Effects of Heat Treatments on Microstructures and Mechanical Properties of Ti6Al4V Alloy Produced by Laser Solid Forming

Abstract

1. Introduction

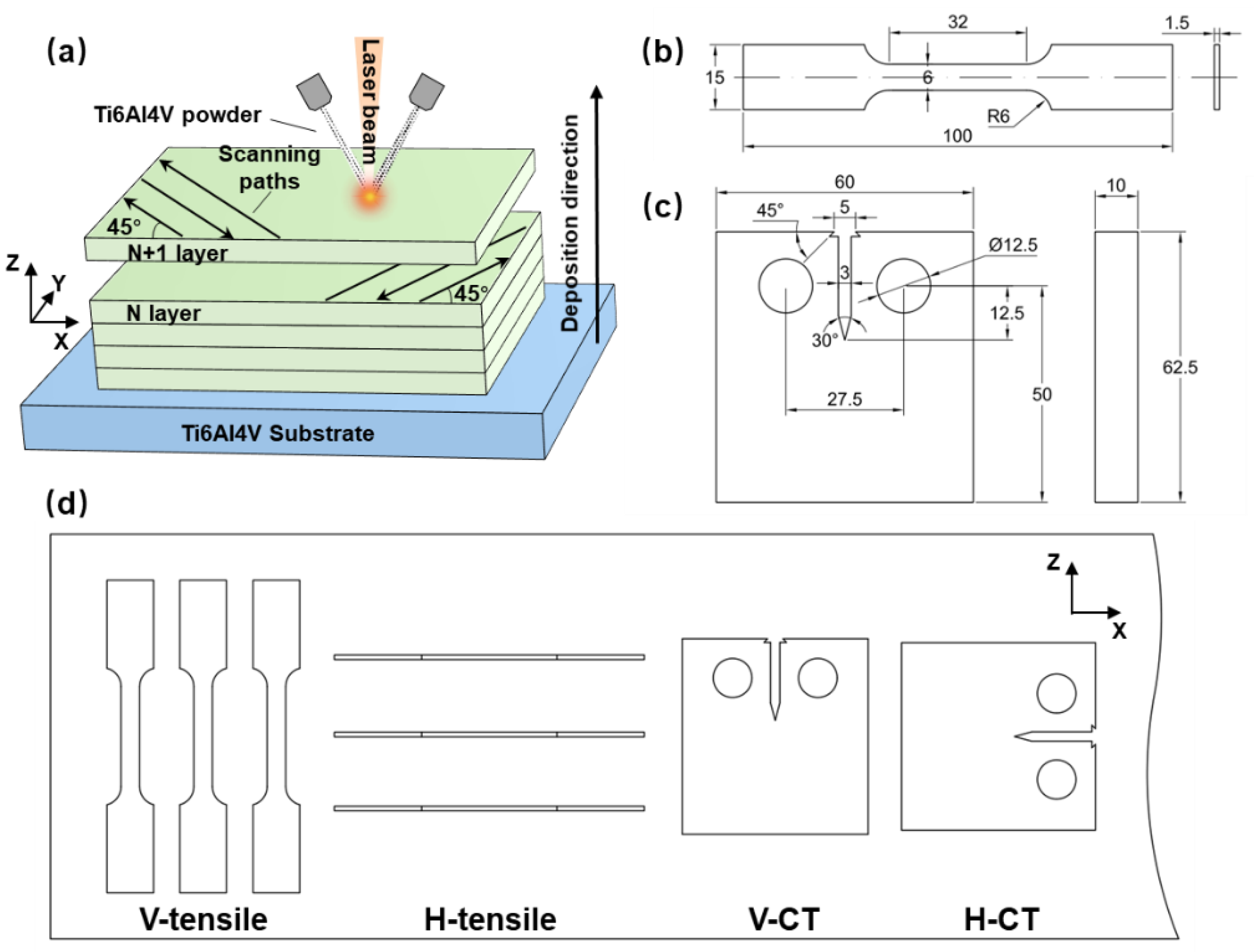

2. Materials and Methods

2.1. Materials

2.2. Heat Treatment

2.3. Microstructure and Mechanical Property Measurements

3. Results

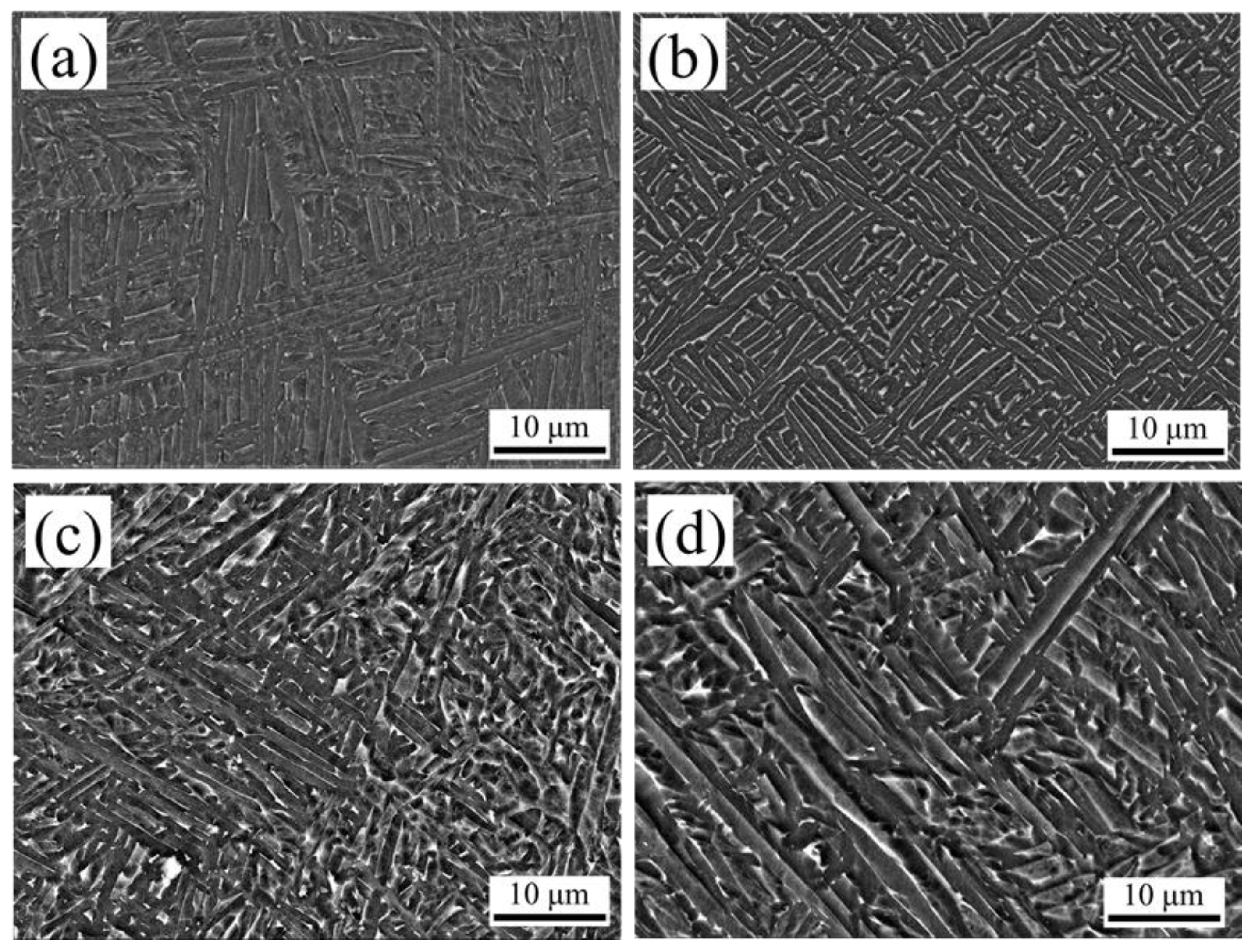

3.1. The Microstructures of LSFed Ti6Al4V Alloy before and after Heat Treatment

3.2. Mechanical Properties

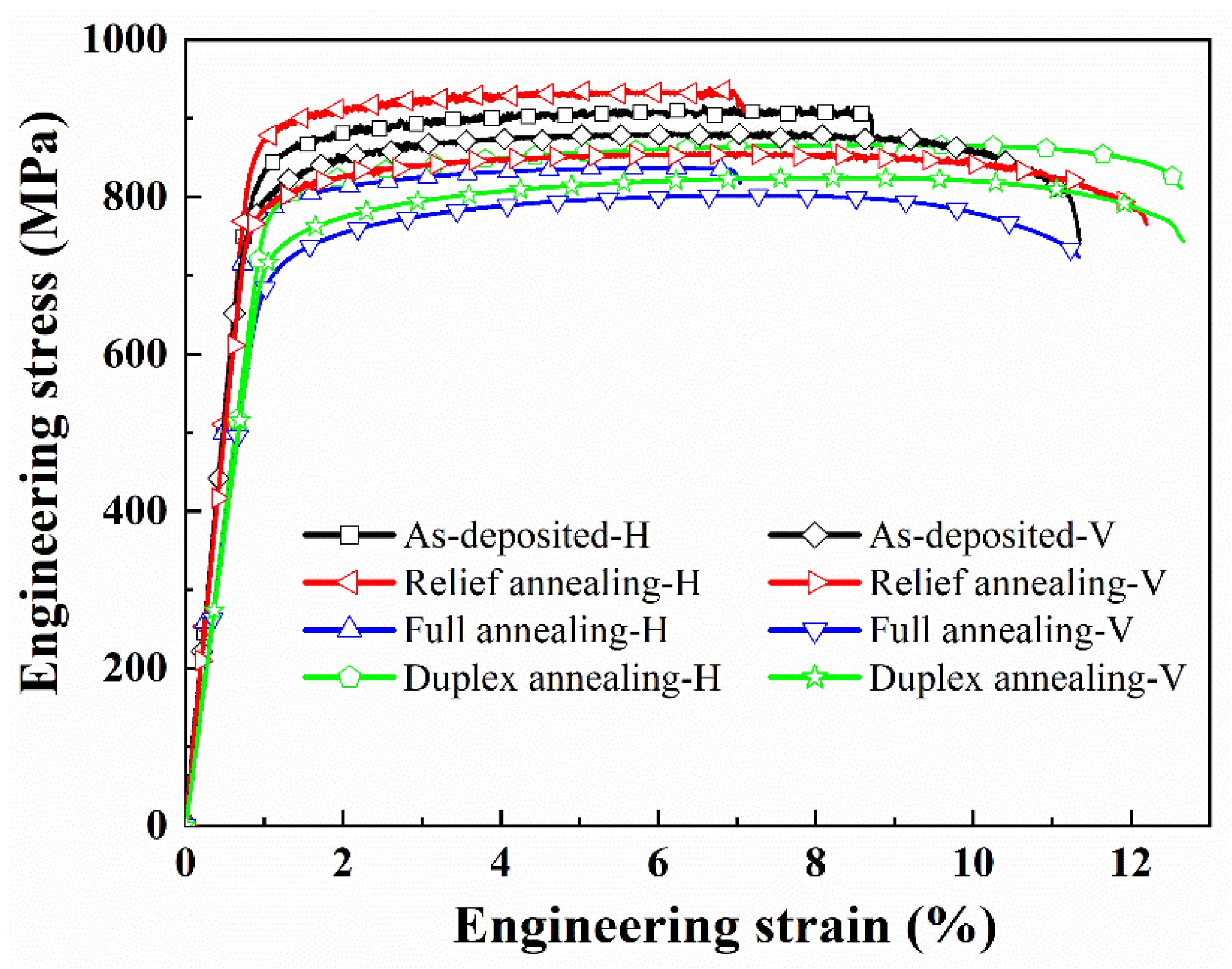

3.2.1. Microhardness and Tensile Behavior

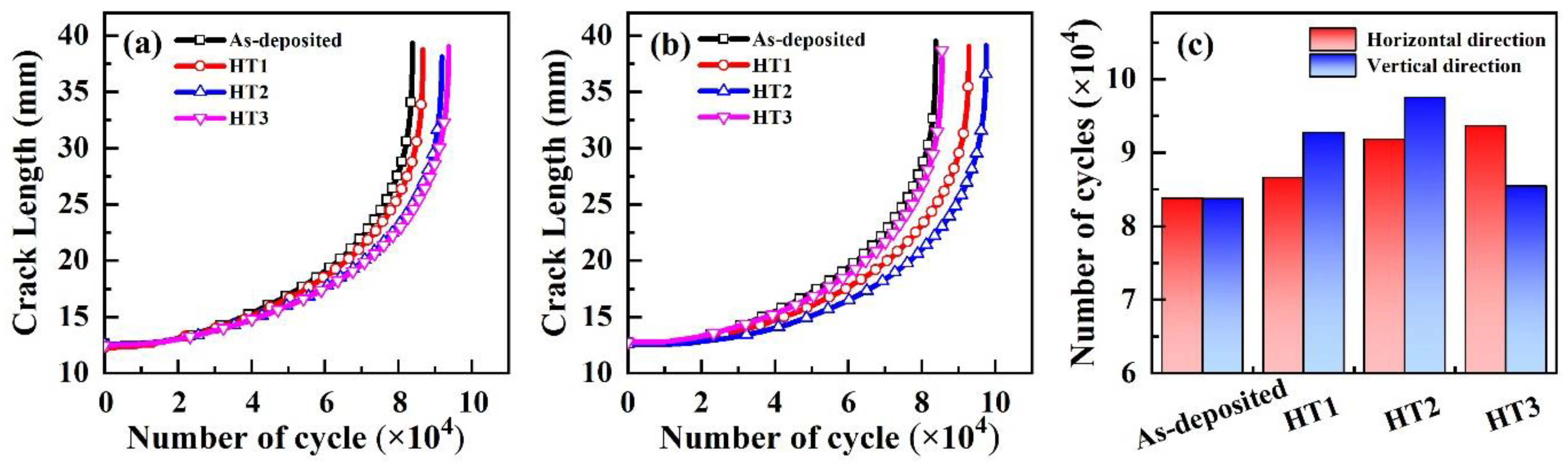

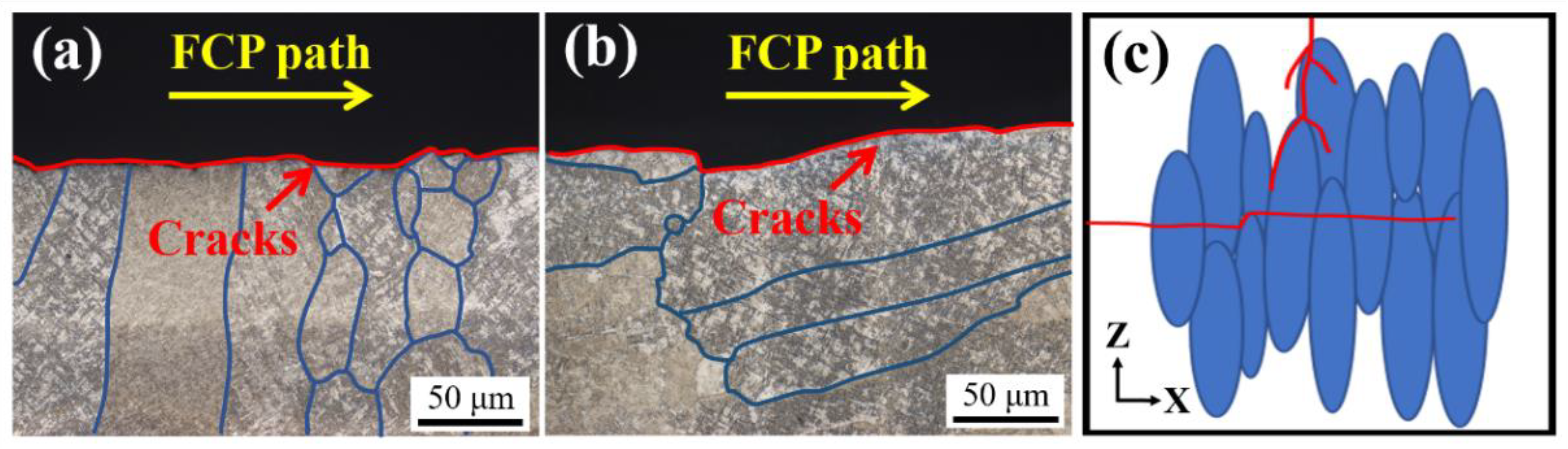

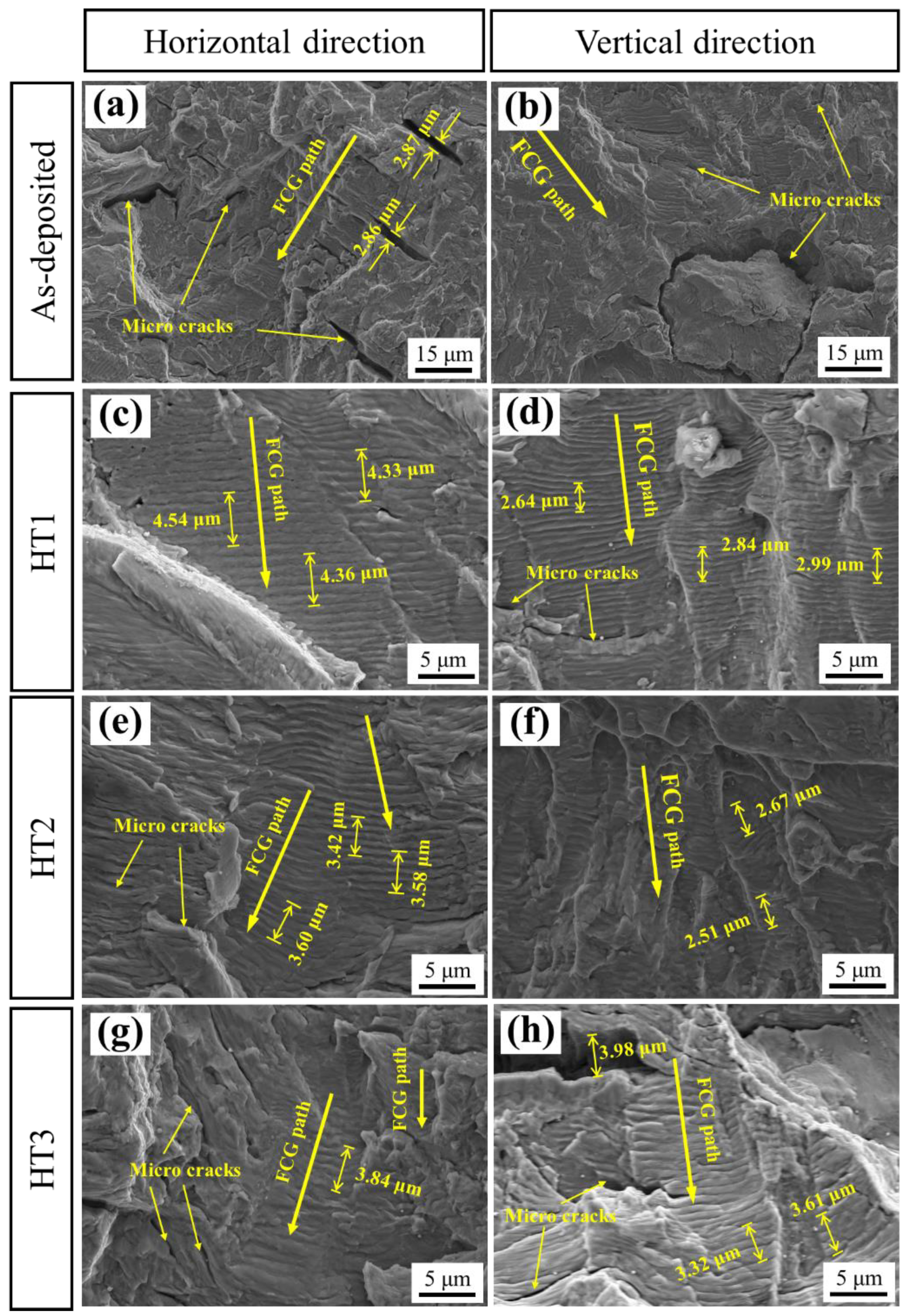

3.2.2. FCG Tests

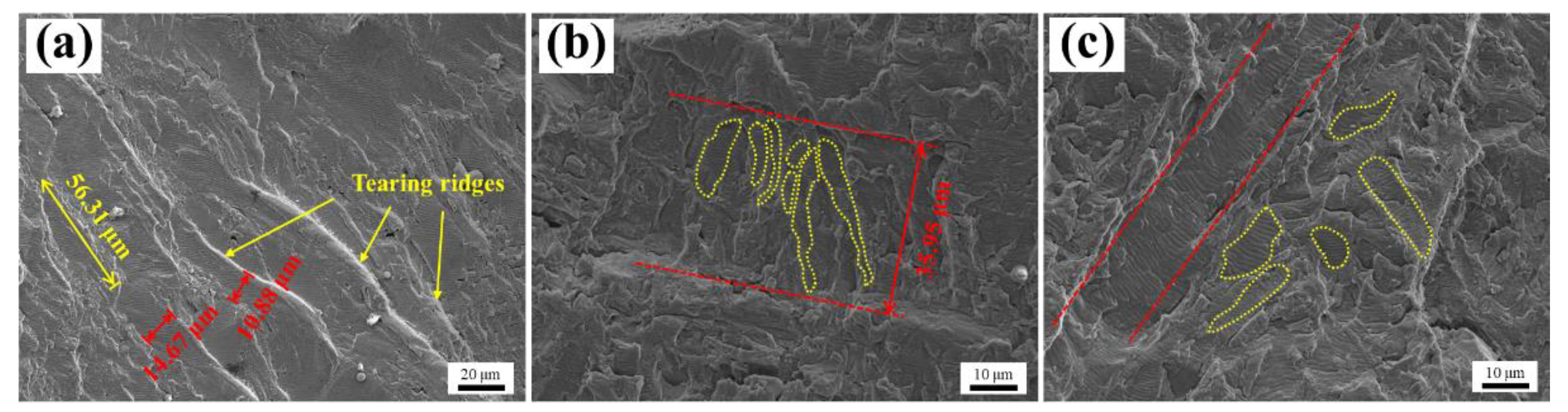

3.2.3. FCG Fracture Morphology

4. Conclusions

- HT1 promotes the transformation of α phases into α + β lamellar structure, while the fragmentation of α phases was facilitated in HT2 and HT3 due to higher temperature. The coarsening of α phase was more obvious during HT3 with low-temperature aging process.

- The microhardness of the heat-treated specimens under vacuum condition were reduced and that of the specimen after HT1 was higher due to the increase in the volume fraction of β phase. The strength of the HT1 specimen was improved as continuous β phase hinders the dislocation transfer between α phases.

- Tensile tests present the increase of elongations in the horizontal and vertical directions by 12.4% and 13.2% for specimens treated by two-step heat treatment (750 °C × 4 h + 500 °C × 1 h). Fatigue crack growth (FCG) testing shows specimens treated at 800 °C for 4 h exhibits a high fatigue life due to the refined a + β dual-phase structures.

- By comparing FCG rate of specimens in horizontal and vertical directions, it is found that the crack propagation perpendicular to the deposited direction seems to be more harmful than the parallel one.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Z.; Chen, J.; Lu, X.; Tan, H.; Lin, X.; Huang, W. Formation mechanism of the α variant and its influence on the tensile properties of laser solid formed Ti-6Al-4V titanium alloy. Mater. Sci. Eng. A 2017, 691, 16–24. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, J.; Zhao, Z.; Tan, H.; Lin, X.; Huang, W. Microstructure and anisotropic tensile behavior of laser additive manufactured TC21 titanium alloy. Mater. Sci. Eng. A 2016, 673, 204–212. [Google Scholar] [CrossRef]

- Paydas, H.; Mertens, A.; Carrus, R.; Lecomtebeckers, J.; Tchuindjang, J.T. Laser cladding as repair technology for Ti–6Al–4V alloy: Influence of building strategy on microstructure and hardness. Mater. Des. 2015, 85, 497–510. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Oliveira, J.; LaLonde, A.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Pham, M.-S.; Dovgyy, B.; Hooper, P.A.; Gourlay, C.M.; Piglione, A. The role of side-branching in microstructure development in laser powder-bed fusion. Nat. Commun. 2020, 11, 1–12. [Google Scholar] [CrossRef]

- Lopes, J.; Machado, C.M.; Duarte, V.R.; Rodrigues, T.A.; Santos, T.G.; Oliveira, J. Effect of milling parameters on HSLA steel parts produced by Wire and Arc Additive Manufacturing (WAAM). J. Manuf. Process. 2020, 59, 739–749. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Oliveira, J.; Panton, B.; Zeng, Z.; Andrei, C.; Zhou, Y.; Miranda, R.; Fernandes, F.B. Laser joining of NiTi to Ti6Al4V using a Niobium interlayer. Acta Mater. 2016, 105, 9–15. [Google Scholar] [CrossRef]

- Xue, A.; Wang, L.; Lin, X.; Wang, J.; Chen, J.; Huang, W. Effect of boron on the microstructure and mechanical properties of Ti-6Al-4V produced by laser directed energy deposition after heat treatment. J. Laser Appl. 2020, 32, 012007. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.S.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Yan, M.; Yu, M.Y.A.P. An Overview of Densification, Microstructure and Mechanical Property of Additively Manufactured Ti-6Al-4V—Comparison among Selective Laser Melting, Electron Beam Melting, Laser Metal Deposition and Selective Laser Sintering, and with Conventional Powder. In Sintering Techniques of Materials; IntechOpen: London, UK, 2015. [Google Scholar]

- Vilaro, T.; Colin, C.; Bartout, J.-D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Met. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Ter Haar, G.M.; Becker, T.H. Selective Laser Melting Produced Ti-6Al-4V: Post-Process Heat Treatments to Achieve Superior Tensile Properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef] [PubMed]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Kumar, P.; Ramamurty, U. Microstructural optimization through heat treatment for enhancing the fracture toughness and fatigue crack growth resistance of selective laser melted Ti 6Al 4V alloy. Acta Mater. 2019, 169, 45–59. [Google Scholar] [CrossRef]

- Li, J.; Lin, X.; Wang, J.; Zheng, M.; Guo, P.; Zhang, Y.; Ren, Y.; Liu, J.; Huang, W. Effect of stress-relief annealing on anodic dissolution behaviour of additive manufactured Ti-6Al-4V via laser solid forming. Corros. Sci. 2019, 153, 314–326. [Google Scholar] [CrossRef]

- Wycisk, E.; Solbach, A.; Siddique, S.; Herzog, D.; Walther, F.; Emmelmann, C. Effects of Defects in Laser Additive Manufactured Ti-6Al-4V on Fatigue Properties. Phys. Procedia 2014, 56, 371–378. [Google Scholar] [CrossRef]

- Irving, P.; Beevers, C. Microstructural influences on fatigue crack growth in Ti6Al4V. Mater. Sci. Eng. 1974, 14, 229–238. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.; Maier, H. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16ae1. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- ASTM E647-15e1. Standard Test Method for Measurement of Fatigue Crack Growth Rates; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti–6Al–4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Fu, M.; Yuan, Y.; Ma, X.; Lin, X. A study of α variant selection in laser solid forming Ti-6Al-4V. J. Alloys Compd. 2019, 792, 1261–1266. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Toh, W.Q.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Revealing martensitic transformation and α/β interface evolution in electron beam melting three-dimensional-printed Ti-6Al-4V. Sci. Rep. 2016, 6, 26039. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M. Fatigue crack growth mechanisms at the microstructure scale in as-fabricated and heat treated Ti-6Al-4V ELI manufactured by electron beam melting (EBM). Eng. Fract. Mech. 2017, 176, 263–280. [Google Scholar] [CrossRef]

- Kumar, P.; Prakash, O.; Ramamurty, U. Micro-and meso-structures and their influence on mechanical properties of selectively laser melted Ti-6Al-4V. Acta Mater. 2018, 154, 246–260. [Google Scholar] [CrossRef]

- Edwards, P.D.; O’Conner, A.; Ramulu, M. Electron Beam Additive Manufacturing of Titanium Components: Properties and Performance. J. Manuf. Sci. Eng. 2013, 135, 061016. [Google Scholar] [CrossRef]

- Edwards, P.G.; Ramulu, M. Effect of build direction on the fracture toughness and fatigue crack growth in selective laser melted Ti-6Al-4V. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1228–1236. [Google Scholar] [CrossRef]

- Rans, C.; Michielssen, J.; Walker, M.; Wang, W.; Hoen-Velterop, L.’T. Beyond the orthogonal: On the influence of build orientation on fatigue crack growth in SLM Ti-6Al-4V. Int. J. Fatigue 2018, 116, 344–354. [Google Scholar] [CrossRef]

- Schroeder, G.; Albrecht, J.; Luetjering, G. Fatigue crack propagation in titanium alloys with lamellar and bi-lamellar microstructures. Mater. Sci. Eng. A 2001, 319, 602–606. [Google Scholar] [CrossRef]

| Abbreviation | Meaning |

|---|---|

| LSF | laser solid forming |

| FCG | Fatigue crack growth |

| AM | Additive manufacturing |

| ΔKth | Stress intensity threshold factor |

| ΔK | Stress intensity factor |

| FC | Furnace cooling |

| OM | Optical microscope |

| SEM | Scanning electron microscope |

| CT specimens | Compact tensile specimens |

| COD | Crack opening displacement |

| αGB | α phases in grain boundary |

| αW | the Widmanstätten structure with parallel α plates |

| αWM | Intragranular basket-weave microstructure |

| YS | Yield strength |

| UTS | Ultimate tensile strength |

| EBAM | Electron beam additive manufacturing |

| da/dN | FCG rate |

| Heat Treatment | Temperature (°C) | Hold Time (h) | Method of Cooling | |

|---|---|---|---|---|

| As-deposited | ||||

| HT1 | 550 | 2 | FC | |

| HT2 | 800 | 4 | FC | |

| HT3 | Step 1 | 750 | 4 | FC |

| Step 2 | 500 | 1 | FC | |

| Heat Treatment | β Phase Fraction | α Phase Width (Min–Max) |

|---|---|---|

| As-deposited | <2% | 0.2–1.8 μm |

| HT1 | 19% | 0.4–1.5 μm |

| HT2 | 8% | 0.3–0.9 μm |

| HT3 | 6% | 0.6–1.8 μm |

| Specimen | Direction | Microhardness (HV) | YS (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| As-deposited | H | 370 ± 8 | 831 ± 6 | 909 ± 8 | 11.5 ± 0.8 |

| V | 366 ± 9 | 789 ± 12 | 885 ± 11 | 12.1 ± 0.7 | |

| HT1 | H | 356 ± 5 | 866 ± 6 | 934 ± 4 | 11.1 ± 0.4 |

| V | 355 ± 5 | 787 ± 6 | 862 ± 6 | 12.1 ± 1.2 | |

| HT2 | H | 344 ± 8 | 768 ± 21 | 837 ± 29 | 8.2 ± 1.6 |

| V | 347 ± 10 | 711 ± 13 | 809 ± 20 | 12.7 ± 1.0 | |

| HT3 | H | 352 ± 9 | 786 ± 17 | 852 ± 19 | 12.4 ± 0.4 |

| V | 348 ± 11 | 740 ± 5 | 821 ± 9 | 13.2 ± 0.6 |

| Specimens | Direction | m | C |

|---|---|---|---|

| As-deposited | H | 2.66 | 7.39 × 10−8 |

| V | 2.51 | 1.07 × 10−7 | |

| HT1 | H | 2.72 | 5.44 × 10−8 |

| V | 2.34 | 1.79 × 10−7 | |

| HT2 | H | 2.68 | 6.36 × 10−8 |

| V | 2.59 | 8.71 × 10−8 | |

| HT3 | H | 2.54 | 9.80 × 10−8 |

| V | 2.74 | 4.98 × 10−8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Qi, B.; Zhang, Y.; Guo, W.; Peng, P.; Zhang, H.; He, G.; Zhu, D.; Yan, J. Effects of Heat Treatments on Microstructures and Mechanical Properties of Ti6Al4V Alloy Produced by Laser Solid Forming. Metals 2021, 11, 346. https://doi.org/10.3390/met11020346

Li F, Qi B, Zhang Y, Guo W, Peng P, Zhang H, He G, Zhu D, Yan J. Effects of Heat Treatments on Microstructures and Mechanical Properties of Ti6Al4V Alloy Produced by Laser Solid Forming. Metals. 2021; 11(2):346. https://doi.org/10.3390/met11020346

Chicago/Turabian StyleLi, Fei, Bojin Qi, Yongxin Zhang, Wei Guo, Peng Peng, Hepeng Zhang, Guangzhi He, Dezhi Zhu, and Jianfeng Yan. 2021. "Effects of Heat Treatments on Microstructures and Mechanical Properties of Ti6Al4V Alloy Produced by Laser Solid Forming" Metals 11, no. 2: 346. https://doi.org/10.3390/met11020346

APA StyleLi, F., Qi, B., Zhang, Y., Guo, W., Peng, P., Zhang, H., He, G., Zhu, D., & Yan, J. (2021). Effects of Heat Treatments on Microstructures and Mechanical Properties of Ti6Al4V Alloy Produced by Laser Solid Forming. Metals, 11(2), 346. https://doi.org/10.3390/met11020346