Surface Structuring via Additive Manufacturing to Improve the Performance of Metal and Polymer Joints

Abstract

1. Introduction

2. Experimental

2.1. Base Materials

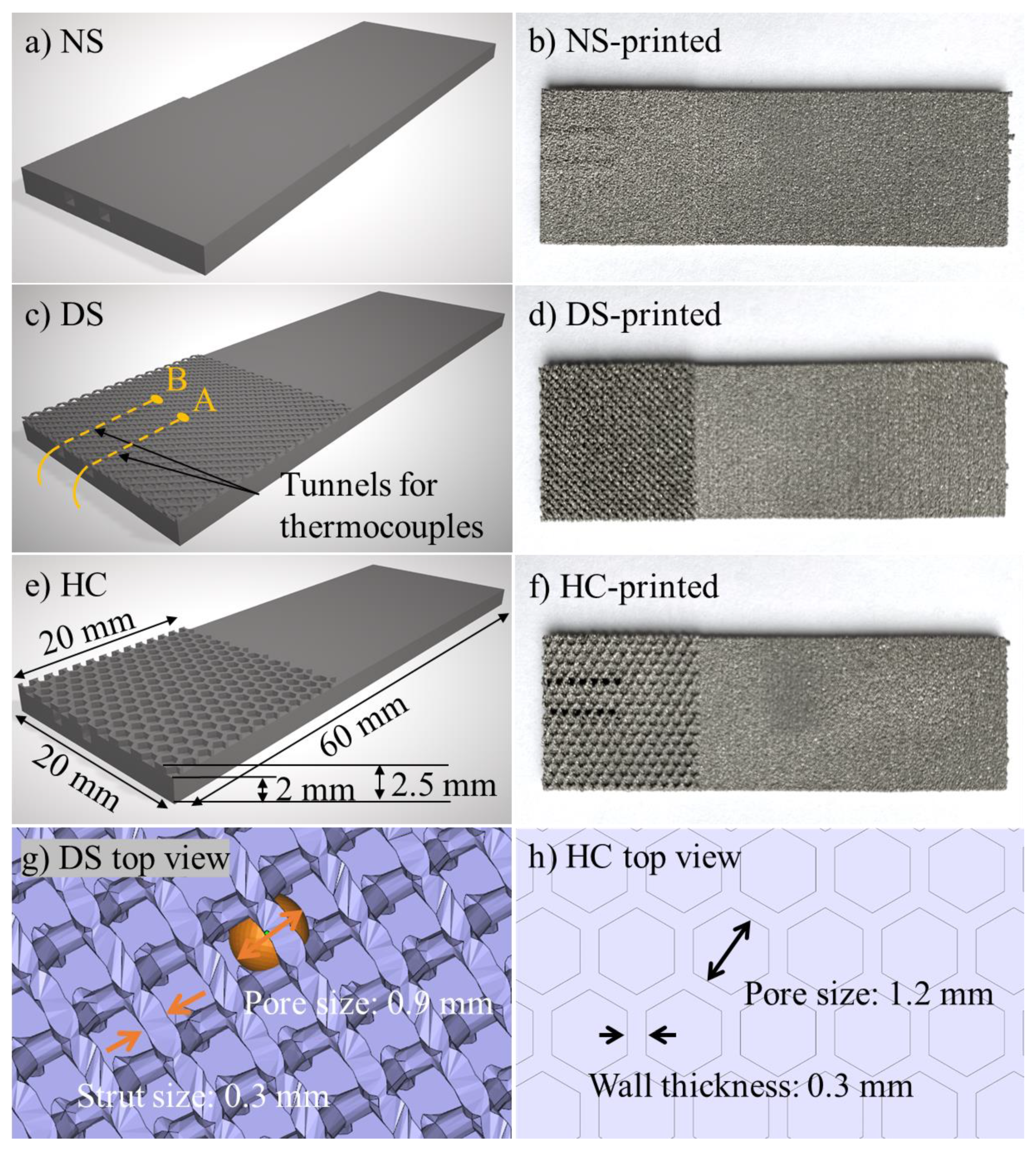

2.2. Surface Structure

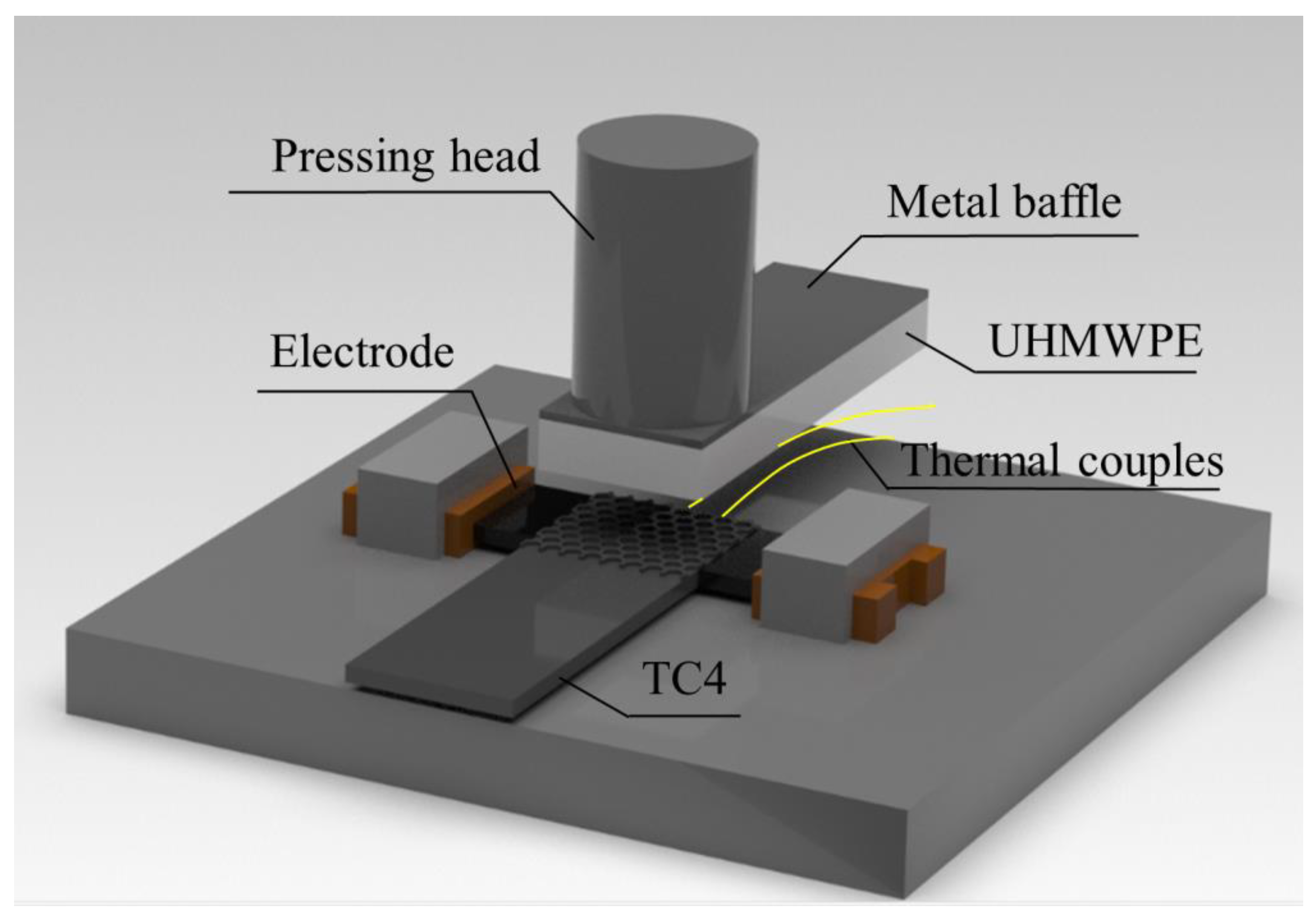

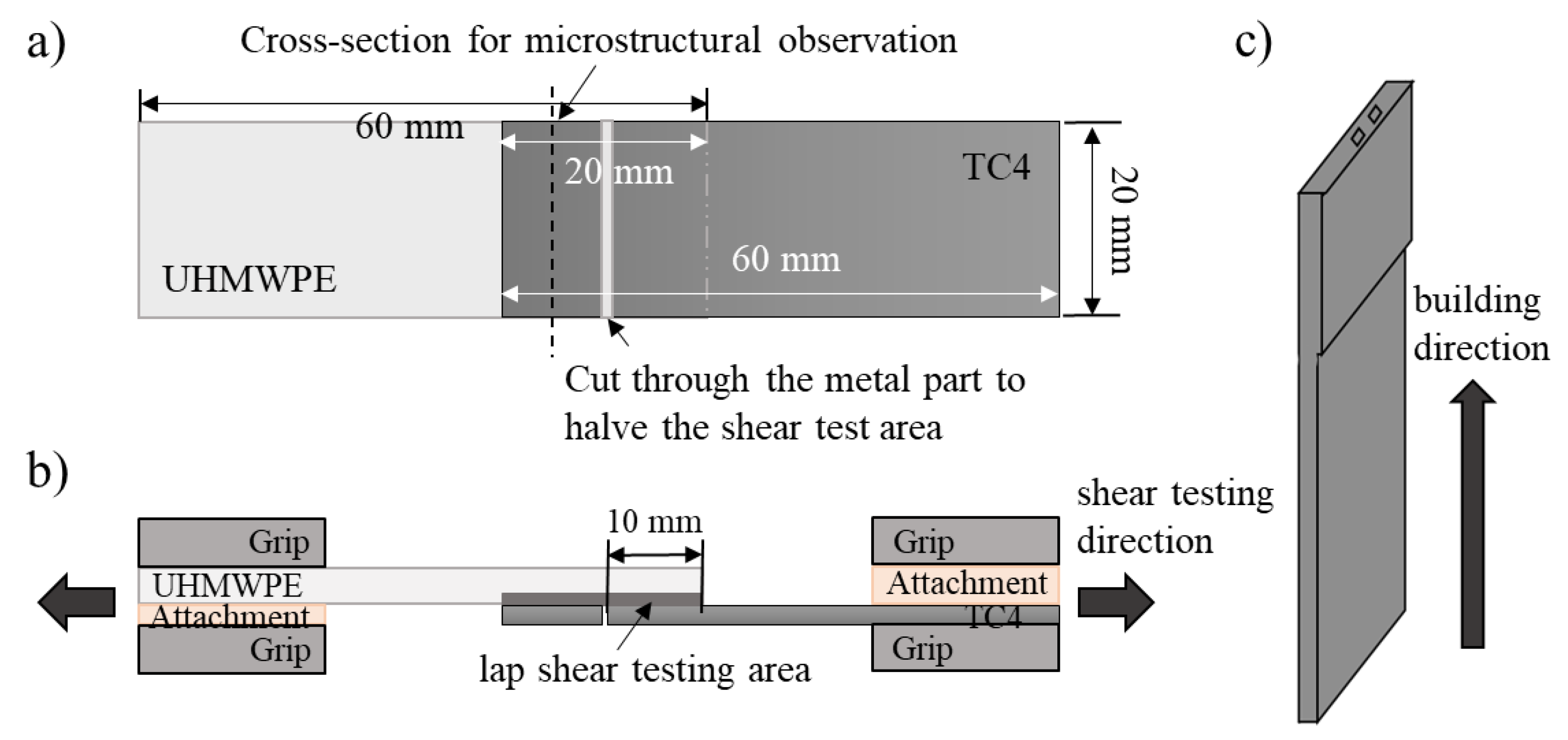

2.3. Joining Technique and Characterization Methods

3. Results

3.1. Macroscale Morphologies of the Joints

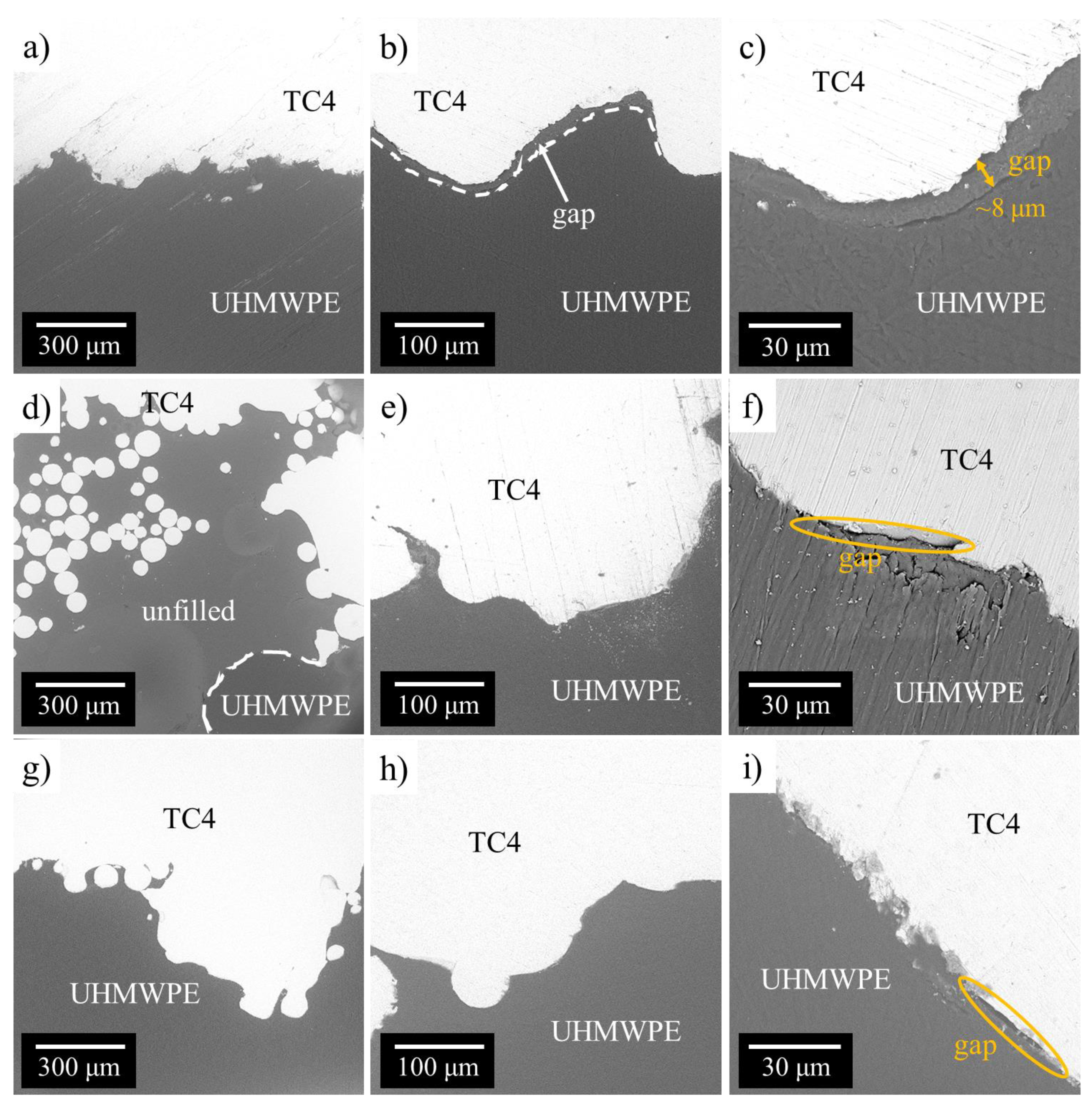

3.2. Evaluation of Microscale Interfaces

3.3. Mechanical Properties of the Joints

3.4. Analyses of Fracture Surface

4. Discussions

4.1. Interfacial Bonding Mechanisms

4.2. Effect of Surface Structuring

4.3. Influence of the Complexity of the Porous Architecture

5. Conclusions

- (1)

- The mechanical properties (ultimate force and failure displacement) of the joints were significantly improved through surface structuring via EBM additive manufacturing. Increasing the surface roughness produced via EBM method processing enhanced the microinterlocking between UHMWPE and TC4, while macroscale porous structuring further enhanced the joint performance at both the macro- and microscale;

- (2)

- The structure complexity and the defects in additive manufacturing should be considered during the surface structure design. Compared with the diamond-shaped architecture, the simplified honeycomb architecture improved the filling efficiency and the mechanical performance, showing better stability;

- (3)

- The interfacial bonding mechanisms of the TC4–UHMWPE joint were mainly attributed to macro- and micromechanical interlocking, along with van der Waals forces and chemical bonding (through -C=O and Ti). Specifically, mechanical interlocking played the dominant role in enhancing the joint strength. Additionally, combining macro- and micromechanical interlocking is a promising strategy to significantly impede the shrinkage of polymer during cooling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shen, F.W. Ultrahigh-molecular-weight polyethylene (UHMWPE) in joint replacement. In Biomedical Polymers; Jenkins, M., Ed.; Woodhead Publishing: Sawston, UK, 2007; pp. 141–173. [Google Scholar]

- Kurtz, S.M. UHMWPE Biomaterials Handbook: Ultra High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices; Academic Press: Cambridge, MA, USA, 2009. [Google Scholar]

- Geetha, M.; Singh, A.; Asokamani, R. Ti based biomaterials, the ultimate choice for orthopaedic implants–a review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Wolford, L.M.; Mercuri, L.G.; Schneiderman, E.D.; Movahed, R.; Allen, W. Twenty-Year Follow-up Study on a Patient-Fitted Tem-poromandibular Joint Prosthesis: The Techmedica/TMJ Concepts Device. J. Oral Maxillofac. Surg. 2015, 73, 952–960. [Google Scholar] [CrossRef]

- Leandro, L.L.; Ono, H.; Loureiro, C.D.S.; Marinho, K.; Guevara, H.G. A ten-year experience and follow-up of three hundred patients fitted with the Biomet/Lorenz Microfixation TMJ replacement system. Int. J. Oral Maxillofac. Surg. 2013, 42, 1007–1013. [Google Scholar] [CrossRef]

- Pan, L.; Hu, J.; Lv, Y.; Ma, W.; Ding, W.; Wang, Y.; Zhang, A.; Wang, F.; Pang, X.; Tao, J. Modification of Ti-6Al-4V plates with Schiff base complex and adhesive performance of Ti-6Al-4V/PEEK. Mater. Des. 2018, 144, 271–280. [Google Scholar] [CrossRef]

- Jiang, Z.; Wan, S.; Fang, Z.; Song, A. Static and fatigue behaviours of a bolted GFRP/steel double lap joint. Thin-Walled Struct. 2021, 158, 107170. [Google Scholar] [CrossRef]

- Feistauer, E.; Guimarães, R.; Ebel, T.; Dos Santos, J.; Amancio-Filho, S. Ultrasonic joining: A novel direct-assembly technique for metal-composite hybrid structures. Mater. Lett. 2016, 170, 1–4. [Google Scholar] [CrossRef]

- Zou, X.; Jiang, M.; Chen, K.; Chen, B.; Reddy, K.; Zhang, S.; Kondoh, K.; Wang, M.; Hua, X.; Zhang, L.; et al. Mechanism of defect formation during friction spot joining of 3D-printed TC4 alloy and ultra-high molecular weight polyethylene. Mater. Des. 2020, 195, 108989. [Google Scholar] [CrossRef]

- Jia, L.; Yang, H.; Wang, Y.; Zhang, B.; Liu, H.; Hao, J. Direct bonding of copper foil and liquid crystal polymer by laser etching and welding. Opt. Lasers Eng. 2021, 139, 106509. [Google Scholar] [CrossRef]

- Zhao, S.; Kimura, F.; Wang, S.; Kajihara, Y. Chemical interaction at the interface of metal–plastic direct joints fabricated via injection molded direct joining. Appl. Surf. Sci. 2021, 540, 148339. [Google Scholar] [CrossRef]

- Sandeep, R.; Arivazhagan, N. Innovation of thermoplastic polymers and metals hybrid structure using friction stir welding technique: Challenges and future perspectives. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–32. [Google Scholar] [CrossRef]

- Alsheghri, A.A.; Alageel, O.; Mezour, M.A.; Sun, B.; Yue, S.; Tamimi, F.; Song, J. Bio-inspired and optimized interlocking features for strengthening metal/polymer interfaces in additively manufactured prostheses. Acta Biomater. 2018, 80, 425–434. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Kimura, F.; Kadoya, S.; Kajihara, Y. Experimental analysis on mechanical interlocking of metal–polymer direct joining. Precis. Eng. 2020, 61, 120–125. [Google Scholar] [CrossRef]

- Nasr Esfahani, S.; Taheri Andani, M.; Shayesteh Moghaddam, N.; Mirzaeifar, R.; Elahinia, M. Independent tuning of stiffness and toughness of additively manufactured titanium-polymer composites: Simulation, fabrication, and experimental studies. J. Mater. Process. Technol. 2016, 238, 22–29. [Google Scholar] [CrossRef]

- Yeh, R.-Y.; Hsu, R.-Q. Development of ultrasonic direct joining of thermoplastic to laser structured metal. Int. J. Adhes. Adhes. 2016, 65, 28–32. [Google Scholar] [CrossRef]

- Chen, K.; Chen, B.; Zhang, S.; Wang, M.; Zhang, L.; Shan, A. Friction spot welding between porous TC4 titanium alloy and ultra high molecular weight polyethylene. Mater. Des. 2017, 132, 178–187. [Google Scholar] [CrossRef]

- Jiang, M.; Chen, K.; Chen, B.; Wang, M.; Hua, X.; Zhang, L.; Shan, A. Friction spot joining of TC4 alloy and ultra-high molecular weight polyethylene: Focused on temperature-force relationship. Mater. Des. 2020, 188, 108419. [Google Scholar] [CrossRef]

- Heinl, P.; Müller, L.; Körner, C.; Singer, R.F.; Müller, F.A. Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 2008, 4, 1536–1544. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2010, 3, 249–259. [Google Scholar] [CrossRef]

- Xia, X.; Chen, X.; Zhang, Z.; Zhao, W.; Liao, B.; Hur, B. Effects of porosity and pore size on the compressive properties of closed-cell Mg alloy foam. J. Magnes. Alloy. 2013, 1, 330–335. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure—Using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, W.; Jacobs, O.; Schädel, B. Tribological behaviour of UHMWPE/HDPE blends reinforced with multi-wall carbon nanotubes. Polym. Test. 2006, 25, 221–229. [Google Scholar] [CrossRef]

- Fu, J.; Ghali, B.W.; Lozynsky, A.J.; Oral, E.; Muratoglu, O.K. Ultra high molecular weight polyethylene with improved plasticity and toughness by high temperature melting. Polymer 2010, 51, 2721–2731. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.M.; Pernicone, N.; Ramsay, J.D.F.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids (Technical Report). Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R.; Young, P. Advanced lattice support structures for metal additive manufacturing. J. Mater. Process. Technol. 2013, 213, 1019–1026. [Google Scholar] [CrossRef]

- Feng, C.; Xia, Y.; Xiang, L.I.; Wang, C. Micro-pore structure and mechanical properties of porous titanium scaffold using 3D print technology. J. Med. Biomech. 2017, 32, 256–260. [Google Scholar]

- Rocha, M.; Mansur, A.; Mansur, H. Characterization and Accelerated Ageing of UHMWPE Used in Orthopedic Prosthesis by Peroxide. Materials 2009, 2, 562–576. [Google Scholar] [CrossRef]

- Slink WE, DeGroot PB, Vanadium-titanium oxide catalysts for oxidation of butene to acetic acid. J. Catal. 1981, 68, 423–432. [CrossRef]

- Lhoest, J.-B.; Bertrand, P.; Weng, L.T.; Dewez, J.-L. Combined Time-of-Flight Secondary Ion Mass Spectrometry and X-ray Photoelectron Spectroscopy Study of the Surface Segregation of Poly(methyl methacrylate) (PMMA) in Bisphenol A Polycarbonate/PMMA Blends. Macromolecules 1995, 28, 4631–4637. [Google Scholar] [CrossRef]

- Chan, C.-W.; Smith, G.C. Fibre laser joining of highly dissimilar materials: Commercially pure Ti and PET hybrid joint for medical device applications. Mater. Des. 2016, 103, 278–292. [Google Scholar] [CrossRef]

- Kawahito, Y.; Niwa, Y.; Katayama, S. Laser direct joining between stainless steel and polyethylene terephthalate plastic and reli-ability evaluation of joints. Weld. Int. 2014, 28, 107–113. [Google Scholar] [CrossRef]

- Kondoh, K.; Umeda, J. CO bond enhancing direct bonding strength between plastic and pure titanium. Mater. Lett. 2018, 211, 331–334. [Google Scholar] [CrossRef]

| Material | Density | Melting Point | Yield strength | Elongation |

|---|---|---|---|---|

| UHMWPE | 931 kg/m3 | 137 °C | 20 MPa | 380% |

| Material | Al | V | C | Fe | O | N | H | Ti |

|---|---|---|---|---|---|---|---|---|

| Ti6Al4V | 6 | 4 | 0.03 | 0.1 | 0.15 | 0.01 | 0.003 | Bal. |

| Group | Strut Size (mm) | Pore Size (mm) | Porosity (%) |

|---|---|---|---|

| NS | / | / | / |

| DS | 0.3 | 0.9 | 71 |

| HC | 0.3 | 1.2 | 66 |

| Group | Ultimate Force/N | Failure Displacement/mm |

|---|---|---|

| SP | / | / |

| NS | 1131 ± 348 | 0.96 ± 0.53 |

| DS | 1641 ± 280 | 2.32 ± 0.44 |

| HC | 1751 ± 82 | 1.78 ± 0.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Huang, L.; Chen, K.; Jiang, M.; Zhang, S.; Wang, M.; Hua, X.; Shan, A. Surface Structuring via Additive Manufacturing to Improve the Performance of Metal and Polymer Joints. Metals 2021, 11, 567. https://doi.org/10.3390/met11040567

Zou X, Huang L, Chen K, Jiang M, Zhang S, Wang M, Hua X, Shan A. Surface Structuring via Additive Manufacturing to Improve the Performance of Metal and Polymer Joints. Metals. 2021; 11(4):567. https://doi.org/10.3390/met11040567

Chicago/Turabian StyleZou, Xin, Lifu Huang, Ke Chen, Muyang Jiang, Shanyong Zhang, Min Wang, Xueming Hua, and Aidang Shan. 2021. "Surface Structuring via Additive Manufacturing to Improve the Performance of Metal and Polymer Joints" Metals 11, no. 4: 567. https://doi.org/10.3390/met11040567

APA StyleZou, X., Huang, L., Chen, K., Jiang, M., Zhang, S., Wang, M., Hua, X., & Shan, A. (2021). Surface Structuring via Additive Manufacturing to Improve the Performance of Metal and Polymer Joints. Metals, 11(4), 567. https://doi.org/10.3390/met11040567