Large Eddy Simulation of Multi-Phase Flow and Slag Entrapment in Molds with Different Widths

Abstract

1. Introduction

2. Mathematical Model

2.1. Basic Assumptions

2.2. Governing Equations

2.3. Discrete Particle Model (DPM)

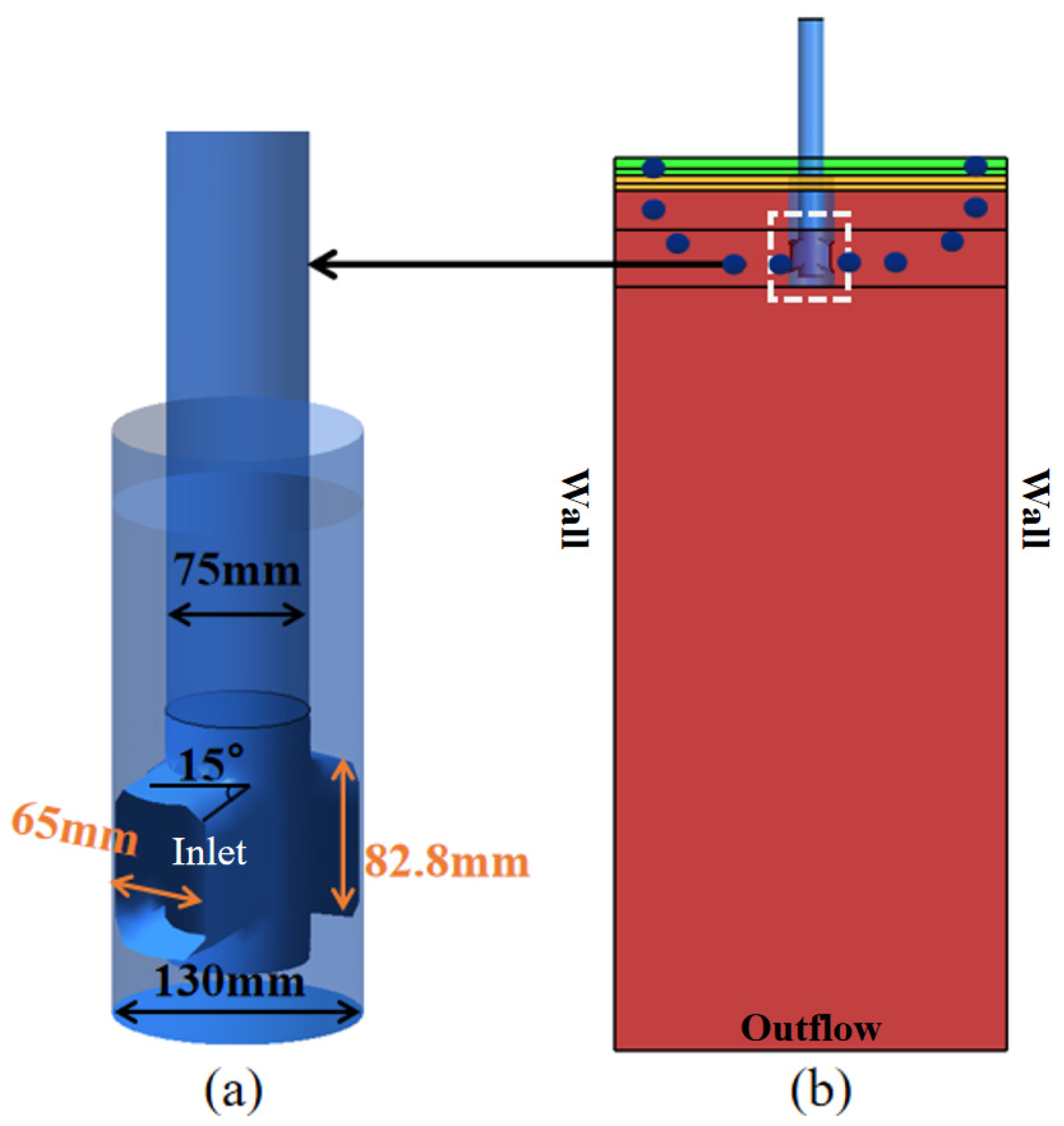

2.4. Boundary Conditions and Numerical Details

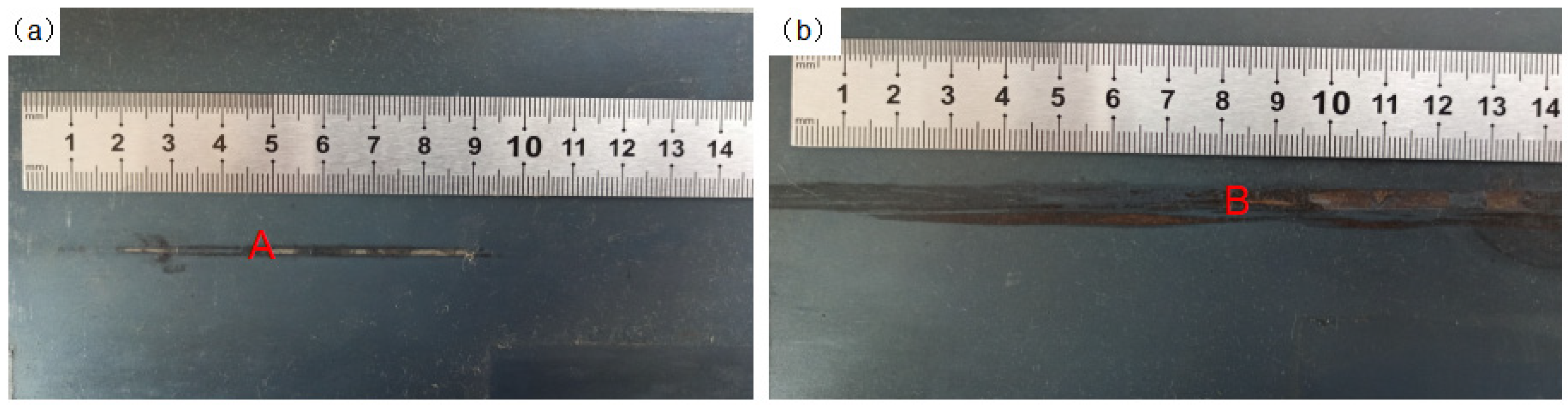

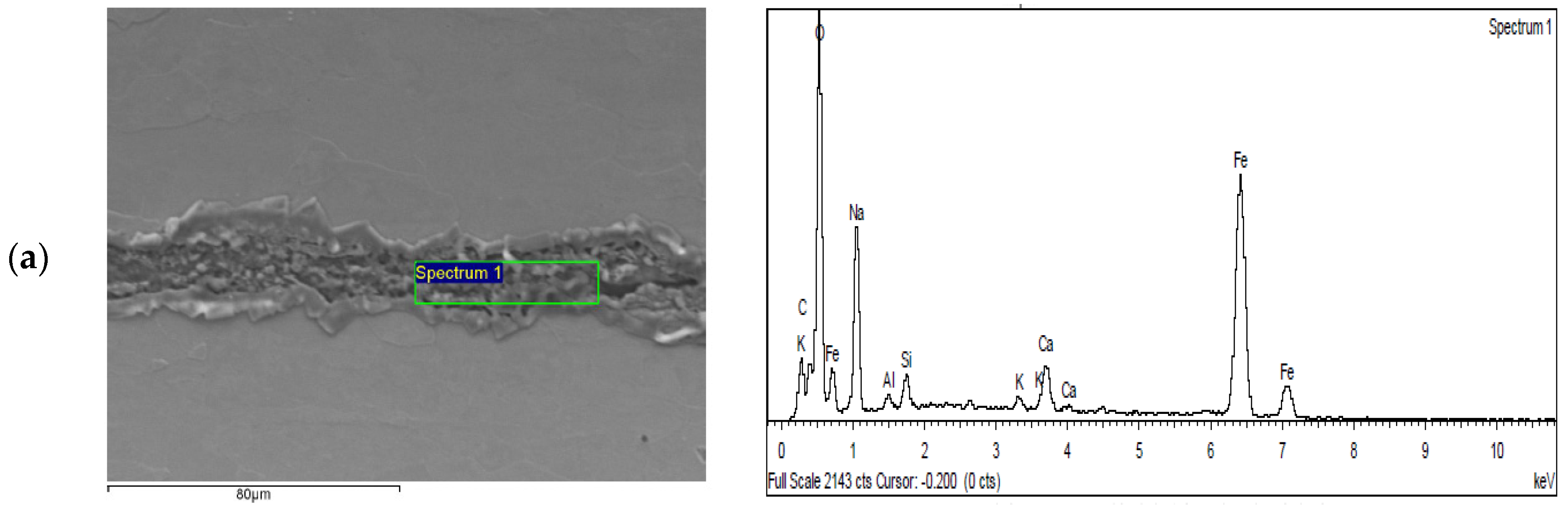

3. Analysis of Inclusions on Slab

4. Results and Discussion

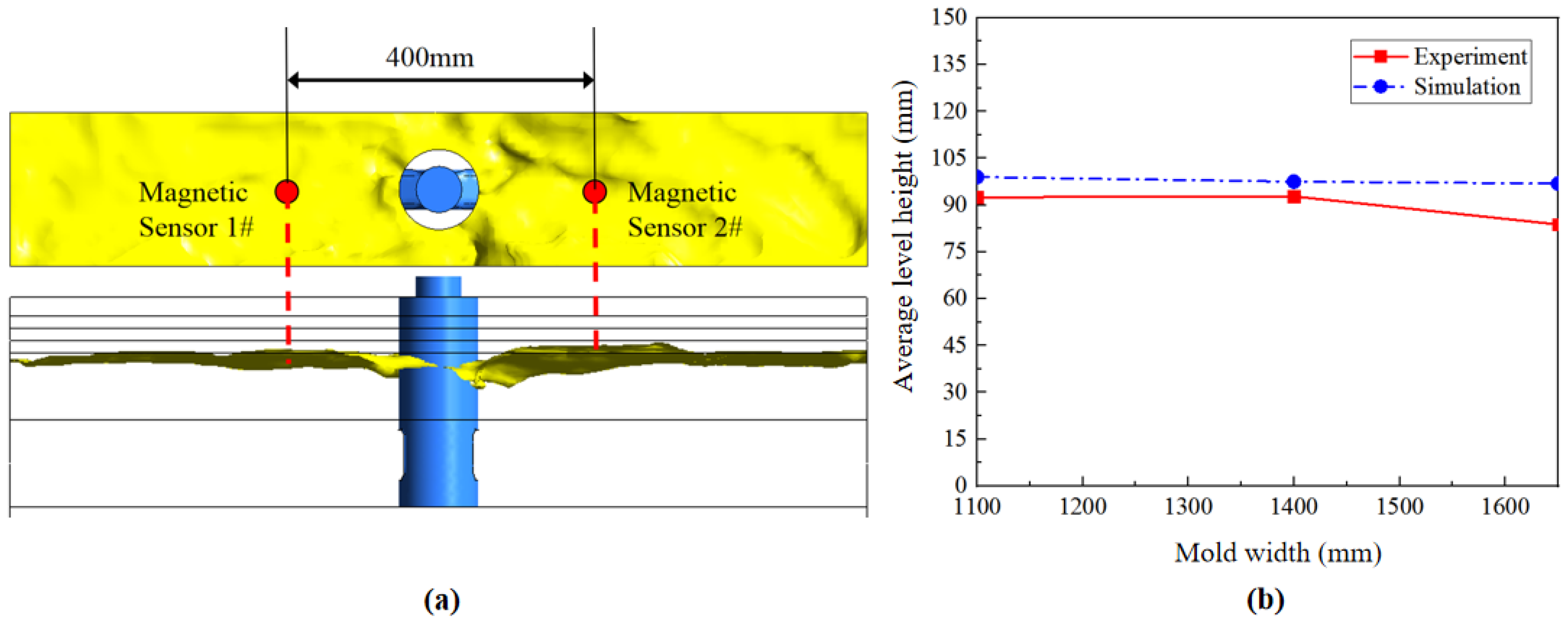

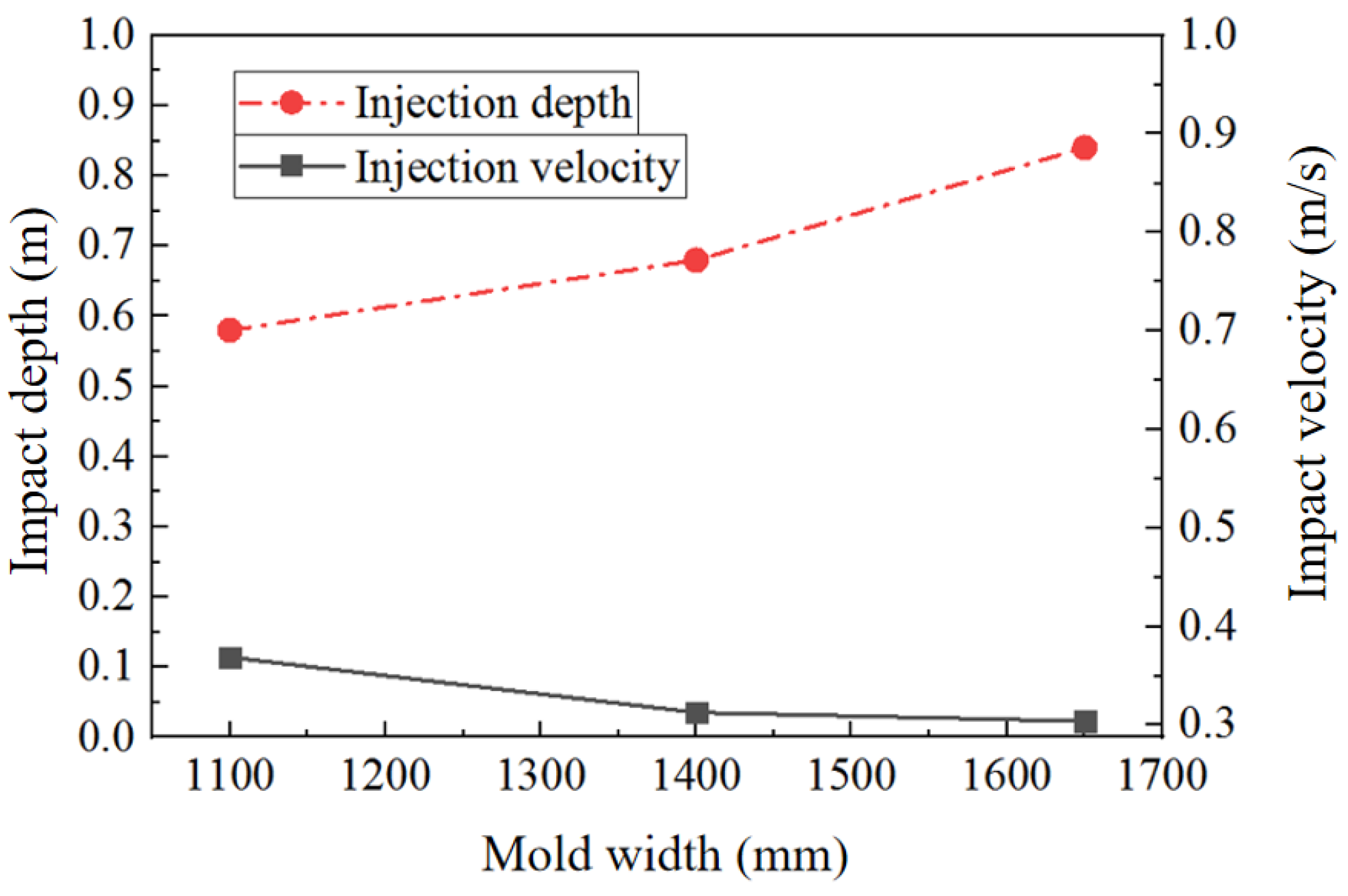

4.1. Level Height of Slag–Metal Interface

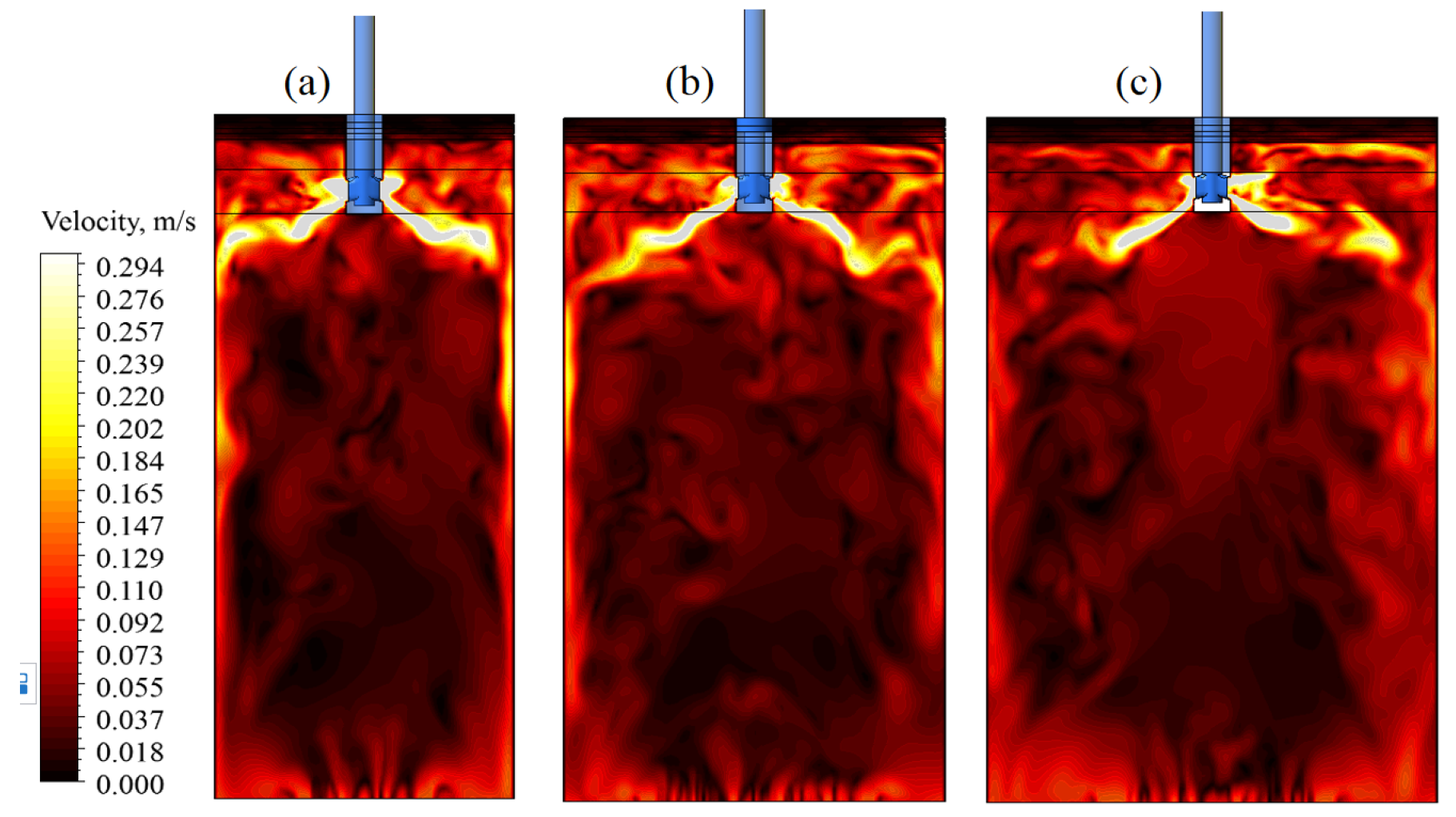

4.2. Transient Flow Spectrum Analysis of Mold

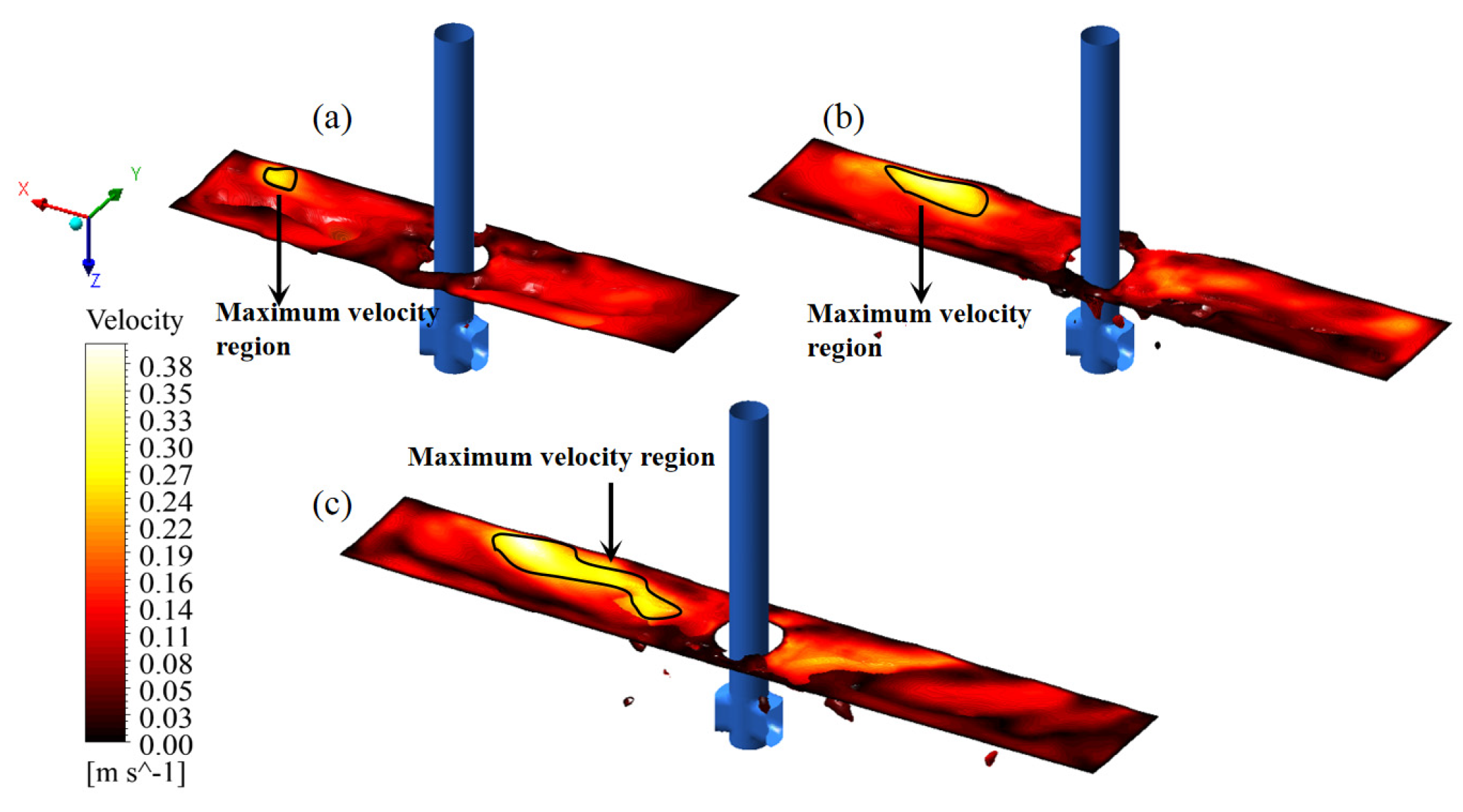

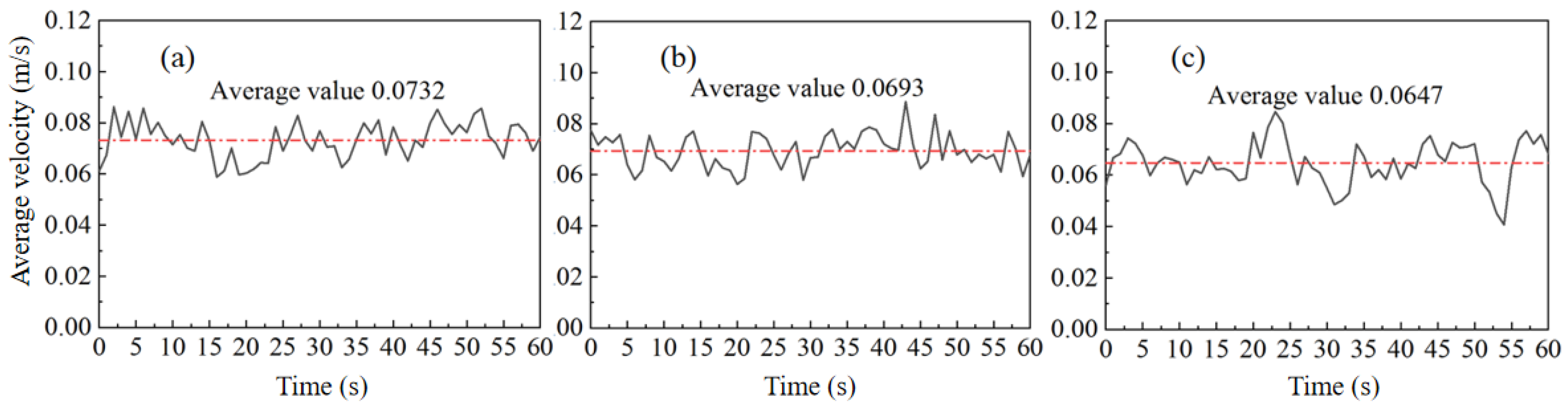

4.3. Analysis of Velocity Characteristics of Slag–Metal Interface

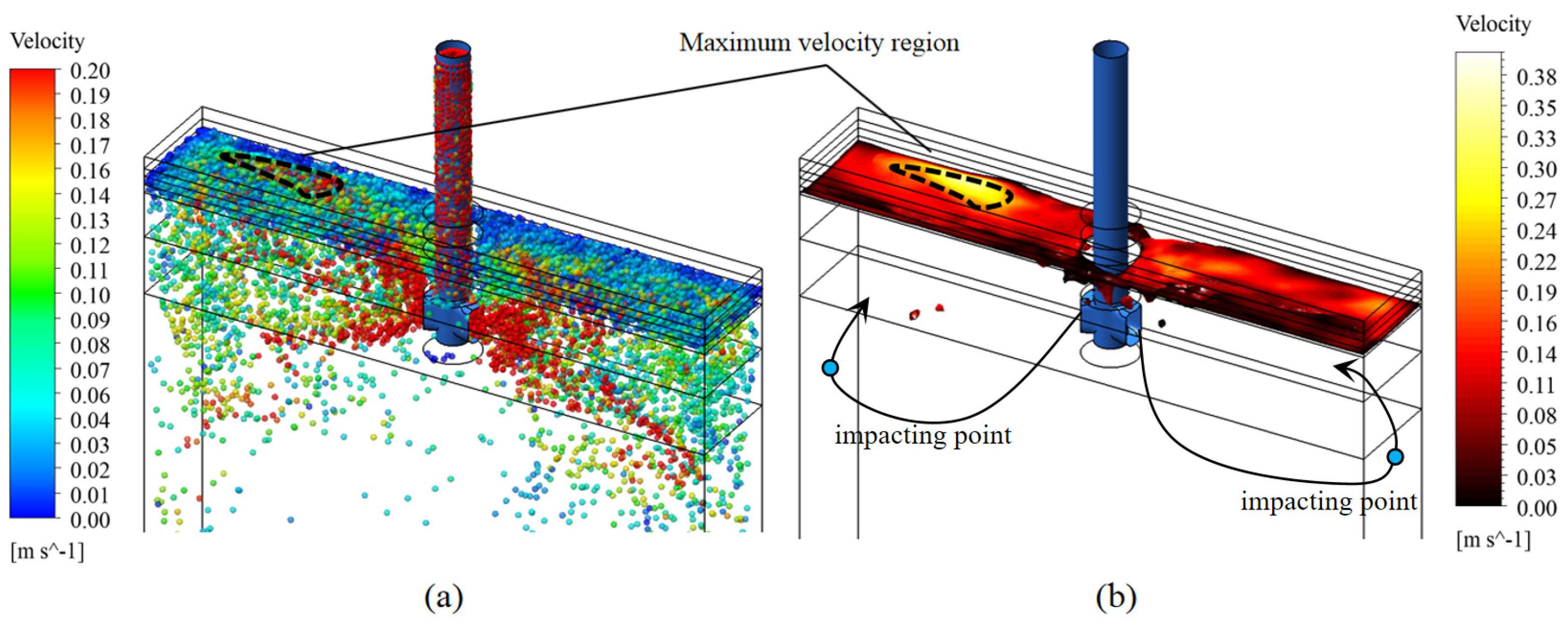

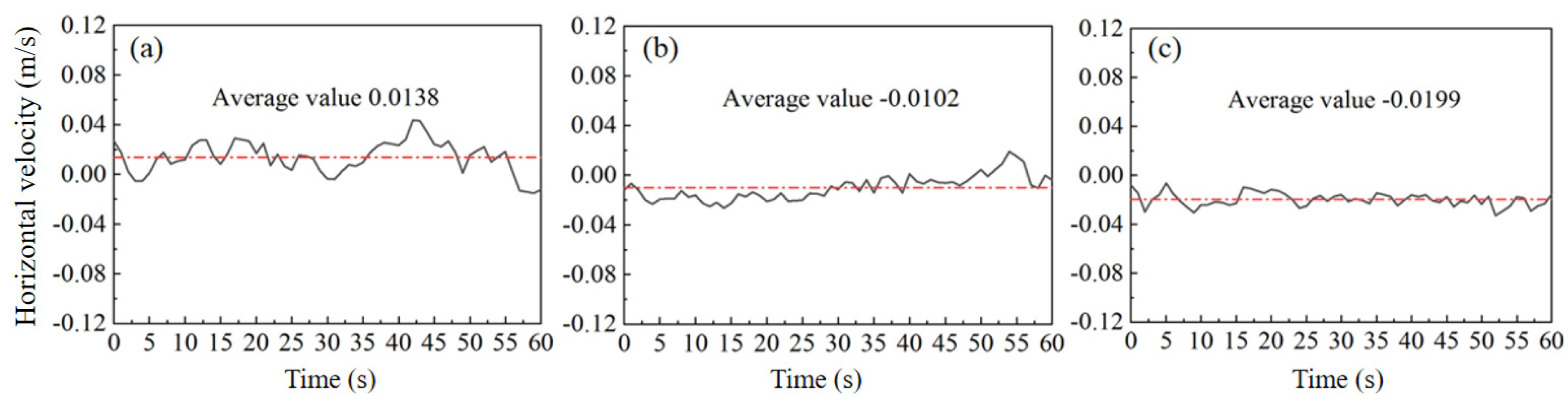

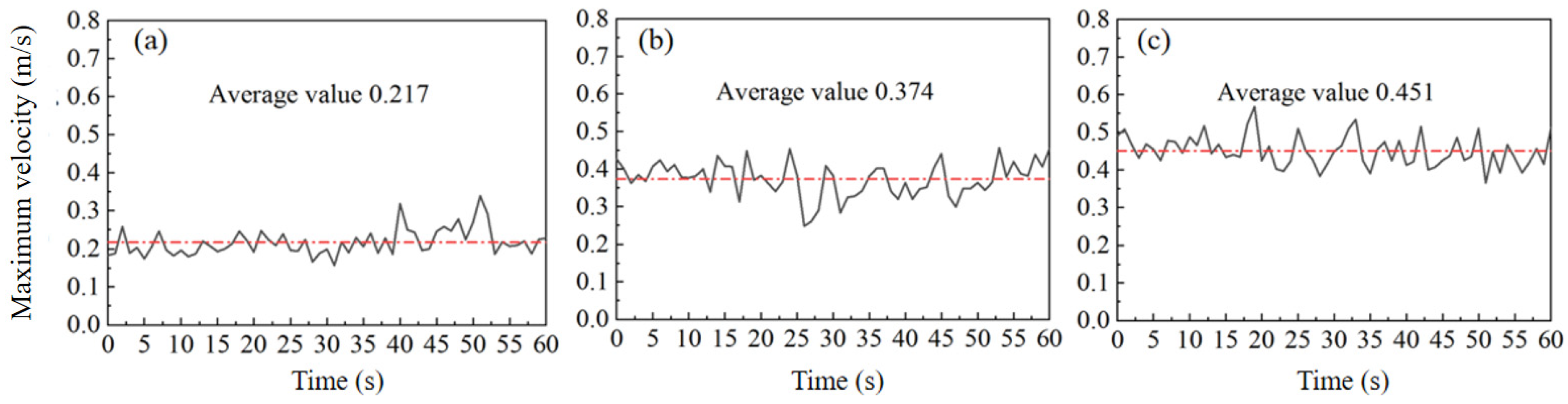

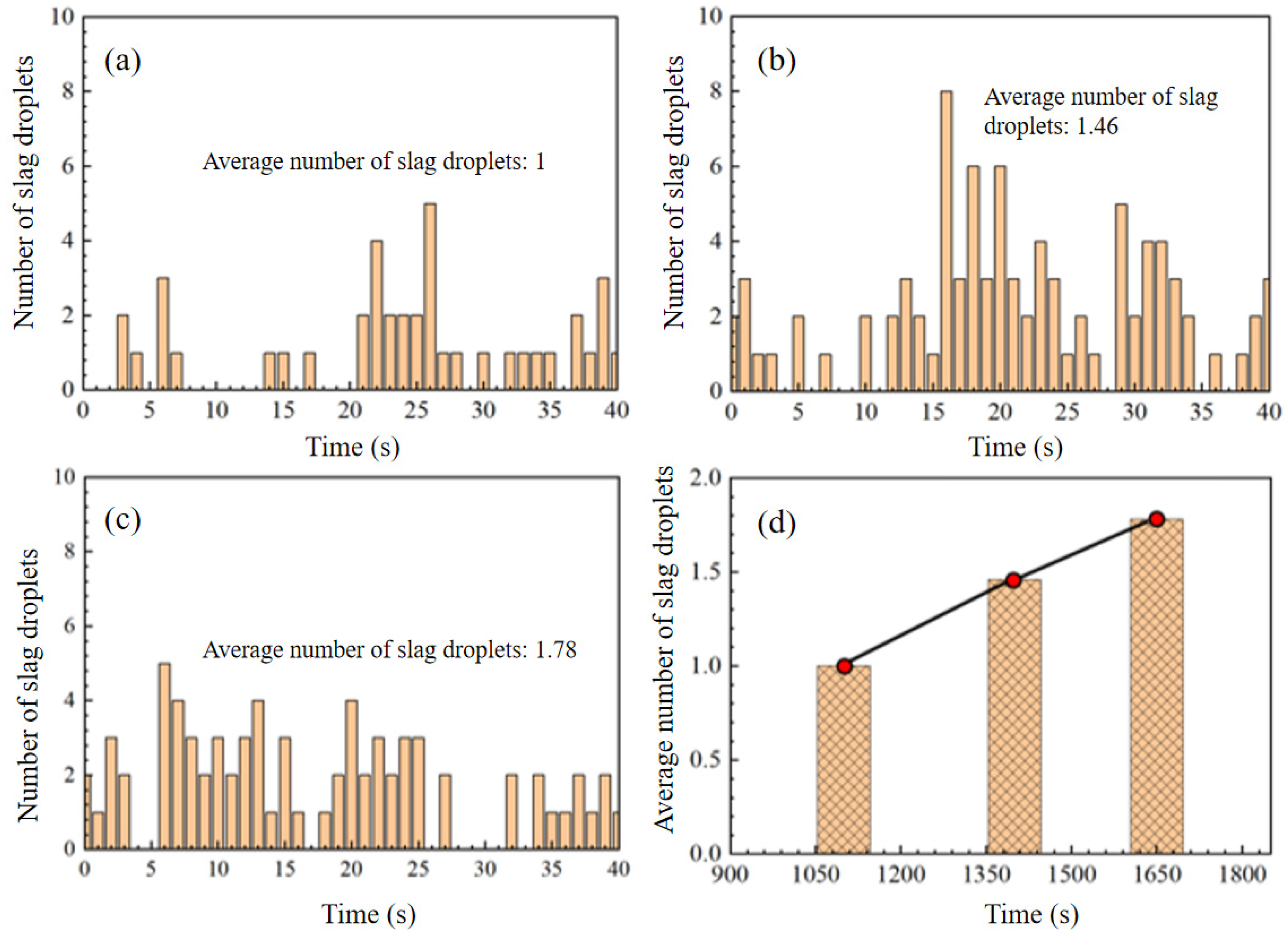

4.4. Prediction of Slag Entrapment in Mold

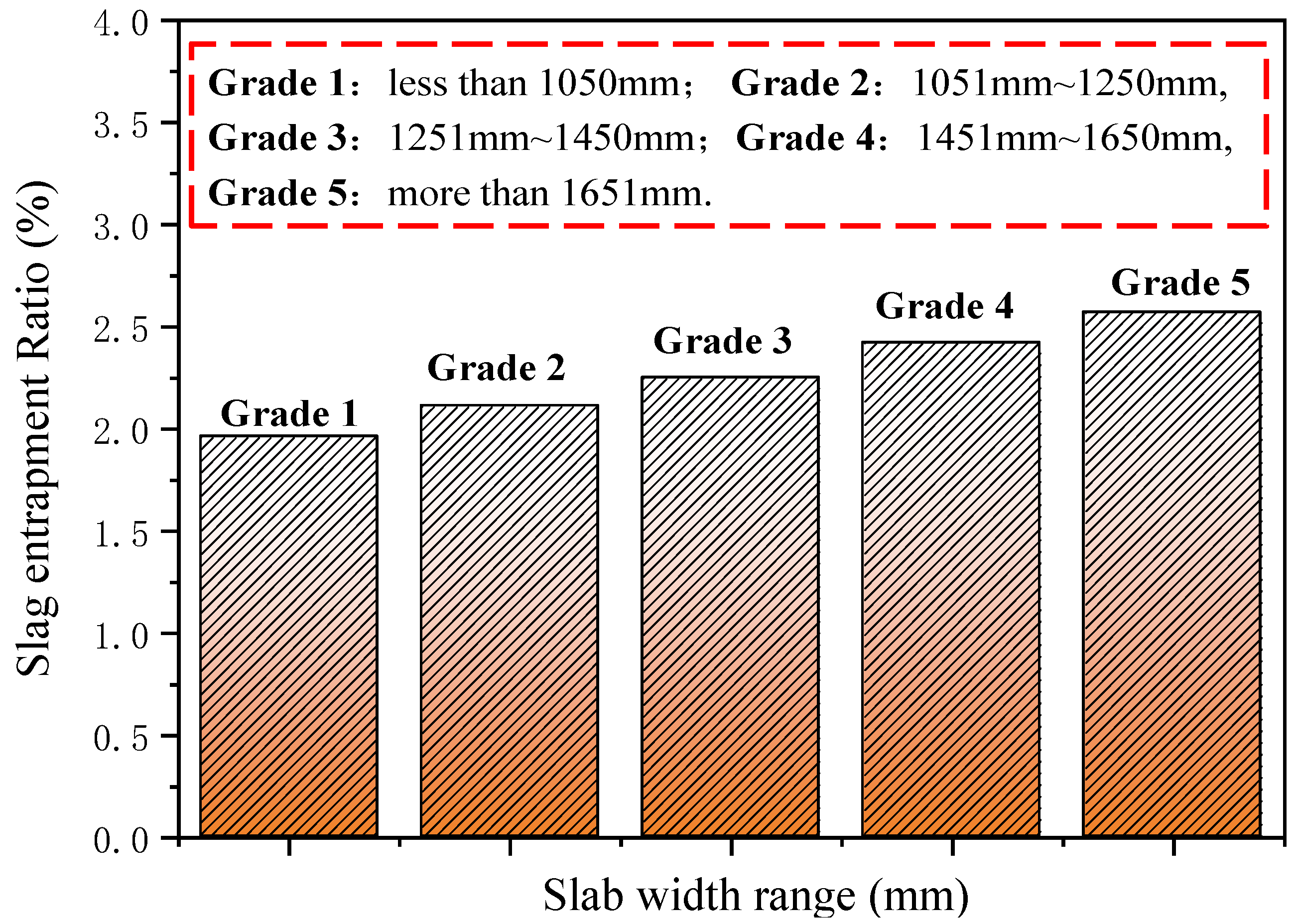

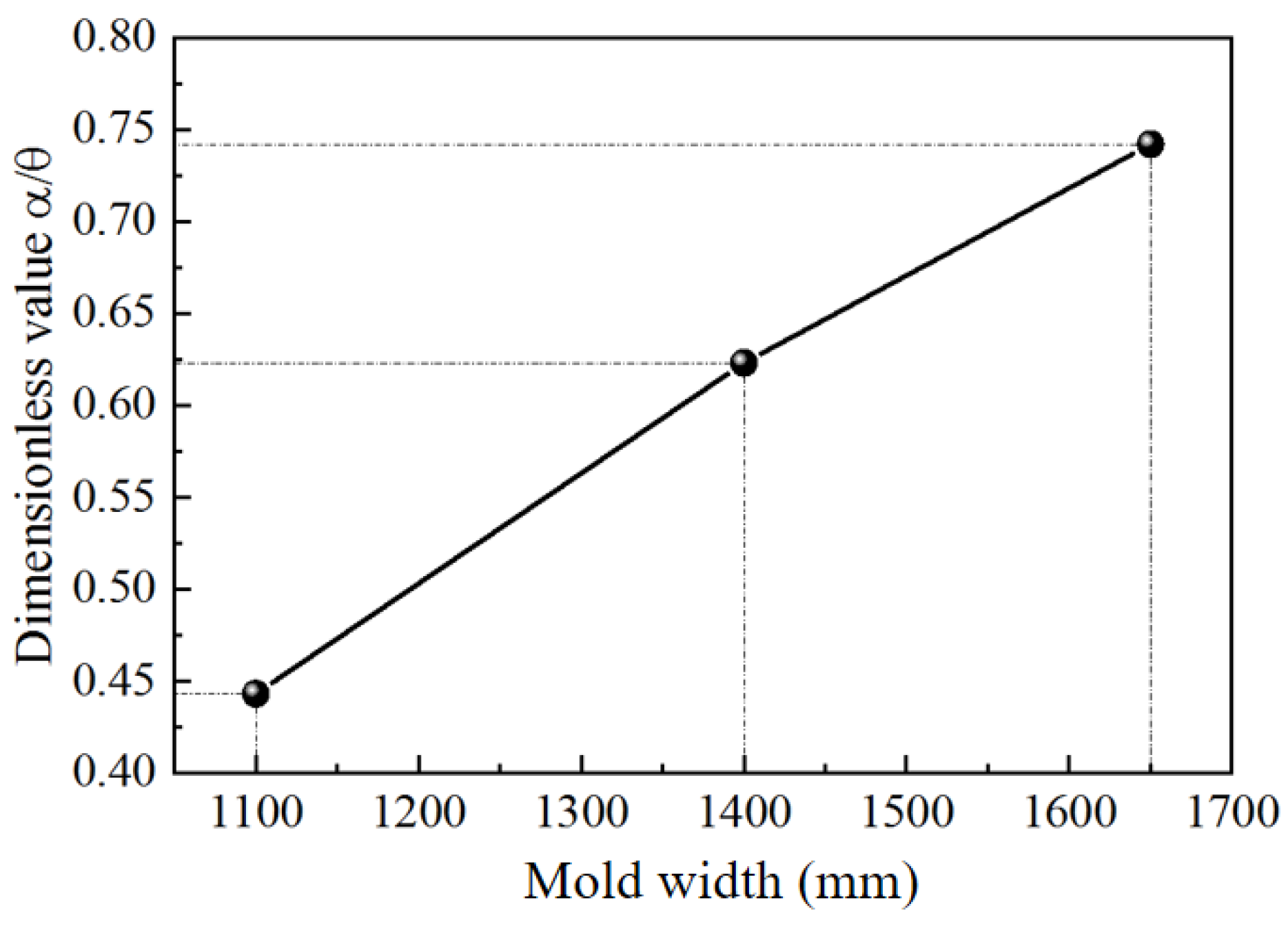

5. Slag Entrapment Evaluation Criteria

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gupta, D.; Lahiri, A.K. Water-modeling study of the surface disturbances in continuous slab caster. Metall. Mater. Trans. B 1994, 25, 227–233. [Google Scholar] [CrossRef]

- Li, B.K.; Li, D.H. Water model observation and numerical simulation of vortexing flow at molten steel surface in continuous casting mold. Acta Metall. Sin. 2002, 38, 315–320. [Google Scholar] [CrossRef]

- Iguchi, M.; Yoshida, J.; Shimizu, T.; Mizuno, Y. Model study on the entrapment of mold powder into molten steel. ISIJ Int. 2000, 40, 685–691. [Google Scholar] [CrossRef]

- Watanabe, T.; Iguchi, M. Water model experiments on the effect of an argon bubble on the meniscus near the immersion nozzle. ISIJ Int. 2009, 49, 182–188. [Google Scholar] [CrossRef][Green Version]

- Yamashita, S.; Iguchi, M. Mechanism of mold powder entrapment caused by large argon bubble in continuous casting mold. ISIJ Int. 2001, 41, 1529–1531. [Google Scholar] [CrossRef]

- Savolainen, J.; Fabritius, T.; Mattila, O. Effect of fluid physical properties on the emulsification. ISIJ Int. 2009, 49, 29–36. [Google Scholar] [CrossRef]

- Yamada, W.; Kiyose, A.; Fukuda, J.; Tanaka, H.; Nakashima, J.I. Simulation of coagulation of non-metallic inclusions in tundish and their trapping into solidified shell in continuous casting mould. Ironmak. Steelmak. 2003, 30, 151–157. [Google Scholar] [CrossRef]

- Jonsson, L.; Jönsson, P. Modeling of fluid flow conditions around the slag/metal interface in a gas-stirred ladle. ISIJ Int. 1996, 36, 1127–1134. [Google Scholar] [CrossRef]

- Gupta, D.; Lahiri, A.K. Cold model study of the surface profile in a continuous slab casting mold: Effect of second phase. Metall. Mater. Trans. B 1996, 27, 695. [Google Scholar] [CrossRef]

- Funada, T.; Joseph, D.D. Viscous potential flow analysis of Kelvin-Helmholtz instability in a channel. J. Fluid Mech. 2001, 445, 263–283. [Google Scholar] [CrossRef]

- Lei, H.; Zhu, M.Y.; He, J.C. Mathematical modeling of slag entrapment in continuous casting mould. Acta Metall. Sin. 2000, 36, 1113–1117. [Google Scholar] [CrossRef]

- Chung, Y.; Cramb, A.W. Dynamic and equilibrium interfacial phenomena in liquid steel-slag systems. Metall. Mater. Trans. B 2000, 31, 957–971. [Google Scholar] [CrossRef]

- Harman, J.M.; Cramb, A.W. A study of the effect of fluid physical properties upon droplet emulsification. In Proceedings of the 79th Steelmaking Conference, Pittsburgh, PA, USA, 24–27 March 1996; pp. 773–784. [Google Scholar]

- Saeedipour, M.; Puttinger, S.; Doppelhammer, N.; Pirker, S. Modelling slag entrainment in the continuous casting mold with LES-VOF simulations and comparison to a water/oil benchmark experiment. In Proceedings of the 9th European Continuous Casting Conference, Vienna, Austria, 26–29 June 2017; pp. 26–29. [Google Scholar]

- Liu, Z.Q.; Sun, Z.B.; Li, B.K. Modeling of quasi-four-phase flow in continuous casting mold using hybrid Eulerian and Lagrangian approach. Metall. Mater. Trans. B 2017, 48, 1248–1267. [Google Scholar] [CrossRef]

- Li, X.L.; Li, B.K.; Liu, Z.Q.; Niu, R.; Liu, Y.Q.; Zhao, C.L.; Huang, C.D.; Qiao, H.S.; Yuan, T.X. Large Eddy simulation of multi-phase flow and slag entrapment in a continuous casting mold. Metals 2019, 9, 7. [Google Scholar] [CrossRef]

- Li, X.L.; Li, B.K.; Liu, Z.Q.; Niu, R.; Liu, Q.; Huang, X.C.; Xu, G.D.; Ruan, X.M. Detection and numerical simulation of non-metallic inclusions in continuous casting slab. Steel Res. Int. 2019, 90, 1800423. [Google Scholar] [CrossRef]

- Li, X.L.; Li, B.K.; Liu, Z.Q.; Niu, R. Large Eddy simulation of electromagnetic three-phase flow in a round bloom considering solidified shell. Steel Res. Int. 2019, 90, 1800133. [Google Scholar] [CrossRef]

- Sun, M.J.; Li, B.K.; Li, L.M. A multi-scale mathematical model of growth and coalescence of bubbles beneath the anode in an aluminum reduction cell. Metall. Mater. Trans. B 2018, 49, 2821–2834. [Google Scholar] [CrossRef]

- Huang, X.C.; Li, B.K.; Liu, Z.Q.; Li, X.L.; Sun, M.J. Numerical investigation and experimental validation of motion and distribution of nonmetallic inclusions in argon protection electroslag remelting process. Metals 2018, 8, 392. [Google Scholar] [CrossRef]

| Source Term | Formula | Annotations |

|---|---|---|

| Buoyancy force plus gravity force, | The net effect acts on the difference between particle and fluid densities. The variable is gravity acceleration, is particle diameter. | |

| Drag force | Where drag coefficient ,and is particle velocity, Rep is particle Reynolds number. | |

| Pressure gradient force | Pressure gradient force is significant when | |

| Lift force | Where variable , , is stream-wise liquid velocity. | |

| Virtual mass force | Where the virtual mass force coefficient . |

| Parameters | Data |

|---|---|

| Casting speed (m·min−1) | 1.10, 0.86, 0.73 |

| Slab size/mm × mm | 1100 × 250, 1400 × 250, 1650 × 250 |

| Argon blowing rate (L·min−1) | 49.2 (1800 K) |

| Submerged depth of nozzle (mm) | 166.5 |

| Mold height (mm) | 900 |

| Air layer thickness (mm) | 50 |

| Thickness of slag layer (mm) | 40 |

| Nozzle angle (°) | 15°, downward |

| Dynamic viscosity of molten steel, slag, and air (kg·m−1·s−1) | 0.0051, 0.39, 1.7894 × 10−5 |

| Density of molten steel, slag, and argon (1809.15 K) (kg·m−3) | 7100, 3000, 0.266 |

| Interfacial tension between slag and liquid metal (N·m−1) | 1.2 |

| Interfacial tension between slag and air (N·m−1) | 0.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Li, X.; Zhang, J. Large Eddy Simulation of Multi-Phase Flow and Slag Entrapment in Molds with Different Widths. Metals 2021, 11, 374. https://doi.org/10.3390/met11020374

Zhao X, Li X, Zhang J. Large Eddy Simulation of Multi-Phase Flow and Slag Entrapment in Molds with Different Widths. Metals. 2021; 11(2):374. https://doi.org/10.3390/met11020374

Chicago/Turabian StyleZhao, Xianjiu, Xianglong Li, and Jieyu Zhang. 2021. "Large Eddy Simulation of Multi-Phase Flow and Slag Entrapment in Molds with Different Widths" Metals 11, no. 2: 374. https://doi.org/10.3390/met11020374

APA StyleZhao, X., Li, X., & Zhang, J. (2021). Large Eddy Simulation of Multi-Phase Flow and Slag Entrapment in Molds with Different Widths. Metals, 11(2), 374. https://doi.org/10.3390/met11020374