Ultrasonic-Assisted Brazing of Titanium Joints Using Modified Al-Si-Cu Based Fillers: Brazing at Liquid—Semisolid States under Load

Abstract

1. Introduction

2. Materials and Methods

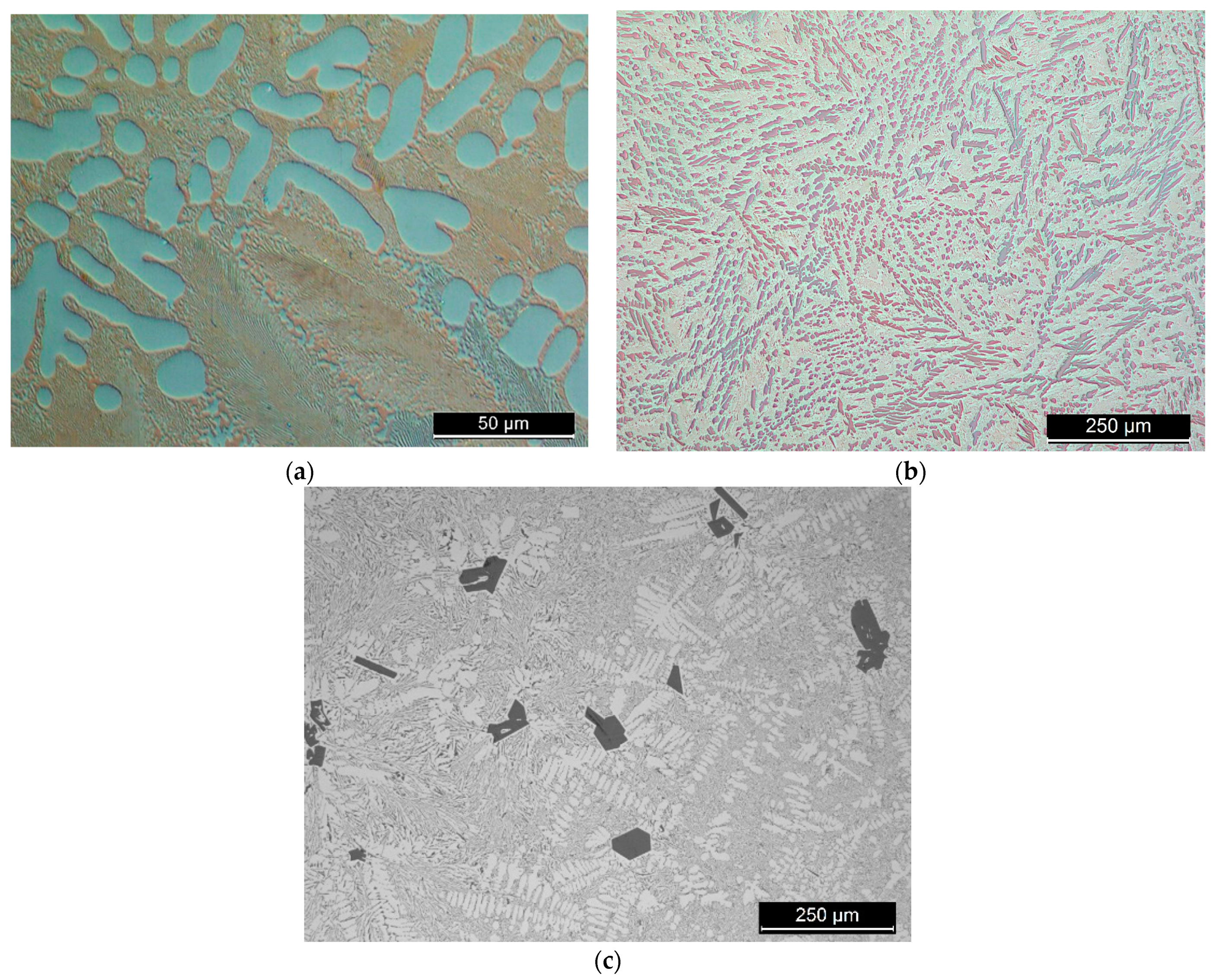

2.1. Preparation of Bulk Filler Alloys

2.2. Preparation of the Brazing Assembly

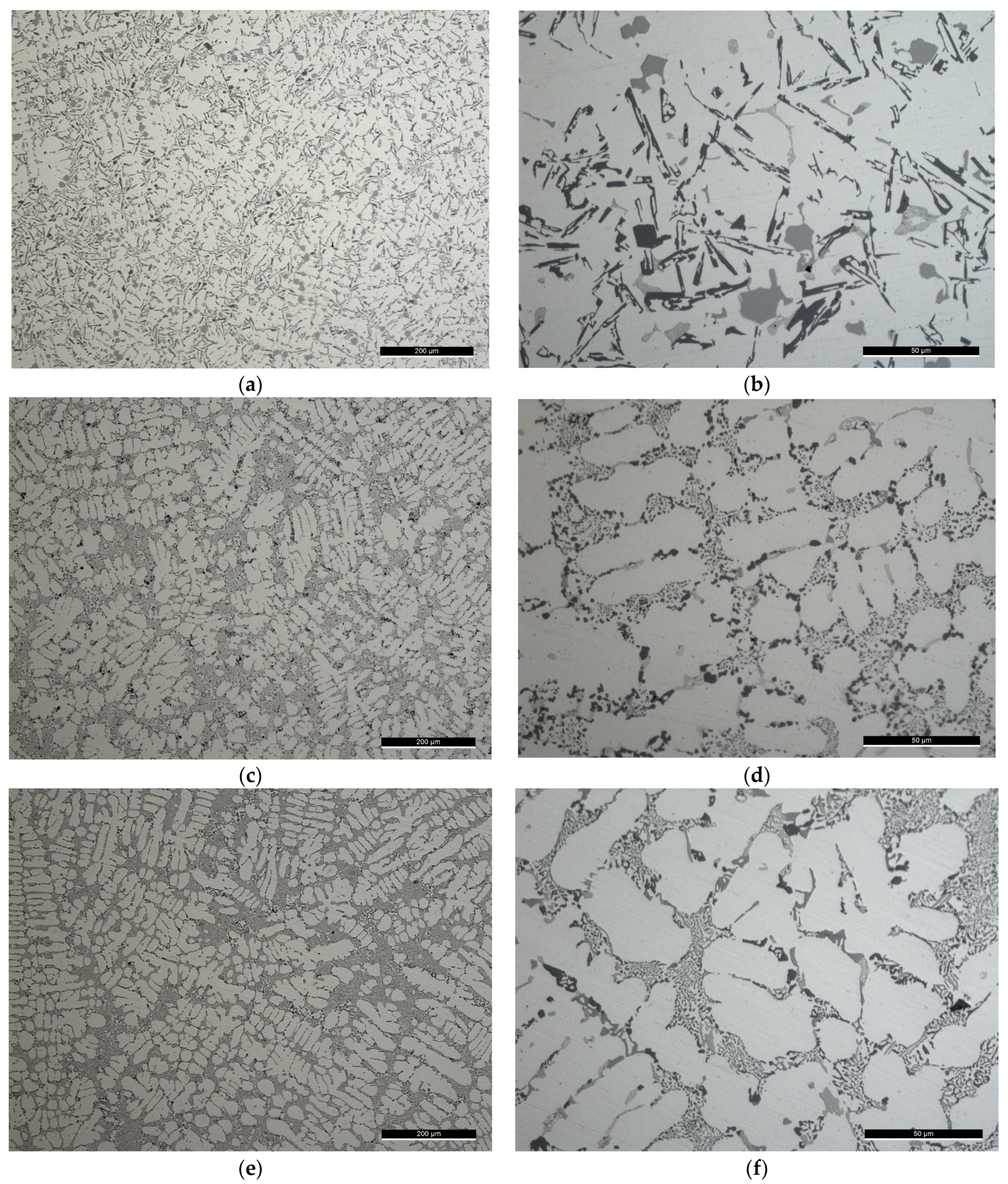

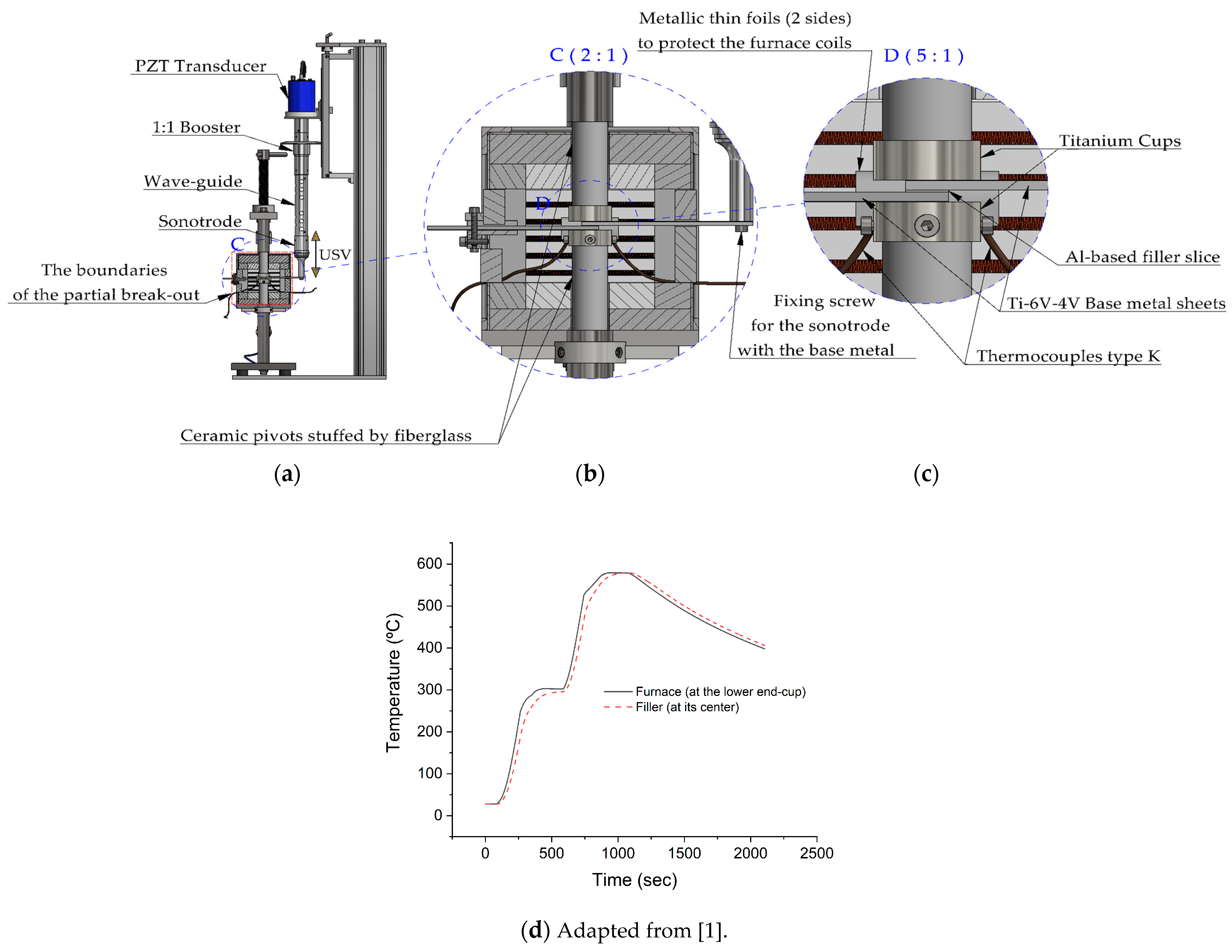

2.3. Fillers and Joints Characterization

2.4. Experimental Set-Up

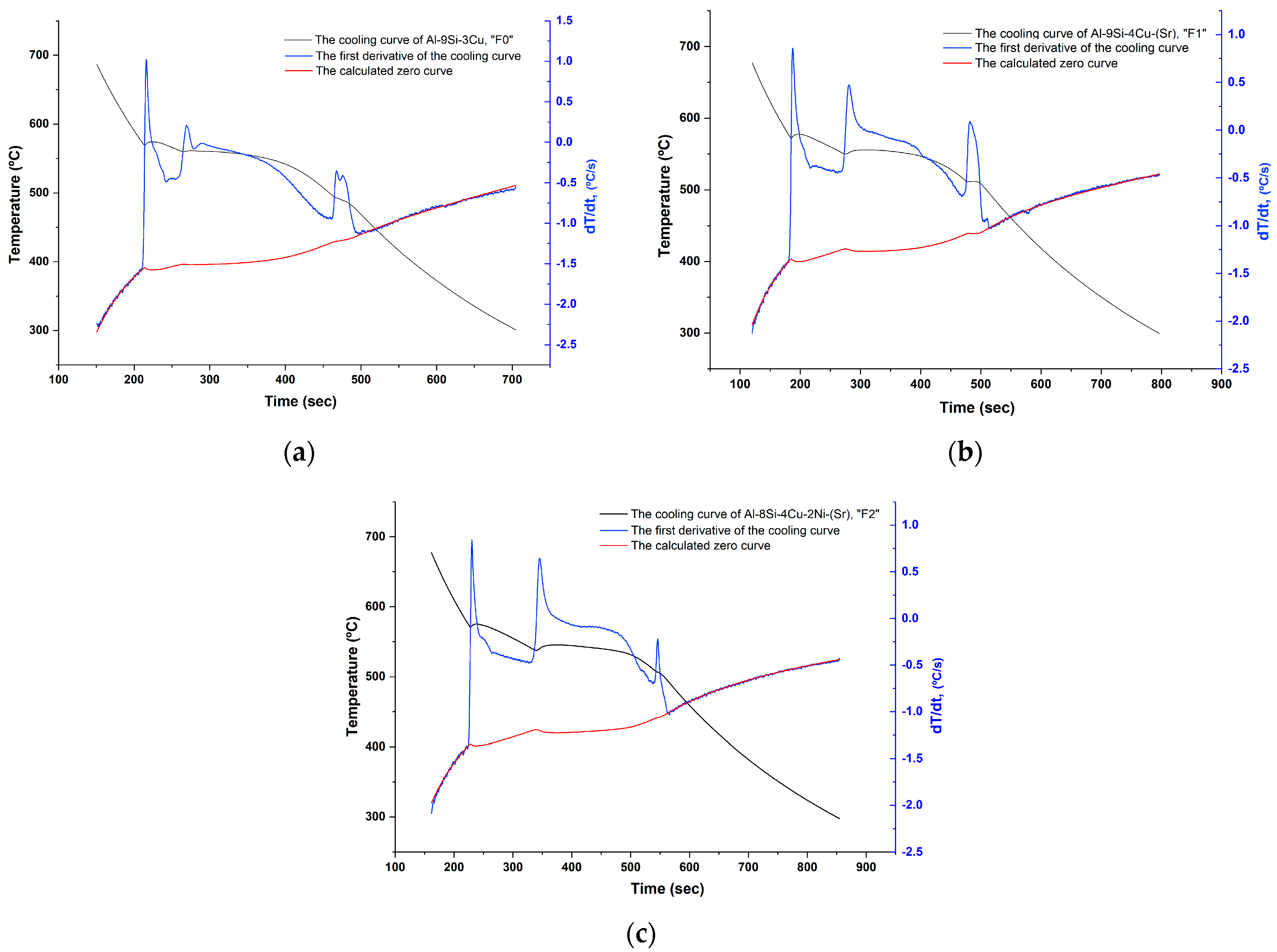

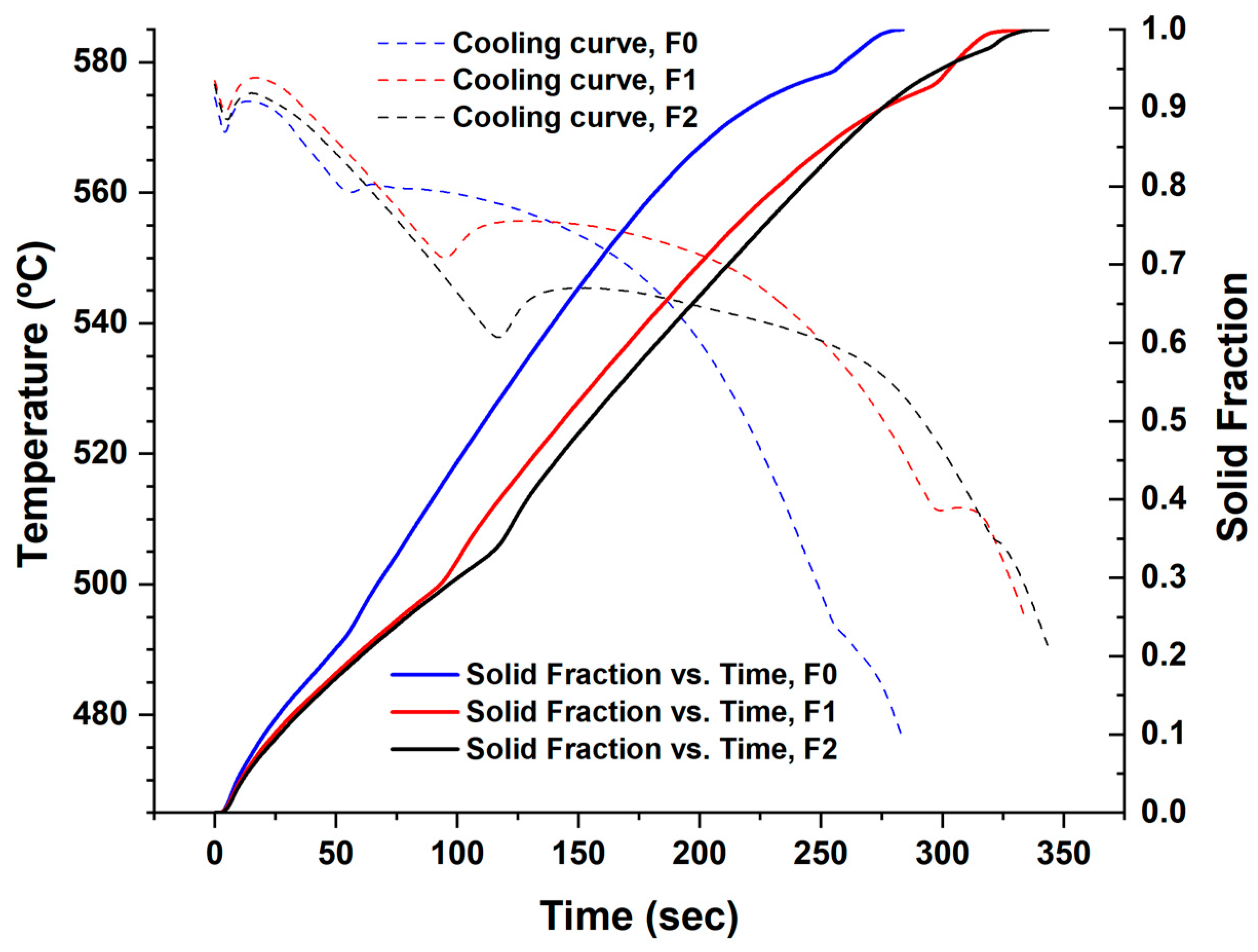

2.5. Cooling Curves and Solid Fraction Calculation

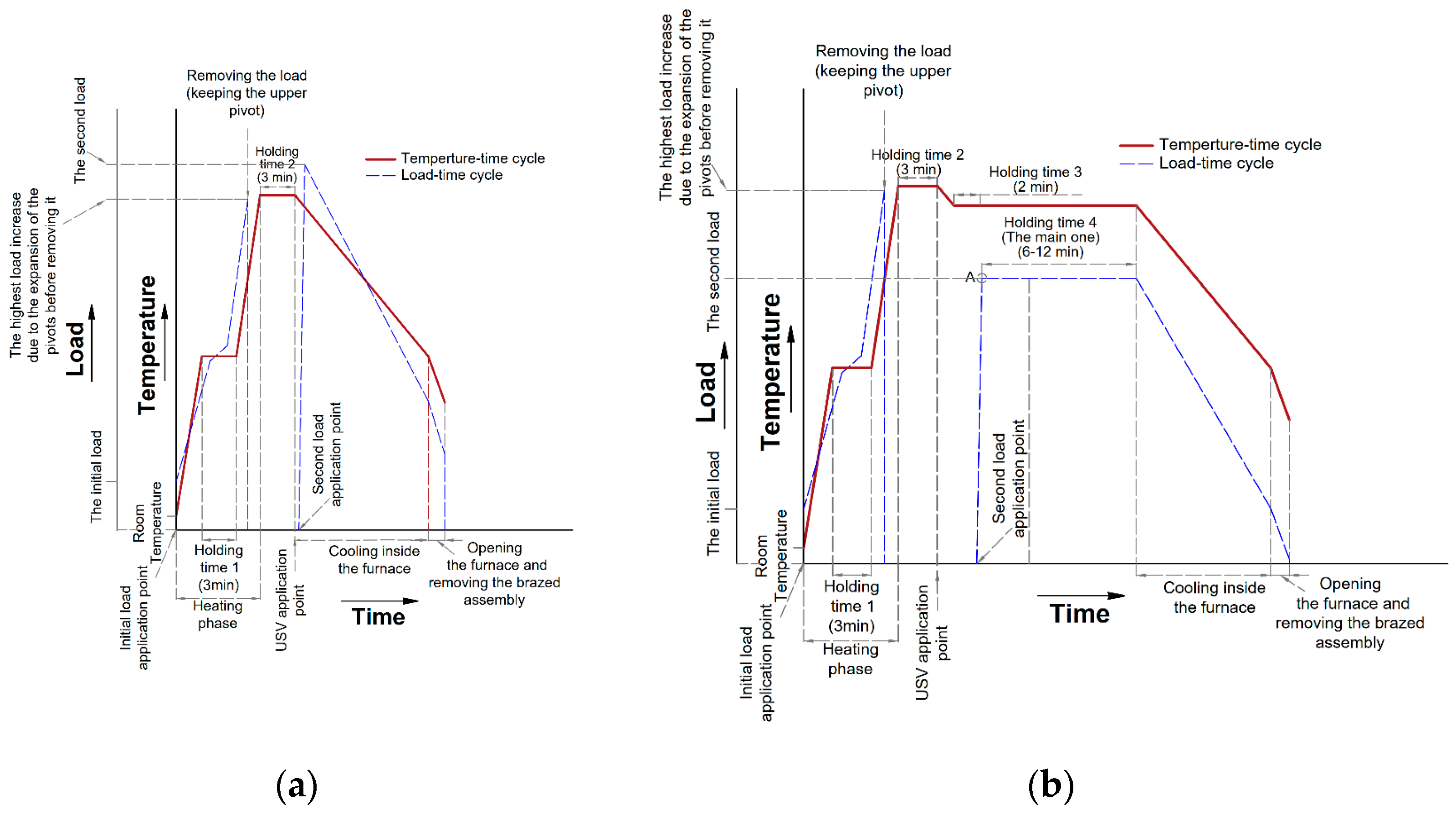

2.6. Brazing Methods and Conditions

3. Results and Discussion

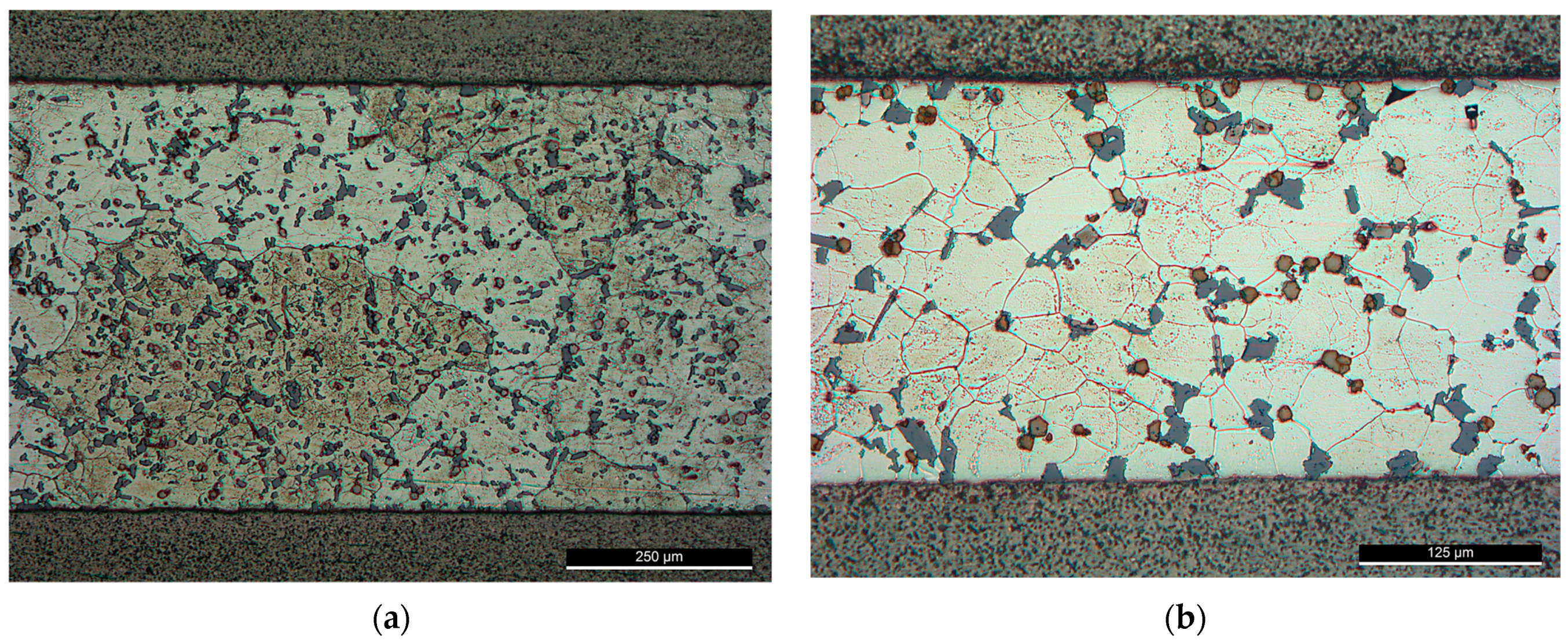

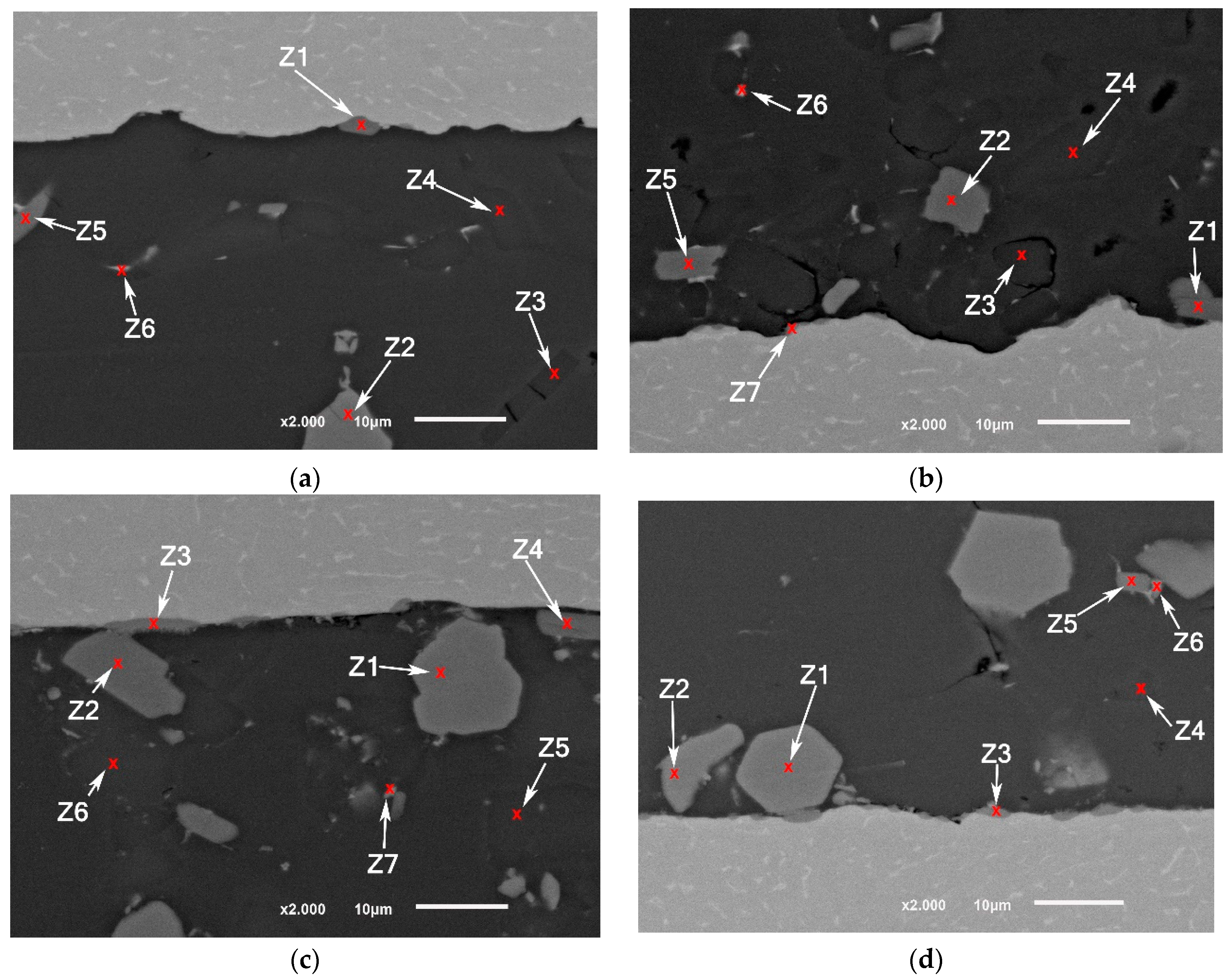

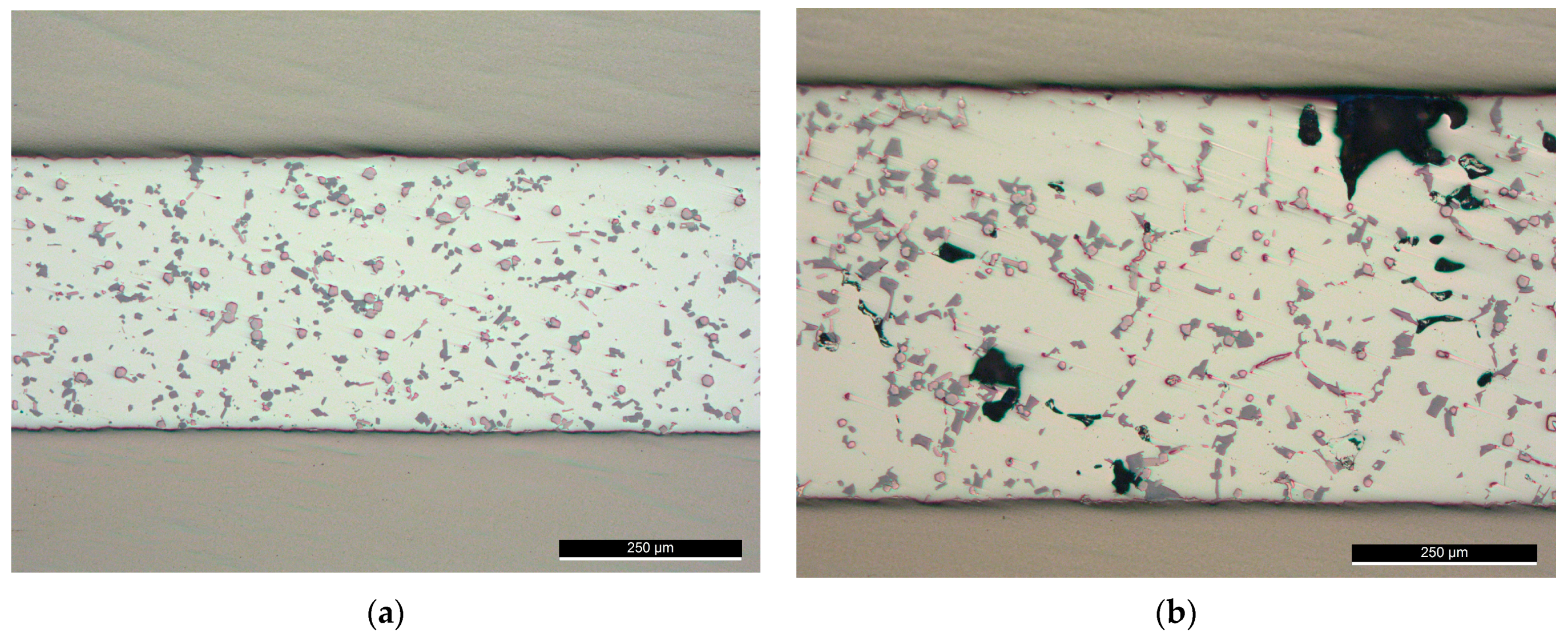

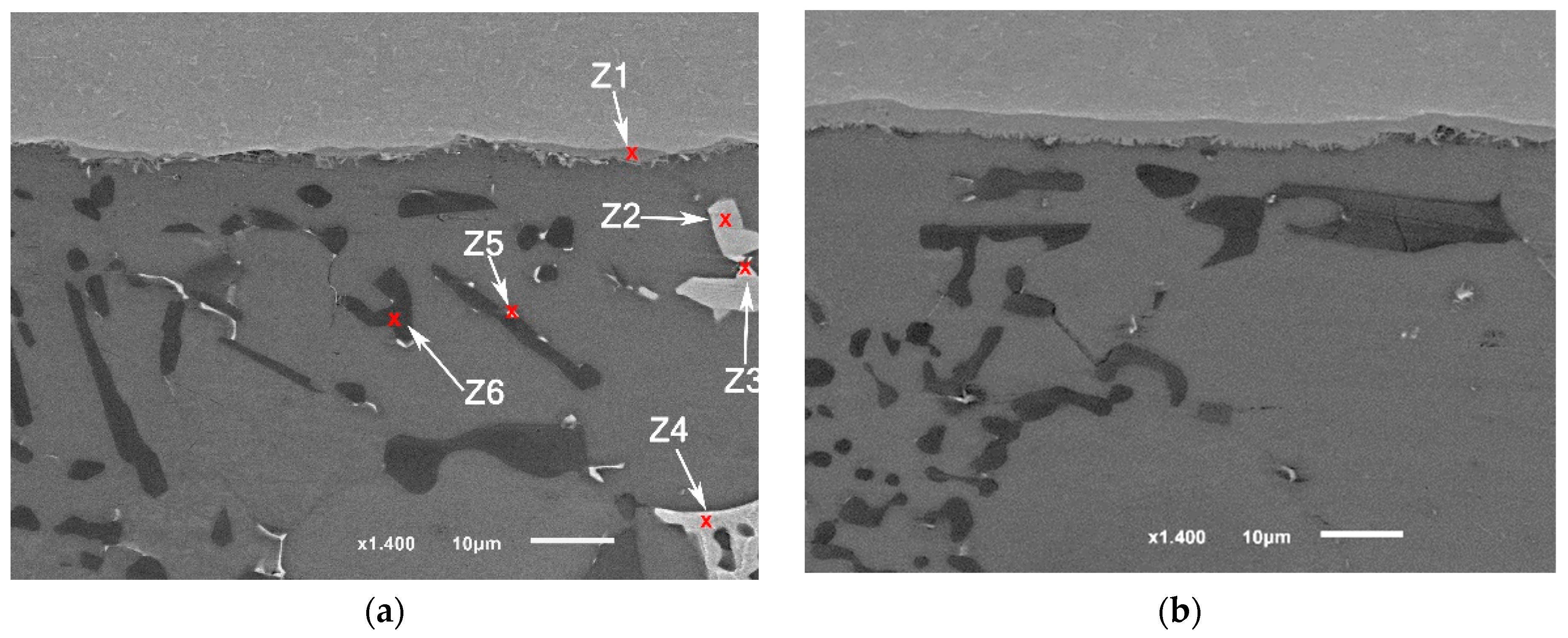

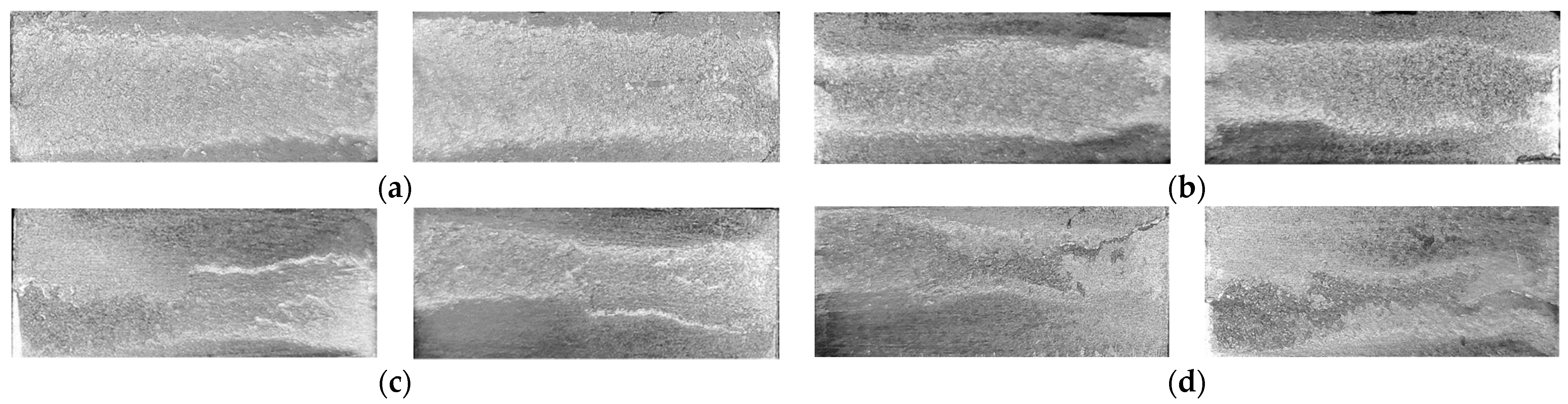

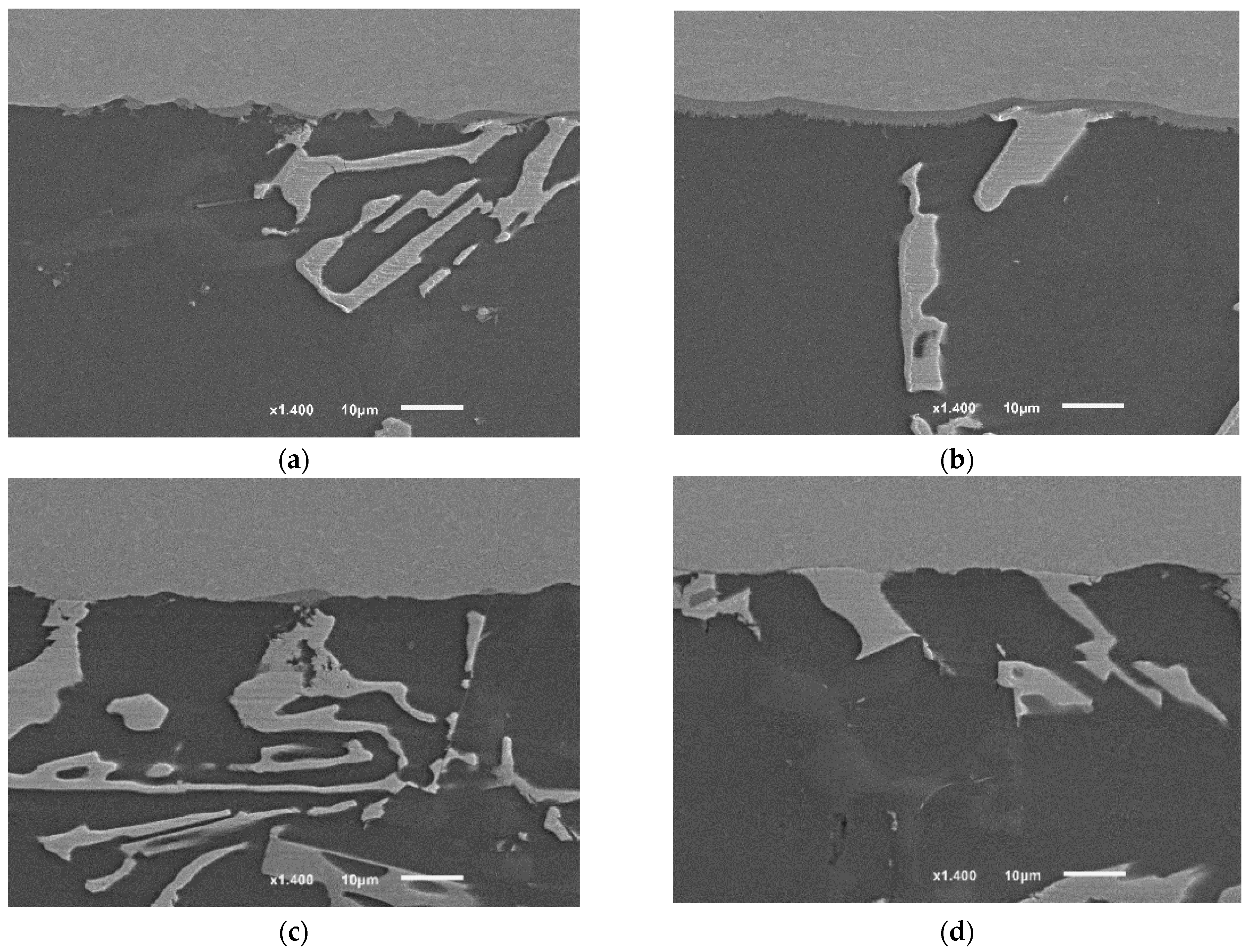

3.1. Results by Using Brazing Cycle A

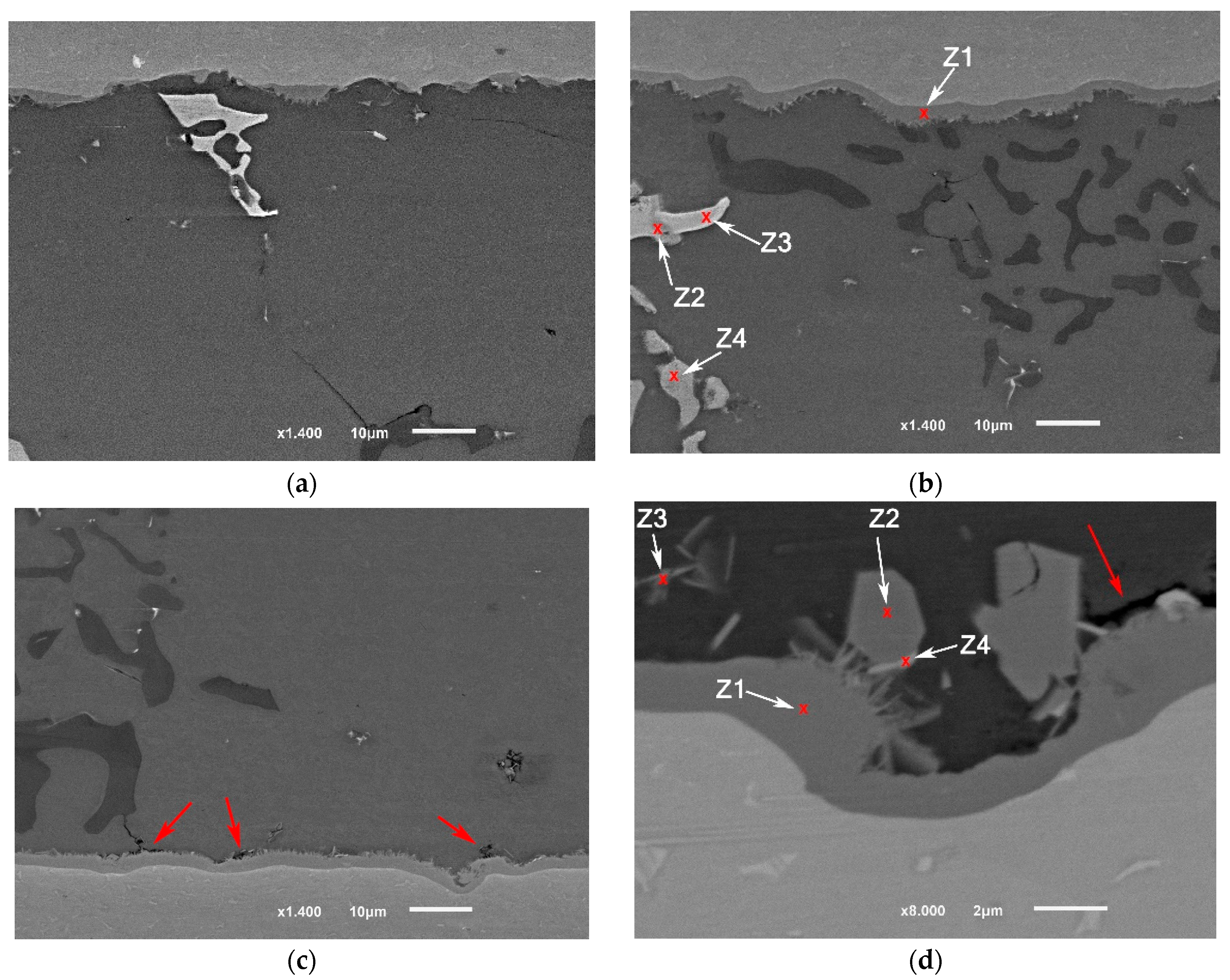

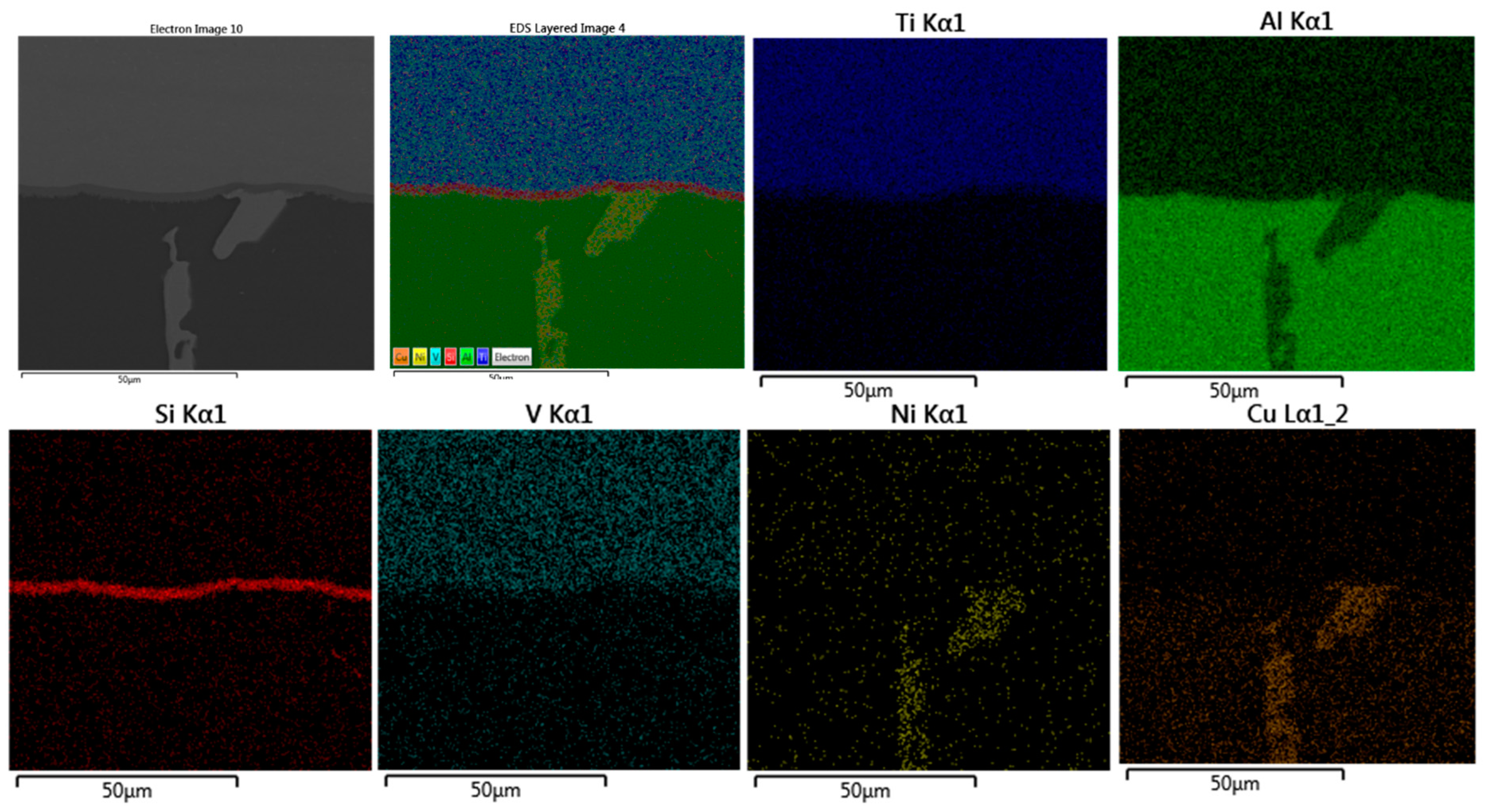

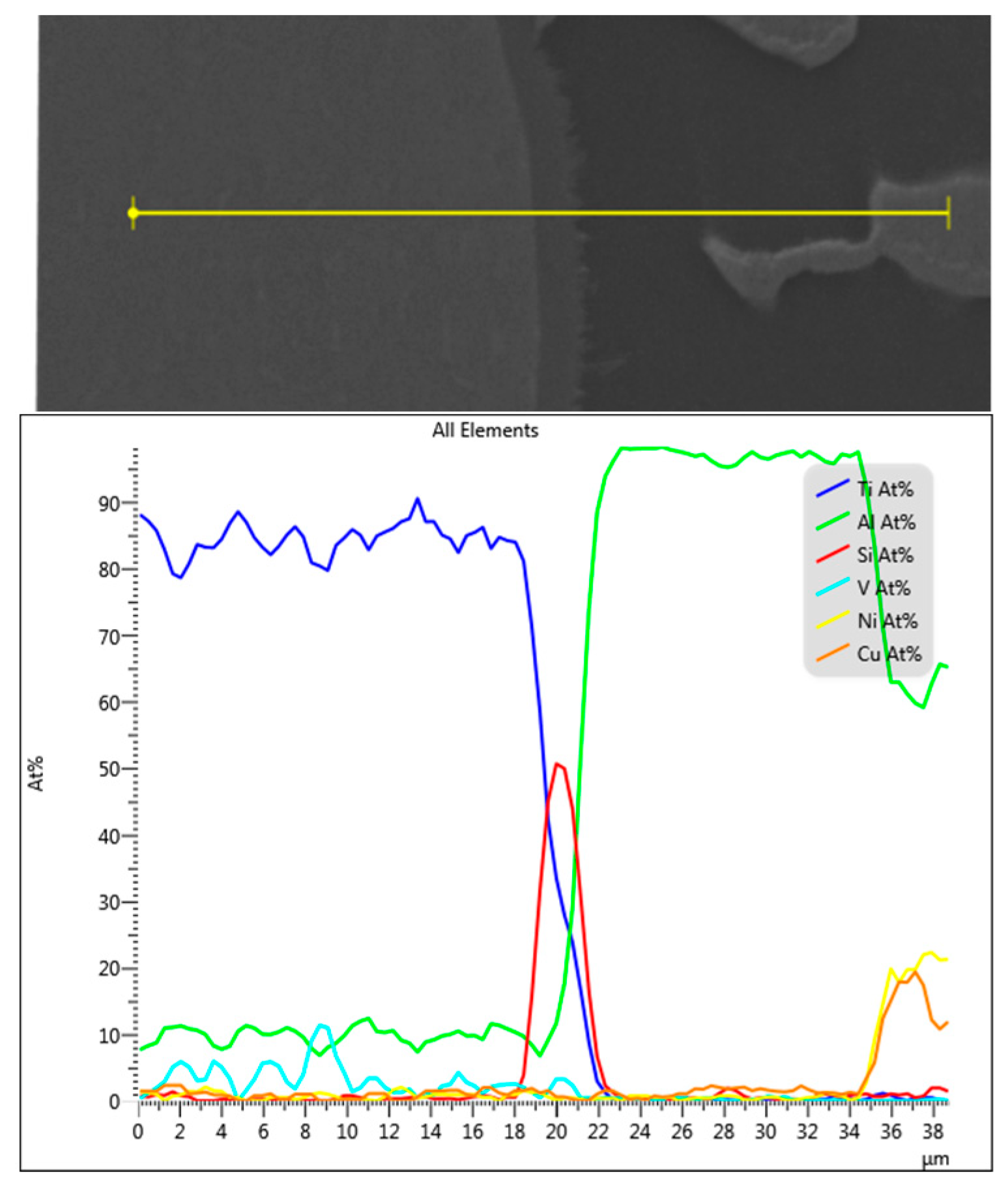

3.2. Results by Using Brazing Cycle B

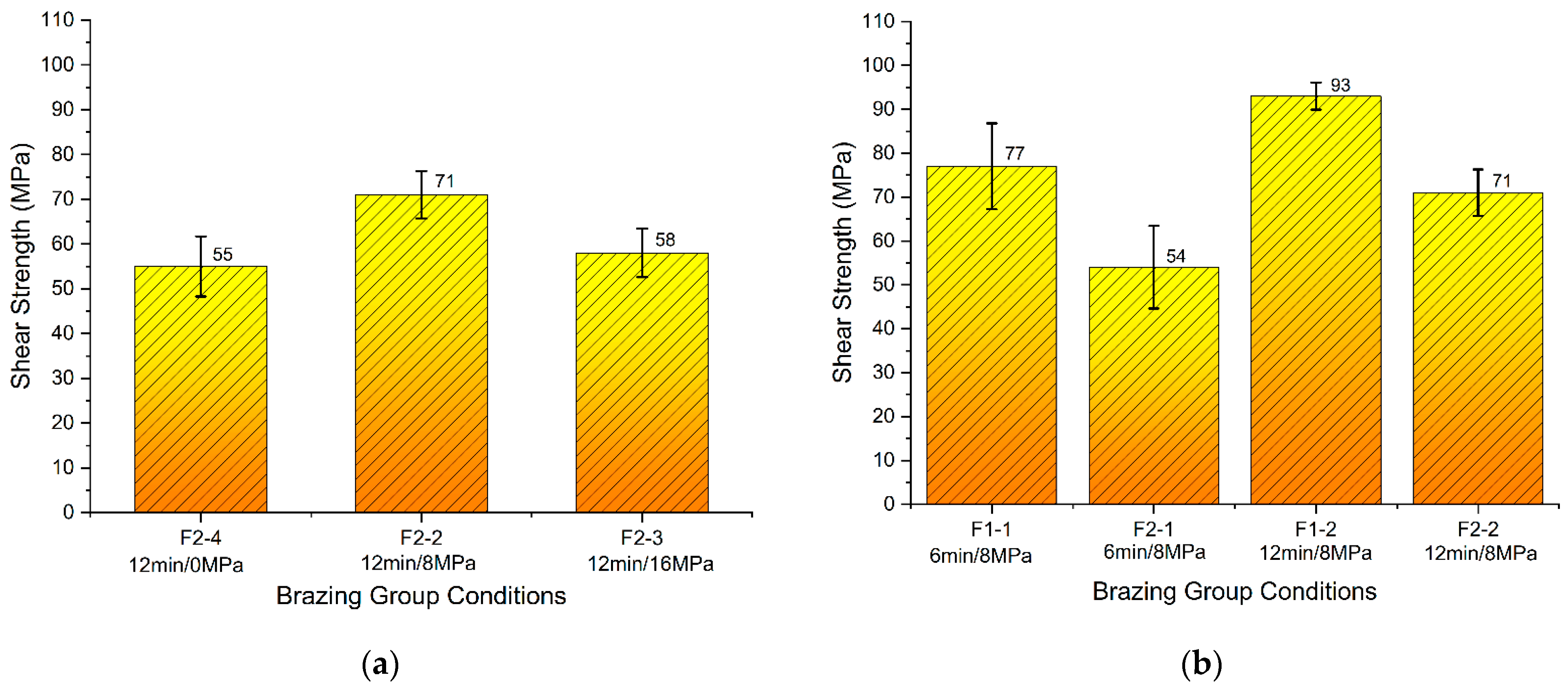

3.3. The Effect of the Second Load and Filler Composition on the Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Muhrat, A.; Barbosa, J. Ultrasonic-Assisted Brazing of Titanium Joints Using Al-Si Based Fillers: Numerical and Experimental Process Design. Metals 2021, 11, 1686. [Google Scholar] [CrossRef]

- Shapiro, A.E.; Flom, Y.A. Brazing of Titanium at Temperatures below 800 °C: Review and Prospective Applications. DVS Ber. 2007, 243, 254. [Google Scholar]

- Chen, X.; Yan, J.; Gao, F.; Wei, J.; Xu, Z.; Fan, G. Interaction Behaviors at the Interface between Liquid Al-Si and Solid Ti–6Al–4V in Ultrasonic-Assisted Brazing in Air. Ultrason. Sonochem. 2013, 20, 144–154. [Google Scholar] [CrossRef]

- Chen, X.; Xie, R.; Lai, Z.; Liu, L.; Zou, G.; Yan, J. Ultrasonic-Assisted Brazing of Al–Ti Dissimilar Alloy by a Filler Metal with a Large Semi-Solid Temperature Range. Mater. Des. 2016, 95, 296–305. [Google Scholar] [CrossRef]

- Chen, X.; Yan, J.; Ren, S.; Wei, J.; Wang, Q. Microstructure and Mechanical Properties of Ti–6Al–4V/Al1060 Joints by Ultrasonic-Assisted Brazing in Air. Mater. Lett. 2013, 95, 197–200. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Z.; Ma, L.; Wang, S.; Liu, X.; Yan, J. Cavitation at Filler Metal/Substrate Interface during Ultrasonic-Assisted Soldering. Part I: Cavitation Characteristics. Ultrason. Sonochem. 2018, 49, 249–259. [Google Scholar] [CrossRef]

- Elrefaey, A.; Wojarski, L.; Pfeiffer, J.; Tillmann, W. Preliminary Investigation on Ultrasonic-Assisted Brazing of Titanium and Titanium/Stainless Steel Joints. Weld. J. 2013, 92, 148–153. [Google Scholar]

- Wang, Q.G.; Caceres, C.H.; Griffiths, J.R. Damage by Eutectic Particle Cracking in Aluminum Casting Alloys A356/357. Met. Mater. Trans. A 2003, 34, 2901–2912. [Google Scholar] [CrossRef]

- Joseph, S.; Kumar, S.; Bhadram, V.S.; Narayana, C. Stress States in Individual Si Particles of a Cast Al–Si Alloy: Micro-Raman Analysis and Microstructure Based Modeling. J. Alloys Compd. 2015, 625, 296–308. [Google Scholar] [CrossRef]

- Timpel, M.; Wanderka, N.; Schlesiger, R.; Yamamoto, T.; Lazarev, N.; Isheim, D.; Schmitz, G.; Matsumura, S.; Banhart, J. The Role of Strontium in Modifying Aluminium–Silicon Alloys. Acta Mater. 2012, 60, 3920–3928. [Google Scholar] [CrossRef]

- Djurdjevic, M.; Stockwell, T.; Sokolowski, J. The Effect of Strontium on the Microstructure of the Aluminium-Silicon and Aluminium-Copper Eutectics in the 319 Aluminium Alloy. Int. J. Cast Met. Res. 1999, 12, 67–73. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Modification Mechanism and Microstructural Characteristics of Eutectic Si in Casting Al-Si Alloys: A Review on Experimental and Numerical Studies. JOM 2014, 66, 726–738. [Google Scholar] [CrossRef]

- Omran, A.; Ali, M.; Kh, M.; Ezzeldien, M. Effect of strontium content on the mechanical properties of hypo and hyper al-si cast alloys. J. Al-Azhar Univ. Eng. Sect. 2018, 13, 1322–1331. [Google Scholar] [CrossRef]

- Sun, X.; Wu, W.; Wang, D.; Deng, P. The Influence of Sr Addition on the Microstructure and Mechanical Properties of Aluminum Die-Casting Alloys. MATEC Web Conf. 2016, 67, 05027. [Google Scholar] [CrossRef]

- Qingjie, W.; Hong, Y.; Yuan, L.; Zhi, H. Effect of Sr Modification on Microstructures and Mechanical Properties of Al3Ti/ADC12 Composites. Rare Met. Mater. Eng. 2018, 47, 742–747. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, K.; Li, Y.; Zhao, D.; Liu, X. Evolution of Nickel-Rich Phases in Al–Si–Cu–Ni–Mg Piston Alloys with Different Cu Additions. Mater. Des. 2012, 33, 220–225. [Google Scholar] [CrossRef]

- Muhrat, A.; Puga, H.; Barbosa, J. Low-Temperature Brazing of Titanium Using Al-Based Filler Alloys. Adv. Mater. Sci. Eng. 2018, 2018, 4570120. [Google Scholar] [CrossRef]

- Školáková, A.; Novák, P.; Mejzlíková, L.; Průša, F.; Salvetr, P.; Vojtěch, D. Structure and Mechanical Properties of Al-Cu-Fe-X Alloys with Excellent Thermal Stability. Materials 2017, 10, 1269. [Google Scholar] [CrossRef] [PubMed]

- Koç, F.G.; Karakulak, E.; Yamanoğlu, R.; Zeren, M. Mechanical properties of al-ni cast alloys. Mater. Test. 2014, 7, 1283–1287. [Google Scholar]

- Samuel, A.M.; Samuel, F.H. Effect of Melt Treatment, Solidification Conditions and Porosity Level on the Tensile Properties of 319.2 Endchill Aluminium Castings. J. Mater. Sci. 1995, 30, 4823–4833. [Google Scholar] [CrossRef]

- Cáceres, C.H.; Djurdjevic, M.B.; Stockwell, T.J.; Sokolowski, J.H. The Effect of Cu Content on the Level of Microporosity in Al-Si-Cu-Mg Casting Alloys. Scr. Mater. 1999, 40, 631–637. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Shabestari, S. The Effect of Iron and Manganese on the Formation of Intermetallic Compounds in Aluminum–Silicon Alloys. Mater. Sci. Eng. A 2004, 383, 289–298. [Google Scholar] [CrossRef]

- Pehlke, R.D. Formation of Porosity During Solidification of Cast Metals. In Foundry Processes; Katz, S., Landefeld, C.F., Eds.; Springer: Boston, MA, USA, 1988; pp. 427–445. ISBN 978-1-4612-8292-1. [Google Scholar]

- Muhrat, A.; Puga, H.; Barbosa, J. Ultrasonic Vibration as a Primary Mixing Tool in Accelerating Aluminum–Copper Alloys Preparation from Their Pure Elements. Metals 2019, 9, 781. [Google Scholar] [CrossRef]

- De Giovanni, M.; Kaduk, J.A.; Srirangam, P. Modification of Al-Si Alloys by Ce or Ce with Sr. JOM 2019, 71, 426–434. [Google Scholar] [CrossRef]

- Farahany, S.; Ourdjini, A.; Bakar, T.A.A.; Idris, M.H. On the Refinement Mechanism of Silicon in Al-Si-Cu-Zn Alloy with Addition of Bismuth. Met. Mater. Trans. A 2014, 45, 1085–1088. [Google Scholar] [CrossRef]

- Djurdjevic, M.; Jiang, H.; Sokolowski, J. On-Line Prediction of Aluminum–Silicon Eutectic Modification Level Using Thermal Analysis. Mater. Charact. 2001, 46, 31–38. [Google Scholar] [CrossRef]

- Farahany, S.; Ourdjini, A.; Idris, M.H. The Usage of Computer-Aided Cooling Curve Thermal Analysis to Optimise Eutectic Refiner and Modifier in Al–Si Alloys. J. Therm. Anal. Calorim. 2012, 109, 105–111. [Google Scholar] [CrossRef]

- Tupaj, M.; Orłowicz, A.W.; Mróz, M.; Trytek, A.; Dolata, A.J.; Dziedzic, A. A Study on Material Properties of Intermetallic Phases in a Multicomponent Hypereutectic Al-Si Alloy with the Use of Nanoindentation Testing. Materials 2020, 13, 5612. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.; Ren, L.; Geng, X.; Hu, H.; Nie, X.; Tjong, J. Solidification and Microstructure of Ni-Containing Al-Si-Cu Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2018, 301, 012002. [Google Scholar] [CrossRef]

- Taylor, J.A. The Effect of Iron in Al-Si Casting Alloys. In Proceedings of the 35th Australian Foundry Institute National Conference, Adeiaide, SA, Australia, 31 October–3 November 2004. [Google Scholar]

- Dinnis, C.M.; Taylor, J.A.; Dahle, A.K. Porosity formation and eutectic growth in Al-Si-Cu-Mg alloys containing Iron and Manganese. In Proceedings of the Proceedings of the 9th International Conference on Aluminium Alloys (ICAA9), Brisbane, Australia, 2–5 August 2004; pp. 1016–1021. [Google Scholar]

- Taylor, J.A.; Schaffer, G.B.; StJohn, D.H. The Role of Iron in the Formation of Porosity in Al-Si-Cu-Based Casting Alloys: Part III. A Microstructural Model. Met. Mater. Trans. A 1999, 30, 1657–1662. [Google Scholar] [CrossRef]

- Taylor, J.A. Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys. Procedia Mater. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

- Feng, Y.; Založnik, M.; Thomas, B.; Phillion, A. A 3D Discrete-Element Model for Simulating Liquid Feeding during Dendritic Solidification of Steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 529, 012031. [Google Scholar] [CrossRef]

- Pola, A.; Tocci, M.; Kapranos, P. Microstructure and Properties of Semi-Solid Aluminum Alloys: A Literature Review. Metals 2018, 8, 181. [Google Scholar] [CrossRef]

- Perez, M.; Barbé, J.-C.; Neda, Z.; Bréchet, Y.; Salvo, L. Computer Simulation of the Microstructure and Rheology of Semi-Solid Alloys under Shear. Acta Mater. 2000, 48, 3773–3782. [Google Scholar] [CrossRef][Green Version]

- Shi, L.; Yan, J.; Peng, B.; Han, Y. Deformation Behavior of Semi-Solid Zn–Al Alloy Filler Metal during Compression. Mate. Sci. Eng. A 2011, 528, 7084–7092. [Google Scholar] [CrossRef]

- Xiao, J.; Li, S.; Bai, S.; Xiong, D.; Tang, Y. Semisolid Compression Brazing of Al50Si Alloy Using Zn-Al-Cu Filler Metal Assisted by SiC Particles. Adv. Mater. Sci. Eng. 2019, 2019, 3275810. [Google Scholar] [CrossRef]

- Yu, X.; Xing, W.; Ding, M. Ultrasonic Semi-Solid Coating Soldering 6061 Aluminum Alloys with Sn–Pb–Zn Alloys. Ultrason. Sonochem. 2016, 31, 216–221. [Google Scholar] [CrossRef]

- Emadi, D.; Whiting, L.V.; Djurdjevic, M.; Kierkus, W.T.; Sokolowski, J. Comparison of Newtonian and Fourier Thermal Analysis Techniques for Calculation of Latent Heat and Solid Fraction of Aluminum Alloys. MJoM 2004, 10, 91–106. [Google Scholar] [CrossRef]

- Marchwica, P.; Sokolowski, J.H.; Kierkus, W.T. Fraction Solid Evolution Characteristics of AlSiCu Alloys—Dynamic Baseline Approach. J. Achiev. Mater. Manuf. Eng. 2011, 47, 22. [Google Scholar]

- Upadhya, K.G.; Stefanescu, D.M.; Lieu, K.; Yeager, D.P. Computer-Aided Cooling Curve Analysis: Principles and Applications in Metal Casting. In Transactions American Foundrymen’s Soc; American Foundry Society: Schaumburg, IL, USA, 1989; Volume 97, pp. 61–66. [Google Scholar]

- Fras, E.; Kapturkiewicz, W.; Burbielko, A.; Lopez, H.F. A New Concept in Thermal Analysis of Castings. 8. AFS Trans. 1993, 101, 505–511. [Google Scholar]

- Chaturvedi, M.C.; Chaturvedi, M.C. (Eds.) Welding and Joining of Aerospace Materials; Woodhead Publishing in Materials; WP, Woodhead Publishing: Oxford, UK, 2012; ISBN 978-0-85709-516-9. [Google Scholar]

- Riggs, B.; Benatar, A.; Alexandrov, B.T.; Xu, R. Experimental Validation of Damage Zone Models for Lap Shear Brazed Joints Using DIC. Weld. J. 2017, 96, 8. [Google Scholar]

- Broughton, W.R.; Hinopoulos, G. Evaluation of the Single-Lap Joint Using Finite Element Analysis. Mater. Sci. 1999. Available online: https://eprintspublications.npl.co.uk/1281/ (accessed on 20 October 2021).

- Flom, Y.; Wang, L. Flaw tolerance in lap shear brazed joints-part 1. Weld. J. 2004, 83, 32–38. [Google Scholar]

- Zhang, C.; Robson, J.D.; Haigh, S.J.; Prangnell, P.B. Interfacial Segregation of Alloying Elements During Dissimilar Ultrasonic Welding of AA6111 Aluminum and Ti6Al4V Titanium. Met. Mater. Trans. A 2019, 50, 5143–5152. [Google Scholar] [CrossRef]

- Takemoto, T.; Okamoto, I. Intermetallic Compounds Formed during Brazing of Titanium with Aluminium Filler Metals. J. Mater. Sci. 1988, 23, 1301–1308. [Google Scholar] [CrossRef]

| Master Alloy | Alloy Origin | Treatments | Composition, wt.% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Si | Cu | Fe | Ti | Sr | Mg | Al | |||

| Al-16Ni | Lab-made | Melted and degassed for 2 times | 16.04 | - | - | - | - | - | - | Bal. |

| Al-27Cu | Lab-made | Melted and degassed for 2 times | - | - | 27.1 | - | - | - | - | Bal. |

| Al-13Si | Commercially available ingot | Melted and degassed | - | 13.12 | 0.022 | 0.47 | 0.012 | - | 0.007 | Bal. |

| Al-5Sr (Nominal composition) | Commercially available rod | Added to the melt directly | - | - | - | - | - | 5 | - | Bal. |

| Filler Code | Filler Alloy | Ni | Si | Cu | Fe | Ti | Sr | Mg | Zn | Mn | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| F0 | Al-9Si-3Cu * | 0.097 | 9.183 | 3.178 | 0.891 | 0.029 | - | 0.178 | 0.835 | 0.253 | Bal. |

| F1 | Al-9Si-4Cu-(Sr) | 0.084 | 9.054 | 3.903 | 0.318 | 0.0087 | 0.0193 | - | 0.019 | 0.033 | Bal. |

| F2 | Al-8Si-4Cu-2Ni-(Sr) | 2.345 | 7.905 | 4.078 | 0.302 | 0.0096 | 0.0258 | - | 0.014 | 0.031 | Bal. |

| Stage | Temperture (°C) | |||

|---|---|---|---|---|

| F0 | F1 | F2 | ||

| 1 | ) | =575 =569 = 574 | 577 572 578 | 577 571 575 |

| 2 | ) + Si | =562 =560 = 561 | 552 550 556 | 540 538 545 |

| 3 | Formation of complex intermetallic/eutectics Starting by Al-Cu-(Ni) intermetallic followed by at a lower temperature, ending by Al-Cu-Mg-Si complex intermetallic for F0 | = 498 | 516 | 510 |

| 4 | Non-equilibrium solidus temperature | = 476 | 495 | 491 |

| Brazing Cycle ** | Condition Code (Starting by Filler Type F0, F1, or F2) | Initial Load, kg | Heating to, C/Holding, min | USV Temp., °C | USV Period, sec (Furnace Off) | Pressure, MPa, (Second Load, kg) / Temp.,°C (Furnace Off) | |

|---|---|---|---|---|---|---|---|

| A | F0-1 | 20 | 550/3 | 550 | 10 | )/~549 * | |

| F0-2 | 20 | 565/3 | 565 | 10 | )/~564 * | ||

| F0-3 | 20 | 580/3 | 580 | 10 | )/~569 * | ||

| F0-4 | 20 | 565/3 | 565 | 10 | 6 **)/~564 * | ||

| F0-5 | 20 | 565/3 | 565 | 10 | - | ||

| USV Period, sec (No Heat Provided ***) | Pressure, MPa, (Second Load, kg) /Solid Fraction **** | Holding under Load, min (Holding Time No. 4) | |||||

| B | F1-1 | 20 | 580/3 | 580 | 10 | 8 **)/0.7 | 6 |

| F1-2 | 20 | 580/3 | 580 | 10 | )/0.7 | 12 | |

| F2-1 | 20 | 580/3 | 580 | 10 | )/0.7 | 6 | |

| F2-2 | 20 | 580/3 | 580 | 10 | )/0.7 | 12 | |

| F1-3 | 20 | 580/3 | 580 | 10 | 16 **)/0.7 | 12 | |

| F2-3 | 20 | 580/3 | 580 | 10 | )/0.7 | 12 | |

| F2-4 | 20 | 580/3 | 580 | 10 | 0/0.7 | 12 | |

| Ti | Si | Al | Fe | O | Cu | Mn | Cr | Estimated Phase (s) | |

|---|---|---|---|---|---|---|---|---|---|

| Z1 | 9.6 | 15.8 | 60.8 | 13.4 | 0.5 | ||||

| Z2 | 11.9 | 70.9 | 10.7 | 1.2 | 4.3 | 1.0 | |||

| Z3 | 75.8 | 24.2 | Silicon particles | ||||||

| Z4 | 91.3 | 8.7 | |||||||

| Z5 | 17.2 | 70.6 | 11.4 | 0.8 | |||||

| Z6 | 2.4 | 86.1 | 3.5 | 7.9 |

| Ti | Si | Al | Fe | Mg | Cu | Mn | Ni | Cr | Estimated Phase (s) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Z1 | 0.8 | 18.2 | 67.8 | 12.7 | 0.5 | |||||

| Z2 | 18.3 | 67.5 | 12.9 | 0.6 | 0.7 | |||||

| Z3 | 85.4 | 14.6 | Silicon particles | |||||||

| Z4 | 98.2 | 1.8 | ||||||||

| Z5 | 0.3 | 18.4 | 68.3 | 12.5 | 0.4 | |||||

| Z6 | 42.6 | 49.5 | 2.2 | 5.0 | 0.7 | |||||

| Z7 | 19.2 | 32.1 | 45.8 | 2.0 | 1 | Al-Ti intermetallic |

| Ti | Si | Al | Fe | Cu | Mn | Cr | Estimated Phase (s) | |

|---|---|---|---|---|---|---|---|---|

| Z1 | 0.3 | 11.1 | 69.5 | 11.9 | 1.4 | 4.5 | 1.3 | |

| Z2 | 0.4 | 18.1 | 66.5 | 14.3 | 0.7 | |||

| Z3 | 32.0 | 41.0 | 26.3 | 0.0 | 0.7 | Al-Ti intermetallic | ||

| Z4 | 1.9 | 17.7 | 65.7 | 14.2 | 0.6 | |||

| Z5 | 97.7 | 2.3 | Silicon particles | |||||

| Z6 | 98.2 | 1.8 | ||||||

| Z7 | 0.4 | 7.8 | 82.1 | 4.1 | 4 | 1.6 |

| Ti | Si | Al | V | Fe | Cu | Mn | Cr | Estimated Phase (s) | |

|---|---|---|---|---|---|---|---|---|---|

| Z1 | 0.4 | 11.6 | 70.8 | 10.9 | 0.9 | 4.3 | 1.1 | ||

| Z2 | 0.6 | 10.7 | 71.5 | 11.6 | 1.3 | 3.6 | 0.7 | ||

| Z3 | 42.2 | 31.0 | 25.2 | 1.6 | Al-Ti intermetallic | ||||

| Z4 | 81.4 | 18.6 | Silicon particle | ||||||

| Z5 | 0.8 | 16.0 | 70.9 | 11.7 | 0.6 | ||||

| Z6 | 7.2 | 17.1 | 68 | 4.0 | 3.7 | 0.0 |

| Al | Si | Ti | Fe | Mn | Cr | Cu | Ni | O | Mg | V | Estimated Phase (s) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Z1 | 12.3 | 51.0 | 35.0 | 1.8 | ||||||||

| Z2 | 70.7 | 10.6 | 13.3 | 1.9 | 3.5 | |||||||

| Z3 | 74.7 | 3.1 | 22.3 | |||||||||

| Z4 | 69.7 | 30.3 | ||||||||||

| Z5 | 65.8 | 18.5 | 15.7 | + Si | ||||||||

| Z6 | 20.7 | 79.3 | Si particle |

| Al | Si | Ti | Fe | Mn | Cr | Cu | Ni | Mg | V | Estimated Phase (s) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Z1-b | 11.3 | 51.8 | 35.6 | 1.4 | |||||||

| Z2-b | 69.5 | 5.2 | 4.6 | 6.5 | 14.2 | ||||||

| Z3-b | 61 | 17.8 | 21.2 | Al-Cu-Ni intermetallic | |||||||

| Z4-b | 81 | 1.8 | 3.7 | 13.4 | |||||||

| Z1-d | 13.0 | 53.6 | 30.0 | 3.4 | |||||||

| Z2-d | 11.2 | 56.8 | 32.0 | ||||||||

| Z3-d | 72.4 | 16.9 | 10.8 | Al-Ti intermetallic | |||||||

| Z4-d | 55.5 | 25.3 | 11.0 | 8.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhrat, A.; Barbosa, J. Ultrasonic-Assisted Brazing of Titanium Joints Using Modified Al-Si-Cu Based Fillers: Brazing at Liquid—Semisolid States under Load. Metals 2021, 11, 1968. https://doi.org/10.3390/met11121968

Muhrat A, Barbosa J. Ultrasonic-Assisted Brazing of Titanium Joints Using Modified Al-Si-Cu Based Fillers: Brazing at Liquid—Semisolid States under Load. Metals. 2021; 11(12):1968. https://doi.org/10.3390/met11121968

Chicago/Turabian StyleMuhrat, Abdulsalam, and Joaquim Barbosa. 2021. "Ultrasonic-Assisted Brazing of Titanium Joints Using Modified Al-Si-Cu Based Fillers: Brazing at Liquid—Semisolid States under Load" Metals 11, no. 12: 1968. https://doi.org/10.3390/met11121968

APA StyleMuhrat, A., & Barbosa, J. (2021). Ultrasonic-Assisted Brazing of Titanium Joints Using Modified Al-Si-Cu Based Fillers: Brazing at Liquid—Semisolid States under Load. Metals, 11(12), 1968. https://doi.org/10.3390/met11121968