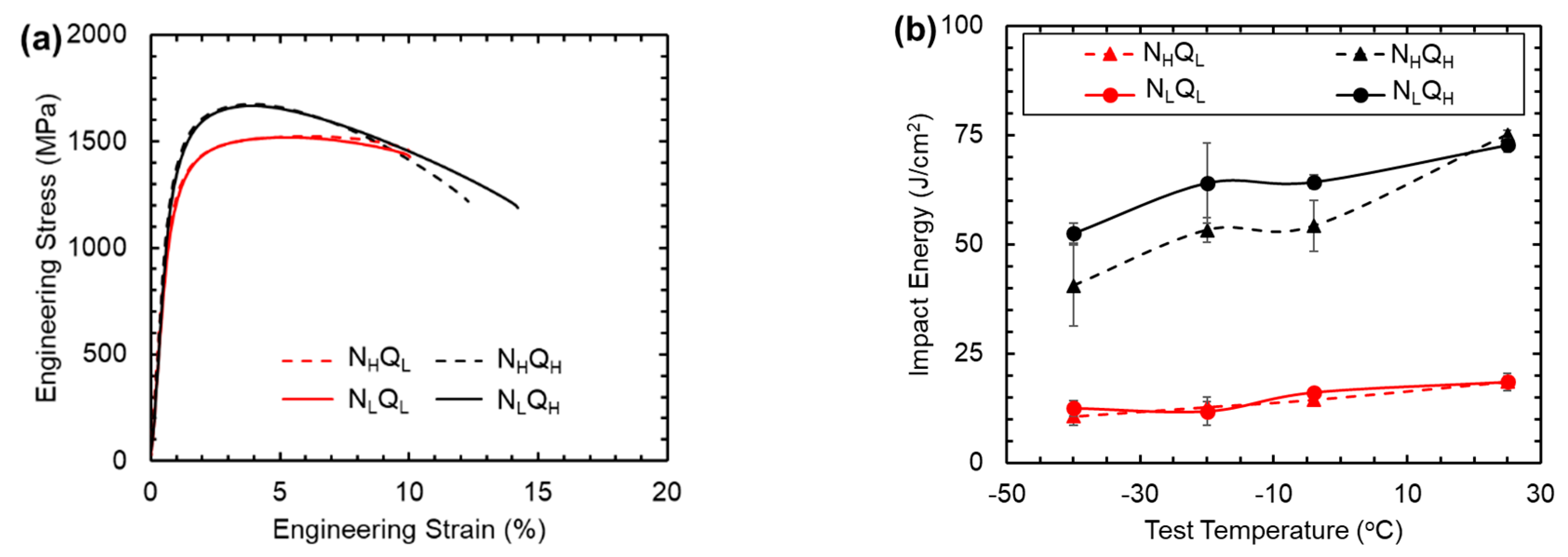

Representative stress–strain plots of the heat-treated alloys are shown in

Figure 9a and a summary of the properties is provided in

Table 4. Both the N

HQ

L and N

LQ

L samples exhibit lower strengths and ductility compared to the heat treatments that concluded with the Q

H processing step. It should be noted that Grydin et al. [

9] demonstrated that when a steel is not fully austenitized the strength was significantly reduced as compared to the fully austenitized and quenched steel. They report a loss of ~30% of the strength according to Vickers hardness. The loss of yield strength between the Q

L and Q

H processed alloy ranged from 11 to 18%. It is interesting to note that the Q

L processed steels provide slightly higher uniform elongation compared to the Q

H condition (6.6% vs. 5.6%) however the amount of post-necking deformation is significantly increased in the Q

H processed steel. It can be inferred that the Q

H processing imparts significantly higher plasticity to the alloy leading to a greater reduction in area which is considered a true measure of plasticity compared to total engineering strain. The Q

H condition produces an additional 120% increase in elongation after necking while the Q

L processed steels only provide an increase of 50–40% beyond necking.

The CVN toughness as a function of test temperature is shown in

Figure 9b. The N

LQ

H condition exhibits the best toughness at all test temperatures, except ambient. This is potentially due to the finer prior austenite grain size as noted in

Figure 3 and the higher sum of misorientation angles >46°; it should be noted however that the higher misorientation is within a standard deviation of the N

HQ

H condition. The N

HQ

H has a similar breaking energy at room temperature however the breaking energy is reduced as the temperature decreases. These results are consistent to what has been reported in literature for quenched and tempered martensite. The combination of grain refinement and increased internal misorientation are of the highest utility at a fixed strength. Unsurprisingly the two low austenitized (Q

L) samples behave statistically similar and are brittle at all temperatures, which is consistent with the quasi-static tensile results as well as the presence of recrystallized ferrite as discussed previously.

The higher normalization processing yields a reduction in properties. There is a slight loss of 1% strain in total ductility for both the Q

L and Q

H processed steels during quasi-static testing as well as a loss in toughness at the −40 °C CVN testing. The root cause of this can be related to the misorientation structure of the alloy. As shown in

Table 3 the sum of misorientations >46° is always higher during the NL processing route regardless of the post quench hardening process. This would identify that the lower normalization processing is beneficial for these wrought alloys, it is possible that the high temperature rolling process (1260 °C) was effective as a normalization that was not utilized on previously investigated cast steels with a similar composition. From the prior austenite reconstruction results, the packet boundaries can be identified by their relationship to the austenite orientations and plotted alongside the parent austenite boundaries.

Figure 8 demonstrates the packet/austenite boundary structures that result for the N

HQ

H and N

LQ

H samples.

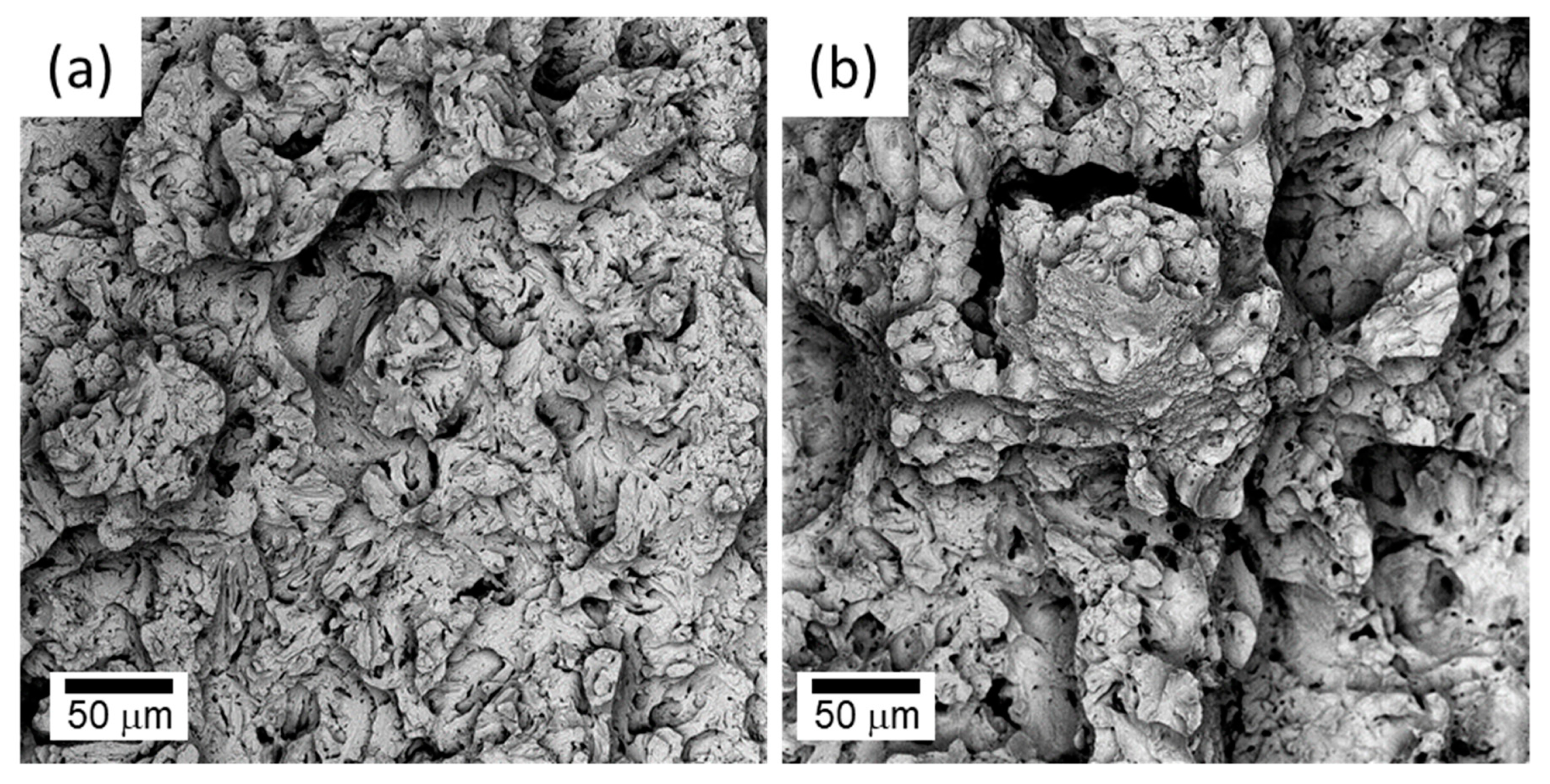

Representative fracture surfaces of the CVN bars tested at −40 °C are shown in

Figure 10. It can be seen that the N

LQ

L exhibits significant cleavage fracture, dimple rupture behavior was not observed on the fracture surface and is consistent with the impact energies recorded. The N

LQ

H fracture is dominated by dimple rupture, as expected based on the measured impact energy of 52.6 ± 2.3 J.