Investigation of Al-B4C Metal Matrix Composites Produced by Friction Stir Additive Processing

Abstract

:1. Introduction

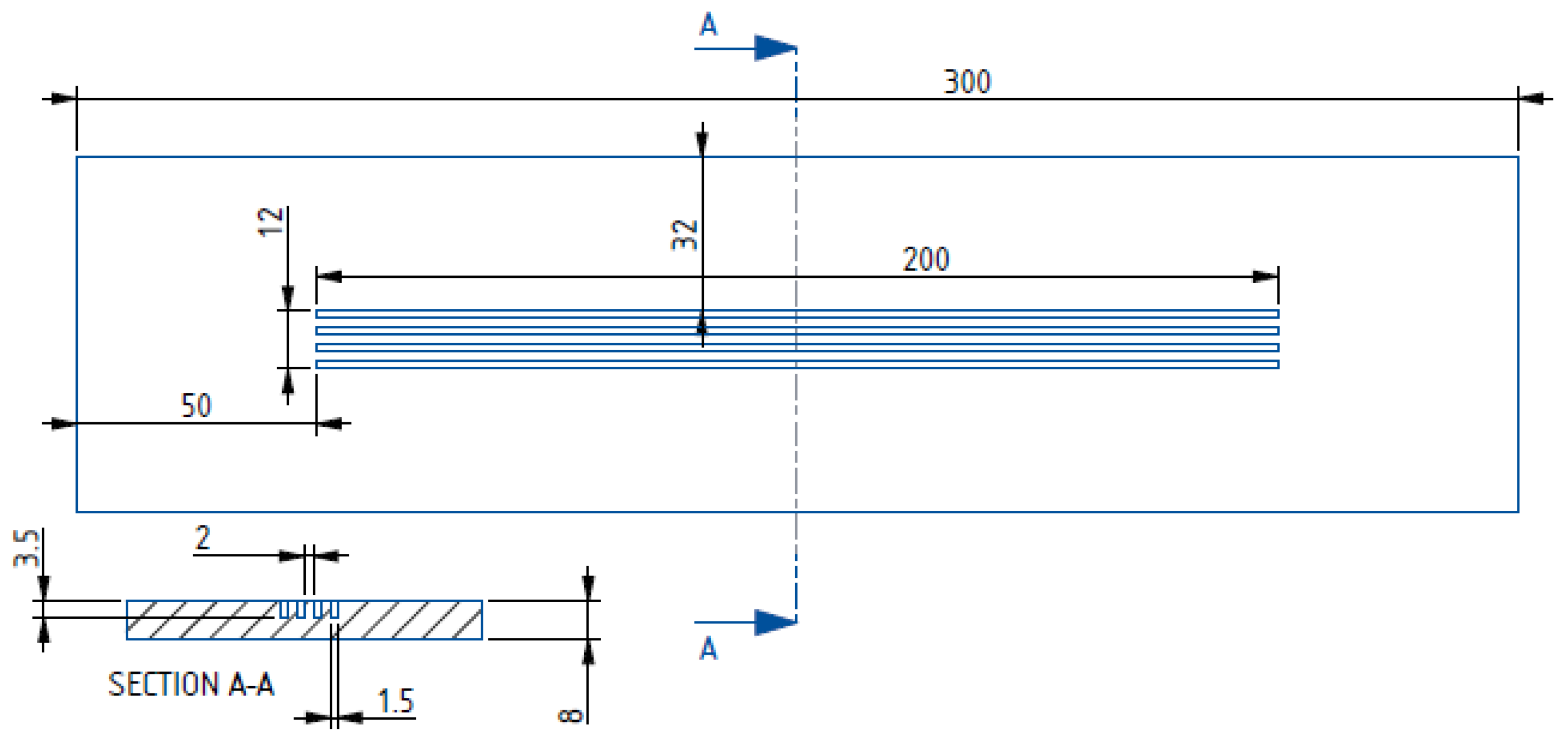

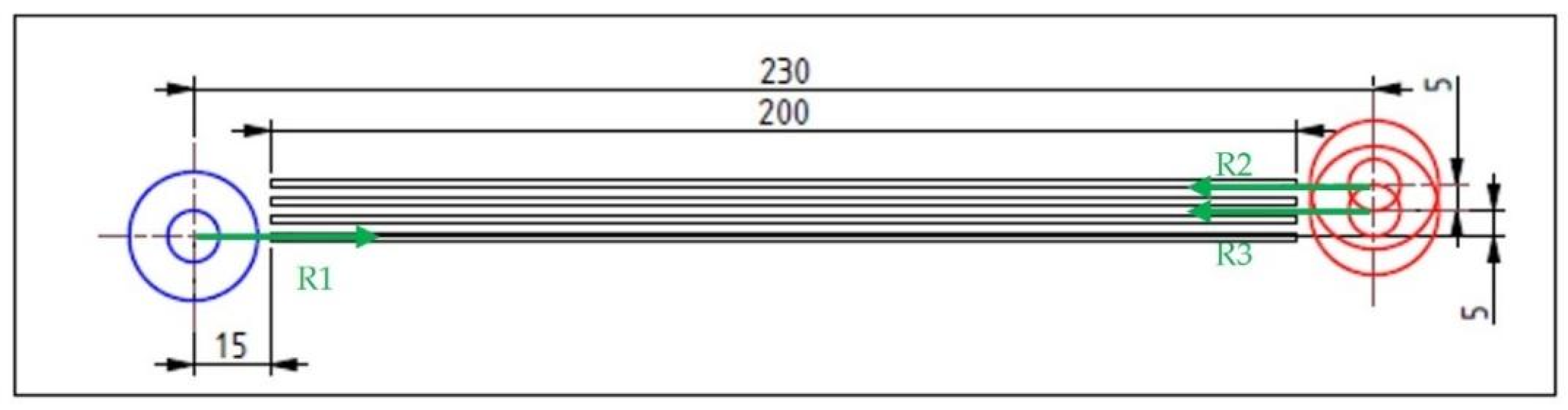

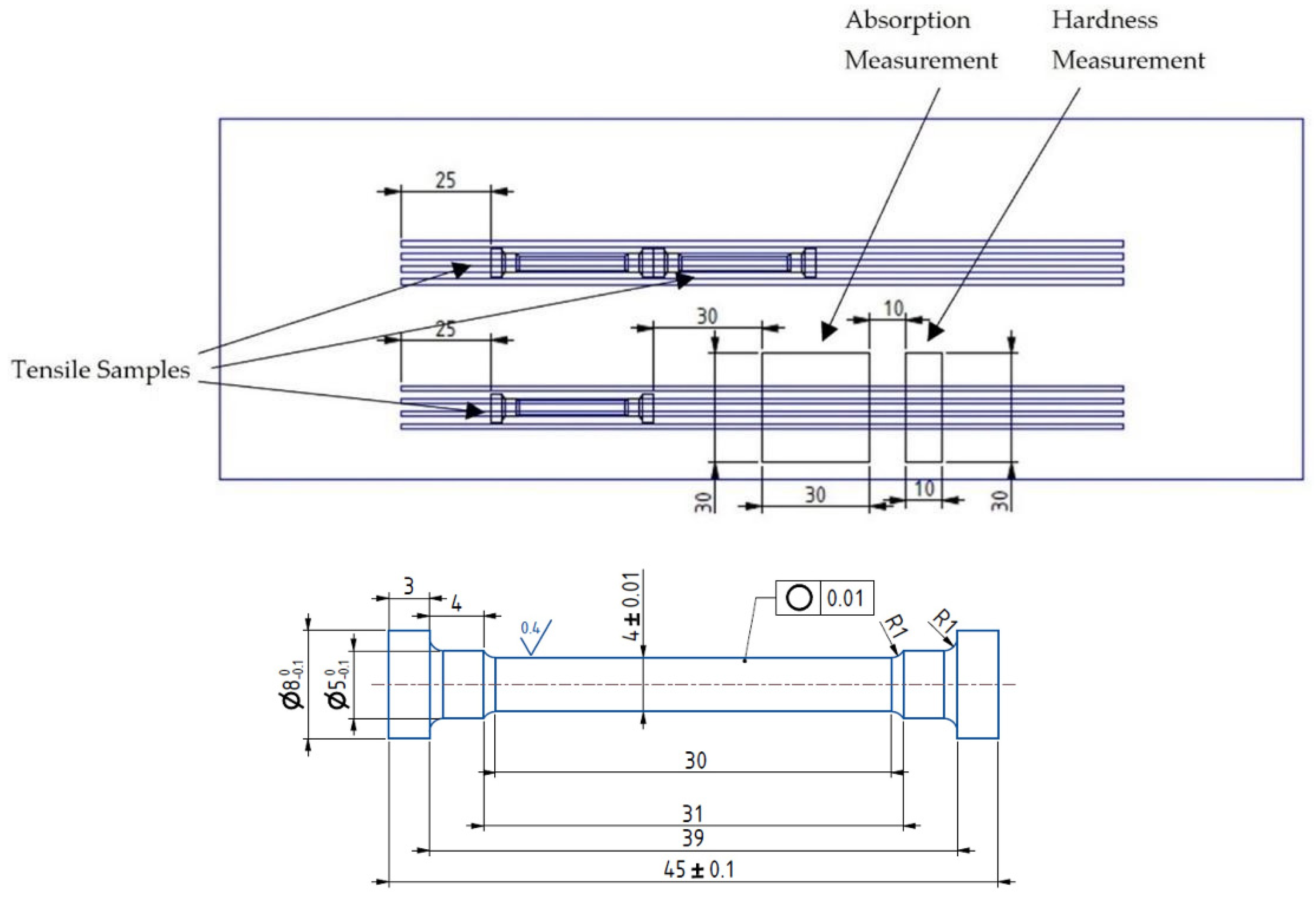

2. Materials and Methods

3. Results

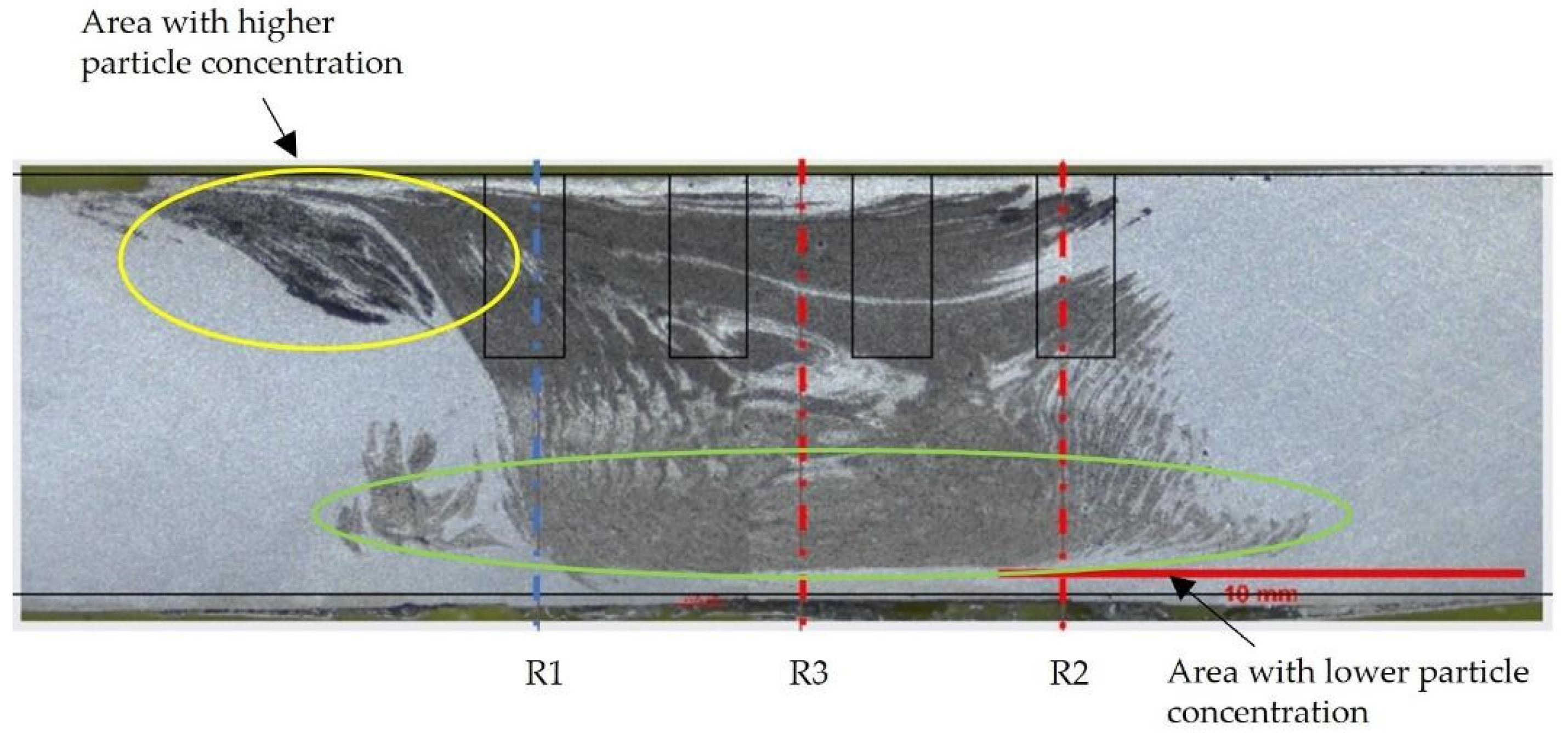

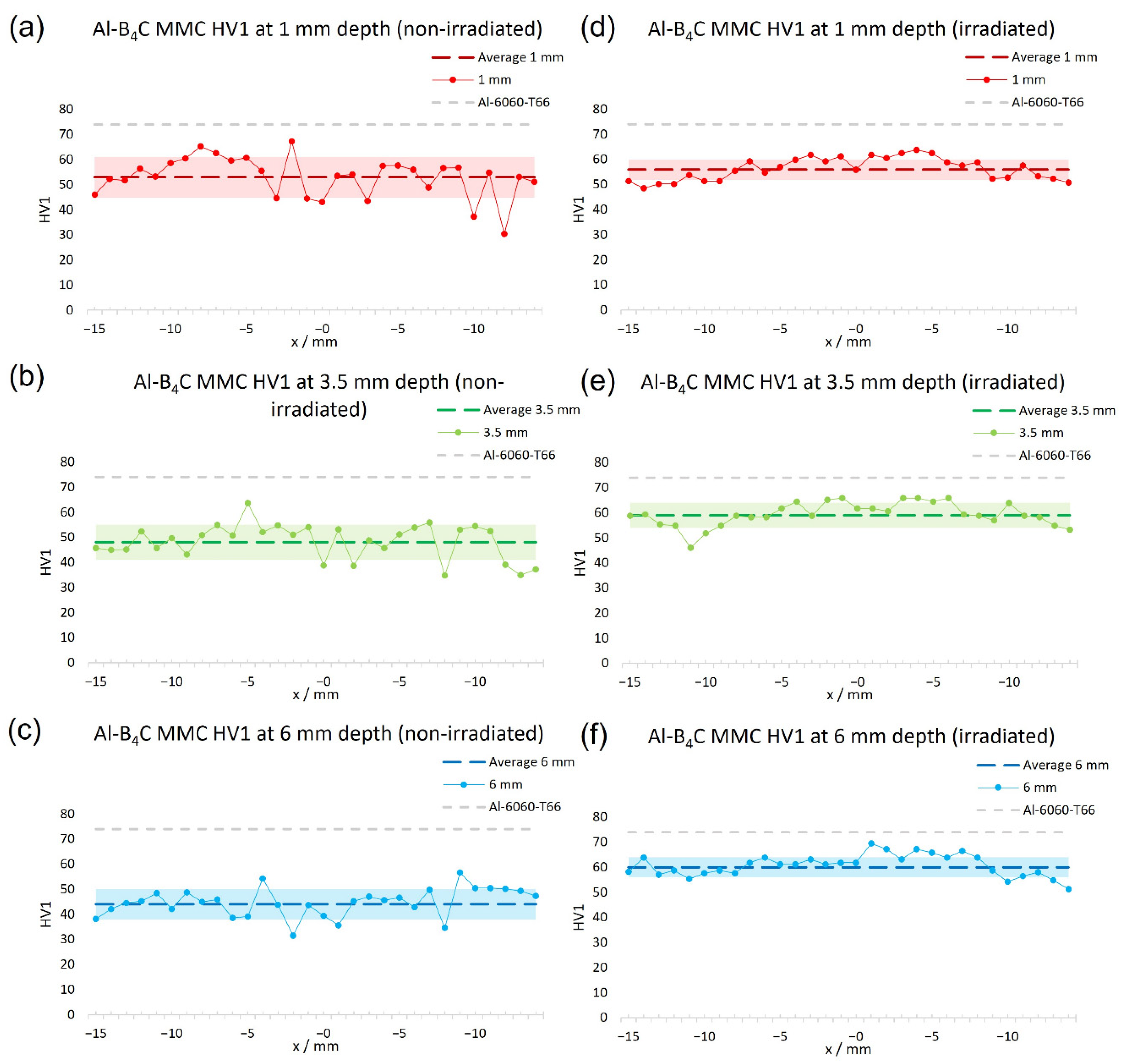

3.1. Metallography and Hardness Measurement

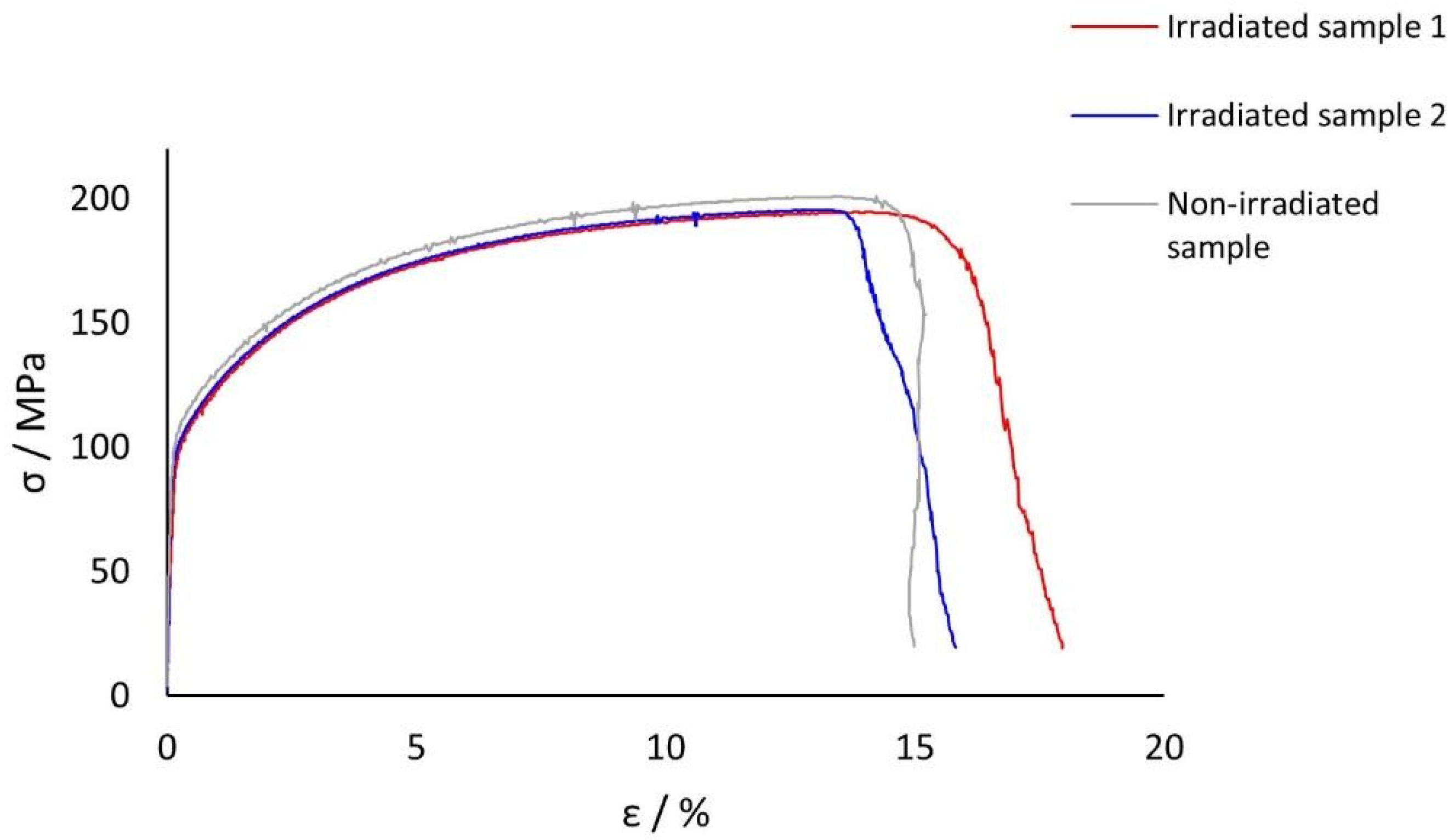

3.2. Thermal Neutron Absorption and Tensile Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wierschke, J.B.; Wang, L. Evaluation of Aluminum-Boron Carbide Neutron Absorbing Materials for Interim Storage of Used Nuclear Fuel; University of Michigan: Ann Arbor, MI, USA, 2015. [Google Scholar]

- Sanada, K. MAXUS Neutron Absorber Presentation; Nippon Light Metal Company, Ltd.: Shizuoka, Japan, 2013. Available online: https://www.nrc.gov/docs/ML1308/ML13080A006.pdf (accessed on 1 June 2021).

- Nexus 3000 Product Sheet. Available online: http://group.nikkeikin.co.jp/act/pdf/product/neutron/nexus3000_en.pdf (accessed on 18 February 2020).

- Cong, S.; Li, Y.; Ran, G.; Zhou, W.; Feng, Q. Microstructure and its effect on mechanical and thermal properties of Al-based Gd2O3 MMCs used as shielding materials in spent fuel storage. Ceram. Int. 2020, 46, 12986–12995. [Google Scholar] [CrossRef]

- Akhtar, M.J.; Ahamed, M.; Alhadlaq, H. Gadolinium Oxide Nanoparticles Induce Toxicity in Human Endothelial HUVECs via Lipid Peroxidation, Mitochondrial Dysfunction and Autophagy Modulation. Nanomaterials 2020, 10, 1675. [Google Scholar] [CrossRef] [PubMed]

- Kusui, J.; Hayashi, K.; Iwasa, K.; Iwase, M. Development of Basket for Transport/Storage Cask using Square Tube made of Aluminium Alloy containing Neutron Absorbing Materials. In Proceedings of the 14th International Symposium on the Packaging and Transportation of Radioactive Materials (PATRAM 2004), Berlin, Germany, 20–24 September 2004. [Google Scholar]

- Sahu, P.S.; Banchhor, R. Fabrication methods used to prepare Al metal matrix composites—A review. Int. Res. J. Eng. Technol. 2016, 3, 123–132. [Google Scholar]

- Aluko, A.O.; Alaneme, K.K. Fracture toughness and tensile properties of as-cast and age-hardened aluminium (6063)–silicon carbide particulate composites. Sci. Iran. 2012, 19, 992–996. [Google Scholar]

- Lin, J.; Ran, G.; Le, P.; Ye, C.; Huang, S.; Zhao, S.; Li, N. Mechanical and Thermal Neutron Absorbing Properties of B4C/Aluminum Alloy Composites Fabricated by Stir Casting and Hot Rolling Process. Metals 2021, 11, 413. [Google Scholar]

- Raj, R.; Thakur, D. Influence of boron carbide content on the microstructure, tensile strength and fracture behavior of boron carbide reinforced aluminum metal matrix composites. Mater. Und Werkst. 2018, 49, 1068–1080. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Y.; Wang, W.; Gao, Z.; Wang, B. The design, fabrication and properties of B4C/Al neutron absorbers. J. Nucl. Mater. 2013, 437, 350–358. [Google Scholar] [CrossRef]

- Park, J.-J.; Hong, S.-M.; Lee, M.-K.; Rhee, C.-K.; Rhee, W.-H. Enhancement in the microstructure and neutron shielding efficiency of sandwich type of 6061Al–B4C composite material via hot isostatic pressing. Nucl. Eng. Des. 2015, 282, 1–7. [Google Scholar] [CrossRef]

- Mishra, R.; Ma, Z.; Charit, I. Friction stir processing: A novel technique for fabrication of surface composite. Mater. Sci. Eng. A 2003, 341, 307–310. [Google Scholar] [CrossRef]

- Buradagunta, R.S.; Dumpala, R. Surface Composites by Friction Stir Processing. In Reference Module in Materials Science and Materials Engineering; Elsevier: Dublin, Ireland, 2021. [Google Scholar] [CrossRef]

- Reza-E-Rabby. Quantification of the Effect of Tool Geometric Features on Aspects of Friction Stir Welding; University of South Carolina: Columbia, SC, USA, 2015. [Google Scholar]

- Woo, W.; Balogh, L.; Ungár, T.; Choo, H.; Feng, Z. Grain structure and dislocation density measurements in a friction-stir welded aluminum alloy using X-ray peak profile analysis. Mater. Sci. Eng. A 2008, 498, 308–313. [Google Scholar] [CrossRef]

- Cao, X.; Shi, Q.; Liu, D.; Feng, Z.; Liu, Q.; Chen, G. Fabrication of in situ carbon fiber/aluminum composites via friction stir processing: Evaluation of microstructural, mechanical and tribological behaviors. Compos. Part B Eng. 2018, 139, 97–105. [Google Scholar] [CrossRef]

- Don-Hyun, C.; Yong-Il, K.; Dae-Up, K.; Seung-Boo, J. Effect of SiC particles on microstructure and mechanical property of friction stir processed AA6061-T4. Trans. Nonferrous Met. Soc. China 2012, 22, 614–618. [Google Scholar]

- Abioye, T.E.; Zuhailawati, H.; Anasyida, A.S.; Yahaya, S.A.; Dhindaw, B.K. Investigation of the microstructure, mechanical and wear properties of AA6061-T6 friction stir weldments with different particulate reinforcements addition. J. Mater. Res. Technol. 2019, 5, 3917–3928. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.; Švec, P. Fabrication of a high strength ultra-fine grained Al-Mg-SiC nanocomposite by multi-step friction-stir processing. Mater. Sci. Eng. A 2017, 698, 313–325. [Google Scholar] [CrossRef]

- Weiss, C.S. Herstellung von Funktionellen Oberflächen Mittels Friction Stir Processing; TU Graz: Graz, Austria, 2017. [Google Scholar]

- Chena, C.-L.; Richter, A.; Kögler, R.; Wu, L.-T. Dual-beam irradiation of friction stir spot welding of nanostructured ferritic oxide dispersion strengthened alloy. J. Alloys Compd. 2012, 536, 194–195. [Google Scholar] [CrossRef]

- Chemical Composition of Al Plate. Available online: https://www.bikar.com/fileadmin/download/6060-komplett.pdf (accessed on 24 July 2018).

- B4C Certificate of Analysis; Alfa Aesar: Ward Hill, MA, USA, 2020.

- Zubcak, M. Investigation of Al-B4C Metal Matrix Composites Produced by Friction Stir Additive Processing. Master’s Thesis, TU Graz, Graz, Austria, 2021. [Google Scholar]

- Soltes, J.; Viererbl, L.; Lahodova, Z.; Koleska, M.; Vins, M. Thermal Neutron Filter Design for the Neutron Radiography Facility at the LVR-15 Reactor. IEEE Trans. Nucl. Sci. 2016, 63, 1640–1644. [Google Scholar] [CrossRef]

- Choi, J.-S.; Farmer, J.; Lee, C.; Fischer, L.; Boussoufi, M.; Liu, B.; Egbert, H. Neutron-Absorbing Coatings for Safe Storage of Fissile Materials with Enhanced Shielding & Criticality Safety. In Proceedings of the Materials Science & Technology 2007 Conference and Exhibition, Detroit, Michigan, 16–20 September 2007. [Google Scholar]

- Olea, C.A.W. Influence of Energy Input in Friction Stir Welding on Structure Evolution and Mechanical Behaviour of Precipitation-Hardening in Aluminium Alloys (AA2024-T351, AA6013-T6 and Al-Mg-Sc); GKSS-Forschungszentrum Geesthacht GmbH: Geesthacht, Germany, 2008. [Google Scholar]

- Palanivel, R.; Dinaharan, I.; Laubscher, R.F.; Davim, J.P. Influence of boron nitride nanoparticles on microstructure and wear behavior of AA6082/TiB2 hybrid aluminum composites synthesized by friction stir processing. Mater. Des. 2016, 106, 195–204. [Google Scholar] [CrossRef]

- Čekan, P. Návrh Koše Kontejneru Typu Castor pro Palivo Reaktoru Typu VVER 1000; University of West Bohemia: Pilsen, Czech Republic, 2013. [Google Scholar]

- Jung, Y.; Lee, M.; Kim, K.; Ahn, S. 10B(n, α)7Li reaction-induced gas bubble formation in Al–B4C neutron absorber irradiated in spent nuclear fuel pool. J. Nucl. Mater. 2020, 533, 152077. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Zolotorevskiy, V.S.; Barkov, R.Y.; Lotfy, A.; Bazlov, A.I. Microstructure and material characterization of 6063/B4C and 1545K/B4C composites produced by two stir casting techniques for nuclear applications. J. Alloys Compd. 2016, 664, 317–320. [Google Scholar] [CrossRef]

- Yao, X.; Zheng, Y.F.; Liang, J.M.; Zhang, D.L. Microstructures and tensile mechanical properties of an ultrafine grained AA6063–5 vol%SiC metal matrix nanocomposite synthesized by powder metallurgy. Mater. Sci. Eng. A 2015, 648, 225–234. [Google Scholar] [CrossRef]

- Patel, V.B.V.V.; Kumar, A. Friction Stir Processing as a Novel Technique to Achieve Superplasticity in Aluminum Alloys: Process Variables, Variants, and Applications. Metallogr. Microstruct. Anal. 2016, 5, 278–293. [Google Scholar] [CrossRef]

- Bastürk, M.; Kardjilov, N.; Lehmann, E.; Zawisky, E. Monte Carlo Simulation of Neutron Transmission of Boron-Alloyed Steel. IEEE Trans. Nucl. Sci. 2005, 52, 394–399. [Google Scholar] [CrossRef]

- Nordlund, K.; Zinkle, S.J.; Sand, A.E.; Granberg, F.; Averback, R.S.; Stoller, R.E.; Suzudo, T.; Malerb, L.; Banhart, F.; Weber, W.J.; et al. Primary radiation damage: A review of current understanding and models. J. Nucl. Mater. 2018, 512, 450–479. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|

| 0.3–0.6 | 0.1–0.3 | 0.1 | 0.1 | 0.35–0.6 | 0.05 | 0.15 | 0.1 |

| B | C | B2O3 | Fe | O | N | Si |

|---|---|---|---|---|---|---|

| 79.1 | 20.5 | 0.05 | 0.024 | 0.06 | 0.24 | 0.012 |

| Groove Closing | FSAP | |

|---|---|---|

| Shoulder design | Concave (1°) 22 mm diameter | Scrolled 25 mm diameter |

| Tool material | H11 tool steel hardened to 52 HRC | |

| Pin design | Without pin | Threaded triflute 10 mm diameter 7 mm length |

| Tool tilt | 3° | 1.5° |

| Rotational speed [rpm] | 1200 | 500 |

| Processing speed [mm/min] | 80 | 240 |

| Neutron Energy | Neutron Fluence [1013 n/cm2] |

|---|---|

| <0.5 eV | 4.32 |

| 0.5 eV–100 keV | 2.24 |

| 100 keV–20 MeV | 1.50 |

| Total | 8.06 |

| Depth/mm | HV1 Non-Irradiated | HV1 Irradiated |

|---|---|---|

| 1 | 53 ± 8 | 56 ± 4 |

| 3.5 | 48 ± 7 | 59 ± 5 |

| 6 | 44 ± 6 | 60 ± 4 |

| d/mm | I0/I | Σ/cm−1 |

|---|---|---|

| 8.1 | 30.46 | 4.2 |

| Type | Σ/cm−1 |

|---|---|

| Boron infused stainless steel | 1.67 to 2.65 |

| Stainless steel + SAM 2X5 coating | 5.82 to 7.18 |

| NiGd | 3.77 to 3.89 |

| Metamic (Al-B4C MMC) | 16.9 |

| Rm/MPa | A/% | |

|---|---|---|

| Irradiated Sample 1 | 194 | 19.5 |

| Irradiated Sample 2 | 195 | 15.7 |

| Non-irradiated Sample | 200 | 15.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zubcak, M.; Soltes, J.; Zimina, M.; Weinberger, T.; Enzinger, N. Investigation of Al-B4C Metal Matrix Composites Produced by Friction Stir Additive Processing. Metals 2021, 11, 2020. https://doi.org/10.3390/met11122020

Zubcak M, Soltes J, Zimina M, Weinberger T, Enzinger N. Investigation of Al-B4C Metal Matrix Composites Produced by Friction Stir Additive Processing. Metals. 2021; 11(12):2020. https://doi.org/10.3390/met11122020

Chicago/Turabian StyleZubcak, Martin, Jaroslav Soltes, Mariia Zimina, Thomas Weinberger, and Norbert Enzinger. 2021. "Investigation of Al-B4C Metal Matrix Composites Produced by Friction Stir Additive Processing" Metals 11, no. 12: 2020. https://doi.org/10.3390/met11122020

APA StyleZubcak, M., Soltes, J., Zimina, M., Weinberger, T., & Enzinger, N. (2021). Investigation of Al-B4C Metal Matrix Composites Produced by Friction Stir Additive Processing. Metals, 11(12), 2020. https://doi.org/10.3390/met11122020