Grain Structure, Crystallographic Texture, and Hardening Behavior of Dissimilar Friction Stir Welded AA5083-O and AA5754-H14

Abstract

1. Introduction

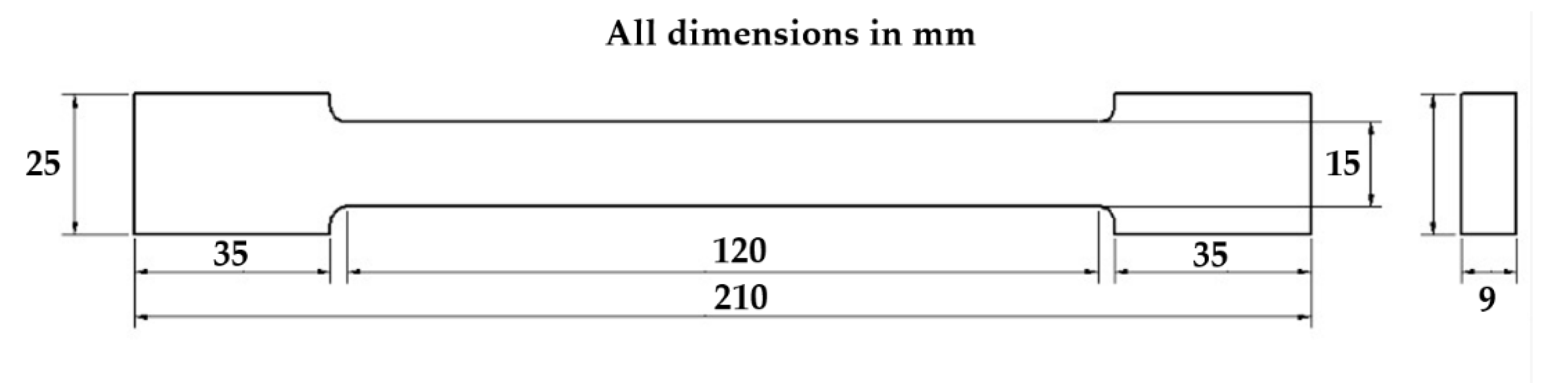

2. Materials and Methods

3. Results and Discussion

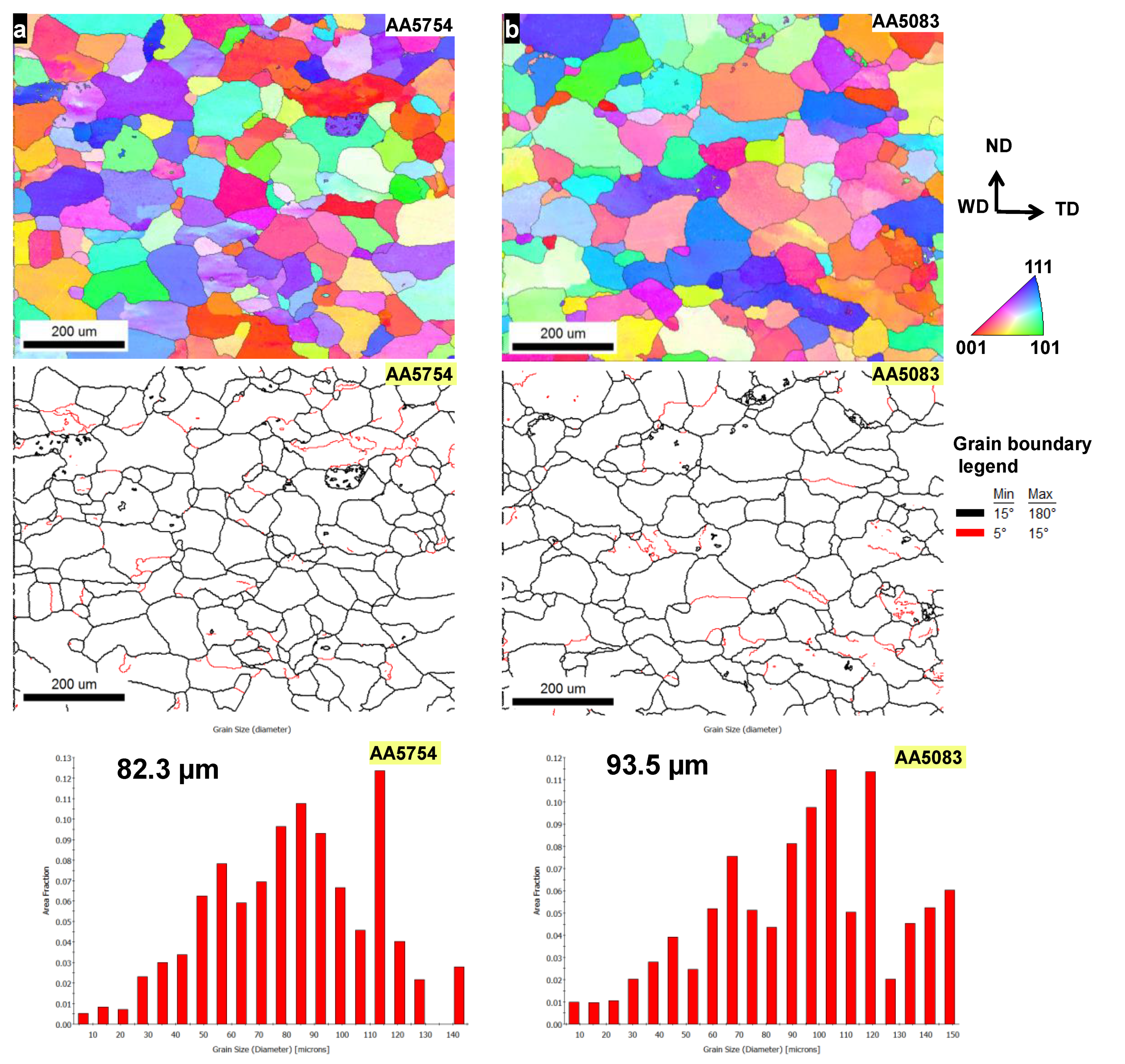

3.1. Microstructural Features of the Base Aluminum Alloys

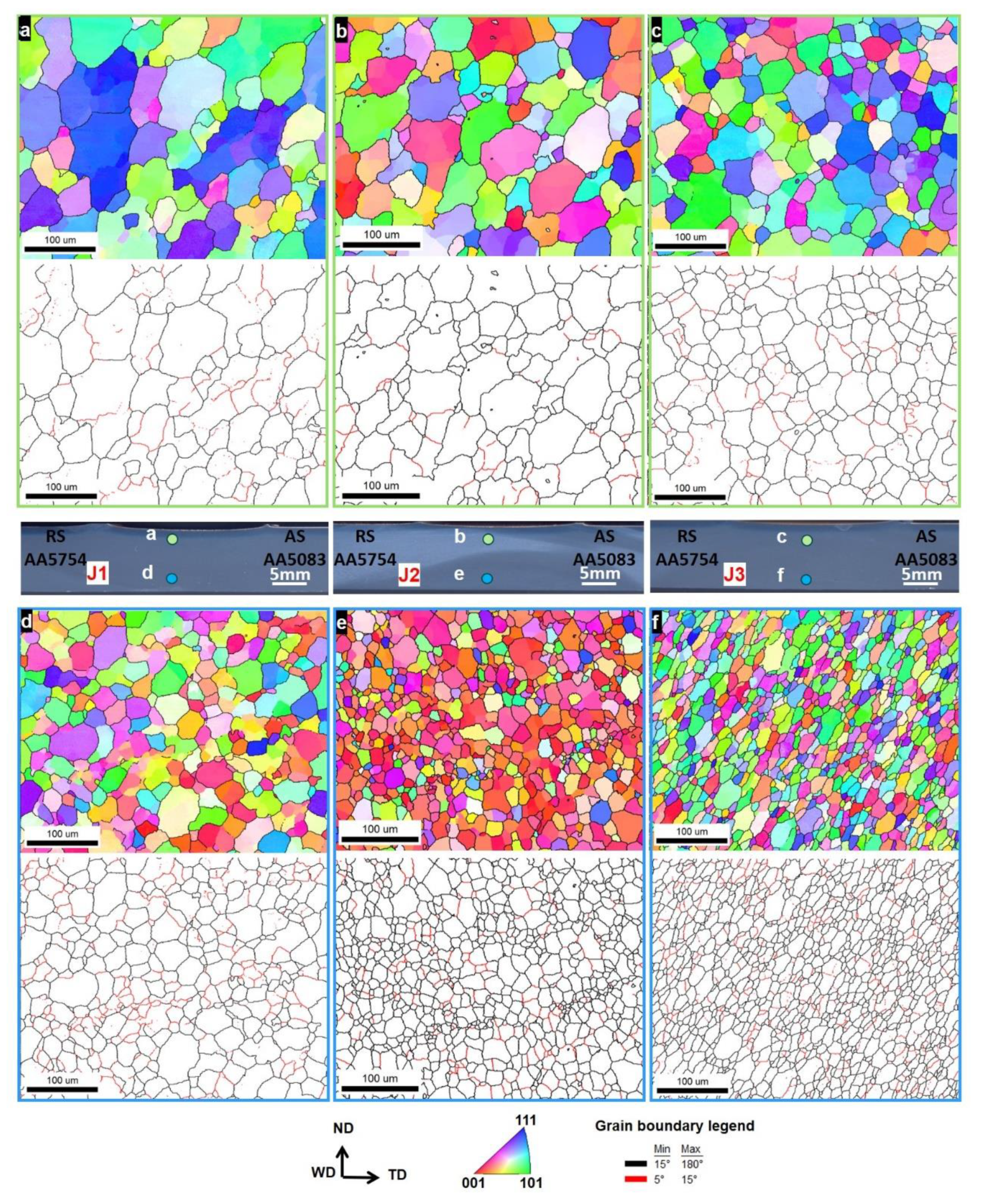

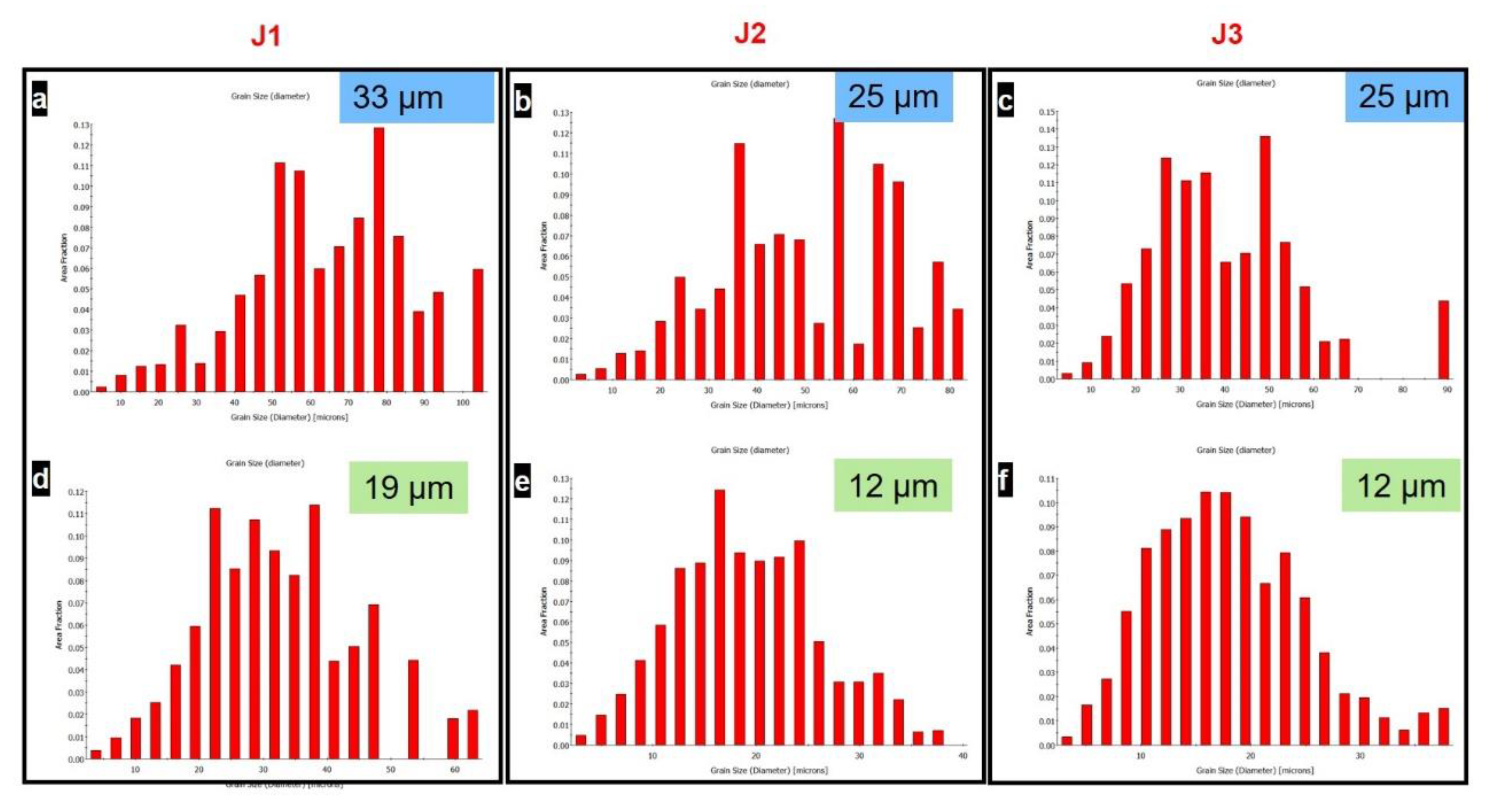

3.2. Microstructural Features of the FSWed Dissimilar AA5083-AA5754 Joints

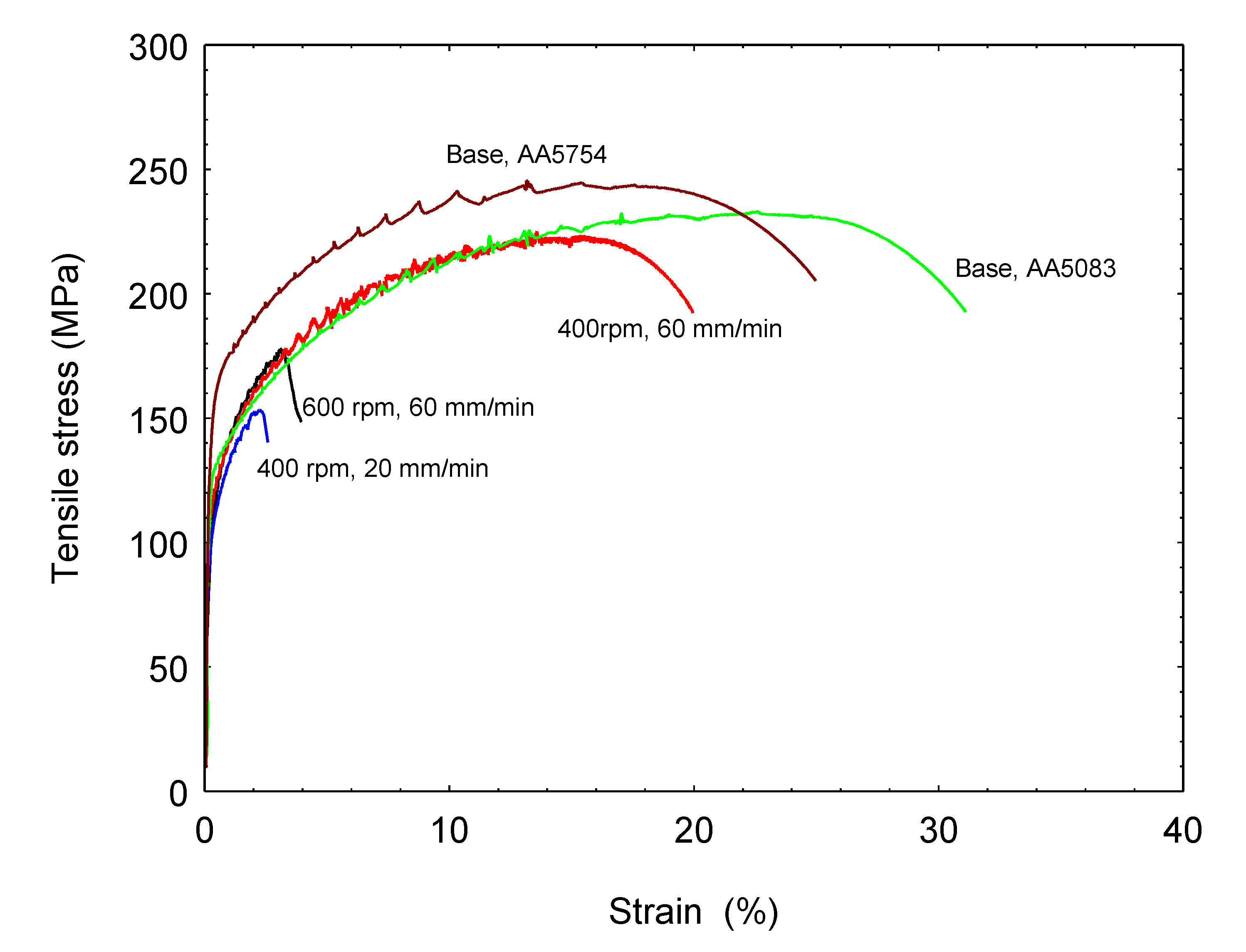

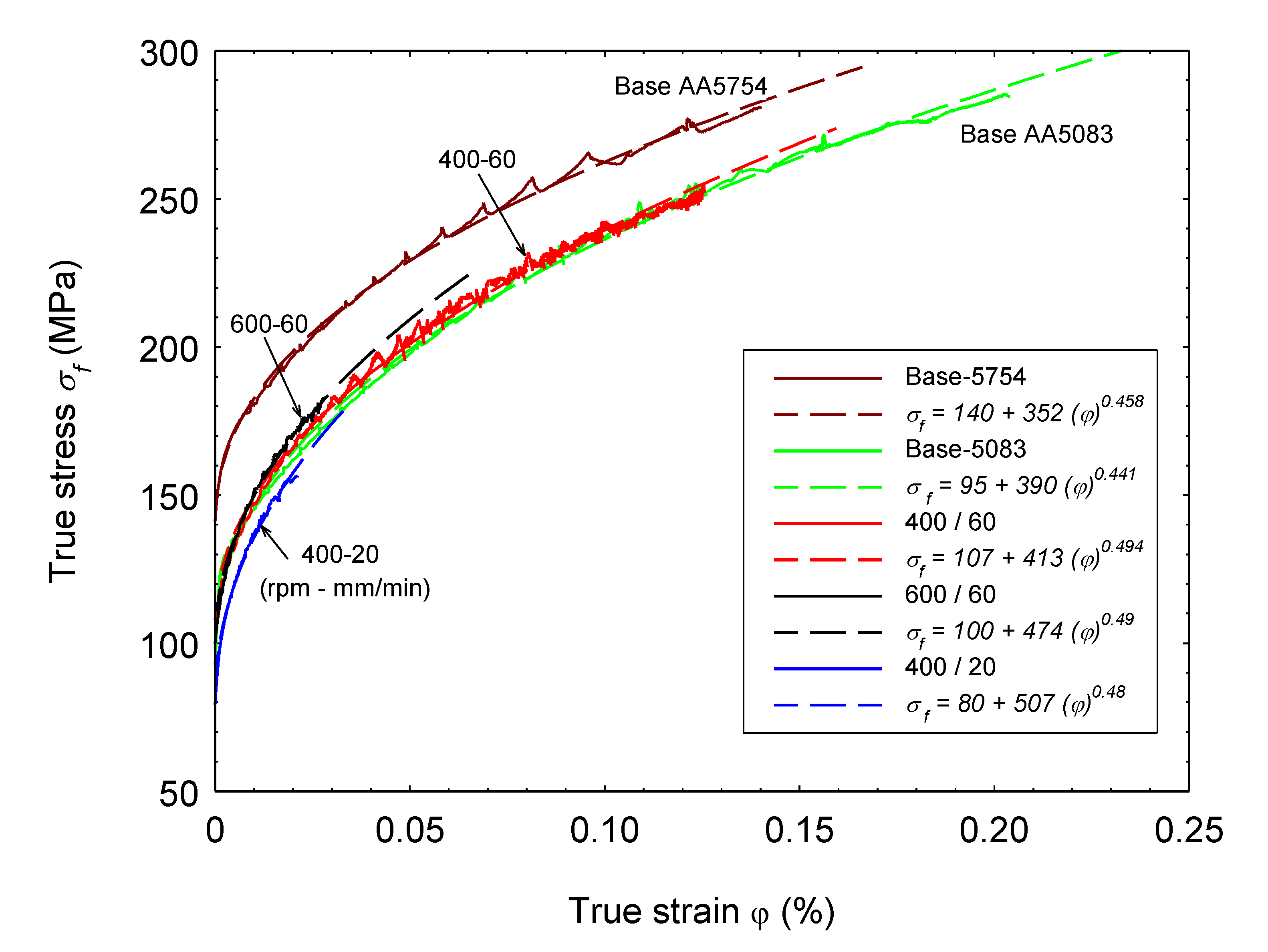

3.3. Mechanical Properties

4. Conclusions

- Microstructure observations using EBSD revealed a significant grain refinement effect for the rotation rate than that of the welding speed during dissimilar FSW of AA5754-AA5083 joints. The average grain size reduced from 19 µm to 12 µm by the reduction of the rotation rate from 600 rpm to 400 rpm at a constant welding speed of 60 mm/min, while almost similar average grain size (12 µm) was obtained by the reduction of welding speed from 60 mm/min to 20 mm/min at a constant rotation rate of 400 rpm.

- The combination of the lowest applied tool rotation rate of 400 rpm and welding speed of 20 mm/min promoted a significant grain structure refinement, attributable to a decreased heat input compared with other welded joints at 400 rpm-40 mm/min and 600 rpm-60 mm/min.

- The generally observed fine grain structure in the bottom region of nugget zones for all joints was explained by the thickness-induced high cooling capacity, preventing grain growth, besides being the bottom region affected by the pin not by the shoulder and pin together as the case in the top regions.

- Hardness distribution maps revealed the softening of the nugget zone. The increased heat generated by the pin shoulder made the upper region of the nugget zone more soft than the lower zone.

- Tensile flow curves of the tested materials were well described using the Ludwik formula, and the materials parameters were sensitive to the hardening effect resulting from the FSW-ing process. The FSWed joint (400-60) showed the highest strengthening parameter (n = 0.494) with a moderate k value of 413 MPa.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Nomenclature

| AA | Aluminum alloy |

| AS | Advancing side |

| BM | Base material |

| DRV | Dynamic recovery |

| DRX | Dynamic recrystallization |

| EBSD | Electron backscatter diffraction |

| EDAX | Energy dispersive analysis of X-rays |

| EDX | Energy-dispersive X-ray |

| FSW | Friction stir welding |

| FSWed | Friction stir welded |

| HABs | High angle grain boundaries |

| HAZ | Heat affected zone |

| HI | Heat input, J/mm |

| HV | Hardness Vickers |

| HRC | Hardnedd Rockwell C |

| IPF | Inverse pole figure |

| k | Material parameter |

| LABs | Low angle grain boundaries |

| Mg | Magnesium |

| Mn | Manganese |

| n | Strengthening parameter |

| ND | Normal direction |

| NG | Nugget zone |

| rpm | Revolution per minute |

| RS | Retreating side |

| SEM | Scanning electron microscope |

| SZ | Stirred zone |

| TD | Transverse direction |

| TMAZ | Thermomechanical affected zone |

| v | Welding speed, mm/min |

| WD | Welding direction |

| WN | Welding nugget |

| ε | Engineering strain |

| σ | Engineering stress |

| σ0.2%: | 0.2 offset yield stress, MPa |

| σf | Flow stress, MPa |

| σUTS: | Ultimate tensile strength, MPa |

| φ | True strain |

| ω | Rotational speed, rpm |

References

- Sahu, P.K.; Pal, S.; Pal, S.K.; Jain, R. Influence of Plate Position, Tool Offset and Tool Rotational Speed on Mechanical Properties and Microstructures of Dissimilar Al/Cu Friction Stir Welding Joints. J. Mater. Process. Technol. 2016, 235, 55–67. [Google Scholar] [CrossRef]

- Mabuwa, S.; Msomi, V. Review on Friction Stir Processed Tig and Friction Stirwelded Dissimilar Alloy Joints. Metals 2020, 10, 142. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Ranjan, A.; Kuriachen, B. Recent Research Progress in Solid State Friction-Stir Welding of Aluminium–Magnesium Alloys: A Critical Review. J. Mater. Res. Technol. 2020, 9, 6217–6256. [Google Scholar] [CrossRef]

- Mehta, K.P. A review on friction-based joining of dissimilar aluminum-steel joints. J. Mater. Res. 2019, 34, 78–96. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-T4/AA7075-T6 T-Butt Joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Santecchia, E.; Paoletti, C.; Spigarelli, S.; Simoncini, M. New Approaches to Friction Stir Welding of Aluminum Light-Alloys. Metals 2020, 10, 233. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Ponder, K.; Brizes, E.; Abke, T.; Edwards, P.; Ramirez, A.J. Combining Resistance Spot Welding and Friction Element Welding for Dissimilar Joining of Aluminum to High Strength Steels. J. Mater. Process. Technol. 2019, 273, 116192. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ahmed, E.; Hamada, A.S.; Khodir, S.A.; Seleman, M.E.-S.; Wynne, B.P. Microstructure and Mechanical Properties Evolution of Friction Stir Spot Welded High-Mn Twinning-Induced Plasticity Steel. Mater. Des. 2016, 91. [Google Scholar] [CrossRef]

- Merklein, M.; Johannes, M.; Lechner, M.; Kuppert, A. A Review on Tailored Blanks—Production, Applications and Evaluation. J. Mater. Process. Technol. 2014, 214, 151–164. [Google Scholar] [CrossRef]

- El Rayes, M.M.; Soliman, M.S.; Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Abdel-mawla, M.M. Effect of Feed Rate in FSW on the Mechanical and Microstructural Properties of AA5754 Joints. Adv. Mater. Sci. Eng. 2019, 2019, 4156176. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; Seleman, M.M.E.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020. Metals 2021, 11, 68. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; Seleman, M.E.-S.; Ammar, H.R.; Ahmed, E. Friction Stir Welding of Similar and Dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Sangalli, G.; Lemos, G.V.B.; Martinazzi, D.; De Lima Lessa, C.R.; Beskow, A.B.; Reguly, A. Towards Qualification of Friction Stir Welding to AA5083-O and AA5052-O Aluminum Alloys. Mater. Res. 2019. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.E.-S.; Shazly, M.; Attallah, M.M.; Ahmed, E. Microstructural Development and Mechanical Properties of Friction Stir Welded Ferritic Stainless Steel AISI 409. J. Mater. Eng. Perform. 2019, 28, 6391–6406. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Martin, J.P. Effect of Friction Stir Welding Speed on Mechanical Properties and Microstructure of Nickel Based Super Alloy Inconel 718. Sci. Technol. Weld. Join. 2013, 18, 680–687. [Google Scholar] [CrossRef]

- Hamada, A.S.; Järvenpää, A.; Ahmed, M.M.Z.; Jaskari, M.; Wynne, B.P.; Porter, D.A.; Karjalainen, L.P. The Microstructural Evolution of Friction Stir Welded AA6082-T6 Aluminum Alloy during Cyclic Deformation. Mater. Sci. Eng. A 2015, 642, 366–376. [Google Scholar] [CrossRef]

- Khodir, S.A.; Ahmed, M.M.Z.; Ahmed, E.; Mohamed, S.M.R.; Abdel-Aleem, H. Effect of Intermetallic Compound Phases on the Mechanical Properties of the Dissimilar Al/Cu Friction Stir Welded Joints. J. Mater. Eng. Perform. 2016, 25, 4637–4648. [Google Scholar] [CrossRef]

- Refat, M.; Elashery, A.; Toschi, S.; Ahmed, M.M.Z.; Morri, A.; El-Mahallawi, I.; Ceschini, L. Microstructure, Hardness and Impact Toughness of Heat-Treated Nanodispersed Surface and Friction Stir-Processed Aluminum Alloy AA7075. J. Mater. Eng. Perform. 2016, 25, 5087–5101. [Google Scholar] [CrossRef]

- Hoziefa, W.; Toschi, S.; Ahmed, M.M.Z.; Morri, A.; Mahdy, A.A.; Seleman, M.E.-S.; El-Mahallawi, I.; Ceschini, L.; Atlam, A. Influence of Friction Stir Processing on the Microstructure and Mechanical Properties of a Compocast AA2024-Al2O3 Nanocomposite. Mater. Des. 2016, 106, 273–284. [Google Scholar] [CrossRef]

- Zayed, E.M.; El-Tayeb, N.S.M.; Ahmed, M.M.Z.; Rashad, R.M. Development and Characterization of AA5083 Reinforced with SiC and Al2O3 Particles by Friction Stir Processing. In Engineering Design Applications; Springer: Cham, Switzerland, 2019; Volume 92. [Google Scholar]

- Oliveira, J.P.; Duarte, J.F.; Inácio, P.; Schell, N.; Miranda, R.M.; Santos, T.G. Production of Al / NiTi Composites by Friction Stir Welding Assisted by Electrical Current. JMADE 2017, 113, 311–318. [Google Scholar] [CrossRef]

- Tonelli, L.; Refat, M.; Toschi, S.; Ahmed, M.M.Z.; Ahmed, E.; Morri, A.; El-Mahallawi, I.; Ceschini, L. Production of AlSi12CuNiMg/Al2O3 Micro/Nanodispersed Surface Composites Using Friction Stir Processing for Automotive Applications BT—Friction Stir Welding and Processing X. In Friction Stir Welding and Processing X; Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 233–242. [Google Scholar]

- Costa, A.M.S.; Oliveira, J.P.; Pereira, V.F.; Nunes, C.A.; Ramirez, A.J.; Tschiptschin, A.P. Ni-Based Mar-M247 Superalloy as a Friction Stir Processing Tool. J. Mater. Process. Technol. 2018, 262, 605–614. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.Z.; Wynne, B.P.; Rainforth, W.M.; Addison, A.; Martin, J.P.; Threadgill, P.L. Effect of Tool Geometry and Heat Input on the Hardness, Grain Structure, and Crystallographic Texture of Thick-Section Friction Stir-Welded Aluminium. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 271–284. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; El Mehtedi, M.; Simoncini, M. Double Side Friction Stir Welding of AA6082 Sheets: Microstructure and Nanoindentation Characterization. Mater. Sci. Eng. A 2014, 590, 209–217. [Google Scholar] [CrossRef]

- Su, H.; Wu, C.S.; Bachmann, M.; Rethmeier, M. Numerical Modeling for the Effect of Pin Profiles on Thermal and Material Flow Characteristics in Friction Stir Welding. Mater. Des. 2015, 77, 114–125. [Google Scholar] [CrossRef]

- Sarkari Khorrami, M.; Kazeminezhad, M.; Kokabi, A.H. Microstructure Evolutions after Friction Stir Welding of Severely Deformed Aluminum Sheets. Mater. Des. 2012, 40, 364–372. [Google Scholar] [CrossRef]

- Kumbhar, N.T.; Sahoo, S.K.; Samajdar, I.; Dey, G.K.; Bhanumurthy, K. Microstructure and Microtextural Studies of Friction Stir Welded Aluminium Alloy 5052. Mater. Des. 2011, 32, 1657–1666. [Google Scholar] [CrossRef]

- Kim, N.K.; Kim, B.C.; An, Y.G.; Jung, B.H.; Song, S.W.; Kang, C.Y. The Effect of Material Arrangement on Mechanical Properties in Friction Stir Welded Dissimilar A5052/A5J32 Aluminum Alloys. Met. Mater. Int. 2009, 15, 671–675. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Reddy, G.M. Dissimilar Friction Stir Welds in AA2219-AA5083 Aluminium Alloys: Effect of Process Parameters on Material Inter-Mixing, Defect Formation, and Mechanical Properties. Trans. Indian Inst. Met. 2016, 67, 1397–1415. [Google Scholar] [CrossRef]

- Kalemba-Rec, I.; Kopyściański, M.; Miara, D.; Krasnowski, K. Effect of Process Parameters on Mechanical Properties of Friction Stir Welded Dissimilar 7075-T651 and 5083-H111 Aluminum Alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 2767–2779. [Google Scholar] [CrossRef]

- Essa, A.R.S.; Ahmed, M.M.Z.; Mohamed, A.Y.A.; El-Nikhaily, A.E. An Analytical Model of Heat Generation for Eccentric Cylindrical Pin in Friction Stir Welding. J. Mater. Res. Technol. 2016, 5, 234–240. [Google Scholar] [CrossRef]

- Kasman, Ş.; Yenier, Z. Analyzing Dissimilar Friction Stir Welding of AA5754/AA7075. Int. J. Adv. Manuf. Technol. 2014, 70, 145–156. [Google Scholar] [CrossRef]

- Threadgill, P.L. Terminology in Friction Stir Welding. Sci. Technol. Weld. Join. 2007, 12, 357–360. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction Stir Welding of Aluminium Alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Rollett, A.; Humphreys, F.; Rohrer, G.S.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004; ISBN 9780080441641. [Google Scholar]

- McQueen, H.J.; Blum, W. Dynamic Recovery: Sufficient Mechanism in the Hot Deformation of Al (<99.99). Mater. Sci. Eng. A 2000, 290, 95–107. [Google Scholar] [CrossRef]

- Su, J.-Q.Q.; Nelson, T.W.; Sterling, C.J. Microstructure Evolution during FSW/FSP of High Strength Aluminum Alloys. Mater. Sci. Eng. A 2005, 405, 277–286. [Google Scholar] [CrossRef]

- Fonda, R.W.; Bingert, J.F.; Colligan, K.J. Development of Grain Structure during Friction Stir Welding. Scr. Mater. 2004, 51, 243–248. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Elnaml, A.; Shazly, M.; Seleman, M.M.E. The Effect of Top Surface Lubrication on the Friction Stir Welding of Polycarbonate Sheets. Intern. Polym. Process. 2021, 1–9. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Threadgill, P.L. Microstructure, Crystallographic Texture and Mechanical Properties of Friction Stir Welded AA2017A. Mater. Charact. 2012, 64, 107–117. [Google Scholar] [CrossRef]

- Zhang, F.; Su, X.; Chen, Z.; Nie, Z. Effect of Welding Parameters on Microstructure and Mechanical Properties of Friction Stir Welded Joints of a Super High Strength Al-Zn-Mg-Cu Aluminum Alloy. Mater. Des. 2015, 67, 483–491. [Google Scholar] [CrossRef]

- Cao, X.; Jahazi, M. Effect of Welding Speed on the Quality of Friction Stir Welded Butt Joints of a Magnesium Alloy. Mater. Des. 2009, 30, 2033–2042. [Google Scholar] [CrossRef]

- Bagheri, B.; Abbasi, M.; Dadaei, M. Effect of Water Cooling and Vibration on the Performances of Friction-Stir-Welded AA5083 Aluminum Joints. Metallogr. Microstruct. Anal. 2020, 9, 33–46. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Threadgill, P.L. Quantifying Crystallographic Texture in the Probe-Dominated Region of Thick-Section Friction-Stir-Welded Aluminium. Scr. Mater. 2008, 59, 507–510. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Threadgill, P.L. Through-Thickness Crystallographic Texture of Stationary Shoulder Friction Stir Welded Aluminium. Scr. Mater. 2011, 64, 45–48. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Lin, S.B.; Qu, F.X.; Wu, L. Influence of Pin Geometry on Material Flow in Friction Stir Welding Process. Mater. Sci. Technol. 2006, 22, 45–50. [Google Scholar] [CrossRef]

- Sajuri, Z.; Mohamad Selamat, N.F.; Baghdadi, A.H.; Rajabi, A.; Omar, M.Z.; Kokabi, A.H.; Syarif, J. Cold-Rolling Strain Hardening Effect on the Microstructure, Serration-Flow Behaviour and Dislocation Density of Friction Stir Welded AA5083. Metals 2020, 10, 70. [Google Scholar] [CrossRef]

- Bintu, A.; Vincze, G.; Picu, R.C.; Lopes, A.B. Effect of Symmetric and Asymmetric Rolling on the Mechanical Properties of AA5182. Mater. Des. 2016, 100, 151–156. [Google Scholar] [CrossRef]

- Gabrielli, F.; Forcellese, A.; El Mehtedi, M.; Simoncini, M. Mechanical Properties and Formability of Cold Rolled Friction Stir Welded Sheets in AA5754 for Automotive Applications. Procedia Eng. 2017, 183, 245–250. [Google Scholar] [CrossRef]

- Hollomon, J.H. Tensile Deformation. Trans. AIME 1945, 126, 268–290. [Google Scholar]

- Yamada, H.; Kami, T.; Mori, R.; Kudo, T.; Okada, M. Strain Rate Dependence of Material Strength in AA5xxx Series Aluminum Alloys and Evaluation of Their Constitutive Equation. Metals 2018, 8, 576. [Google Scholar] [CrossRef]

- Swift, H.W. Plastic Instability under Plane Stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Meckings, H.; Koccks, U.F. Kinetics of Flow and Strain Hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Estrin, Y.; Mecking, H. A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Met. 1984, 32, 57–70. [Google Scholar] [CrossRef]

- Ludwik, P. Fließvorgänge Bei Einfachen Beanspruchungen. In Elemente der Technologischen Mechanik; Springer: Berlin/Heidelberg, Germany, 1909. [Google Scholar] [CrossRef]

| State | Welding Conditions | Tensile Properties | |||

|---|---|---|---|---|---|

| # | Heat Index ω2/v | σUTS (MPa) | Total Strain (%) | Welding Efficiency (%) | |

| Base AA5754 | - | - | 251 | 28.50 | -- |

| Base AA5083 | - | - | 233 | 34 | -- |

| AA5083-AA5754 | J1 | 6000 | 178 | 5.50 | 77 |

| J2 | 2666 | 224 | 23 | 96 | |

| J3 | 8000 | 153 | 4.30 | 66 | |

| State | ω (rpm) | v (mm/min) | (MPa) | k (MPa) | n (--) |

|---|---|---|---|---|---|

| Base 5754 | -- | -- | 140 | 352 | 0.458 |

| Base 5083 | -- | -- | 95 | 390 | 0.441 |

| FSWed | 600 | 60 | 100 | 474 | 0.490 |

| 400 | 60 | 107 | 413 | 0.494 | |

| 400 | 20 | 80 | 507 | 0.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.M.Z.; Ataya, S.; Seleman, M.M.E.-S.; Allam, T.; Alsaleh, N.A.; Ahmed, E. Grain Structure, Crystallographic Texture, and Hardening Behavior of Dissimilar Friction Stir Welded AA5083-O and AA5754-H14. Metals 2021, 11, 181. https://doi.org/10.3390/met11020181

Ahmed MMZ, Ataya S, Seleman MME-S, Allam T, Alsaleh NA, Ahmed E. Grain Structure, Crystallographic Texture, and Hardening Behavior of Dissimilar Friction Stir Welded AA5083-O and AA5754-H14. Metals. 2021; 11(2):181. https://doi.org/10.3390/met11020181

Chicago/Turabian StyleAhmed, Mohamed Mohamed Zaky, Sabbah Ataya, Mohamed Mohamed El-Sayed Seleman, Tarek Allam, Naser Abdulrahman Alsaleh, and Essam Ahmed. 2021. "Grain Structure, Crystallographic Texture, and Hardening Behavior of Dissimilar Friction Stir Welded AA5083-O and AA5754-H14" Metals 11, no. 2: 181. https://doi.org/10.3390/met11020181

APA StyleAhmed, M. M. Z., Ataya, S., Seleman, M. M. E.-S., Allam, T., Alsaleh, N. A., & Ahmed, E. (2021). Grain Structure, Crystallographic Texture, and Hardening Behavior of Dissimilar Friction Stir Welded AA5083-O and AA5754-H14. Metals, 11(2), 181. https://doi.org/10.3390/met11020181