Phase Formation and Wear Resistance of Carbon-Doped TiZrN Nanocomposite Coatings by Laser Carburization

Abstract

1. Introduction

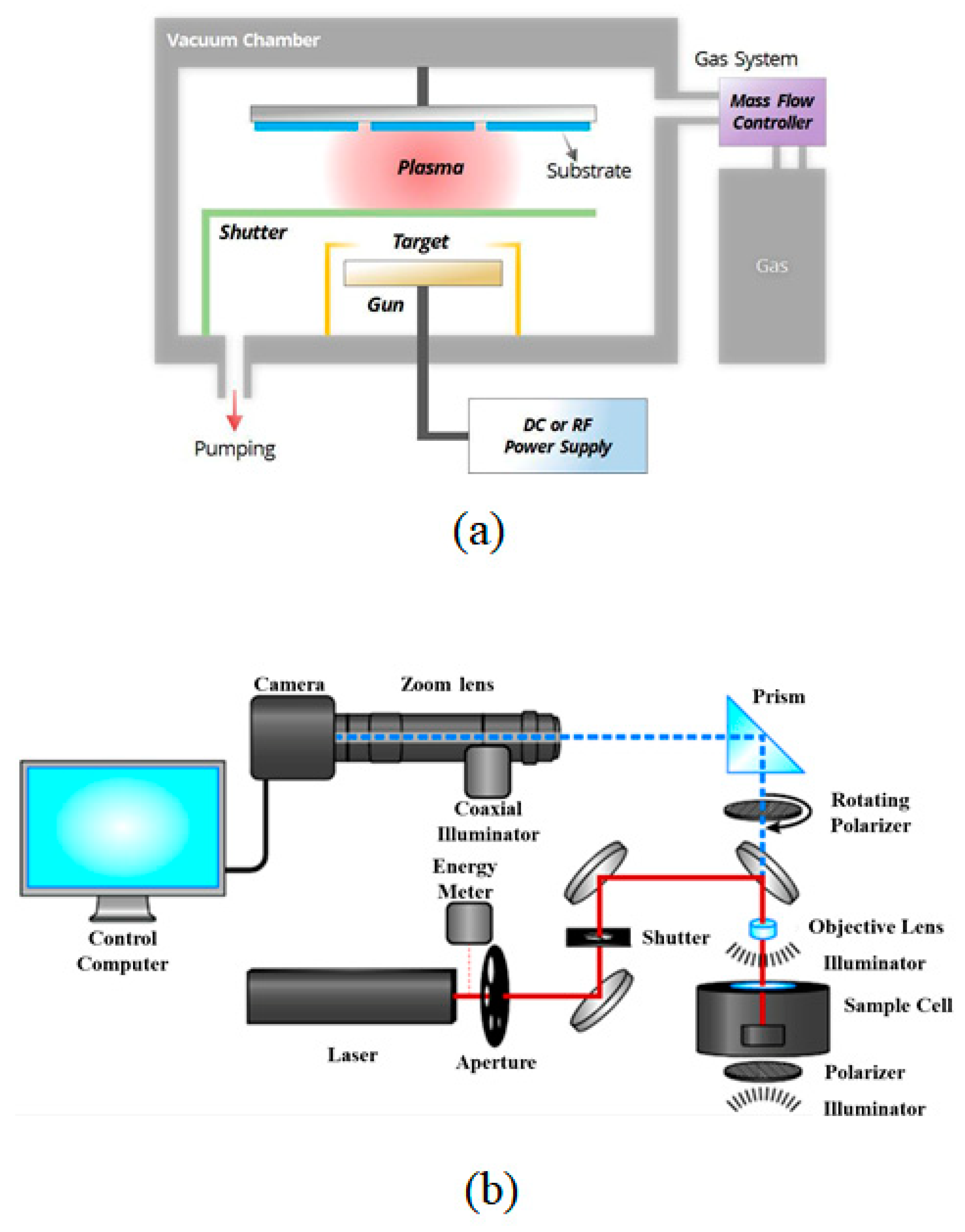

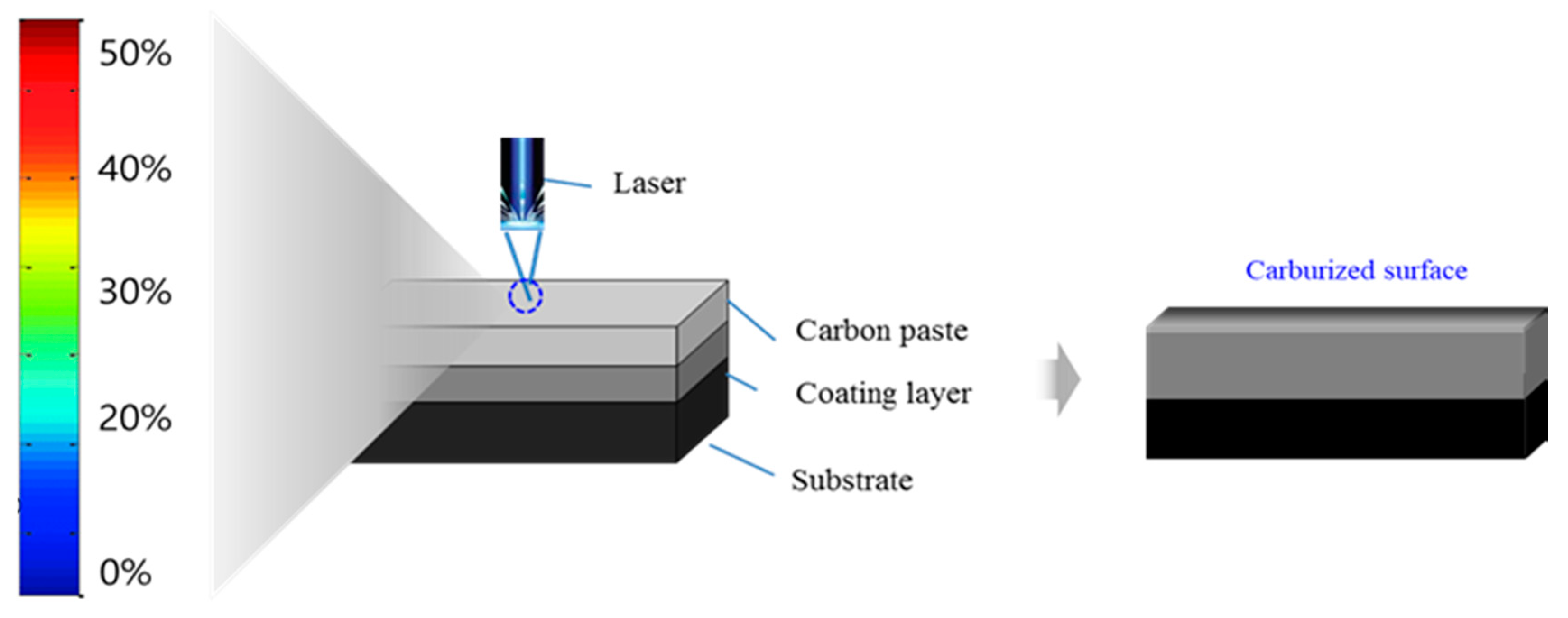

2. Materials and Methods

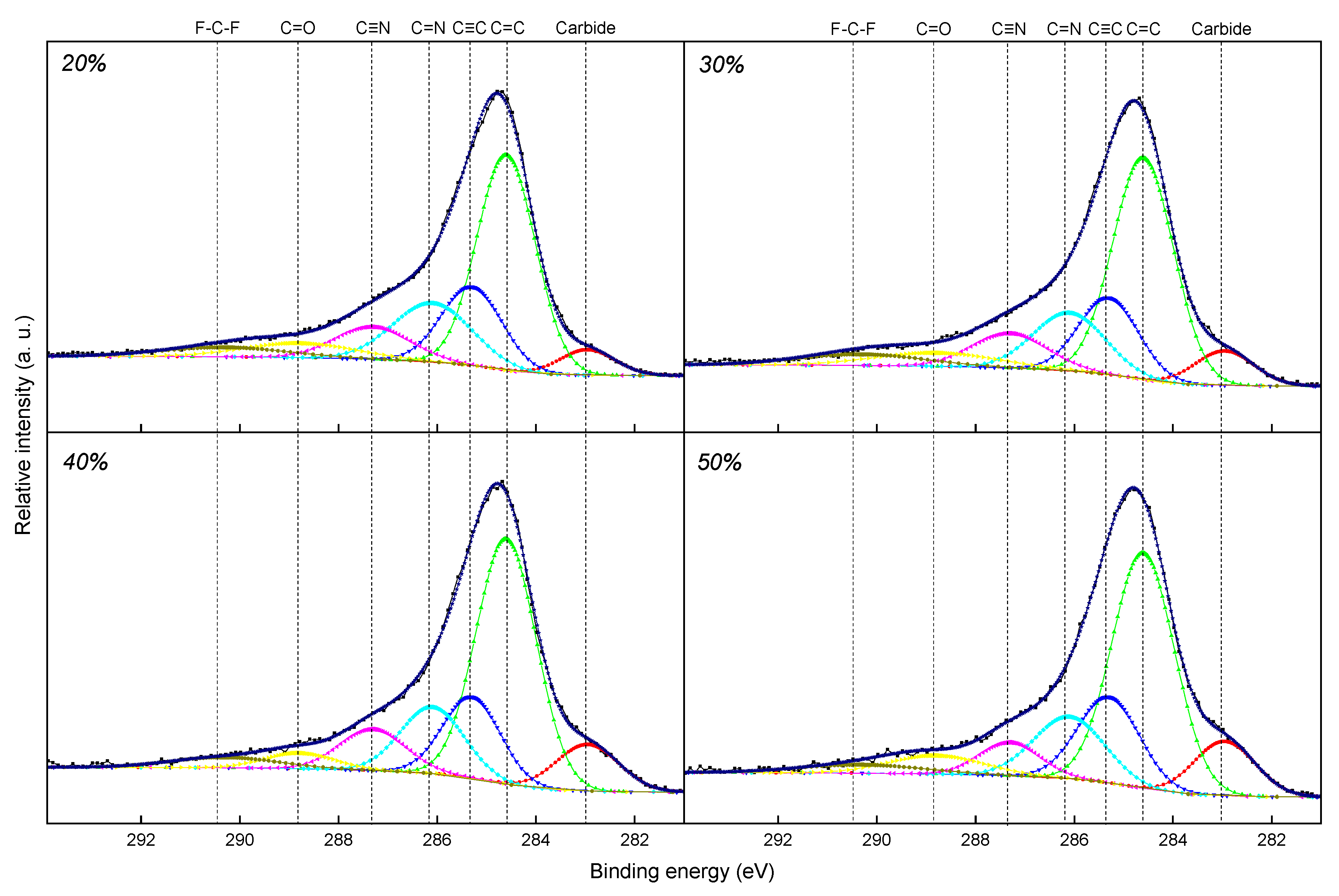

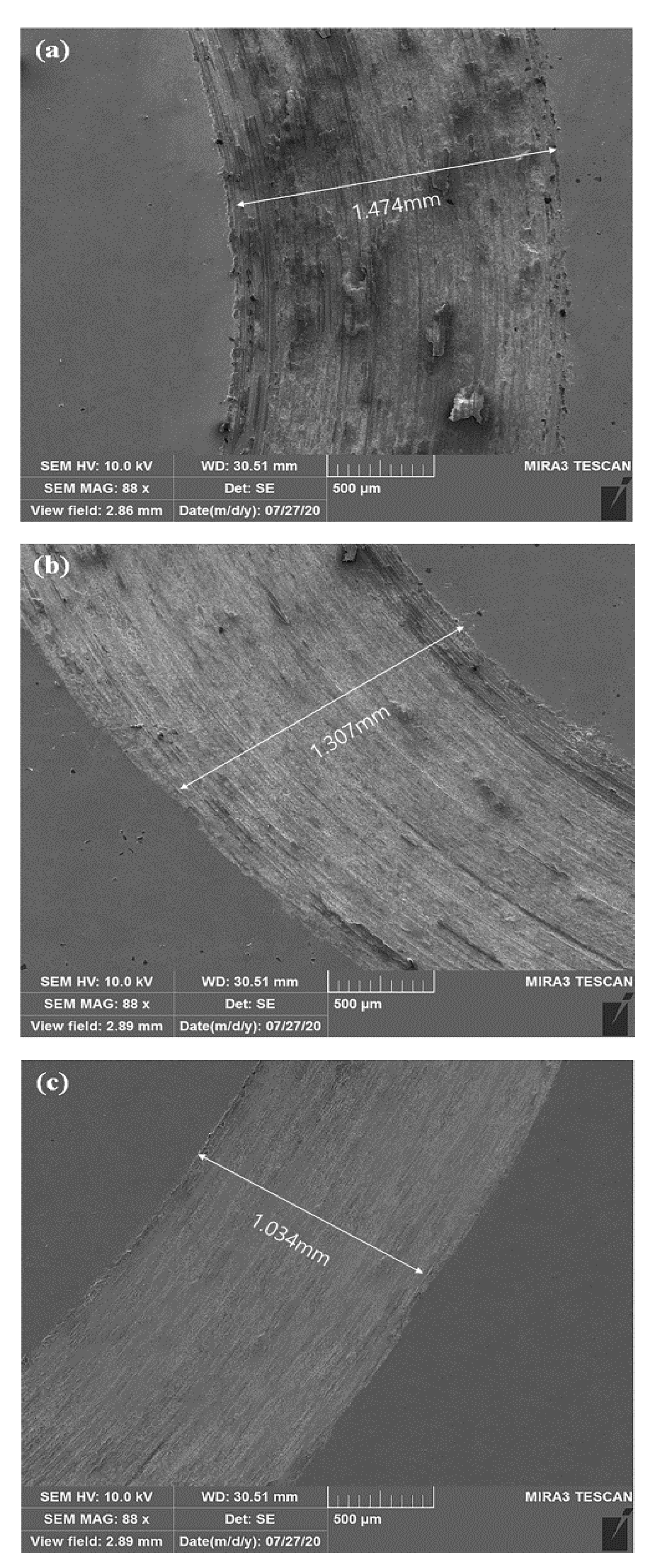

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Djafer, A.Z.A.; Saoula, N.; Madaoui, N.; Zerizer, A. Deposition and characterization of titanium carbide thin films by magnetron sputtering using Ti and TiC targets. Appl. Surf. Sci. 2014, 312, 57–62. [Google Scholar] [CrossRef]

- Yate, L.; Coy, L.E.; Wang, G.; Beltrán, M.; Díaz-Barriga, E.; Załęski, K.; Llarena, I.; Möller, M.; Saucedo, E.M.; Ceniceros, M.A.; et al. Tailoring mechanical properties and electrical conductivity of flexible niobium carbide nanocomposite thin films. RSC Adv. 2014, 4, 61355–61362. [Google Scholar] [CrossRef]

- Bressan, J.; Hesse, R.; Silva, E. Abrasive wear behavior of high speed steel and hard metal coated with TiAlN and TiCN. Wear 2001, 250, 561–568. [Google Scholar] [CrossRef]

- Chuan, S.P.; Ghani, J.A.; Tomadi, S.H.; Hassan, C.H.C. Analysis of Ti-base Hard Coating Performance in Machining Process: A Review. J. Appl. Sci. 2012, 12, 1882–1890. [Google Scholar] [CrossRef]

- Liu, S.; Wheeler, J.M.; Howie, P.R.; Zeng, X.T.; Michler, J.; Clegg, W.J. Measuring the fracture resistance of hard coatings. Appl. Phys. Lett. 2013, 102, 171907. [Google Scholar] [CrossRef]

- Ghareshabani, E.; Rawat, R.S.; Sobhanian, S.; Verma, R.; Karamat, S.; Pan, Z. Synthesis of nanostructured multiphase Ti(C,N)/a-C films by a plasma focus device. Nucl. Instruments Methods Phys. Res. Sect. B: Beam Interactions Mater. Atoms 2010, 268, 2777–2784. [Google Scholar] [CrossRef]

- Cheng, K.-Y.; Pagan, N.; Bijukumar, D.; Mathew, M.T.; McNallan, M. Carburized titanium as a solid lubricant on hip implants: Corrosion, tribocorrosion and biocompatibility aspects. Thin Solid Films 2018, 665, 148–158. [Google Scholar] [CrossRef]

- Robertson, J. Amorphous carbon. Adv. Phys. 1986, 35, 317–374. [Google Scholar] [CrossRef]

- Bhushan, B. Modern Tribology Handbook, Two Volume Set; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Ye, Y.; Wang, Y.; Chen, H.; Li, J.; Yao, Y.; Wang, C. Doping carbon to improve the tribological performance of CrN coatings in seawater. Tribol. Int. 2015, 90, 362–371. [Google Scholar] [CrossRef]

- Stueber, M.; Barna, P.; Simmonds, M.; Albers, U.; Leiste, H.; Ziebert, C.; Holleck, H.; Kovács, A.; Hovsepian, P.; Gee, I. Constitution and microstructure of magnetron sputtered nanocomposite coatings in the system Ti–Al–N–C. Thin Solid Films 2005, 493, 104–112. [Google Scholar] [CrossRef]

- Stueber, M.; Albers, U.; Leiste, H.; Ulrich, S.; Holleck, H.; Barna, P.; Kovacs, A.; Hovsepian, P.; Gee, I. Multifunctional nanolaminated PVD coatings in the system Ti–Al–N–C by combination of metastable fcc phases and nanocomposite microstructures. Surf. Coatings Technol. 2006, 200, 6162–6171. [Google Scholar] [CrossRef]

- Hong, E.; Kim, T.; Kim, S.; Lee, S.; Lee, H. Carbon depth profile and internal stress by thermal energy variation in carbon-doped TiZrN coating. J. Am. Ceram. Soc. 2021, 104, 564–571. [Google Scholar] [CrossRef]

- Kim, T.; Jo, S.-H.; Lee, J.W.; Cho, H.; Lee, H. Surface graphitization of carbon-doped TiZrN coatings. Ceram. Int. 2019, 45, 1790–1793. [Google Scholar] [CrossRef]

- Li, J.; Zhang, S.; Li, M. Influence of the C2H2 flow rate on gradient TiCN films deposited by multi-arc ion plating. Appl. Surf. Sci. 2013, 283, 134–144. [Google Scholar] [CrossRef]

- Lackner, J.; Waldhauser, W.; Ebner, R.; Keckés, J.; Schöberl, T. Room temperature deposition of (Ti,Al)N and (Ti,Al)(C,N) coatings by pulsed laser deposition for tribological applications. Surf. Coatings Technol. 2004, 177–178, 447–452. [Google Scholar] [CrossRef]

- Korotaev, A.D.; Litovchenko, I.Y.; Ovchinnikov, S.V. Structural-Phase State, Elastic Stress, and Functional Properties of Nanocomposite Coatings Based on Amorphous Carbon. Phys. Mesomech. 2019, 22, 488–495. [Google Scholar] [CrossRef]

- Park, S.-I.; Quan, Y.-J.; Kim, S.-H.; Kim, H.; Kim, S.; Chun, D.-M.; Lee, C.S.; Taya, M.; Chu, W.-S.; Ahn, S.-H. A review on fabrication processes for electrochromic devices. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 397–421. [Google Scholar] [CrossRef]

- CETAC LSX-213 G2+/LSX-266 Operator’s Manual. Available online: http://minerva.union.edu/hollochk/laser_ablation/other_documents/480141_LSX213_Operators_Manual_rev2f.pdf (accessed on 2 April 2021).

- Iso 20808, (ISO standard, Fine ceramics (Advanced ceramics, advanced technical ceramics) – Determination of friction and wear characteristics of monolithic ceramics by ball-on-disc method, 2016).

- Lesiak, B.; Kövér, L.; Tóth, J.; Zemek, J.; Jiricek, P.; Kromka, A.; Rangam, N. C sp2/sp3 hybridisations in carbon nanomaterials – XPS and (X)AES study. Appl. Surf. Sci. 2018, 452, 223–231. [Google Scholar] [CrossRef]

- Li, X.; Zhang, N.; Lee, K.-R.; Wang, A. Effect of metal doping on structural characteristics of amorphous carbon system: A first-principles study. Thin Solid Films 2016, 607, 67–72. [Google Scholar] [CrossRef]

- Liu, D.; Zheng, L.; Liu, J.; Luo, L.; Wu, Y. Residual stress relief of hard a-C films though buckling. Ceram. Int. 2018, 44, 3644–3648. [Google Scholar] [CrossRef]

- Rai, S.K.; Kumar, A.; Shankar, V.; Jayakumar, T.; Rao, K.B.S.; Raj, B. Characterization of microstructures in Inconel 625 using X-ray diffraction peak broadening and lattice parameter measurements. Scr. Mater. 2004, 51, 59–63. [Google Scholar] [CrossRef]

- Ungár, T. Microstructural parameters from X-ray diffraction peak broadening. Scr. Mater. 2004, 51, 777–781. [Google Scholar] [CrossRef]

- Zehnder, T.; Patscheider, J. Nanocomposite TiC/a–C:H hard coatings deposited by reactive PVD. Surf. Coatings Technol. 2000, 133–134, 138–144. [Google Scholar] [CrossRef]

- Park, I.-W.; Choi, S.R.; Suh, J.H.; Park, C.-G.; Kim, K.H. Deposition and mechanical evaluation of superhard Ti–Al–Si–N nanocomposite films by a hybrid coating system. Thin Solid Films 2004, 447–448, 443–448. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Xue, Z.; Ma, F.; Zhang, K.; Chen, X.; Feng, R.; Liaw, P.K. Microstructures, mechanical behavior and strengthening mechanism of TiSiCN nanocomposite films. Sci. Rep. 2017, 7, 2140. [Google Scholar] [CrossRef]

- Wu, Y.; Hong, S.; Zhang, J.; He, Z.; Guo, W.; Wang, Q.; Li, G. Microstructure and cavitation erosion behavior of WC–Co–Cr coating on 1Cr18Ni9Ti stainless steel by HVOF thermal spraying. Int. J. Refract. Met. Hard Mater. 2012, 32, 21–26. [Google Scholar] [CrossRef]

- Forsh, E.; Abakumov, A.; Zaytsev, V.; Konstantinova, E.; Forsh, P.; Rumyantseva, M.; Gaskov, A.; Kashkarov, P. Optical and photoelectrical properties of nanocrystalline indium oxide with small grains. Thin Solid Films 2015, 595, 25–31. [Google Scholar] [CrossRef]

- Okubo, H.; Tadokoro, C.; Sasaki, S. Tribological properties of a tetrahedral amorphous carbon (ta-C) film under boundary lubrication in the presence of organic friction modifiers and zinc dialkyldithiophosphate (ZDDP). Wear 2015, 332–333, 1293–1302. [Google Scholar] [CrossRef]

- Gulbinski, W.; Mathur, S.; Shen, H.; Suszko, T.; Gilewicz, A.; Warcholinski, B. Evaluation of phase, composition, microstructure and properties in TiC/a-C:H thin films deposited by magnetron sputtering. Appl. Surf. Sci. 2005, 239, 302–310. [Google Scholar] [CrossRef]

- Van de Sanden, M.C.M.; Severens, R.J.; Bastiaanssen, J.; Schram, D.C. High-quality a-Si:H growth at high rate using an expanding thermal plasma. Surf. Coatings Technol. 1997, 97, 719–722. [Google Scholar] [CrossRef]

- Li, X.; Deng, X.; Kousaka, H.; Umehara, N. Comparative study on effects of load and sliding distance on amorphous hydrogenated carbon (a-C:H) coating and tetrahedral amorphous carbon (ta-C) coating under base-oil lubrication condition. Wear 2017, 392–393, 84–92. [Google Scholar] [CrossRef]

- Martini, C.; Ceschini, L.; Casadei, B.; Boromei, I.; Guion, J. Dry sliding behaviour of hydrogenated amorphous carbon (a-C:H) coatings on Ti-6Al-4V. Wear 2011, 271, 2025–2036. [Google Scholar] [CrossRef]

| Laser Output (%) | Carbide (%) | sp2 C=C (%) | sp3 C–C (%) | sp2 C=N (%) | sp3 C–N (%) | C=O (%) | FC–F (%) |

|---|---|---|---|---|---|---|---|

| 20 | 4 | 43.6 | 16.9 | 16.2 | 7.5 | 5.6 | 4.8 |

| 30 | 6.2 | 44.2 | 16.2 | 14.5 | 8.7 | 5.4 | 4.7 |

| 40 | 9.4 | 45.1 | 14.9 | 13.2 | 8.4 | 5.1 | 3.5 |

| 50 | 10.1 | 46.2 | 14.2 | 12.7 | 7.2 | 5.3 | 3.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, T.; Hong, E.; Jo, I.; Kim, J.; Lee, H. Phase Formation and Wear Resistance of Carbon-Doped TiZrN Nanocomposite Coatings by Laser Carburization. Metals 2021, 11, 590. https://doi.org/10.3390/met11040590

Kim S, Kim T, Hong E, Jo I, Kim J, Lee H. Phase Formation and Wear Resistance of Carbon-Doped TiZrN Nanocomposite Coatings by Laser Carburization. Metals. 2021; 11(4):590. https://doi.org/10.3390/met11040590

Chicago/Turabian StyleKim, Seonghoon, Taewoo Kim, Eunpyo Hong, Ilguk Jo, Jaeyoung Kim, and Heesoo Lee. 2021. "Phase Formation and Wear Resistance of Carbon-Doped TiZrN Nanocomposite Coatings by Laser Carburization" Metals 11, no. 4: 590. https://doi.org/10.3390/met11040590

APA StyleKim, S., Kim, T., Hong, E., Jo, I., Kim, J., & Lee, H. (2021). Phase Formation and Wear Resistance of Carbon-Doped TiZrN Nanocomposite Coatings by Laser Carburization. Metals, 11(4), 590. https://doi.org/10.3390/met11040590