Improving Mechanical Properties of Mg–Sc Alloy by Surface AZ31 Layer

Abstract

:1. Introduction

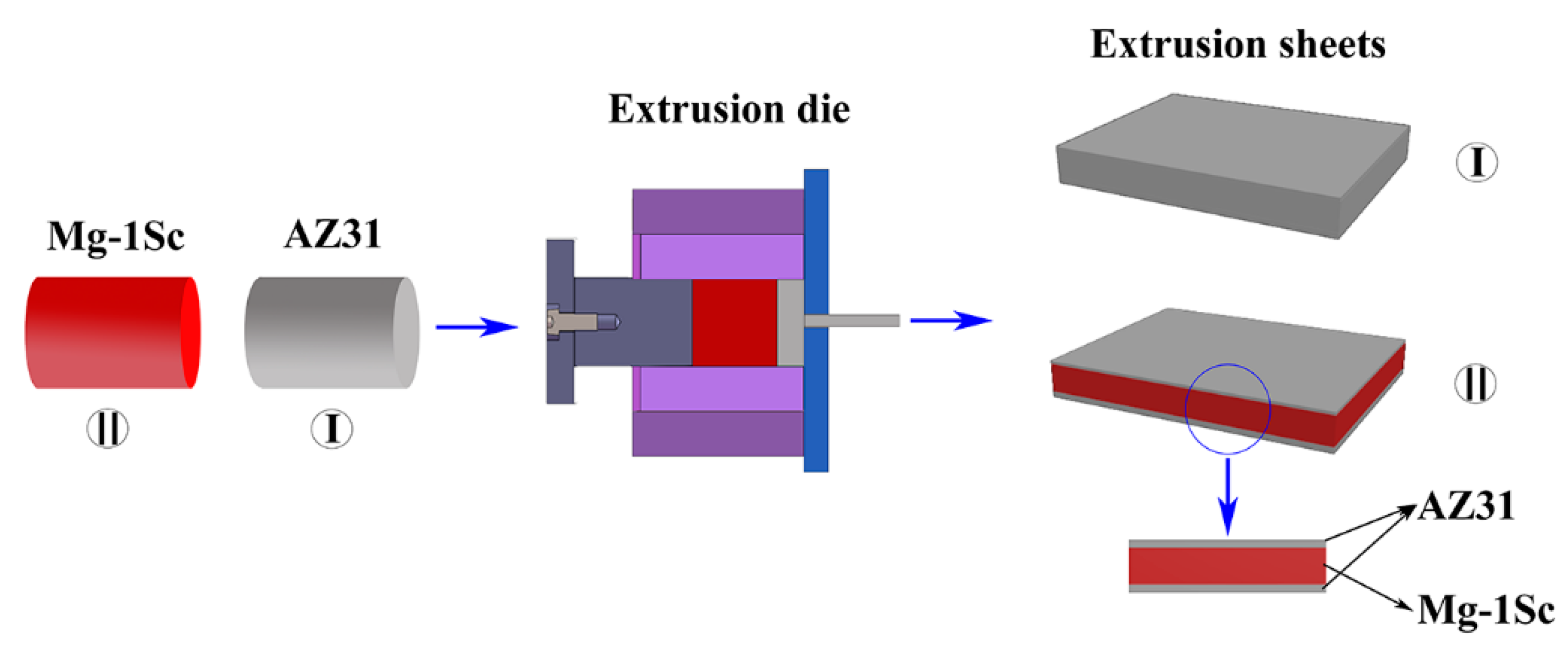

2. Materials and Methods

2.1. Materials

2.2. Microstructure Characterization

2.3. Hardness and Tensile Tests

3. Results

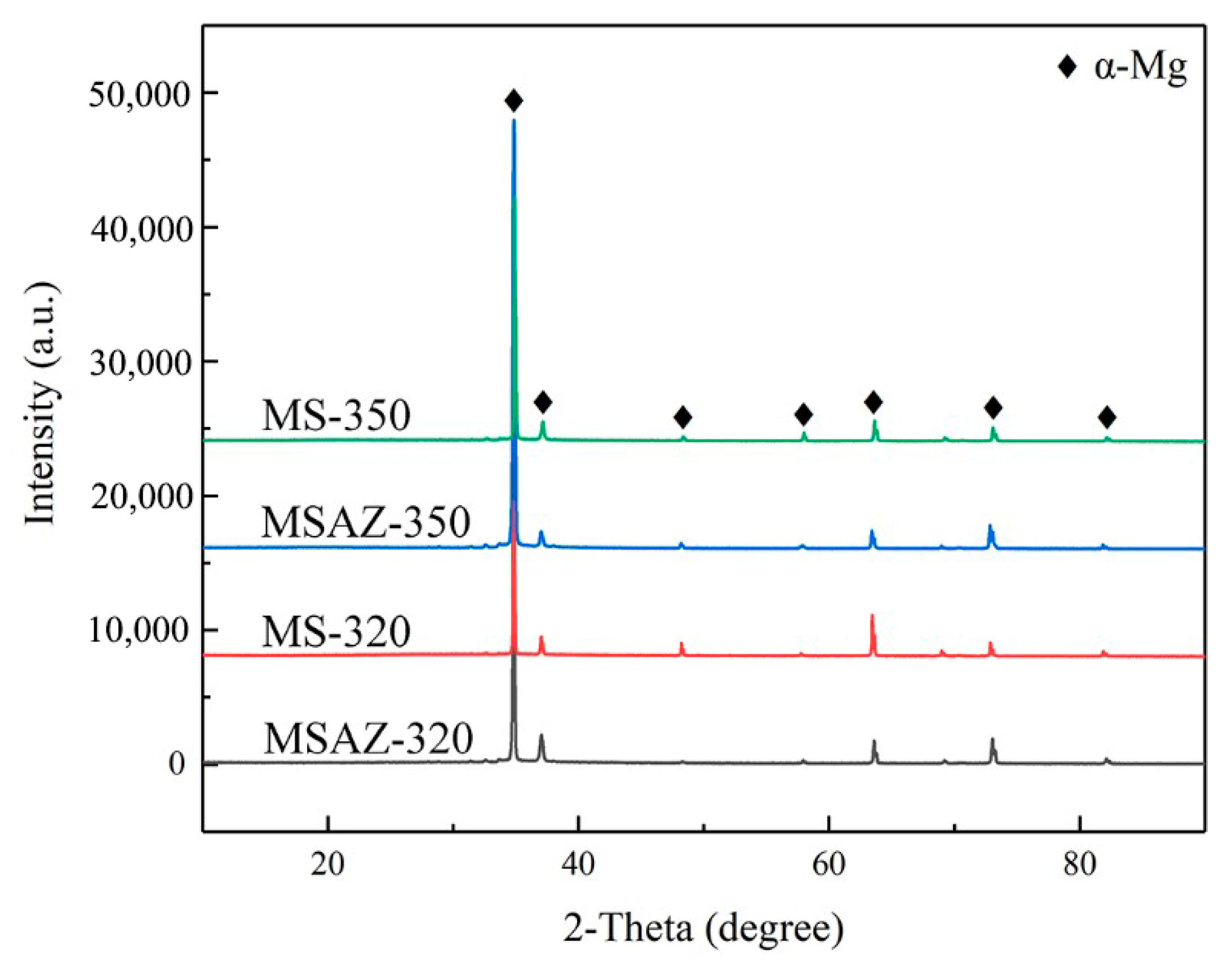

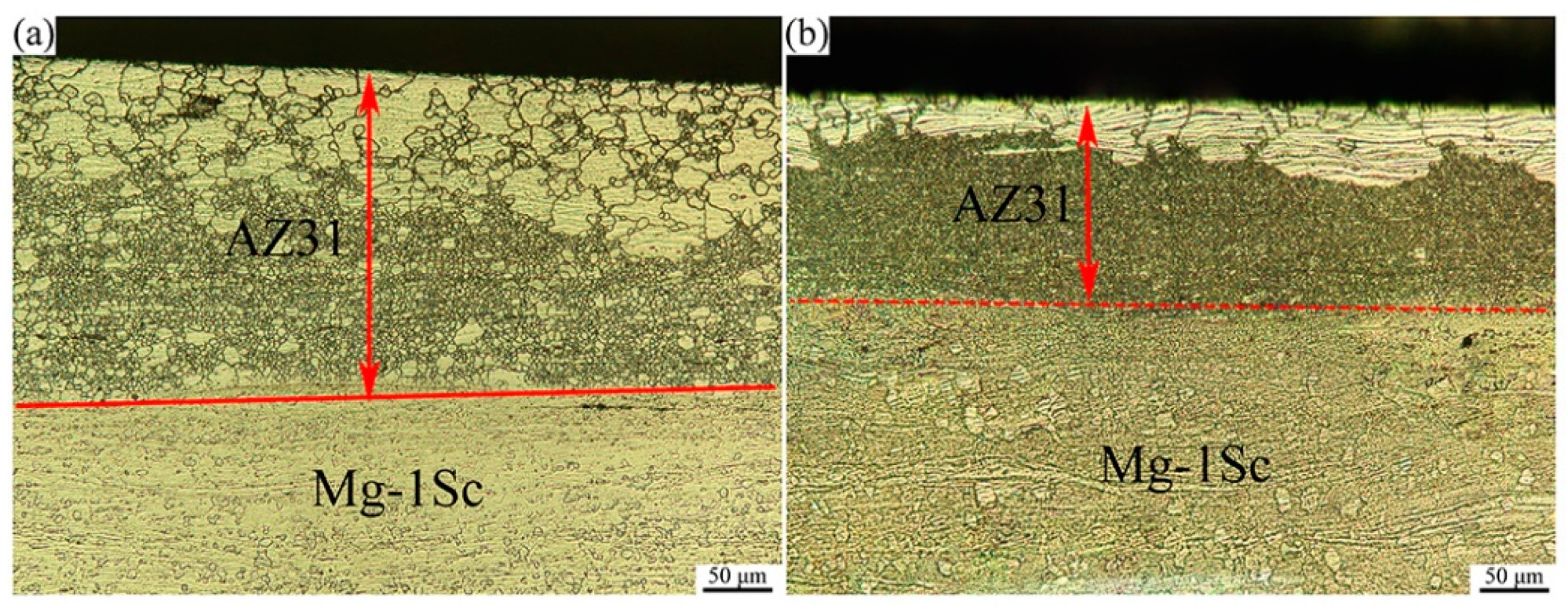

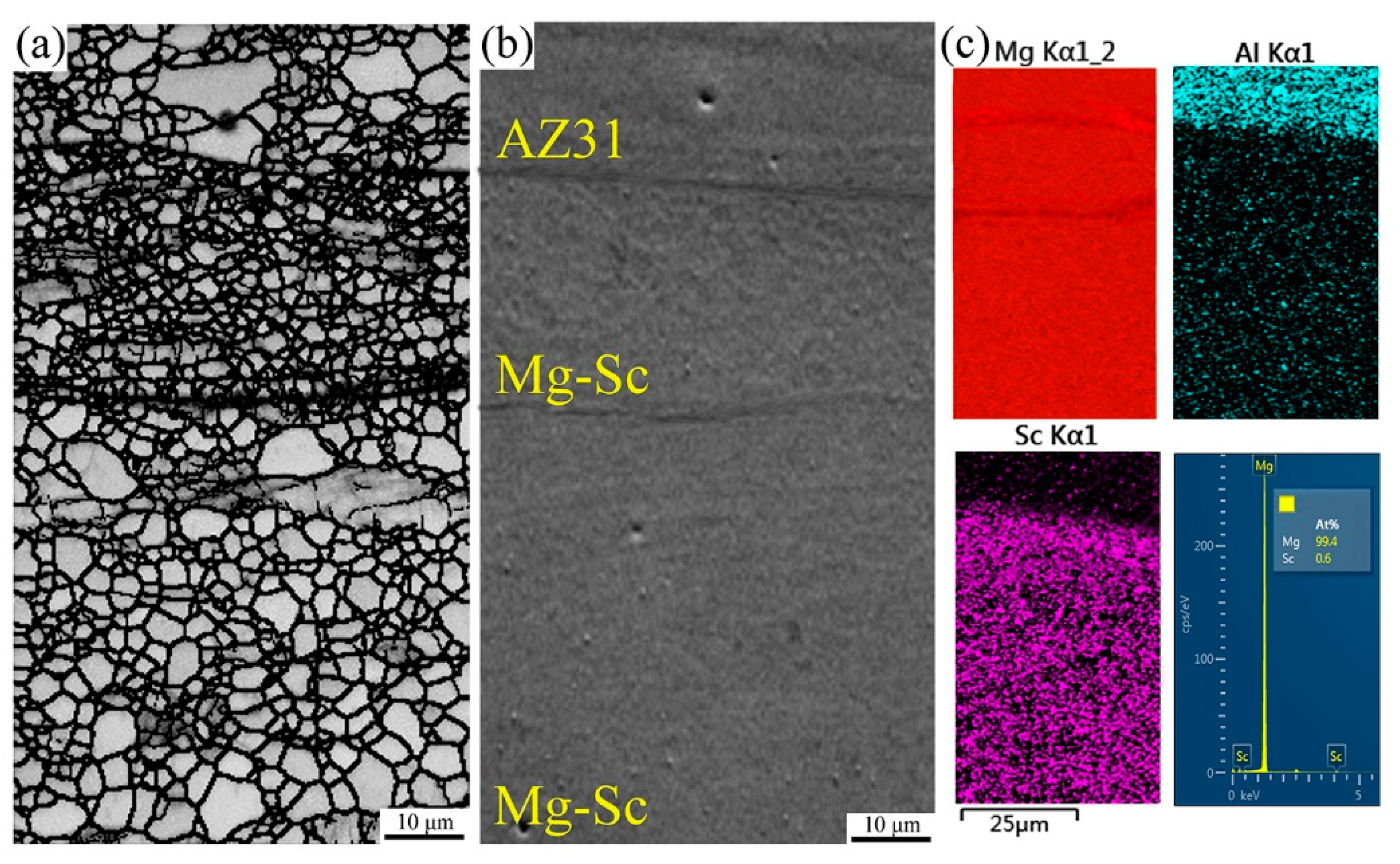

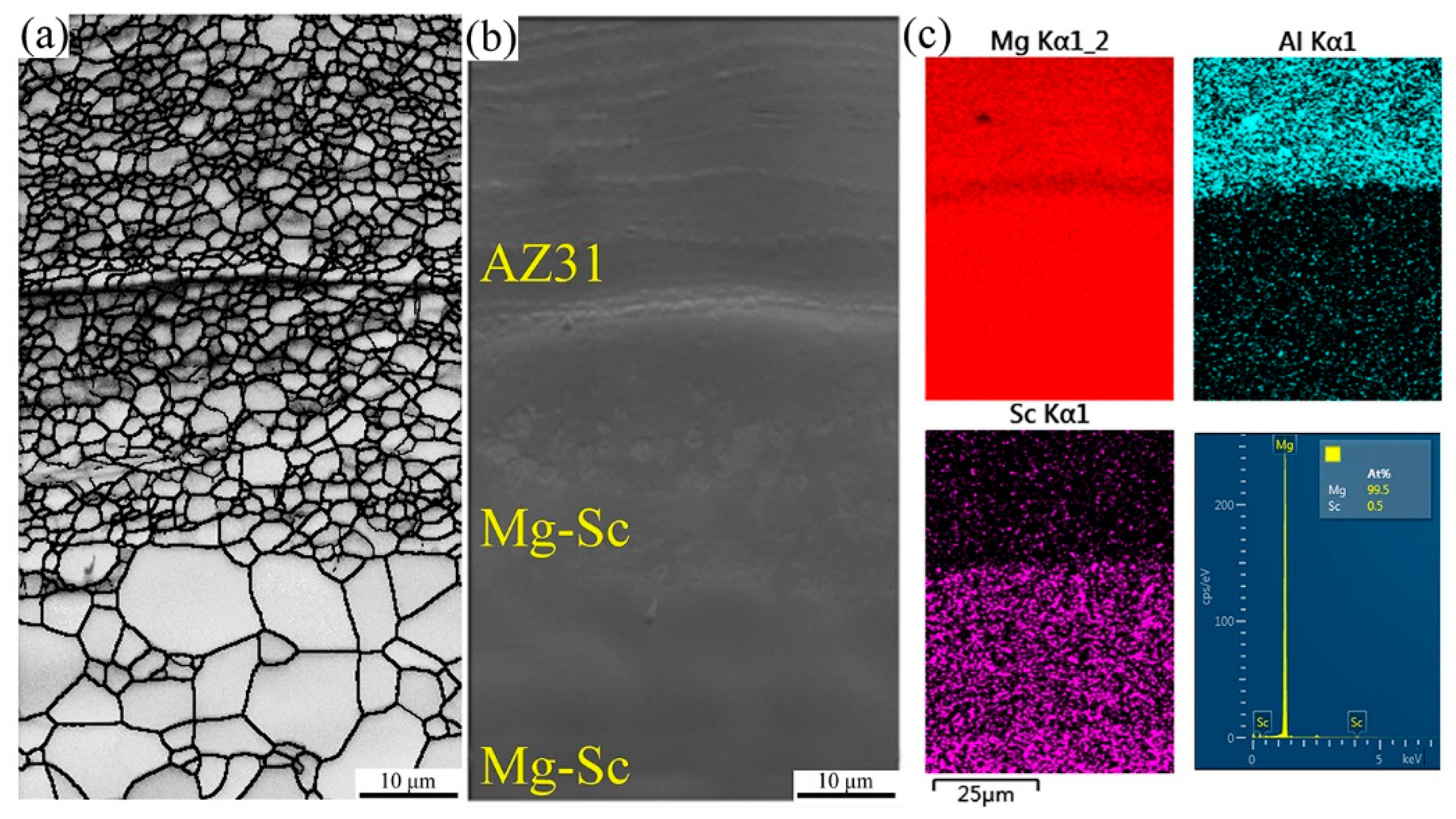

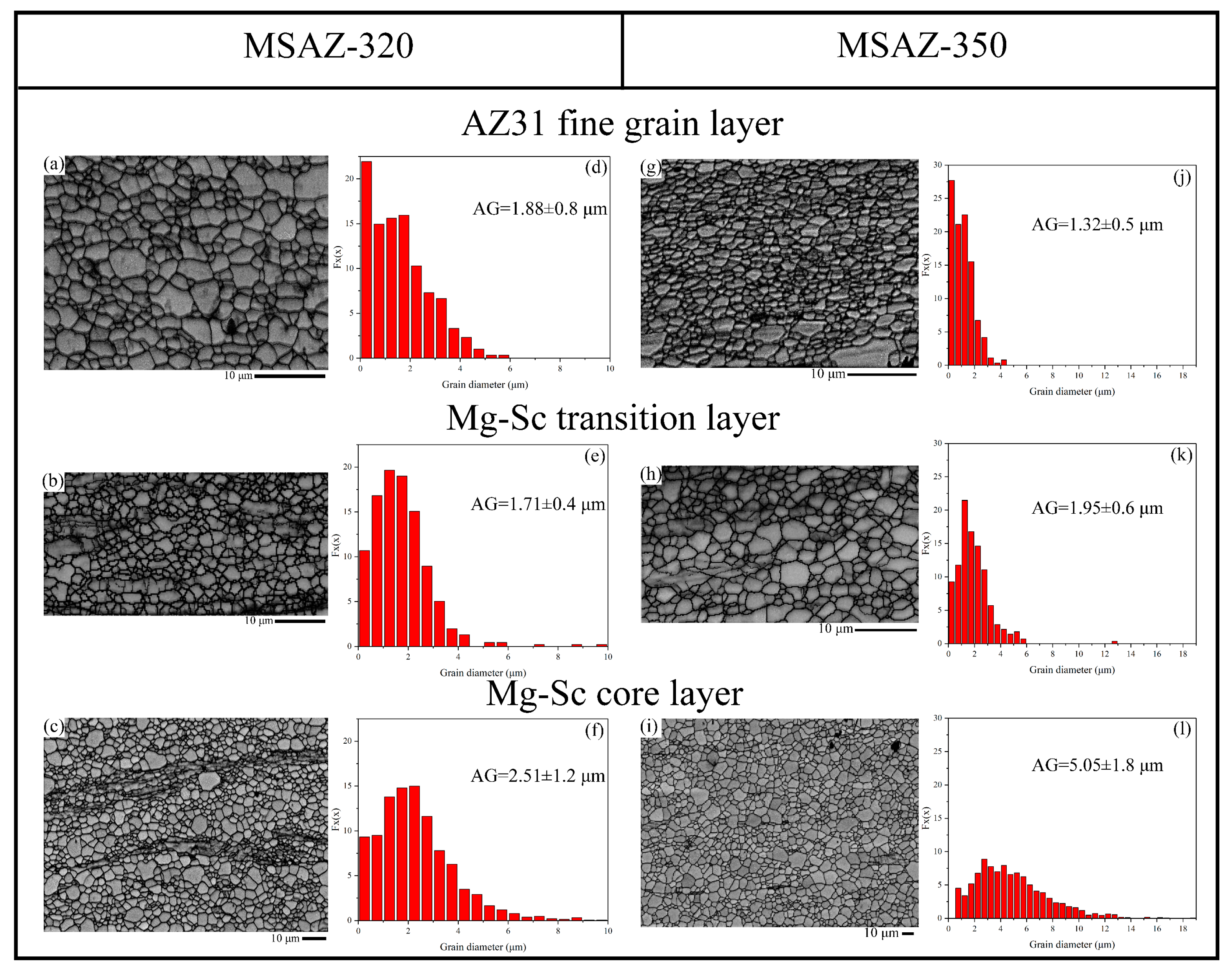

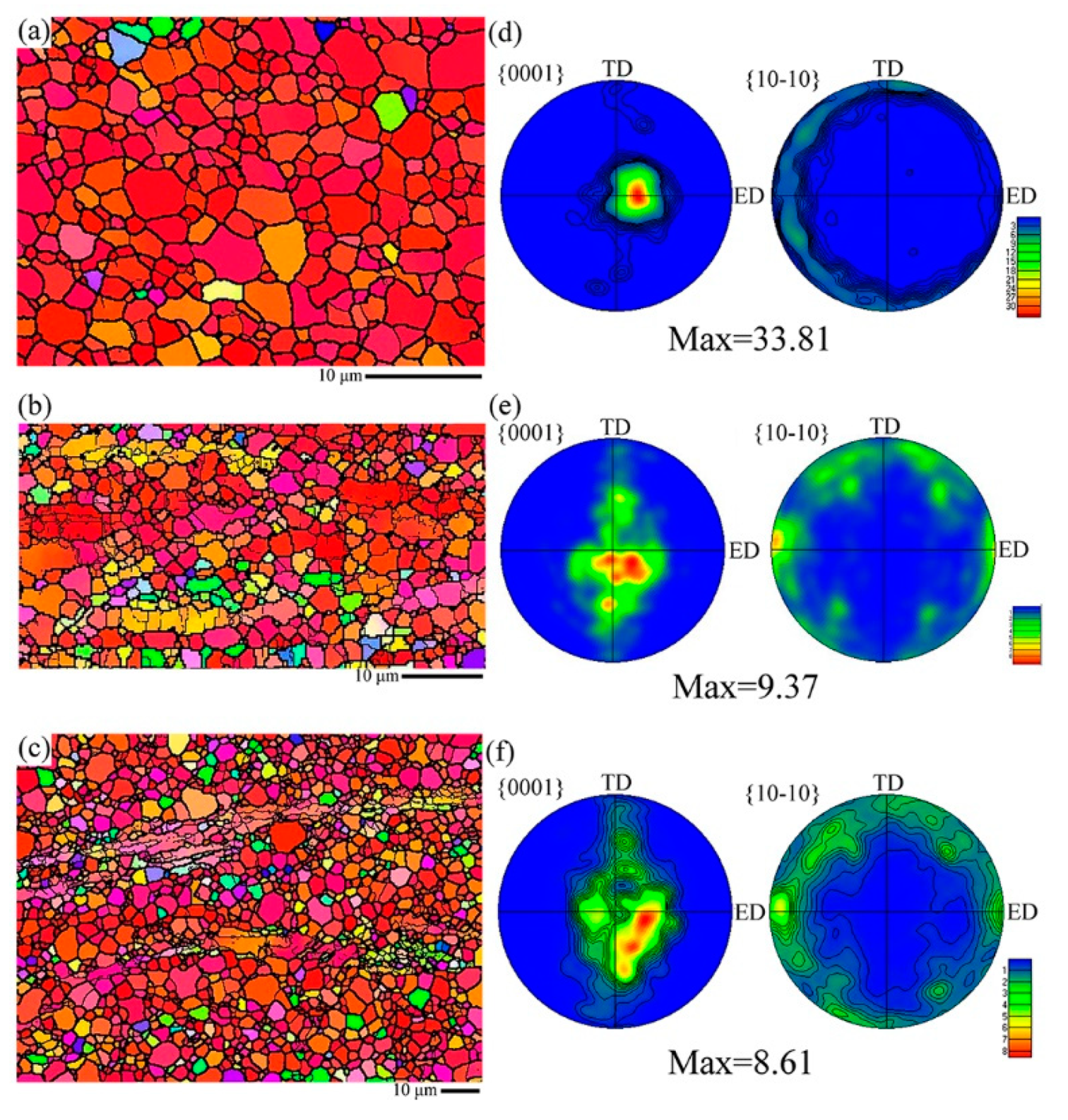

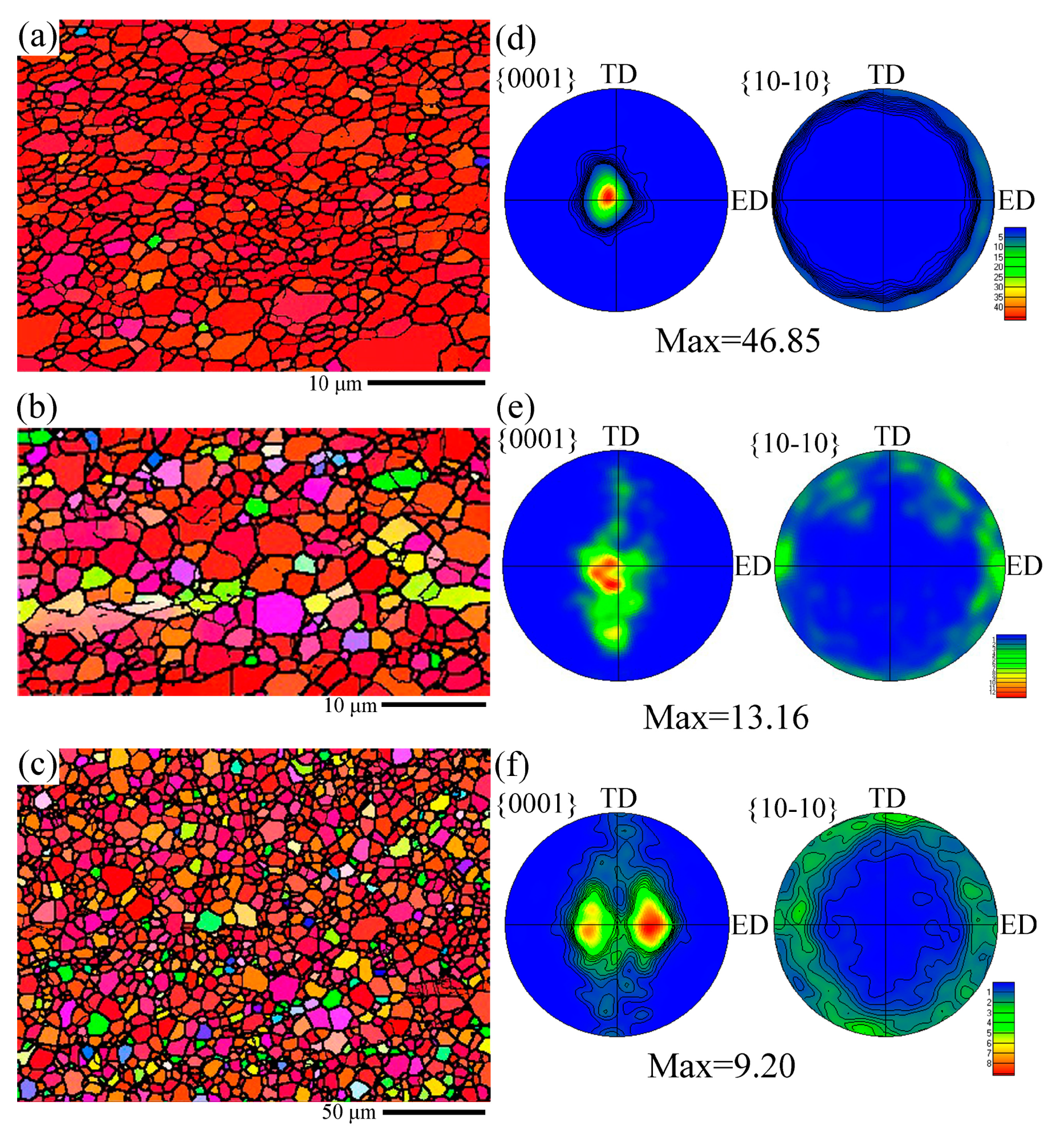

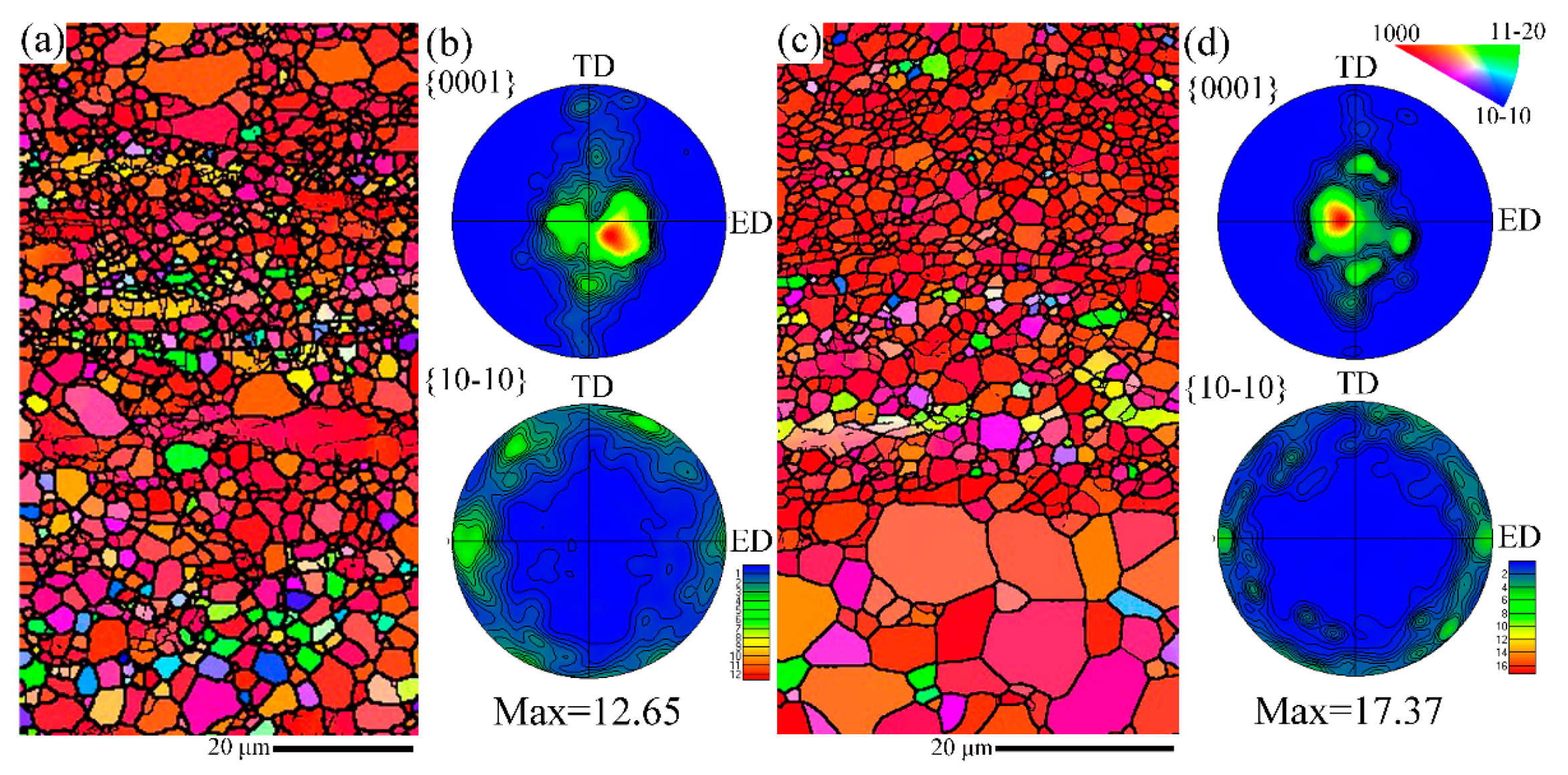

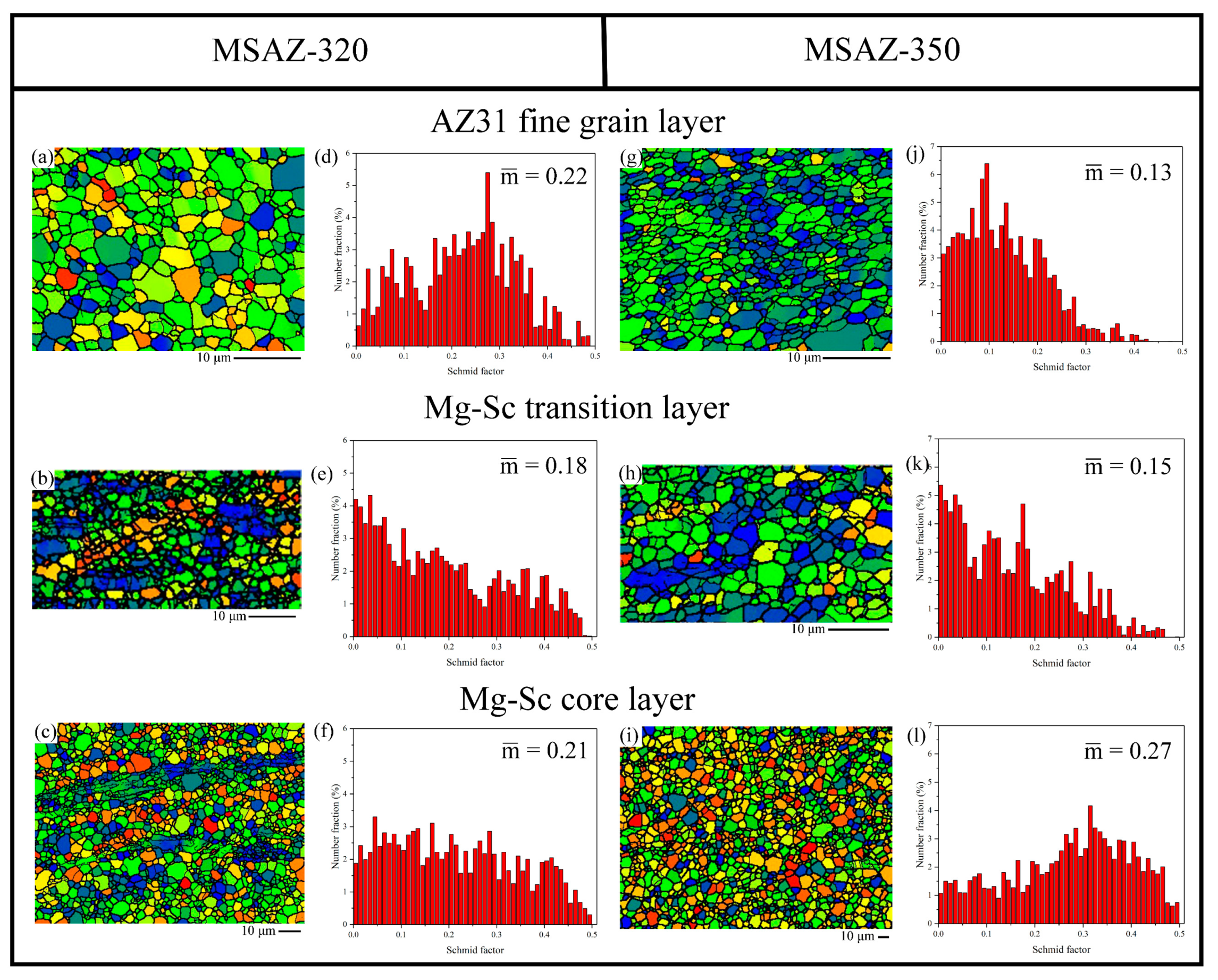

3.1. Microstructure Characterization

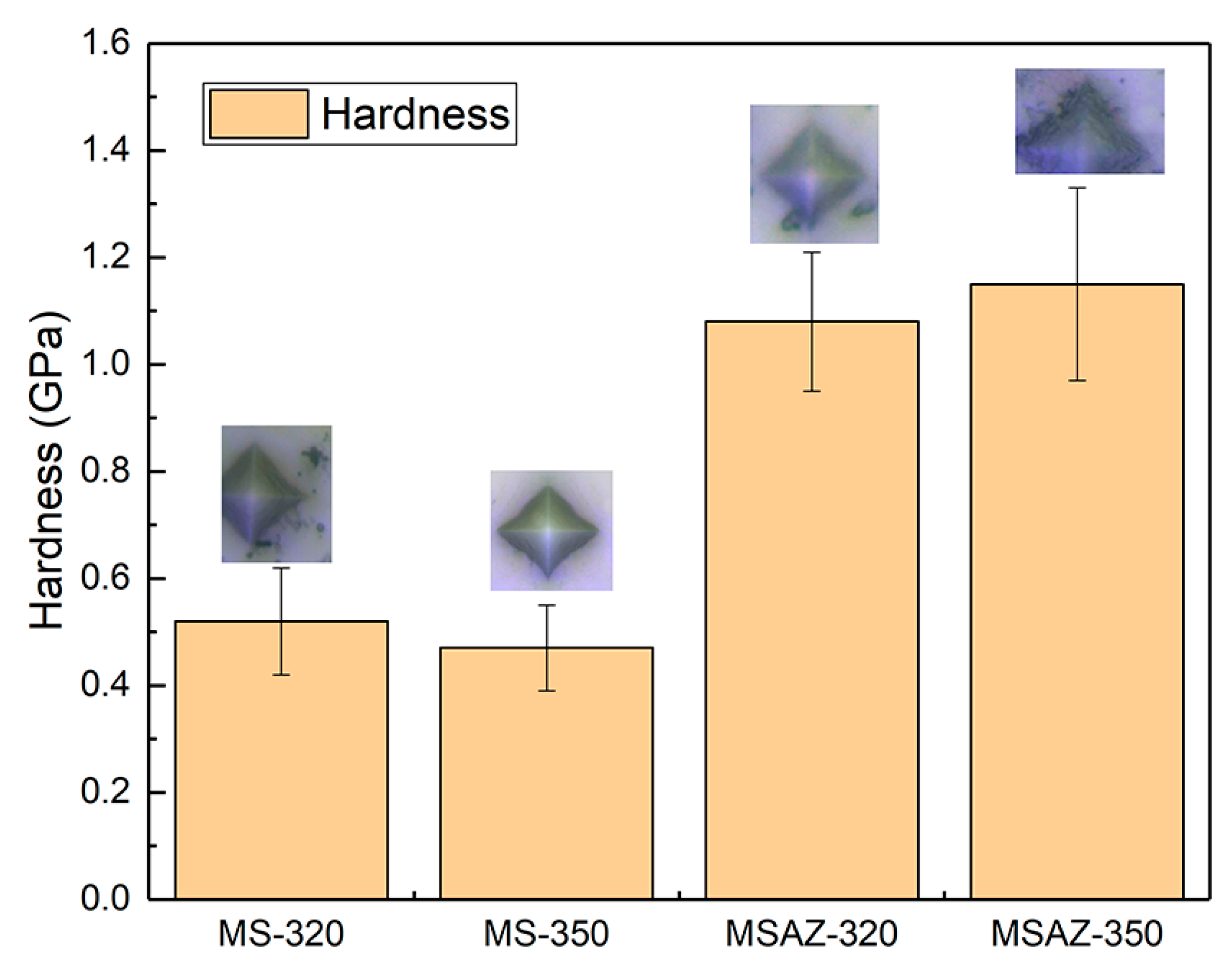

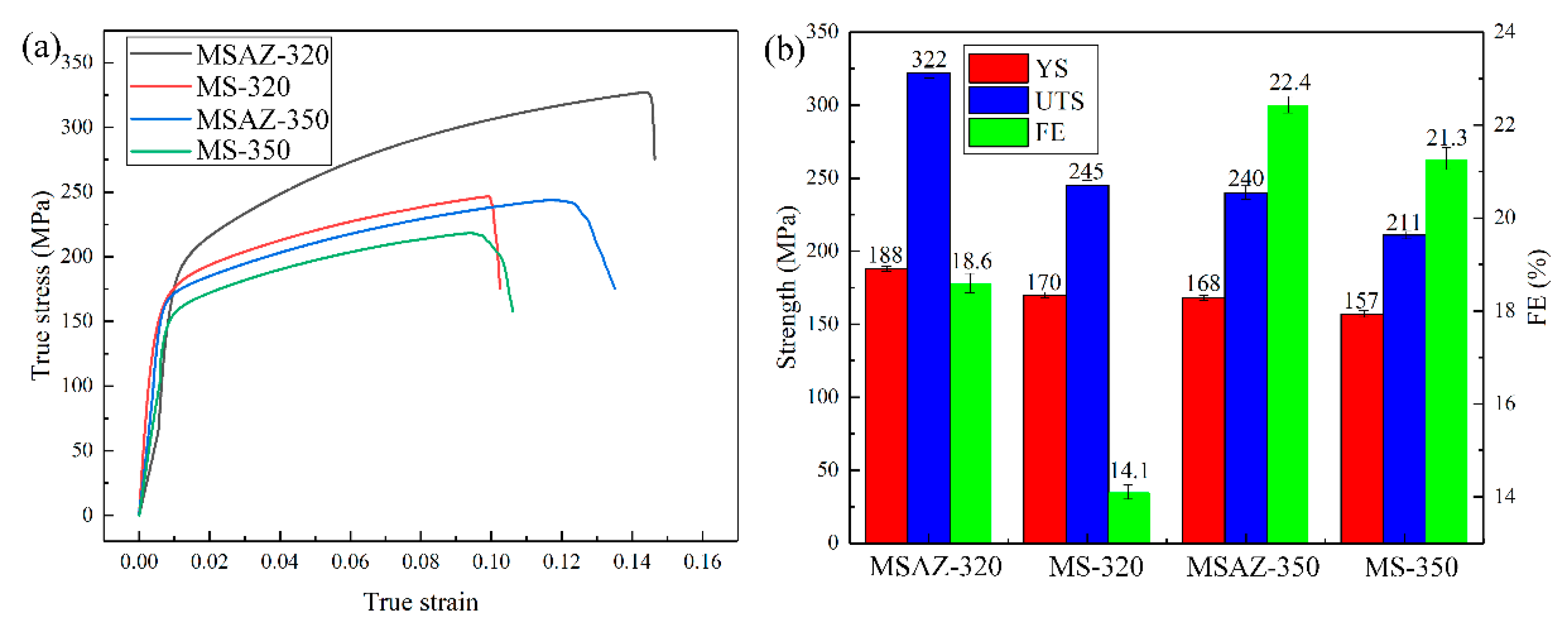

3.2. Nanoindentation and Mechanical Properties

4. Discussion

4.1. Effect of AZ31 Surface Fine Layer on Microstructure

4.2. Effect of AZ31 Surface Fine Layer on Hardness

4.3. Mechanical Properties of the Alloys

4.3.1. Effect of Temperature on Mechanical Properties

4.3.2. Effect of AZ31 Surface Fine Layer on Mechanical Properties

5. Conclusions

- (1)

- AZ31/Mg–Sc composites with gradient grain structure were prepared by hot extrusion. The thickness of AZ31 accounts for 15% and 12% of the composition of the whole alloy when extruded at 320 °C and 350 °C, respectively;

- (2)

- The nanoscale hardness value of Mg–1Sc alloy is increased more than two times through fine-grain strengthening and solution strengthening of the surface AZ31 fine-grain layer;

- (3)

- The surface AZ31 fine-grain layer improves the strength of the Mg–1Sc alloy through fine-grain strengthening and dislocation strengthening, and increases the elongation by improving the distribution of microstructure;

- (4)

- Different extrusion temperatures have different control effects on the microstructure of the AZ31/Mg–Sc composites. In this paper, the alloy has a more obvious gradient microstructure when extruded at 350 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Wang, L.; Xiao, R.; Zhong, X.; Huang, G.; Liu, Q. Comparison of annealing on microstructure and anisotropy of magnesium alloy AZ31 sheets processed by three different routes. J. Alloys Compd. 2014, 604, 112–116. [Google Scholar] [CrossRef]

- Han, T.; Zou, J.; Ma, L.; Huang, G.; Che, C.; Jia, W.; Wang, L.; Pan, F.; Zhang, Y. Microstructure Evolution and Mechanical Properties of Mg-1.5Zn-0.2Ca-0.2Ce Alloy Processed by Accumulated Extrusion Bonding. JOM 2020, 72, 2597–2602. [Google Scholar] [CrossRef]

- Jia, W.; Ma, L.; Le, Q.; Zhi, C.; Liu, P. Deformation and fracture behaviors of AZ31B Mg alloy at elevated temperature under uniaxial compression. J. Alloys Compd. 2019, 783, 863–876. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, L.; Zhao, Z.; Huang, G.; Jiang, B.; Atrens, A.; Pan, F. Effect of the Al–Si eutectic on the microstructure and corrosion behavior of the single-phase Mg alloy Mg–4Li. J. Magnes. Alloys 2021, 9, 1339–1348. [Google Scholar] [CrossRef]

- Wang, X.J.; Xu, D.K.; Wu, R.Z.; Chen, X.B.; Peng, Q.M.; Jin, L.; Xin, Y.C.; Zhang, Z.Q.; Liu, Y.; Chen, X.H.; et al. What is going on in magnesium alloys? J. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Fan, J.; Roven, H.J.; Cheng, W.; Xu, B.; Dong, H. Microstructure evolution and mechanical properties of twinned AZ31 alloy plates at lower elevated temperature. J. Alloys Compd. 2014, 615, 687–692. [Google Scholar] [CrossRef]

- Han, T.; Zou, J.; Huang, G.; Ma, L.; Che, C.; Jia, W.; Wang, L.; Pan, F. Improved strength and ductility of AZ31B Mg alloy sheets processed by accumulated extrusion bonding with artificial cooling. J. Magnes. Alloys 2021, 9, 1715–1724. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Y.; Zhu, L.; Liu, Y.; Lei, X.; Wang, G.; Wu, Y.; Mi, Z.; Liu, J.; Wang, H. Evading the strength–ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fang, T.H.; Tao, N.R.; Lu, K. Tension-induced softening and hardening in gradient nanograined surface layer in copper. Scripta. Mater. 2014, 77, 17–20. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.; Duan, M.; Luo, L.; Zhan, D.; Jin, B.; Jin, Y.; Rao, X.-X.; Liu, Y.; Lu, J. The deformation behavior of AZ31 Mg alloy with surface mechanical attrition treatment. Mater. Sci. Eng. A 2017, 707, 636–646. [Google Scholar] [CrossRef]

- Rai, P.K.; Pandey, V.; Chattopadhyay, K.; Singhal, L.K.; Singh, V. Effect of Ultrasonic Shot Peening on Microstructure and Mechanical Properties of High-Nitrogen Austenitic Stainless Steel. J. Mater. Eng. Perform. 2014, 23, 4055–4064. [Google Scholar] [CrossRef]

- Dai, S.; Zhu, Y.; Huang, Z. Microstructure evolution and strengthening mechanisms of pure titanium with nano-structured surface obtained by high energy shot peening. Vacuum 2016, 125, 215–221. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, F.; Jiang, P.; Xie, J.; Wu, X. Mechanical properties and deformation mechanism of Mg-Al-Zn alloy with gradient microstructure in grain size and orientation. Mater. Sci. Eng. A 2017, 694, 98–109. [Google Scholar] [CrossRef] [Green Version]

- Peng, J.; Zhang, Z.; Guo, P.; Liu, Z.; Li, Y.; Zhou, W.; Wu, Y. The effect of surface mechanical attrition treatment on texture evolution and mechanical properties of AZ31 magnesium alloy. Mater. Charact. 2019, 148, 26–34. [Google Scholar] [CrossRef]

- Jamalian, M.; Field, D.P. Effects of shot peening parameters on gradient microstructure and mechanical properties of TRC AZ31. Mater. Charact. 2019, 148, 9–16. [Google Scholar] [CrossRef]

- Kula, A.; Silva, C.J.; Niewczas, M. Grain size effect on deformation behaviour of Mg–Sc alloys. J. Alloys Compd. 2017, 727, 642–657. [Google Scholar] [CrossRef]

- Mordike, B.; Stulikova, I.; Smola, B. Mechanisms of creep deformation in Mg-Sc-based alloys. Metall. Mater. Trans. A 2005, 36, 1729–1736. [Google Scholar] [CrossRef]

- Silva, C.J.; Kula, A.; Mishra, R.K.; Niewczas, M. The effect of Sc on plastic deformation of Mg–Sc binary alloys under tension. J. Alloys Compd. 2018, 761, 58–70. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, L.; Liu, H.; Huang, G.; Jiang, B.; Atrens, A.; Pan, F. Microstructure and corrosion behavior of Mg-Sc binary alloys in 3.5 wt.% NaCl solution. Corros. Sci. 2020, 174, 108831. [Google Scholar] [CrossRef]

- Fan, X.; Chen, L.; Chen, G.; Zhao, G.; Zhang, C. Joining of 1060/6063 aluminum alloys based on porthole die extrusion process. J. Mater. Process. Technol. 2017, 250, 65–72. [Google Scholar] [CrossRef]

- Li, N.; Huang, G.; Xin, R.; Liu, Q. Influence of extrusion ratio on microstructure and texture developments of high-temperature extruded AZ31 Mg alloy. Sci. China Technol. Sci. 2012, 55, 490–495. [Google Scholar] [CrossRef]

- Han, T.; Huang, G.; Deng, Q.; Wang, G.; Jiang, B.; Tang, A.; Zhu, Y.; Pan, F. Grain refining and mechanical properties of AZ31 alloy processed by accumulated extrusion bonding. J. Alloys Compd. 2018, 745, 599–608. [Google Scholar] [CrossRef]

- Han, T.; Huang, G.; Ma, L.; Wang, G.; Wang, L.; Pan, F. Evolution of microstructure and mechanical properties of AZ31 Mg alloy sheets processed by accumulated extrusion bonding with different relative orientation. J. Alloys Compd. 2019, 784, 584–591. [Google Scholar] [CrossRef]

- Han, L.; Hu, H.; Northwood, D.O.; Li, N. Microstructure and nano-scale mechanical behavior of Mg–Al and Mg–Al–Ca alloys. Mater. Sci. Eng. A 2008, 473, 16–27. [Google Scholar] [CrossRef]

- Somekawa, H.; Schuh, C.A. Effect of solid solution elements on nanoindentation hardness, rate dependence, and incipient plasticity in fine grained magnesium alloys. Acta Mater. 2011, 59, 7554–7563. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Liao, W.; Guo, W.; Ye, B.; Li, W.; Jiang, H.; Ding, W. Effects of cyclic extrusion and compression on the microstructure and mechanical properties of AZ91D magnesium composites reinforced by SiC nanoparticles. Mater. Charact. 2017, 126, 17–27. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.; Chen, G.; Zhang, X.; Liu, Q. Improving tensile and compressive properties of magnesium alloy plates by pre-cold rolling. Scripta. Mater. 2012, 66, 1061–1064. [Google Scholar] [CrossRef]

- Yin, S.M.; Wang, C.H.; Diao, Y.D.; Wu, S.D.; Li, S.X. Influence of Grain Size and Texture on the Yield Asymmetry of Mg-3Al-1Zn Alloy. J. Mater. Sci. Technol. 2011, 27, 29–34. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Wang, L.; Roven, H.J.; Xu, Z.; Pan, F. Improved ductility of magnesium alloys by a simple shear process followed by annealing. Scripta. Mater. 2013, 69, 49–52. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Wang, L.; Li, J. Improved formability of Mg–3Al–1Zn alloy by pre-stretching and annealing. Scripta. Mater. 2012, 67, 495–498. [Google Scholar] [CrossRef]

- Wang, G.; Huang, G.; Huang, Y.; Zhang, C.; Pan, F. Achieving High Ductility in Hot-Rolled Mg-xZn-0.2Ca-0.2Ce Sheet by Zn Addition. JOM 2020, 72, 1607–1618. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Jiang, P.; Chen, L.; Zhang, J.; Yuan, F.; Zhu, Y. Synergetic strengthening by gradient structure. Mater. Res. Lett. 2014, 2, 185–191. [Google Scholar] [CrossRef]

| Alloys | Sc | Al | Zn | Mn | Mg |

|---|---|---|---|---|---|

| Mg–1Sc | 1.05 | - | - | - | Bal. |

| AZ31 | - | 3.22 | 0.94 | 0.37 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Peng, C.; Huang, J.; Zhao, Y.; Han, T.; Wang, G.; Wu, L.; Huang, G. Improving Mechanical Properties of Mg–Sc Alloy by Surface AZ31 Layer. Metals 2021, 11, 2021. https://doi.org/10.3390/met11122021

Zhang C, Peng C, Huang J, Zhao Y, Han T, Wang G, Wu L, Huang G. Improving Mechanical Properties of Mg–Sc Alloy by Surface AZ31 Layer. Metals. 2021; 11(12):2021. https://doi.org/10.3390/met11122021

Chicago/Turabian StyleZhang, Cheng, Cheng Peng, Jin Huang, Yanchun Zhao, Tingzhuang Han, Guangang Wang, Liang Wu, and Guangsheng Huang. 2021. "Improving Mechanical Properties of Mg–Sc Alloy by Surface AZ31 Layer" Metals 11, no. 12: 2021. https://doi.org/10.3390/met11122021

APA StyleZhang, C., Peng, C., Huang, J., Zhao, Y., Han, T., Wang, G., Wu, L., & Huang, G. (2021). Improving Mechanical Properties of Mg–Sc Alloy by Surface AZ31 Layer. Metals, 11(12), 2021. https://doi.org/10.3390/met11122021