Recent Progress in Understanding the Nano/Micro-Mechanical Behavior of Austenite in Advanced High Strength Steels

Abstract

:1. Introduction

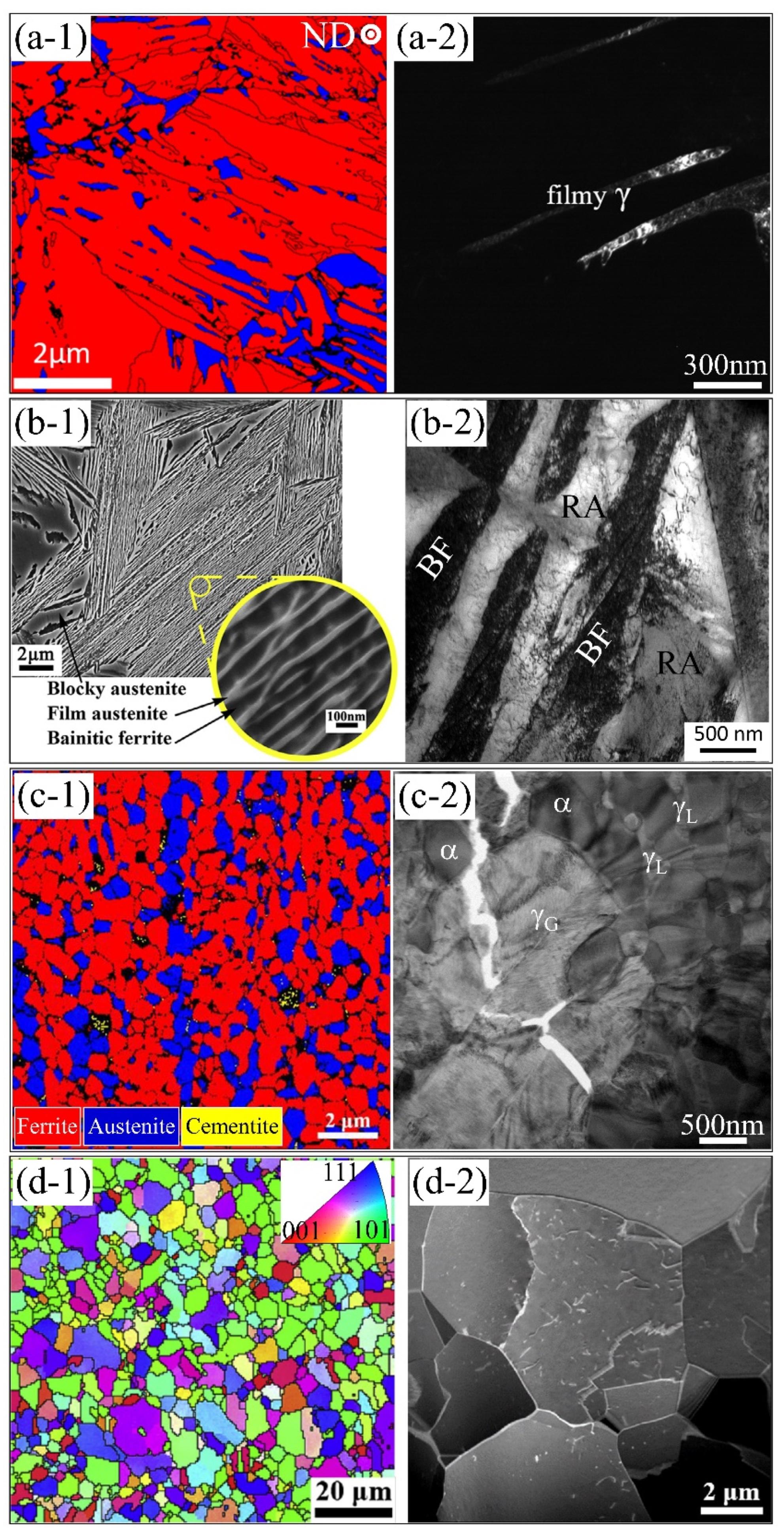

2. Austenite in AHSS

3. Nano/Micro-Mechanical Behavior of Austenite

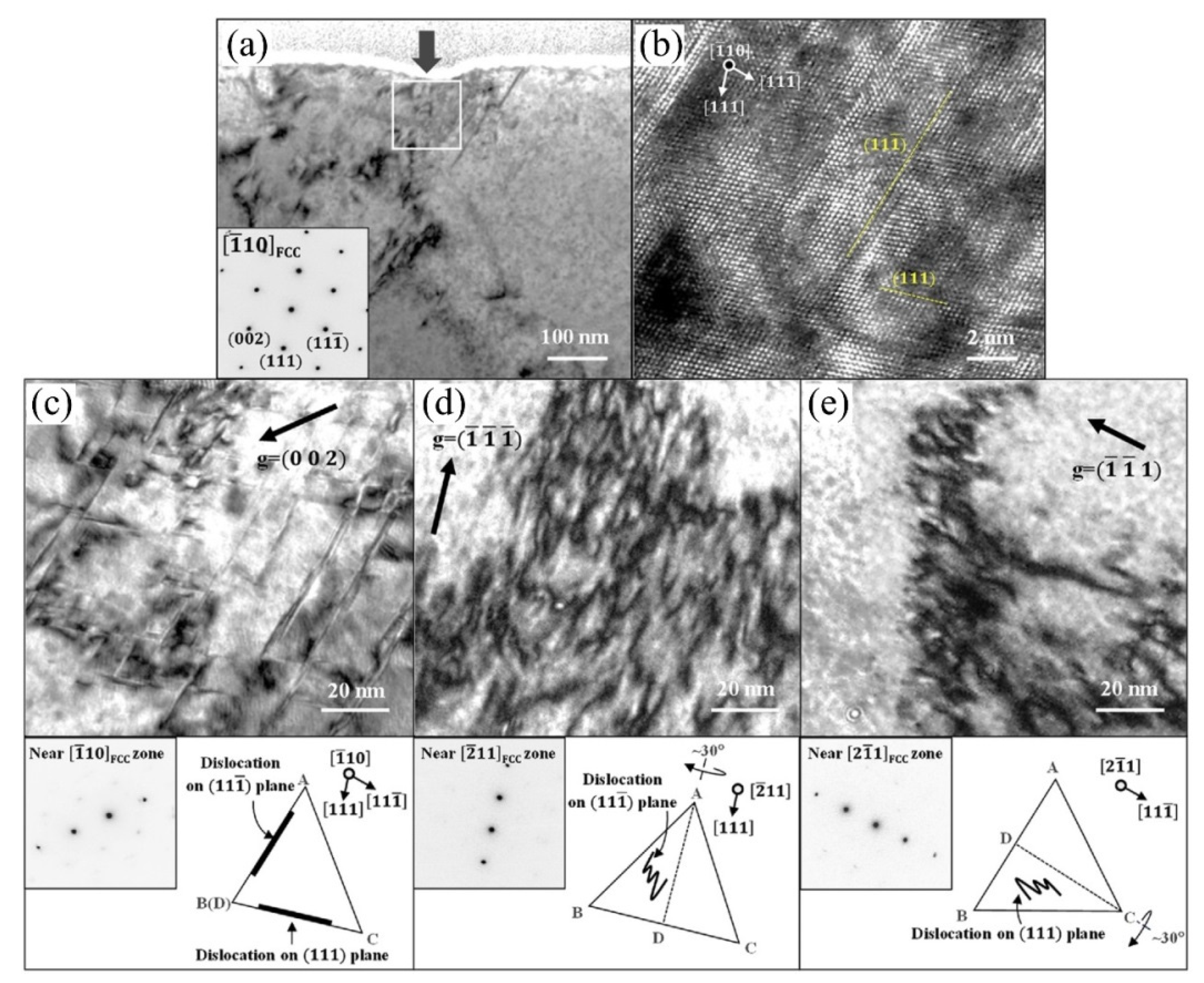

3.1. Dislocation Plasticity

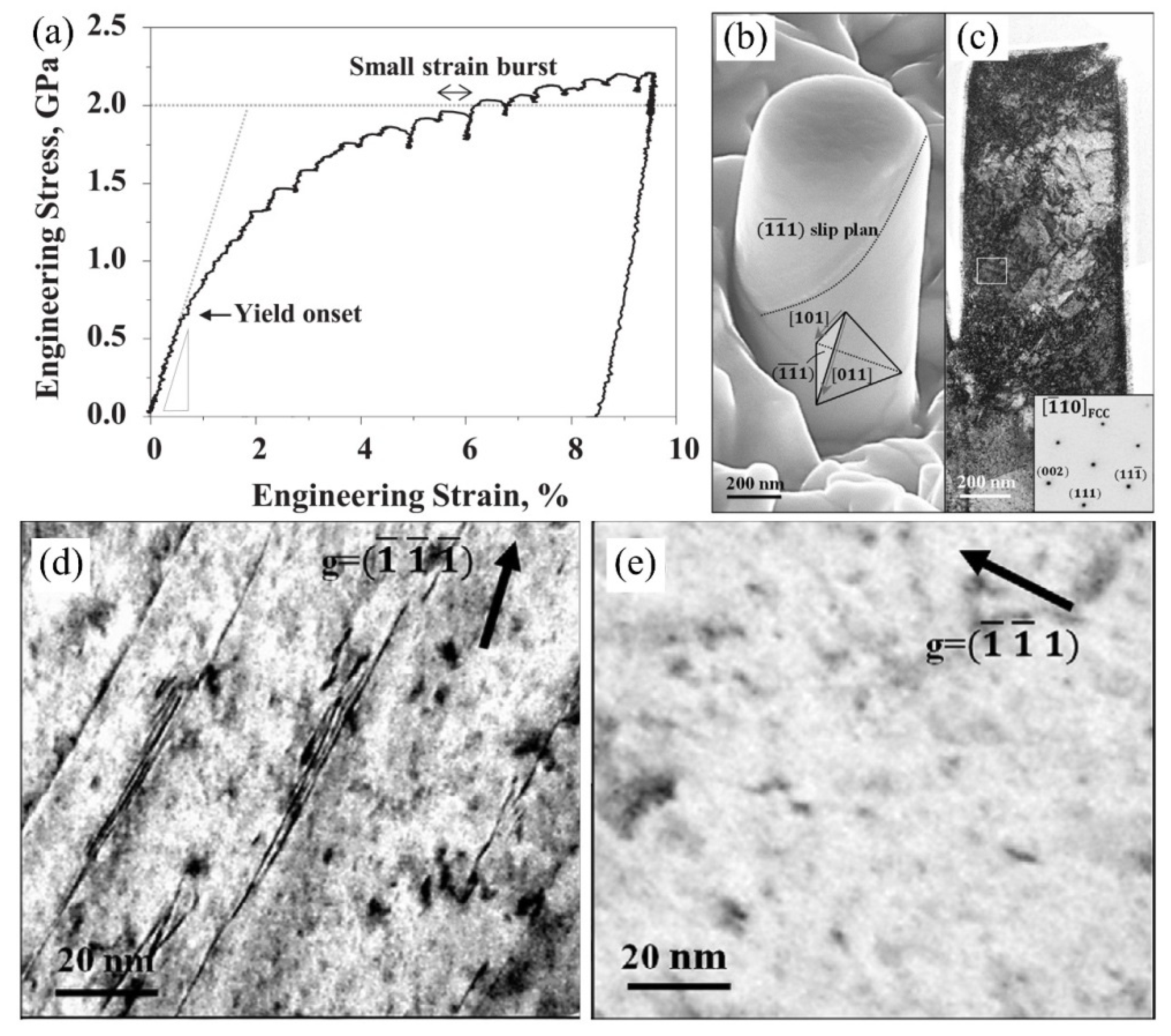

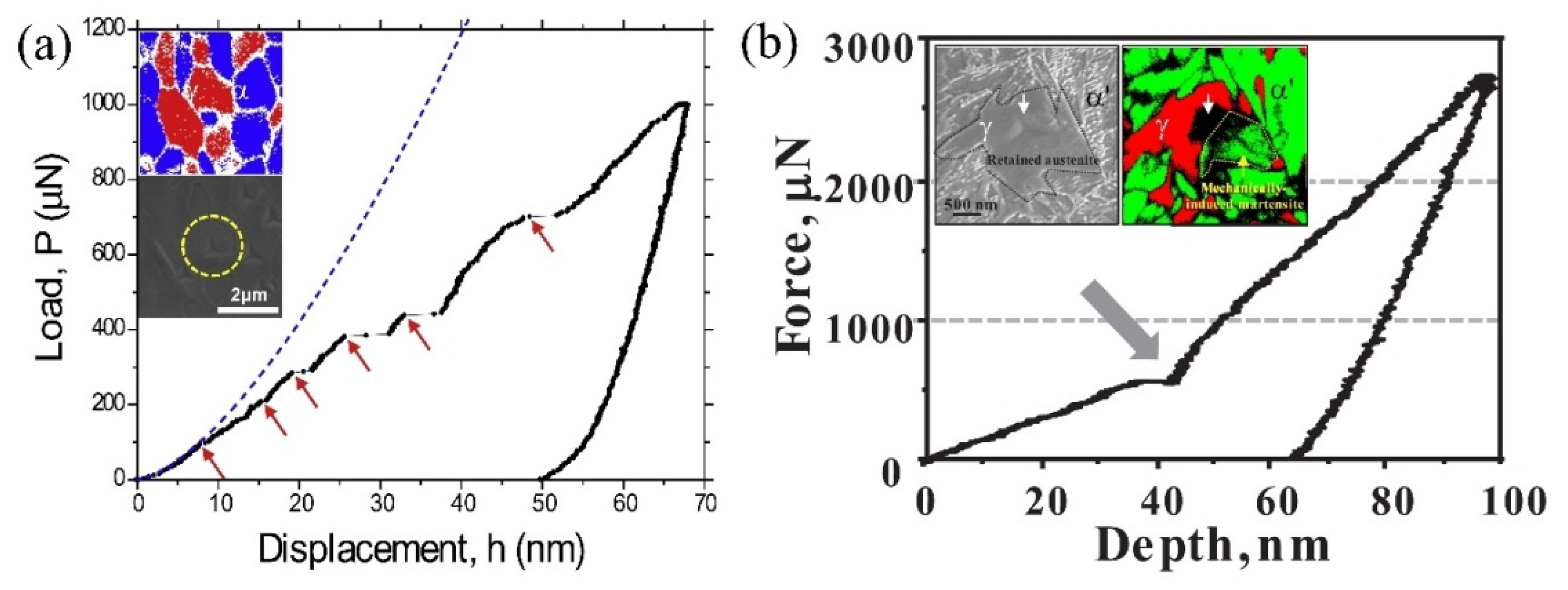

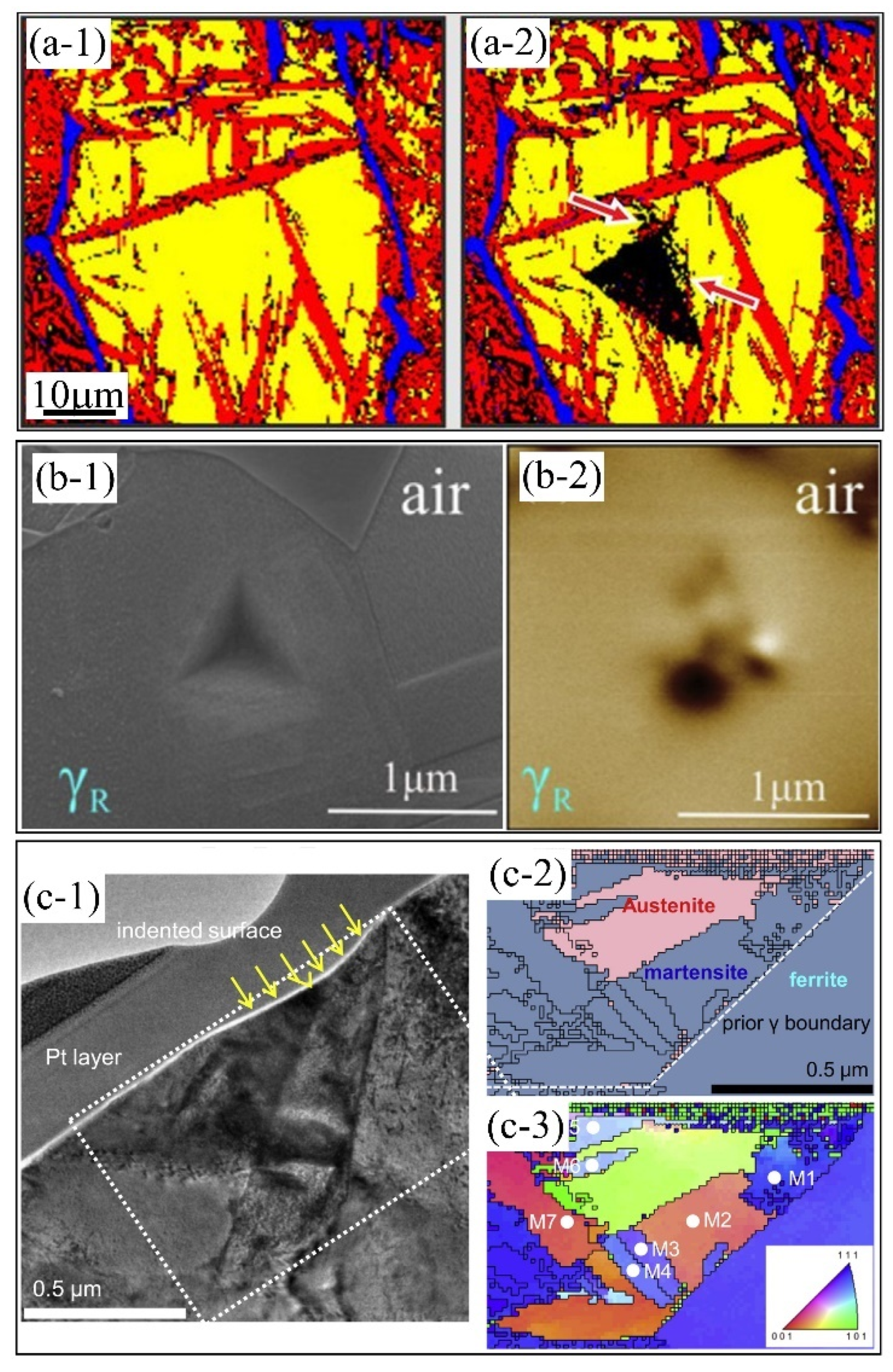

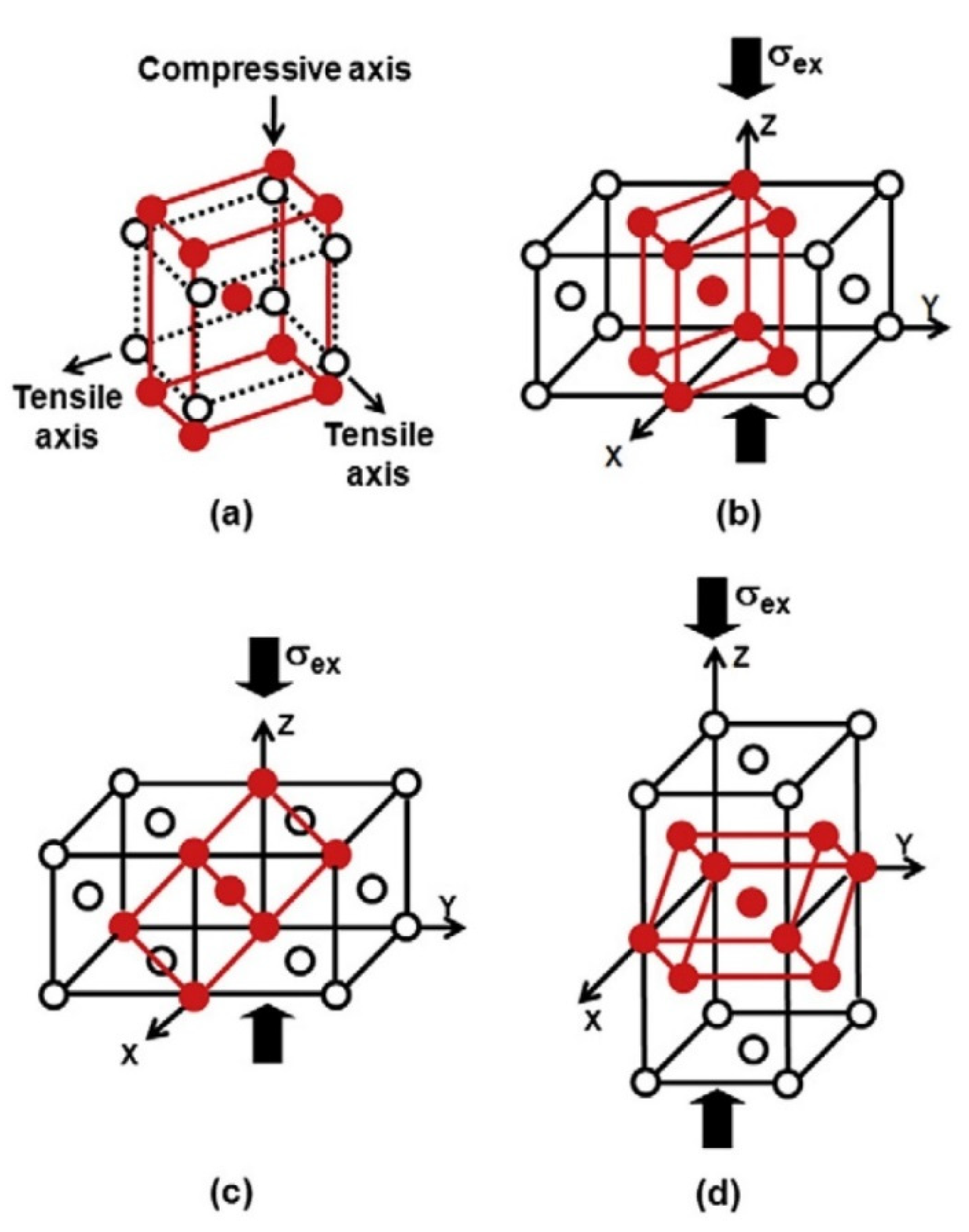

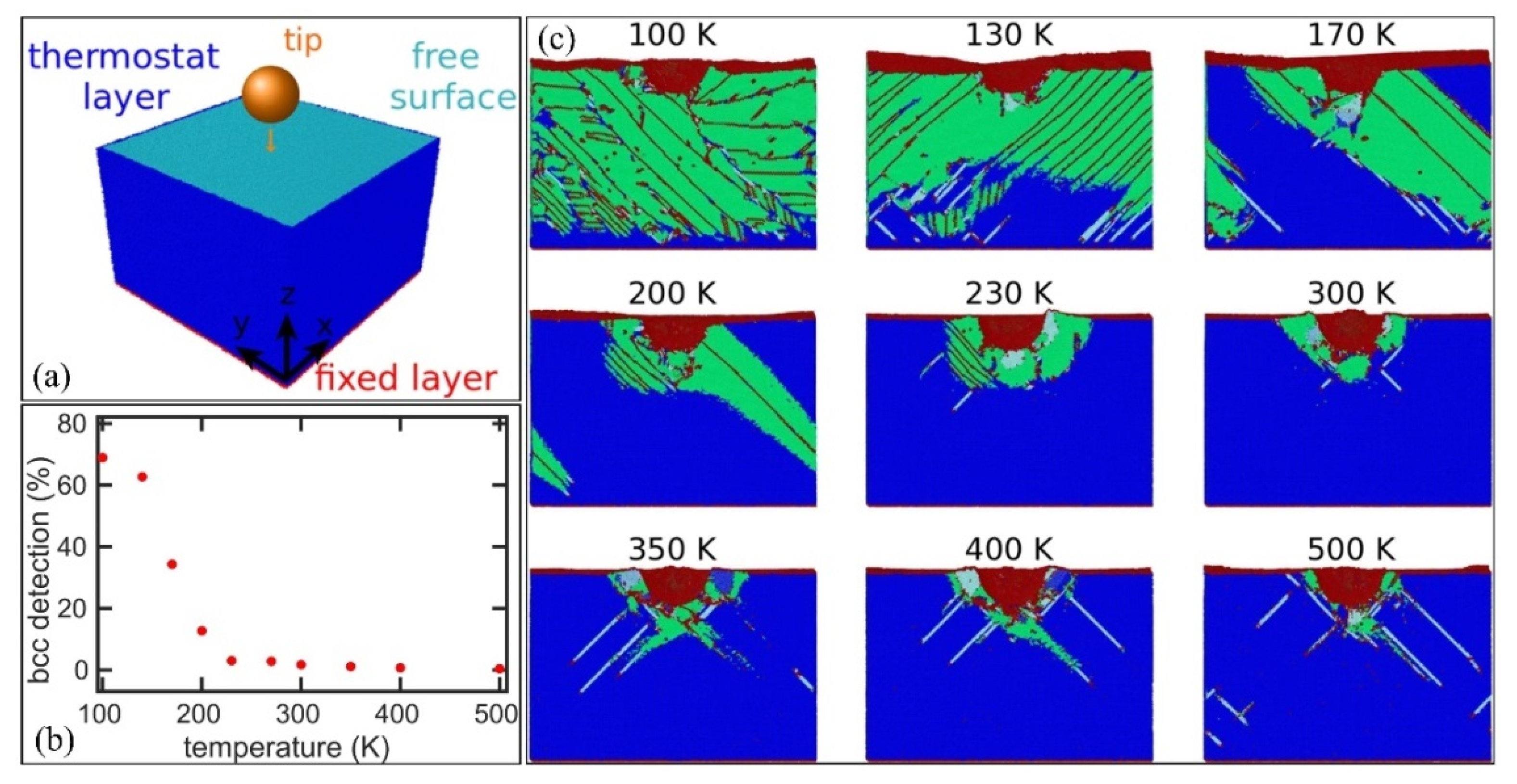

3.2. Martensitic Transformation

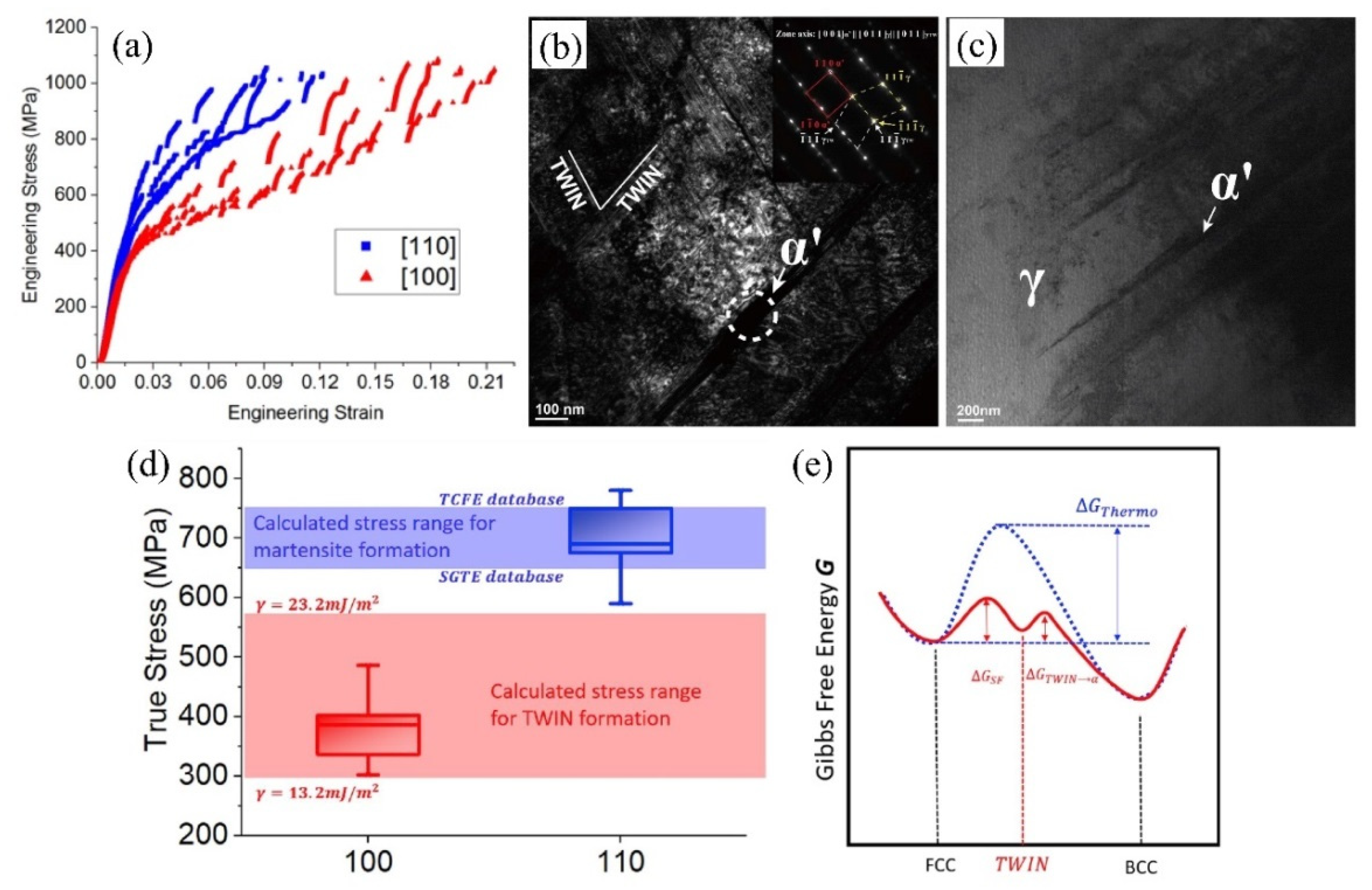

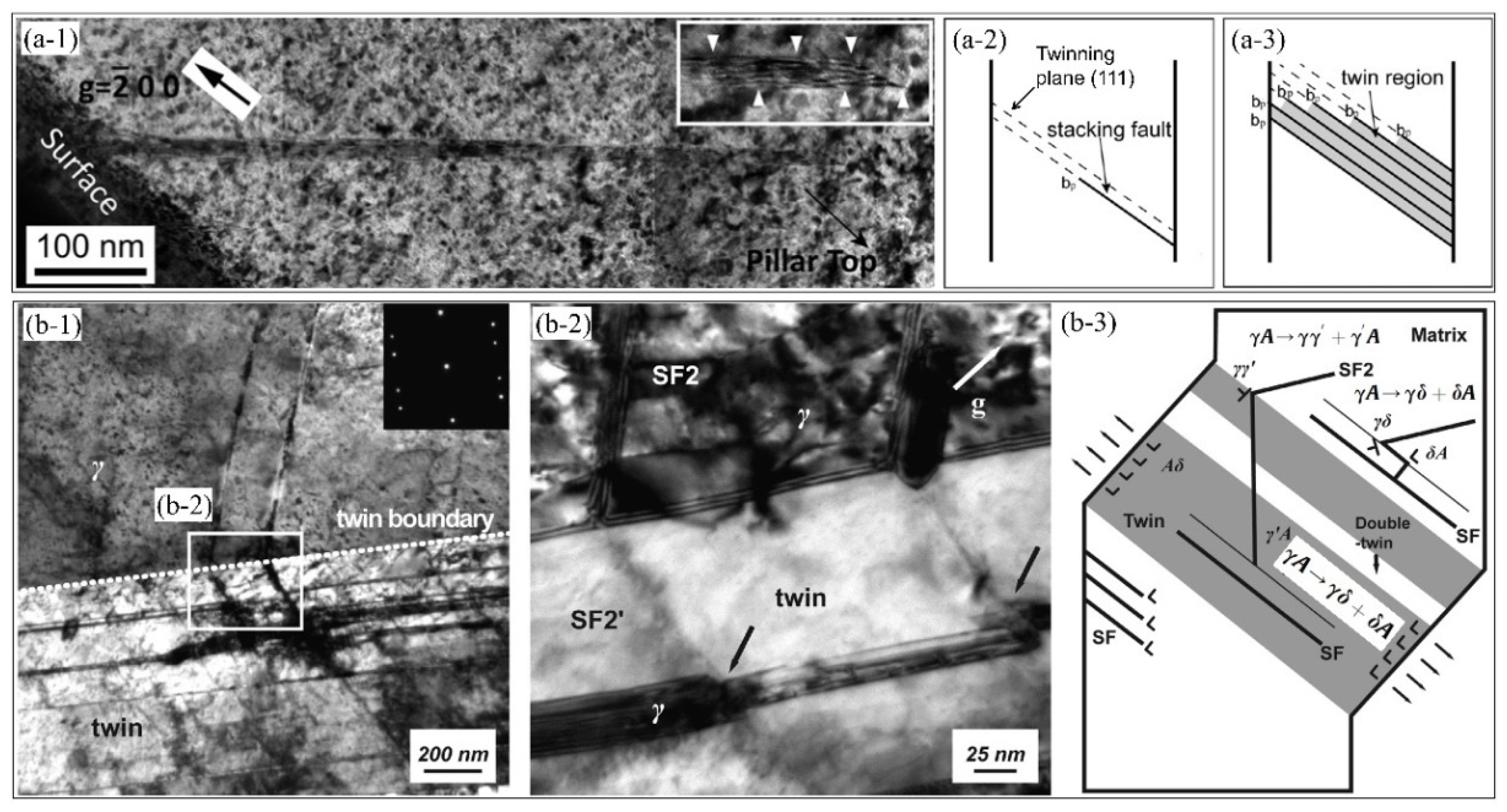

3.3. Deformation Twins

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuziak, R.; Kawalla, R.; Waengler, S. Advanced high strength steels for automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 103–117. [Google Scholar] [CrossRef]

- Bouaziz, O.; Zurob, H.; Huang, M. Driving Force and Logic of Development of Advanced High Strength Steels for Automotive Applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Owen, W.S. Can a simple heat treatment help to save Detroit? Metals Technol. 1980, 7, 1–13. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta. Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Ding, R.; Yao, Y.; Sun, B.; Liu, G.; He, J.; Li, T.; Wan, X.; Dai, Z.; Ponge, D.; Raabe, D. Chemical boundary engineering: A new route toward lean, ultrastrong yet ductile steels. Sci. Adv. 2020, 6, 1430. [Google Scholar] [CrossRef] [Green Version]

- He, B.B.; Hu, B.; Yen, H.W.; Cheng, G.J.; Wang, Z.K.; Luo, H.W.; Huang, M.X. High dislocation density–induced large ductility in deformed and partitioned steels. Science 2017, 357, 1029–1032. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.; Bhadeshia, H.; Mawella, K.; Jones, D.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Sun, X.J.; Wang, M.Q.; Hui, W.J.; Dong, H.; Cao, W.Q. Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite. Scripta. Mater. 2010, 63, 815–818. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.J.; De Cooman, B.C. Austenite stability of ultrafine-grained transformation-induced plasticity steel with Mn partitioning. Scripta. Mater. 2011, 65, 225–228. [Google Scholar] [CrossRef]

- Niikura, M.; Morris, J. Thermal processing of ferritic 5Mn steel for toughness at cryogenic temperatures. MTA. 1980, 11, 1531–1540. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.; De Cooman, B.; Schroth, J. Carbon partitioning into austenite after martensite transformation. Acta. Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Wang, L.; Speer, J.G. Quenching and partitioning steel heat treatment. Metallogr. Microstruct. Anal. 2013, 2, 268–281. [Google Scholar] [CrossRef] [Green Version]

- Luo, H. Comments on “Austenite stability of ultrafine-grained transformation-induced plasticity steel with Mn partitioning” by S. Lee, S.J. Lee and B.C. De Cooman, Scripta Materialia 65 (2011) 225–228. Scripta Mater. 2012, 66, 829–831. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.-J.; De Cooman, B.C. Reply to comments on “Austenite stability of ultrafine-grained transformation-induced plasticity steel with Mn partitioning”. Scripta Mater. 2012, 66, 832–833. [Google Scholar] [CrossRef]

- He, B.B.; Huang, B.M.; He, S.H.; Qi, Y.; Yen, H.W.; Huang, M.X. Increasing yield strength of medium Mn steel by engineering multiple strengthening defects. Mater. Sci. Eng. A 2018, 724, 11–16. [Google Scholar] [CrossRef]

- Lee, S.; De Cooman, B.C. Tensile Behavior of Intercritically Annealed 10 pct Mn Multi-phase Steel. Metall. Mater. Trans. A 2014, 45, 709–716. [Google Scholar] [CrossRef] [Green Version]

- He, B.; Luo, H.; Huang, M. Experimental investigation on a novel medium Mn steel combining transformation-induced plasticity and twinning-induced plasticity effects. Int. J. Plast. 2016, 78, 173–186. [Google Scholar] [CrossRef]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Jacques, P.; Furnémont, Q.; Mertens, A.; Delannay, F. On the sources of work hardening in multiphase steels assisted by transformation-induced plasticity. Philos. Mag. A 2001, 81, 1789–1812. [Google Scholar] [CrossRef]

- Wang, M.M.; Tasan, C.C.; Ponge, D.; Dippel, A.C.; Raabe, D. Nanolaminate transformation-induced plasticity–twinning-induced plasticity steel with dynamic strain partitioning and enhanced damage resistance. Acta Mater. 2015, 85, 216–228. [Google Scholar] [CrossRef]

- Ashby, M.F. The deformation of plastically non-homogeneous materials. Philos. Mag. 1970, 21, 399–424. [Google Scholar] [CrossRef]

- He, B. On the Factors Governing Austenite Stability: Intrinsic versus Extrinsic. Materials 2020, 13, 3440. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; He, B.; Huang, M. The Role of Transformation-Induced Plasticity in the Development of Advanced High Strength Steels. Adv. Eng. Mater. 2018, 20, 1701083. [Google Scholar] [CrossRef]

- Furnémont, Q.; Kempf, M.; Jacques, P.J.; Göken, M.; Delannay, F. On the measurement of the nanohardness of the constitutive phases of TRIP-assisted multiphase steels. Mater. Sci. Eng. A 2002, 328, 26–32. [Google Scholar] [CrossRef]

- Morales-Rivas, L.; González-Orive, A.; Garcia-Mateo, C.; Hernández-Creus, A.; Caballero, F.G.; Vázquez, L. Nanomechanical characterization of nanostructured bainitic steel: Peak Force Microscopy and Nanoindentation with AFM. Sci. Rep. 2015, 5, 17164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, K.; Park, S.-J.; Choi, Y.S.; Kim, S.-J.; Lee, T.-H.; Oh, K.H.; Han, H.N. Dual-scale correlation of mechanical behavior in duplex low-density steel. Scripta Mater. 2013, 69, 618–621. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; Kim, J.K.; Mola, J.; Zhao, L.; De Cooman, B.C. Constituent-specific properties in quenching and partitioning (Q&P) processed steel. Mater. Sci. Eng. A 2019, 740, 439–444. [Google Scholar]

- Park, H.S.; Han, J.C.; Lim, N.S.; Seol, J.-B.; Park, C.G. Nano-scale observation on the transformation behavior and mechanical stability of individual retained austenite in CMnSiAl TRIP steels. Mater. Sci. Eng. A 2015, 627, 262–269. [Google Scholar] [CrossRef]

- Mao, K.S.; Sun, C.; Shiau, C.-H.; Yano, K.H.; Freyer, P.D.; El-Azab, A.A.; Garner, F.A.; French, A.; Shao, L.; Wharry, J.P. Role of cavities on deformation-induced martensitic transformation pathways in a laser-welded, neutron irradiated austenitic stainless steel. Scripta Mater. 2020, 178, 1–6. [Google Scholar] [CrossRef]

- Roa, J.J.; Fargas, G.; Mateo, A.; Jiménez-Piqué, E. Dependence of nanoindentation hardness with crystallographic orientation of austenite grains in metastable stainless steels. Mater. Sci. Eng. A 2015, 645, 188–195. [Google Scholar] [CrossRef]

- Pan, S.; He, B. The respective strain hardening of constituting phases during Lüders deformation of a medium-Mn steel. Philos. Mag. Lett. 2021, 101, 211–221. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T.M. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464. [Google Scholar] [CrossRef]

- Suh, D.-W.; Kim, S.-J. Medium Mn transformation-induced plasticity steels: Recent progress and challenges. Scripta Mater. 2017, 126, 63–67. [Google Scholar] [CrossRef]

- Yi, H.; Sun, L.; Xiong, X. Challenges in the formability of the next generation of automotive steel sheets. Mater. Sci. Technol. 2018, 34, 1112–1117. [Google Scholar] [CrossRef]

- Huang, M.; Liang, Z.; Luo, Z. Critical Assessment 15: Science of deformation and failure mechanisms in twinning induced plasticity steels. Mater. Sci. Technol. 2015, 31, 1265–1270. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Jiang, Z. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- Dai, Z.; Chen, H.; Ding, R.; Lu, Q.; Zhang, C.; Yang, Z.; van der Zwaag, S. Fundamentals and application of solid-state phase transformations for advanced high strength steels containing metastable retained austenite. Mater. Sci. Eng. R Rep. 2021, 143, 100590. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M. An overview of dual-phase steels: Advances in microstructure-oriented processing and micromechanically guided design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Raabe, D.; Sun, B.; Da Silva, A.K.; Gault, B.; Yen, H.-W.; Sedighiani, K.; Sukumar, P.T.; Souza Filho, I.R.; Katnagallu, S.; Jägle, E. Current Challenges and Opportunities in Microstructure-Related Properties of Advanced High-Strength Steels. Metall. Mater. Trans. A 2020, 51, 5517–5586. [Google Scholar] [CrossRef]

- Uchic, M.D.; Dimiduk, D.M.; Florando, J.N.; Nix, W.D. Sample dimensions influence strength and crystal plasticity. Science 2004, 305, 986–989. [Google Scholar] [CrossRef]

- Xiong, X.C.; Chen, B.; Huang, M.X.; Wang, J.F.; Wang, L. The effect of morphology on the stability of retained austenite in a quenched and partitioned steel. Scripta Mater. 2013, 68, 321–324. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Edmonds, D. The mechanism of bainite formation in steels. Acta Metall. 1980, 28, 1265–1273. [Google Scholar] [CrossRef]

- Greenwood, G.W.; Johnson, R.H. The Deformation of Metals Under Small Stresses During Phase Transformations. Proc. R. Soc. Lond. A 1965, 283, 403–422. [Google Scholar]

- He, B.B.; Wang, M.; Huang, M.X. Improving Tensile Properties of Room-Temperature Quenching and Partitioning Steel by Dislocation Engineering. Metall. Mater. Trans. A 2019, 50, 4021–4026. [Google Scholar] [CrossRef]

- Han, J.; Lee, S.-J.; Jung, J.-G.; Lee, Y.-K. The effects of the initial martensite microstructure on the microstructure and tensile properties of intercritically annealed Fe–9Mn–0.05 C steel. Acta Mater. 2014, 78, 369–377. [Google Scholar] [CrossRef]

- Han, Q.; Zhang, Y.; Wang, L. Effect of annealing time on microstructural evolution and deformation characteristics in 10Mn1. 5Al TRIP steel. Metall. Mater. Trans. A 2015, 46, 1917–1926. [Google Scholar] [CrossRef]

- Chbihi, A.; Barbier, D.; Germain, L.; Hazotte, A.; Gouné, M. Interactions between ferrite recrystallization and austenite formation in high-strength steels. J. Mater. Sci. 2014, 49, 3608–3621. [Google Scholar] [CrossRef]

- Lawrynowicz, Z. Carbon partitioning during bainite transformation in low alloy steels. Mater. Sci. Technol. 2002, 18, 1322–1324. [Google Scholar] [CrossRef]

- Bracke, L.; Verbeken, K.; Kestens, L.; Penning, J. Microstructure and texture evolution during cold rolling and annealing of a high Mn TWIP steel. Acta Mater. 2009, 57, 1512–1524. [Google Scholar] [CrossRef]

- Haase, C.; Ingendahl, T.; Güvenç, O.; Bambach, M.; Bleck, W.; Molodov, D.A.; Barrales-Mora, L.A. On the applicability of recovery-annealed twinning-induced plasticity steels: Potential and limitations. Mater. Sci. Eng. A 2016, 649, 74–84. [Google Scholar] [CrossRef]

- Xiong, T.; Zheng, S.; Zhou, Y.; Pang, J.; Jin, Q.; Ge, H.; Zheng, X.; Yang, L.; Beyerlein, I.; Ma, X. Enhancing strength and thermal stability of TWIP steels with a heterogeneous structure. Mater. Sci. Eng. A 2018, 720, 231–237. [Google Scholar] [CrossRef]

- Zhou, P.; Liang, Z.Y.; Liu, R.D.; Huang, M.X. Evolution of dislocations and twins in a strong and ductile nanotwinned steel. Acta Mater. 2016, 111, 96–107. [Google Scholar] [CrossRef]

- Liu, L.; He, B.; Cheng, G.; Yen, H.; Huang, M. Optimum properties of quenching and partitioning steels achieved by balancing fraction and stability of retained austenite. Scripta Mater. 2018, 150, 1–6. [Google Scholar] [CrossRef]

- Gong, W.; Tomota, Y.; Harjo, S.; Su, Y.H.; Aizawa, K. Effect of prior martensite on bainite transformation in nanobainite steel. Acta Mater. 2015, 85, 243–249. [Google Scholar] [CrossRef]

- Beladi, H.; Tari, V.; Timokhina, I.B.; Cizek, P.; Rohrer, G.S.; Rollett, A.D.; Hodgson, P.D. On the crystallographic characteristics of nanobainitic steel. Acta Mater. 2017, 127, 426–437. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; He, B.; Liu, C.; Jiang, C.; Huang, M. Extraordinary Lüders-strain-rate in medium Mn steels. Materialia 2019, 6, 100288. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Cao, Z.H.; Lu, J.; Huang, M.X.; Tasan, C.C. Influence of co-existing medium Mn and dual phase steel microstructures on ductility and Lüders band formation. Acta Mater. 2021, 117418. [Google Scholar] [CrossRef]

- Liang, Z.; Wang, X.; Huang, W.; Huang, M. Strain rate sensitivity and evolution of dislocations and twins in a twinning-induced plasticity steel. Acta Mater. 2015, 88, 170–179. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Li, Y.Z.; Huang, M.X. The respective hardening contributions of dislocations and twins to the flow stress of a twinning-induced plasticity steel. Scripta Mater. 2016, 112, 28–31. [Google Scholar] [CrossRef]

- Mahajan, S.; Chin, G. Formation of deformation twins in fcc crystals. Acta Metall. 1973, 21, 1353–1363. [Google Scholar] [CrossRef]

- Hung, C.-Y.; Bai, Y.; Shimokawa, T.; Tsuji, N.; Murayama, M. A correlation between grain boundary character and deformation twin nucleation mechanism in coarse-grained high-Mn austenitic steel. Sci. Rep. 2021, 11, 8468. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387, 158–162. [Google Scholar] [CrossRef]

- Dumay, A.; Chateau, J.-P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe–Mn–C steel. Mater. Sci. Eng. A 2008, 483, 184–187. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.-T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. A general mechanism of martensitic nucleation: Part II. FCC → BCC and other martensitic transformations. Metall. Mater. Trans. A 1976, 7, 1905–1914. [Google Scholar]

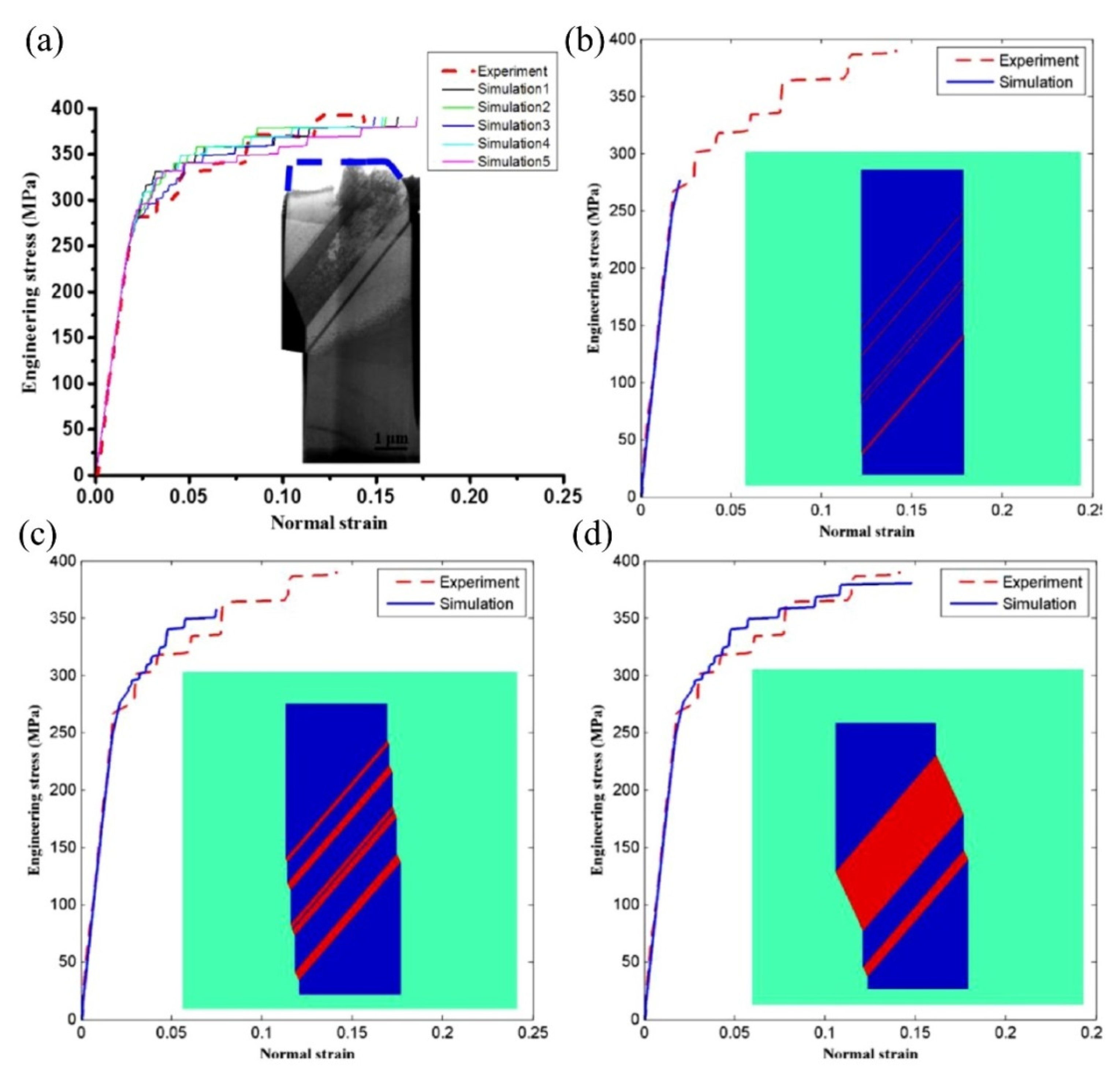

- Liang, Z.; Huang, M. Deformation twinning in small-sized face-centred cubic single crystals: Experiments and modelling. J. Mech. Phys. Solids 2015, 85, 128–142. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Chiu, Y.L.; Ngan, A.H.W. A TEM investigation on indentation plastic zones in Ni3Al(Cr,B) single crystals. Acta Mater. 2002, 50, 2677–2691. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Choi, W.S.; Sandlöbes, S.; Malyar, N.V.; Kirchlechner, C.; Korte-Kerzel, S.; Dehm, G.; De Cooman, B.C.; Raabe, D. Dislocation interaction and twinning-induced plasticity in face-centered cubic Fe-Mn-C micro-pillars. Acta Mater. 2017, 132, 162–173. [Google Scholar] [CrossRef]

- Honeycombe, R. The Plastic Deformation of Metals; Edward Arnold Ltd.: London, UK, 1984. [Google Scholar]

- Soer, W.A.; Aifantis, K.E.; De Hosson, J.T.M. Incipient plasticity during nanoindentation at grain boundaries in body-centered cubic metals. Acta Mater. 2005, 53, 4665–4676. [Google Scholar] [CrossRef] [Green Version]

- Durst, K.; Backes, B.; Franke, O.; Göken, M. Indentation size effect in metallic materials: Modeling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 2006, 54, 2547–2555. [Google Scholar] [CrossRef]

- Durst, K.; Franke, O.; Böhner, A.; Göken, M. Indentation size effect in Ni–Fe solid solutions. Acta Materialia 2007, 55, 6825–6833. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Ohmura, T.; Minor, A.; Stach, E.; Morris, J. Dislocation–grain boundary interactions in martensitic steel observed through in situ nanoindentation in a transmission electron microscope. J. Mater. Res. 2004, 19, 3626–3632. [Google Scholar] [CrossRef]

- Seo, E.J.; Kim, J.K.; Cho, L.; Mola, J.; Oh, C.Y.; De Cooman, B.C. Micro-plasticity of medium Mn austenitic steel: Perfect dislocation plasticity and deformation twinning. Acta Mater. 2017, 135, 112–123. [Google Scholar] [CrossRef]

- Kurdjumov, G.V.; Sachs, G. Over the mechanisms of steel hardening. Z. Physik 1930, 64, 325–343. [Google Scholar]

- Wassermann, G.; Mitt, K. About the mechanism of α–γ transformation of the iron. Wilh. Inst. Eisenforsch 1935, 17, 149. [Google Scholar]

- He, B.; Pan, S. Revealing the intrinsic nanohardness of retained austenite grain in a medium Mn steel with heterogeneous structure. Mater. Charact. 2021, 171, 110745. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O. A physical model of the twinning-induced plasticity effect in a high manganese austenitic steel. Mater. Sci. Eng. A 2004, 387, 143–147. [Google Scholar] [CrossRef]

- Nimaga, O.; Cheng, G.; Yen, H.; Huang, M. Large strain burst induced by martensitic transformation in austenitic micropillars. Scripta Mater. 2017, 137, 64–68. [Google Scholar] [CrossRef]

- Nimaga, O.; He, B.; Cheng, G.; Yen, H.; Huang, M. Revealing orientation-dependent martensitic transformation in a medium Mn steel by micropillar compression. Int. J. Plast. 2019, 123, 165–177. [Google Scholar] [CrossRef]

- Csikor, F.F.; Motz, C.; Weygand, D.; Zaiser, M.; Zapperi, S. Dislocation avalanches, strain bursts, and the problem of plastic forming at the micrometer scale. Science 2007, 318, 251–254. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kirchlechner, C.; Keckes, J.; Motz, C.; Grosinger, W.; Kapp, M.W.; Micha, J.-S.; Ulrich, O.; Dehm, G. Impact of instrumental constraints and imperfections on the dislocation structure in micron-sized Cu compression pillars. Acta Mater. 2011, 59, 5618–5626. [Google Scholar] [CrossRef]

- Choi, W.S.; De Cooman, B.C.; Sandlöbes, S.; Raabe, D. Size and orientation effects in partial dislocation-mediated deformation of twinning-induced plasticity steel micro-pillars. Acta Mater. 2015, 98, 391–404. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, D.-I.; Kim, H.S.; Bhadeshia, H.K.D.H.; Suh, D.-W. Strain partitioning and mechanical stability of retained austenite. Scripta Mater. 2010, 63, 297–299. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC → HCP transformation. Metall. Mater. Trans. A 1976, 7, 1897–1904. [Google Scholar]

- Lehnert, R.; Weidner, A.; Motylenko, M.; Biermann, H. Strain hardening of phases in high-alloy CrMnNi steel as a consequence of pre-deformation studied by nanoindentation. Adv. Eng. Mater. 2019, 21, 1800801. [Google Scholar] [CrossRef]

- Kim, Y.; Ahn, T.-H.; Suh, D.-W.; Han, H.N. Variant selection during mechanically induced martensitic transformation of metastable austenite by nanoindentation. Scripta Mater. 2015, 104, 13–16. [Google Scholar] [CrossRef]

- He, B.B.; Shang, X.K. Stress-induced martensitic transformation in metastable austenite grains during nanoindentation investigation. Philos. Mag. Lett. 2021, 101, 1–15. [Google Scholar] [CrossRef]

- He, B.; Pan, S. Correlation between Martensitic Transformation and Strain Burst in Retained Austenite Grains During Nanoindentation Investigation. Met. Mater. Int. 2021, 16, 1–6. [Google Scholar] [CrossRef]

- Zeisig, J.; Hufenbach, J.; Wendrock, H.; Gemming, T.; Eckert, J.; Kühn, U. A study of the micro-and nanoscale deformation behavior of individual austenitic dendrites in a FeCrMoVC cast alloy using micro-and nanoindentation experiments. Appl. Phys. Lett. 2016, 108, 143103. [Google Scholar] [CrossRef]

- He, B.B.; Huang, M.X.; Liang, Z.Y.; Ngan, A.H.W.; Luo, H.W.; Shi, J.; Cao, W.Q.; Dong, H. Nanoindentation investigation on the mechanical stability of individual austenite grains in a medium-Mn transformation-induced plasticity steel. Scripta Mater. 2013, 69, 215–218. [Google Scholar] [CrossRef]

- Ahn, T.H.; Oh, C.S.; Kim, D.H.; Oh, K.H.; Bei, H.; George, E.P.; Han, H.N. Investigation of strain-induced martensitic transformation in metastable austenite using nanoindentation. Scripta Mater. 2010, 63, 540–543. [Google Scholar] [CrossRef]

- Babu, R.P.; Irukuvarghula, S.; Harte, A.; Preuss, M. Nature of gallium focused ion beam induced phase transformation in 316L austenitic stainless steel. Acta Mater. 2016, 120, 391–402. [Google Scholar] [CrossRef]

- Knipling, K.; Rowenhorst, D.; Fonda, R.; Spanos, G. Effects of focused ion beam milling on austenite stability in ferrous alloys. Mater. Charact. 2010, 61, 1–6. [Google Scholar] [CrossRef]

- He, B.B.; Huang, M.X.; Ngan, A.H.W.; Van Der Zwaag, S. Effect of Free Surface on the Stability of Individual Retained Austenite Grains in a Duplex Stainless Steel. Metall. Mater. Trans. A 2014, 45, 4875–4881. [Google Scholar] [CrossRef]

- Gadelrab, K.R.; Li, G.; Chiesa, M.; Souier, T. Local characterization of austenite and ferrite phases in duplex stainless steel using MFM and nanoindentation. J. Mater. Res. 2012, 27, 1573. [Google Scholar] [CrossRef] [Green Version]

- Sort, J.; Concustell, A.; Menéndez, E.; Suriñach, S.; Baró, M.; Farran, J.; Nogués, J. Selective generation of local ferromagnetism in austenitic stainless steel using nanoindentation. Appl. Phys. Lett. 2006, 89, 032509. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Ma, Y.; Zamanzade, M.; Deng, Y.; Wang, D.; Bleck, W.; Song, W.; Barnoush, A. Insight into hydrogen effect on a duplex medium-Mn steel revealed by in-situ nanoindentation test. Int. J. Hydrog. Energy 2019, 44, 20545–20551. [Google Scholar] [CrossRef]

- Pöhl, F. Local deformation and transformation behavior of retained austenite in 18CrNiMo7-6 after high-carbon carburizing treatment. Mater. Charact. 2020, 167, 110446. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C.; Nicholson, D. Nanoindentation. Mechanical engineering series. Appl. Mech. Rev. 2004, 57, B12. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, R. Steels: Microstructure and Properties, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2006. [Google Scholar]

- Patel, J.R.; Cohen, M. Criterion for the action of applied stress in the martensitic transformation. Acta Metall. 1953, 1, 531–538. [Google Scholar] [CrossRef]

- Meng, Q.; Rong, Y.; Hsu, T. Effect of internal stress on autocatalytic nucleation of martensitic transformation. Metall. Mater. Trans. A 2006, 37, 1405–1411. [Google Scholar] [CrossRef]

- Wechsler, M.S. On the theory of the formation of martensite. Trans. Aime. 1953, 197, 1503–1515. [Google Scholar]

- Takashima, K.; Higo, Y.; Nunomura, S. The propagation velocity of the martensitic transformation in 304 stainless steel. Philos. Mag. A 1984, 49, 231–241. [Google Scholar] [CrossRef]

- Meiser, J.; Alhafez, I.A.; Beck, T.; Smaga, M.; Müller, R.; Urbassek, H.M. Nanoindentation into a metastable austenite triggers the martensitic phase transformation—An atomistic study. AIP Adv. 2019, 9, 015228. [Google Scholar] [CrossRef] [Green Version]

- Hossain, R.; Pahlevani, F.; Sahajwalla, V. Stability of retained austenite in high carbon steel–Effect of post-tempering heat treatment. Mater. Charact. 2019, 149, 239–247. [Google Scholar] [CrossRef]

- Lu, X.; Li, W.; Zhao, H.; Jin, X. Local plastic indentation resistance of retained austenite in bearing steel. ISIJ Int. 2016, 56, 851–854, ISIJINT-2015-480. [Google Scholar]

- He, B.B.; Huang, M.X. Revealing heterogeneous C partitioning in a medium Mn steel by nanoindentation. Mater. Sci. Technol. 2017, 33, 552–558. [Google Scholar] [CrossRef]

- Sabooni, S.; Aghaei, Z.; Karimzadeh, F.; Enayati, M.H.; Ngan, A.H.W. Austenite Stability during Nanoindentation of Ultrafine and Coarse Grained AISI 304L Stainless Steels. Int. J. Iron Steel Soc. Iran 2014, 11, 1–5. [Google Scholar]

- Sadeghpour, S.; Kermanpur, A.; Najafizadeh, A. Investigation of the effect of grain size on the strain-induced martensitic transformation in a high-Mn stainless steel using nanoindentation. Mater. Sci. Eng. A 2014, 612, 214–216. [Google Scholar] [CrossRef]

- Man, T.; Ohmura, T.; Tomota, Y. Mechanical behavior of individual retained austenite grains in high carbon quenched-tempered steel. ISIJ Int. 2019, 59, 559–566. [Google Scholar] [CrossRef] [Green Version]

- Misra, R.; Zhang, Z.; Jia, Z.; Somani, M.; Karjalainen, L. Probing deformation processes in near-defect free volume in high strength–high ductility nanograined/ultrafine-grained (NG/UFG) metastable austenitic stainless steels. Scripta Mater. 2010, 63, 1057–1060. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. A mechanism for the strain-induced nucleation of martensitic transformations. J. Less Common Met. 1972, 28, 107–118. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Mater. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Taboada, M.; Elizalde, M.; Jorge-Badiola, D. Austempering in low-C steels: Microstructure development and nanohardness characterization. J. Mater. Sci. 2019, 54, 5044–5060. [Google Scholar] [CrossRef]

- Weidner, A.; Hangen, U.D.; Biermann, H. Nanoindentation measurements on deformation-induced α’-martensite in a metastable austenitic high-alloy CrMnNi steel. Philos. Mag. Lett. 2014, 94, 522. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Yoo, B.-G.; Choi, I.-C.; Seok, M.-Y.; Kim, J.-Y.; Ohmura, T.; Jang, J.-i. Martensitic phase transformation and pop-in in compression of austenitic steel nanoplates observed in situ by transmission electron microscopy. Mater. Lett. 2012, 75, 107–110. [Google Scholar] [CrossRef]

- Wu, S.; Liang, Z.; He, B.; Huang, M. Martensitic Transformation in Micron-Sized Fcc Single Crystals. Metall. Mater. Trans. A 2014, 45, 4731–4736. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A Perspective on Martensitic Nucleation. Annu. Rev. Mater. Sci. 1981, 11, 1–32. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; De Cooman, B.C. Influence of Intra-granular Ferrite on the Tensile Behavior of Intercritically Annealed 12 pct Mn TWIP+ TRIP Steel. Metall. Mater. Trans. A 2015, 46, 1012–1018. [Google Scholar] [CrossRef]

- Lee, S.; Lee, K.; De Cooman, B.C. Observation of the TWIP+ TRIP Plasticity-Enhancement Mechanism in Al-Added 6 Wt Pct Medium Mn Steel. Metall. Mater. Trans. A 2015, 46, 2356–2363. [Google Scholar] [CrossRef]

- Bouaziz, O.; Guelton, N. Modelling of TWIP effect on work-hardening. Mater. Sci. Eng. A 2001, 319, 246–249. [Google Scholar] [CrossRef]

- Bouaziz, O. Strain-hardening of twinning-induced plasticity steels. Scripta Mater. 2012, 66, 982–985. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Salem, A.A.; Doherty, R.D. Role of deformation twinning on strain hardening in cubic and hexagonal polycrystalline metals. Adv. Eng. Mater. 2003, 5, 229–232. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Dislocation and twin substructure evolution during strain hardening of an Fe–22wt.% Mn–0.6 wt.% C TWIP steel observed by electron channeling contrast imaging. Acta Mater. 2011, 59, 6449–6462. [Google Scholar] [CrossRef]

- Steinmetz, D.R.; Jäpel, T.; Wietbrock, B.; Eisenlohr, P.; Gutierrez-Urrutia, I.; Saeed–Akbari, A.; Hickel, T.; Roters, F.; Raabe, D. Revealing the strain-hardening behavior of twinning-induced plasticity steels: Theory, simulations, experiments. Acta Mater. 2013, 61, 494–510. [Google Scholar] [CrossRef]

- Luo, Z.C.; Huang, M.X. The role of interstitial carbon atoms on the strain-hardening rate of twinning-induced plasticity steels. Scripta Mater. 2020, 178, 264–268. [Google Scholar] [CrossRef]

- Luo, Z.C.; Huang, M.X. Revisit the role of deformation twins on the work-hardening behaviour of twinning-induced plasticity steels. Scripta Mater. 2018, 142, 28–31. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chao, C.-G. Effects of carbon contents on the tensile properties and deformed microstructures of austentitic Fe-28Mn-9Al-XC alloys. Scripta Metall. Mater. 1992, 27, 1229–1234. [Google Scholar] [CrossRef]

- Kang, S.; Jung, Y.-S.; Yoo, B.-G.; Jang, J.-i.; Lee, Y.-K. Orientation-dependent indentation modulus and yielding in a high Mn twinning-induced plasticity steel. Mater. Sci. Eng. A 2012, 532, 500–504. [Google Scholar] [CrossRef]

- Liang, Z.; Huang, M. Effects of Crystal Orientation on Deformation Twinning and Dislocation Slip in Single Crystal Micro-pillars of a Twinning-Induced Plasticity Steel. Metall. Mater. Trans. A 2021, 1–8. [Google Scholar] [CrossRef]

- Wu, S.Z.; Yen, H.W.; Huang, M.X.; Ngan, A.H.W. Deformation twinning in submicron and micron pillars of twinning-induced plasticity steel. Scripta Mater. 2012, 67, 641–644. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Liang, Z.Y.; De Hosson, J.T.M.; Huang, M.X. Size effect on deformation twinning in face-centred cubic single crystals: Experiments and modelling. Acta Mater. 2017, 129, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Greer, J.R.; Oliver, W.C.; Nix, W.D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 2005, 53, 1821–1830. [Google Scholar] [CrossRef]

- Greer, J.R.; Nix, W.D. Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 2006, 73, 245410. [Google Scholar] [CrossRef] [Green Version]

- Parthasarathy, T.A.; Rao, S.I.; Dimiduk, D.M.; Uchic, M.D.; Trinkle, D.R. Contribution to size effect of yield strength from the stochastics of dislocation source lengths in finite samples. Scripta Mater. 2007, 56, 313–316. [Google Scholar] [CrossRef]

- Volkert, C.A.; Lilleodden, E.T. Size effects in the deformation of sub-micron Au columns. Philos. Mag. 2006, 86, 5567–5579. [Google Scholar] [CrossRef]

- Kiener, D.; Zhang, Z.; Šturm, S.; Cazottes, S.; Imrich, P.J.; Kirchlechner, C.; Dehm, G. Advanced nanomechanics in the TEM: Effects of thermal annealing on FIB prepared Cu samples. Philos. Mag. 2012, 92, 3269–3289. [Google Scholar] [CrossRef]

- Marien, J.; Plitzko, J.; Spolenak, R.; Keller, R.; Mayer, J. Quantitative electron spectroscopic imaging studies of microelectronic metallization layers. J. Microsc. 1999, 194, 71–78. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, J.; Kim, Y.; Han, S.M.; Kiener, D.; Oh, S.H. FIB-induced dislocations in Al submicron pillars: Annihilation by thermal annealing and effects on deformation behavior. Acta Mater. 2016, 110, 283–294. [Google Scholar] [CrossRef]

- Karnthaler, H.P.; Wintner, E. Weak beam Tem studies of composite dislocations in f.c.c. alloys. Acta Metall. 1975, 23, 1501–1509. [Google Scholar] [CrossRef]

- Cohen, J.B.; Weertman, J. A dislocation model for twinning in f.c.c. metals. Acta Metall. 1963, 11, 996–998. [Google Scholar] [CrossRef]

- Cheng, G.; Choi, K.S.; Hu, X.; Sun, X. Determining individual phase properties in a multi-phase Q&P steel using multi-scale indentation tests. Mater. Sci. Eng. A 2016, 652, 384–395. [Google Scholar]

- Jeong, H.J.; Lim, N.S.; Lee, B.H.; Park, C.G.; Lee, S.; Kang, S.-H.; Lee, H.W.; Kim, H.S. Local and Global Stress–Strain Behaviors of Transformation-Induced Plasticity Steel Using the Combined Nanoindentation and Finite Element Analysis Method. Metall. Mater. Trans. A 2014, 45, 6008–6015. [Google Scholar] [CrossRef] [Green Version]

- Roa, J.; Sapezanskaia, I.; Fargas, G.; Kouitat, R.; Redjaïmia, A.; Mateo, A. Dynamic deformation of metastable austenitic stainless steels at the nanometric length scale. Metall. Mater. Trans. A 2018, 49, 6034–6039. [Google Scholar] [CrossRef]

- Roa, J.; Sapezanskaia, I.; Fargas, G.; Kouitat, R.; Redjaïmia, A.; Mateo, A. Influence of testing mode on the fatigue behavior of<111> austenitic grain at the nanometric length scale for TRIP steels. Mater. Sci. Eng. A 2018, 713, 287–293. [Google Scholar]

- Roa, J.J.; Sapezanskaia, I.; Fargas, G.; Kouitat, R.; Redjaïmia, A.; Mateo, A.M. Reversible phase transformation in polycrystalline TRIP steels induced by cyclic indentation performed at the nanometric length scale. Steel Res. Int. 2018, 89, 1800234. [Google Scholar] [CrossRef]

- Chavoshi, S.Z.; Xu, S. Temperature-dependent nanoindentation response of materials. MRS Commun. 2018, 8, 15–28. [Google Scholar] [CrossRef] [Green Version]

- He, B.B.; Wang, M.; Liu, L.; Huang, M.X. High-strength medium Mn quenching and partitioning steel with low yield ratio. Mater. Sci. Technol. 2019, 35, 1–6. [Google Scholar] [CrossRef]

- Sun, L.; He, X.; Lu, J. Nanotwinned and hierarchical nanotwinned metals: A review of experimental, computational and theoretical efforts. npj Comput. Mater. 2018, 4, 6. [Google Scholar] [CrossRef]

- Choi, W.S.; Sandlöbes, S.; Malyar, N.V.; Kirchlechner, C.; Korte-Kerzel, S.; Dehm, G.; Choi, P.-P.; Raabe, D. On the nature of twin boundary-associated strengthening in Fe-Mn-C steel. Scripta Mater. 2018, 156, 27–31. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, Q.; Lu, W.; He, B. Recent Progress in Understanding the Nano/Micro-Mechanical Behavior of Austenite in Advanced High Strength Steels. Metals 2021, 11, 1927. https://doi.org/10.3390/met11121927

Guan Q, Lu W, He B. Recent Progress in Understanding the Nano/Micro-Mechanical Behavior of Austenite in Advanced High Strength Steels. Metals. 2021; 11(12):1927. https://doi.org/10.3390/met11121927

Chicago/Turabian StyleGuan, Qingwen, Wenjun Lu, and Binbin He. 2021. "Recent Progress in Understanding the Nano/Micro-Mechanical Behavior of Austenite in Advanced High Strength Steels" Metals 11, no. 12: 1927. https://doi.org/10.3390/met11121927

APA StyleGuan, Q., Lu, W., & He, B. (2021). Recent Progress in Understanding the Nano/Micro-Mechanical Behavior of Austenite in Advanced High Strength Steels. Metals, 11(12), 1927. https://doi.org/10.3390/met11121927