Response of Floc Networks in Cemented Paste Backfill to a Pumping Agent

Abstract

:1. Introduction

2. Materials and Methods

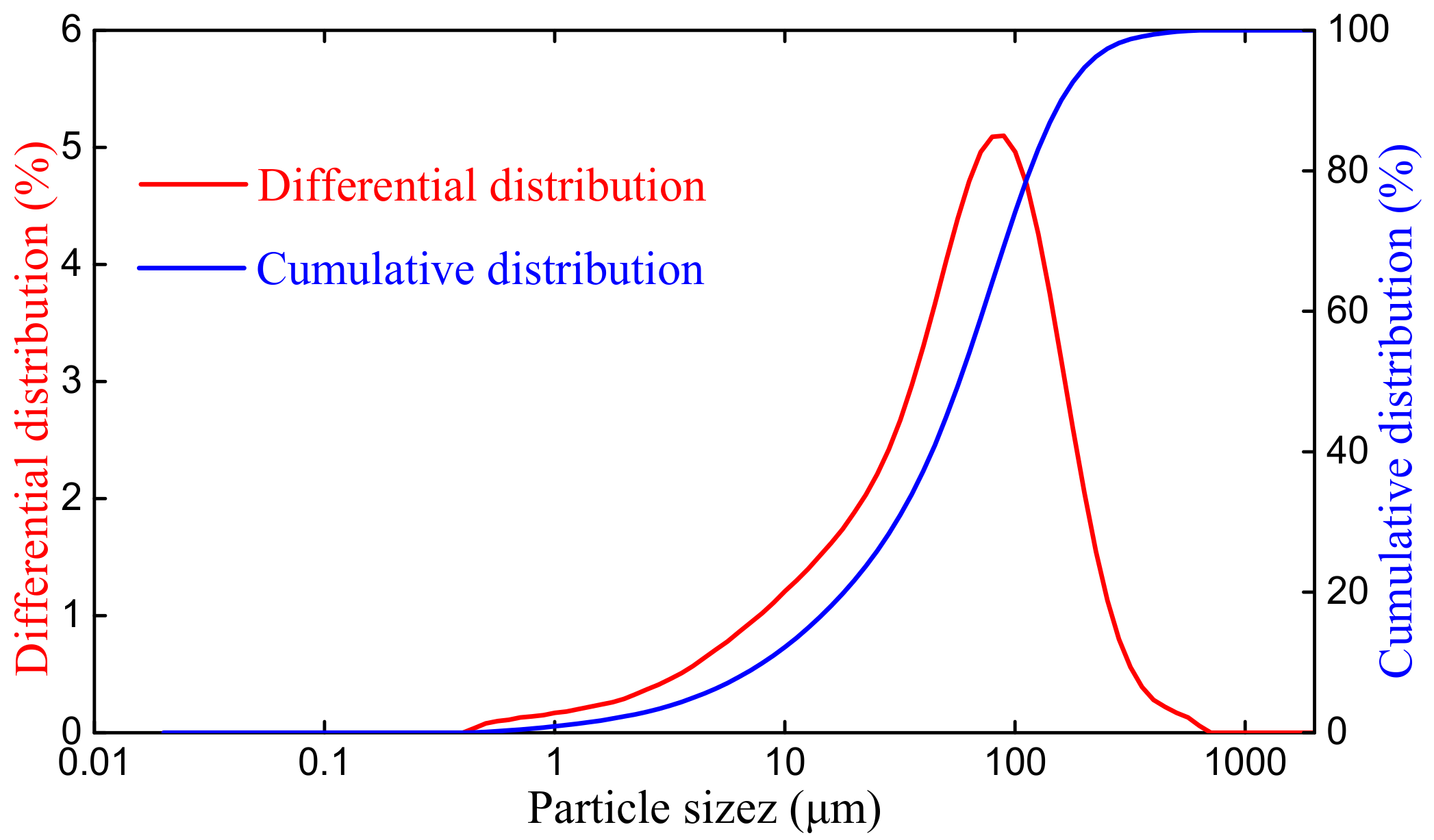

2.1. Materials

2.2. Testing Procedures

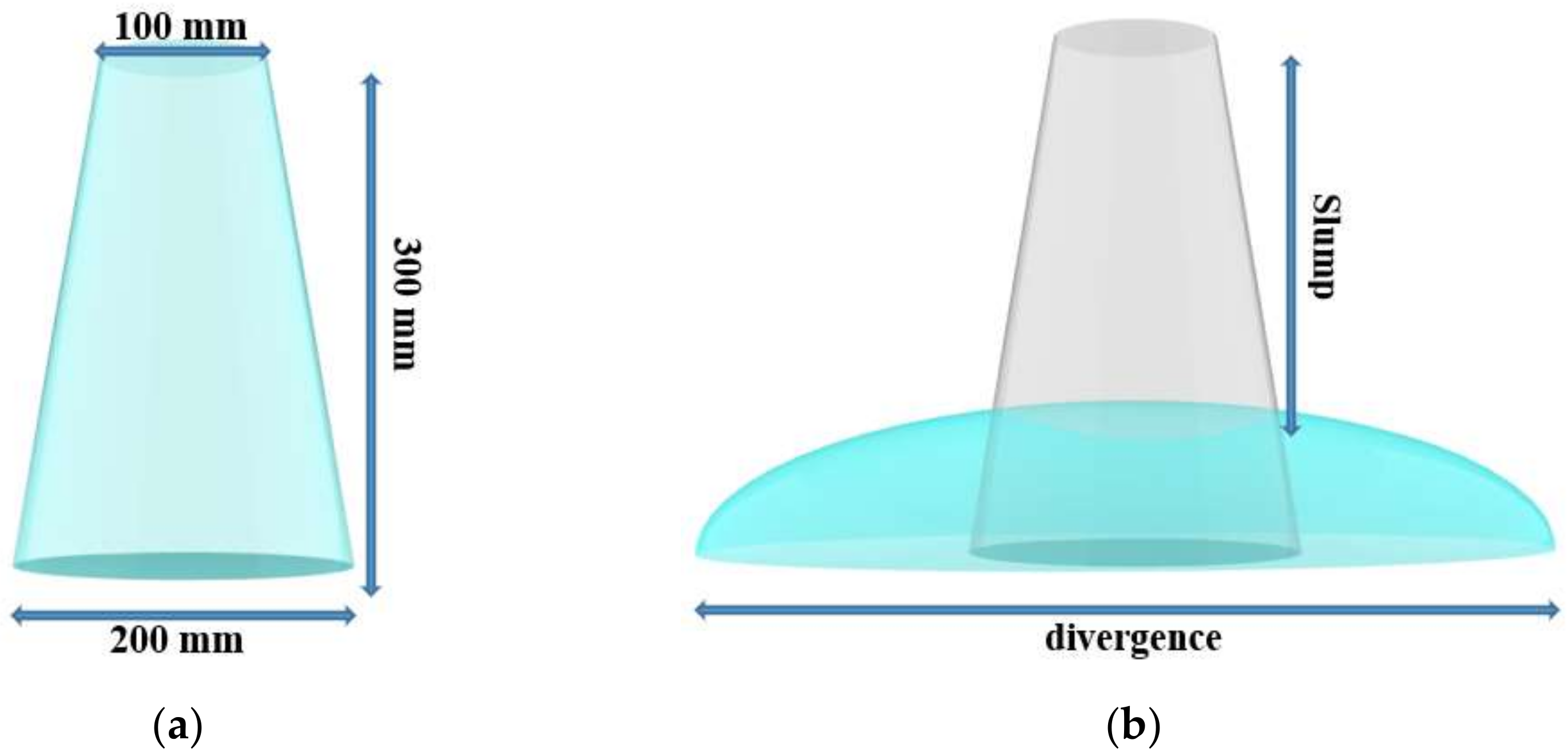

2.2.1. Fluidity Tests

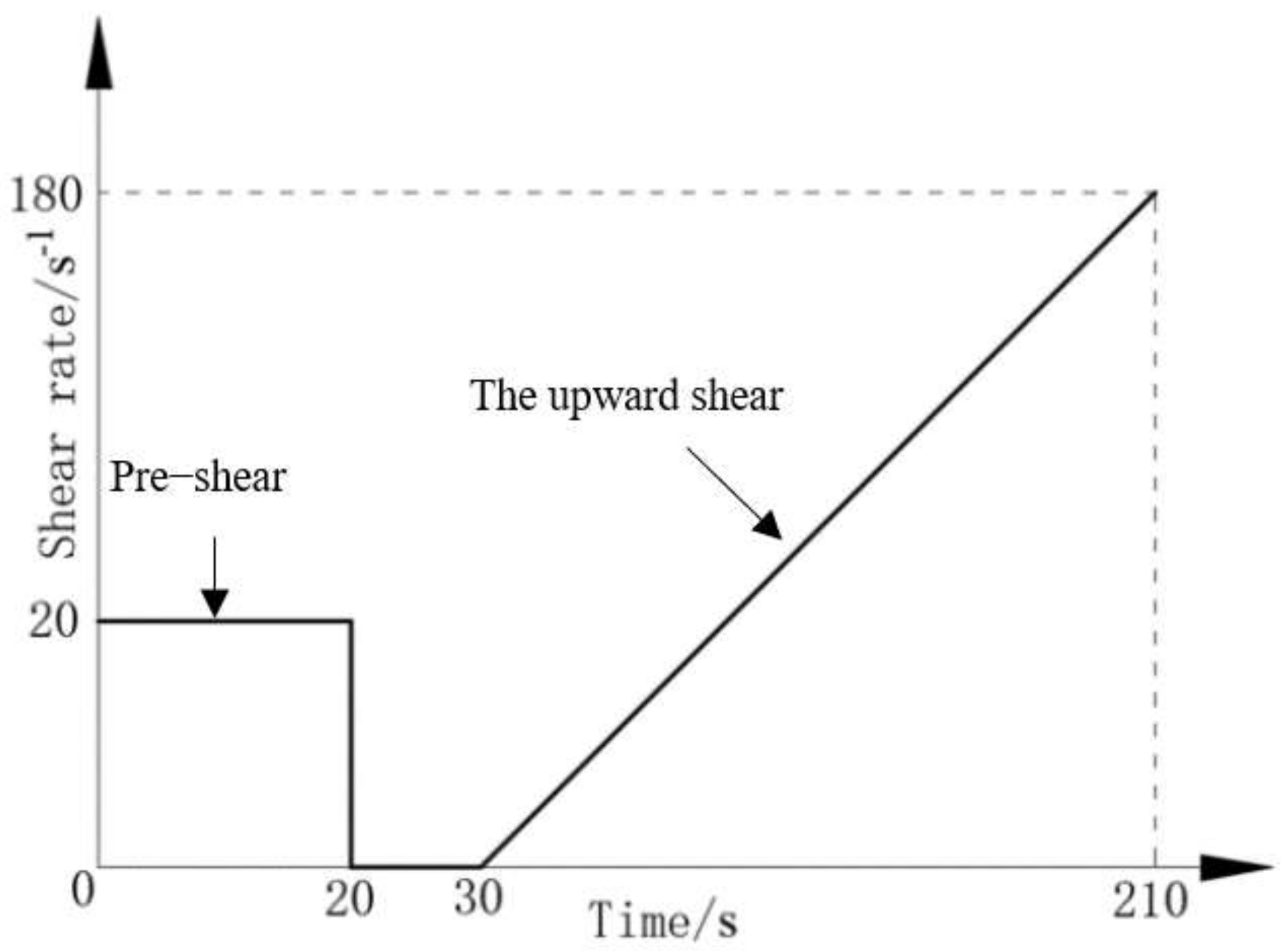

2.2.2. Rheological Tests

2.2.3. ESEM Experiments

3. Results

3.1. Experimental Results

- 1.

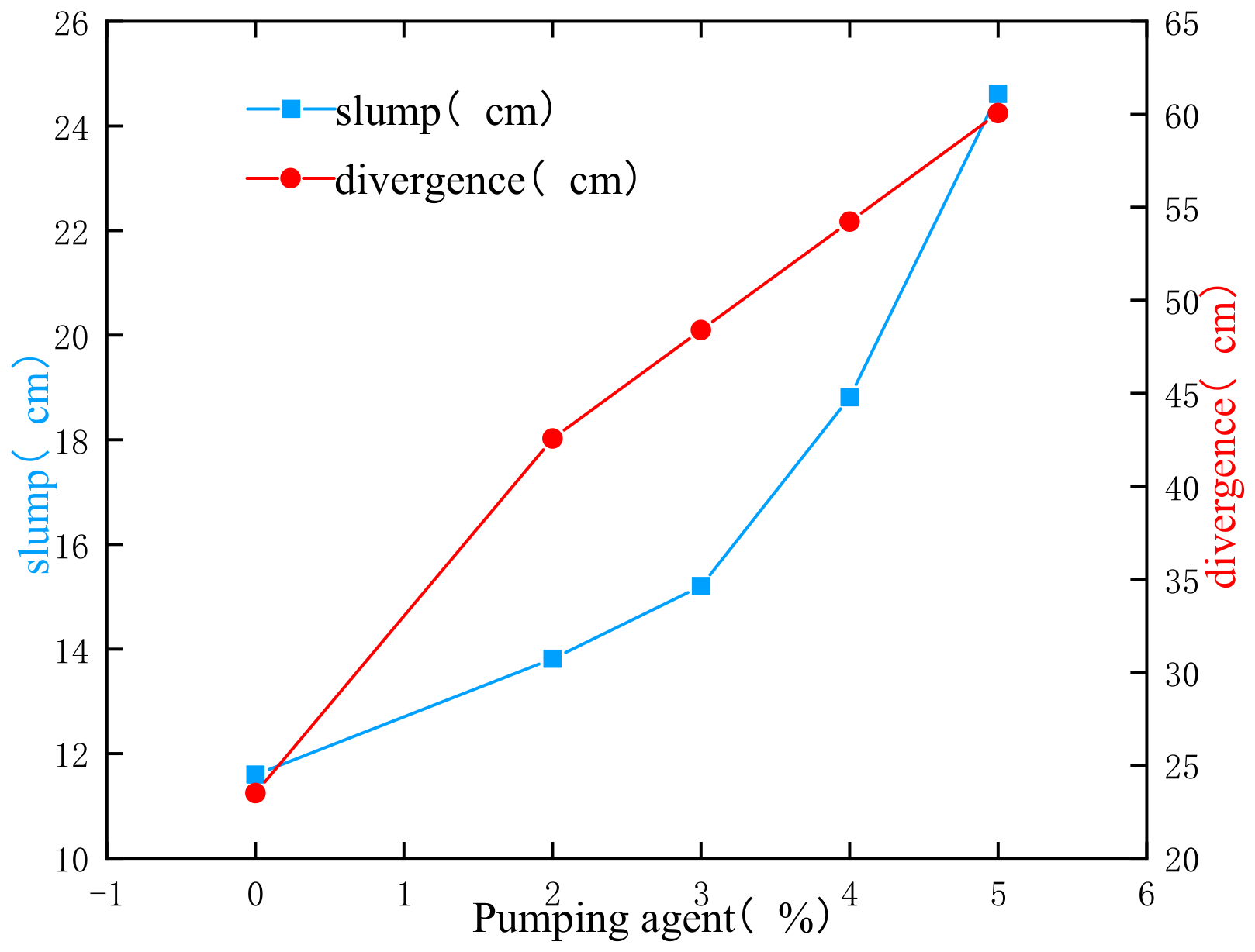

- The results of the slump and divergence of paste with different contents of pumping agent are shown in Figure 5. The following trend was identified: the better the slump and divergence, the stronger the paste flow performance and the smoother the pipeline transportation flow. It can be seen that the two parameters were at a relatively low level before the pumping agent was added. As the dosage increased, the slump and divergence gradually increased. When the dosage reached 5%, the slump increased from 11 to about 24 cm, and the divergence increased from 25 to 60 cm. This shows that the pumping agent can effectively improve the fluidity of paste.

- 2.

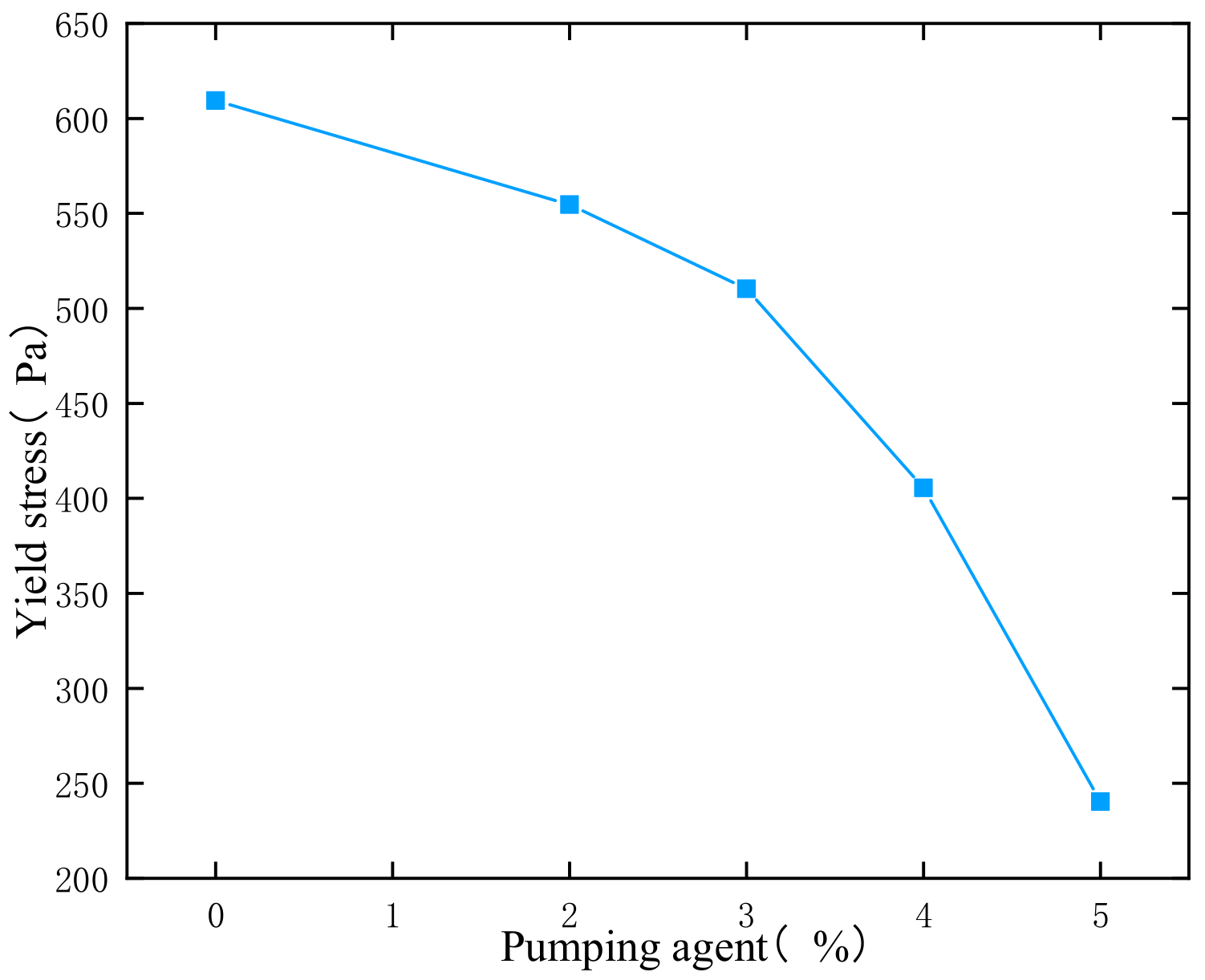

- The yield stresses of paste at different dosages of pumping agent are shown in Figure 6. The paste with large yield stress had poor fluidity compared to the paste with small yield stress, which was found to be more likely to have greater pipeline friction in the transportation process and more likely to lead to pipe plugging. As shown in Figure 6, the yield stress of paste without pumping agent reached 600 Pa and did not have fluidity. With the increase in pumping agent, the yield stress gradually decreased. When the content reached 5%, the yield stress decreased to 200 Pa, about 1/3 of the original quantity, and the rheological properties of the paste were significantly improved.

- 3.

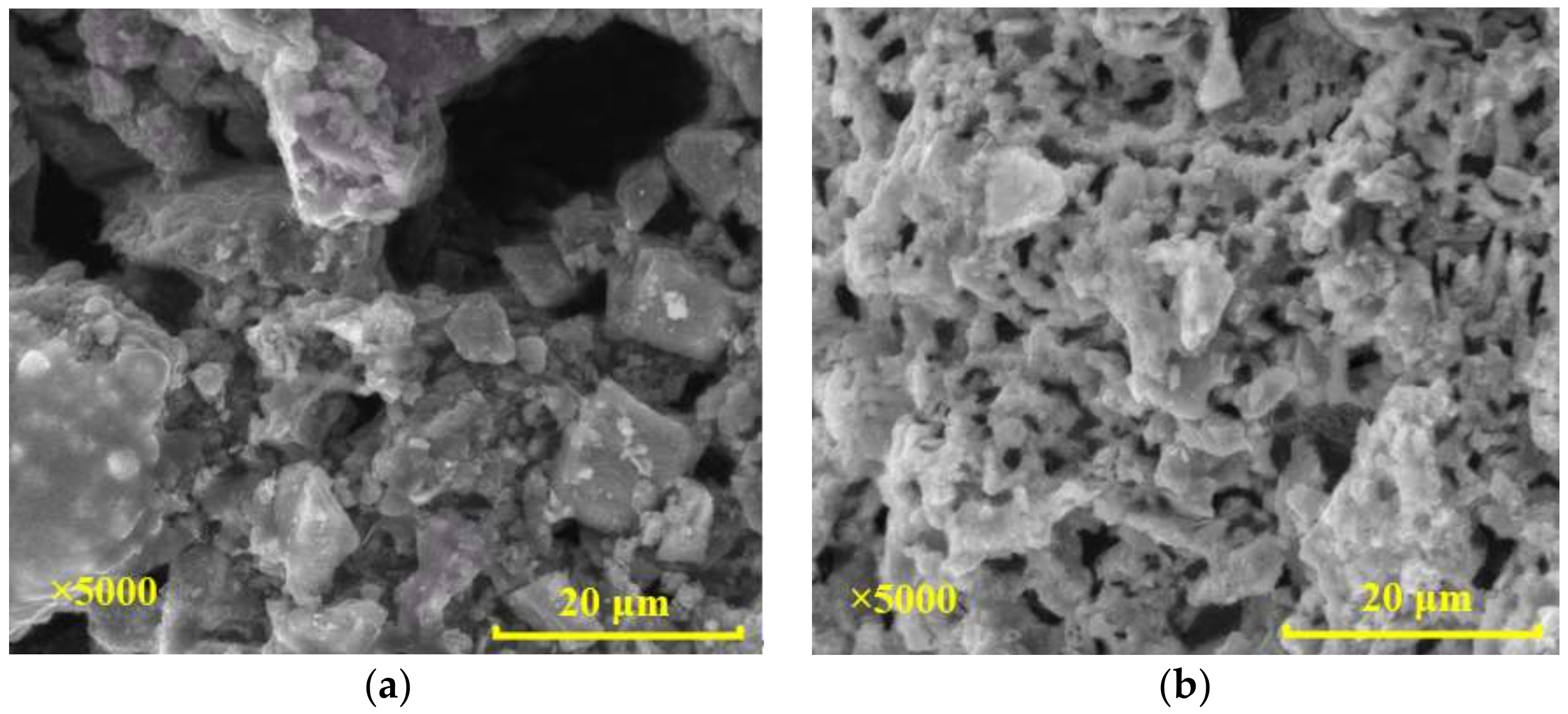

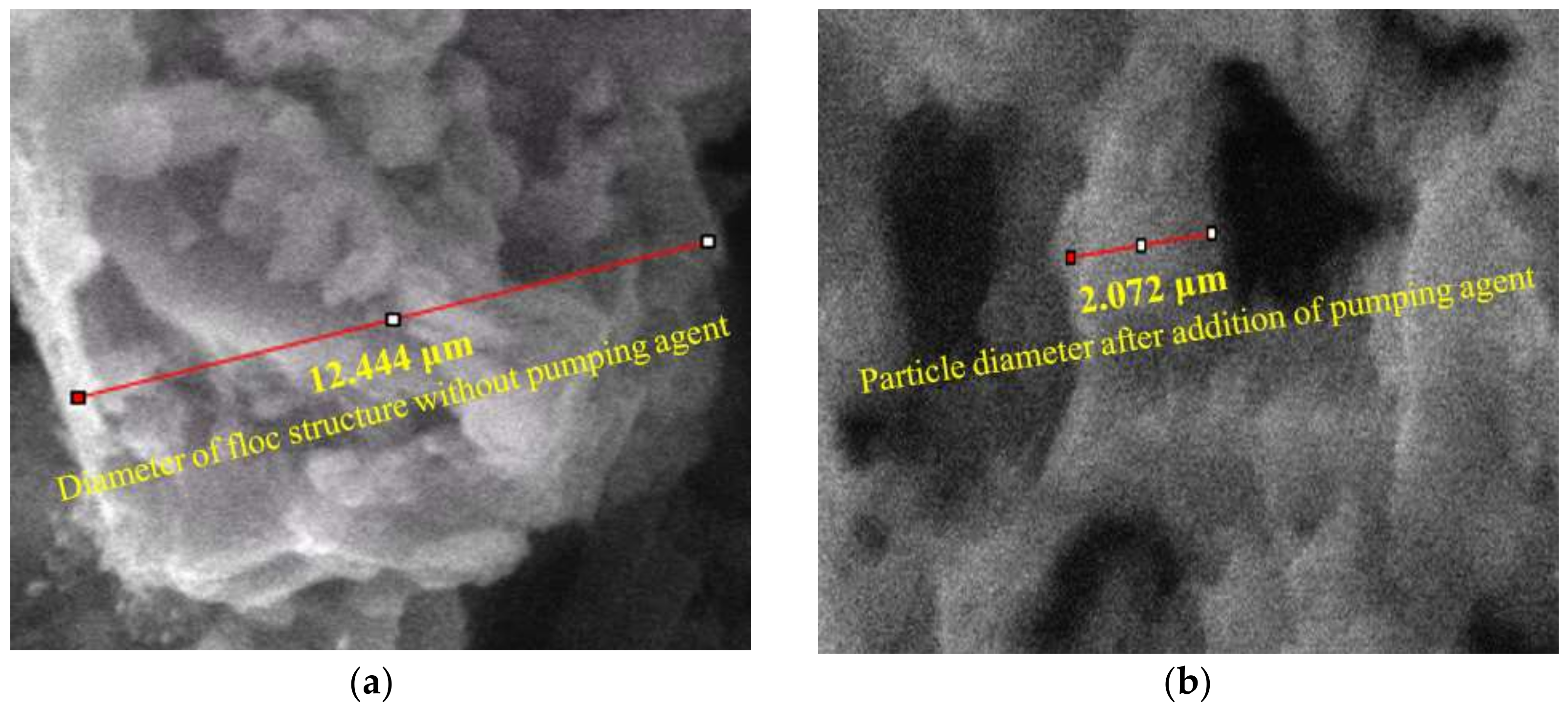

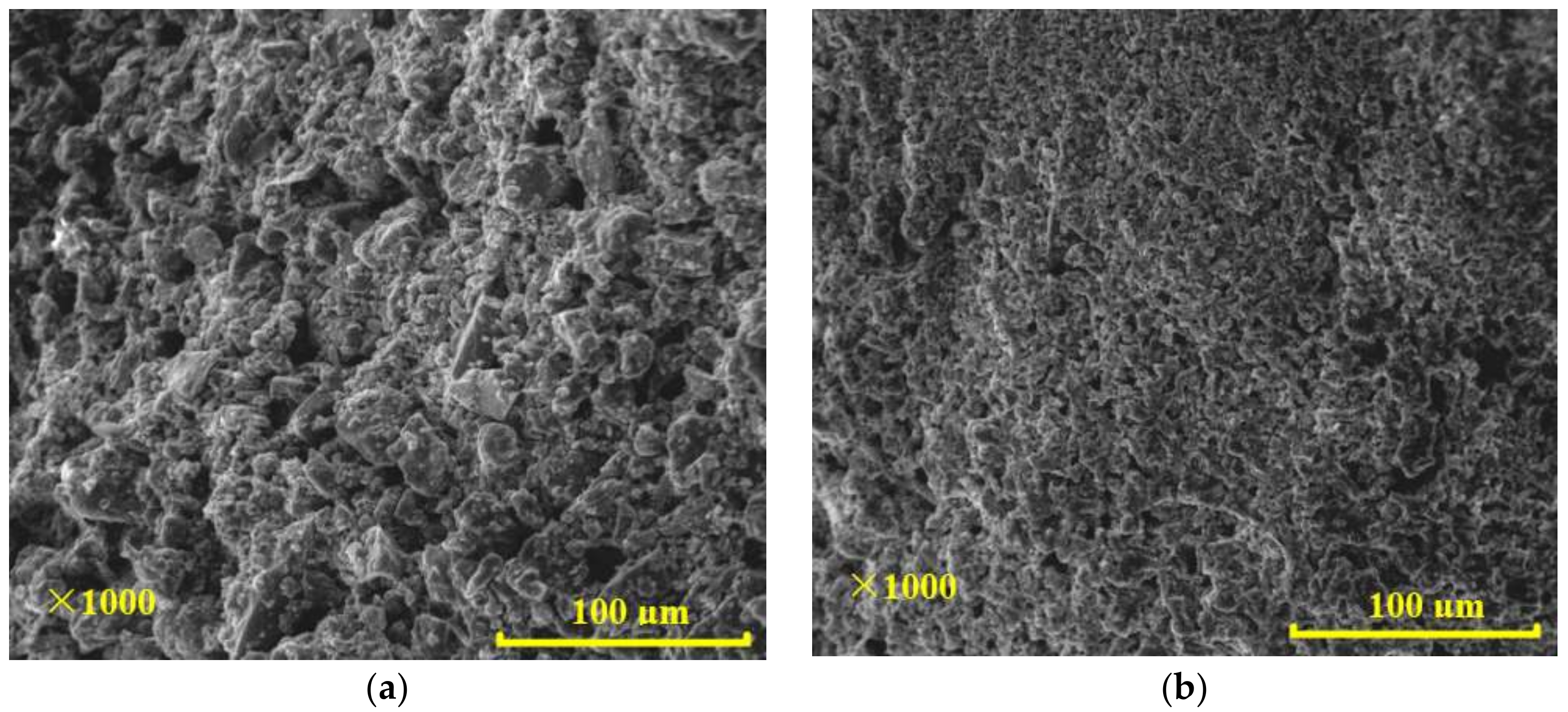

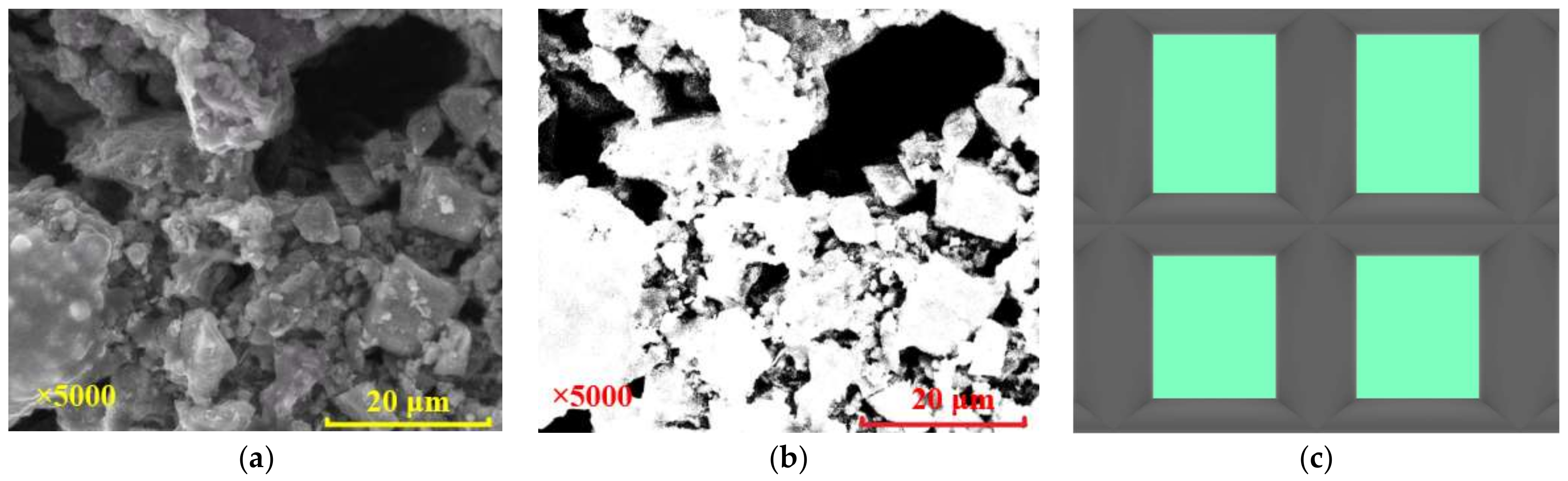

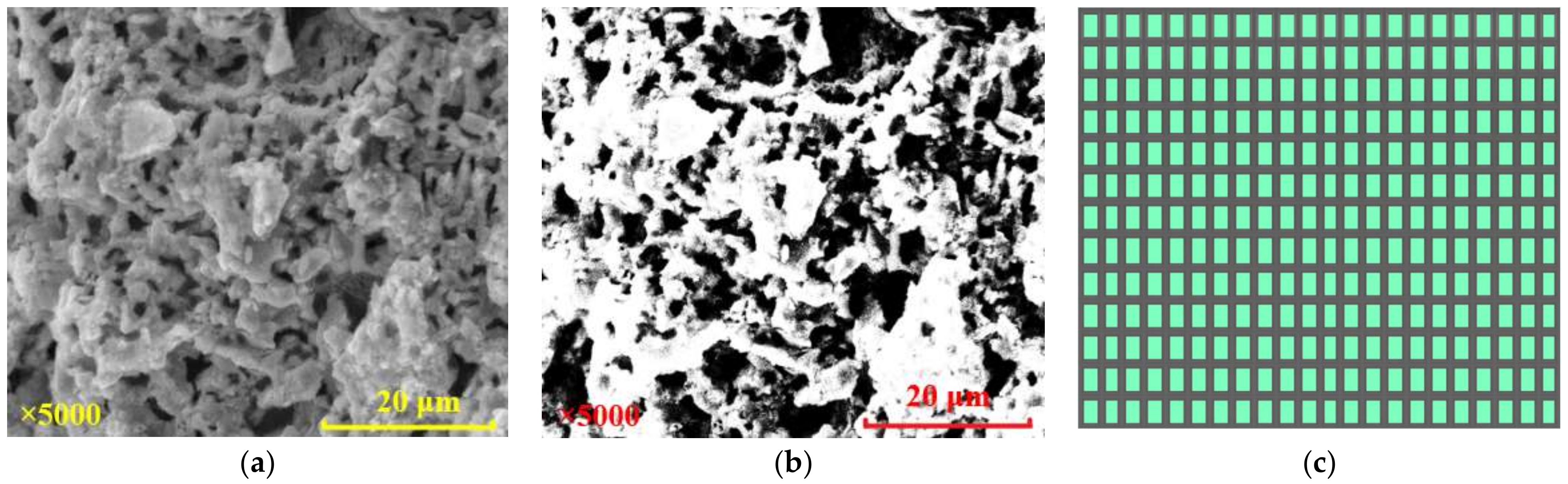

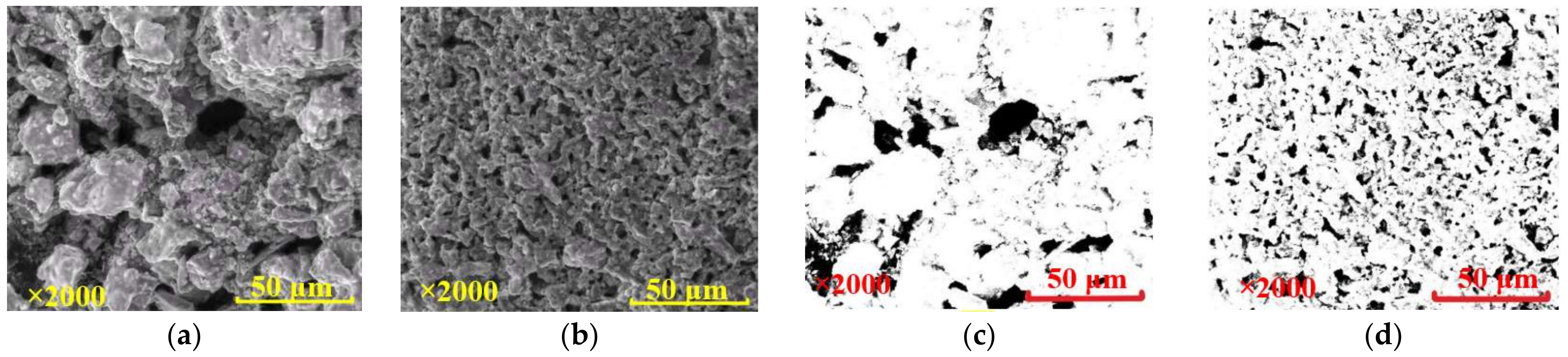

- The ESEM images facilitate an insight into the microstructure of freshly prepared paste. As shown in Figure 7, the particles clustered into a dense structure and the pores between the clusters had a small number (a single pore area is large) and a nonuniform distribution without pumping agent. For those pastes that included pumping agent, flocs were disintegrated into smaller and uniformly-distributed particles; although the number of pores increased, the area of individual pores between particles decreased and the pore distribution was relatively uniform.

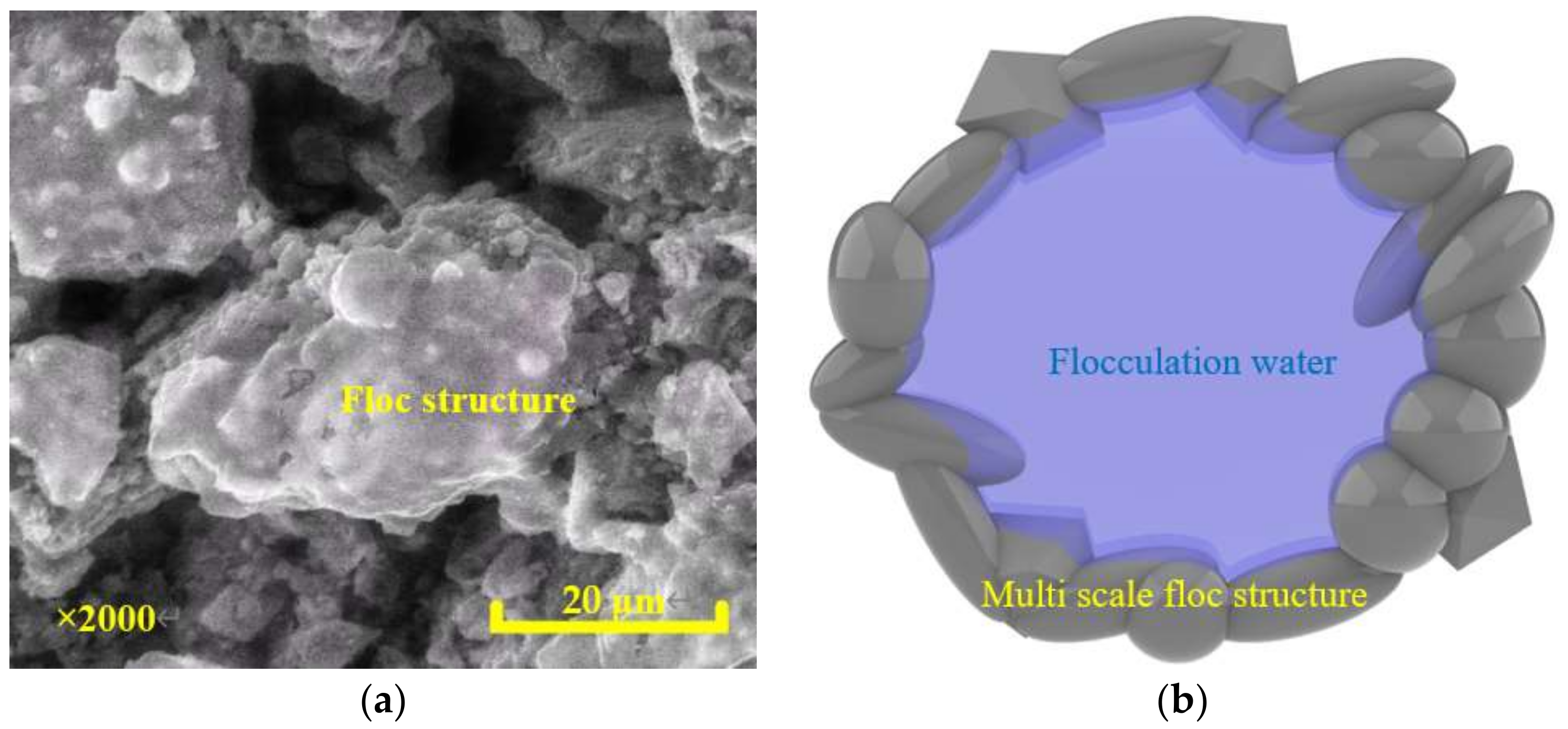

3.2. Effects of Pumping Agent on Flocs

3.3. Evolution of Force Chains under the Effect of Pumping Agent

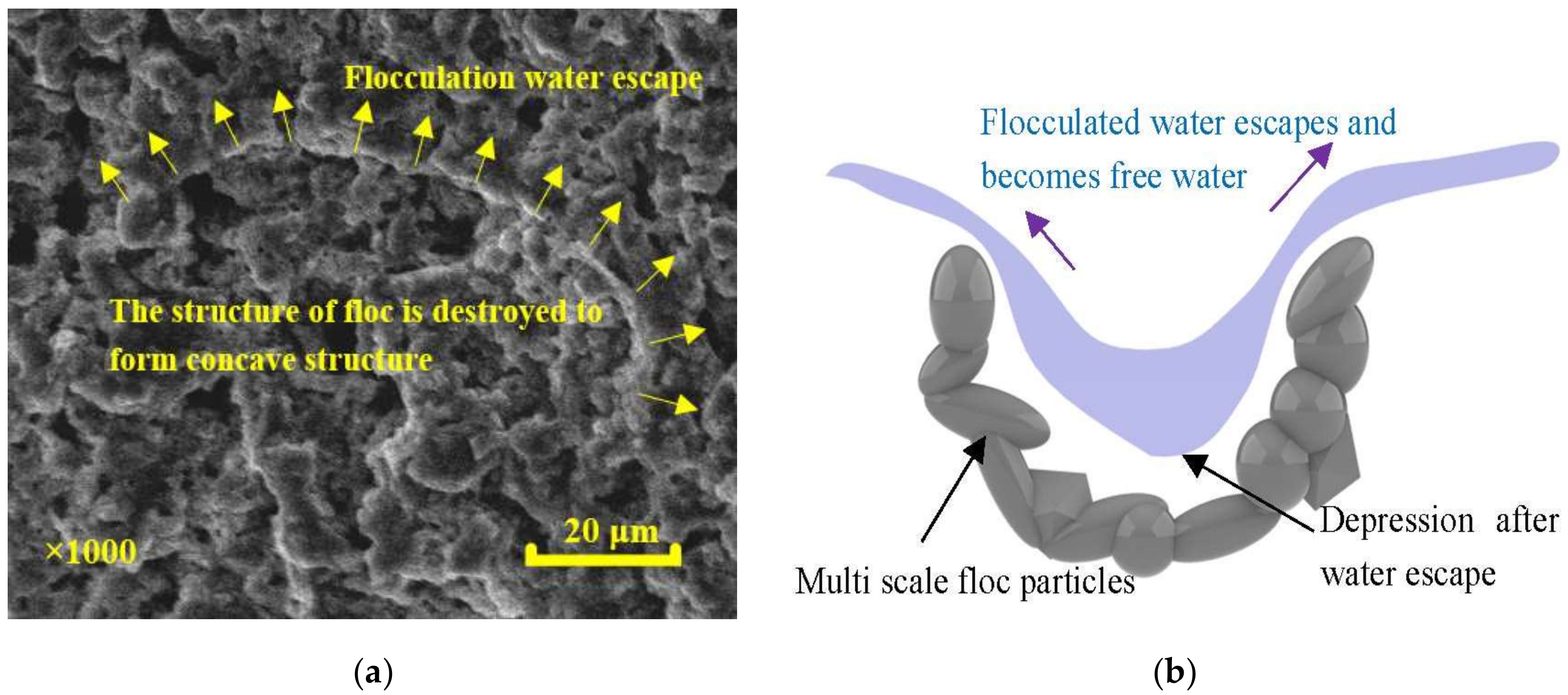

3.4. Evolution of Liquid Network

3.5. Analysis of Pore Area and Fractal Characteristics

4. Conclusions

- 1.

- The pumping agent could effectively improve the fluidity of paste and led to a larger slump and divergence. Flocs of more than 10 microns were, to a significant extent, broken into particles of several microns. In addition, the pumping agent caused the force chains to become fragile and scattered and, as a result, caused the yield stress to decrease.

- 2.

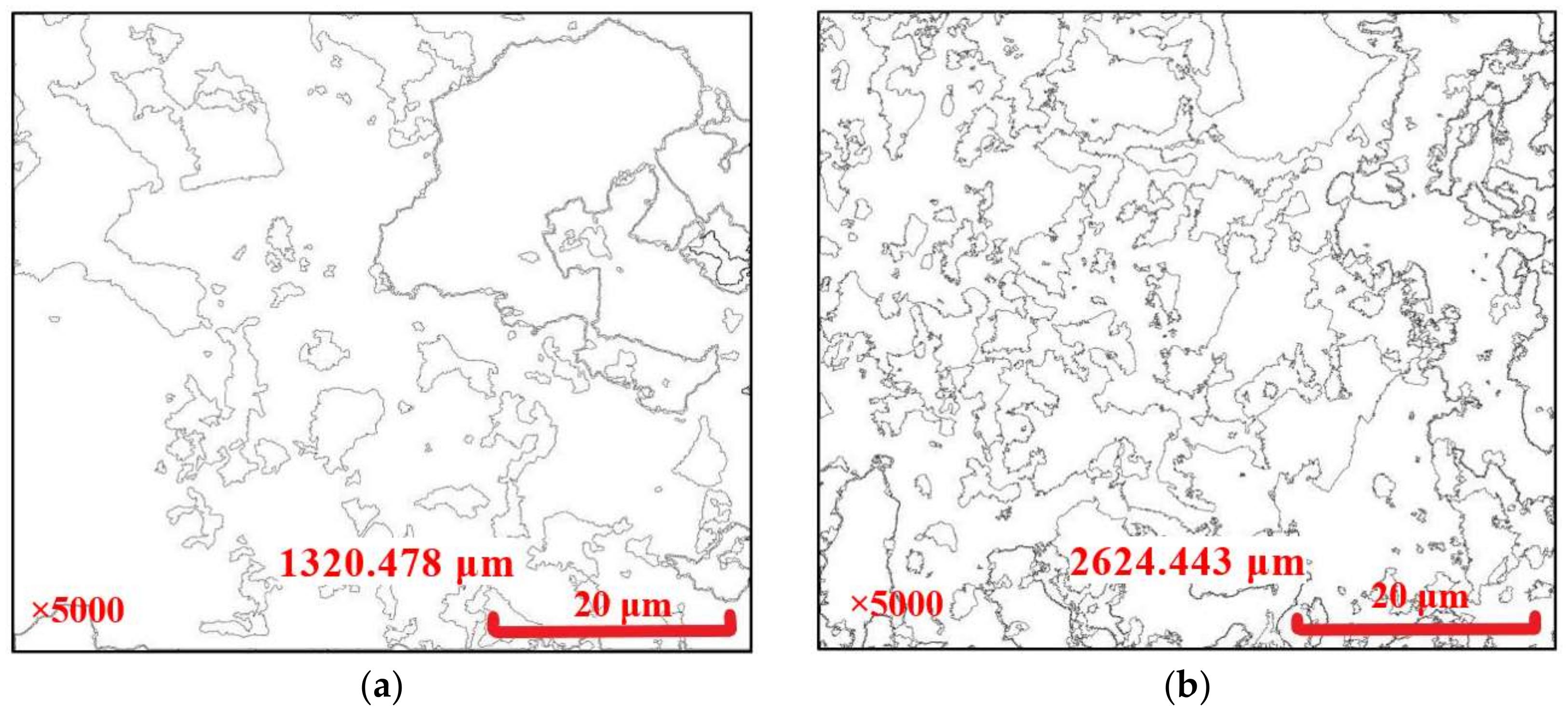

- The pumping agent could facilitate the development of liquid networks. The boundaries between the pores and the particles increased from 1324.478 to 2624.443 um after using the pumping agent, allowing the particles to fully make contact with the free water. This allowed the lubrication and promotion of particles.

- 3.

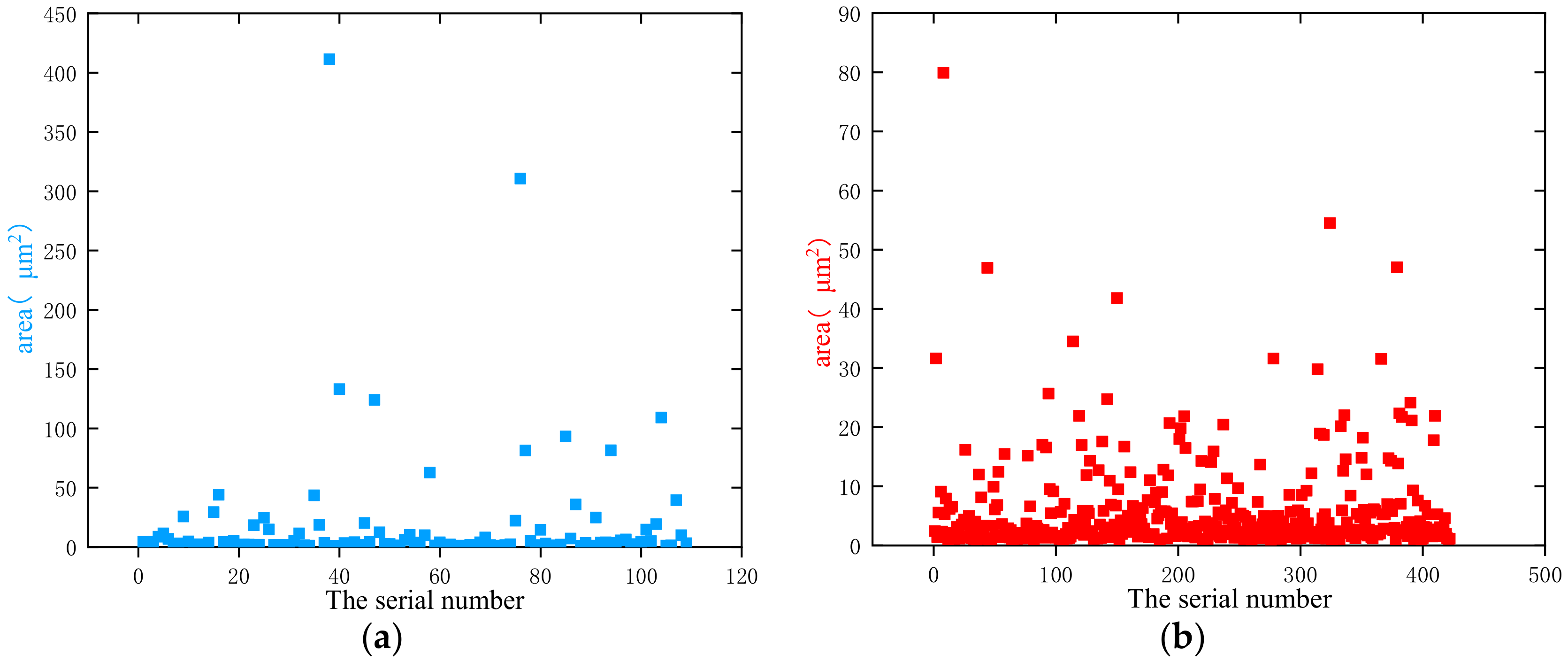

- There were 109 pores nonuniformly distributed in the specified area of the paste without pumping agent. The maximum number of pores reached 411.301 um2 and the proportion of pores was 10.89%. In contrast, for paste with pumping agent added, the number of pores increased to 422, and these were of relatively uniform distribution, with a maximum pore area of 79.887 um2 and a pore proportion of 12.58%. The addition of pumping agent contributed to the development of a liquid network with more pores and more uniform pore distribution.

- 4.

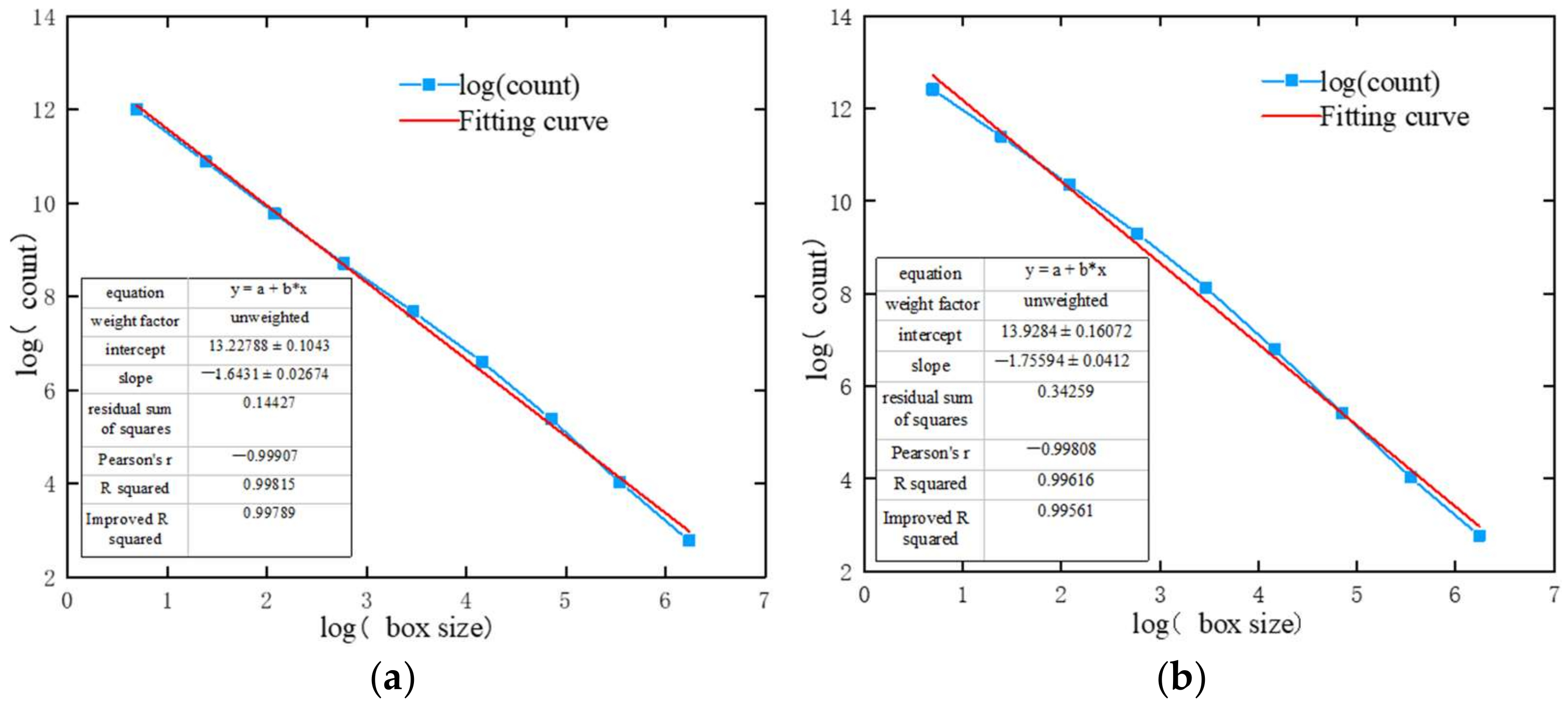

- The fractal dimensions of pores in specified areas before and after the addition of pumping agent were 1.6431 and 1.7559, respectively. The increase in fractal dimension indicated that the self-similarity at the micro level was higher, the pore structure became more complicated, and the more complicated pore structure promoted the free water flow and the development of the liquid network. The enhancement of the liquid network made it possible to better promote and lubricate the migration of particles. The changes in the microstructure enabled the enhancement of the fluidity and rheological properties of the paste.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiao, H.; Wang, S.; Yang, Y.; Chen, X. Water recovery improvement by shearing of gravity-thickened tailings for cemented paste backfill. J. Clean. Prod. 2020, 245, 118882. [Google Scholar]

- Cheng, H.; Wu, S.; Li, H.; Zhang, X. Influence of time and temperature on rheology and flow performance of cemented paste backfill. Constr. Build. Mater. 2020, 231, 117117. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, T.; Jiao, H.; Wang, Y.; Li, H. Potential Effect of Porosity Evolution of Cemented Paste Backfill on Selective Solidification of Heavy Metal Ions. Int. J. Environ. Res. Public Health 2020, 17, 814. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Wu, S.; Zhang, X.; Wu, A. Effect of particle gradation characteristics on yield stress of cemented paste backfill. Int. J. Miner. Metall. Mater. 2020, 27, 10–17. [Google Scholar] [CrossRef]

- Mascaro, I.; Benvenuti, M.; Corsini, F.; Costagliola, P.; Lattanzi, P.; Parrini, P.; Tanelli, G. Mine wastes at the polymetallic deposit of Fenice Capanne (southern Tuscany, Italy). Mineralogy, geochemistry, and environmental impact. Environ. Geol. 2001, 41, 417–429. [Google Scholar]

- Wu, Y.Y.A.; Cheng, H.; Chen, S.; Han, Y. Status and prospects of paste technology in China. Chin. J. Eng. 2018, 40, 517–525. [Google Scholar]

- Henriquez, J.; Simms, P. Dynamic imaging and modelling of multilayer deposition of gold paste tailings. Miner. Eng. 2009, 22, 128–139. [Google Scholar] [CrossRef]

- Deschamps, T.; Benzaazoua, M.; Bussière, B.; Aubertin, M. Laboratory study of surface paste disposal for sulfidic tailings: Physical model testing. Miner. Eng. 2011, 24, 794–806. [Google Scholar] [CrossRef]

- Xue, Z.; Gan, D.; Zhang, Y.; Liu, Z. Rheological behavior of ultrafine-tailings cemented paste backfill in high-temperature mining conditions. Constr. Build. Mater. 2020, 253, 119212. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, S.; Wu, A.; Cheng, W. Grading characterization and yield stress prediction based on paste stability coefficient. Chin. J. Eng. 2018, 40, 1168–1176. [Google Scholar]

- Lim, S.; Kim, S.; Ahn, K.; Lee, S. The effect of binders on the rheological properties and the microstructure formation of lithium-ion battery anode slurries. J. Power Sources 2015, 299, 221–230. [Google Scholar] [CrossRef]

- Uchikawa, H.; Sawaki, D.; Hanehara, S. Influence of kind and added timing of organic admixture on the composition, structure and property of fresh cement paste. Cem. Concr. Res. 1995, 25, 353–364. [Google Scholar] [CrossRef]

- Huynh, L.; Beattie, D.A.; Fornasiero, D.; Ralston, J. Effect of polyphosphate and naphthalene sulfonate formaldehyde condensate on the rheological properties of dewatered tailings and cemented paste backfill. Miner. Eng. 2006, 19, 28–36. [Google Scholar] [CrossRef]

- Liu, S.; Wang, H.; Wu, A.; Peng, N.; Yang, P. Study on the Rheological Properties of the Unclassified-tailings Paste Mixed with Pumping Agent. J. Wuhan Univ. Technol. 2014, 38, 919–922. [Google Scholar]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H.; Alp, I. Utilization of water-reducing admixtures in cemented paste backfill of sulphide-rich mill tailings. J. Hazard. Mater. 2010, 179, 940–946. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H.; Wu, A.; Pan, G.; Liu, S.; Li, H. The Effect of Pumping Aid on Paste Pipeline Transportation. Metal Mine. 2014, 11, 22–26. [Google Scholar]

- Wu, A.; Ruan, Z.; Wang, Y.; Yin, S.; Wang, S.; Wang, Y.; Wang, J. Simulation of long-distance pipeline transportation properties of whole-tailings paste with high sliming. J. Cent. South Univ. 2018, 25, 141–150. [Google Scholar] [CrossRef]

- Wu, A.; Liu, X.; Wang, H.; Wang, Y.; Jiao, H.; Liu, S. Resistance characteristics of structure fluid backfilling slurry in pipeline transort. J. Cent. South Univ. 2014, 45, 4325–4330. [Google Scholar]

- Li, G.; Wang, H.; Wu, A.; Yang, P. Experimental study and mechanism analysis on the effect of pumping agents on the compressive strength of paste slurries. Chin. J. Eng. 2016, 38, 595–601. [Google Scholar]

- Zheng, J.; Gu, D. Study on influence of water-reducing agent on properties of total tailings cemented paste backfill. Nonferrous Met. 2014, 66, 60–65. [Google Scholar]

- Zuo, Y.; Wang, D.; Li, W.; Song, S. Review of interaction between superplasticizer and cement. Concrete 2007, 12, 79–83. [Google Scholar]

- Zheng, J.; Zhao, Z.; Lu, S. Effect of Superplasticizers on the Fluidity of Microfine Slurry. Met. Mine 2014, 01, 154–157. [Google Scholar]

- Yang, P.; Wu, A.; Wang, H.; Li, G.; Peng, N.; Chen, H. Microstructure model of paste slurry rheological properties with pumping admixture. Nonferrous Met. 2015, 67, 59–64. [Google Scholar]

- Wu, A.; Ai, C.; Wang, Y.; Yang, X.; Zhou, F. Test and mechanism analysis on improving rheological property of paste with pumping agent. J. Cent. South Univ. 2016, 47, 2752–2758. [Google Scholar]

- Zhang, L.; Wu, A.; Wang, H. Effects and mechanism of pumping agent on rheological properties of highly muddy paste. Chin. J. Eng. 2018, 40, 918–924. [Google Scholar]

- Hoang, Q.G.; Kaci, A.; Kadri, E.H.; Gallias, J.L. A new methodology for characterizing segregation of cement grouts during rheological tests. Constr. Build. Mater. 2015, 96, 119–126. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, P.; Jin, M. Backfill Mining Technology and Application, 1st ed.; Metallurgical Industry Press: Beijing, China, 2001. [Google Scholar]

- Wu, A.X.; Jiao, H.Z.; Wang, H.J.; Li, H.; Yi, H.; Liu, X.; Liu, S. Yield stress measurements and optimization of paste tailings. J. Cent. South Univ. 2013, 44, 3371–3376. [Google Scholar]

- Boger, D.V. Rheology forming process. Int. J. Mech. Sci. 2009, 64, 4225–4536. [Google Scholar]

- Wu, A.; Li, H.; Cheng, H.; Wang, Y.; Li, C.; Ruan, Z.-E. Status and prospects of researches on rheology of paste backfill using unclassified-tailings (Part 1): Concepts, characteristics and models. Chin. J. Eng. 2020, 42, 803–813. [Google Scholar]

- Adeyinka, O.B.; Samiei, S.; Xu, Z.; Masliyah, J.H. Effect of particle size on the rheology of Athabasca clay suspensions. Can. J. Chem. Eng. 2009, 87, 422–434. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, S.; Zhang, X.; Li, J. A novel prediction model of strength of paste backfill prepared from waste-unclassified tailings. Adv. Mater. Sci. Eng. 2019, 2019, 357419. [Google Scholar] [CrossRef] [Green Version]

- Tombácz, E.; Szekeres, M. Surface charge heterogeneity of kaolinite in aqueous suspension in comparison with montmorillonite. Appl. Clay Sci. 2006, 34, 105–124. [Google Scholar] [CrossRef]

- McFarlane, A.; Bremmell, K.; Addai-Mensah, J. Improved dewatering behavior of clay minerals dispersions via interfacial chemistry and particle interactions optimization. J. Colloid Interface Sci. 2006, 293, 116–127. [Google Scholar] [CrossRef] [PubMed]

- Cao, S.; Xue, G.; Song, W.; Teng, Q. Strain rate effect on dynamic mechanical properties and microstructure of cemented tailings composites. Constr. Build. Mater. 2020, 247, 118537. [Google Scholar] [CrossRef]

- Sun, W.; Hou, K.; Yang, Z.; Wen, Y. X-ray CT three-dimensional reconstruction and discrete element analysis of the cement paste backfill pore structure under uniaxial compression. Constr. Build. Mater. 2017, 138, 69–78. [Google Scholar] [CrossRef]

| Component | Tailings (wt.%) | Crushed Mine Waste Rocks (wt.%) | Cement (wt.%) |

|---|---|---|---|

| SiO2 | 36.41 | 37.31 | 21.5 |

| Al2O3 | 7.77 | 3.39 | 4.5 |

| Fe2O3 | 9.90 | - 1 | 2.0 |

| CaO | 3.09 | 3.86 | 63.5 |

| MgO | 27.79 | 28.15 | 4.0 |

| SO3 | 1.63 | - 1 | 2.5 |

| Others | 13.41 | 10.38 | 2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Wu, S.; Cheng, H.; Geng, X.; Liu, J. Response of Floc Networks in Cemented Paste Backfill to a Pumping Agent. Metals 2021, 11, 1906. https://doi.org/10.3390/met11121906

Zhu J, Wu S, Cheng H, Geng X, Liu J. Response of Floc Networks in Cemented Paste Backfill to a Pumping Agent. Metals. 2021; 11(12):1906. https://doi.org/10.3390/met11121906

Chicago/Turabian StyleZhu, Jiaqi, Shunchuan Wu, Haiyong Cheng, Xiaojie Geng, and Jin Liu. 2021. "Response of Floc Networks in Cemented Paste Backfill to a Pumping Agent" Metals 11, no. 12: 1906. https://doi.org/10.3390/met11121906

APA StyleZhu, J., Wu, S., Cheng, H., Geng, X., & Liu, J. (2021). Response of Floc Networks in Cemented Paste Backfill to a Pumping Agent. Metals, 11(12), 1906. https://doi.org/10.3390/met11121906