The Corrosion and Wear Behaviors of a Medium-Carbon Bainitic Steel Treated by Boro-Austempering Process

Abstract

1. Introduction

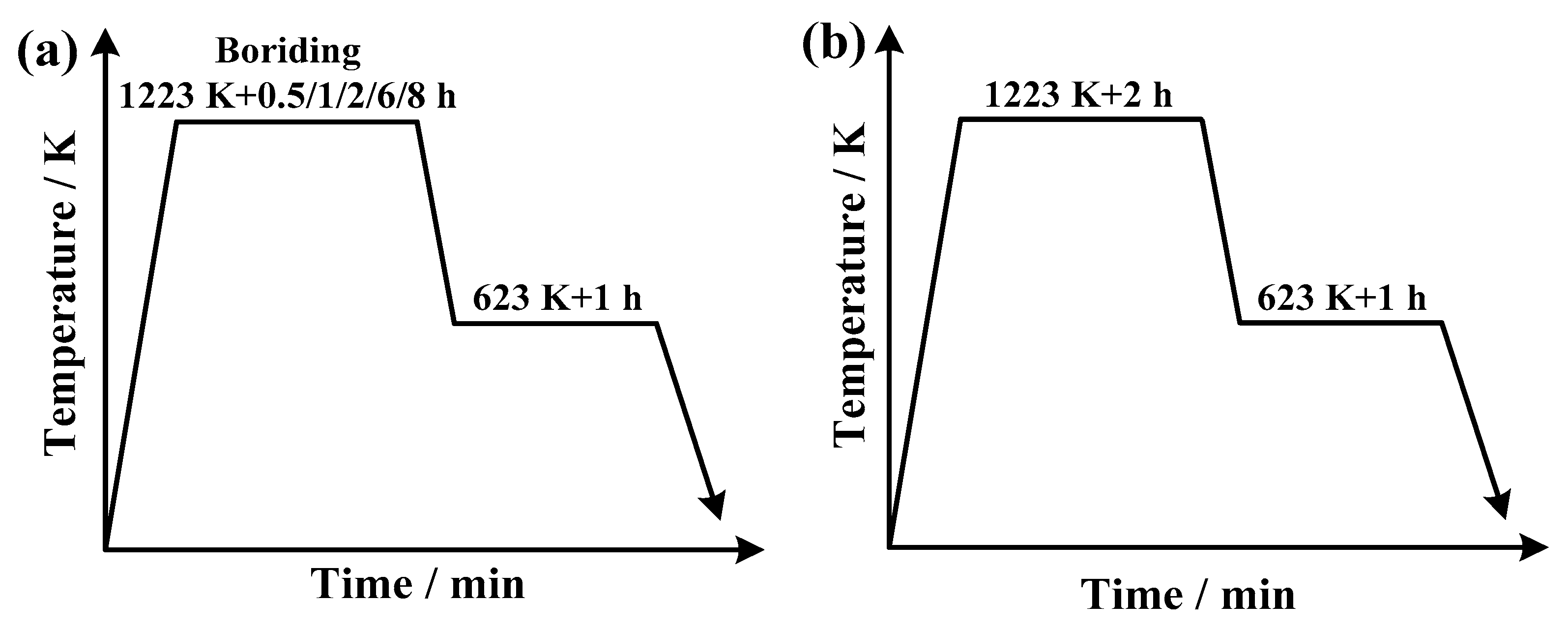

2. Materials and Methods

3. Results and Discussion

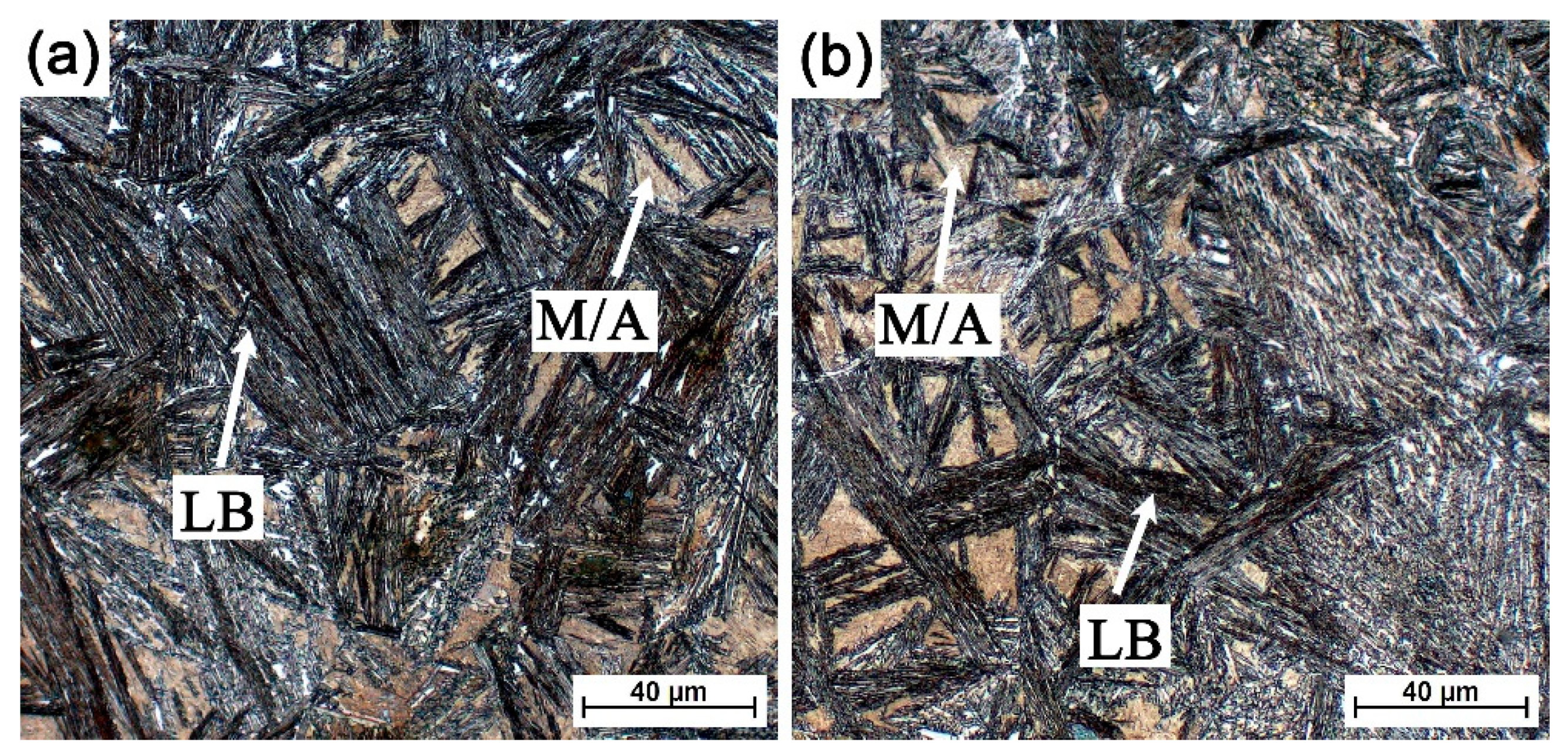

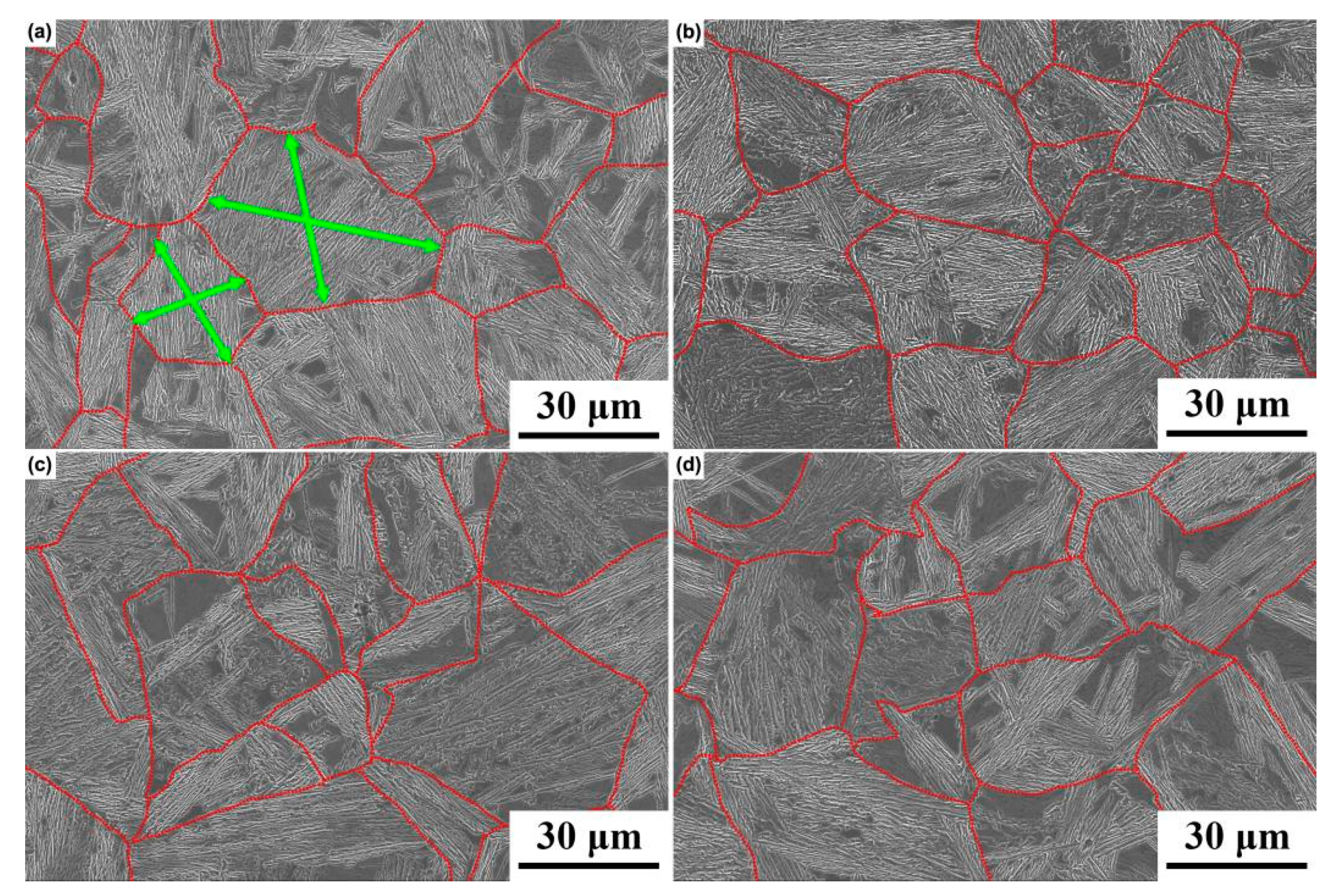

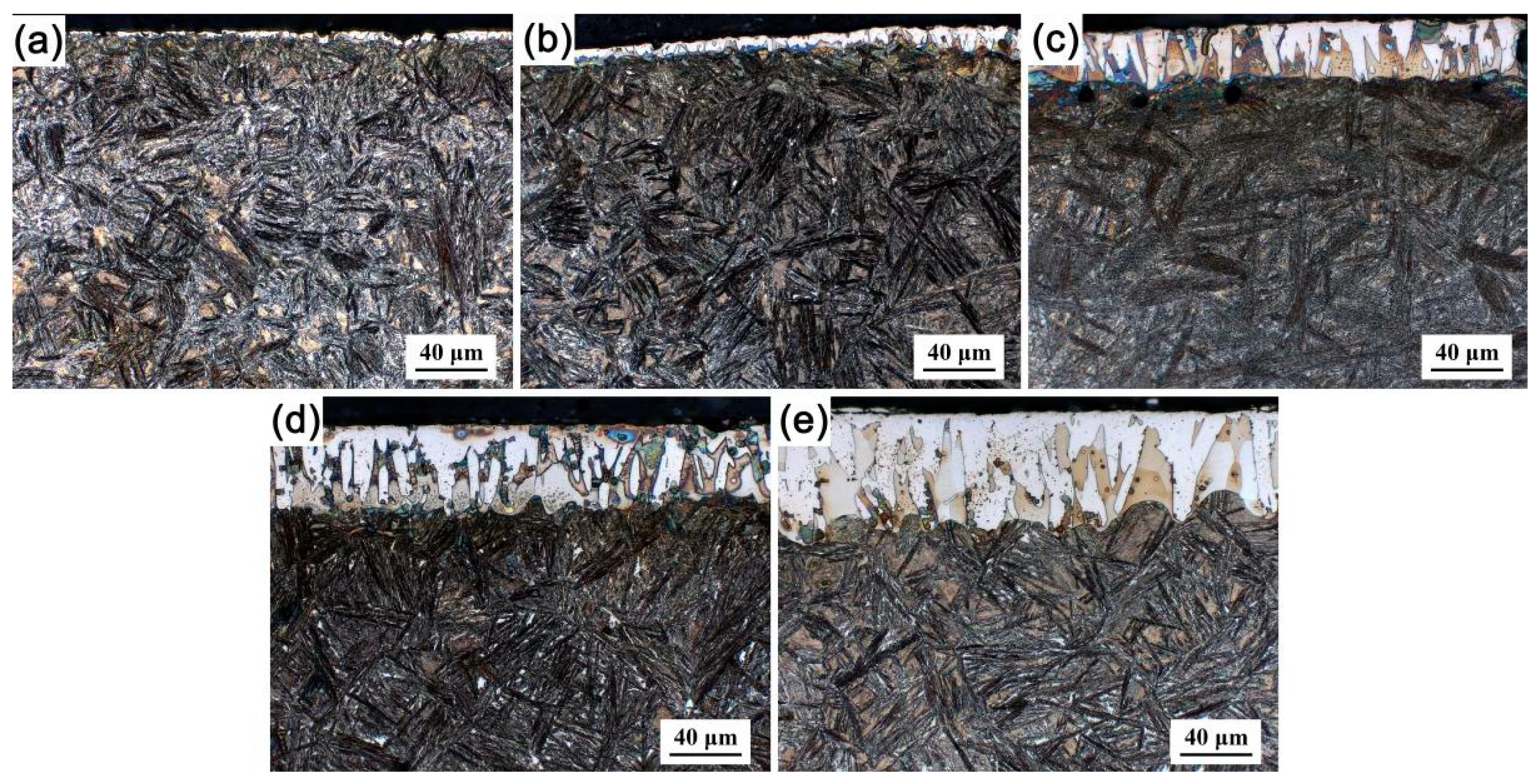

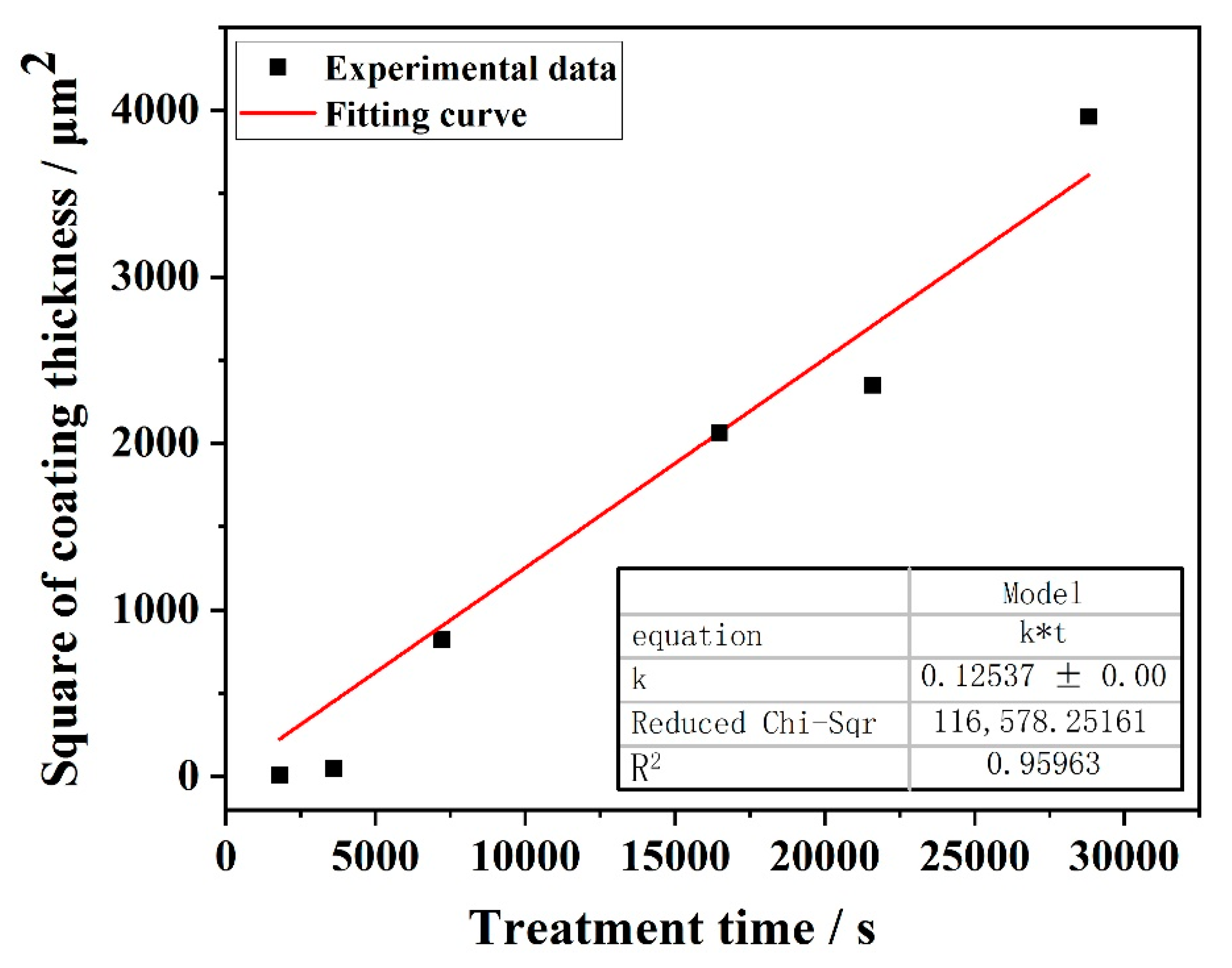

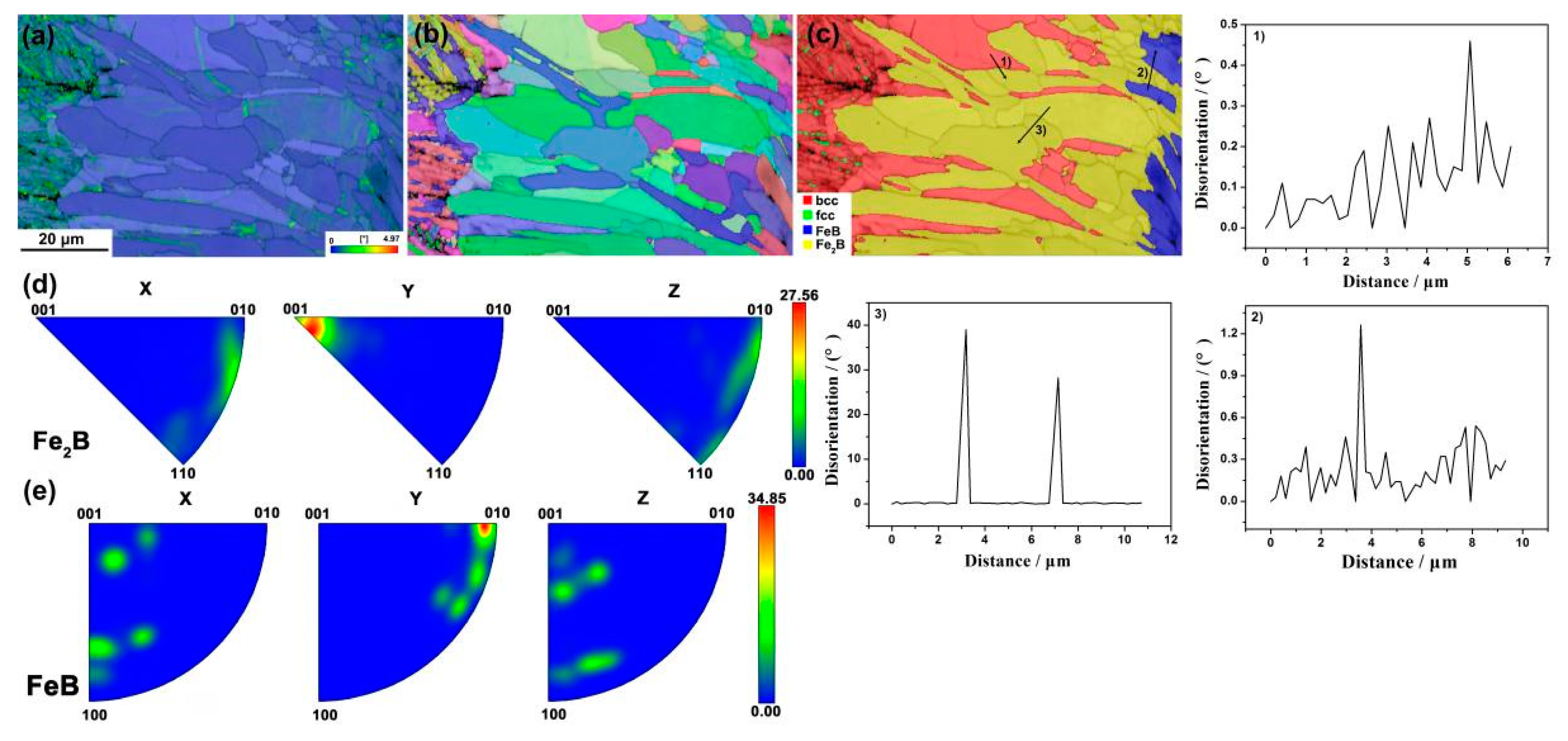

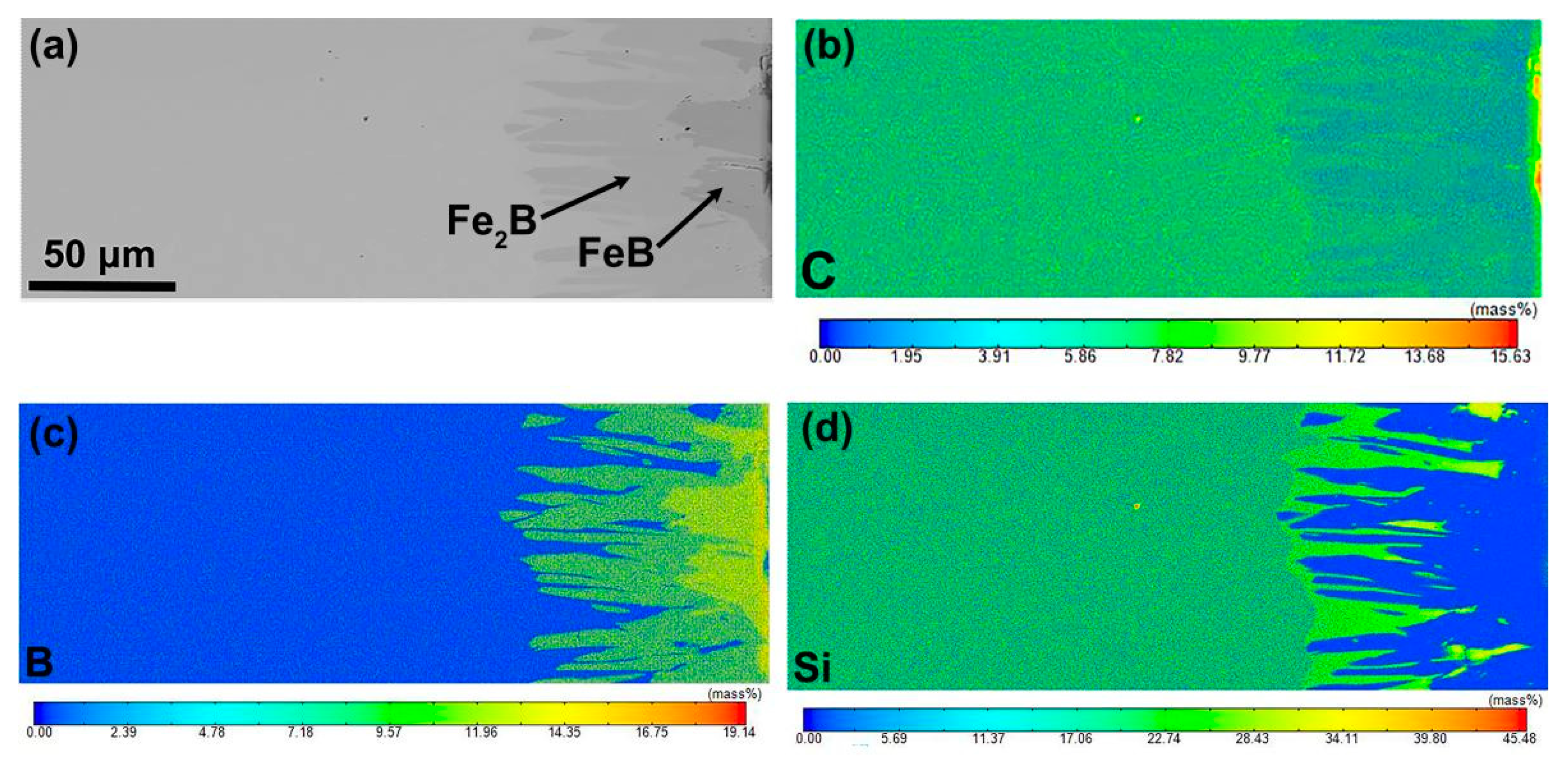

3.1. Microstructure Characterization and Kinetics Analysis

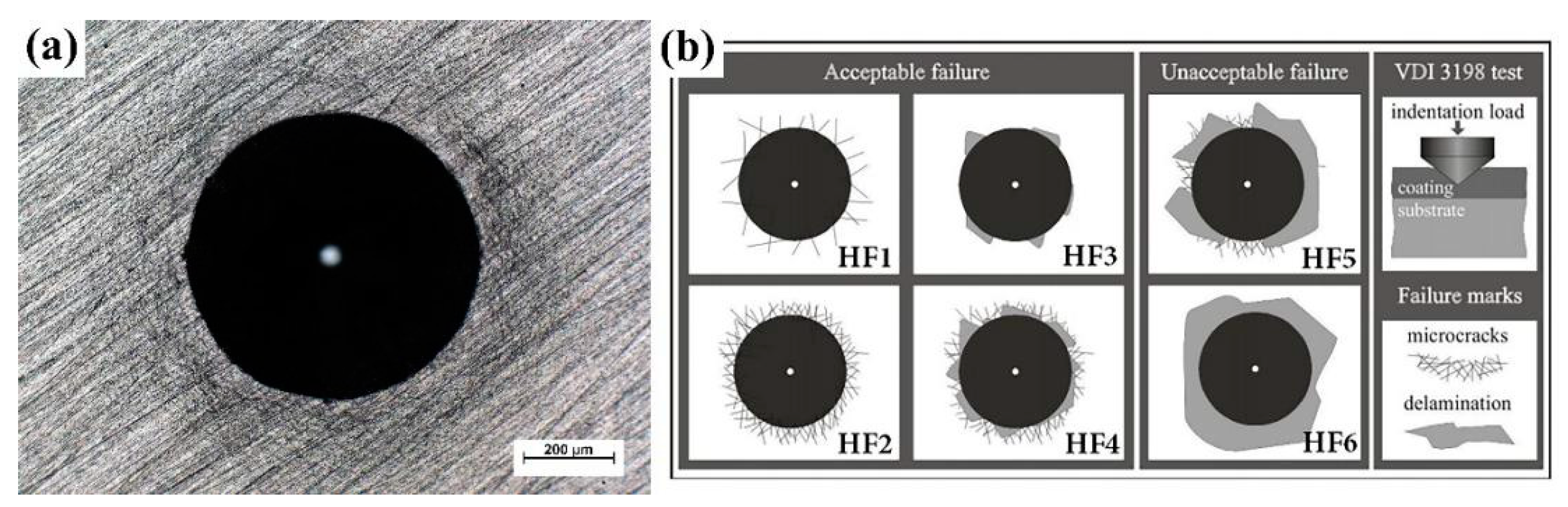

3.2. Evaluation of Adhesion Strength and Hardness Profiles

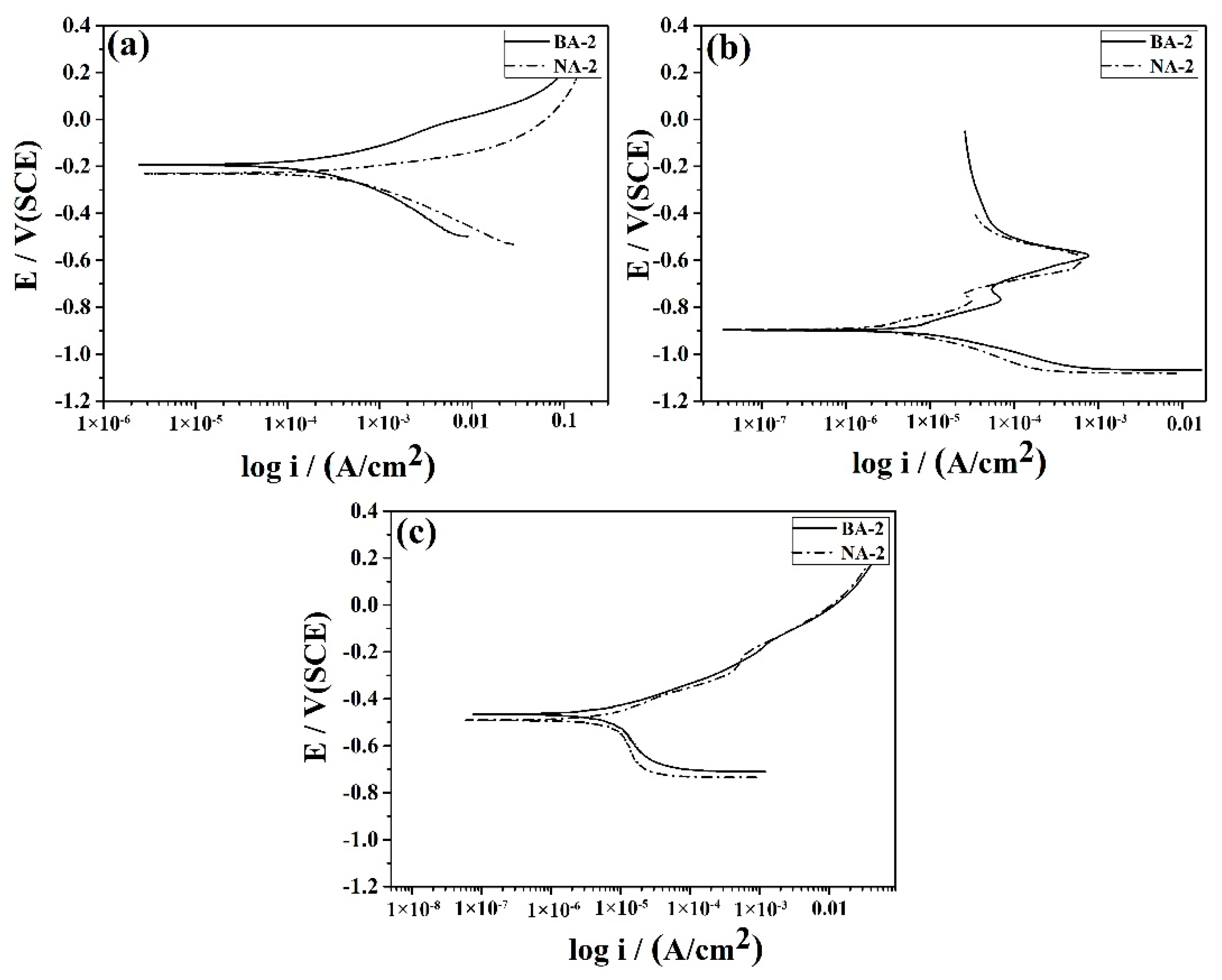

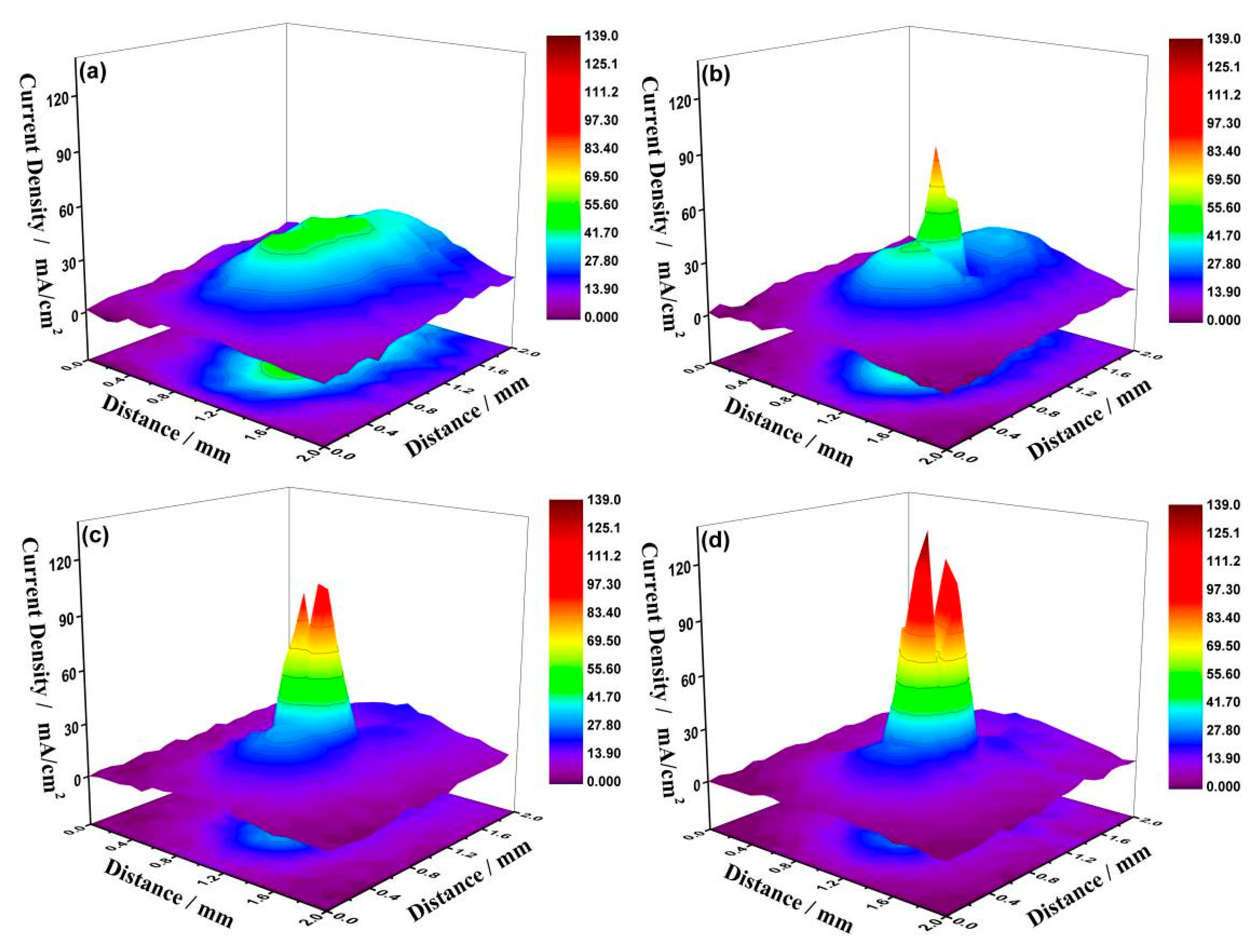

3.3. Corrosion Behavior

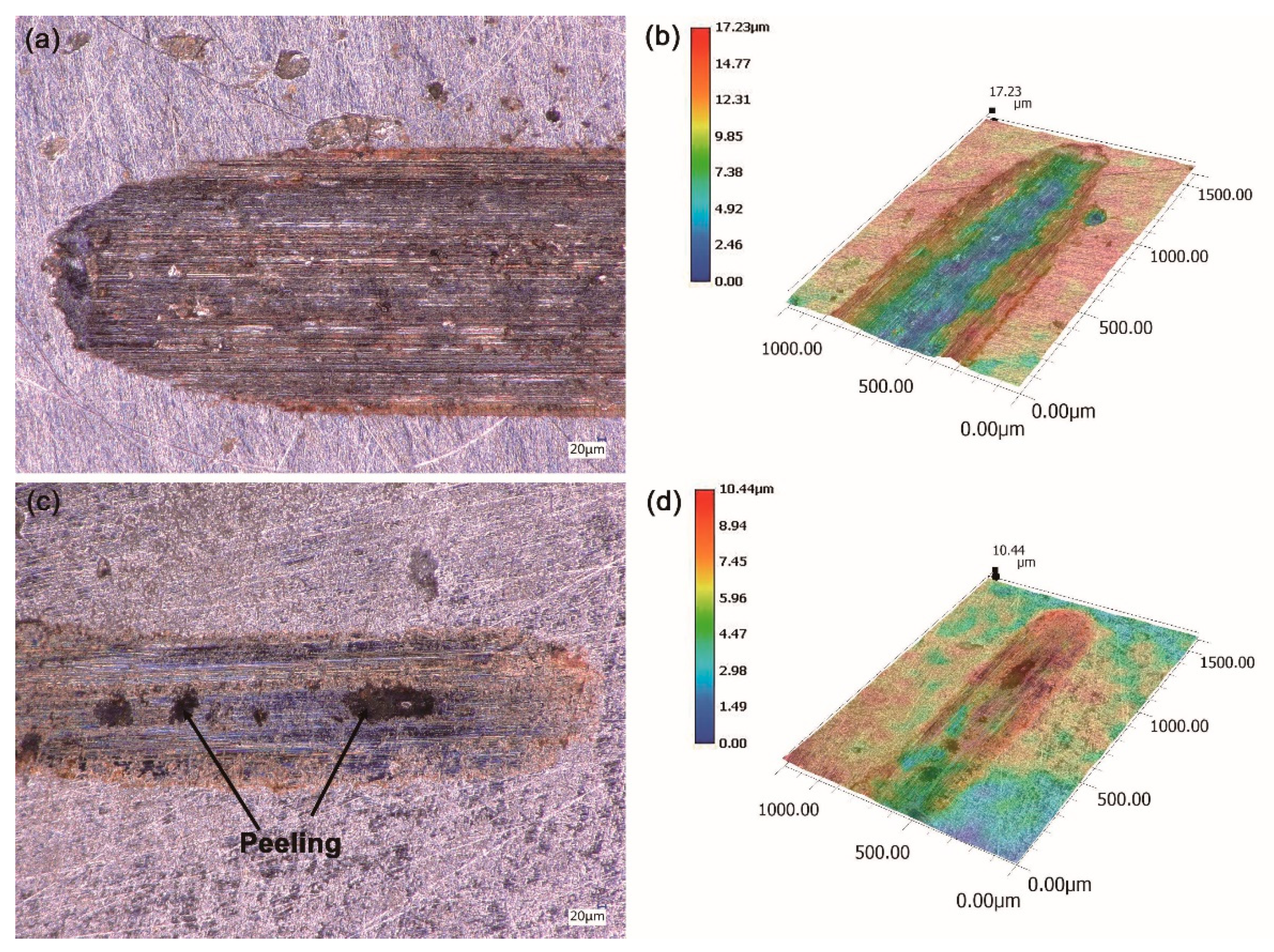

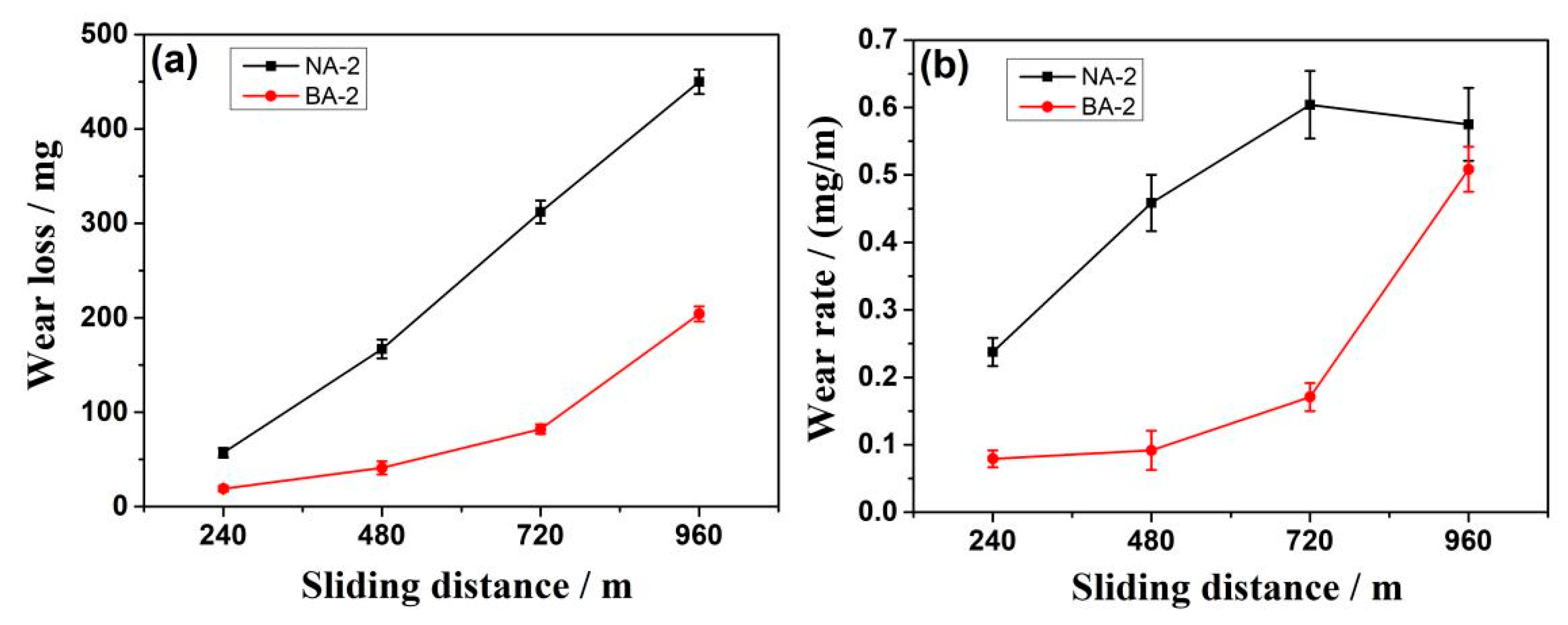

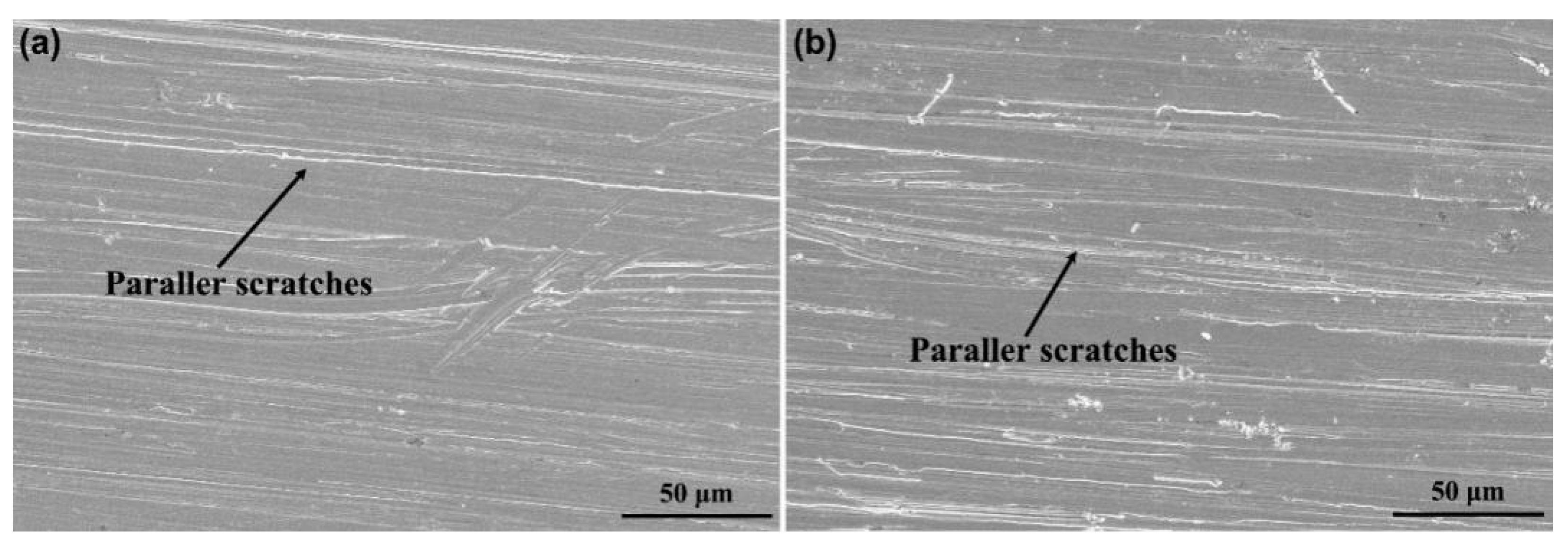

3.4. Wear Behaviors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Development of hard bainite. ISIJ Int. 2003, 43, 1238–1243. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Nanostructured bainite. Proc. R. Soc. A 2010, 466, 3–18. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Mechanical properties of low-temperature bainite. Mater. Sci. Forum. 2005, 500, 495–502. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhang, F.C.; Wang, T.S. A novel bainitic steel comparable to maraging steel in mechanical properties. Scr. Mater. 2013, 68, 763–766. [Google Scholar] [CrossRef]

- Tian, J.Y.; Xu, G.; Jiang, Z.Y.; Hu, H.J.; Zhou, M.X. Effect of Ni addition on bainite transformation and properties in a 2000 MPa grade ultrahigh strength bainitic steel. Met. Mater. Int. 2018, 24, 1202–1212. [Google Scholar] [CrossRef]

- Chen, G.H.; Hu, H.J.; Xu, G.; Tian, J.Y.; Wan, X.L.; Wang, X. Optimizing microstructure and property by ausforming in a medium-carbon bainitic steel. ISIJ Int. 2020, 60, 2007–2014. [Google Scholar] [CrossRef]

- Tian, J.Y.; Xu, G.; Hu, H.J.; Wang, X.; Zurob, H.S. Transformation kinetics of carbide-free bainitic steels during isothermal holding above and below MS. J. Mater. Res. Technol. 2020, 9, 13594–13606. [Google Scholar] [CrossRef]

- Gao, G.H.; Guo, H.R.; Gui, X.L.; Tan, Z.L.; Bai, B.Z. Inverted multi-step bainitic austempering process routes: Enhanced strength and ductility. Mater. Sci. Eng. A 2018, 736, 298–305. [Google Scholar] [CrossRef]

- Wang, Z.H.; Hui, W.J.; Chen, Z.; Zhang, Y.J.; Zhao, X.L. Effect of vanadium on microstructure and mechanical properties of bainitic forging steel. Mater. Sci. Eng. A 2020, 771, 138653. [Google Scholar] [CrossRef]

- Senthil, P.P.; Rao, K.S.; Nandi, H.K.; Singh, V.; Kumar, S.; Sankaran, S.; Kumar, K.S.; Madhu, V. Influence of niobium microalloying on the microstructure and mechanical properties of high carbon nano bainitic steel. Procedia Struct. Integr. 2019, 14, 729–737. [Google Scholar] [CrossRef]

- Kirbiš, P.; Anžel, I.; Rudolf, R.; BrunÄko, M. Novel approach of nanostructured bainitic steels’ production with improved toughness and strength. Materials 2020, 13, 1220. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, A. Toughness dependence of nano-bainite on phase fraction and morphology. Mater. Sci. Eng. A 2018, 729, 439–443. [Google Scholar] [CrossRef]

- Golchin, S.; Avishan, B.; Yazdani, S. Effect of 10% ausforming on impact toughness of nano bainite austempered at 300 °C. Mater. Sci. Eng. A 2016, 656, 94–101. [Google Scholar] [CrossRef]

- Edwards, R.H.; Kennon, N.F. The morphology and mechanical properties of bainite formed from deformed austenite. Metall. Mater. Trans. A 1978, 9, 801–1809. [Google Scholar] [CrossRef]

- Fabijanic, D.; Timokhina, I.; Beladi, H.; Hodgson, P. The nitrocarburising response of low temperature bainite steel. Metals 2017, 7, 234. [Google Scholar] [CrossRef]

- Natori, M.; Mizuno, Y.; Song, S.M.; Sugimoto, K.I. Effects of fine particle peening on fatigue strength of TRIP-aided bainitic ferrite steel. J. Soc. Mater. Sci. Jpn. 2015, 64, 620–627. [Google Scholar] [CrossRef][Green Version]

- Oliveira, P.G.B.D.; Mariani, F.E.; Casteletti, L.C.; Filho, A.I.; Neto, A.L.; Totten, G.E. Boro-austempering treatment of high-strength bainitic steels. J. Mater. Eng. Perform. 2020, 17, 3486–3493. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Z.T.; Pan, C.G.; Zhang, Q.; Hu, H.J.; Xu, G. Microstructure and properties of a medium-carbon high-strength bainitic steel treated by boro-austempering treatment. Steel Res. Int. 2020, 91, 2000128. [Google Scholar] [CrossRef]

- Mariani, F.E.; Bortoluci de Assis, G.; Casteletti, L. Austempering and boro-austempering treatments in gray cast iron. Mater. Perform. Charact. 2017, 6, 262–271. [Google Scholar] [CrossRef]

- Mariani, F.E.; Soares, C.; Neto, A.L. Boro-austempering treatment of ductile cast irons. Mater. Res. 2018, 21, e20170927. [Google Scholar] [CrossRef]

- Moreto, J.A.; Marino, C.E.B.; Filho, W.W.B.; Rocha, L.A.; Fernandes, J.C.S. SVET, SKP and EIS study of the corrosion behaviour of high strength Al and Al-Li alloys used in aircraft fabrication. Corros. Sci. 2014, 84, 30–41. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, W.Z.; Cheng, L.; Liu, J.; Wu, K.M.; Liu, M. Effects of niobium and rare earth elements on microstructure and initial marine corrosion behavior of low-alloy steels. Appl. Surf. Sci. 2019, 475, 83–93. [Google Scholar] [CrossRef]

- Tian, J.Y.; Xu, G.; Jiang, Z.Y.; Yuan, Q.; Chen, G.H.; Hu, H.J. Effect of austenisation temperature on bainite transformation below martensite starting temperature. Mater. Sci. Technol. 2019, 35, 1539–1550. [Google Scholar] [CrossRef]

- Chen, F.S.; Wang, K.L. The kinetics and mechanism of multi-component diffusion on AISI 1045 steel. Surf. Coat. Technol. 1999, 115, 239–248. [Google Scholar] [CrossRef]

- Zhong, J.R.; Qin, W.; Wang, X.; Medvedovski, E.; Szpunar, J.A.; Guan, K.S. Mechanism of texture formation in iron boride coatings on low-carbon steel. Metall. Mater. Trans. A 2019, 50, 58–62. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure Normen; VDI 3198; VDI-Verlag: Dusseldorf, Germany, 1991.

- Sireli, G.K.; Bora, A.S.; Timur, S. Evaluating the mechanical behavior of electrochemically borided low-carbon steel. Surf. Coat. Technol. 2020, 381, 125177. [Google Scholar] [CrossRef]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J. Mater. Process. Technol. 2003, 143, 481–485. [Google Scholar] [CrossRef]

- Türkmen, İ.; Yalamaç, E.; Keddam, M. Investigation of tribological behaviour and diffusion model of Fe2B layer formed by pack-boriding on SAE 1020 steel. Surf. Coat. Technol. 2019, 377, 124888. [Google Scholar] [CrossRef]

- Tokta, A.; Tokta, G.; Gülsün, K. Effect of boronizing parameters and matrix structures on the wear property of ductile iron. Int. Sci. J. Mach. Technol. Mater. 2018, 12, 33–36. [Google Scholar]

- Zhang, H.W.; Man, C.; Wang, L.W.; Dong, N.C.F.; Wang, L.; Kong, D.C.; Wang, X. Different corrosion behaviors between α and β phases of Ti6Al4V in fluoride-containing solutions: Influence of alloying element Al. Corros. Sci. 2020, 169, 108605. [Google Scholar] [CrossRef]

- Wei, W.Z.; Wu, K.M.; Zhang, X.; Liu, J.; Qiu, P.; Cheng, L. In-situ characterization of initial marine corrosion induced by rare-earth elements modified inclusions in Zr-Ti deoxidized low-alloy steels. J. Mater. Res. Technol. 2020, 9, 1412–1424. [Google Scholar] [CrossRef]

- Carrera-Espinoza, R.; Figueroa-López, U.; Martínez-Trinidad, J.; Campos-Silva, I.; Hernández-Sánchez, E.; Motallebzadeh, A. Tribological behavior of borided AISI 1018 steel under linear reciprocating sliding conditions. Wear 2016, 362, 1–7. [Google Scholar] [CrossRef]

- Dos, S.; de Almeida, E.A.; Milan, J.C.G.; Costa, H.L.; Krelling, A.P.; da Costa, C.E. Sliding wear of borided sintered AISI M2 steel coated with AlTiN/CrN multilayer. Wear 2018, 410, 11–24. [Google Scholar]

- Gutierrez-Noda, L.; Cuao-Moreu, C.A.; Perez-Acosta, O.; Lorenzo-Bonet, E.; Zambrano-Robledo, P.; Hernandez-Rodriguez, M.A.L. The effect of a boride diffusion layer on the tribological properties of AISI M2 steel. Wear 2019, 426, 1667–1671. [Google Scholar] [CrossRef]

| Treatments | 1223 K + 2 h | Boriding 1223 K + 0.5 h | Boriding 1223 K + 1 h | Boriding 1223 K + 2 h | Boriding 1223 K + 6 h | Boriding 1223 K + 8 h |

|---|---|---|---|---|---|---|

| Samples | NA-2 | BA-0.5 | BA-1 | BA-2 | BA-6 | BA-8 |

| Samples | BA-0.5 | BA-1 | BA-2 | BA-6 | BA-8 |

|---|---|---|---|---|---|

| Average PAGS (μm) | / | 31.1 ± 8.4 | 30.4 ± 7.8 | 34.0 ± 8.9 | 34.0 ± 9.2 |

| Coating thickness (μm) | 3.4 ± 0.8 | 6.9 ± 1.1 | 28.6 ± 1.4 | 48.4 ± 2.1 | 62.9 ± 3.7 |

| Samples | 10% NaOH | 0.5 mol/L HCl | 3.5% NaCl | |||

|---|---|---|---|---|---|---|

| Icorr (A/cm2) | Ecorr (V) | Icorr (A/cm2) | Ecorr (V) | Icorr (A/cm2) | Ecorr (V) | |

| BA-2 | 2.54 × 10−6 | −0.895 | 5.50 × 10−5 | −0.193 | 2.13 × 10−6 | −0.466 |

| NA-2 | 3.93 × 10−6 | −0.899 | 1.49 × 10−4 | −0.230 | 3.04 × 10−6 | −0.491 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Wang, W.; Hu, H.; Cai, F.; Liu, S.; Xu, G. The Corrosion and Wear Behaviors of a Medium-Carbon Bainitic Steel Treated by Boro-Austempering Process. Metals 2021, 11, 1959. https://doi.org/10.3390/met11121959

Liu M, Wang W, Hu H, Cai F, Liu S, Xu G. The Corrosion and Wear Behaviors of a Medium-Carbon Bainitic Steel Treated by Boro-Austempering Process. Metals. 2021; 11(12):1959. https://doi.org/10.3390/met11121959

Chicago/Turabian StyleLiu, Man, Wei Wang, Haijiang Hu, Feng Cai, Sheng Liu, and Guang Xu. 2021. "The Corrosion and Wear Behaviors of a Medium-Carbon Bainitic Steel Treated by Boro-Austempering Process" Metals 11, no. 12: 1959. https://doi.org/10.3390/met11121959

APA StyleLiu, M., Wang, W., Hu, H., Cai, F., Liu, S., & Xu, G. (2021). The Corrosion and Wear Behaviors of a Medium-Carbon Bainitic Steel Treated by Boro-Austempering Process. Metals, 11(12), 1959. https://doi.org/10.3390/met11121959