GPU-Accelerated Cellular Automaton Model for Grain Growth during Directional Solidification of Nickel-Based Superalloy

Abstract

1. Introduction

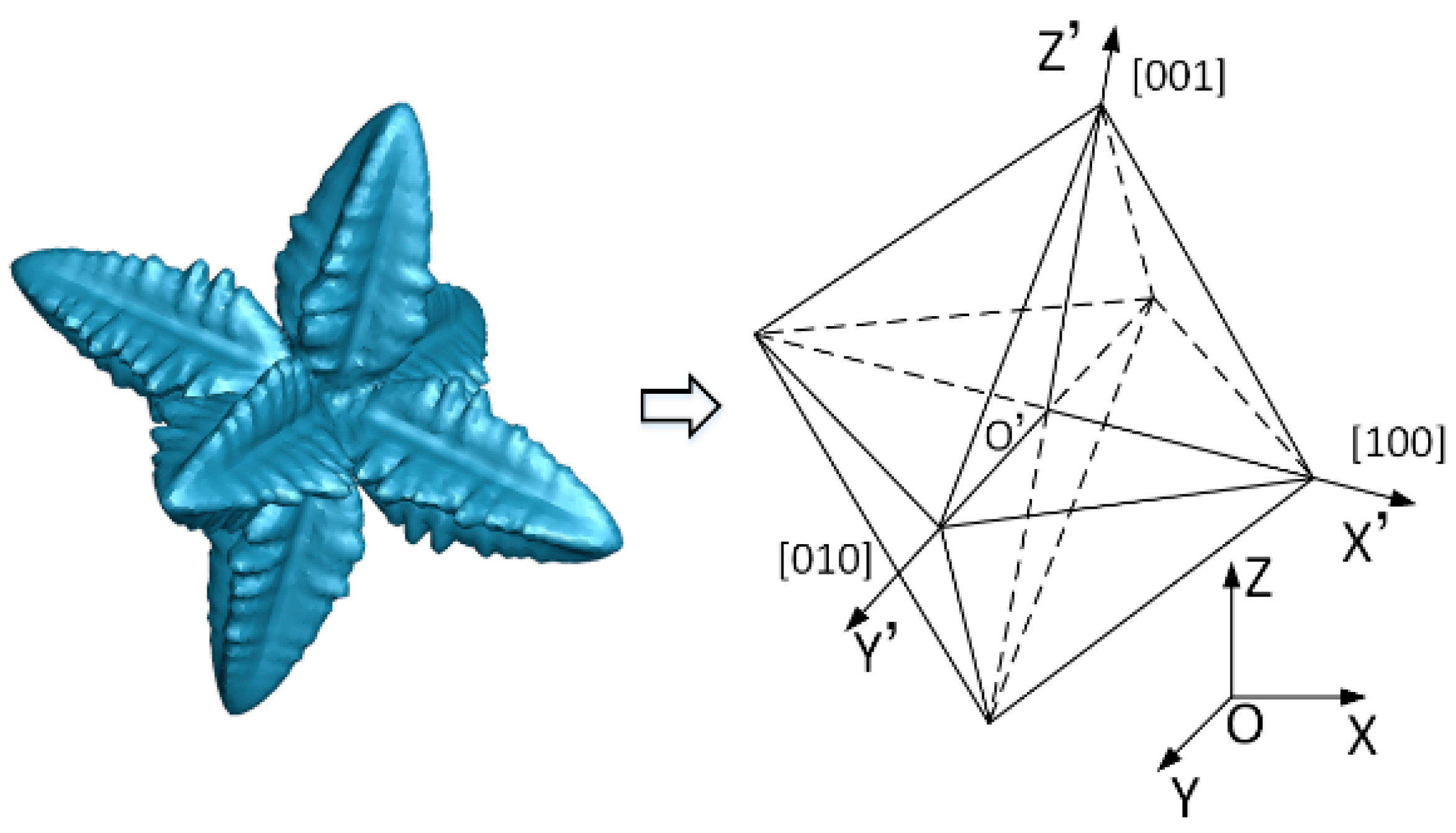

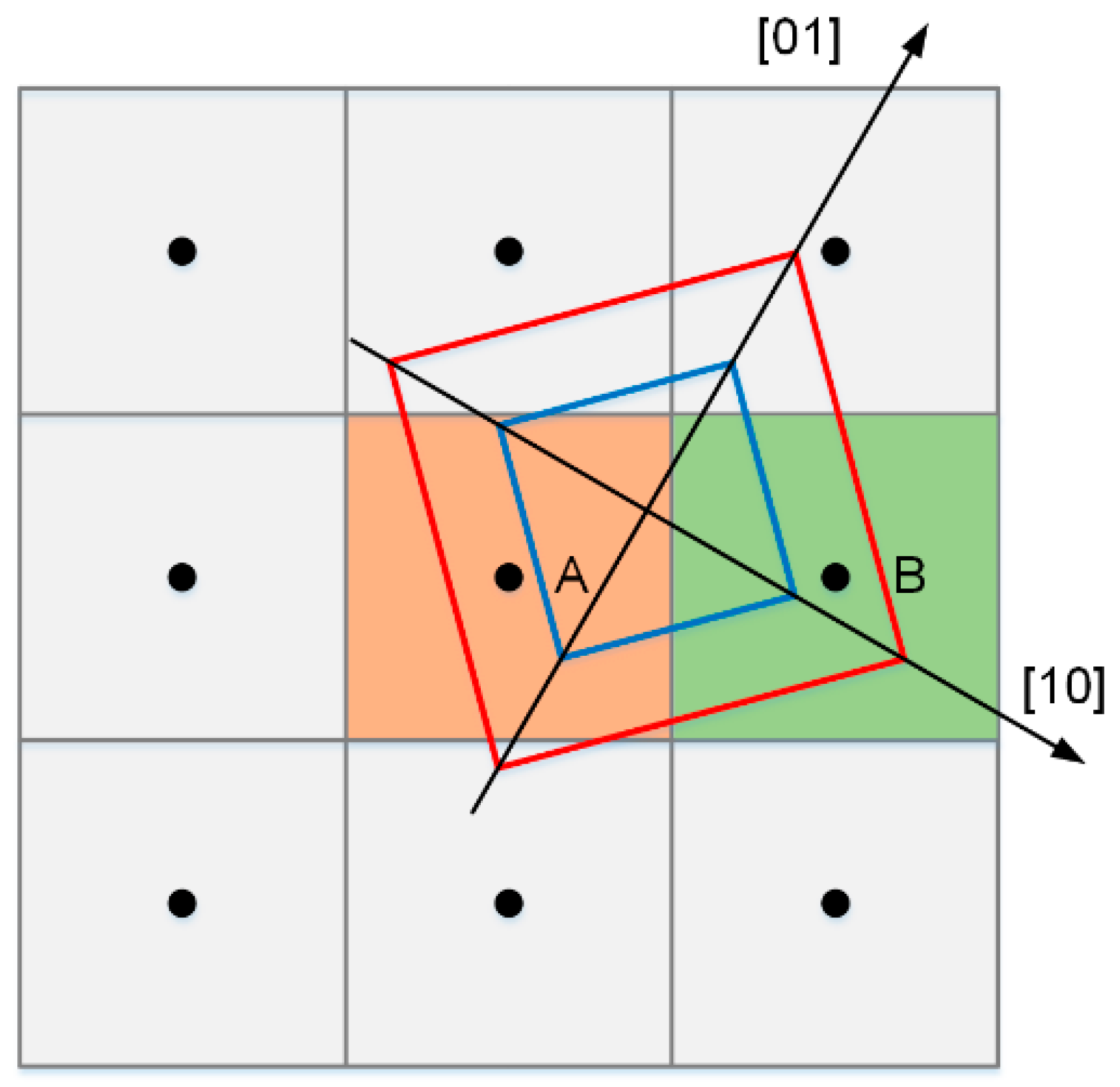

2. A Cellular Automaton Model

2.1. Nucleation Model and Grain Growth Algorithm

2.2. Algorithm Implementation on GPU

- (1)

- Heat transfer calculation on grids by FDM.

- (2)

- Temperature interpolation from FDM grids to CA cells.

- (3)

- Check nucleation of each liquid cell by the continuous nucleation model in Equation (1).

- (4)

- Grain growth by updating the dendrite tip length of each interface cell according to Equation (2).

- (5)

- Cell capture by searching the Moore neighborhoods of the interface cells following the rule shown in Figure 2.

- (6)

- Status transition of the interface cells and the corresponding captured liquid cells.

3. Model Verification

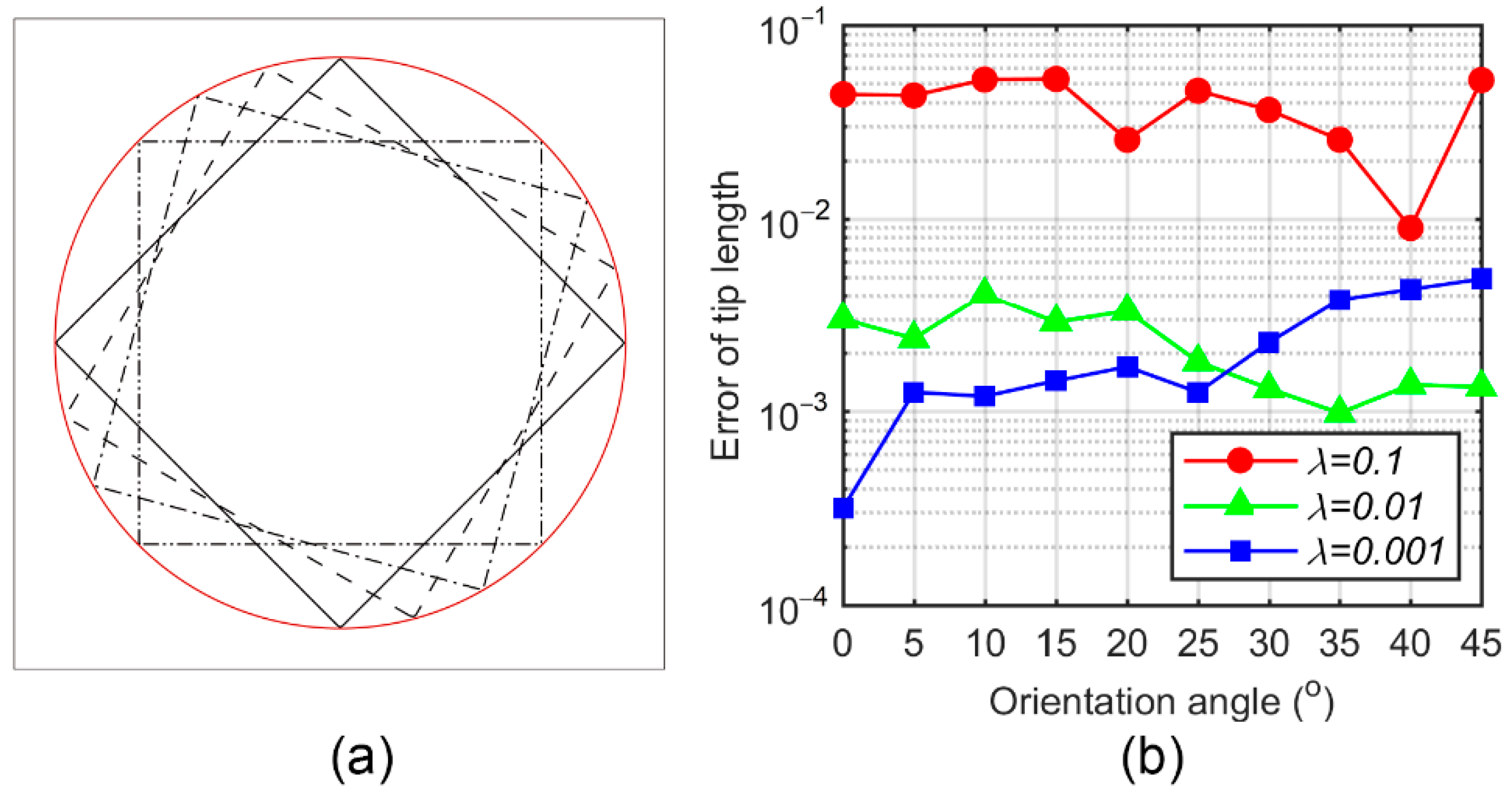

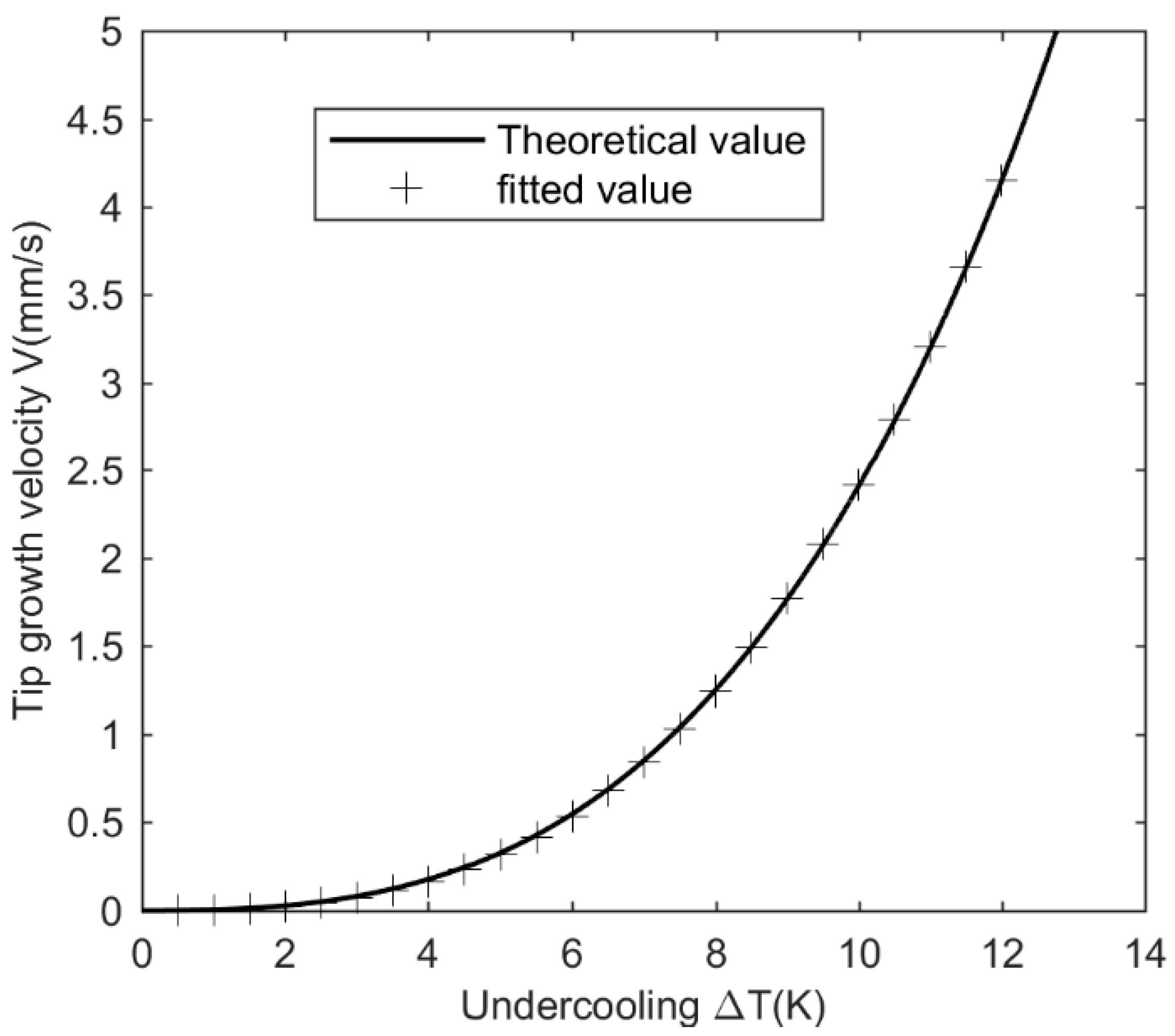

3.1. Single Grain Growth

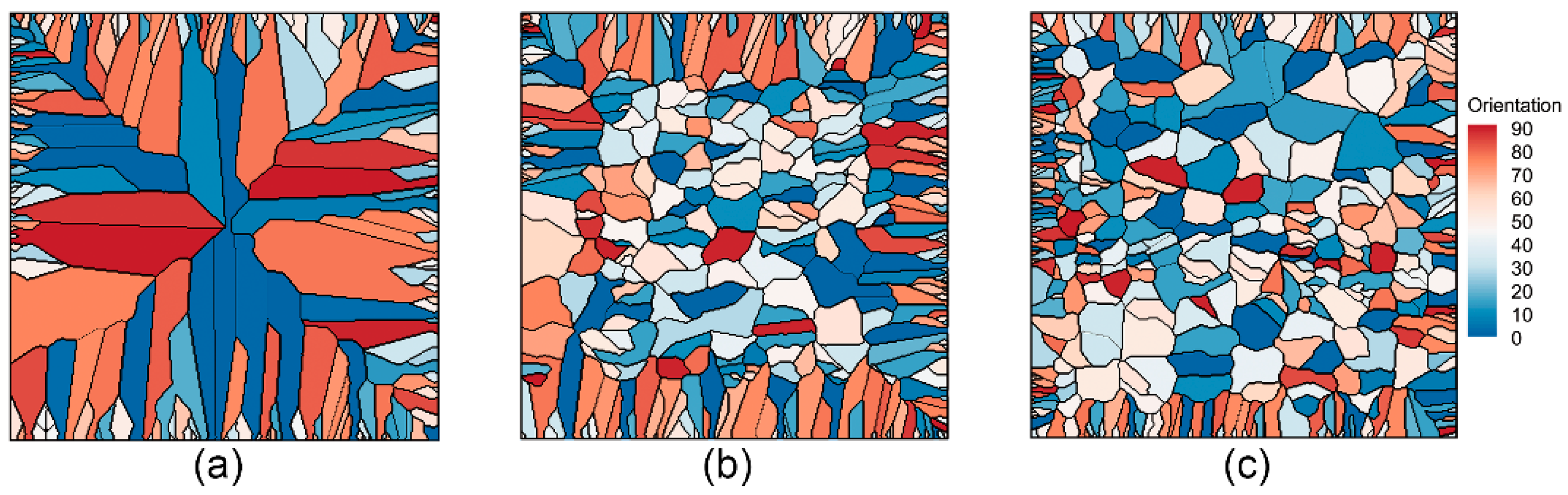

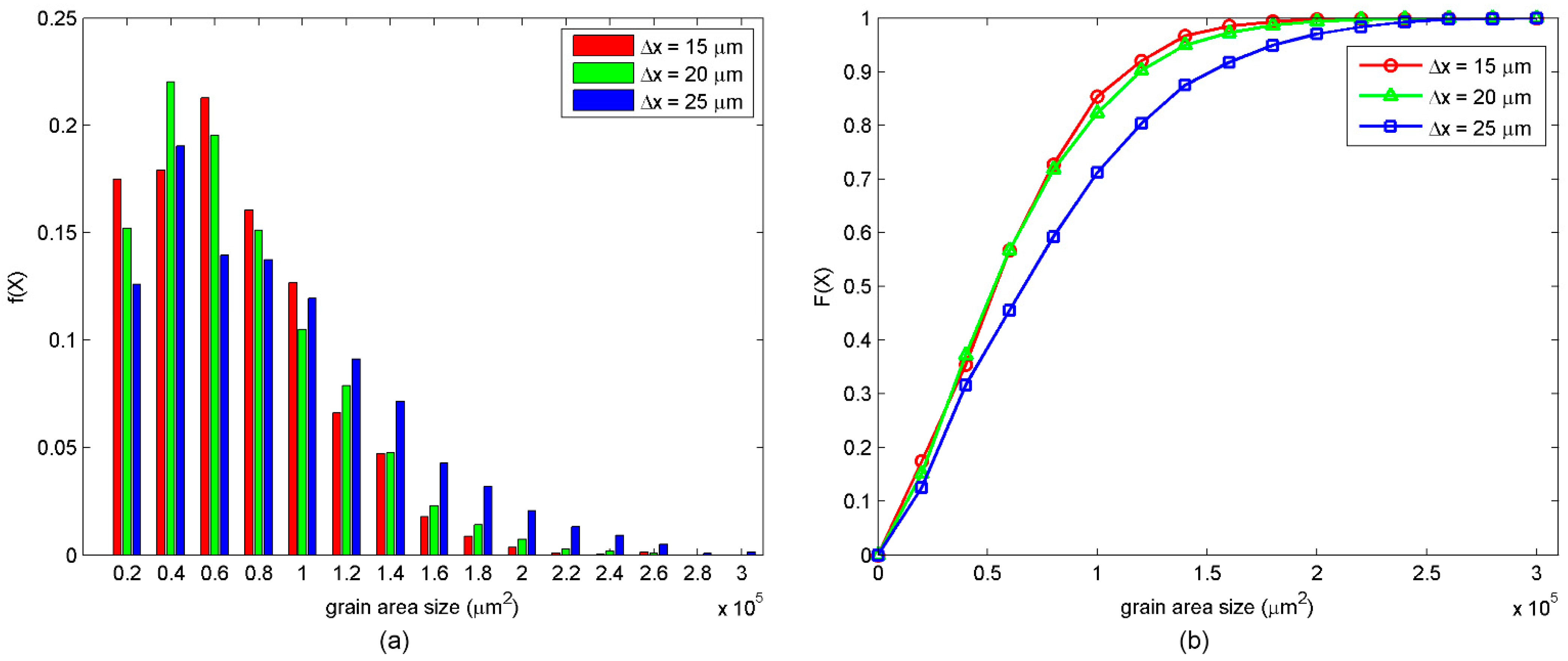

3.2. Grain Growth with a Uniform Undercooling

4. Simulation and Discussion

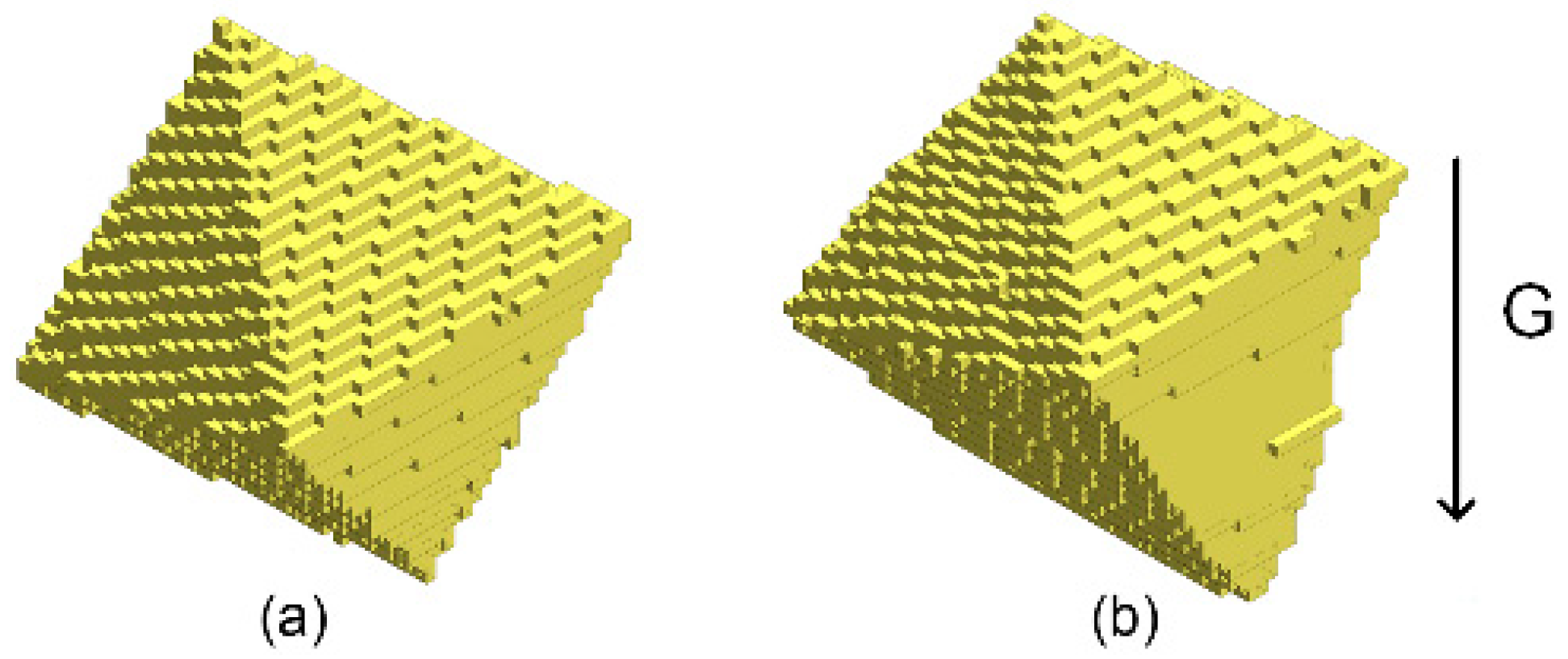

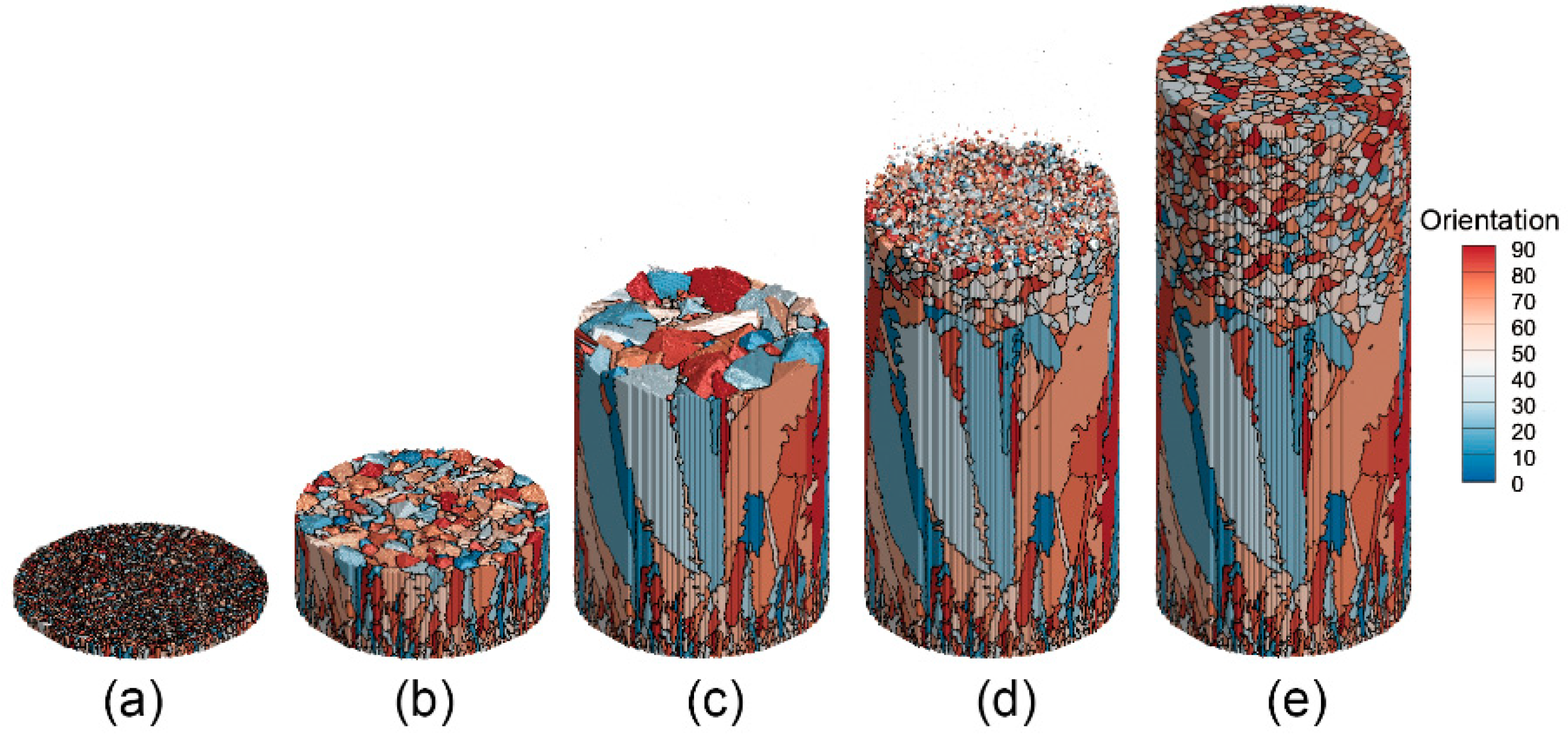

4.1. Grain Growth during Directional Solidification

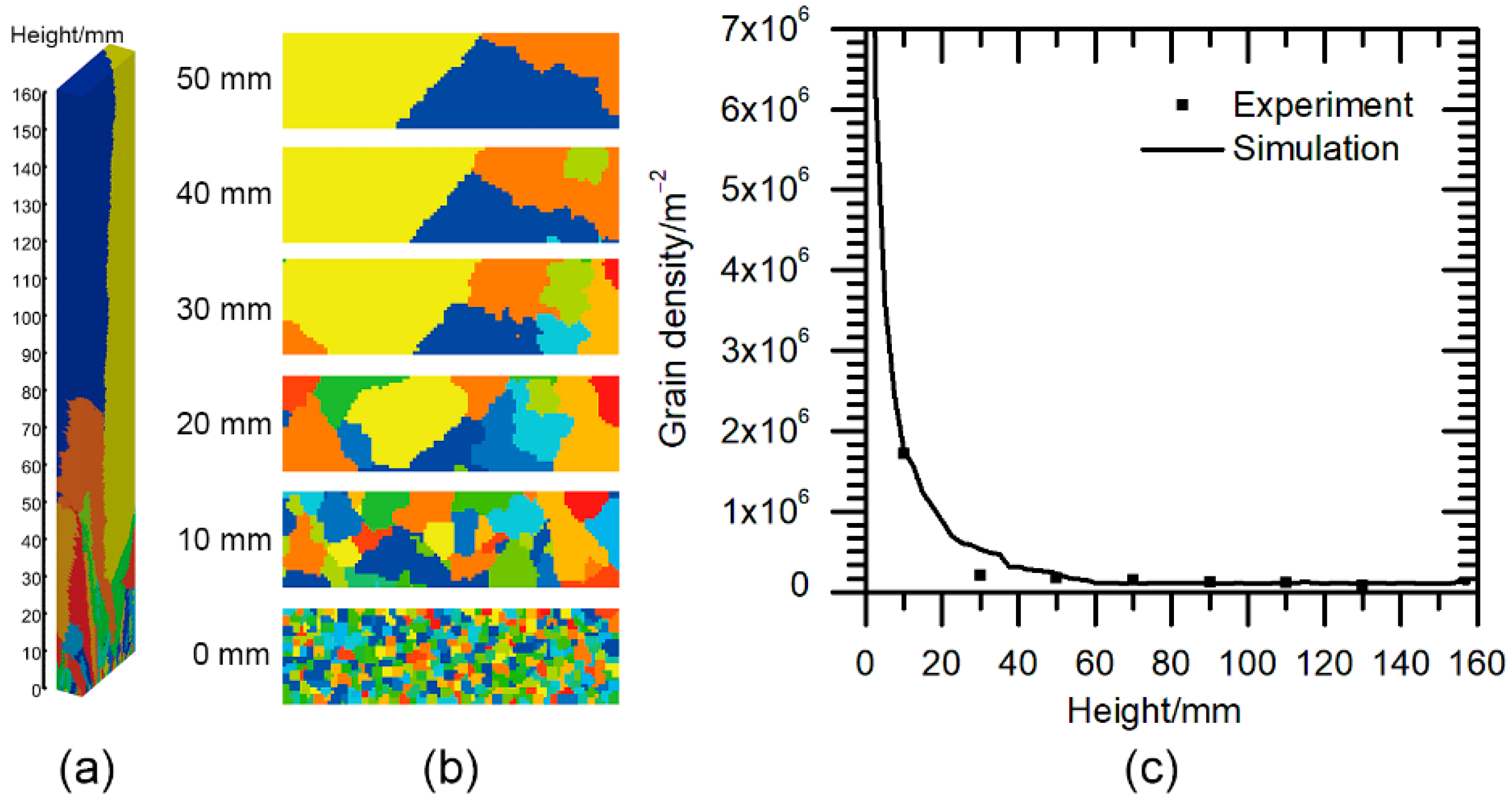

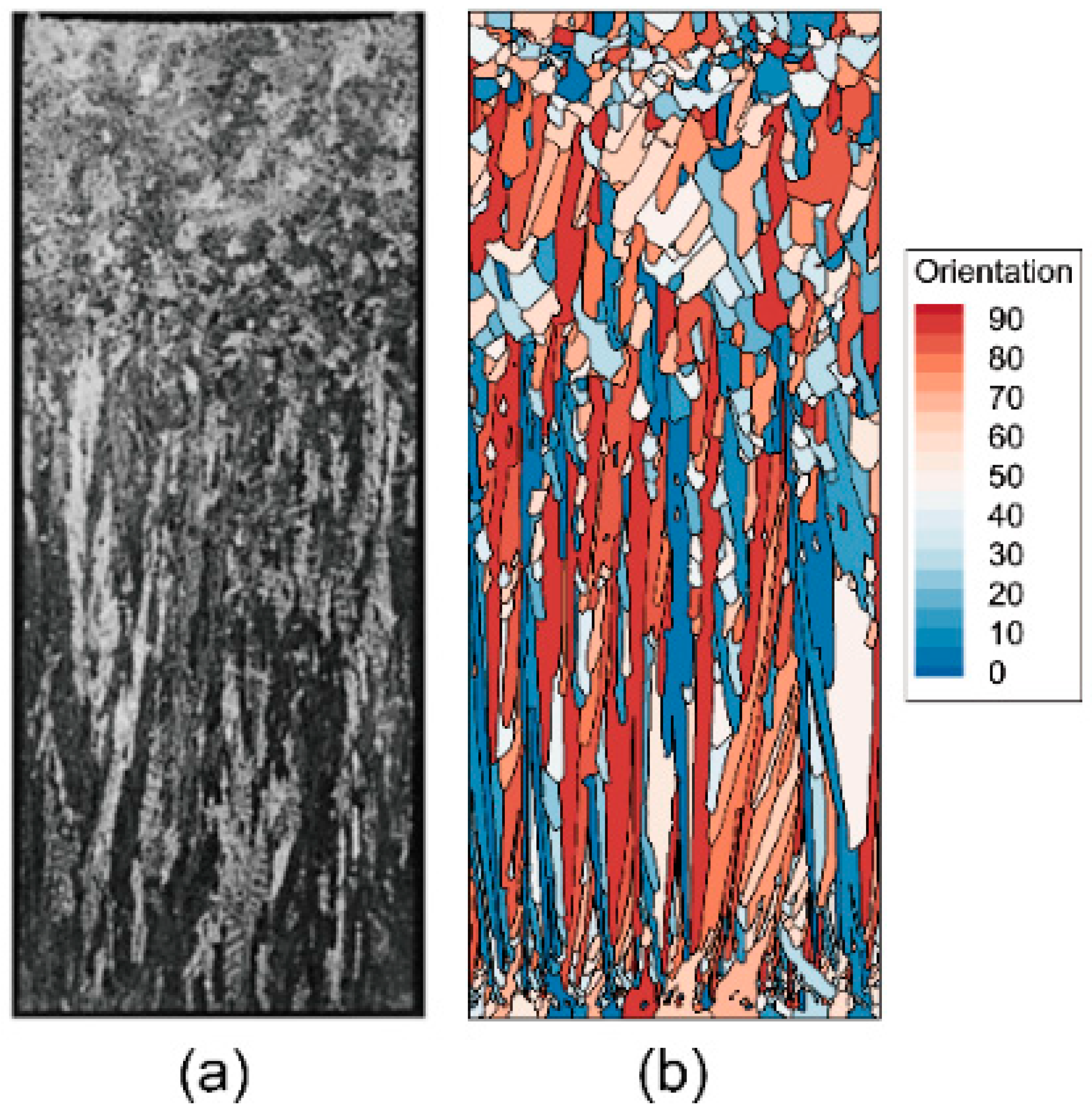

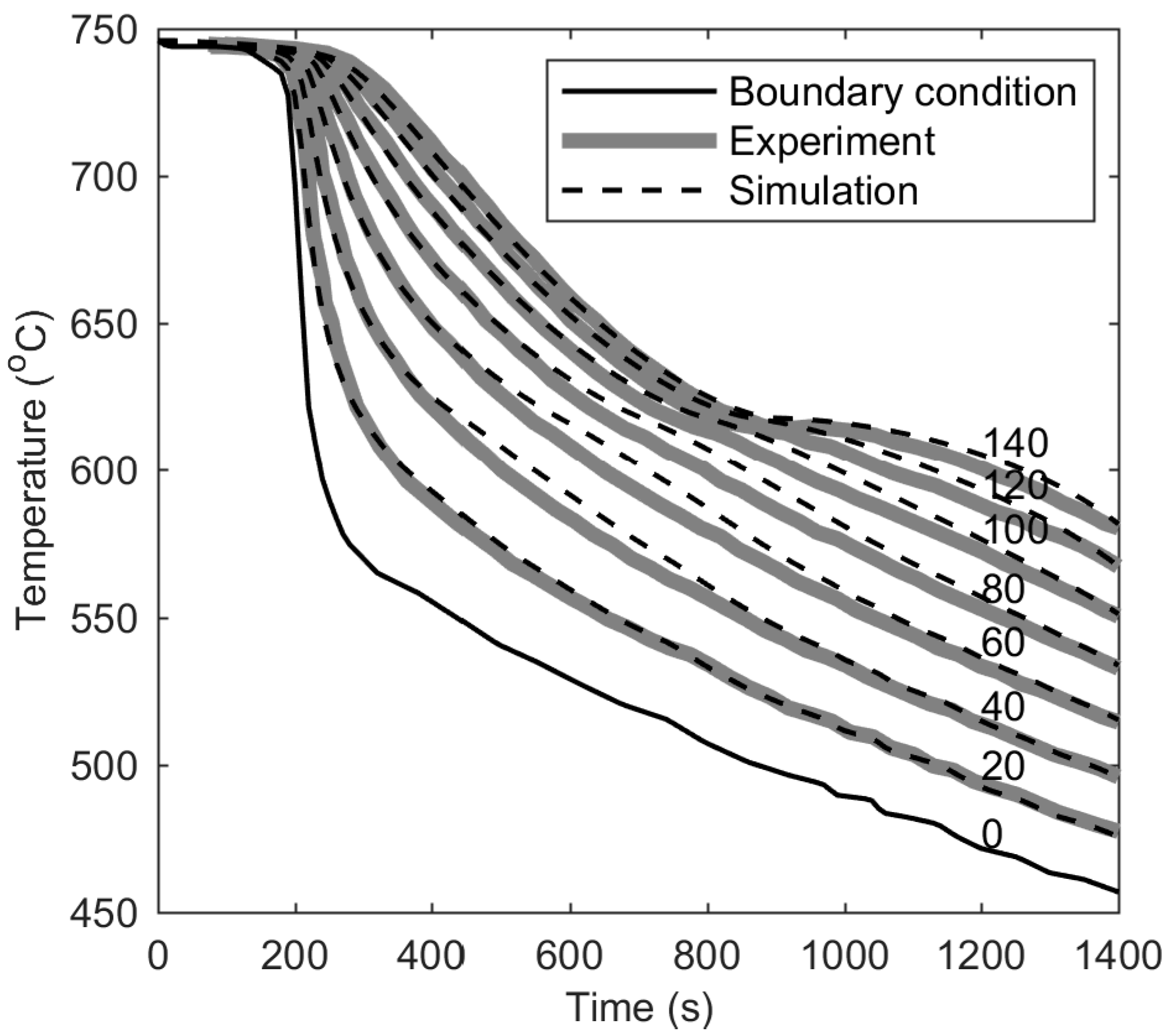

4.2. Grain Growth in Directional Solidified Al-7 wt% Si Ingot

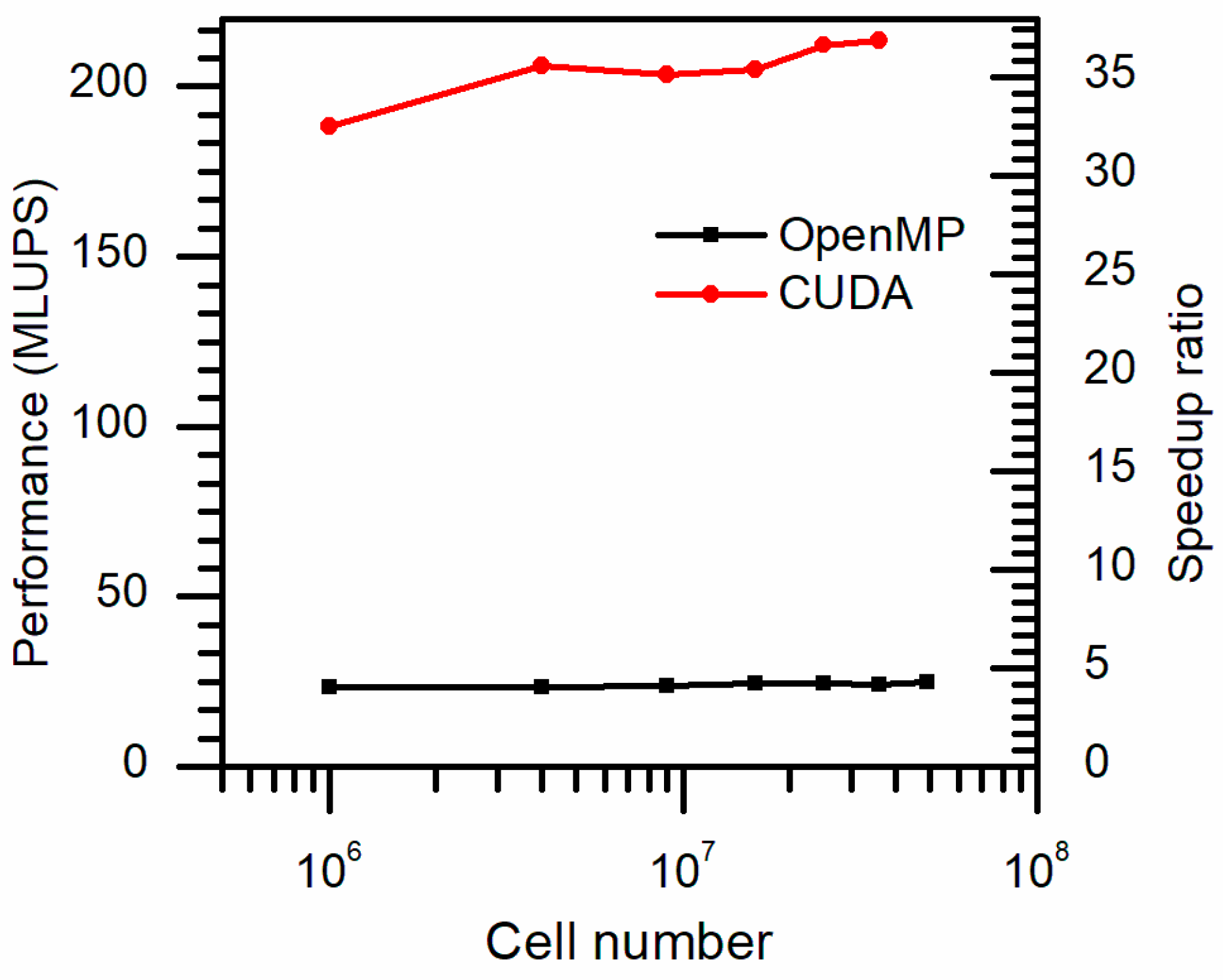

4.3. Parallel Performance Evaluation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rappaz, M. Modelling of microstructure formation in solidification processes. Int. Mater. Rev. 1989, 34, 93–124. [Google Scholar] [CrossRef]

- Thévoz, P.; Desbiolles, J.L.; Rappaz, M. Modeling of equiaxed microstructure formation in casting. Metall. Mater. Trans. A 1989, 20, 311. [Google Scholar] [CrossRef]

- Gandin, C.A.; Rappaz, M. A 3D cellular automaton algorithm for the prediction of dendritic grain growth. Acta Mater. 1997, 45, 2187. [Google Scholar] [CrossRef]

- Gandin, C.A.; Desbiolles, J.L.; Rappaz, M.; Thevoz, P. A three-dimensional cellular automation-finite element model for the prediction of solidification grain structures. Metall. Mater. Trans. A 1999, 30, 3153. [Google Scholar] [CrossRef]

- Nastac, L.; Stefanescu, D.M. Stochastic modelling of microstructure formation in solidification processes. Model. Simul. Mater. Sci. 1997, 5, 391. [Google Scholar] [CrossRef]

- Wang, W.; Lee, P.D.; McLean, M. A model of solidification microstructures in nickel-based superalloys: Predicting primary dendrite spacing selection. Acta Mater. 2003, 51, 2971. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Q.; Tang, N.; Pan, D.; Liu, B. Numerical simulation of microstructure evolution during directional solidification process in directional solidified (DS) turbine blades. Sci. China Technol. Sci. 2011, 54, 3191. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Q. Simulation and experimental studies on grain selection and structure design of the spiral selector for casting single crystal Ni-based superalloy. Materials 2017, 10, 1236. [Google Scholar] [CrossRef]

- Viardin, A.; Souhar, Y.; Fernández, M.C.; Apel, M.; Založnik, M. Mesoscopic modeling of equiaxed and columnar solidification microstructures under forced flow and buoyancy-driven flow in hypergravity: Envelope versus phase-field model. Acta Mater. 2020, 199, 680. [Google Scholar] [CrossRef]

- Spittle, J.A. Columnar to equiaxed grain transition in as solidified alloys. Int. Mater. Rev. 2006, 51, 247. [Google Scholar] [CrossRef]

- Kurz, W.; Rappaz, M.; Trivedi, R. Progress in modelling solidification microstructures in metals and alloys. Part II: Dendrites from 2001 to 2018. Int. Mater. Rev. 2020, 66, 30. [Google Scholar] [CrossRef]

- Dong, H.B.; Lee, P.D. Simulation of the columnar-to-equiaxed transition in directionally solidified Al–Cu alloys. Acta Mater. 2005, 53, 659. [Google Scholar] [CrossRef]

- Satbhai, O.; Roy, S.; Ghosh, S. A parametric multi-scale.; multiphysics numerical investigation in a casting process for Al-Si alloy and a macroscopic approach for prediction of ECT and CET events. Appl. Therm. Eng. 2017, 113, 386. [Google Scholar] [CrossRef]

- Ahmadein, M.; Wu, M.; Ludwig, A. Analysis of macrosegregation formation and columnar-to-equiaxed transition during solidification of Al-4wt.%Cu ingot using a 5-phase model. J. Cryst. Growth 2015, 417, 65. [Google Scholar] [CrossRef] [PubMed]

- Geng, S.; Jiang, P.; Shao, X.; Guo, L.; Gao, X. Heat transfer and fluid flow and their effects on the solidification microstructure in full-penetration laser welding of aluminum sheet. J. Mater. Sci. Technol. 2020, 46, 50. [Google Scholar] [CrossRef]

- Nabavizadeh, S.A.; Eshraghi, M.; Felicelli, S.D. Three-dimensional phase field modeling of columnar to equiaxed transition in directional solidification of Inconel 718 alloy. J. Cryst. Growth 2020, 549, 125879. [Google Scholar] [CrossRef]

- Lenart, R.; Eshraghi, M. Modeling columnar to equiaxed transition in directional solidification of Inconel 718 alloy. Comput. Mater. Sci. 2020, 172, 109374. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Y.; Yang, Y. Influence of the low voltage pulsed magnetic field on the columnar-to-equiaxed transition during directional solidification of superalloy K4169. J. Mater. Sci. Technol. 2020, 48, 9. [Google Scholar] [CrossRef]

- Hou, Y.; Ren, Z.; Zhang, Z.; Ren, X. Columnar to equiaxed transition during directionally solidifying GCr18Mo steel affected by thermoelectric magnetic force under an axial static magnetic field. ISIJ Int. 2019, 59, 60. [Google Scholar] [CrossRef]

- Li, Y.Z.; Mangelinck-Noël, N.; Zimmermann, G.; Sturz, L.; Nguyen-Thi, H. Comparative study of directional solidification of Al-7wt% Si alloys in Space and on Earth: Effects of gravity on dendrite growth and Columnar-to-equiaxed transition. J. Cryst. Growth 2019, 513, 20. [Google Scholar] [CrossRef]

- Zimmermann, G.; Hamacher, M.; Sturz, L. Effect of zero.; normal and hyper-gravity on columnar dendritic solidification and the columnar-to-equiaxed transition in Neopentylglycol-(D)Camphor alloy. J. Cryst. Growth 2019, 512, 47. [Google Scholar] [CrossRef]

- Jelinek, B.; Eshraghi, M.; Felicelli, S.; Peters, J.F. Large-scale parallel lattice Boltzmann–cellular automaton model of two-dimensional dendritic growth. Comput. Phys. Commun. 2014, 185, 939. [Google Scholar] [CrossRef]

- Eshraghi, M.; Jelinek, B.; Felicelli, S.D. Large-scale three-dimensional simulation of dendritic solidification using lattice Boltzmann method. Jom 2015, 67, 1786. [Google Scholar] [CrossRef]

- Kao, A.; Krastins, I.; Alexandrakis, M.; Shevchenko, N.; Eckert, S.; Pericleous, K. A parallel cellular automata lattice Boltzmann method for convection-driven solidification. Jom 2019, 71, 48. [Google Scholar] [CrossRef]

- Dobravec, T.; Mavrič, B.; Šarler, B. A cellular automaton-finite volume method for the simulation of dendritic and eutectic growth in binary alloys using an adaptive mesh refinement. J. Comput. Phys. 2017, 349, 351. [Google Scholar] [CrossRef]

- Carozzani, T.; Gandin, C.; Digonnet, H. Optimized parallel computing for cellular automaton-finite element modeling of solidification grain structures. Model. Simul. Mater. Sci. 2014, 22, 15012. [Google Scholar] [CrossRef]

- Gandin, C.A.; Carozzani, T.; Digonnet, H.; Chen, S.; Guillemot, G. Direct modeling of structures and segregations up to industrial casting scales. Jom 2013, 65, 1122. [Google Scholar] [CrossRef]

- Lian, Y.; Lin, S.; Yan, W.; Liu, W.K.; Wagner, G.J. A parallelized three-dimensional cellular automaton model for grain growth during additive manufacturing. Comput. Mech. 2018, 61, 543. [Google Scholar] [CrossRef]

- Sakane, S.; Takaki, T.; Rojas, R.; Ohno, M.; Shibuta, Y.; Shimokawabe, T.; Aoki, T. Multi-GPUs parallel computation of dendrite growth in forced convection using the phase-field-lattice Boltzmann model. J. Cryst. Growth 2017, 474, 154. [Google Scholar] [CrossRef]

- Yang, C.; Xu, Q.; Liu, B. GPU-accelerated three-dimensional phase-field simulation of dendrite growth in a nickel-based superalloy. Comput. Mater. Sci. 2017, 136, 133. [Google Scholar] [CrossRef]

- Sun, W.; Yan, R.; Zhang, Y.; Dong, H.; Jing, T. GPU-accelerated three-dimensional large-scale simulation of dendrite growth for Ti6Al4V alloy based on multi-component phase-field model. Comput. Mater. Sci. 2019, 160, 149. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, J.; Yin, Y.; Shen, X.; Ji, X. Numerical simulation of three-dimensional mesoscopic grain evolution: Model development, vlidation, and application to nickel-based superalloys. Metals 2019, 9, 57. [Google Scholar] [CrossRef]

- Rappaz, M.; Gandin, C.A. Probabilistic modelling of microstructure formation in solidification processes. Acta Metall. Mater. 1993, 41, 345. [Google Scholar] [CrossRef]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Metall. 1986, 34, 823. [Google Scholar] [CrossRef]

- Marek, M. Grid anisotropy reduction for simulation of growth processes with cellular automaton. Phys. D Nonlinear Phenom. 2013, 253, 73. [Google Scholar] [CrossRef]

- Gandin, C.A. From constrained to unconstrained growth during directional solidification. Acta Mater. 2000, 48, 2483. [Google Scholar] [CrossRef]

- Raghavan, S.; Singh, G.; Sondhi, S.; Srikanth, S. Construction of a pseudo-binary phase diagram for multi-component Ni-base superalloys. Calphad 2012, 38, 85. [Google Scholar] [CrossRef]

- Lipton, J.; Glicksman, M.E.; Kurz, W. Dendritic growth into undercooled alloy metals. Mater. Sci. Eng. 1984, 65, 57. [Google Scholar] [CrossRef]

- Gandin, C.A. Experimental study of the transition from constrained to unconstrained growth during directional solidification. ISIJ Int. 2000, 40, 971. [Google Scholar] [CrossRef]

- Carozzani, T.; Digonnet, H.; Gandin, C. 3D CAFE modeling of grain structures: Application to primary dendritic and secondary eutectic solidification. Model. Simul. Mater. Sci. 2012, 20, 15010. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhou, J.; Yin, Y.; Shen, X.; Shehabeldeen, T.A.; Ji, X. GPU-Accelerated Cellular Automaton Model for Grain Growth during Directional Solidification of Nickel-Based Superalloy. Metals 2021, 11, 298. https://doi.org/10.3390/met11020298

Zhang Y, Zhou J, Yin Y, Shen X, Shehabeldeen TA, Ji X. GPU-Accelerated Cellular Automaton Model for Grain Growth during Directional Solidification of Nickel-Based Superalloy. Metals. 2021; 11(2):298. https://doi.org/10.3390/met11020298

Chicago/Turabian StyleZhang, Yongjia, Jianxin Zhou, Yajun Yin, Xu Shen, Taher A. Shehabeldeen, and Xiaoyuan Ji. 2021. "GPU-Accelerated Cellular Automaton Model for Grain Growth during Directional Solidification of Nickel-Based Superalloy" Metals 11, no. 2: 298. https://doi.org/10.3390/met11020298

APA StyleZhang, Y., Zhou, J., Yin, Y., Shen, X., Shehabeldeen, T. A., & Ji, X. (2021). GPU-Accelerated Cellular Automaton Model for Grain Growth during Directional Solidification of Nickel-Based Superalloy. Metals, 11(2), 298. https://doi.org/10.3390/met11020298