Comparison of Optimization-Regulation Algorithms for Secondary Cooling in Continuous Steel Casting

Abstract

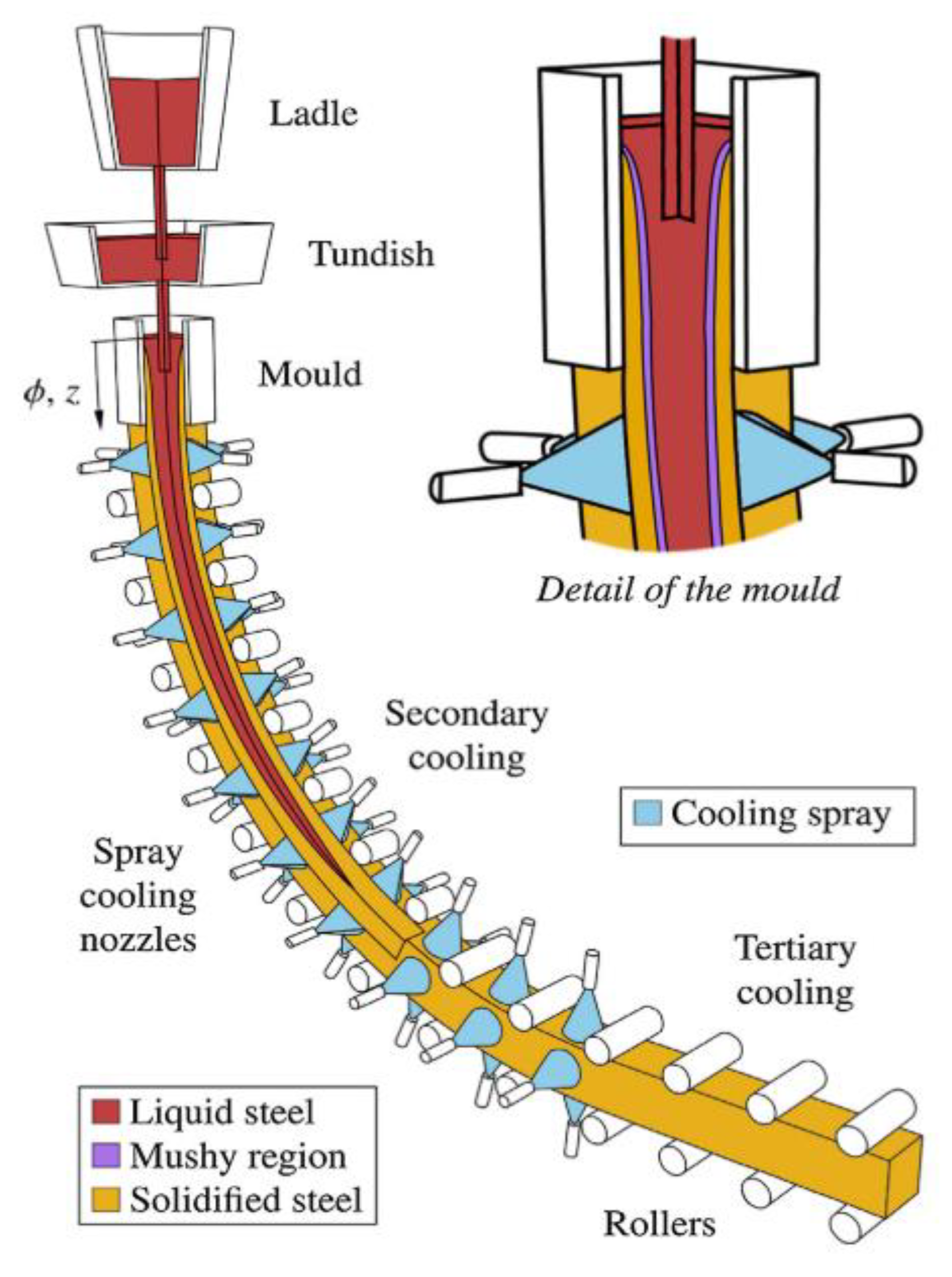

1. Introduction

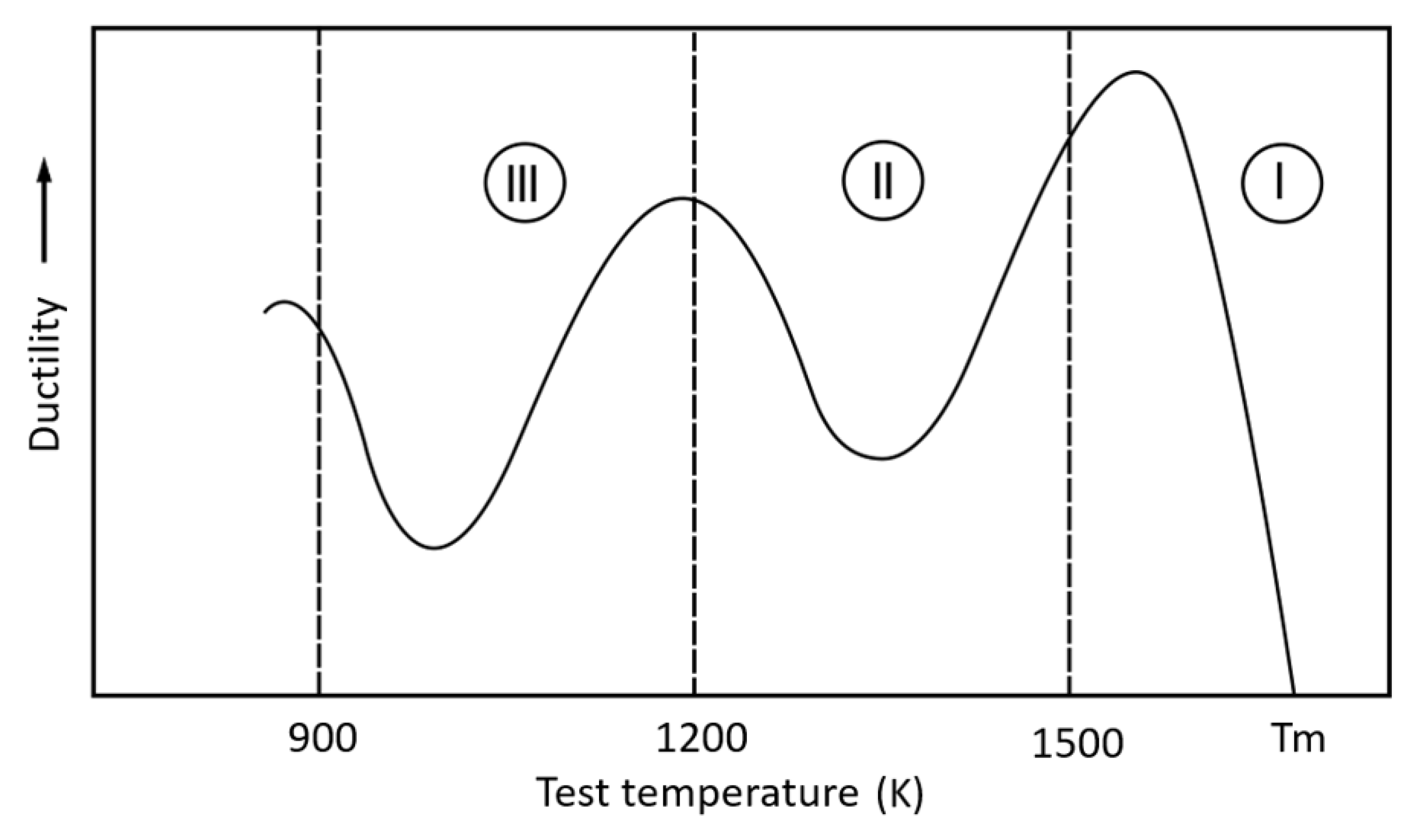

1.1. Conditions towards High-Quality Steel Casting

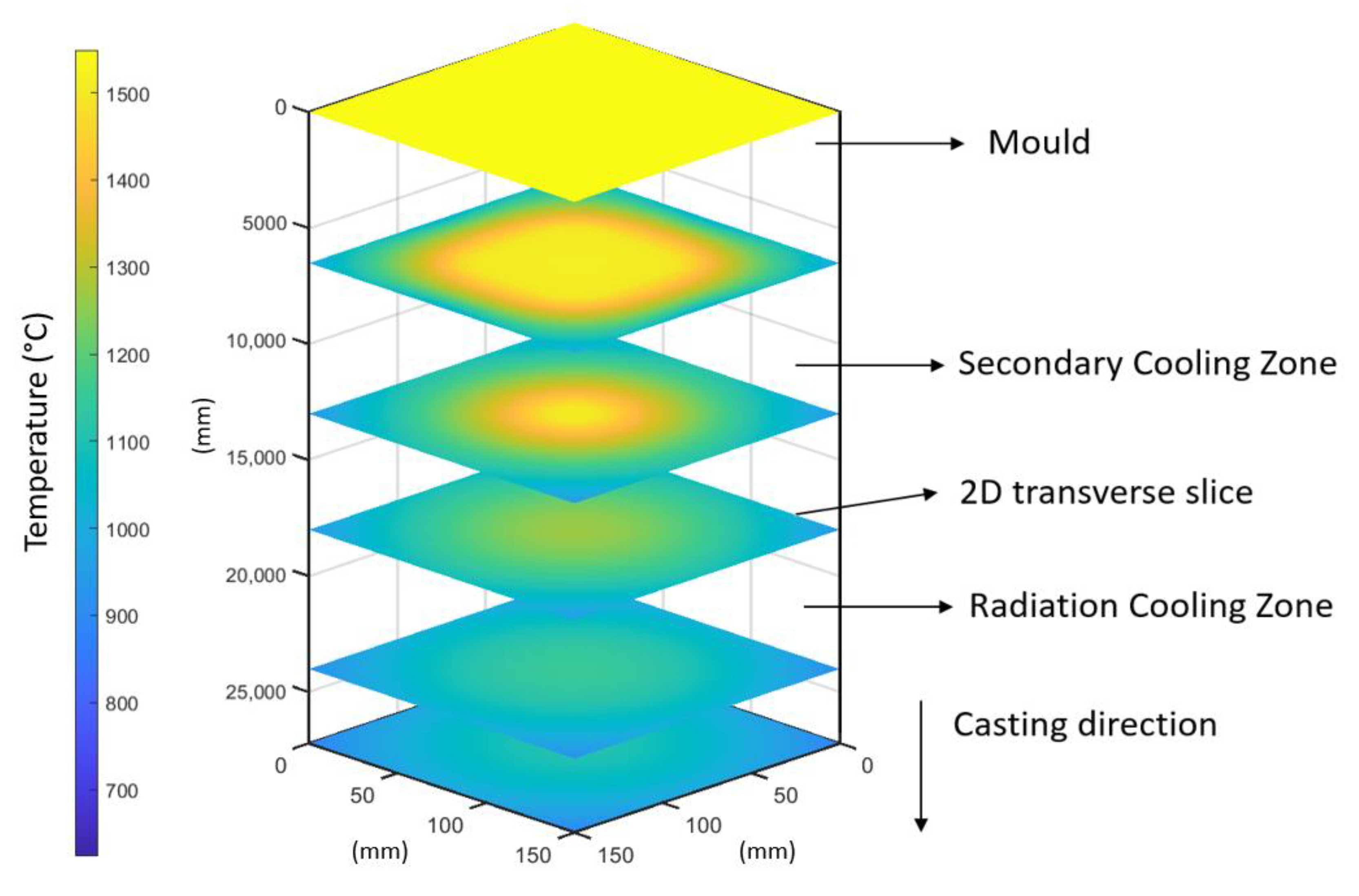

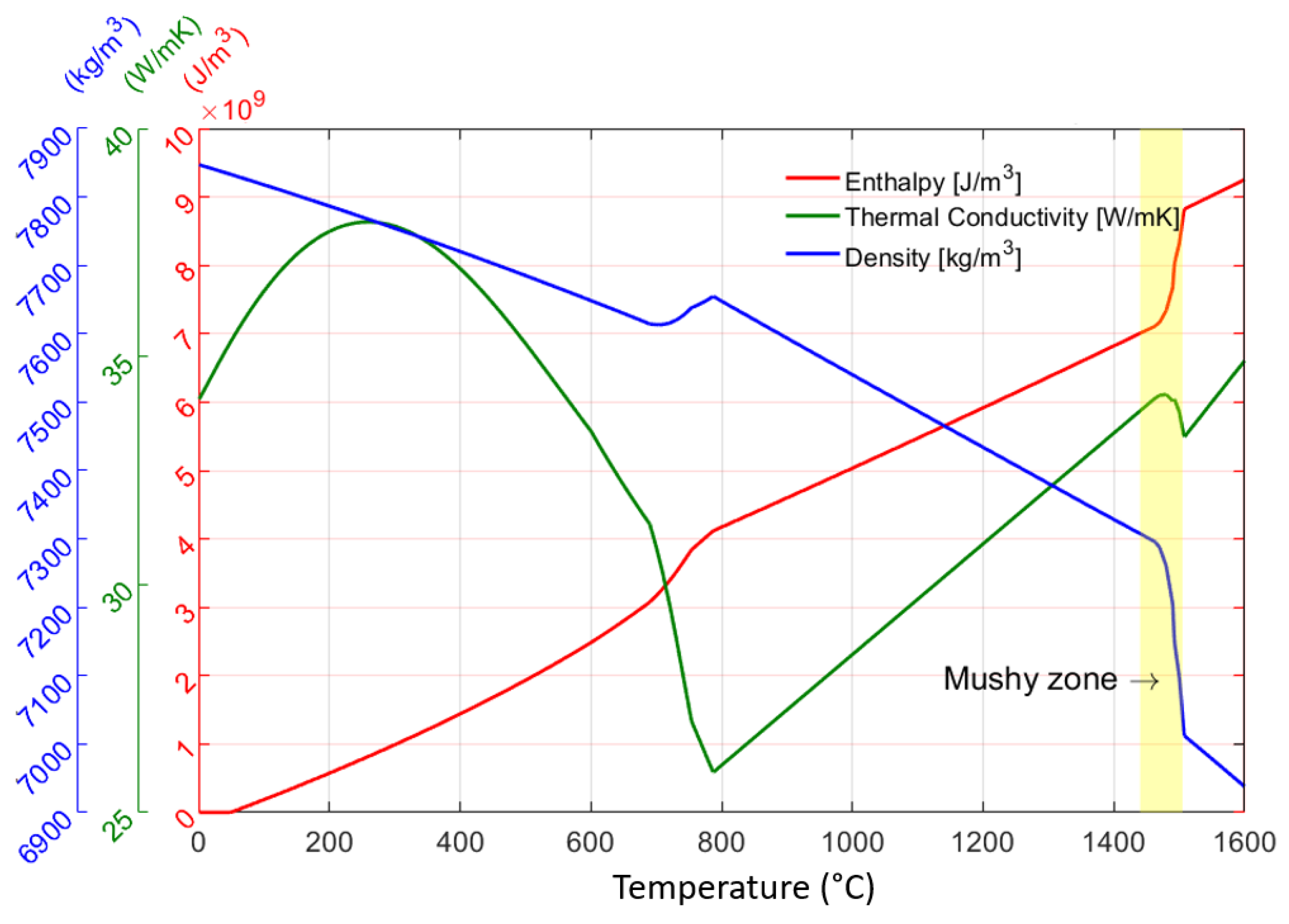

1.2. Numerical Modeling of Thermal Behavior in CC

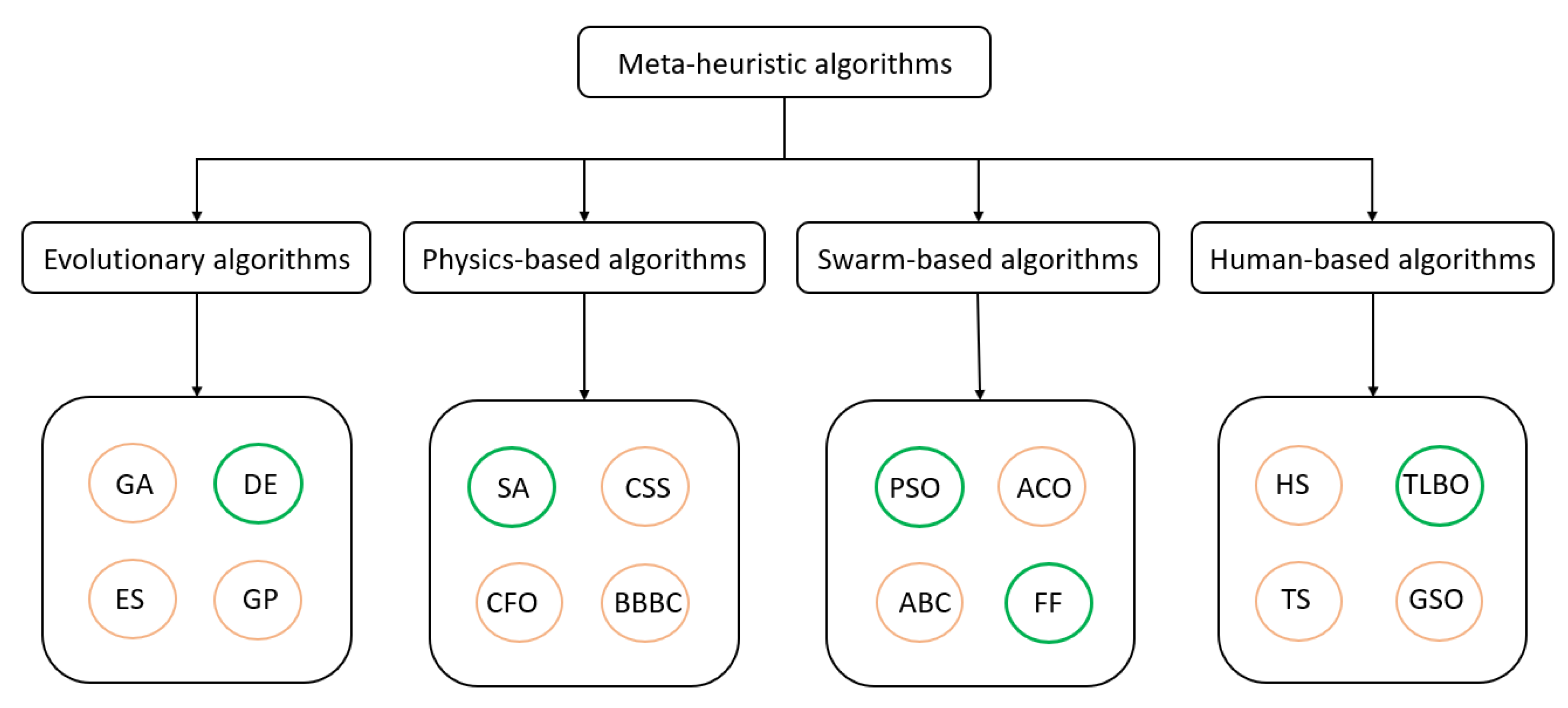

1.3. Optimization and Regulation Algorithms in CC

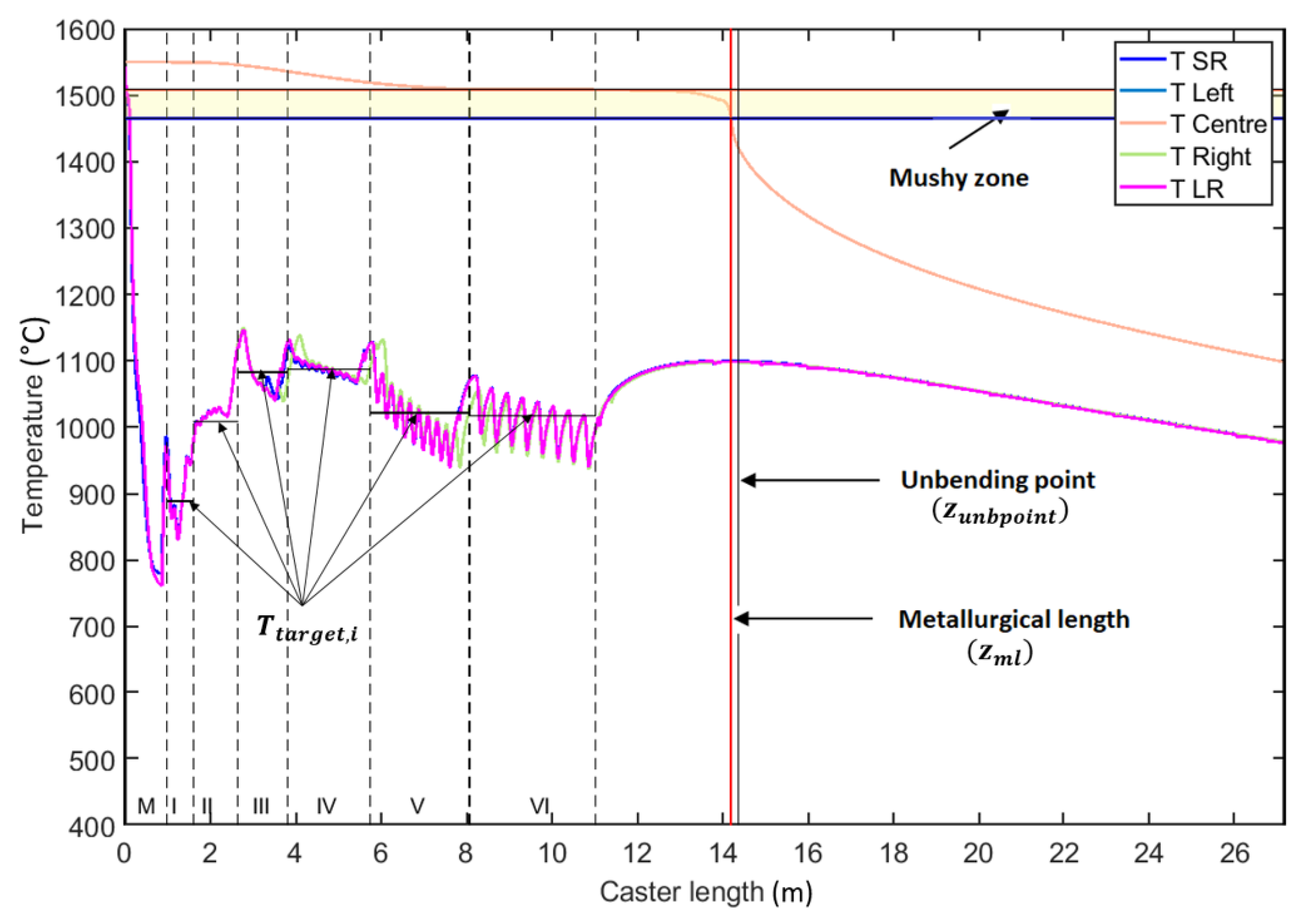

2. Slice Solidification Model

Thermophysical Properties

3. Optimization Approach

3.1. Simulated Annealing (SA)

3.2. Differential Evolution (DE)

3.3. Particle Swarm Optimization (PSO)

3.4. Firefly (FF) Algorithm

3.5. Teaching Learning-Based Optimization (TLBO)

4. Results and Discussion

5. Conclusions

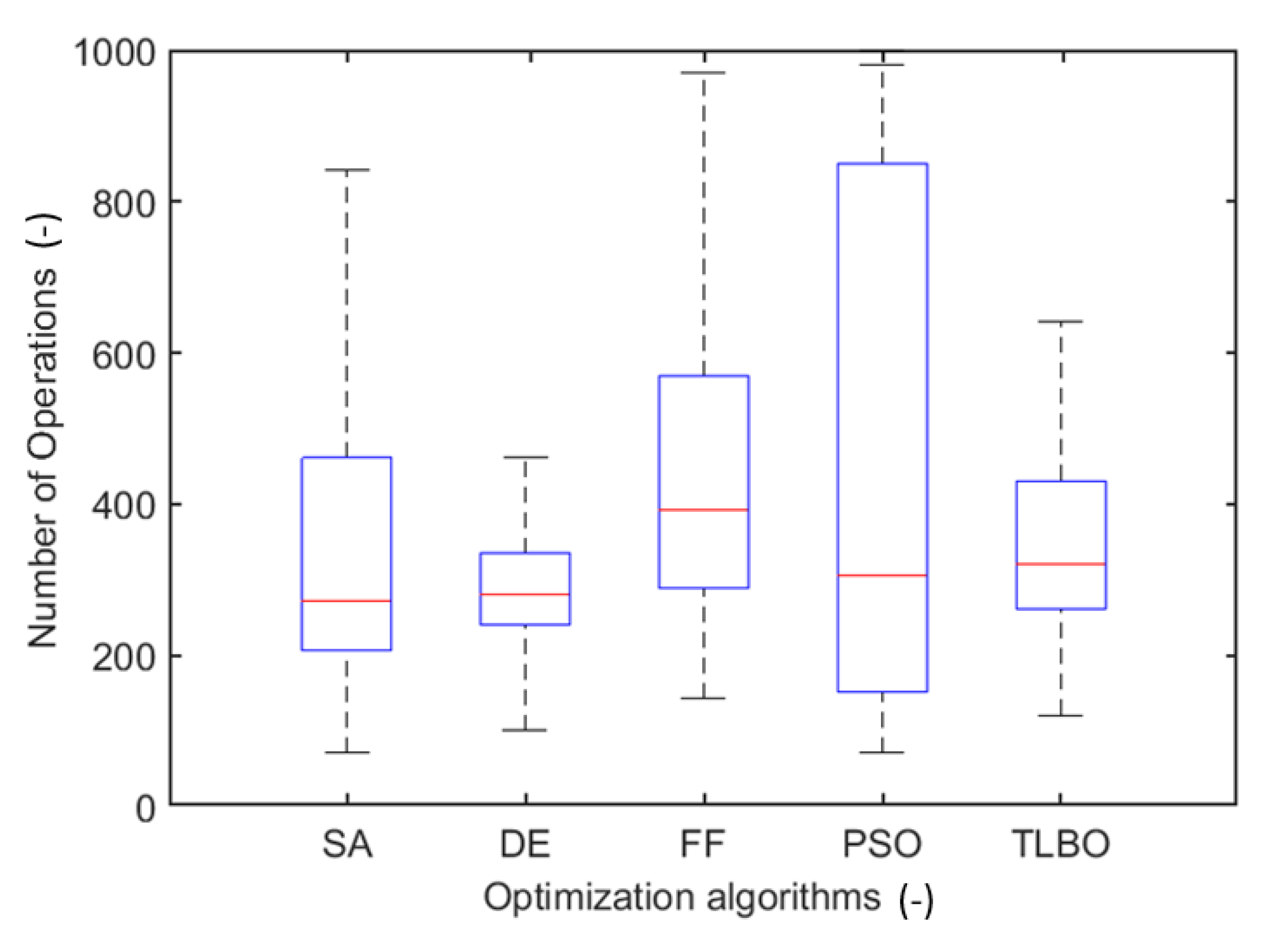

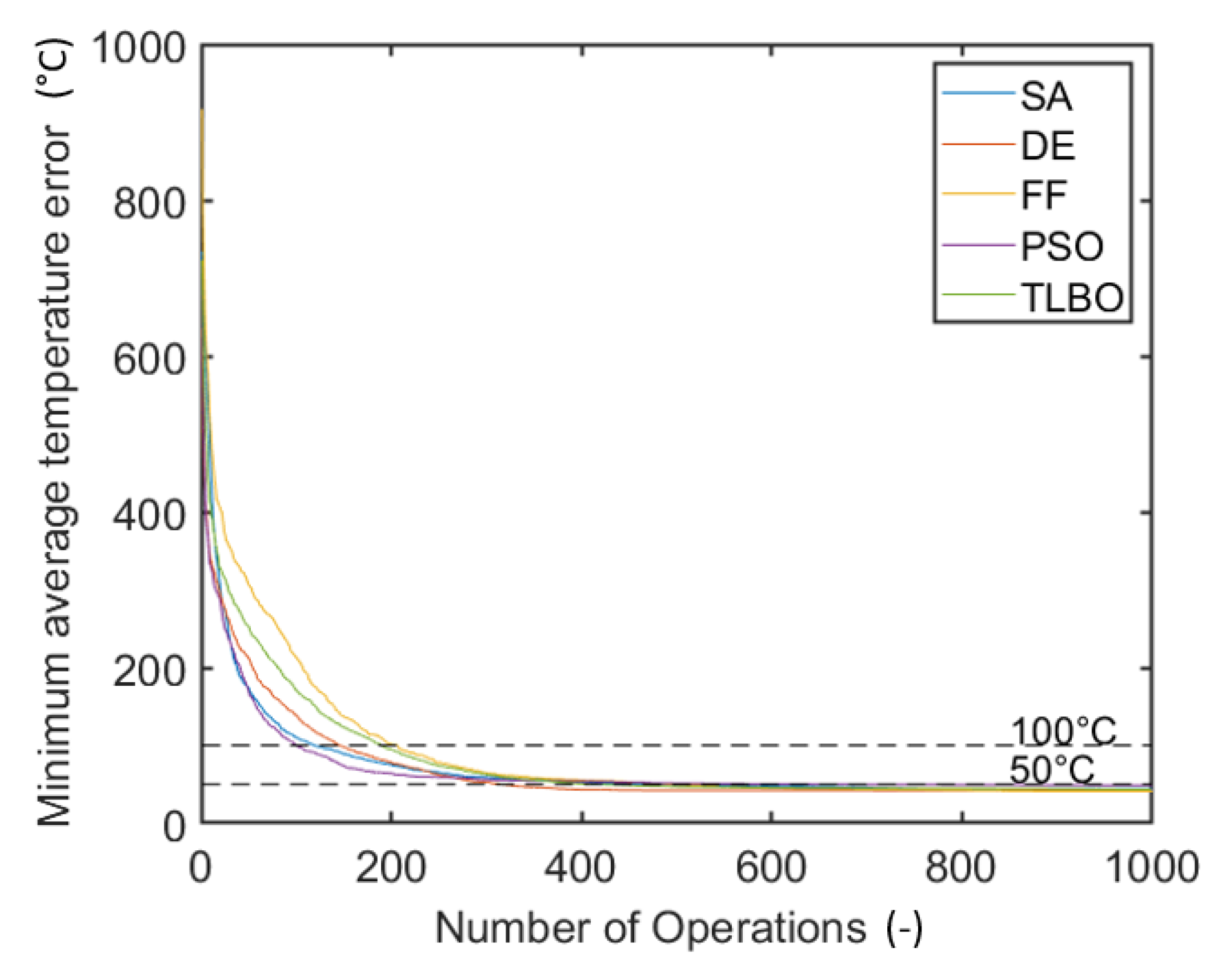

- The best median value in terms of the number of operations needed by the algorithms to reach the solution was observed for the simulated annealing (SA) algorithm (with 271 operations per run and with the convergence rate of 96%) and for the differential evolution (DE) algorithm (with 280 operations per run and with the convergence rate of 99%).

- The best convergence rate was achieved in case of the FF algorithm in which all the runs reached the stop criterium, but with approximately 121 more operations per run than the DE algorithm.

- The particle swarm optimization (PSO) was surprisingly the worst algorithm among the considered algorithms, with 22 non-converged runs. A better behavior and performance of the algorithms could further be achieved by tuning of parameters of the individual algorithms.

- The teaching-learning-based optimization (TLBO), which is a method containing no algorithm-specific control parameters, exhibited medium performance among the considered algorithms and its convergence rate was 95%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomas, B.G. Review on Modeling and Simulation of Continuous Casting. Steel Res. Int. 2017, 89, 21. [Google Scholar] [CrossRef]

- Seetharaman, S. Treatise on Process Metallurgy; Elsevier: Oxford, UK, 2014; Volume 3, ISBN 9780080969886. [Google Scholar]

- Klimeš, L.; Štětina, J. A rapid GPU-based heat transfer and solidification model for dynamic computer simulations of continuous steel casting. J. Mater. Process. Technol. 2015, 226, 1–14. [Google Scholar] [CrossRef]

- Brimacombe, J.K. The challenge of quality in continuous casting processes. Metall. Mater. Trans. A 1999, 30, 1899–1912. [Google Scholar] [CrossRef]

- Santos, C.A.; Spim, J.A.; Garcia, A. Mathematical modeling of heat transfer in the Twin-Roll continuous casting process. Am. Soc. Mech. Eng. Heat Transf. Div. HTD 1998, 357, 133–138, ISBN: 8415683111. [Google Scholar]

- Brimacombe, J.K.; Sorimachi, K. Crack formation in the continuous casting of steel. Metall. Trans. B 1977, 8, 489–505. [Google Scholar] [CrossRef]

- Xia, G.; Schiefermüller, A. The influence of support rollers of continuous casting machines on heat transfer and on stress-strain of slabs in secondary cooling. Steel Res. Int. 2010, 81, 652–659. [Google Scholar] [CrossRef]

- Kulkarni, M.S.; Babu, A.S. Managing quality in continuous casting process using product quality model and simulated annealing. J. Mater. Process. Technol. 2005, 166, 294–306. [Google Scholar] [CrossRef]

- Cheung, N.; Santos, C.A.; Spim, J.A.; Garcia, A. Application of a heuristic search technique for the improvement of spray zones cooling conditions in continuously cast steel billets. Appl. Math. Model. 2006, 30, 104–115. [Google Scholar] [CrossRef]

- Kong, Y.; Chen, D.; Liu, Q.; Long, M. A prediction model for internal cracks during slab continuous casting. Metals (Basel) 2019, 9, 18. [Google Scholar] [CrossRef]

- Santos, C.A.; Spim, J.A.; Garcia, A. Mathematical modeling and optimization strategies (genetic algorithm and knowledge base) applied to the continuous casting of steel. Eng. Appl. Artif. Intell. 2003, 16, 511–527. [Google Scholar] [CrossRef]

- Cheung, N.; Garcia, A. Use of a heuristic search technique for the optimization of quality of steel billets produced by continuous casting. Eng. Appl. Artif. Intell. 2001, 14, 229–238. [Google Scholar] [CrossRef]

- Kim, K.; Yeo, T.J.; Oh, K.H.; Lee, D.N. Effect of Carbon and Sulfur in Continuously Cast Strand on Longitudinal Surface Cracks. ISIJ Int. 1996, 36, 284–289. [Google Scholar] [CrossRef]

- Böttger, B.; Apel, M.; Santillana, B.; Eskin, D.G. Relationship between solidification microstructure and hot cracking susceptibility for continuous casting of low-carbon and high-strength low-alloyed steels: A phase-field study. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 3765–3777. [Google Scholar] [CrossRef]

- El-Bealy, M.O. On the Formation of Interdendritic Internal Cracks During Dendritic Solidification of Continuously Cast Steel Slabs. Metall. Mater. Trans. B 2012, 43, 1488–1516. [Google Scholar] [CrossRef]

- Suzuki, H.G.; Elyon, D. Hot ductility of titanium alloy: A challenge for continuous casting process. Mater. Sci. Eng. A 1998, 243, 126–133. [Google Scholar] [CrossRef]

- Fic, A.; Nowak, A.J.; Bialecki, R. Heat transfer analysis of the continuous casting process by the front tracking BEM. Eng. Anal. Bound. Elem. 2000, 24, 215–223. [Google Scholar] [CrossRef]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, computational tools for materials science. Calphad Comput. Coupling Phase Diagr. Thermochem. 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Miettinen, J.; Louhenkilpi, S.; Kytönen, H.; Laine, J. IDS: Thermodynamic-kinetic-empirical tool for modelling of solidification, microstructure and material properties. Math. Comput. Simul. 2010, 80, 1536–1550. [Google Scholar] [CrossRef]

- Meng, Y.; Thomas, B.G. Heat-Transfer and Solidification Model of Continuous Slab Casting: CON1D. Metall. Mater. Trans. B 2003, 34B, 685–705. [Google Scholar] [CrossRef]

- Alizadeh, M.; Edris, H.; Shafyei, A. Mathematical Modeling of Heat Transfer for Steel Continuous Casting. Int. J. ISSI 2006, 3, 7–16, ISBN: 8415683111. [Google Scholar]

- Hardin, R.A.; Liu, K.A.I.; Kapoor, A.; Beckermann, C. A Transient Simulation and Dynamic Spray Cooling Control Model for Continuous Steel Casting. Metall. Mater. Trans. 2003, 34B, 297–307. [Google Scholar] [CrossRef]

- Tieu, A.K.; Kim, I.S. Simulation of the continuous casting process by a mathematical model. Int. J. Mech. Sci. 1997, 39, 185–192. [Google Scholar] [CrossRef]

- Tambunan, B. Simulation of Heat Transfer Solidification with Improved Latent Heat Parameter in Continuous Casting. In Proceedings of the Seminar National MIPA 2005; FMIPA: Depok, Indonesia, 25–26 November 2005; p. 7. [Google Scholar]

- Ji, Z.; Wang, B.; Xie, Z.; Lai, Z. Ant colony optimization based heat transfer coefficient identification for secondary cooling zone of continuous caster. IEEE Int. Conf. Integr. Technol. 2007, 558–562. [Google Scholar] [CrossRef]

- Zheng, P.; Guo, J.; Hao, X.J. Hybrid strategies for optimizing continuous casting process of steel. In Proceedings of the 2004 IEEE International Conference on Industrial Technology, Hammamet, Tunisia, 8–10 December 2004; Volume 3, pp. 1156–1161. [Google Scholar] [CrossRef]

- Rao, R.V.; Kalyankar, V.D.; Waghmare, G. Parameters optimization of selected casting processes using teaching-learning-based optimization algorithm. Appl. Math. Model. 2014, 38, 5592–5608. [Google Scholar] [CrossRef]

- Kulkarni, M.S.; Babu, A.S. Optimization of continuous casting using simulation. Mater. Manuf. Process. 2005, 20, 595–606. [Google Scholar] [CrossRef]

- Bhattacharya, A.K.; Debjani, S.; Roychowdhury, A.; Das, J. Optimization of continuous casting mould oscillation parameters in steel manufacturing process using genetic algorithms. In Proceedings of the IEEE Congress on Evolutionary Computation 2007, Singapore, 25–28 September 2007; pp. 3998–4004. [Google Scholar] [CrossRef]

- Jabri, K.; Dumur, D.; Godoy, D.; Mouchette, A.; Bèle, B. Particle swarm optimization based tuning of a modified smith predictor for mould level control in continuous casting. J. Process. Control. 2011, 21, 263–270. [Google Scholar] [CrossRef]

- Mauder, T.; Sandera, C.; Stetina, J. Optimal Control Algorithm for Continuous Casting Process by Using Fuzzy Logic. Steel Res. Int. 2015, 86, 785–798. [Google Scholar] [CrossRef]

- Incropera, F.P.; Bergman, T.L.; Lavine, A.S.; DeWitt, D.S. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 9780470501979. [Google Scholar]

- Zhang, J.; Chen, D.F.; Zhang, C.Q.; Wang, S.G.; Hwang, W.S.; Han, M.R. Effects of an even secondary cooling mode on the temperature and stress fields of round billet continuous casting steel. J. Mater. Process. Technol. 2015, 222, 315–326. [Google Scholar] [CrossRef]

- Raudenský, M.; Tseng, A.A.; Horský, J.; Komínek, J. Recent developments of water and mist spray cooling in continuous casting of steels. Metall. Res. Technol. 2016, 113. [Google Scholar] [CrossRef]

- Beyer, H.G.; Sendhoff, B. Robust optimization—A comprehensive survey. Comput. Methods Appl. Mech. Eng. 2007, 196, 3190–3218. [Google Scholar] [CrossRef]

- Blum, C.; Roli, A. Metaheuristics in Combinatorial Optimization: Overview and Conceptual Comparison. ACM Comput. Surv. 2003, 35, 268–308. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Maier, H.R.; Razavi, S.; Kapelan, Z.; Matott, L.S.; Kasprzyk, J.; Tolson, B.A. Introductory overview: Optimization using evolutionary algorithms and other metaheuristics. Environ. Model. Softw. 2019, 114, 195–213. [Google Scholar] [CrossRef]

- Das, S.; Suganthan, P.N. Differential evolution: A survey of the state-of-the-art. IEEE Trans. E Comput. 2011, 15, 4–31. [Google Scholar] [CrossRef]

- Yang, X.S. Nature-Inspired Optimization Algorithms; Elsevier Science Publishers, B.V.: Amsterdam, The Netherlands, 2014; ISBN 9780124167452. [Google Scholar]

- Mauder, T.; Sandera, C.; Stetina, J.; Seda, M. Optimization of the quality of continuously cast steel slabs using the firefly algorithm. Mater. Tehnol. 2011, 45, 347–350. [Google Scholar]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential Evolution—A Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. J. Global Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar] [CrossRef]

- Yang, X.S.; Deb, S.; Fong, S. Accelerated particle swarm optimization and support vector machine for business optimization and applications. Commun. Comput. Inf. Sci. 2011, 136, 53–66. [Google Scholar] [CrossRef]

- Yang, X.S. Firefly algorithm, stochastic test functions and design optimization. Int. J. Bio-Inspired Comput. 2010, 2, 78–84. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching-learning-based optimization: A novel method for constrained mechanical design optimization problems. CAD Comput. Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Rao, R.V.; Patel, V. Multi-objective optimization of heat exchangers using a modified teaching-learning-based optimization algorithm. Appl. Math. Model. 2013, 37, 1147–1162. [Google Scholar] [CrossRef]

| Water Flow Rates | |||||||

|---|---|---|---|---|---|---|---|

| Value | Loop 1 (l/min) | Loop 2 (l/min) | Loop 3 (l/min) | Loop 4 (l/min) | Loop 5 (l/min) | Loop 6 (l/min) | Total (l/min) |

| Minimum | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Target | 160 | 170 | 120 | 120 | 100 | 75 | 745 |

| Maximum | 300 | 250 | 140 | 140 | 140 | 100 | 1070 |

| Algorithm | Parameters of Optimization and Their Values |

|---|---|

| SA | , , |

| DE | , |

| FF | , , , |

| PSO | , |

| TLBO | - |

| Water Flow Rates | ||||||||

|---|---|---|---|---|---|---|---|---|

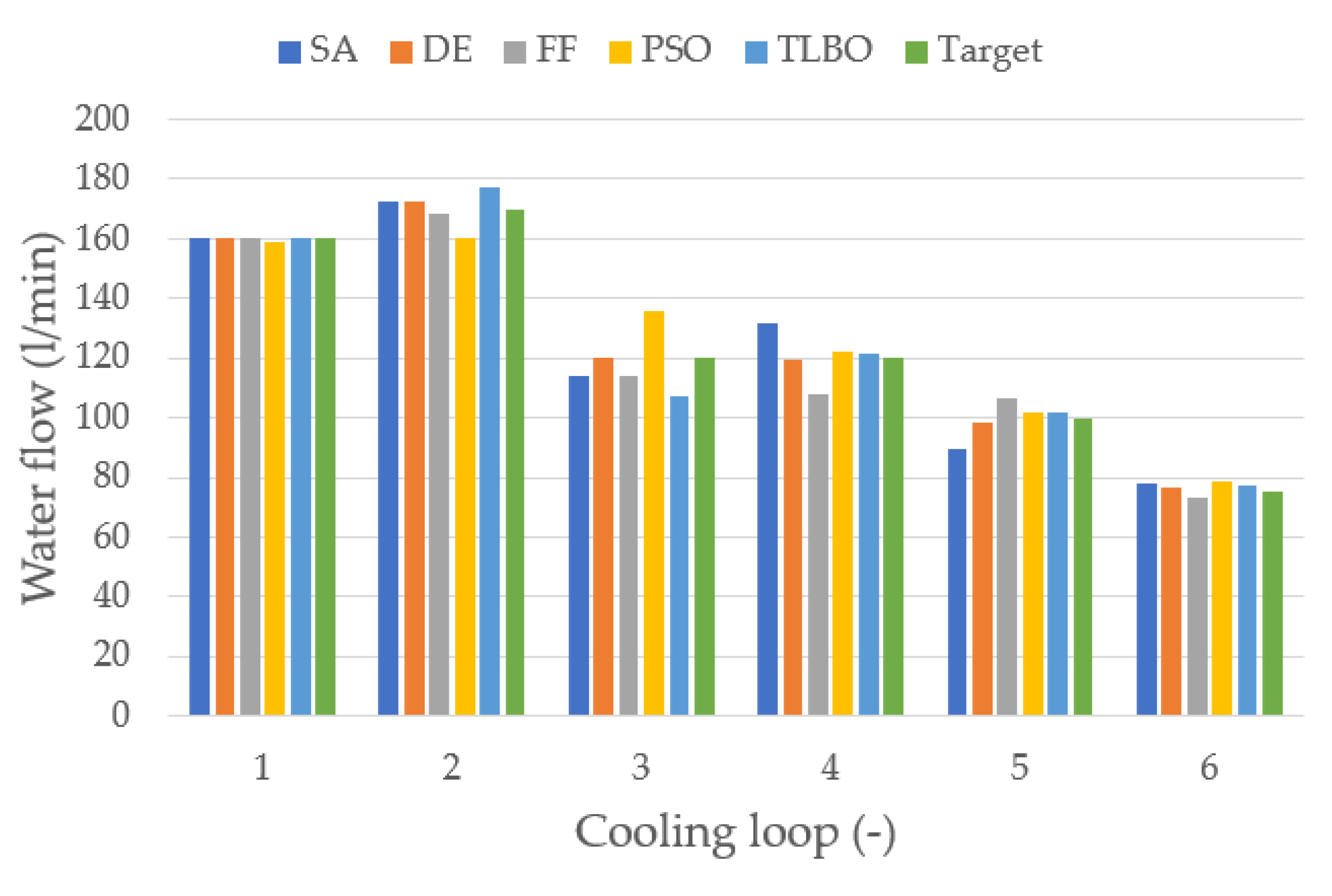

| Optimization Algorithm | Temperature Error (°C) | Loop 1 (l/min) | Loop 2 (l/min) | Loop 3 (l/min) | Loop 4 (l/min) | Loop 5 (l/min) | Loop 6 (l/min) | Total (l/min) |

| SA | 44.19 (23.35) | 160.25 (160.27) | 168.06 (172.78) | 120.36 (113.7) | 118.67 (131.79) | 100.86 (89.31) | 74.23 (77.75) | 742.43 (745.69) |

| DE | 42.11 (11.37) | 160.55 (160.53) | 167.45 (172.29) | 124.61 (119.88) | 122.30 (119.66) | 100.79 (98.21) | 76.32 (76.79) | 752.02 (747.36) |

| FF | 41.09 (21.38) | 159.67 (160.13) | 169.39 (168.41) | 121.72 (114.23) | 119.05 (107.86) | 107.07 (106.71) | 74.89 (73.48) | 746.66 (730.83) |

| PSO | 48.89 (24.31) | 160.04 (159.06) | 167.61 (160.54) | 125.02 (135.46) | 122.10 (121.92) | 107.08 (101.71) | 74.71 (78.83) | 756.56 (757.51) |

| TLBO | 42.96 (23.14) | 161.37 (160.39) | 165.28 (177.22) | 119.84 (107.03) | 118.33 (121.17) | 104.39 (101.94) | 73.45 (77.52) | 742.66 (745.28) |

| - | SA | DE | FF | PSO | TLBO |

|---|---|---|---|---|---|

| Median of the number of operations (-) | 271 | 280 | 392 | 305 | 320 |

| Mean of the number of operations (-) | 369.18 | 294.3 | 433.42 | 451.7 | 382.6 |

| Minimum number of operations (-) | 70 | 68 | 142 | 73 | 120 |

| Percentage of cases in which the stop criterium was reached (%) | 96 | 99 | 100 | 78 | 95 |

| Metallurgical length of the best solution (m) | 14.175 | 14.200 | 14.150 | 14.175 | 14.150 |

| Mean temperature error (°C) | 44.19 | 42.11 | 41.09 | 48.89 | 42.96 |

| Best (lowest) temperature error (°C) | 23.35 | 11.37 | 21.38 | 24.31 | 23.14 |

| Worst (highest) temperature error (°C) | 154.51 | 52.27 | 49.98 | 194.06 | 98.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brezina, M.; Mauder, T.; Klimes, L.; Stetina, J. Comparison of Optimization-Regulation Algorithms for Secondary Cooling in Continuous Steel Casting. Metals 2021, 11, 237. https://doi.org/10.3390/met11020237

Brezina M, Mauder T, Klimes L, Stetina J. Comparison of Optimization-Regulation Algorithms for Secondary Cooling in Continuous Steel Casting. Metals. 2021; 11(2):237. https://doi.org/10.3390/met11020237

Chicago/Turabian StyleBrezina, Michal, Tomas Mauder, Lubomir Klimes, and Josef Stetina. 2021. "Comparison of Optimization-Regulation Algorithms for Secondary Cooling in Continuous Steel Casting" Metals 11, no. 2: 237. https://doi.org/10.3390/met11020237

APA StyleBrezina, M., Mauder, T., Klimes, L., & Stetina, J. (2021). Comparison of Optimization-Regulation Algorithms for Secondary Cooling in Continuous Steel Casting. Metals, 11(2), 237. https://doi.org/10.3390/met11020237