Comparative Study of the Properties of Cu-Cr-Mo System Electrical Contact Material by Sintering and Infiltration Methods

Abstract

1. Introduction

2. Materials and Methods

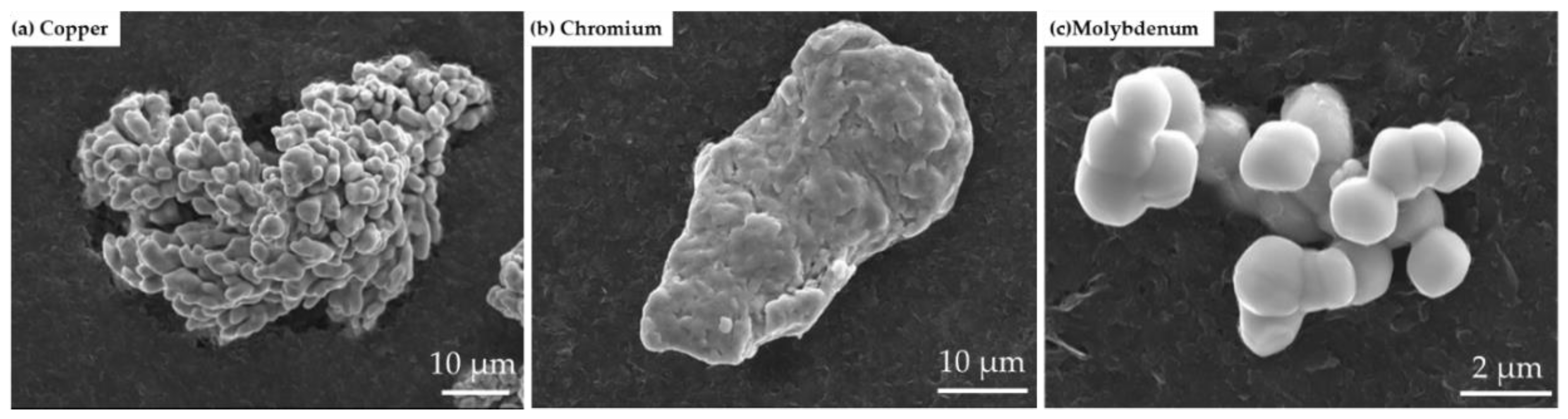

2.1. Materials

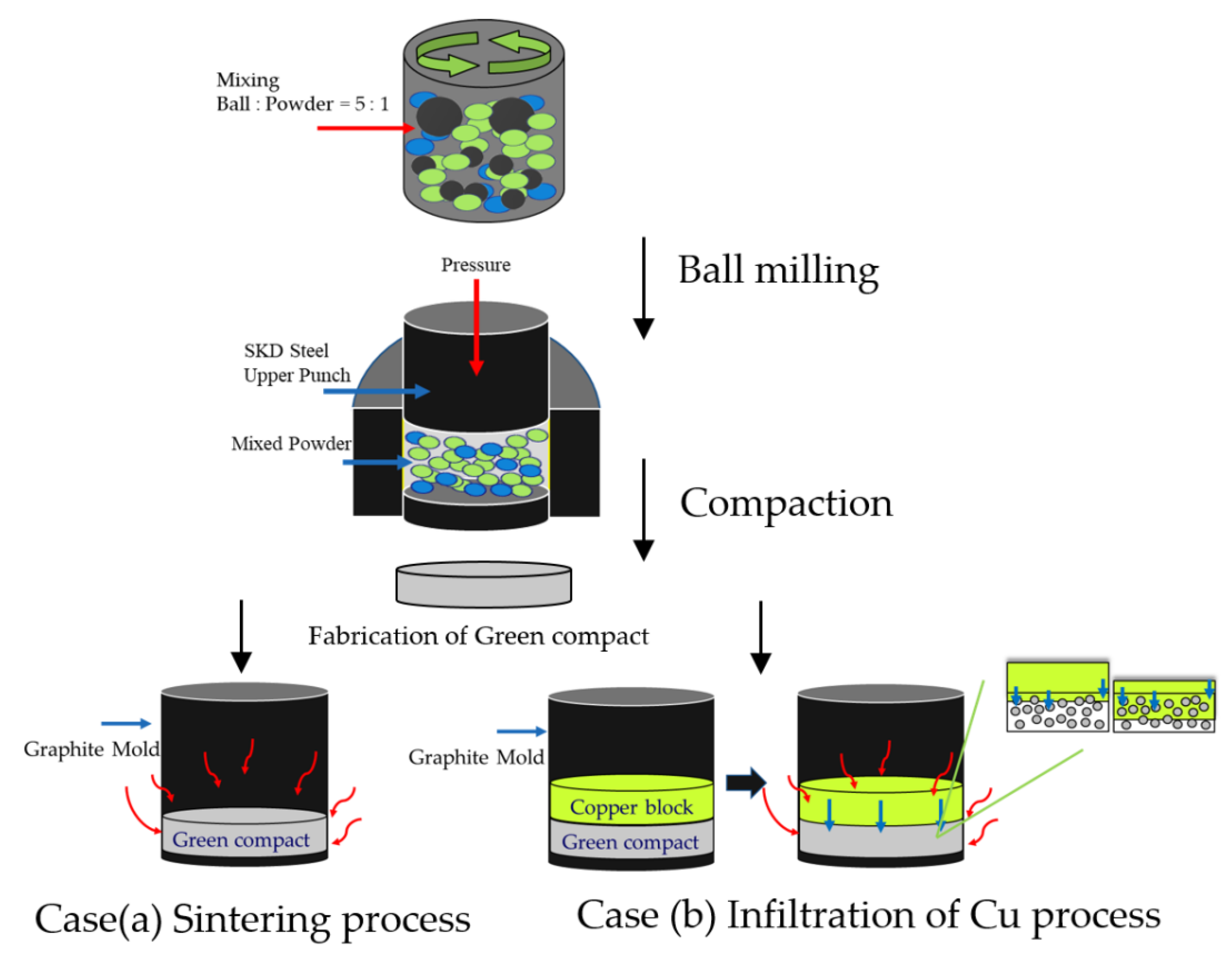

2.2. Experimental Process

2.3. Analysis Technique

3. Results and Discussion

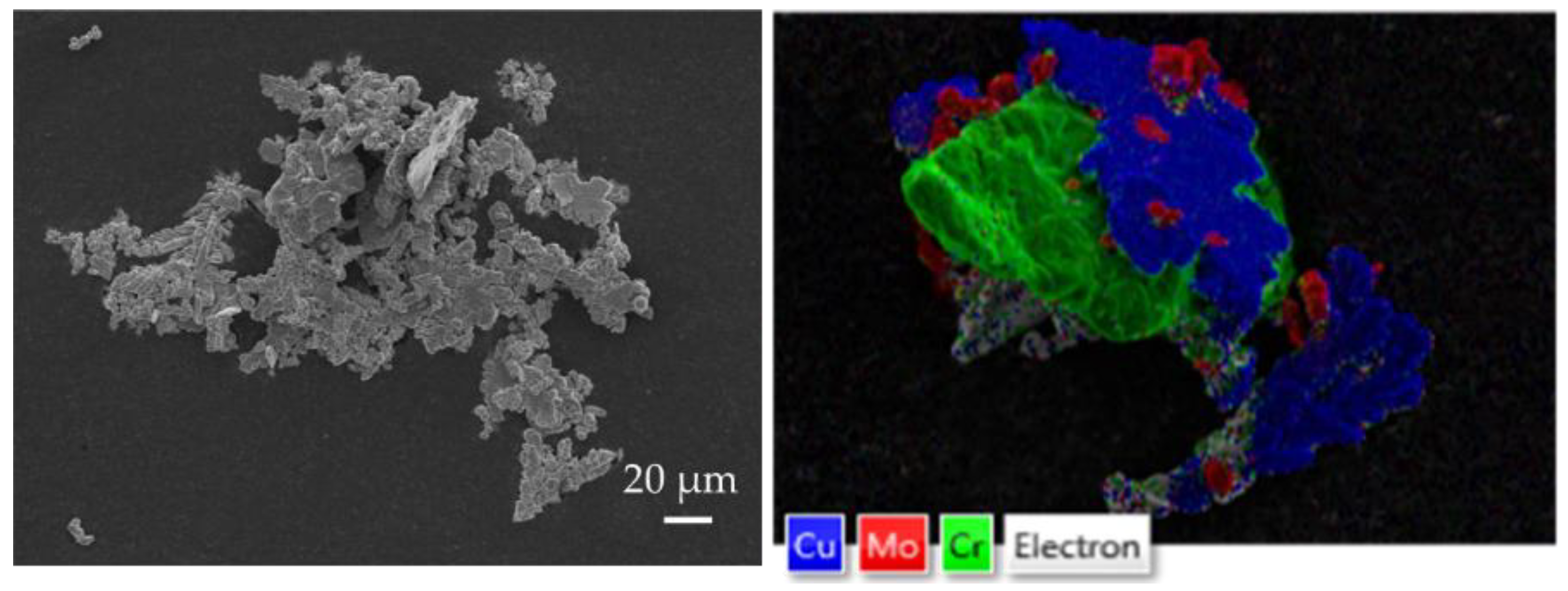

3.1. Materials

3.2. Shrinkage

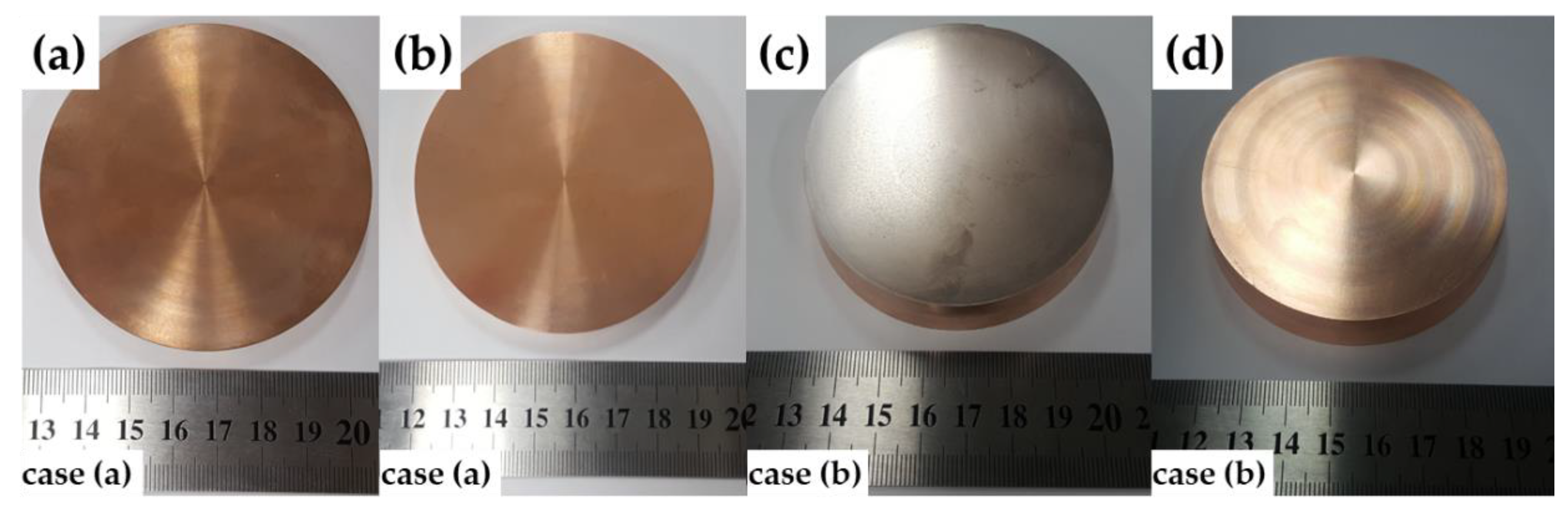

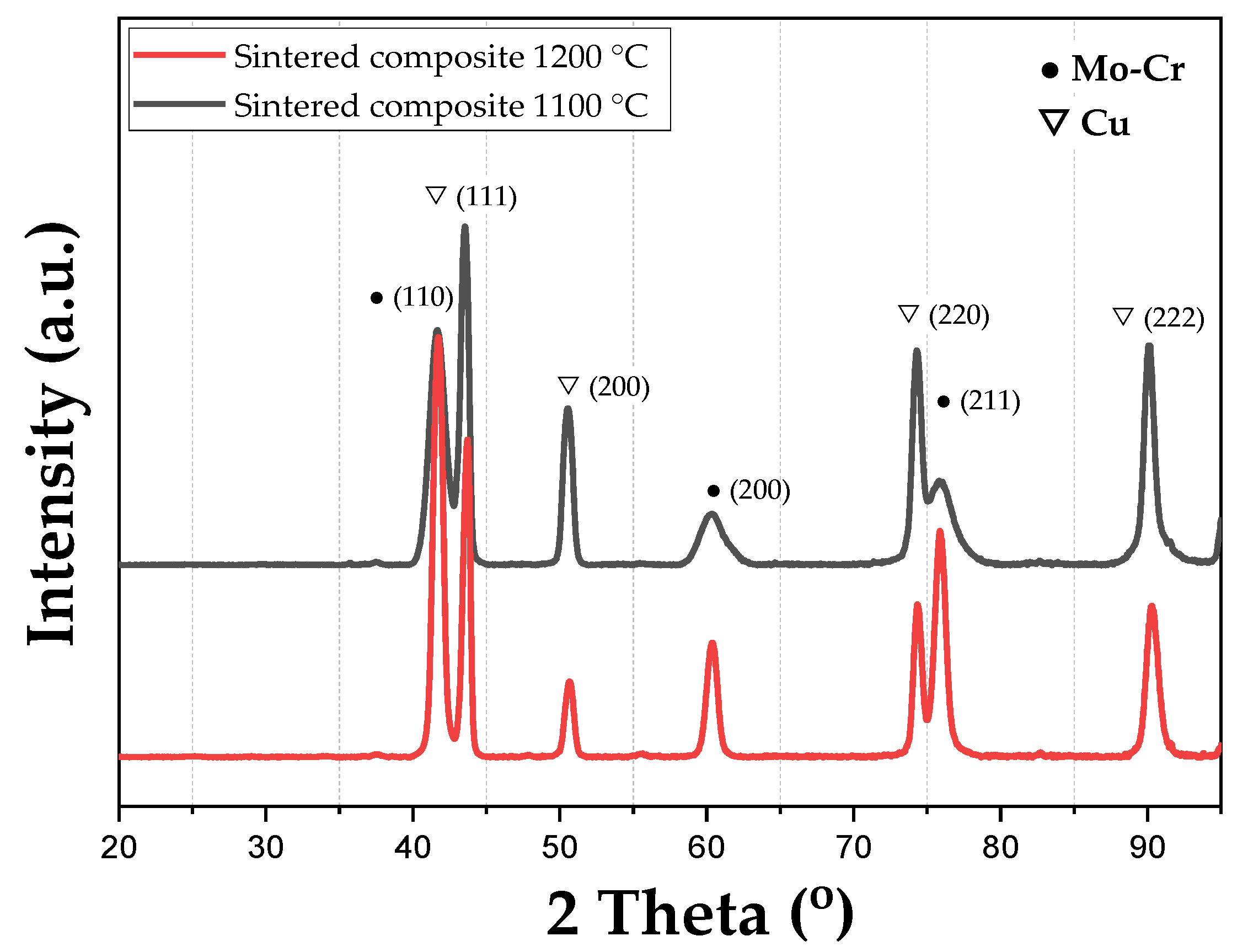

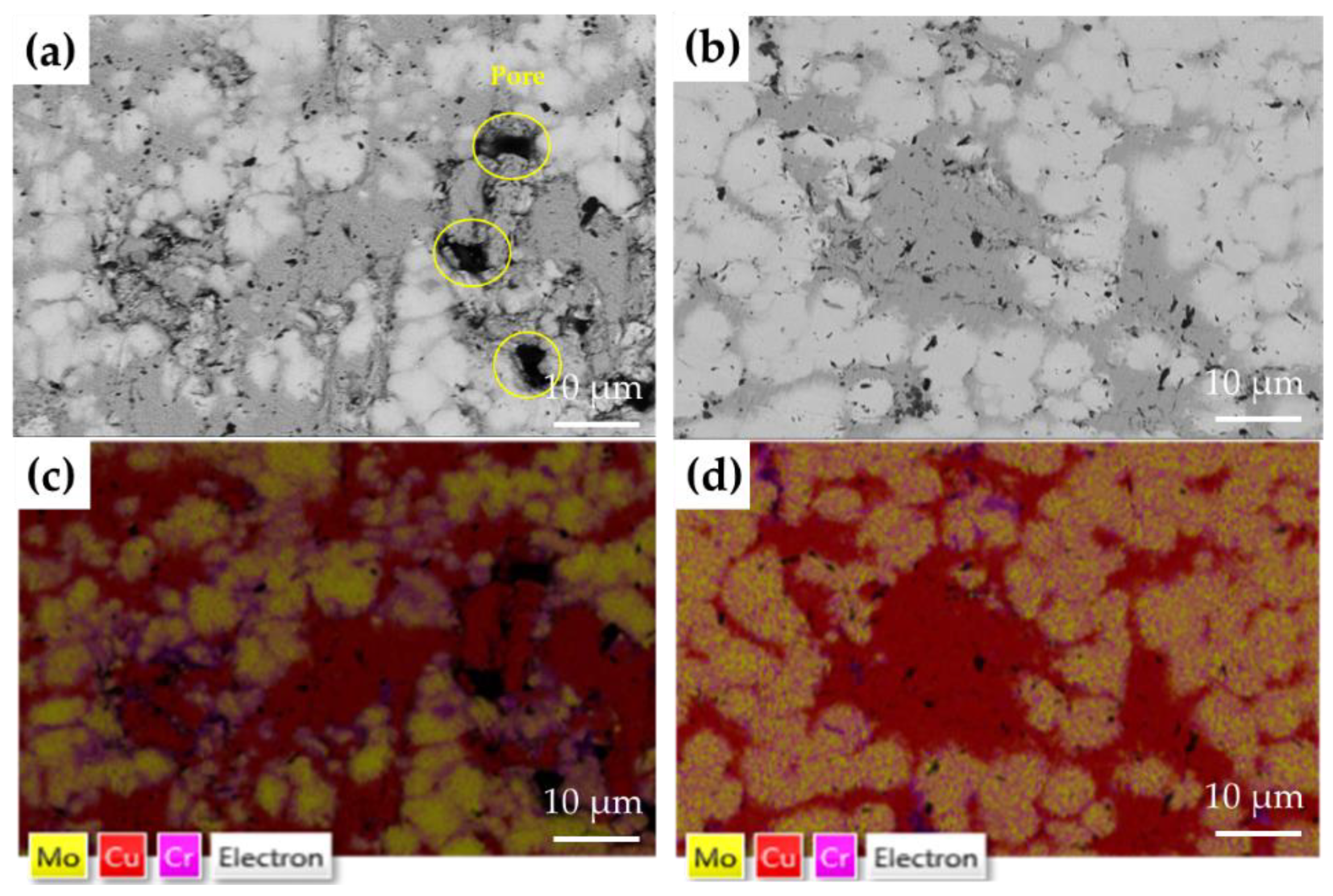

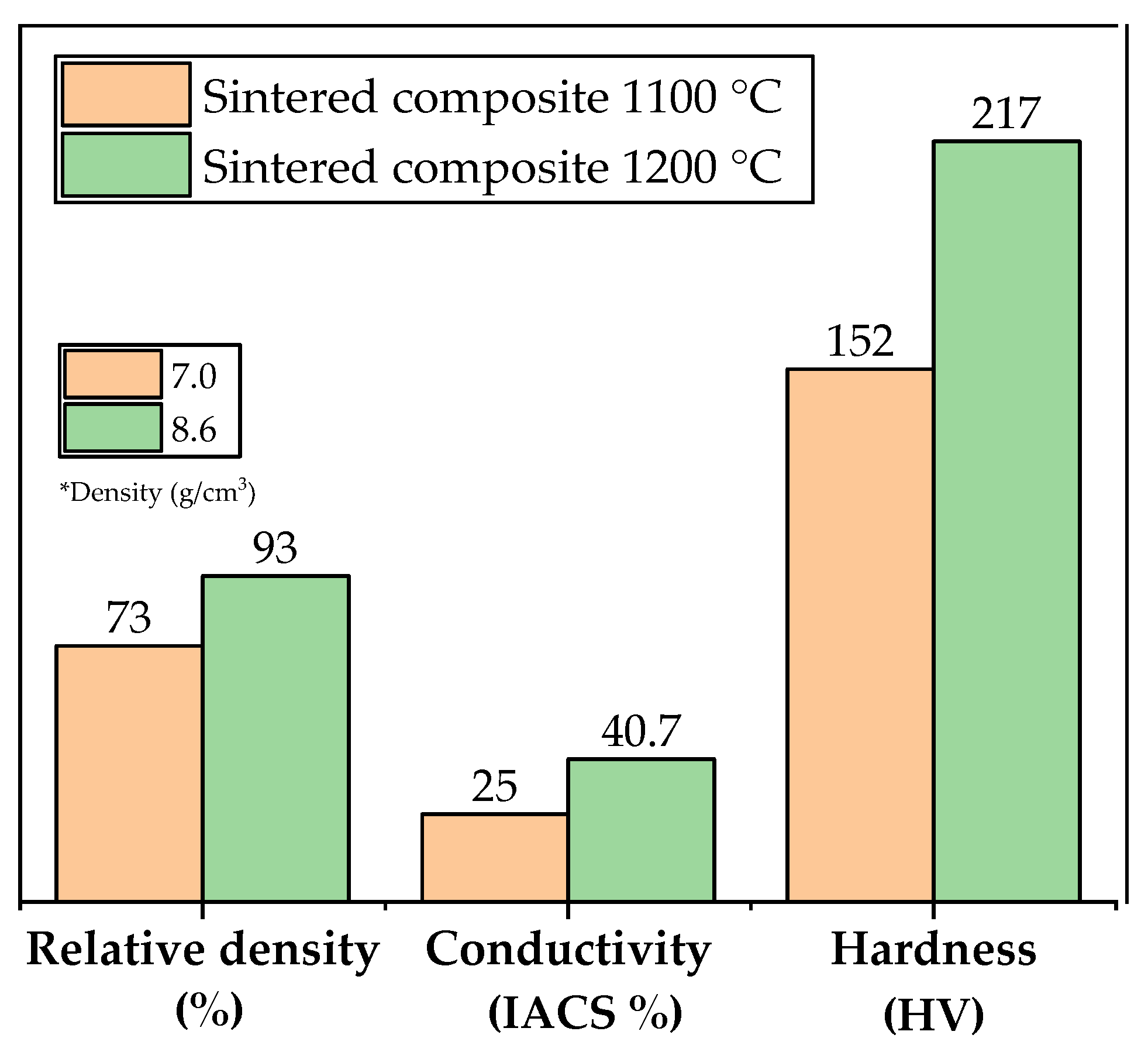

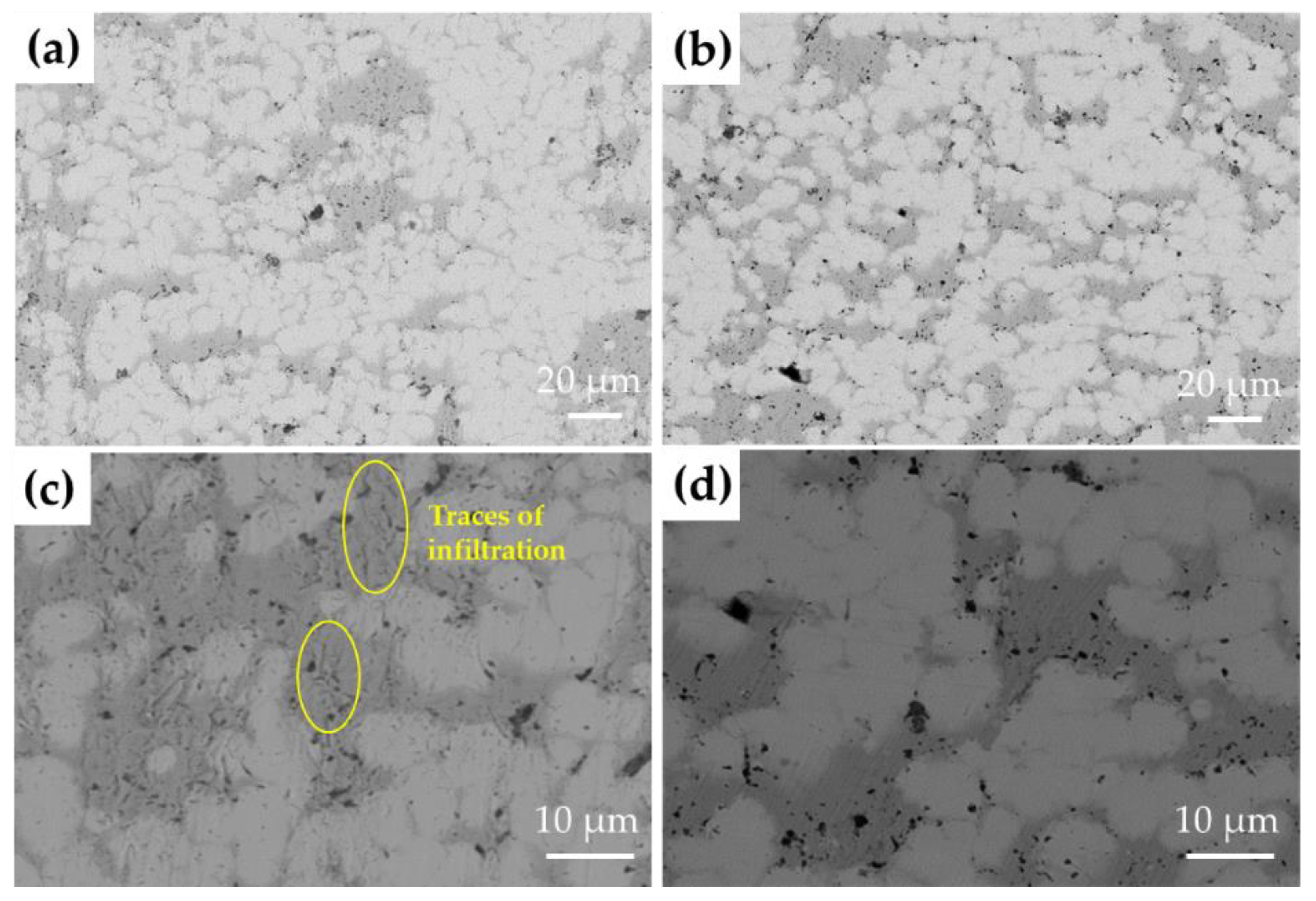

3.3. Sintering (Case (a))

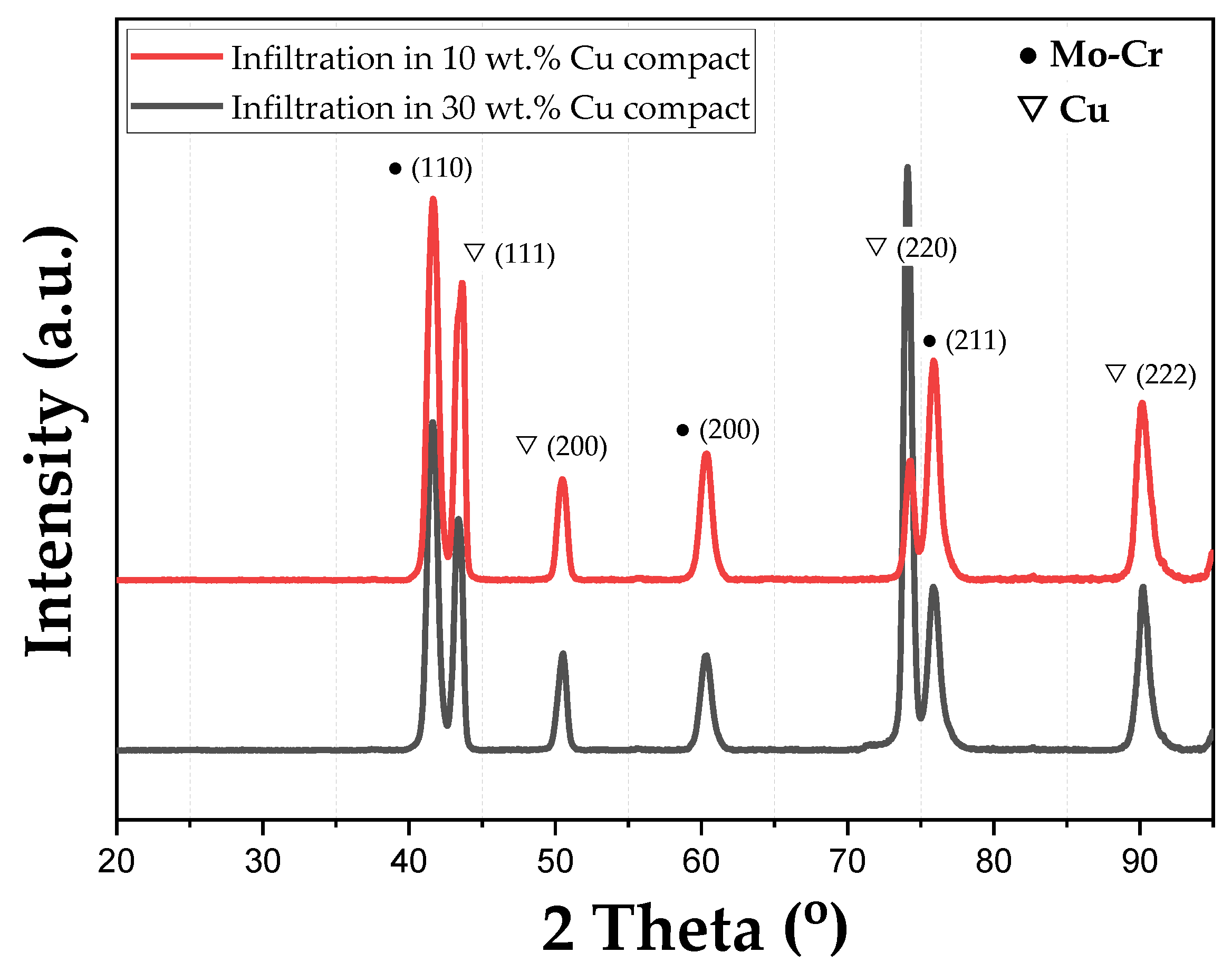

3.4. Infiltration (Case (b))

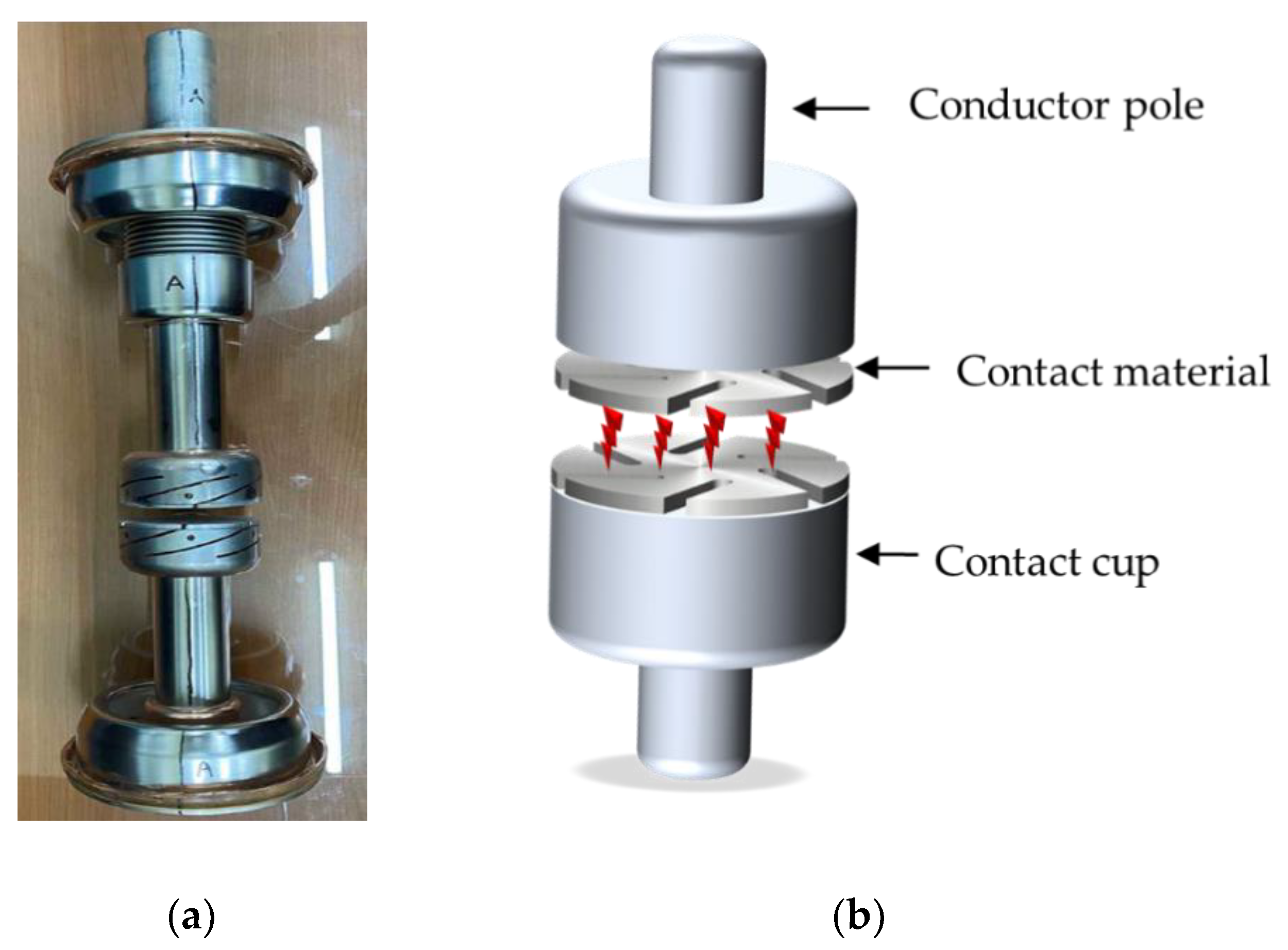

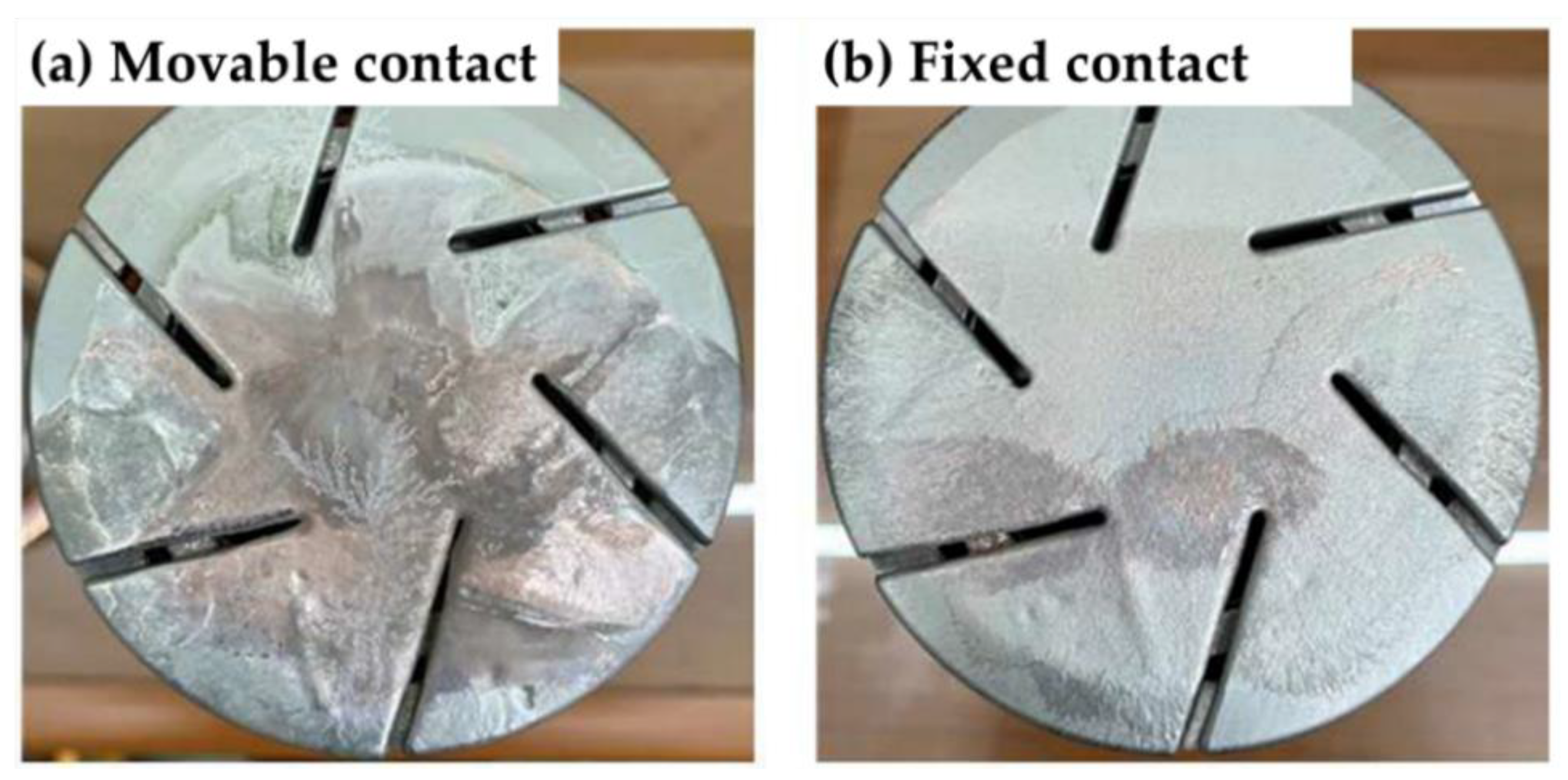

3.5. Short-Circuit Test

4. Conclusions

- Cu–Cr–Mo composite produced by sintering generated better mechanical properties and homogeneous structure at a sintering temperature of 1200 °C (sample no. 2) than at 1100 °C (sample no. 1).

- In case of the Cu–Cr–Mo composite manufactured by Cu infiltration method, sample 3 (10 wt.% Cu compact) showed the high density and hardness. Some segregation was also observed due to infiltration of large amounts of Cu. Sample 4 (30 wt.% Cu compact) exhibited the high electrical conductivity. Composites produced by infiltration method had better mechanical properties than those fabricated by sintering method.

- The measurements of mechanical properties and short-circuit tests depicted a new possibility of using the Cu–Cr–Mo composite as a contact material for high-voltage vacuum interrupters. These preliminary results necessitate further research on this topic.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Slade, P.G. Advances in material development for high power, vacuum interrupter contacts. IEEE Trans. Comp. Pack. Manuf. 1994, 17, 96–106. [Google Scholar] [CrossRef]

- Doh, J.M.; Park, J.K.; Kim, M.J. Method of Controlling the Microstructures of Cu-Cr-Based Contact Materials for Vacuum Interrupters and Contact Materials Manufactured by the Method. U.S. Patent 6,551,374, 22 April 2003. [Google Scholar]

- Miao, B.; Zhang, Y.; Liu, G. Current Status and Developing Trends of Cu-Cr Manufacturing Technique Contact Materials for VCB. In Proceedings of the XXIst International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Yalta Ukraine, Crimea, 27 September–1 October 2004; pp. 311–314. [Google Scholar]

- Xi, S.; Zuo, K.; Li, X.; Ran, G.; Zhou, J. Study on the solid solubility extension of Mo in Cu by mechanical alloying Cu with amorphous Cr(Mo). Acta Mater. 2008, 56, 6050–6060. [Google Scholar] [CrossRef]

- Aguilar, C.; Guzmán, D.; Castro, F.; Martínez, V.; de las Cuevas, F.; Lascano, S.; Muthiah, T. Fabrication of nanocrystalline alloys Cu-Cr-Mo super saturated solid solution by mechanical alloying. Mater. Chem. Phys. 2014, 146, 493–502. [Google Scholar] [CrossRef]

- Kumar, A.; Pradhan, S.K.; Jayasankar, K.; Debata, M.; Sharma, R.K.; Mandal, A. Structural investigations of nanocrystalline Cu-Cr-Mo alloy prepared by high-energy ball milling. J. Electron. Mater. 2017, 46, 1339–1347. [Google Scholar] [CrossRef]

- Venkatraman, M.; Neumann, J.P. The Cr-Mo (chromium–molybdenum) system. Bull. Alloy Phase Diagr. 1987, 8, 216–220. [Google Scholar] [CrossRef]

- He, G.; Zhao, P.; Guo, S.; Chen, Y.; Liu, G.; Li, J. In suit synthesis and bonding of Cu to W–Cu composite by combustion synthesis and centrifugal infiltration. J. Alloys Compd. 2013, 579, 71–74. [Google Scholar] [CrossRef]

- Hamidi, A.G.; Arabi, H.; Rastegari, S. Tungsten–copper composite production by activated sintering and infiltration. Int. J. Refract. Met. Hard Mater. 2011, 29, 538–541. [Google Scholar] [CrossRef]

- Zhou, K.; Chen, W.G.; Wang, J.J.; Yan, G.J.; Fu, Y.Q. W-Cu composites reinforced by copper coated graphene prepared using infiltration sintering and spark plasma sintering: A comparative study. Int. J. Refract. MET 2019, 82, 91–99. [Google Scholar] [CrossRef]

- Maiti, K.; Zinzuwadia, M.; Nemade, J. Preparation and characterization Cu-Cr contact material and study their hardness and conductivity. Adv. Mater. Res. 2012, 585, 250–254. [Google Scholar] [CrossRef]

- Selte, A.; Ozkal, B. Infiltration behavior of mechanical alloyed 75 wt% Cu-25 wt% WC powders into porous WC compacts. Arch. Metall. Mater. 2015, 60, 1556–1568. [Google Scholar] [CrossRef]

- Miao, B.; Zhang, Y.; Zhao, Y.; Liu, G. Two new Cu-Cr alloy contact materials. In Proceedings of the 19th International Symposium on Discharges and Electrical Insulation in Vacuum (Cat. No.00CH37041) ISDEIV, Xi’an, China, 18–22 September 2000; pp. 729–732. [Google Scholar]

- Kumar, M.S.; Natrayan, L.; Henmanth, R.D.; Annamalai, K.; Karthick, E. Experimental investigations on mechanical and microstructure properties of Al2O3/SiC reinforced hybrid metal matrix composite. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 1–9. [Google Scholar] [CrossRef]

- Liu, B.; Xie, J.; Qu, X. Fabrication of W–Cu functionally graded materials with high density by particle size adjustment and solid state hot press. Compos. Sci. Technol. 2008, 68, 1539–1547. [Google Scholar] [CrossRef]

- Lahiri, I.; Bhargava, S. Compaction and sintering response of mechanically alloyed Cu–Cr powder. J. Powder Technol. 2009, 189, 433–438. [Google Scholar] [CrossRef]

- Wang, D.; Dong, X.; Zhou, P.; Sun, A. The sintering behavior of ultra-fine Mo–Cu composite powders and the sintering properties of the composite compacts. Int. J. Refract. Met. Hard Mater. 2016, 42, 240–245. [Google Scholar] [CrossRef]

- Wang, D.; Yin, B.; Sun, A.; Li, X.; Qi, C.; Duan, B. Fabrication of Mo-Cu composite powders by heterogeneous precipitation and the sintering properties of the composite compacts. J. Alloys Compd. 2014, 674, 347–352. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, X.J.; Gang, T.; Du, C.X. CuCr bulk alloy produced by mechanical alloying and explosive compaction. Trans. Nonferr. Metal. Soc. 2009, 19, 626–629. [Google Scholar]

- Hou, C.; Song, X.; Tang, F.; Li, Y.; Cao, L.; Wang, J.; Nie, Z. W–Cu composites with submicron- and nanostructures: Progress and challenges. NPG Asia Mater. 2019, 11, 1–20. [Google Scholar] [CrossRef]

- Borji, S.; Ahangarkani, K. The effect of sintering activator on the erosion behavior of infiltrated W-10wt%Cu composite. Int. J. Refract. Met. Hard Mater. 2017, 66, 150–157. [Google Scholar] [CrossRef]

- Xu, L.; Yan, M.; Xia, Y.; Peng, J.; Li, W.; Zhang, L.; Liu, C.; Chen, G.; Li, Y. Influence of copper content on the property of Cu–W alloy prepared by microwave vacuum infiltration sintering. J. Alloys Compd. 2014, 592, 202–206. [Google Scholar] [CrossRef]

- Kim, K.H.; Yoon, W.Y. Estimation of the infiltration potential of Cu-Alloy for core bits. Korean J. Met. Mater. 2016, 54, 138–144. [Google Scholar] [CrossRef]

- Ahangarkani, M.; Zangeneh-Madar, K. Investigation on the microstructure and properties of W-10wt% Cu prepared by sintering and infiltration. Int. J. Refract. Met. Hard Mater. 2018, 75, 1–9. [Google Scholar] [CrossRef]

- Jiang, K.; Wang, F.; Zhang, J. Experimental study on sintering and infiltration process of metal part fabricated by mold decomposed injection sculpturing. Rev. Adv. Mater. Sci. 2013, 33, 322–329. [Google Scholar]

- Hakamada, M.; Kuromura, T.; Chen, Y.; Kusuda, H.; Mabuchi, M. Influence of porosity and pore size on electrical resistivity of porous aluminum produced by spacer method. Mater. Trans. 2007, 48, 32–36. [Google Scholar] [CrossRef]

- Liu, J.; Wang, K.; Chou, K.; Zhang, G. Fabrication of ultrafine W-Cu composite powders and its sintering behavior. J. Mater. Sci. Technol. 2020, 9, 2154–2163. [Google Scholar] [CrossRef]

- Ibrahim, H.; Aziz, A.; Rahmat, A. Enhanced liquid-phase sintering of W–Cu composites by liquid infiltration. Int. J. Refract. Met. Hard Mater. 2014, 43, 222–226. [Google Scholar] [CrossRef]

- Shi-Xin, X.; Ren, Y.; Jun, X.; Jin-xing, W.; Jia-yi, W. Microstructure and properties of CuCr contact materials with different Cr content. Trans. Nonferr. Met. Soc. 2011, 21, 389–393. [Google Scholar]

- Dietmar, G. Welding behavior of vacuum interrupters equipped with CuCr contact material caused by making and breaking operations under short circuit current interruption. In Proceedings of the 2012 25th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Tomsk, Russia, 2–7 September 2012; Volume 978, pp. 213–216. [Google Scholar]

- Peng, L.; Xiaofei, Y.; Shi, Z. Comparison of electrical performance of CuCr contact materials manufactured by two methods. In Proceedings of the 2018 28th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Greifswald, Germany, 23–28 September 2018; pp. 607–610. [Google Scholar]

- Gentsch, D. Contact Material for Vacuum Interrupters based on CuCr with a Specific High Short Circuit Interruption Ability. In Proceedings of the XXIInd International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Matsue, Japan, 25–29 September 2006; pp. 437–442. [Google Scholar]

- Wei, X.; Wang, J.; Yang, Z.; Sun, Z.; Yu, D.; Song, X.; Ding, B.; Yang, S. Liquid phase separation of Cu–Cr alloys during the vacuum breakdown. J. Alloys Compd. 2011, 509, 7116–7120. [Google Scholar] [CrossRef]

- Fink, H.; Gentsch, D.; Heimbach, M. Multilayer contact material based on copper and chromium material and its interruption ability. IEEE Trans. Plasma Sci. 2003, 31, 973–976. [Google Scholar] [CrossRef]

- Laijun, Z.; Zhenbiao, L. Electrical properties of nanocrystalline CuCr25 contact material. IEEE Trans. Comp. Pack. Manuf. 2013, 3, 625–632. [Google Scholar]

- Zinzuwadia, M.; Maiti, K.; Kulkarni, S.; Nemade, J.; Rayudu, S. Failure analysis of CuCr Contacts of Vacuum interrupter. In Proceedings of the 2014 XXVth International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Mumbai, India, 28 September–3 October 2014; pp. 745–747. [Google Scholar]

- Aherwar, A.; Patnaik, A.; Bahraminasab, M. Effect of molybdenum contact on structure and properties of a Co-Cr biomedical alloy. J. Mater. Eng. Perform. 2019, 28, 6340–6353. [Google Scholar] [CrossRef]

| Process | Sample No. | Composition (wt.%) | Heat Treatment Temperature (°C) | Shrinkage Rate (%) | |

|---|---|---|---|---|---|

| Sintering | Case (a) | Sample (No. 1) | 60Cu–10Cr–30Mo | 1100 | 3 |

| Sample (No. 2) | 60Cu–10Cr–30Mo | 1200 | 9 | ||

| Infiltration | Case (b) | Sample (No. 3) | 10Cu–10Cr–30Mo + 50Cu block | 1300 | 1 |

| Sample (No. 4) | 30Cu–10Cr–30Mo + 30Cu block | 1300 | 5 | ||

| Contact Properties | This Paper | Maitai et al. [11] | Shi-xin et al. [29] | Peng et al. [31] | Harald et al. [34] | Laijun et al. [35] | |

|---|---|---|---|---|---|---|---|

| Fabrication process | Sintering | Infiltration | Sintering | Vacuum casting | Vacuum arc melting | Sintering and Melting | Sintering by hot pressing |

| Cr content (%) | 10 | 10 | 25 | 40 | 30 | 25 | 25 |

| Mo content (%) | 30 | 30 | 0 | 0 | 0 | 0 | 0 |

| Electrical conductivity (%IACS) | 40.7 | 42.2 | 37.9 to 43.1 | 41.03 | 52.59 | 30 to 35 | 39.83 |

| Hardness (HV) | 217 | 227.5 | 95 | 96 | 98 to 103 | 76 to 85 | 150 |

| Short-circuit breaking current of VI (kA) | 40 | - | - | 21.3 | 25 | 20 to 48 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, Y.-W.; Sim, J.-J.; Byeon, J.-S.; Kim, T.-S.; Lee, K.-A.; Ju, H.-J.; Seo, S.-J.; Park, K.-T. Comparative Study of the Properties of Cu-Cr-Mo System Electrical Contact Material by Sintering and Infiltration Methods. Metals 2021, 11, 700. https://doi.org/10.3390/met11050700

Cho Y-W, Sim J-J, Byeon J-S, Kim T-S, Lee K-A, Ju H-J, Seo S-J, Park K-T. Comparative Study of the Properties of Cu-Cr-Mo System Electrical Contact Material by Sintering and Infiltration Methods. Metals. 2021; 11(5):700. https://doi.org/10.3390/met11050700

Chicago/Turabian StyleCho, Yeong-Woo, Jae-Jin Sim, Jong-Soo Byeon, Taek-Soo Kim, Kee-Ahn Lee, Heung-Jin Ju, Seok-Jun Seo, and Kyoung-Tae Park. 2021. "Comparative Study of the Properties of Cu-Cr-Mo System Electrical Contact Material by Sintering and Infiltration Methods" Metals 11, no. 5: 700. https://doi.org/10.3390/met11050700

APA StyleCho, Y.-W., Sim, J.-J., Byeon, J.-S., Kim, T.-S., Lee, K.-A., Ju, H.-J., Seo, S.-J., & Park, K.-T. (2021). Comparative Study of the Properties of Cu-Cr-Mo System Electrical Contact Material by Sintering and Infiltration Methods. Metals, 11(5), 700. https://doi.org/10.3390/met11050700