1. Introduction

Non-oriented silicon steel is mainly used to manufacture the core component of a drive motor. Its performance determines the drive characteristics and service performance of the drive motor [

1]. With the rapid development of drones, centrifugal compressor and electric vehicles, the applications of high-speed motors with rotor speed up to tens of thousands or even hundreds of thousands of revolutions per minute are gradually increasing [

2]. The centrifugal force borne by the rotor of driving motor increases in proportion to the square of speed and rotor radius. In addition, the complex driving conditions of electric vehicles have high requirements for the driving motor. The rotor cores with complex shapes of high-speed driving motors not only requires good magnetic properties to improve energy conversion efficiency but also excellent mechanical properties and fatigue properties to resist deformation and failure [

3,

4,

5]. As a result, non-oriented silicon steel with high strength has become an important development trend in recent years.

High strength non-oriented silicon steel is not only a functional material but also a structural material. It is generally believed that the methods for improving mechanical properties may often damage the magnetic properties of non-oriented silicon steel, and magnetic properties and mechanical properties are contradictory [

6,

7]. A key issue is to coordinate the contradiction between mechanical properties and magnetic properties of non-oriented silicon steel. Currently, it is difficult to produce thin-gauge non-oriented silicon steel with higher magnetic induction, lower core loss and higher strength in conventional continuous casting–hot rolling processes, where the texture control level almost reaches its limit. Fortunately, strip casting technology with short processes and that save energy provides a novel method for the preparation of non-oriented silicon steel in recent research [

8,

9]. It has been recognized that the initial favorable {100} columnar structure in as-cast strips exhibited strong heredity to increase the intensity of favorable {100} texture and reduces the intensity of harmful γ texture (<111>//normal direction) in the final sheet, which could significantly improve the magnetic properties of non-oriented silicon steel [

10]. Moreover, the characteristics of the near-net shape of strip casting is beneficial for processing ultra-thin non-oriented silicon steel [

11,

12].

In terms of mechanical properties of non-oriented silicon steel, there are mainly three strengthening mechanisms, which involves dislocation strengthening, solid solution strengthening and precipitation strengthening. In the case of dislocation strengthening, dislocation annihilation was inhibited by incomplete recrystallization annealing in order to improve the mechanical properties of non-oriented silicon steel, but its deterioration effect on magnetic properties was significant [

13,

14]. Solid solution strengthening of non-oriented silicon steel was mainly realized by the addition of solid solution elements, such as Si, Al, Mn, P and Ni, to cause lattice distortion in order to improve matrix strength [

7,

15,

16,

17]. The relevant deterioration of magnetic properties is at tolerable levels, but it generally requires additional alloying elements, which not only increases production costs but also brings some difficulties in the rolling and stamping process. Introducing Cu into non-oriented silicon steel for precipitation strengthening to improve mechanical properties is a potential method for non-oriented silicon steel [

18,

19,

20,

21]. Due to the low solubility of Cu in ferrite and low lattice misfit between Cu precipitates and bcc matrix, the high densities of nano-size Cu precipitates form after thermal-aging processes and significantly enhance mechanical properties. Meanwhile, Bian [

19] and Wu [

20] reported that Cu-rich precipitates could improve recrystallization texture by inhibiting γ texture and promoting Goss texture ({110} <100>), resulting in the decrease in core loss without deteriorating magnetic induction. Moreover, it is suggested that Cu precipitates significantly contributed to the yield strength of a 0.35 mm thick non-oriented silicon steel without deteriorating the magnetic properties in the strip casting process [

21]. However, studies on Cu precipitates in thin-gauge non-oriented silicon steel are limited. Cu precipitation behaviors in non-oriented silicon steel and its effect on magnetic properties and mechanical properties in different processes are not clear. Therefore, it is worthwhile to take full technical advantage of strip casting and the strengthening effect of Cu precipitates to prepare ultra-thin non-oriented silicon steel with good magnetic and mechanical properties.

In this study, 0.20 and 0.35 mm thick non-oriented silicon steels with Cu addition were processed by using conventional processes and strip casting processes. The evolutions of microstructure and texture were comparatively studied. Furthermore, Cu precipitation behavior and its effects on magnetic and mechanical properties are discussed in detail.

2. Materials and Methods

The composition of the experimental steel is shown in

Table 1. The hot rolled sheet and as-cast strip with near-identical thickness were prepared by conventional hot rolling processes (denoted as conventional process) and strip casting processes. After normalization, 0.35 and 0.20 mm non-oriented silicon steels were subjected to single-stage and two-stage cold rolling, respectively, followed by annealing and aging treatments. A schematic diagram of the detailed processes is shown in

Figure 1.

In the strip casting process, the as-cast strip that was 2.3 mm thick was directly produced by a vertical twin-roll strip caster (State Key Laboratory of Rolling and Automation, Shenyang, China) at the speed of 30~40 m/min and then air cooled to room temperature. In the conventional process, a 50 kg ingot of experimental steel was cast in vacuum induction and then forged. Before hot rolling, the billet was homogenized at 1150 °C for 3 h. Then, it was hot rolled to 2.3 mm via 7 passes with a finishing temperature of 924 °C; then, it was air cooled to room temperature. After obtaining a hot band and as-cast strip, the subsequent process was kept the same. Subsequently, both as-cast strips and hot rolled sheets were normalized at 1050 °C for 5 min and then pickled. Next, single-stage and two-stage cold rolling processes were adopted to process 0.35 mm and 0.20 mm sheets, respectively. In terms of single-stage cold rolling, total rolling reduction was about 85%. A two-stage process was carried out, involving a first stage of cold rolling with a reduction of 70%, intermediate annealing at 1050 °C for 5 min, and a second stage of cold rolling with a reduction of 71%. All the cold rolled sheets were annealed at 1050 °C for 5 min for recrystallization and then aged at 550 °C for 25, 40, 60, 90, 120 and 240 min, respectively. For convenience, the processes to produce the 0.35 mm and 0.20 mm sheets in the conventional process were denoted as route A and route B, respectively. Similarly, it was named route C and route D in the strip casting process.

Metallographic microstructure was examined by a Leica optical microscope (Leica, Wetzlar, Germany) along the longitudinal section as defined by the rolling direction (RD) and normal direction (ND). The microstructure and micro-texture were characterized by electron backscattered diffraction (EBSD) (Oxford, Aztec, UK) attached to a field emission scanning electron microscope (SEM, Zeiss Ultra 55, Carl Zeiss, Jena, Germany) along the longitudinal section, and data analysis was post-processed with HKL-Channel 5 software. For macrotexture, three incomplete pole figures, {200}, {110} and {211}, were measured by using Bruker D8 Discover X-ray diffraction with CoKα1 radiation along the rolling plane in the subsurface layer. The ODFs (orientation distribution functions) were calculated based on series expansion methods. The precipitation observation was conducted in a TECNAI G2 F20 transmission electron microscope (TEM, FEI, Hillsboro, OR, USA) equipped with energy dispersive X-ray spectroscopy, and data were analyzed by Digital Micrograph. Furthermore, the magnetic properties involving magnetic induction of B50 and core loss of P1.5/50, P1.0/50, P1.0/400 and P1.0/1000 were measured by a using single sheet tester with dimensions of 100 (RD) × 30 mm (transverse direction, TD). For mechanical properties, standard tensile tests were carried out by using an AG-X plus100KN (Shimadzu, Tokyo, Japan) testing machine at room temperature at a crosshead speed of 1 mm/min. The properties are an average of three measurements.

4. Discussion

Considering that the aging temperature of 550 °C was lower than recrystallization temperature, grain size and texture did not vary obviously; thus, magnetic induction retained high stability during the aging process. The improvement of magnetic induction in strip casting is attributed to texture optimization, based on the fact that detrimental γ texture was weakened while the favorable α texture and Goss component were enhanced. In terms of the rolling process, two-stage was much more beneficial for obtaining relatively coarse microstructure and for inhibiting the accumulation of γ texture, which is much more important in the preparation of thin-gauge non-oriented silicon steel. As a result, superior magnetic induction as high as 1.76 T was obtained in route D.

There are many factors affecting core loss, which includes chemical composition, crystallographic texture, grain size and thickness. In this study, relative coarse grain and beneficial texture contributed to decreases in core loss. Thickness reduction exhibited a dominant role in the decrease in total core loss in thinner non-oriented silicon steel, considering that the eddy current loss is proportional to the square of thickness [

26]. As a result, the 0.20 mm sheet in strip casting exhibited superior core loss. The magnetic properties of non-oriented silicon steel did not vary obviously after aging treatment, which indicated that Cu precipitates had negligible detrimental effects on core loss and permeability in this study. It is generally believed that precipitates have a negative impact on the magnetic properties of non-oriented silicon steel [

27]. Weak magnetic or non-magnetic precipitation will directly increase the coercivity and hysteresis loss of non-oriented silicon steel, and higher densities of dislocation around precipitates will also result in higher static magnetic and magnetoelastic properties [

28]. However, Cu precipitates with a maximum size of ~15.2 nm over aging, which was less than the thickness of domain wall, played a weaker role in hindering domain wall motion and reducing saturated magnetic flux density.

In order to further understand the influence of processing route and thickness on core loss, total core loss was separated into hysteresis loss (P

h), eddy currency loss (P

e) and anomaly loss (P

a) via classic loss separation methods [

29], as shown in

Figure 12. It can be observed that the core loss value and proportion of individual loss were sensitive to thickness and test frequency. Thickness reduction significantly reduced eddy current loss, while the proportion of eddy current loss increased from 5.0 to 40.9% when the frequency varied from 50 to 1000 Hz. It was indicated that eddy currency loss and anomaly loss dominated total core loss under high frequency conditions, while hysteresis loss maintained a relatively stable level in different routes. Then, it can be inferred that texture optimization did not show obvious beneficial effects on high-frequency core loss. On the contrary, thickness reduction can effectively reduce the increment of eddy currency loss, thereby significantly reducing high-frequency core losses of non-oriented silicon steel. Moreover, based on the fact that anomaly loss mainly depended on magnetic domain structure [

5], it is also very important to improve the homogeneity of microstructure. Considering that the recrystallization microstructure of thin-gauge sheets is more sensitive to the deformation state and annealing process, the control of process parameters needs to be strict.

In order to clarify the precipitation strengthening mechanism of Cu, it is important to quantitatively calculate the contribution from different strengthening mechanisms of Cu precipitates. It was observed that the crystal structure and size of Cu precipitates varied with aging time, and Cu precipitates retained bcc structure and were coherent with the matrix during the peak-aged stage. According to previous research results, the precipitation strengthening mechanism of coherent bcc

Cu precipitates with sizes less than the critical size is the primarily cutting mechanism [

30,

31]. Therefore, the strengthening increment of tested steel aged at 550 °C for 25–120 min is mainly contributed by three strengthening mechanisms: chemical strengthening, coherency strengthening and modulus strengthening. The equation for the contribution of chemical strengthening is given as follows [

32]:

where M (=2.75) is the Taylor factor of non-oriented silicon steel, γ

interfacial (=0.22 J/m

2) is the average antiphase boundary energy of Cu, b

α-Fe (=2.48 Å) is the Burgers vector in the matrix and λ is the average spacing of the precipitate among the matrix [

33]:

where r is the average particle radius, and N is the number density of the precipitates.

T is the line tension of dislocation, mostly taken by following formula [

33]:

where G

Fe (=8.3 × 10

4 N/m

2) is the shear modulus of matrix.

The equation for the contribution of modulus strengthening has been derived by Russell and Brown [

32] as follows:

where U

p and U

m are the line energies of nanoparticles and matrix, respectively. The ratio U

p/U

m depends on the particle radius r and is described as follows:

where r

i (=2.5 b) and r

0 (=1000 r) are the inner and outer cut-off radii of the dislocation stress field, respectively, and

and

refer to the line energies of the dislocations in precipitation and matrix, respectively. Based on the above calculation, a value of 0.62 for the ratio of U

p/U

m is utilized in this study.

Coherency strengthening due to the coherency strain associated with the nanoscale precipitates is described as follows [

34]:

where ε (=0.0057) is the constrained lattice parameter mismatch.

After the peak aging stage, Cu precipitates transformed from bcc structure to non-coherent fcc structure. The interaction mechanism between dislocation and precipitates changes from cutting through softer bcc

Cu to bypassing harder fcc

Cu, and the main precipitation strengthening mechanism of precipitation strengthening changes to the Orowan mechanism. The strengthening increment of Orowan mechanism is calculated as follows [

35,

36]:

where C (=0.127) is constant, and r

0 (=1.632 r) is the outer cut-off radius of the dislocation stress field during over-aged conditions.

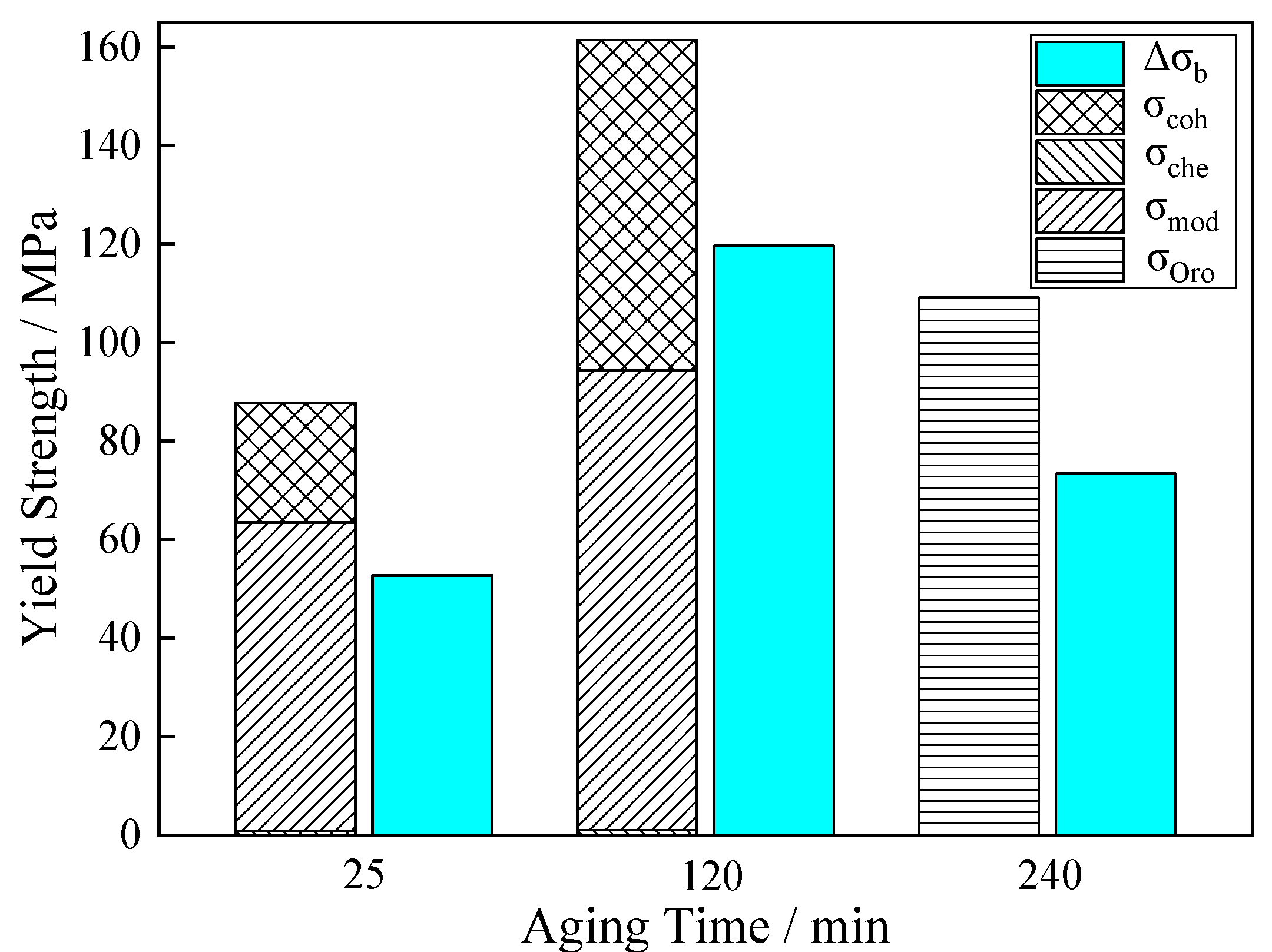

The contributions of various precipitation strengthening mechanisms of non-oriented silicon steel with a thickness of 0.2 mm are represented in

Figure 13. According to the precipitation strengthening mechanism, both density and mean size of precipitates play crucial roles in increasing strength. Then, obtaining high densities of relatively fine Cu precipitates is desired, which achieved a balance for obtaining peak strength when aged for 120 min in this study. It is evident that for the tested steel, modulus strengthening made a major contribution to strengthening under the condition of cutting mechanisms, which was as high as 93.3 MPa. Considering that the high density of Cu precipitates with critical sizes was coherent with the matrix, a maximum coherency strengthening of 67.1 MPa was achieved at the peak aging condition. By contrast, the chemical effect arising from the additional interfaces can be ignored in this study. Moreover, it is worth noting that the calculated values were ~35 MPa lower than the tested yield strength increment at different stages. Given that strength significantly decreased with the thickness close to grain size [

37], the error can be attributed to the detrimental size effect in thin sheets.

Based on above discussion, Cu precipitates can be used to significantly improve yield strength over ~120 MPa without deteriorating the magnetic properties in both conventional processes and strip casting processes. In the conventional process, an initial microstructure with fine grain and relatively strong γ texture was formed after heavy hot rolling, which resulted in unfavorable microstructure and texture after final annealing, as well as poor magnetic properties. On the other hand, improved strengthening effects from Cu precipitates about 20–40 MPa were obtained in the conventional process, which may be related to the uniform distribution of Cu in the matrix. In strip casting processes, due to the initial microstructure with coarse grain and relatively strong {100} texture, beneficial microstructure and texture were obtained in this study. Meanwhile, excellent magnetic properties were obtained both in 0.35 and 0.20 mm non-oriented silicon steels, especially for high-frequency core losses. Moreover, considering that high-frequency core loss was sensitive to thickness and homogeneity of microstructure, balanced magnetic properties and mechanical properties can be achieved in thin-gauge non-oriented silicon steel in strip casting processes. However, it should also be pointed out that thickness reduction would bring about some additional problems, such as inhomogeneity of microstructure and detrimental size effect relative to strength.

Author Contributions

Conceptualization, F.F.; software, S.C.; validation, G.Y.; investigation, Z.W.; resources, Y.Z.; data curation, D.H.; writing—review and editing, F.F. and R.D.K.M.; visualization, Y.W.; supervision, X.Z.; project administration, G.W.; funding acquisition, F.F. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Natural Science Foundation of China (Nos. 52001060 and 51801022), the China Postdoctoral Science Foundation funded project (Nos. 2019TQ0053 and 2020M680963), the Fundamental Research Funds for the Central Universities (Nos. N2007003 and N2007011) and Natural Science Foundation of Liao Ning Province of China (Nos. 2020-BS-047).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to technical or time limitations.

Acknowledgments

The authors are grateful to R.D.K. Misra for their contribution to the discussion.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Oda, Y.; Kohno, M.; Honda, A. Recent development of non-oriented electrical steel sheet for automobile electrical devices. J. Magn. Magn. Mater. 2008, 320, 2430–2435. [Google Scholar] [CrossRef]

- Tanaka, I.; Nitomi, H.; Imanishi, K. Application of high-strength nonoriented electrical steel to interior permanent magnet synchronous motor. IEEE Trans. Magn. 2013, 49, 2997–3001. [Google Scholar] [CrossRef]

- Gerada, D.; Mebarki, A.; Brown, N.L. High-Speed Electrical Machines: Technologies, Trends, and Developments. IEEE Trans. Ind. Electron. 2013, 61, 2946–2959. [Google Scholar] [CrossRef]

- Gong, J.; Luo, H.W. Progress on the Research of High-strength Non-oriented Silicon Steel Sheets in Traction Motors of Hybrid/Electrical Vehicles. J. Mater. Eng. 2015, 43, 102–112. [Google Scholar] [CrossRef]

- Moses, J.A. Energy efficient electrical steels: Magnetic performance prediction and optimization. Scr. Mater. 2012, 67, 560–565. [Google Scholar] [CrossRef]

- Tanaka, I.; Yashiki, H. Magnetic and Mechanical Properties of Newly Developed High-Strength Nonoriented Electrical Steel. IEEE Trans. Magn. 2010, 46, 290–293. [Google Scholar] [CrossRef]

- Kubota, T. Recent Progress on Non-oriented Silicon Steel. Steel Res. Int. 2005, 76, 464–470. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Xu, Y.B.; Liu, H.T.; Li, C.G.; Cao, G.M.; Liu, Z.Y.; Wang, G.D. Microstructure, texture and magnetic properties of strip-cast 1.3% Si non-oriented electrical steels. J. Magn. Magn. Mater. 2012, 324, 3328–3333. [Google Scholar] [CrossRef]

- Jiao, H.T.; Xu, Y.B.; Zhao, L.Z. Texture evolution in twin-roll strip cast non-oriented electrical steel with strong Cube and Goss texture. Acta Mater. 2020, 199, 311–325. [Google Scholar] [CrossRef]

- Fang, F.; Zhang, Y.X.; Lu, X. Abnormal growth of {100} grains and strong Cube texture in strip cast Fe-Si electrical steel. Scr. Mater. 2018, 147, 33–36. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Lan, M.F.; Wang, Y. Microstructure and texture evolution of thin-gauge non-oriented silicon steel with high permeability produced by twin-roll strip casting. Mater. Charact. 2019, 150, 118–127. [Google Scholar] [CrossRef]

- Jiao, H.; Xu, Y.; Xiong, W. High-permeability and thin-gauge non-oriented electrical steel through twin-roll strip casting. Mater. Des. 2017, 136, 23–33. [Google Scholar] [CrossRef]

- De Martínez-Guerenu, A.; Arizti, F.; Díaz-Fuentes, M. Recovery during annealing in a cold rolled low carbon steel. Part I: Kinetics and microstructural characterization. Acta Mater. 2004, 52, 3657–3664. [Google Scholar] [CrossRef]

- De Martínez-Guerenu, A.; Arizti, F.; Gutiérrez, I. Recovery during annealing in a cold rolled low carbon steel. Part II: Modelling the kinetics. Acta Mater. 2004, 52, 3665–3670. [Google Scholar] [CrossRef]

- Barros, J. The effect of Si and Al concentration gradients on the mechanical and magnetic properties of electrical steel. J. Magn. Magn. Mater. 2005, 290, 1457–1460. [Google Scholar] [CrossRef]

- Hong, J.; Choi, H.; Lee, S. Effect of Al content on Magnetic Properties of Fe-Al Non-oriented Electrical Steel. J. Magn. Magn. Mater. 2017, 439, 343–348. [Google Scholar] [CrossRef]

- Lee, S.; Bruno, C.; Cooman, D. Influence of Phosphorous and Boron on the Recrystallization, Grain Growth and Mechanical Properties of 3% Si steel. Mater. Sci. Forum. 2010, 962, 654–656. [Google Scholar] [CrossRef]

- Fujikura, M.; Murakami, H.; Ushigami, Y. Effects of Cu precipitates on magnetic properties of nonoriented electrical steel. IEEE Trans. Magn. 2015, 51, 2001604. [Google Scholar] [CrossRef]

- Bian, X.H.; Zeng, Y.P.; Nan, D.; Wu, M. The effect of copper precipitates on the recrystallization textures and magnetic properties of non-oriented electrical steels. J. Alloy. Compd. 2014, 588, 108–113. [Google Scholar] [CrossRef]

- Wu, M.; Zeng, Y.P. Effect of copper precipitates on the stability of microstructures and magnetic properties of non-oriented electrical steels. J. Magn. Magn. Mater. 2015, 391, 96–100. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Zhang, X.M.; He, Z. Effect of copper precipitates on mechanical and magnetic properties of Cu-bearing non-oriented electrical steel processed by twin-roll strip casting. Mater. Sci. Eng. A 2017, 703, 340–347. [Google Scholar] [CrossRef]

- Goodman, S.R.; Brenner, S.S.; Low, J.R. An FIM-atom probe study of the precipitation of copper from lron-1.4 at. pct copper. Part I: Field-ion microscopy. Metall. Trans. 1973, 4, 2363–2369. [Google Scholar] [CrossRef]

- Wen, Y.R.; Hirata, A.Z.; Zhang, W. Microstructure characterization of Cu-rich nanoprecipitates in a Fe–2.5Cu–1.5 Mn–4.0 Ni–1.0 Al multicomponent ferritic alloy. Acta Mater. 2013, 61, 2133–2147. [Google Scholar] [CrossRef]

- Heo, Y.U.; Kim, Y.K.; Kim, J.S. Phase transformation of Cu precipitates from bcc to fcc in Fe-3Si-2Cu alloy. Acta Mater. 2013, 61, 519–528. [Google Scholar] [CrossRef]

- Othen, P.J.; Jenkins, M.L.; Smith, G.D.W. High-resolution electron microscopy studies of the structure of Cu precipitates in α-Fe. Philos. Mag. A 1994, 70, 1–24. [Google Scholar] [CrossRef]

- Bertotti, G. General properties of power losses in soft ferromagnetic materials. IEEE Trans. Magn. 1988, 24, 621–630. [Google Scholar] [CrossRef]

- Liu, J.Z.; Walle, A.; Ghosh, G. Structure, energetics, and mechanical stability of Fe-Cu bcc alloys from first-principles calculations. Phys. Rev. B Condens. Matter Mater. Phys. 2005, 72, 144109. [Google Scholar] [CrossRef] [Green Version]

- Jenkins, K.; Lindenmo, M. Precipitates in electrical steels. J. Magn. Magn. Mater. 2008, 320, 2423–2429. [Google Scholar] [CrossRef]

- Qin, J.; Yang, P.; Mao, W.; Ye, F. Effect of texture and grain size on the magnetic flux density and core loss of cold-rolled high silicon steel sheets. J. Magn. Magn. Mater. 2015, 393, 537–543. [Google Scholar] [CrossRef]

- Osamura, K.; Okuda, H.; Takashima, M. Small-angle neutron scattering study of phase decomposition in Fe-Cu binary alloy. Mater. Trans. JIM 1993, 34, 305–311. [Google Scholar] [CrossRef] [Green Version]

- Xiong, Z.P.; Timokhina, I.; Pereloma, E. Clustering, nano-scale precipitation and strengthening of steels. Prog. Mater. Sci. 2021, 118, 100764. [Google Scholar] [CrossRef]

- Brown, L.M.; Ham, R.K. Dislocation-particle interactions. In Strengthening Methods in Crystals; Kelly, A., Nicholson, R.B., Eds.; Applied Science Publishers: London, UK, 1965; pp. 9–135. [Google Scholar]

- Xu, S.S.; Zhao, Y.; Chen, D. Nanoscale precipitation and its influence on strengthening mechanisms in an ultra-high strength low-carbon steel. Int. J. Plast. 2019, 113, 99–110. [Google Scholar] [CrossRef]

- Russell, K.C.; Brown, L.M. A Dispersion Strengthening Model based on differing elastic moduli applied to the iron-copper system. Acta Metall. Mater. 1972, 20, 969–974. [Google Scholar] [CrossRef]

- Ashby, M. The theory of the critical shear stress and work hardening of dispersion-hardened crystals. In Metallurgical Society Conference; Ansell, G.S., Cooper, T.D., Lenel, F.V., Eds.; Gordon and Breach: New York, NY, USA, 1968; Volume 47, pp. 143–205. [Google Scholar]

- Sonderegger, B. Modifications of stereological correction methods for precipitate parameters using transmission microscopy. Ultramicroscopy 2006, 106, 941–950. [Google Scholar] [CrossRef] [PubMed]

- Michel, J.F.; Picart, P. Size effects on the constitutive behaviour for brass in sheet metal forming. J. Mater. Process. Technol. 2003, 141, 439–446. [Google Scholar] [CrossRef]

Figure 1.

The schematic diagram of strip casting and conventional hot rolling process.

Figure 2.

Microstructure and micro-texture (ODF section at φ2 = 45°) of (a–c) hot rolled sheet and (d–f) as-cast strip.

Figure 3.

Microstructure and micro-texture (ODF section at φ2 = 45°) of normalized sheets in (a–c) the conventional process and (d–f) strip casting.

Figure 4.

Microstructure and macrotexture (ODF section at φ2 = 45°) of (a,b,e,g) 0.35 mm and (c,d,f,h) 0.20 mm cold rolled sheets in (left) the conventional process and (right) strip casting.

Figure 5.

Microstructure and micro-texture (ODF section at φ2 = 45°) of (a,b,e,g) 0.35 mm and (c,d,f,h) 0.20 mm annealed sheets in (left) the conventional process and (right) strip casting.

Figure 6.

TEM morphology and size distribution of Cu precipitates in (a,b) hot rolled sheet and (c,d) as-cast strip.

Figure 7.

(a) TEM morphology, (b) [111] bcc HR (high resolution)-TEM image, (c) FFT pattern and (d) IFFT image by masking (011) reflection of typical Cu precipitates after aging at 550 °C for 25 min.

Figure 8.

(a) TEM morphology, (b) [100] bcc HR (high resolution)-TEM image, (c) FFT pattern and (d) IFFT image by masking (001) reflection of typical Cu precipitates after aging at 550 °C for 120 min.

Figure 9.

(a) TEM morphology, (b) size distribution and (c) HR-TEM image of Cu precipitates after aging at 550 °C for 240 min.

Figure 10.

Magnetic properties of annealed and aged non-oriented silicon steel: (a) B50; (b) P1.5/50; (c) P1.0/400; (d) P1.0/1000.

Figure 11.

Mechanical properties of annealed and aged non-oriented silicon steels with different times: (a) yield strength; (b) tensile strength; (c) elongation.

Figure 12.

Separated core loss for different routes: (a) P1.0/50, (b) P1.0/400 and (c) P1.0/1000.

Figure 13.

Calculation results of various precipitation strengthening and tested strength increment of non-oriented silicon steel with thickness of 0.2 mm.

Table 1.

Chemical composition of experimental steels (wt. %).

| Process | Si | Mn | Cu | P | S | C | N | Fe |

|---|

| Strip casting | 3.42 | 0.44 | 0.96 | 0.004 | 0.009 | 0.011 | 0.002 | Bal. |

| Conventional process | 3.48 | 0.24 | 1.07 | 0.007 | 0.010 | 0.014 | 0.002 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).