Effects of Silicon and Heat-Treatment on Microstructure and Mechanical Properties of Biomedical Ti-39Nb-6Zr Alloy

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

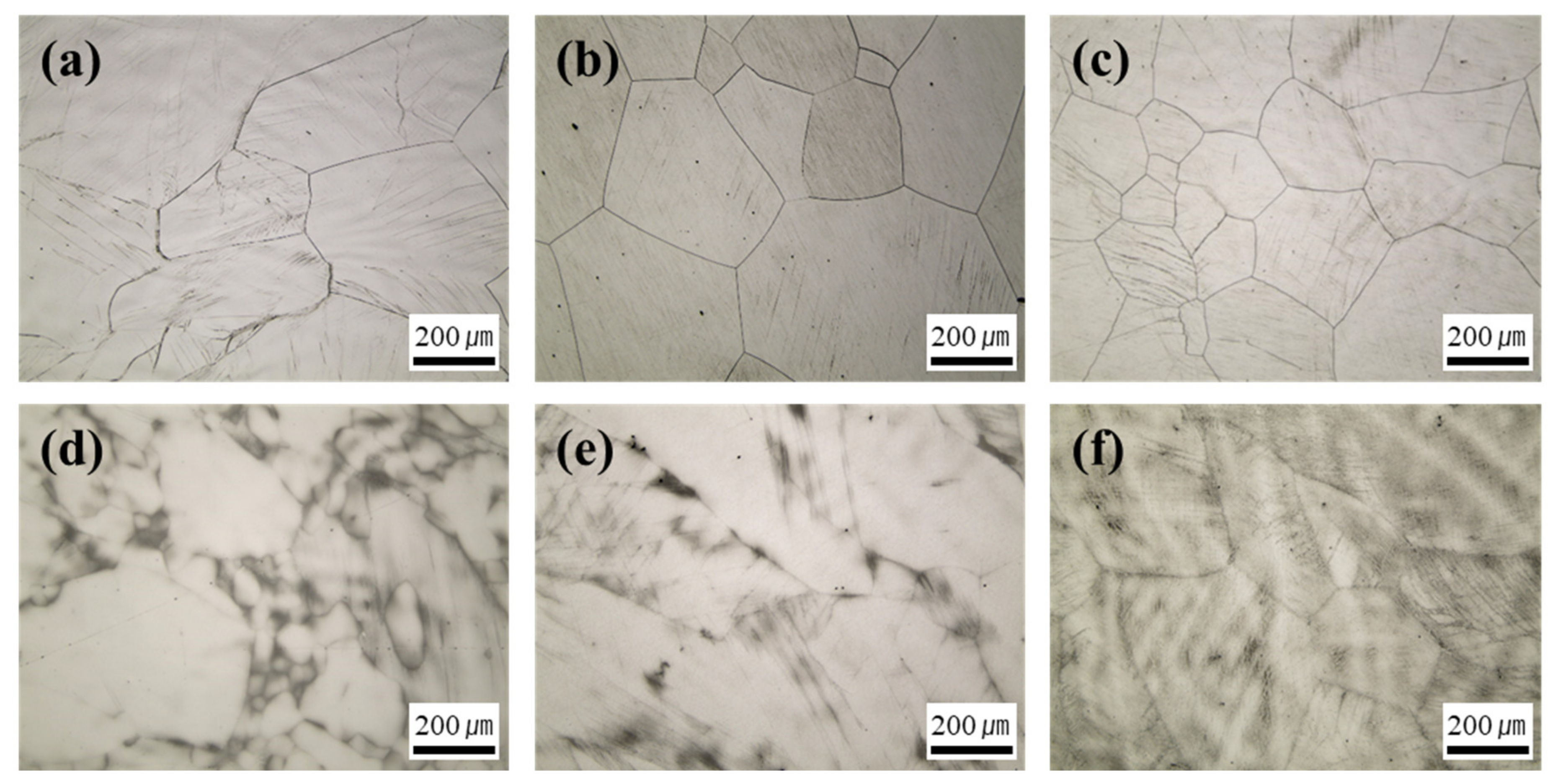

3.1. Variation of Microstructural Characteristics

3.2. Effect of Si Content

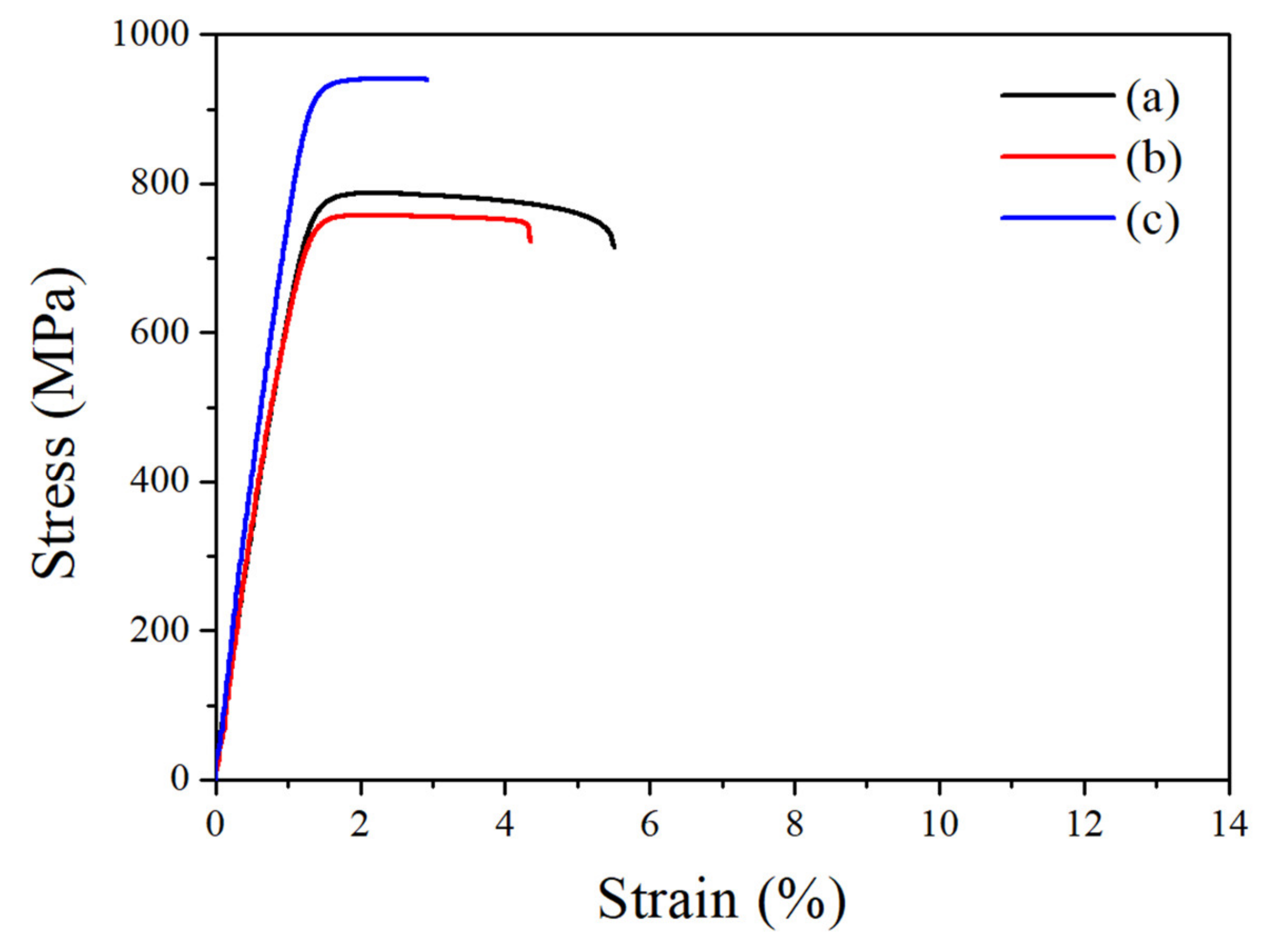

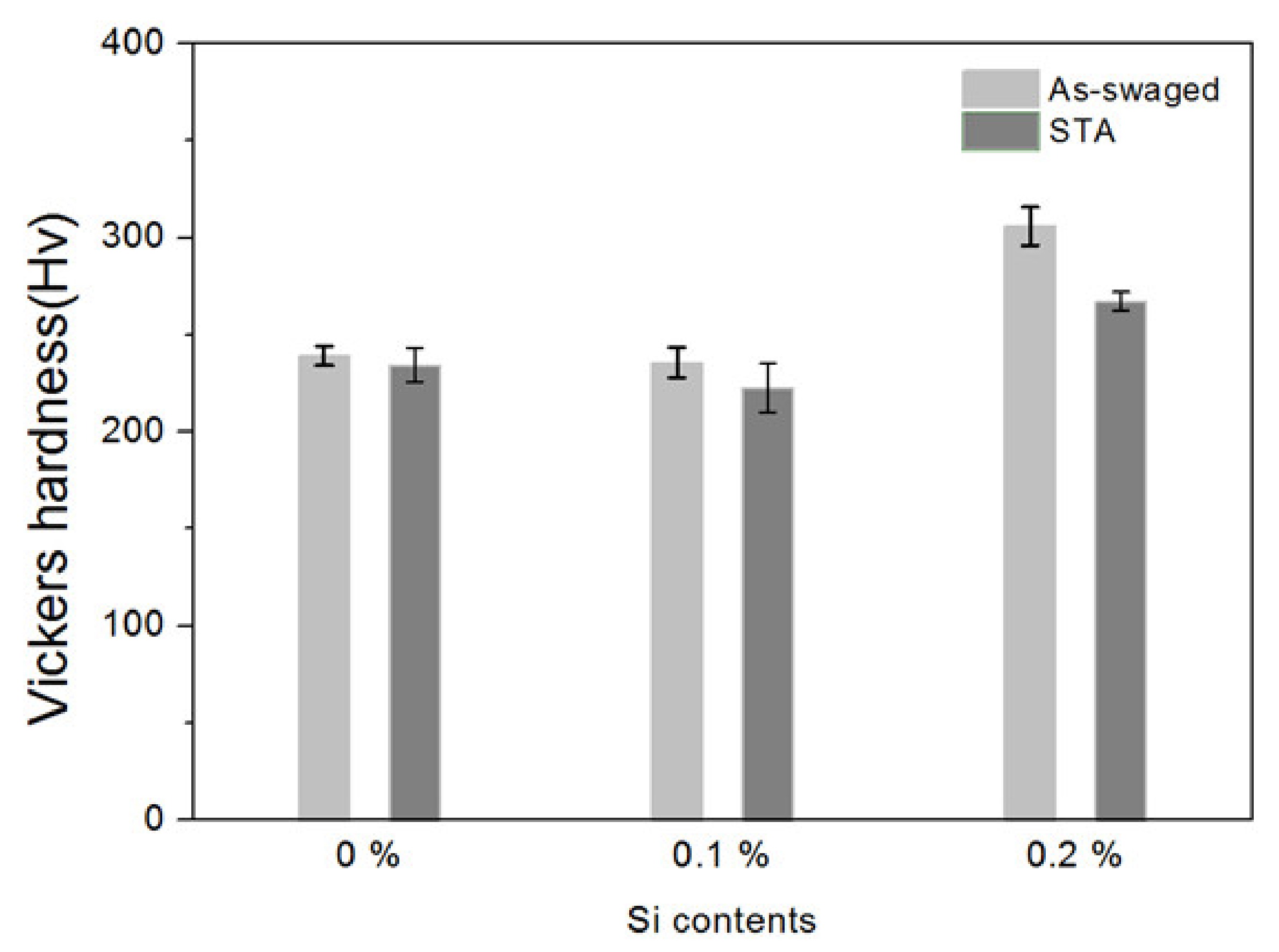

3.3. Variation of Mechanical Properties

4. Conclusions

- (1)

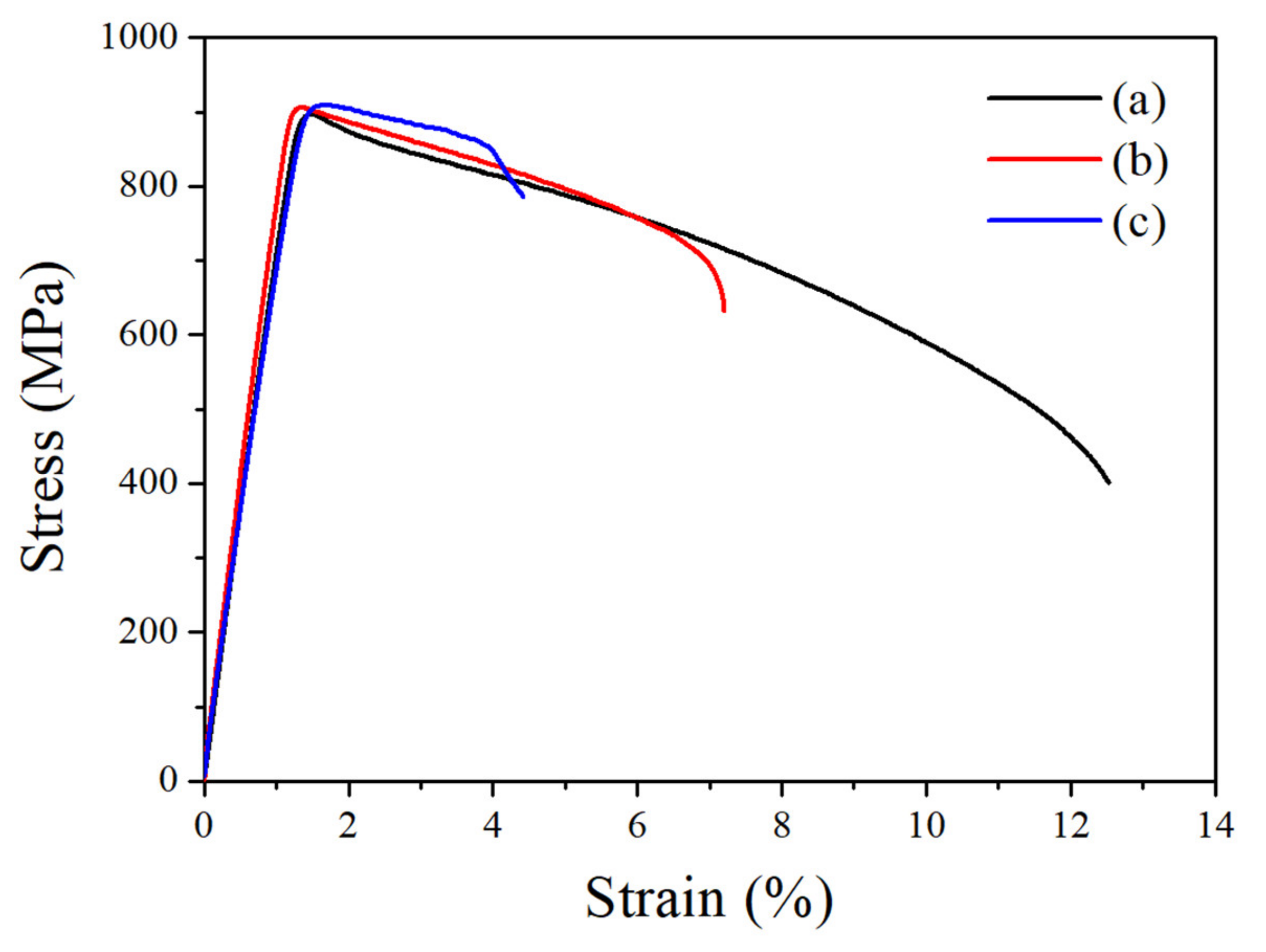

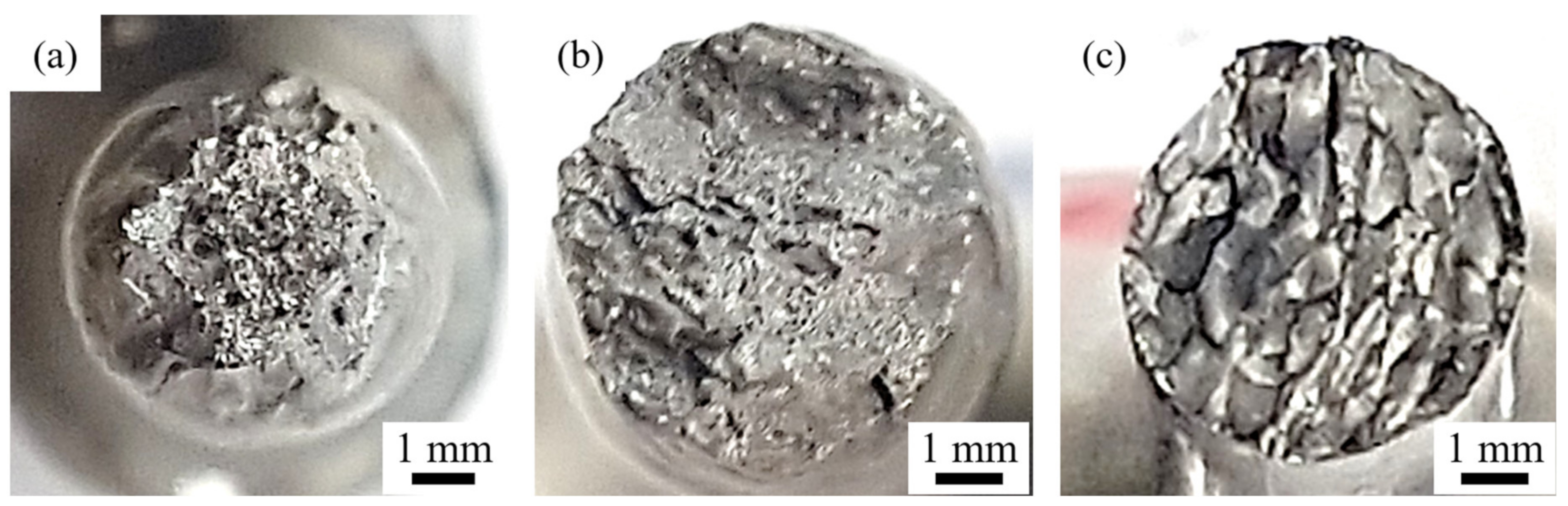

- For the as-swaged alloys, the work hardening effect by cold swaging was much more dominant than the effect of grain refinement hardening. For the decrease in El, the specimens were principally characterized by the brittle intergranular fracture mode with increasing Si content.

- (2)

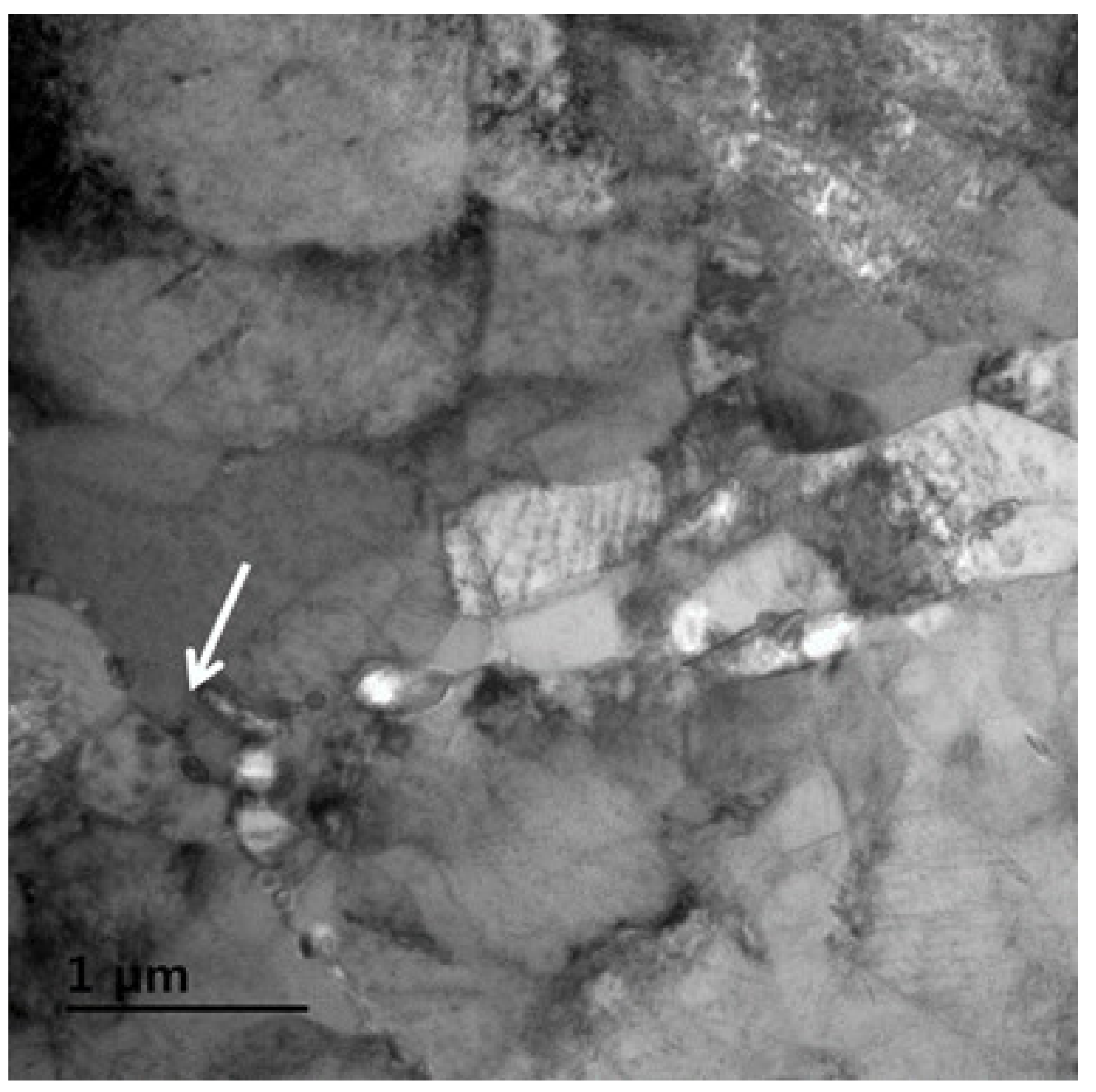

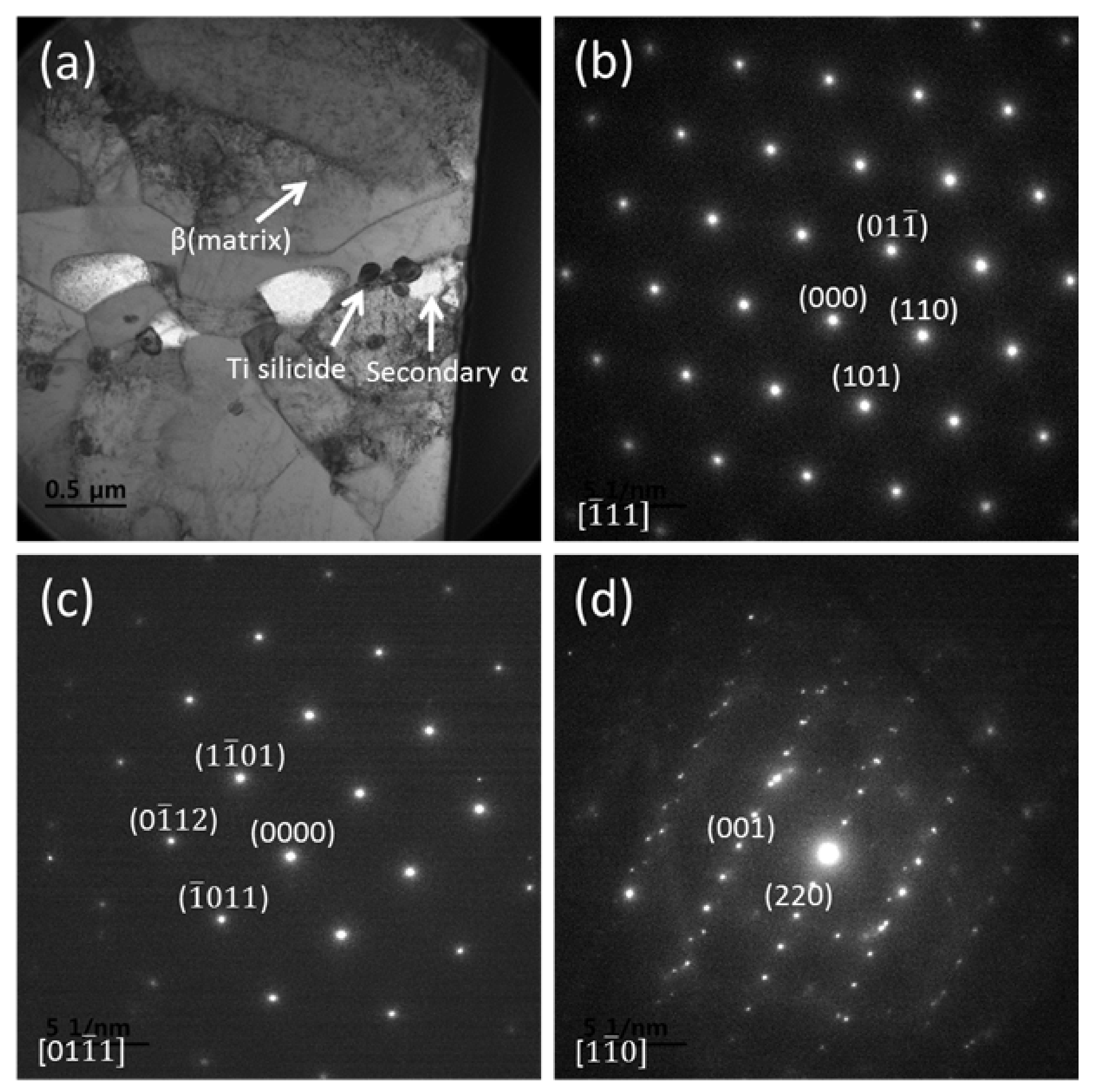

- ω particles in a beta matrix were precipitated in the STA-treated specimen containing no Si content. The continuous increase in Si content interfered with the precipitation of the ω phase, which increased the strength of the β-Ti alloys.

- (3)

- For the STA-treated alloys, the specimen containing 0.1% Si was mainly reinforced by the ω phase rather than the effect of precipitation hardening by Ti silicides. The specimen containing 0.2% Si was mainly reinforced by the precipitation hardening effect by Ti silicides.

- (4)

- Fine spherical Ti silicides (Ti5Si4) grown to a size of 0.1 µm were precipitated along the grain boundaries of the STA-treated specimen containing 0.2% Si. Ti silicides inhibited the grain growth and increased the YS and UTS, but acted as the crack initiation site during the room-temperature tensile test.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Niinomi, M. Mechanical Properties of Biomedical Titanium Alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Eisenbarth, E.; Velten, D.; Muller, M.; Thull, R.; Breme, J. Biocompatibility of β-stabilizing Elements of Titanium Alloys. Biomaterials 2004, 25, 5705–5713. [Google Scholar] [CrossRef] [PubMed]

- Rao, S.; Ushida, T.; Tateishi, T.; Okazaki, Y.; Asao, S. Effect of Ti, Al, and V Ions on the Relative Growth Rate of Fibroblasts (L929) and Osteoblasts (MC3T3-E1) Cells. Bio-Med. Mater. Eng. 1996, 6, 79–86. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Lee, D.G. Effect of Al Addition on Corrosion Protection of Ti-39Nb-6Zr Alloy for Biological Applications. J. Nanosci. Nanotechnol. 2019, 19, 3811–3815. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.J.; Lim, K.R.; Lee, Y.T.; Lee, D.G.; Lee, J.H.; Kim, S.E. Effect of Aging Time and Temperature on Microstructure and Mechanical Properties of Ti-39Nb-6Zr Alloy. Korean J. Met. Mater. 2016, 54, 925–930. [Google Scholar] [CrossRef]

- Ridzwan, M.I.Z.; Shuib, S.; Hassan, A.Y.; Shokri, A.A.; Ibrahim, M.N.M. Problem of Stress Shielding and Improvement to the Hip Implant Designs: A Review. J. Med. Sci. 2007, 7, 460–467. [Google Scholar] [CrossRef]

- Lee, J.H.; Cheon, S.S.; Hwang, G.W.; Cho, J.U. A Simulation Study on the Stress Distribution of the Transplanting Part of Artificial Knee Joint due to Elastic Modulus. Compos. Res. 2015, 28, 89–93. [Google Scholar] [CrossRef][Green Version]

- Lee, D.G.; Mi, X.; Eom, T.K.; Lee, Y.T. Bio-Compatible Properties of Ti-Nb-Zr Titanium Alloy with Extra Low Modulus. J. Biomater. Tissue Eng. 2016, 6, 798–801. [Google Scholar] [CrossRef]

- Beta-Based Titanium Alloy with Low Elastic Modulus. Korea Patent 10-0971649-0000, 2010.

- Lee, Y.T. Titanium; Steel&Metal News: Seoul, Korea, 2016; p. 87. [Google Scholar]

- Low, S.P.; Voelcker, N.H.; Canham, L.T.; Williams, K.A. The Biocompatibility of Porous Silicon in Tissues of The Eye. Biomaterials 2009, 30, 2873–2880. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.G. Production Method of Ti-base Alloy with Low Elastic Modulus and Excellent Bio-Compatibility. Korea Patent 10-0653460-0000, 2006. [Google Scholar]

- Cho, D.H.; Nam, J.H.; Lee, B.W.; Park, J.Y.; Shin, H.J.; Park, I.M. Effect of Si, Mn, Sn on Tensile and Corrosion Properties of Mg-4Zn-0.5Ca Alloys for Biodegradable Implant Materials. Korean J. Met. Mater. 2014, 53, 220–230. [Google Scholar] [CrossRef]

- Amelinckx, S. The Direct Observation of Dislocations; Academic Press: New York, NY, USA, 1964; p. 381. [Google Scholar]

- Ibrahim, K.M.; Hussein, A.H.; Abdelkawy, M. Effect of Si-addition as a Grain Refiner on Microstructure and Properties of Ti-6Al-4V Alloy. T. Nonferr. Met. Soc. China 2013, 23, 1863–1874. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; Dargusch, M.S.; StJohn, D.H. Grain-refinement Mechanisms in Titanium Alloys. J. Mater. Res. 2008, 23, 97–104. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; Dargusch, M.S.; StJohn, D.H. The Mechanism of Grain Refinement of Titanium by Silicon. Scr. Mater. 2008, 58, 1050–1053. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; Dargusch, M.S.; StJohn, D.H. Microstructure of Cast Titanium Alloys. Mater. Forum 2007, 31, 84–89. [Google Scholar]

- Lin, D.J.; Lin, J.H.C.; Ju, C.P. Structure and Properties of Ti-7.5Mo-xFe Alloys. Biomaterials 2002, 23, 1723–1730. [Google Scholar] [CrossRef]

- Tavares, A.M.G.; Ramos, W.S.; de Blas, J.C.G.; Lopes, E.S.N.; Caram, R.; Batista, W.W.; Souza, S.A. Influence of Si Addition on the Microstructure and Mechanical Properties of Ti–35Nb Alloy for Applications in Orthopedic Implants. J. Mech. Behav. Biomed. Mater. 2015, 51, 74–87. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Chen, J.; Ren, Y.J.; He, J.J.; Song, Z.X. Effect of Heat Treatment Variations on the Microstructure Evolution and Mechanical Properties in a β Metastable Ti Alloy. J. Alloy Compd. 2016, 684, 466–473. [Google Scholar] [CrossRef]

- Gaur, R.; Gupta, R.K.; AnilKumar, V.; Banwait, S.S. Effect of Cold Rolling and Heat Treatment on Microstructure and Mechanical Properties of Ti-4Al-1Mn Titanium Alloy. J. Mater. Eng. Perform. 2018, 27, 3217–3233. [Google Scholar] [CrossRef]

- Williams, J.C.; Hickman, B.S.; Marcus, H.L. Effect of Omega Phase on the Mechanical Properties of Titanium Alloys. Metall. Trans. 1971, 2, 1913–1919. [Google Scholar]

- Choe, B.H.; Kim, J.U.; Jeong, H.W.; Hyeon, Y.T.; Kim, S.E.; Lee, Y.T. On Phase Relationship between Ti-Si Precipitates and Beta Matrix in Ti-6Al-4Fe-0.5Si Alloy. J. Korea Inst. Met. Mater. 2004, 42, 1–6. [Google Scholar]

| Sample Conditions | Si Contents | σy (MPa) | σmax (MPa) | El (%) |

|---|---|---|---|---|

| As-swaged | 0% | 895 ± 6 | 900 ± 3 | 12.3 ± 1.5 |

| 0.1% | 907 ± 4 | 910 ± 3 | 7.0 ± 1.2 | |

| 0.2% | 910 ± 4 | 912 ± 5 | 4.2 ± 2.3 | |

| STA | 0% | 753 ± 7 | 788 ± 6 | 5.5 ± 1.6 |

| 0.1% | 731 ± 6 | 758 ± 8 | 4.3 ± 1.7 | |

| 0.2% | 915 ± 8 | 942 ± 12 | 2.9 ± 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, J.-H.; Lee, D.-G. Effects of Silicon and Heat-Treatment on Microstructure and Mechanical Properties of Biomedical Ti-39Nb-6Zr Alloy. Metals 2021, 11, 268. https://doi.org/10.3390/met11020268

Jang J-H, Lee D-G. Effects of Silicon and Heat-Treatment on Microstructure and Mechanical Properties of Biomedical Ti-39Nb-6Zr Alloy. Metals. 2021; 11(2):268. https://doi.org/10.3390/met11020268

Chicago/Turabian StyleJang, Ji-Hoon, and Dong-Geun Lee. 2021. "Effects of Silicon and Heat-Treatment on Microstructure and Mechanical Properties of Biomedical Ti-39Nb-6Zr Alloy" Metals 11, no. 2: 268. https://doi.org/10.3390/met11020268

APA StyleJang, J.-H., & Lee, D.-G. (2021). Effects of Silicon and Heat-Treatment on Microstructure and Mechanical Properties of Biomedical Ti-39Nb-6Zr Alloy. Metals, 11(2), 268. https://doi.org/10.3390/met11020268