Surface Modification of the EBM Ti-6Al-4V Alloy by Pulsed Ion Beam

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Methods

3. Results

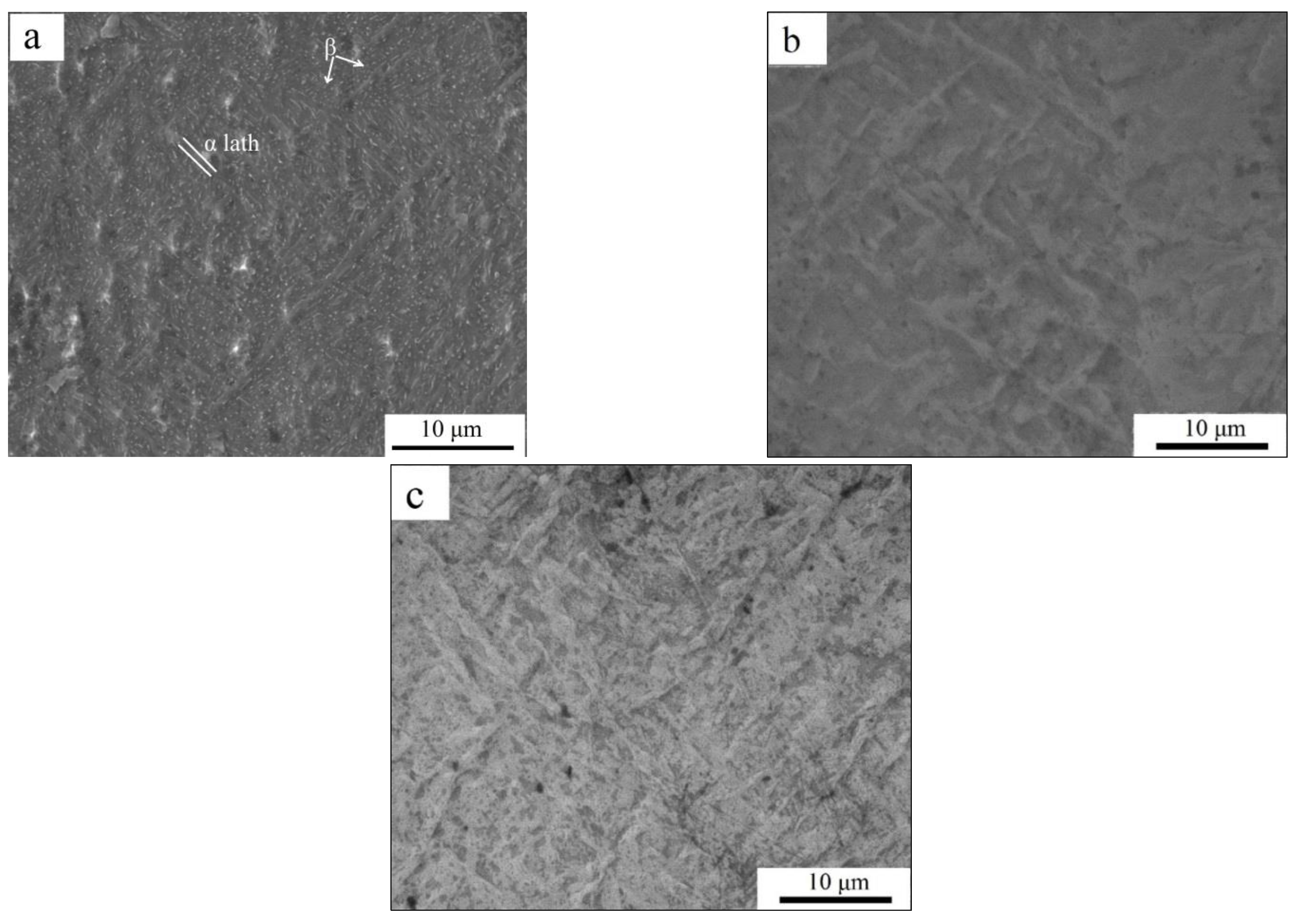

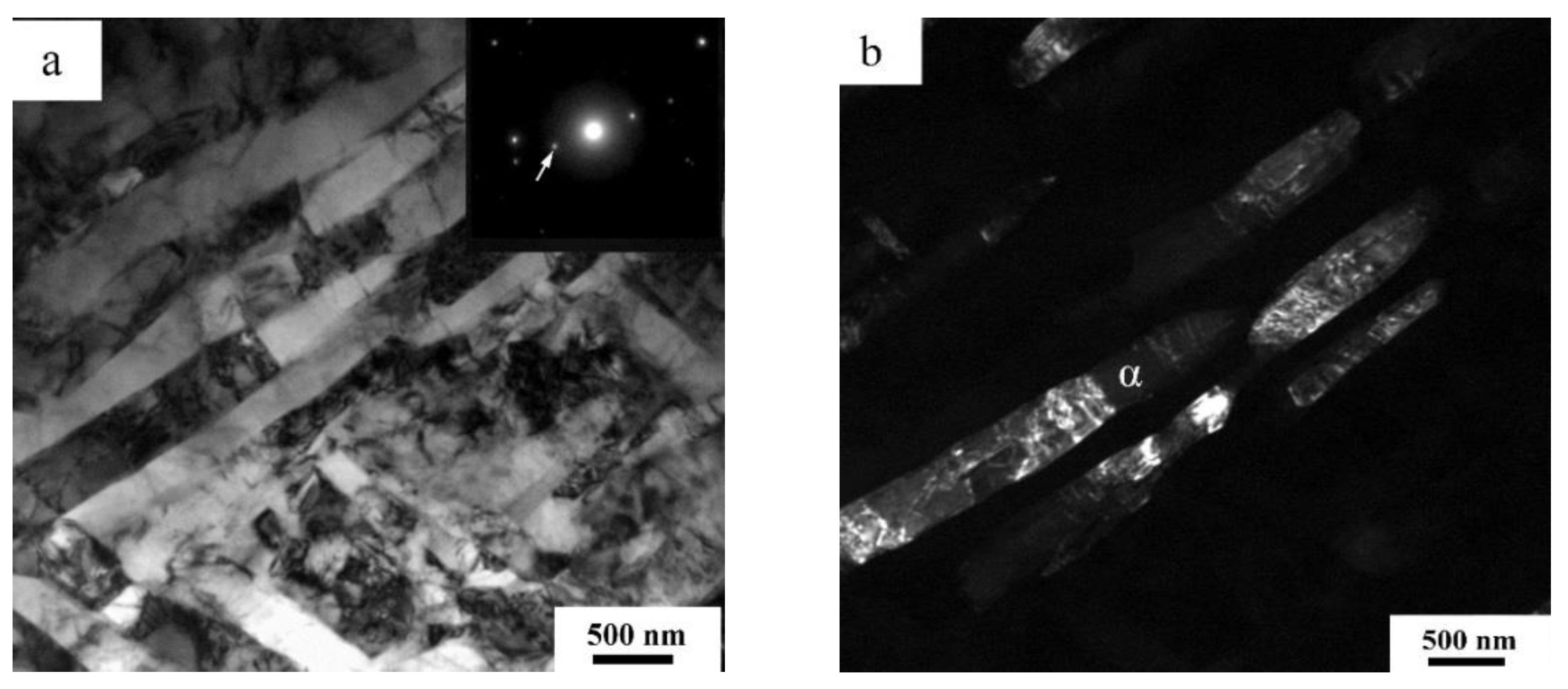

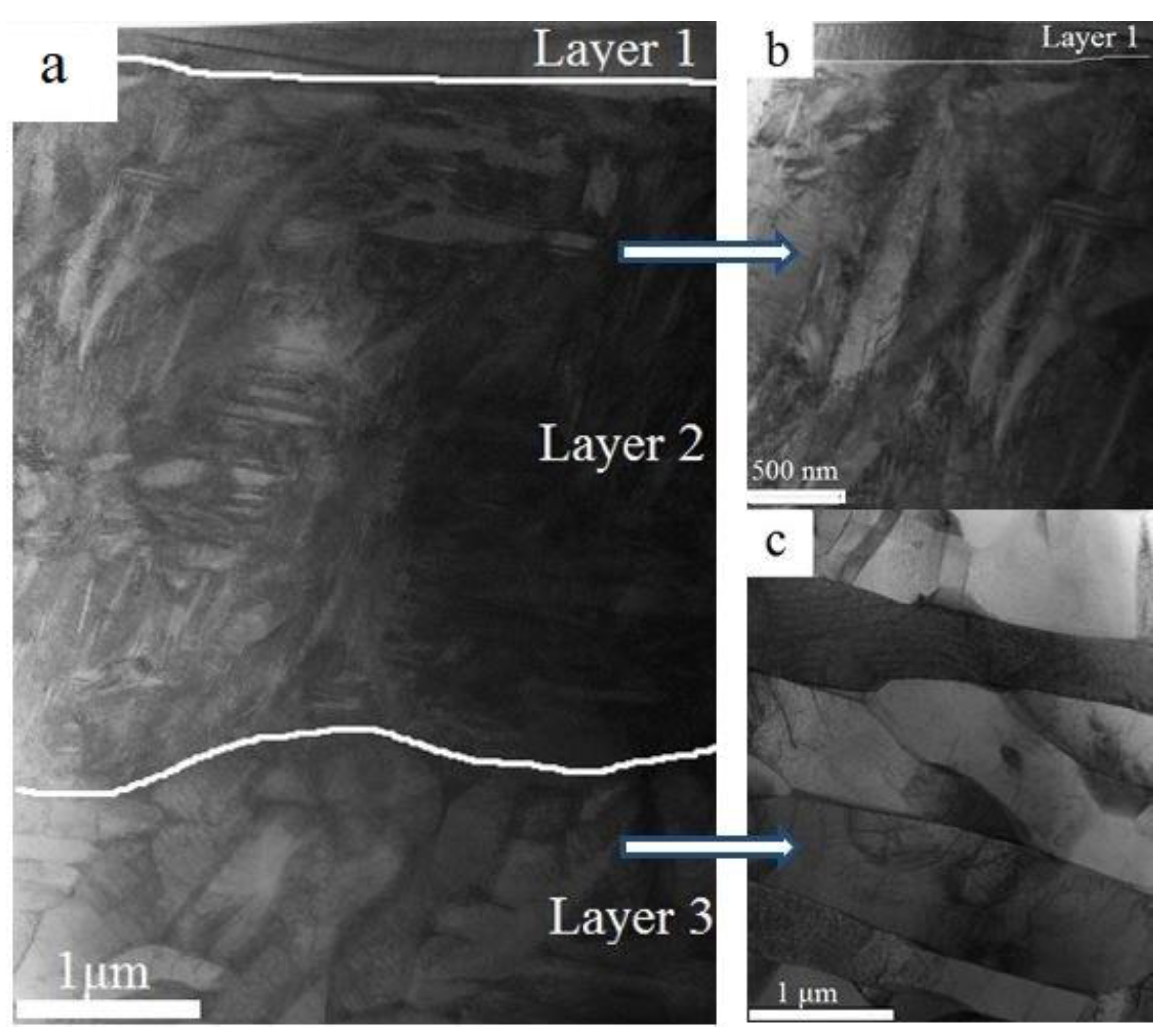

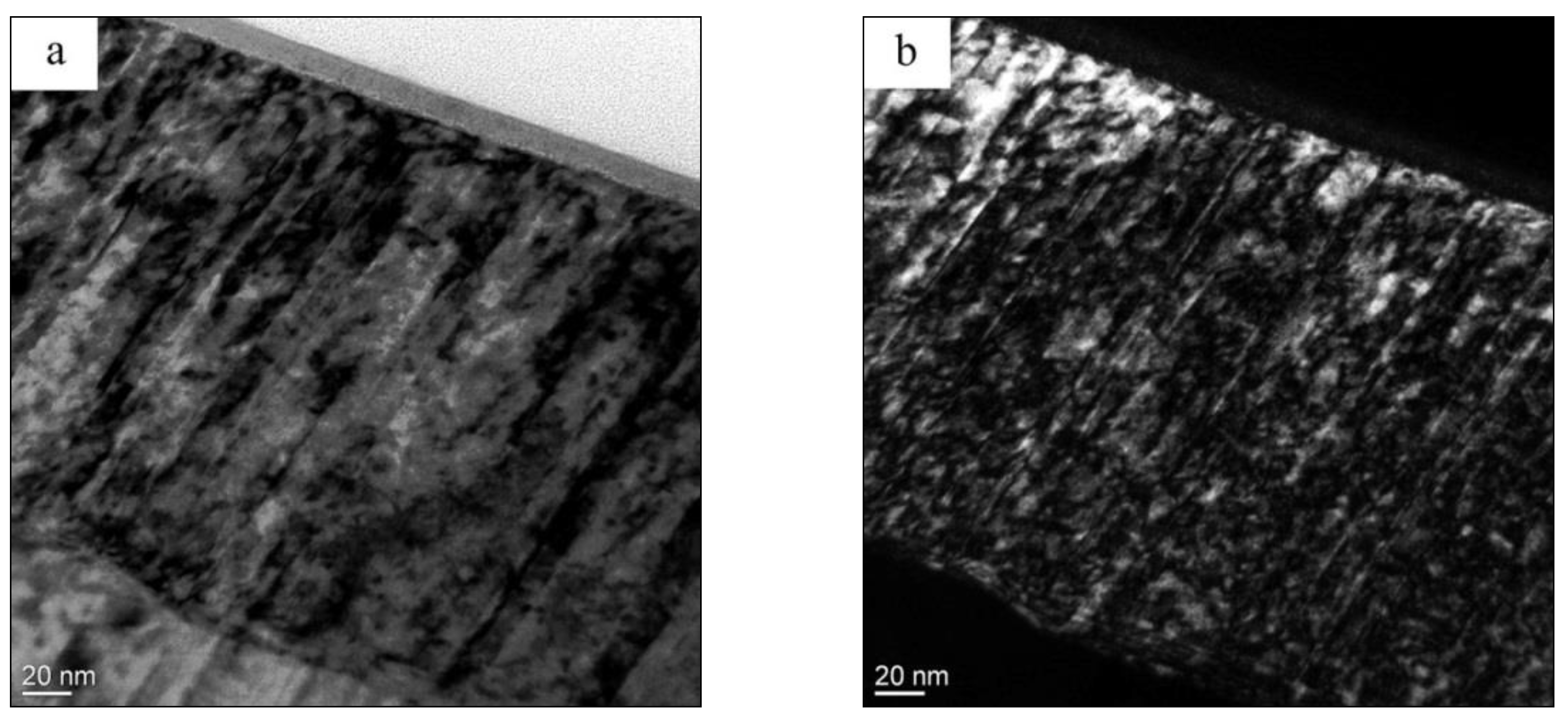

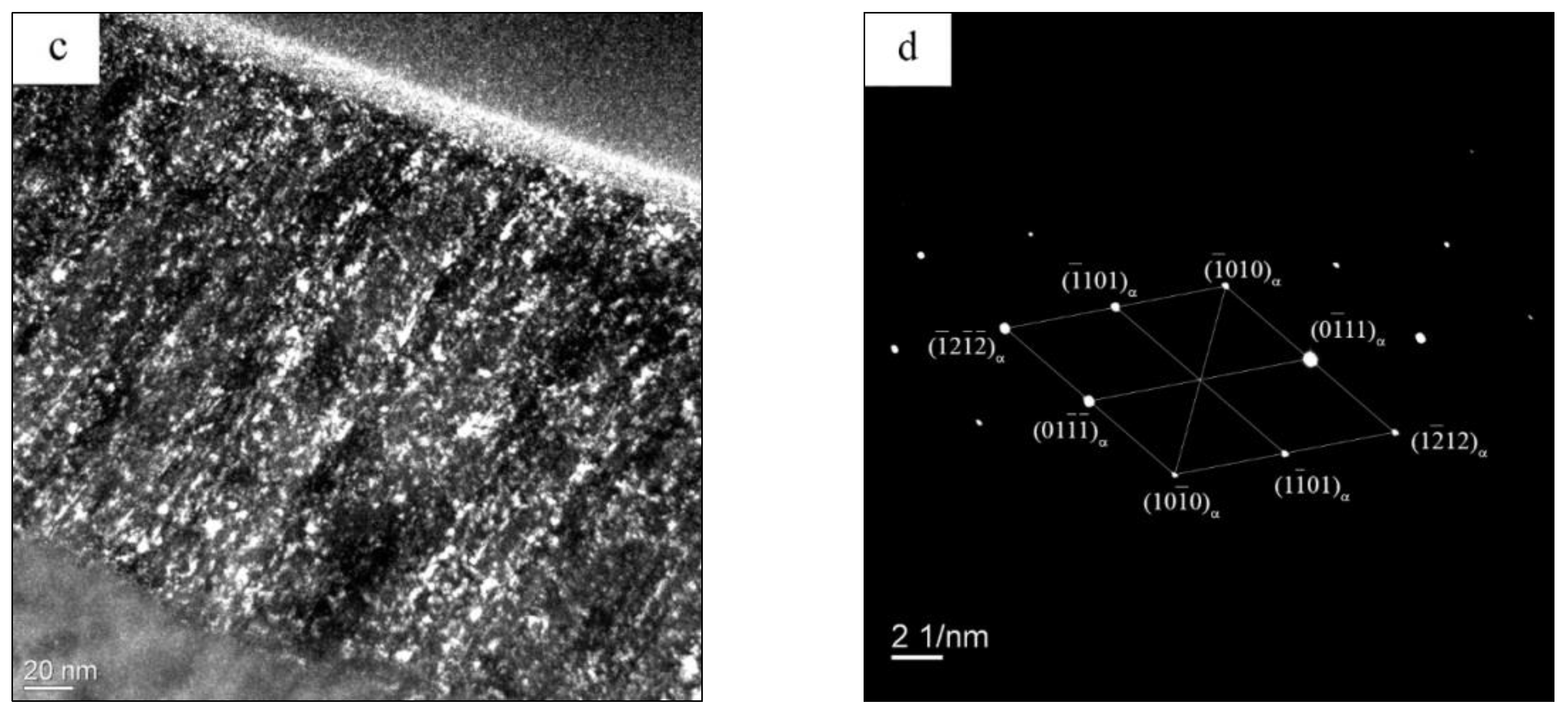

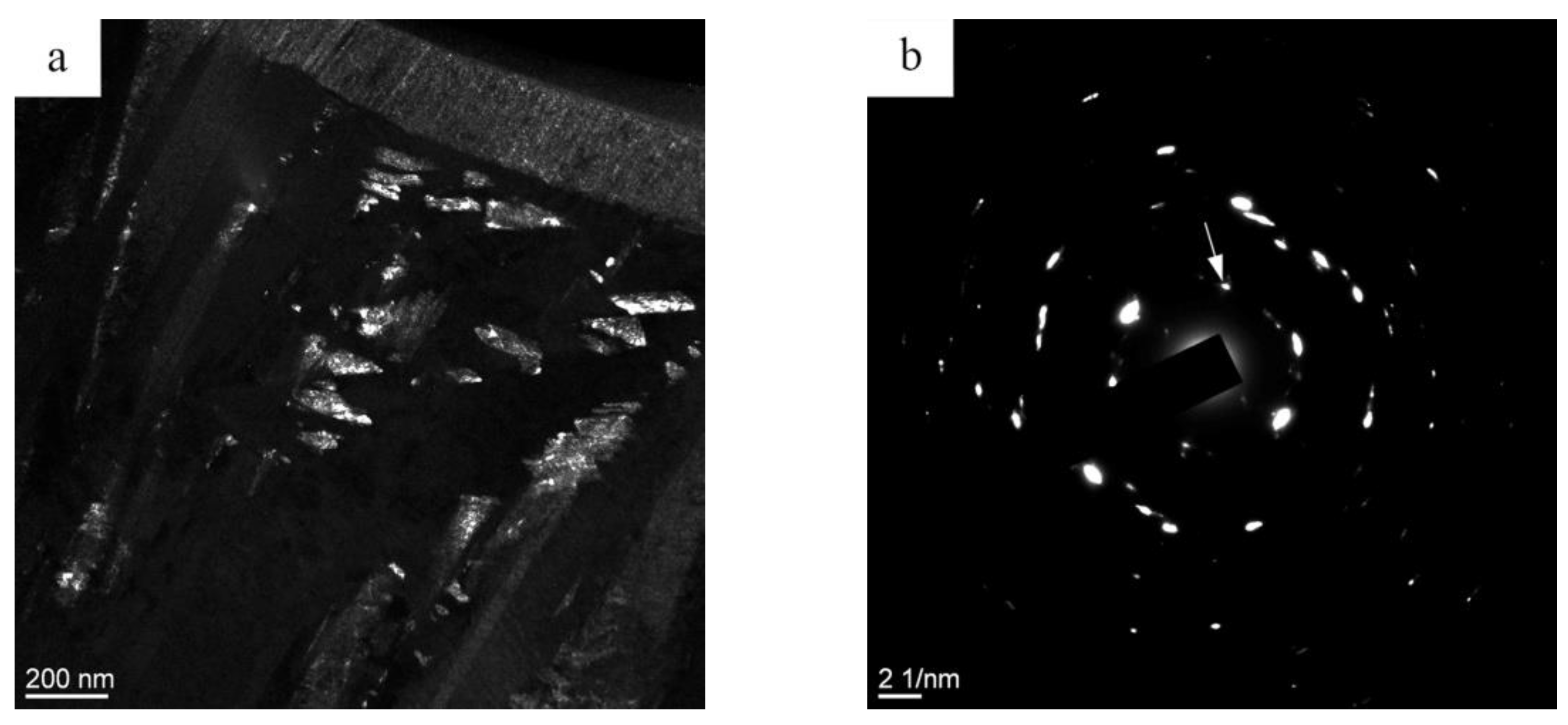

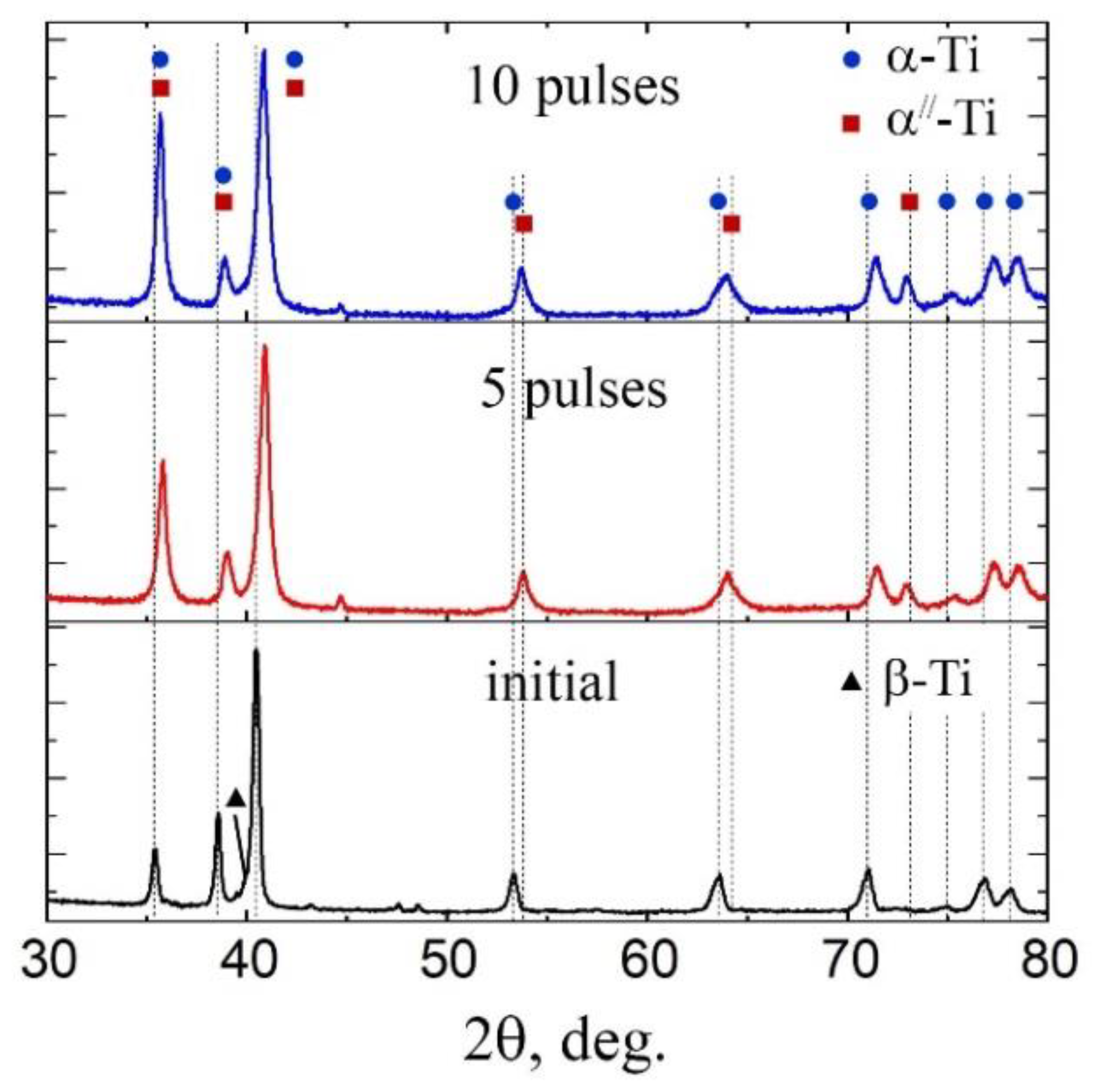

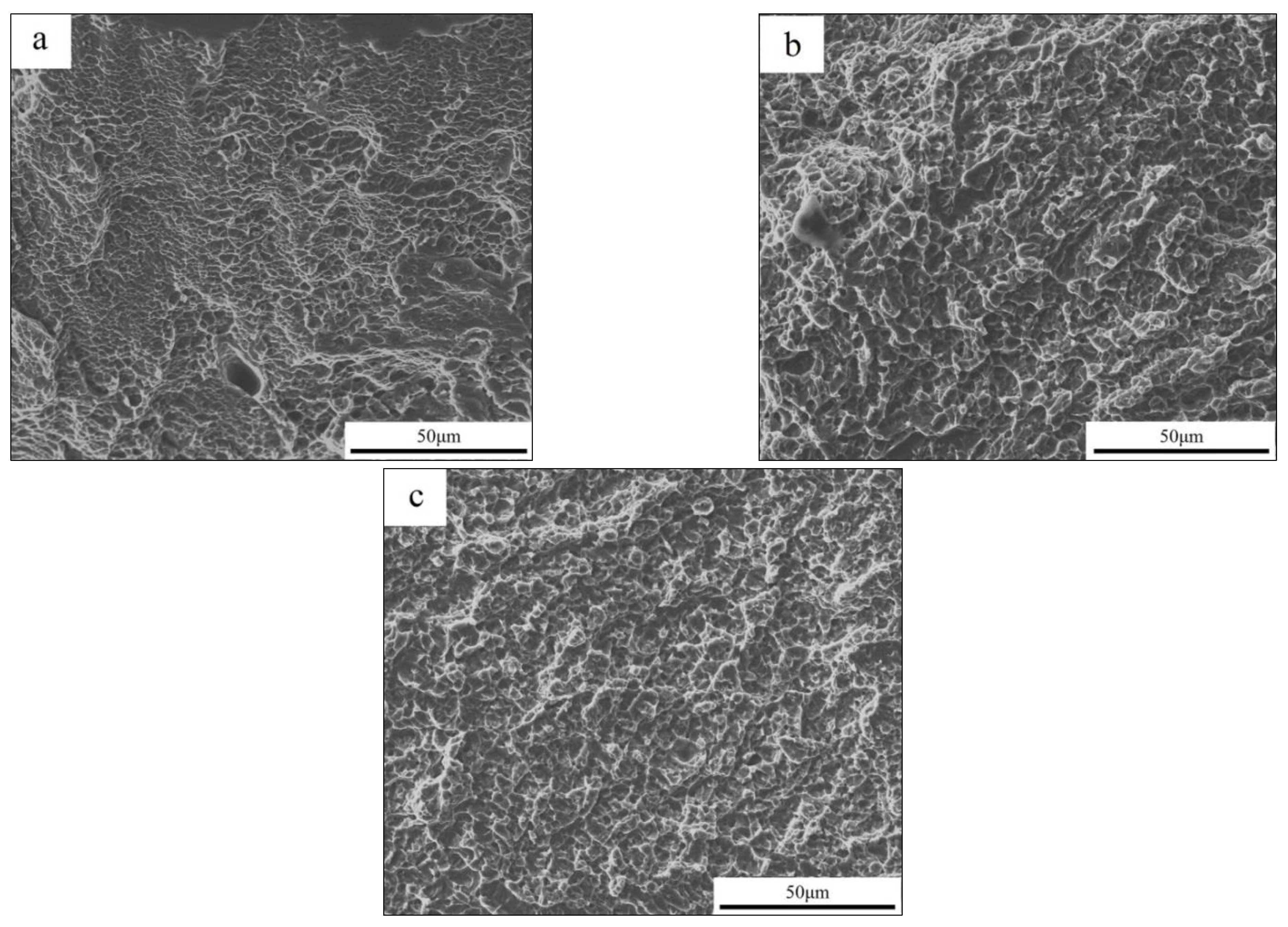

3.1. Microstructure and Phase Composition

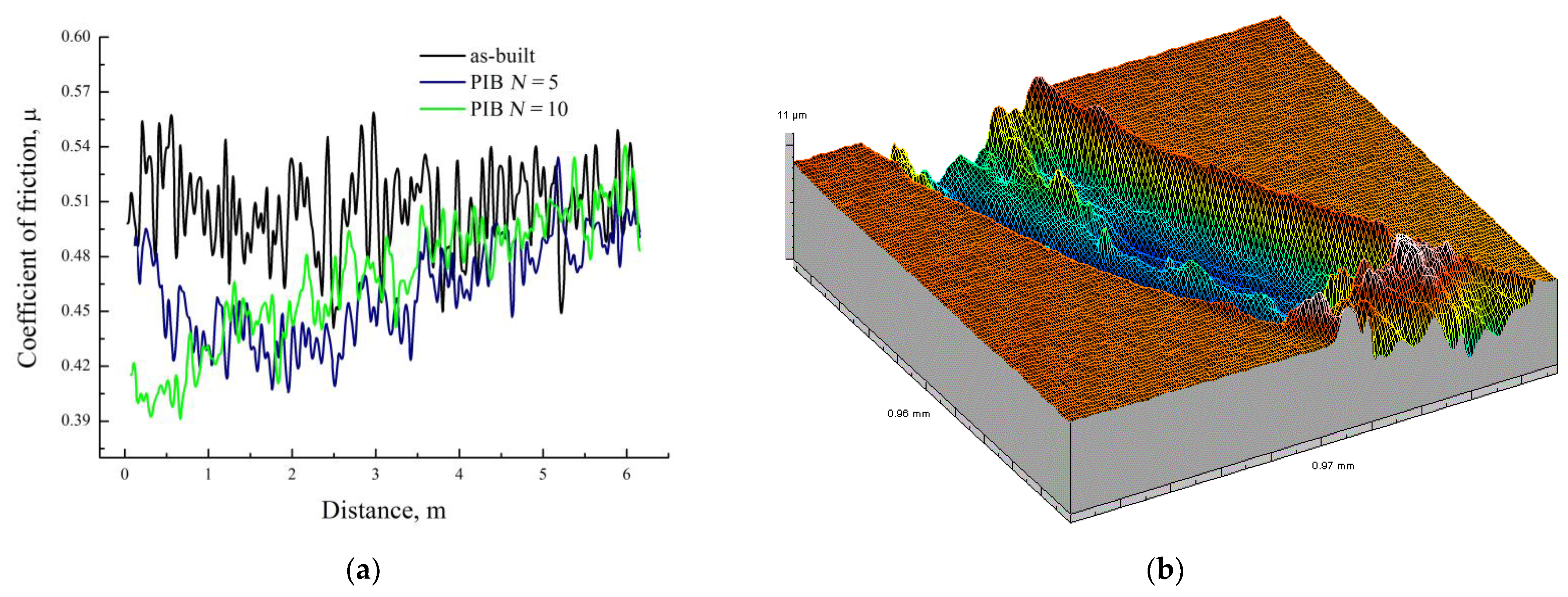

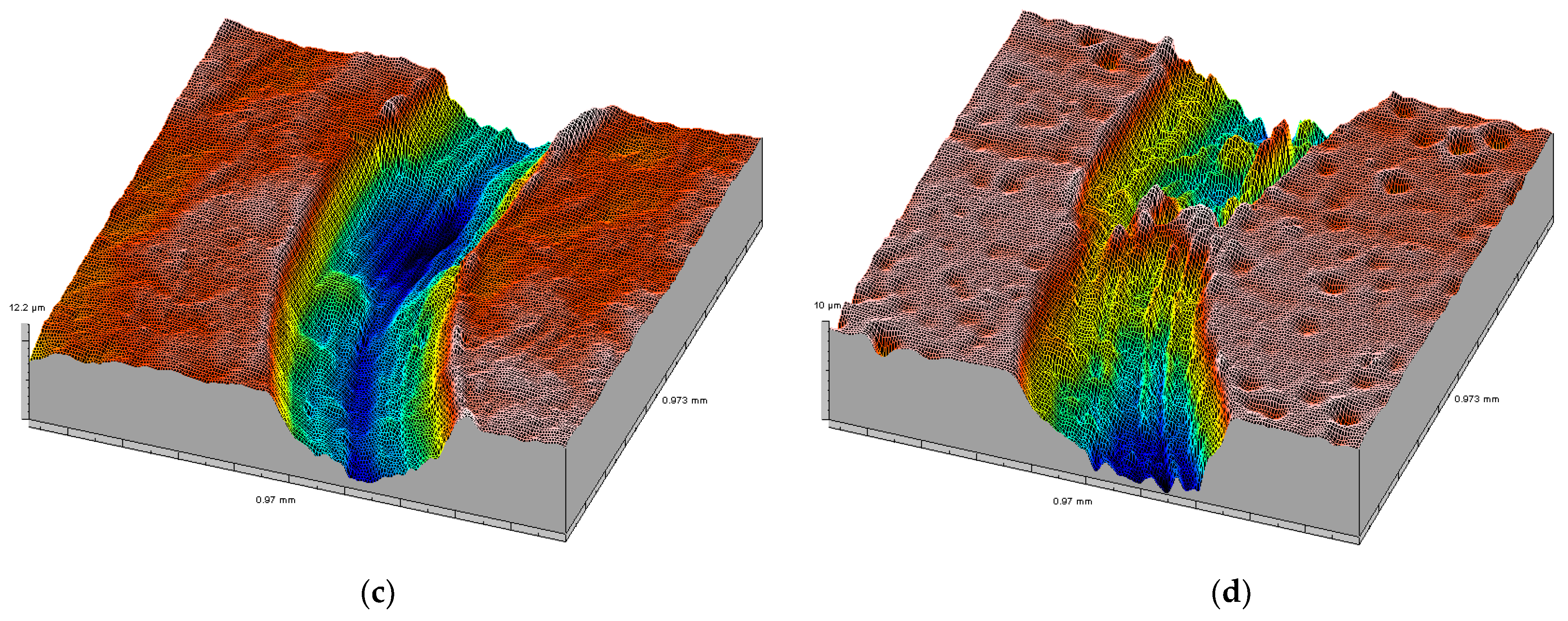

3.2. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Oliveira, J.; Panton, B.; Zeng, Z.; Andrei, C.; Zhou, Y.; Miranda, R.; Fernandes, F.B. Laser joining of NiTi to Ti6Al4V using a Niobium interlayer. Acta Mater. 2016, 105, 9–15. [Google Scholar] [CrossRef]

- Callegari, B.; Oliveira, J.; Aristizabal, K.; Coelho, R.; Brito, P.; Wu, L.; Schell, N.; Soldera, F.; Mücklich, F.; Pinto, H. In-situ synchrotron radiation study of the aging response of Ti-6Al-4V alloy with different starting microstructures. Mater. Charact. 2020, 165, 110400. [Google Scholar] [CrossRef]

- Murr, L. Metallurgy of additive manufacturing: Examples from electron beam melting. Addit. Manuf. 2015, 5, 40–53. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Fernández, A.; Celaya, A.; Lamikiz, A.; De Lacalle, L.L.; Mentxaka, A.L.; De Lacalle, L.N.L. Improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Lasers Eng. 2014, 56, 113–120. [Google Scholar] [CrossRef]

- Pushilina, N.; Panin, A.; Syrtanov, M.; Kashkarov, E.; Kudiiarov, V.; Perevalova, O.; Laptev, R.; Lider, A.; Koptyug, A. Hydrogen-Induced Phase Transformation and Microstructure Evolution for Ti-6Al-4V Parts Produced by Electron Beam Melting. Metals 2018, 8, 301. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Ealo, J.A.; Campa, F.J.; Lamikiz, A.; De Lacalle, L.N.L. Feed rate calculation algorithm for the homogeneous material deposition of blisk blades by 5-axis laser cladding. Int. J. Adv. Manuf. Technol. 2014, 74, 1219–1228. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Analysis of the effect of internal defects on fatigue performance of additive manufactured metals. Mater. Sci. Eng. A 2020, 785, 139385. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue 2018, 117, 163–179. [Google Scholar] [CrossRef]

- Lin, B.; Chen, W.; Yang, Y.; Wu, F.; Li, Z. Anisotropy of microstructure and tensile properties of Ti-48Al-2Cr-2Nb fabricated by electron beam melting. J. Alloy. Compd. 2020, 830, 154684. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.; Wang, P.; Nai, M.; Loh, N.; Liu, E.; Tor, S. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; McDaniels, R.; Dehoff, R.R.; Liaw, P.K.; Tryon, R.; Duty, C.E. Build orientation, surface roughness, and scan path influence on the microstructure, mechanical properties, and flexural fatigue behavior of Ti-6Al-4V fabricated by electron beam melting. Mater. Sci. Eng. A 2020, 772, 138740. [Google Scholar] [CrossRef]

- Leon, A.; Levy, G.K.; Ron, T.; Shirizly, A.; Aghion, E. The effect of hot isostatic pressure on the corrosion performance of Ti-6Al-4 V produced by an electron-beam melting additive manufacturing process. Addit. Manuf. 2020, 33, 101039. [Google Scholar] [CrossRef]

- Popov, V.; Katz-Demyanetz, A.; Garkun, A.; Muller, G.; Strokin, E.; Rosenson, H. Effect of Hot Isostatic Pressure treatment on the Electron-Beam Melted Ti-6Al-4V specimens. Procedia Manuf. 2018, 21, 125–132. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Fang, G.; Leeflang, S.; Böttger, A.J.; Zadpoor, A.A.; Zhou, J. Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy. J. Alloy. Compd. 2018, 735, 1562–1575. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef]

- Sabban, R.; Bahl, S.; Chatterjee, K.; Suwas, S. Globularization using heat treatment in additively manufactured Ti-6Al-4V for high strength and toughness. Acta Mater. 2019, 162, 239–254. [Google Scholar] [CrossRef]

- Panin, A.; Kazachenok, M.; Perevalova, O.; Martynov, S.; Panina, A.; Sklyarova, E. Continuous Electron Beam Post-Treatment of EBF3-Fabricated Ti-6Al-4V Parts. Metals 2019, 9, 699. [Google Scholar] [CrossRef]

- Farayibi, P.; Abioye, T.; Murray, J.; Kinnell, P.; Clare, A. Surface improvement of laser clad Ti-6Al-4V using plain waterjet and pulsed electron beam irradiation. J. Mater. Process. Technol. 2015, 218, 1–11. [Google Scholar] [CrossRef][Green Version]

- Tian, Y.; Gora, W.S.; Cabo, A.P.; Parimi, L.L.; Hand, D.P.; Tammas-Williams, S.; Prangnell, P.B. Material interactions in laser polishing powder bed additive manufactured Ti6Al4V components. Addit. Manuf. 2018, 20, 11–22. [Google Scholar] [CrossRef]

- Hao, S.; Qin, Y.; Mei, X.; Gao, B.; Zuo, J.; Guan, Q.; Dong, C.; Zhang, Q. Fundamentals and applications of material modification by intense pulsed beams. Surf. Coat. Technol. 2007, 201, 8588–8595. [Google Scholar] [CrossRef]

- Ryabchikov, A. Progress in low energy high intensity ion implantation method development. Surf. Coat. Technol. 2020, 388, 125561. [Google Scholar] [CrossRef]

- Li, P.; Peng, T. Surface morphology of magnesium alloy irradiated by high-intensity pulsed ion beam. Appl. Surf. Sci. 2012, 258, 9961–9968. [Google Scholar] [CrossRef]

- Chernov, I.P.; Beloglazova, P.A.; Berezneeva, E.V.; Kireeva, I.V.; Pushilina, N.S.; Remnev, G.E.; Stepanova, E.N. Properties of the VT1-0 titanium surface modified by a pulsed ion beam. Tech. Phys. 2015, 60, 1039–1043. [Google Scholar] [CrossRef]

- Struts, V.; Zakoutaev, A.; Matvienko, V.; Petrov, A.; Shlapakovski, A. Formation of protective coatings on metals by intense pulsed ion beam. Surf. Coat. Technol. 2002, 158, 494–497. [Google Scholar] [CrossRef]

- Shulov, V.; Nochovnaya, N. Fatigue strength of metals and alloys modified by ion beams. Surf. Coat. Technol. 2002, 158, 33–41. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Remnev, G.; Kurakin, I.; Ligachev, A. Structural, physical and chemical changes induced in metals and alloys exposed to high power ion beams. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1989, 36, 286–305. [Google Scholar] [CrossRef]

- Lavrentiev, V.; Hammerl, C.; Rauschenbach, B.; Kukharenko, O. Formation of hardened surface layers in titanium under irradiation with intense ion beams. Scr. Mater. 2001, 44, 625–630. [Google Scholar] [CrossRef]

- Renk, T.; Provencio, P.; Prasad, S.; Shlapakovski, A.; Petrov, A.; Yatsui, K.; Jiang, W.; Suematsu, H. Materials modification using intense ion beams. Proc. IEEE 2004, 92, 1057–1081. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, L.; Guan, T.; Zhang, X.; Remnev, G.E.; Pavlov, S.K.; Wang, Y.; Mei, X. Effect on mechanics properties and microstructure of molybdenum by high intensity pulsed ion beam irradiation. Surf. Coat. Technol. 2020, 384, 125333. [Google Scholar] [CrossRef]

- Remnev, G.; Uglov, V.; Shymanski, V.; Pavlov, S.; Kuleshov, A. Formation of nanoscale carbon structures in the surface layer of metals under the impact of high intensity ion beam. Appl. Surf. Sci. 2014, 310, 204–209. [Google Scholar] [CrossRef]

- Lei, M.; Dong, Z.; Zhang, Z.; Hu, Y.; Zhu, X. Wear and corrosion resistance of Ti6Al4V alloy irradiated by high-intensity pulsed ion beam. Surf. Coat. Technol. 2007, 201, 5613–5616. [Google Scholar] [CrossRef]

- Wang, X.; Han, X.; Lei, M.; Zhang, J. Effect of high-intensity pulsed ion beams irradiation on corrosion resistance of 316L stainless steel. Mater. Sci. Eng. A 2007, 457, 84–89. [Google Scholar] [CrossRef]

- Grabovetskaya, G.P.; Stepanova, E.N.; Mishin, I.P.; Zabudchenko, O.V. The Effect of Irradiation of a Titanium Alloy of the Ti-6Al-4V-H System with Pulsed Electron Beams on Its Creep. Russ. Phys. J. 2020, 63, 932–939. [Google Scholar] [CrossRef]

- Pushilina, N.S.; Klimenov, V.A.; Cherepanov, R.O.; Kashkarov, E.B.; Fedorov, V.V.; Syrtanov, M.S.; Lider, A.M.; Laptev, R.S. Beam Current Effect on Microstructure and Properties of Electron-Beam-Melted Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2019, 28, 6165–6173. [Google Scholar] [CrossRef]

- Stepanov, A.V.; Shamanin, V.I.; Remnev, G.E. The study of operation modes of the self-magnetically insulated ion diode. Rev. Sci. Instrum. 2019, 90, 033302. [Google Scholar] [CrossRef] [PubMed]

- Stepanova, E.; Grabovetskaya, G.; Syrtanov, M.; Mishin, I. Effect of Hydrogen on the Deformation Behavior and Localization of Plastic Deformation of the Ultrafine-Grained Zr—1Nb Alloy. Metals 2020, 10, 592. [Google Scholar] [CrossRef]

- Boiko, V.I.; Valyaev, A.N.; Pogrebnyak, A.D. Metal modification by high-power pulsed particle beams. Phys. Uspekhi 1999, 42, 1243–1271. [Google Scholar] [CrossRef]

- Li, C.; Li, G.; Yang, Y.; Varlioglu, M.; Yang, K. α” Martensitic Twinning in Alpha + Beta Ti-3.5Al-4.5Mo Titanium Alloy. J. Metall. 2011, 2011, 924032. [Google Scholar] [CrossRef]

- Kelly, A.; Growes, G.W. Crystallography and Crystal Defects; Longman: London, UK, 1970. [Google Scholar]

- Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyka, K.K.A.M. Microstructure and Mechanical Properties of High Strength Two-Phase Titanium Alloys; BoD—Books on Demand: Norderstedt, Germany, 2013; pp. 69–80. [Google Scholar] [CrossRef]

- Ma, X.; Li, F.; Sun, Z.; Hou, J.; Fang, X.; Zhu, Y.; Koch, C.C. Achieving Gradient Martensite Structure and Enhanced Mechanical Properties in a Metastable β Titanium Alloy. Metall. Mater. Trans. A 2019, 50, 2126–2138. [Google Scholar] [CrossRef]

| Samples | V ± 0.05, mm3/(N·m) | Hµ ± 0.2, GPa | H ± 0.1, GPa | E, GPa |

|---|---|---|---|---|

| as-built | 0.88 | 3.9 | 4.5 | 108 |

| after PIB, N = 5 pulses | 0.72 | 6.2 | 5.7 | 134 |

| after PIB, N = 10 pulses | 0.76 | 6.7 | 4.8 | 103 |

| Samples | σ0.2 ± 20, MPa | σB ± 20, MPa | δ ± 0.5, % |

|---|---|---|---|

| as-built | 841 | 900 | 12.1 |

| after PIB, N = 5 pulses | 823 | 940 | 13.8 |

| after PIB, N = 10 pulses | 630 | 659 | 13.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pushilina, N.; Stepanova, E.; Stepanov, A.; Syrtanov, M. Surface Modification of the EBM Ti-6Al-4V Alloy by Pulsed Ion Beam. Metals 2021, 11, 512. https://doi.org/10.3390/met11030512

Pushilina N, Stepanova E, Stepanov A, Syrtanov M. Surface Modification of the EBM Ti-6Al-4V Alloy by Pulsed Ion Beam. Metals. 2021; 11(3):512. https://doi.org/10.3390/met11030512

Chicago/Turabian StylePushilina, Natalia, Ekaterina Stepanova, Andrey Stepanov, and Maxim Syrtanov. 2021. "Surface Modification of the EBM Ti-6Al-4V Alloy by Pulsed Ion Beam" Metals 11, no. 3: 512. https://doi.org/10.3390/met11030512

APA StylePushilina, N., Stepanova, E., Stepanov, A., & Syrtanov, M. (2021). Surface Modification of the EBM Ti-6Al-4V Alloy by Pulsed Ion Beam. Metals, 11(3), 512. https://doi.org/10.3390/met11030512