Numerical Study on Vibration Response and Fatigue Damage of Axial Compressor Blade Considering Aerodynamic Excitation

Abstract

:1. Introduction

2. Numerical Methodology

2.1. Structure Dynamic Equations

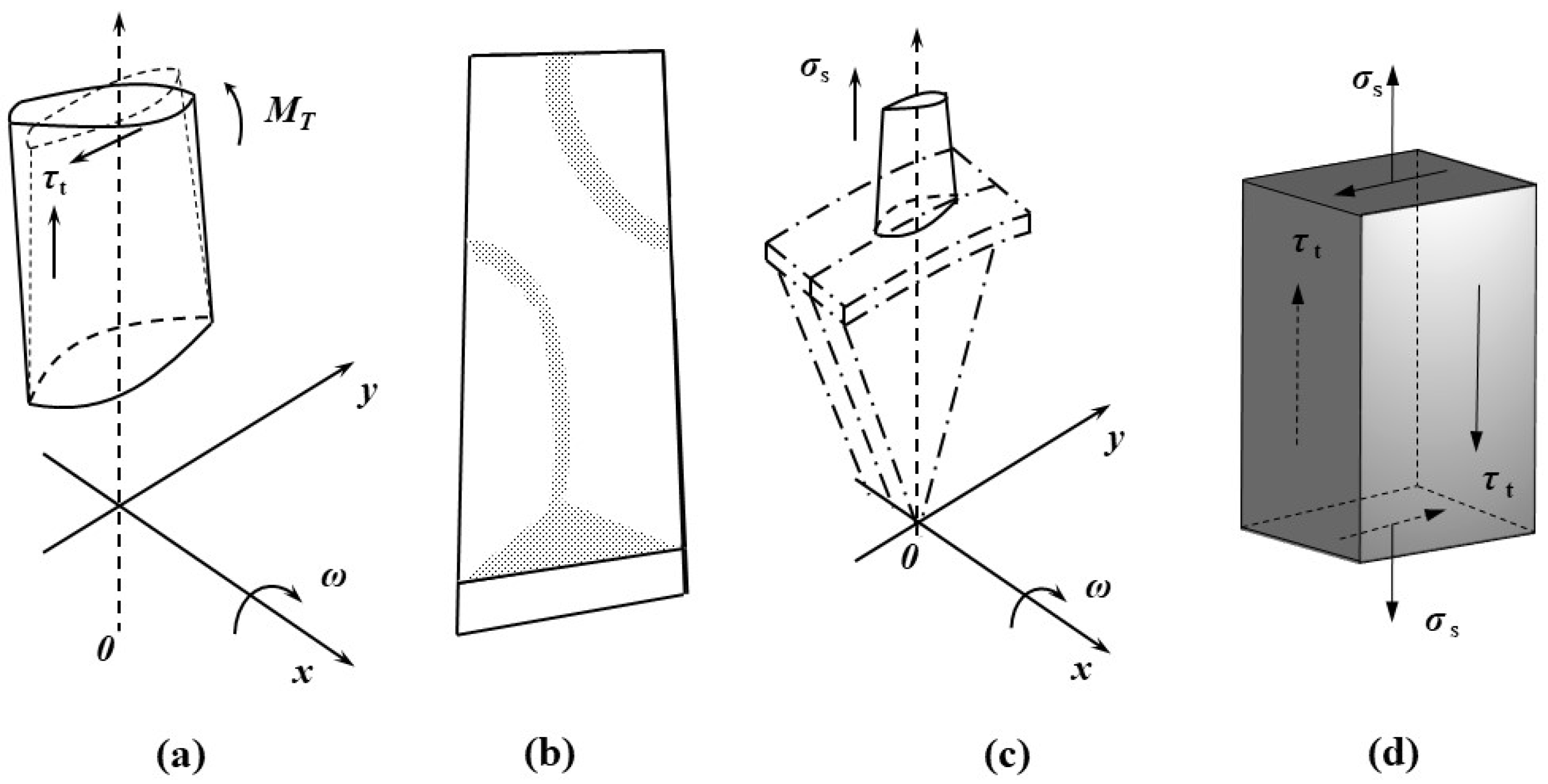

2.2. Modified Fatigue Damage Model

- (a)

- With the increase in fatigue loading cycles, the continuous damage variable D also is increased, which is shown as follows:

- (b)

- In the case of a structure with equal initial damage D0, the damage variable under the larger fatigue load should be greater than the damage variable under the lower fatigue load with the same loading cycles, which is expressed as follows:

- (c)

- In the case of equal fatigue loads, the damage variable with a larger initial damage variable D01 under one loading cycle should be greater than the damage variable with a lower initial damage variable D02 under same loading cycle, which is shown as follows:

3. Numerical Modelling

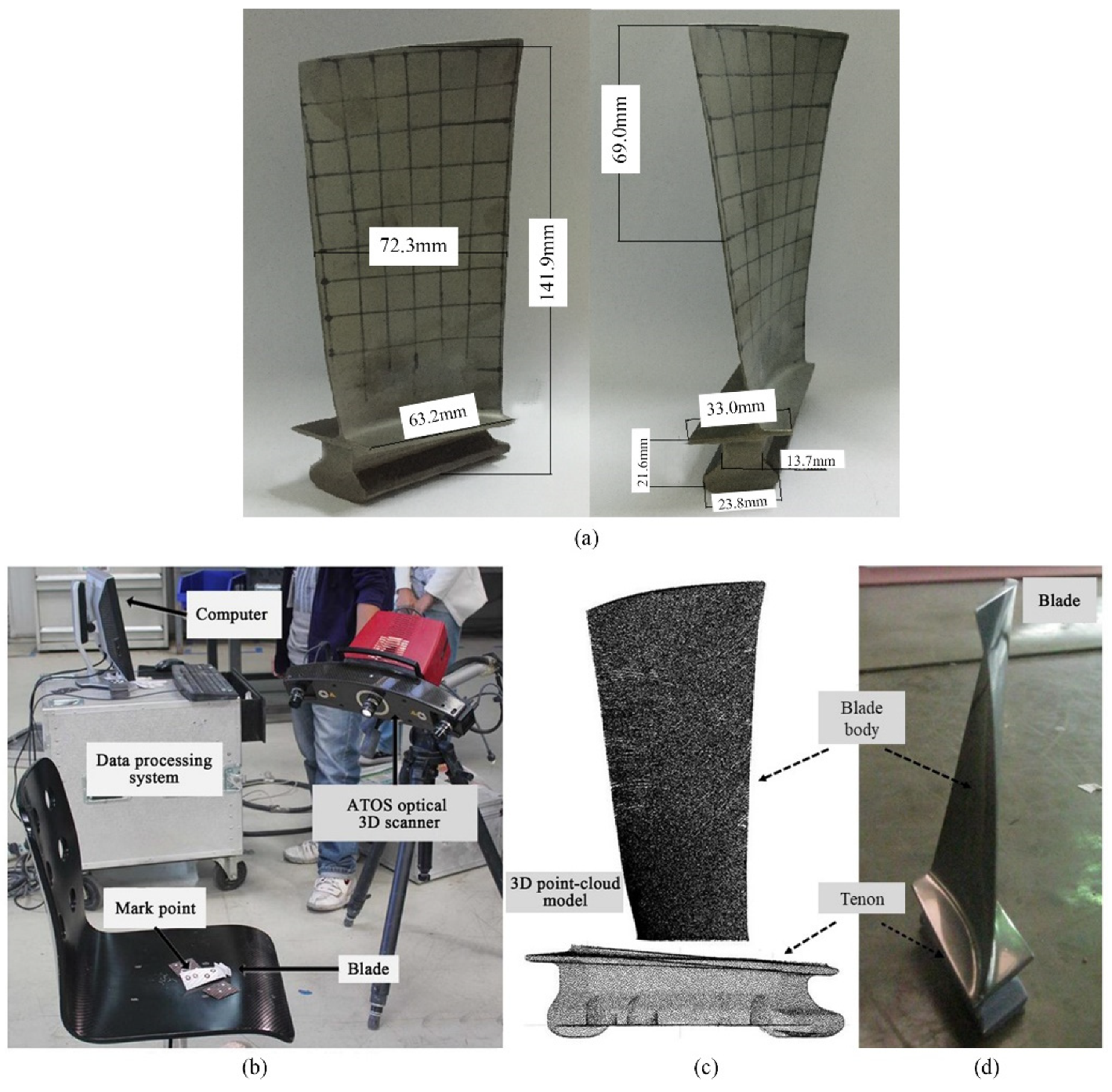

3.1. Finite Element Modeling and Verification

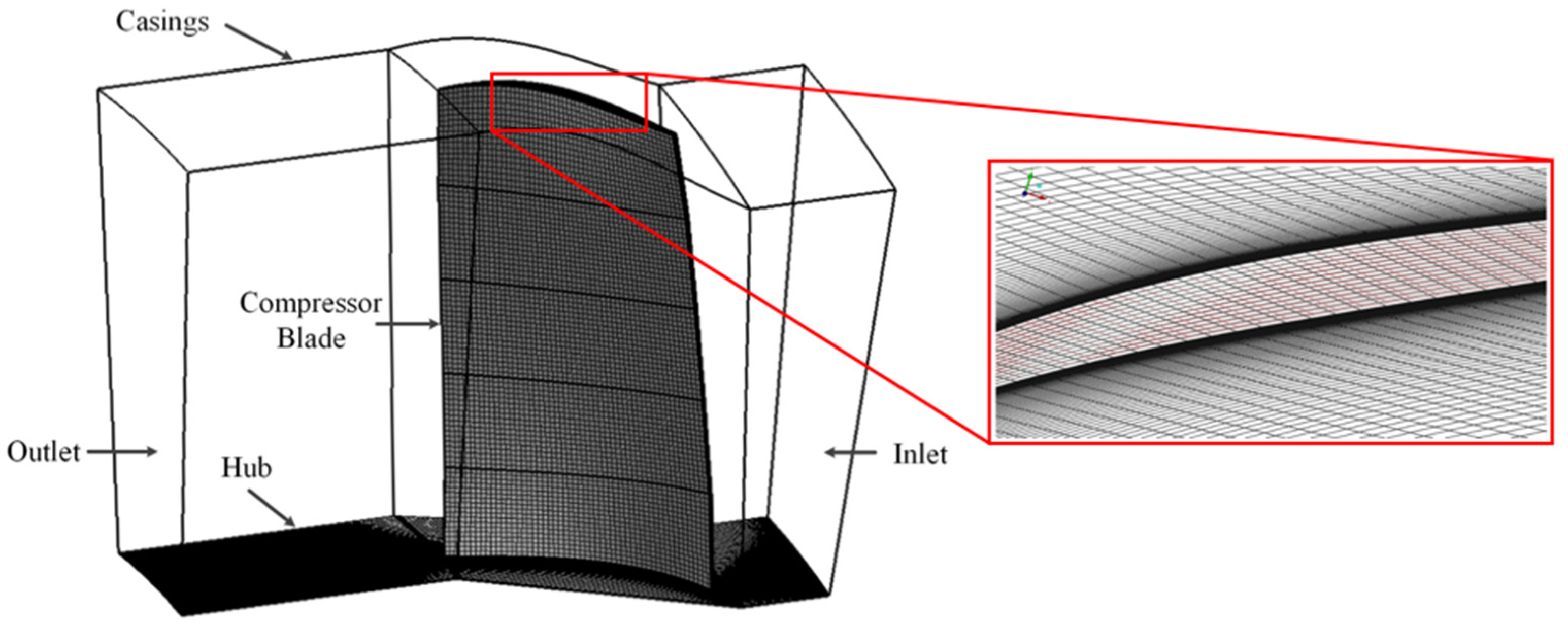

3.2. Flow Field Modeling and Verification

4. Results and Discussion

4.1. Aerodynamic Loads Analysis

4.2. Natural Vibration Analysis

4.3. Harmonic Resonance Analysis

4.4. Fatigue Damage Analysis

5. Conclusions

- A modified nonlinear cumulative damage model is proposed, which is based on the uniaxial tensile-compressive stress, considers the effect of the torsional moment on the cumulative damage rate, and describes the complex stress in the blade after torsional deformation using equivalent stress.

- When considering the airflow excitation, the frequencies in the modes dominated by bending deformation decreased, whereas those dominated by torsional deformation increased, since the blade has an initial twist angle, and the airflow excitation further increases the torsion effect of the blade. Therefore, compared with the blade vibration characteristics considering the centrifugal load alone, the results considering the airflow excitation could better approximate the blade under the real-world operating conditions of the engine.

- The vibration of the compressor blade is the result of the stacking of the vibrations at different orders of low frequencies, first- and second-order frequency modes of vibration were more easily excited than high-order modes of vibration. Thus, the torsional deformation increases the complexity of the stress state in the blade, resulting in the stress concentration that occurred at the blade root and changed its fatigue behavior.

- There is an obvious difference of stress distribution between the normal stress and the equivalent stress including torsional shear stress. Hence, the additional consideration of the torsional shear stress decreased the predicted fatigue life by 4.5%. Moreover, the accumulative damage increased quickly for the last 25% cycle of damage curve, when the blade fracture may occur at any time. Thus, considering the aerodynamic excitation increased the safety factor of blade fatigue life prediction.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| C, CP | damping matrix of solid and fluid |

| D | fatigue damage |

| D0 | initial damage |

| F | external forces |

| K, KP | stiffness matrix of solid and fluid |

| M, MP | mass matrix of solid and fluid |

| MT | torque |

| n | loading cycles |

| N, Nf, Nf′ | fatigue life |

| P | sound pressure |

| Rf | additional node vector |

| , , | structural displacement, velocity and acceleration |

| WP | torsional section modulus |

| σ | stress |

| σa | stress amplitude |

| σb | tensile strength |

| σeq | von Mises equivalent stress |

| σm, σm′ | mean stress, the equivalent mean stress with torque effect |

| σs | centrifugal tensile stress |

| σ−1 | fatigue limit |

| τt | torsional shear stress |

| b0, M0, α, β | material parameters |

| coupling mass matrix |

References

- Sun, X.; Xu, D.; Sun, D. Recent development of casing treatments for aeroengine compressors. Chin. J. Aeronaut. 2019, 32, 1–36. [Google Scholar] [CrossRef]

- Abu, A.O.; Eshati, S.; Laskaridis, P.; Singh, R. Aero-engine turbine blade life assessment using the Neu/Sehitoglu damage model. Int. J. Fatigue 2014, 61, 160–169. [Google Scholar] [CrossRef]

- Poursaeidi, E.; Babati, A.; Behrouzshad, F.; Arhani, M.R. Failure analysis of an axial compressor first row rotating blades. Eng. Fail. Anal. 2013, 28, 25–33. [Google Scholar] [CrossRef]

- Bednarz, A.; Misiolek, W.Z. Numerical and Experimental Assessment of the Effect of Residual Stresses on the Fatigue Strength of an Aircraft Blade. Material 2021, 14, 5279. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wang, Y. The Design Problem of Aero-Engine Structure Strength, 1st ed.; Shanghai Jiao Tong University Press: Shanghai, China, 2014; pp. 5–66. [Google Scholar]

- Tao, C.; Zhong, P.; Wang, R.; Nie, J. Failure Analysis and Prevention for Rotor in Aero-Engine, 1st ed.; Beijing National Defence Industry Press: Beijing, China, 2000; pp. 5–39. [Google Scholar]

- Mårtensson, H. Harmonic Forcing from Distortion in a Boundary Layer Ingesting Fan. Aerospace 2021, 8, 58. [Google Scholar] [CrossRef]

- Arena, M.; Chiariello, A.; Castaldo, M.; Palma, L.D. Vibration Response Aspects of a Main Landing Gear Composite Door Designed for High-Speed Rotorcraft. Aerospace 2021, 8, 52. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, X.; Kou, H.; Lin, J. Numerical study on vibration characteristics of axial flow compressor blade under fluid-structure interaction. J. Vib. Meas. Diagn. 2018, 38, 59–66. [Google Scholar]

- Ernst, M.; Michel, A.; Jeschke, P. Analysis of rotor-stator-interaction and blade-to-blade measurements in a two stage axial flow compressor. J. Turbomach. 2011, 133, 11–27. [Google Scholar] [CrossRef]

- Janardhana, K.; Maharana, S.K. Numerical Study of Vibration Stress and Deformation of Rotating Fan Blade of a Gas Turbine. Int. J. Struct. Mechan. Finite Elem. 2017, 3, 1–11. [Google Scholar]

- Liu, Y.; Lao, D.; Liu, Y.; Yang, C.; Qi, M.; Ma, C. Harmonic resonance and high cycle fatigue of a radial turbine in pressure fluctuation. Trans. Beijing Inst. Technol. 2014, 34, 1120–1124. [Google Scholar]

- Belamri, T.; G.alpin, P.; Braune, A.; Cornelius, C. CFD Analysis of a 15 Stage Axial Compressor: Part I-Methods, ASME Turbo Expo 2005: Power for Land, Sea, and Air; American Society of Mechanical Engineers: Reno, NV, USA, 2005; pp. 1001–1008. [Google Scholar]

- Belamri, T.; G.alpin, P.; Braune, A.; Cornelius, C. CFD Analysis of a 15 Stage Axial Compressor: Part II-Results, ASME Turbo Expo 2005: Power for Land, Sea, and Air; American Society of Mechanical Engineers: Reno, NV, USA, 2005; pp. 1009–1017. [Google Scholar]

- Ni, Q.; Hou, A.; Liu, R.; Zhou, B.; Zhang, M. Separation flow and blade dynamic response characteristic of compressor at high attack angle. J. Beijing Univ. Aeronaut. Astronaut. 2017, 43, 1410–1418. [Google Scholar]

- Berg, D.; Wilson, D.; Resor, B.; Barone, M.; Berg, J.; Kota, S.; Ervin, G. Active aerodynamic blade load control impacts on utility-scale wind turbines. In Proceedings of the Windpower Conference & Exhibition, Chicago, IL, USA, 1 April 2009. [Google Scholar]

- Kaewbumrung, M.; Tangsopa, W.; Thongsri, J. Investigation of the trailing edge modification effect on compressor blade aerodynamics using SST k-ω turbulence model. Aerospace 2019, 6, 48. [Google Scholar] [CrossRef] [Green Version]

- Amoo, L. On the design and structural analysis of jet engine fan blade structures. Prog. Aerosp. Sci. 2013, 60, 1–11. [Google Scholar] [CrossRef]

- Song, X.; Wang, L.; Niinomi, M.; Nakai, M.; Liu, Y. Fatigue characteristics of a biomedical β-type titanium alloy with titanium boride. Mater. Sci. Eng. A 2015, 640, 154–164. [Google Scholar] [CrossRef]

- Zhang, Y.; Maddox, S.; Manteghi, S. Verification of Class B S-N curve for fatigue design of steel forgings. Int. J. Fatigue 2016, 92, 246–261. [Google Scholar] [CrossRef]

- Miner, M.A. Cumulative damage in fatigue. J. Appl. Mech. 1945, 12, 159–164. [Google Scholar] [CrossRef]

- Marco, S.M.; Starkey, W.L. A concept of fatigue damage. Trans. ASME 1954, 76, 627–632. [Google Scholar]

- Gatts, R. Application of a cumulative damage concept to fatigue. J. Fluids Eng. 1961, 83, 529–534. [Google Scholar] [CrossRef]

- Manson, S.S.; Halford, G.R. Practical implementation of the double linear damage rule and damage curve approach for treating cumulative fatigue damage. Int. J. Fract. 1981, 17, 169–192. [Google Scholar] [CrossRef] [Green Version]

- Sonsino, C. Course of SN-curves especially in the high-cycle fatigue regime with regard to component design and safety. Int. J. Fatigue 2007, 29, 2246–2258. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, S.; Lin, L. A nonlinear continuous damage model based on short-crack concept under variable amplitude loading. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 79–94. [Google Scholar] [CrossRef]

- Chaboche, J.; Lesne, M. A non-linear continuous fatigue damage model. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 1–17. [Google Scholar] [CrossRef]

- Dattoma, V.; Giancane, S.; Nobile, R.; Panella, F. Fatigue life prediction under variable loading based on a new non-linear continuum damage mechanics model. Int. J. Fatigue 2006, 28, 89–95. [Google Scholar] [CrossRef]

- Malcher, L.; Mamiya, E. An improved damage evolution law based on continuum damage mechanics and its dependence on both stress triaxiality and the third invariant. Int. J. Plast. 2014, 56, 232–261. [Google Scholar] [CrossRef]

- Yao, Y.; He, X.; Keer, L.; Fine, M. A continuum damage mechanics-based unified creep and plasticity model for solder materials. Acta Mater. 2015, 83, 160–168. [Google Scholar] [CrossRef]

- Van, D.; Lee, C.; Chang, K. High cycle fatigue analysis in presence of residual stresses by using a continuum damage mechanics model. Int. J. Fatigue 2015, 70, 51–62. [Google Scholar]

- Gao, T.; Jing, J.; Chen, C.; Cong, J.; Li, J.; Cao, S. A practical nonlinear damage accumulation method to predict the life and crack propagation of blade subjected to multilevel cyclic fatigue loads. J. Strain Anal. Eng. Des. 2020, 55, 86–98. [Google Scholar] [CrossRef]

- Heylen, W.; Stefan, L.; Paul, S. Modal Analysis Theory and Testing; Katholieke Universiteit Leuven: Leuven, Belgium, 1997. [Google Scholar]

- Ma, Y.; Cao, S.; Guo, H. Nonlinear aeroelastic analysis of rotating shrouded blades under coupled bending and torsional vibration. J. Vib. Shock 2019, 38, 67–74. [Google Scholar]

- Mohaghegh, K.; Sadeghi, M.; Abdullah, A. Reverse engineering of turbine blades based on design intent. Int. J. Adv. Manuf. Technol. 2007, 32, 1009–1020. [Google Scholar] [CrossRef]

- Kou, H.; Lin, J.; Zhang, J.; Fu, X. Dynamic and fatigue compressor blade characteristics during fluid-structure interaction: Part I—Blade modelling and vibration analysis. Eng. Fail. Anal. 2017, 76, 80–98. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, J.; Lin, J. Study on fatigue life and damage accumulation of compressor blade based on a modified nonlinear damage model. Fatigue Fract. Eng. Mater. Struct. 2017, 41, 1077–1088. [Google Scholar] [CrossRef]

- Kielb, R.E.; Barter, J.W.; Thomas, J.P.; Hall, K.C. Blade excitation by aerodynamic instabilities: A compressor blade study. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: Atlanta, GA, USA, 2003; pp. 399–406. [Google Scholar]

- Im, H.S.; Zha, G. Simulation of non-synchronous blade vibration of an axial compressor using a fully coupled fluid/structure interaction. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: Copenhagen, Denmark, 2012; pp. 1395–1407. [Google Scholar]

- Espinal, D.; Im, H.S.; Zha, G. Full-annulus simulation of nonsynchronous blade vibration excitation of an axial compressor. J. Turbomach. 2018, 140, 031008. [Google Scholar] [CrossRef]

| Mode No. | Nature Frequency/Hz | Relative Error/% | Mode Shape | ||

|---|---|---|---|---|---|

| Test Results | Computational Results | ||||

| 1 | 272.94 | 284.90 | 4.38 | 1st order bending |  |

| 2 | 956.94 | 1006.80 | 5.21 | 1st order torsion |  |

| 3 | 1283.13 | 1256.50 | 2.08 | 2nd order bending |  |

| 4 | 2133.93 | 1950.60 | 8.59 | Bending-torsioncomposite |  |

| 5 | 2752.60 | 3011.20 | 9.39 | 2nd order torsion |  |

| Case | Take Off | Maximum Continuous | Cruise | Descending | Flight Idle | Ground Idle |

|---|---|---|---|---|---|---|

| Rotational speed/rpm | 9561 | 9337 | 9172 | 8847 | 6966 | 6278 |

| Mode No. | Load Condition | Dynamic Frequency/Hz | |||||

|---|---|---|---|---|---|---|---|

| 6278 (rpm) | 6966 (rpm) | 8847 (rpm) | 9172 (rpm) | 9337 (rpm) | 9561 (rpm) | ||

| 1 | CL 1 | 357.78 | 371.62 | 413.15 | 420.77 | 424.68 | 430.04 |

| CL+ AL 2 | 356.81 | 370.61 | 412.06 | 419.48 | 423.37 | 428.63 | |

| 2 | CL | 1040.6 | 1044.9 | 1057.9 | 1060.2 | 1061.4 | 1063.1 |

| CL+ AL | 1044.4 | 1050.3 | 1068.6 | 1072.2 | 1074.2 | 1076.2 | |

| 3 | CL | 1348.7 | 1363.1 | 1409.3 | 1418.2 | 1422.8 | 1429.2 |

| CL+ AL | 1347.6 | 1361.3 | 1404.8 | 1413.5 | 1417.9 | 1423.6 | |

| 4 | CL | 2069.7 | 2073.9 | 2087.5 | 2090.2 | 2091.6 | 2093.6 |

| CL+ AL | 2078.8 | 2084.6 | 2103.8 | 2107.9 | 2109.9 | 2112.5 | |

| 5 | CL | 3136.3 | 3140.8 | 3154.8 | 3157.5 | 3159.0 | 3160.9 |

| CL+ AL | 3153.5 | 3164.6 | 3200.3 | 3207.9 | 3211.7 | 3216.0 | |

| 6 | CL | 3288.7 | 3305.8 | 3362.0 | 3373.1 | 3378.8 | 3386.8 |

| CL+ AL | 3290.9 | 3307.7 | 3365.1 | 3378.2 | 3384.5 | 3391.9 | |

| Operating Cycle | Maximum Stress (MPa) | Minimum Stress (MPa) | Number of Loading Cycles (Cycle/1000 h) | Fatigue Life (Cycle) |

|---|---|---|---|---|

| 0—take-off—0 | 563.54 | 0 | 311 | 32,723 |

| Ground idle speed—take-off—ground idle speed | 563.54 | 215.95 | 37 | 50,729 |

| 0—maximum endurance—0 | 525.63 | 0 | 244 | 39,896 |

| flight idle speed—descending—flight idle speed | 437.76 | 264.58 | 8952 | 142,770 |

| Cruising—flight idle speed—cruising | 525.63 | 480.64 | 7494 | 868,250 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Ma, C.; Lin, J.; Zhang, J. Numerical Study on Vibration Response and Fatigue Damage of Axial Compressor Blade Considering Aerodynamic Excitation. Metals 2021, 11, 1835. https://doi.org/10.3390/met11111835

Fu X, Ma C, Lin J, Zhang J. Numerical Study on Vibration Response and Fatigue Damage of Axial Compressor Blade Considering Aerodynamic Excitation. Metals. 2021; 11(11):1835. https://doi.org/10.3390/met11111835

Chicago/Turabian StyleFu, Xi, Chao Ma, Jiewei Lin, and Junhong Zhang. 2021. "Numerical Study on Vibration Response and Fatigue Damage of Axial Compressor Blade Considering Aerodynamic Excitation" Metals 11, no. 11: 1835. https://doi.org/10.3390/met11111835

APA StyleFu, X., Ma, C., Lin, J., & Zhang, J. (2021). Numerical Study on Vibration Response and Fatigue Damage of Axial Compressor Blade Considering Aerodynamic Excitation. Metals, 11(11), 1835. https://doi.org/10.3390/met11111835