Ultrasonic Welding of Nickel with Coarse and Ultrafine Grained Structures

Abstract

1. Introduction

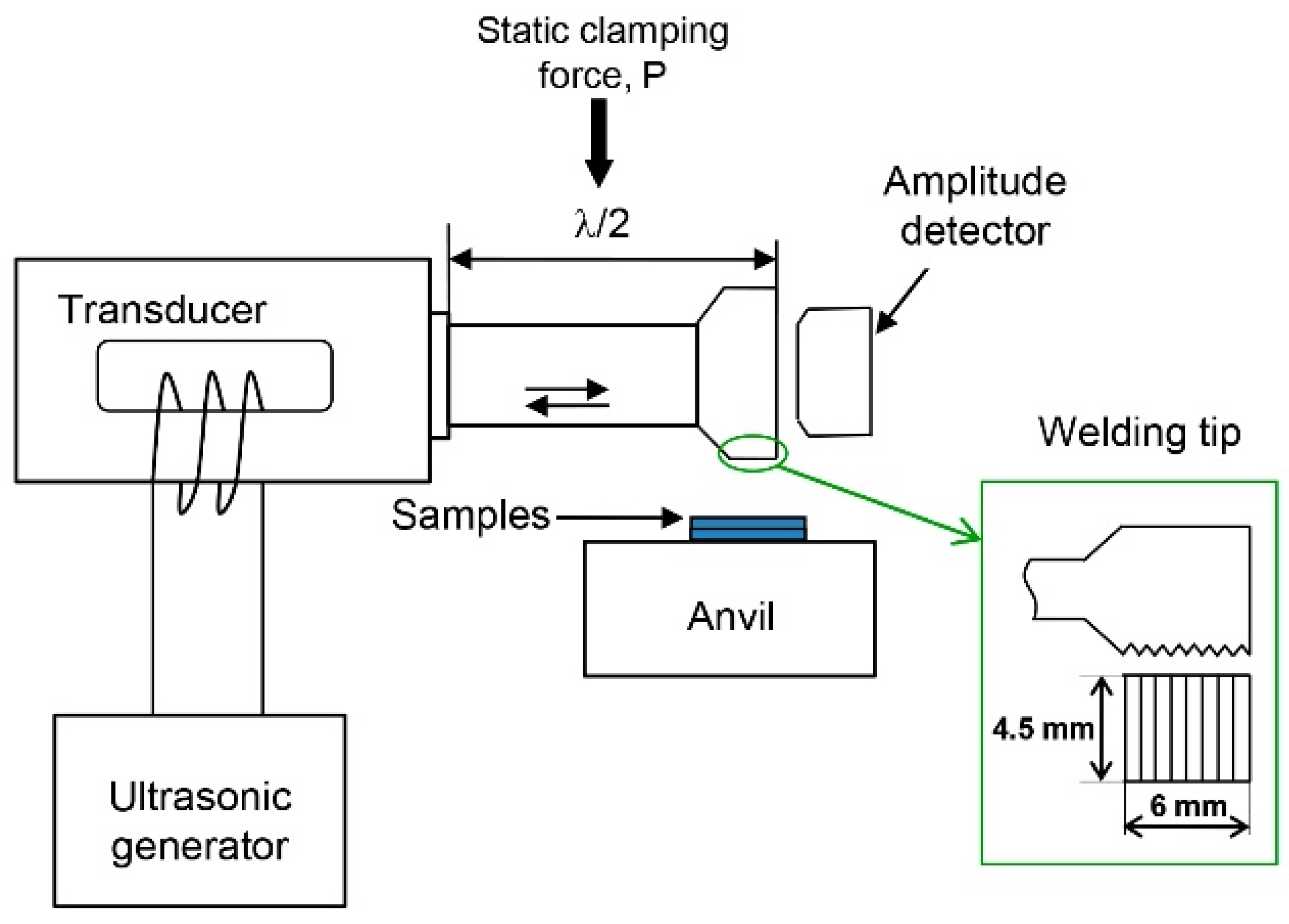

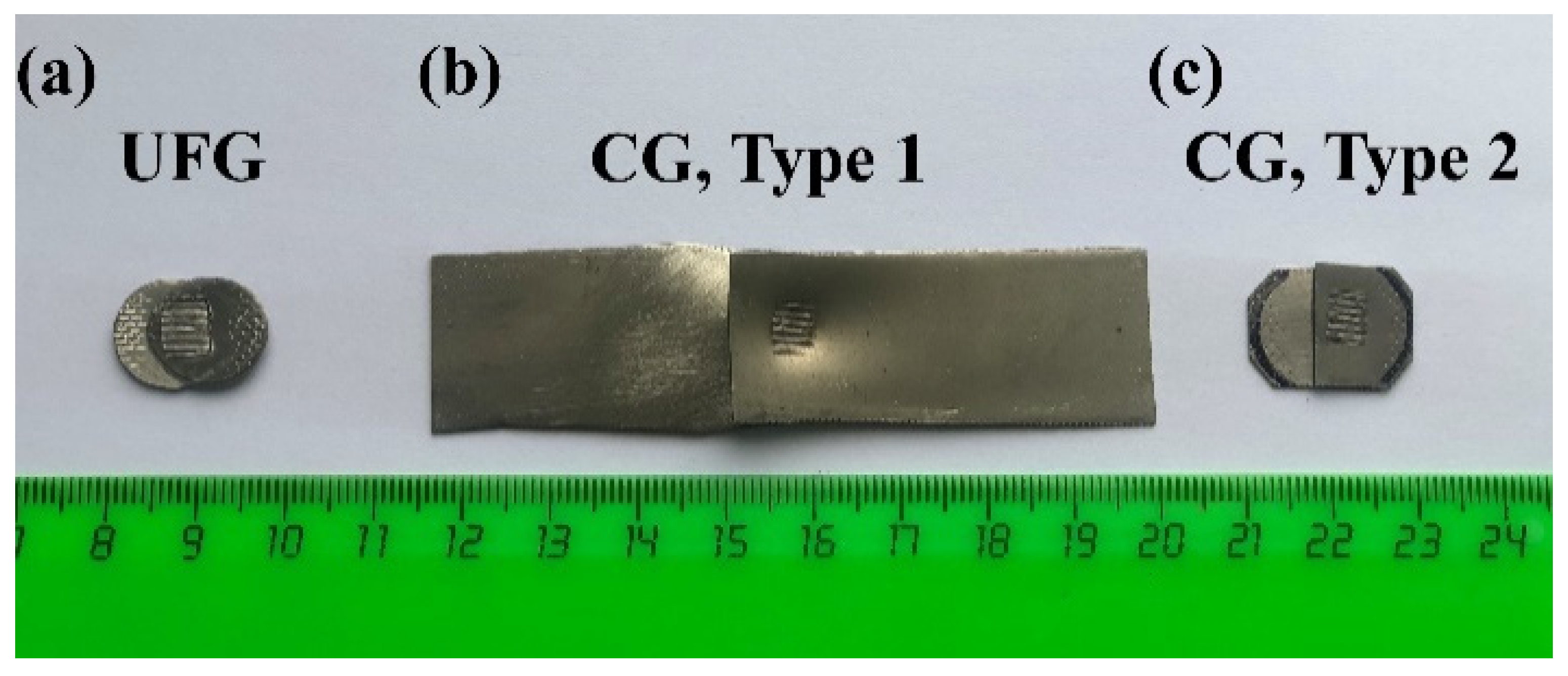

2. Materials and Methods

3. Results and Discussion

3.1. Microstructures of Initial Samples

3.2. Lap Shear Strength of Weld Joints

| Alloy | The Highest Tensile Shear Force, N | Clamping Force, kN | Frequency, kHz/Amplitude, μm/Time, s | Sheet Thickness, mm | Failure Mode | Reference |

|---|---|---|---|---|---|---|

| CP Ni UFG | 3000 | 6 | 20/15/2 | 0.7 | Nugget pull-out | This work |

| CP Ni CG | 1998 | 6 | 20/15/2 | 0.5 | Interface mode | This work |

| Ni 200 | 220 | 2.4 × 10−3 | 40/18/0.28 | 0.1 | Interface mode | [32] |

| Inconel | 2380 | 1.3 | 20/60/1.5 | 0.47 | Nugget pull-out | [28] |

| Inconel | 1425 | - | 0.51 | - | [29] | |

| K-Monel | 3380 | - | 0.51 | - | [29] |

3.3. Examination of Fracture Surfaces

3.4. Misrostructure of Weld Joints

3.4.1. Microstructure Evolution in CG Samples during USW

3.4.2. Microstructure Evolution in UFG Samples during USW

4. Conclusions

- Sound weld joints can be obtained by welding of nickel sheets at certain regimes of spot USW. The highest strength of the joints is obtained with the used apparatus at the welding time of 2 s with clamping force in the range of 4.5 to 6 kN.

- During ultrasonic welding of nickel with initial coarse-grained structure, grain refinement takes place near weld interfaces, and a thin layer of ultra-fine grains is formed. A developed network of sub-boundaries is formed within large grains adjacent to this layer.

- During ultrasonic welding of samples having an UFG initial microstructure, growth of grains up to the sizes of 15–25 µm occurs, and fine grains are observed only along weld interfaces.

- The average lap shear strength of samples made by welding of UFG sheets is about 97 MPa, which is approximately 40% higher than the strength of samples processed by welding coarse-grained sheets.

- Fractographic studies show that a more ductile fracture occurs during lap shear tests of samples processed by welding of UFG samples. These studies suggest that the differences in the formation of weld joints of CG and UFG sheets can be related to different behaviors of the yield stress of nickel in these states: UFG Ni is significantly stronger than the CG Ni, which results in a less plastic deformation at the very beginning of the USW process, while with increasing temperature, the plasticity of UFG Ni, on the contrary, becomes higher.

- More detailed studies of USW of UFG metals are expected to find better regimes for the process, which would limit the grain growth and simultaneously increase the bond strength and the overall strength of structures produced by the ultrasonic consolidation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Silin, L.L.; Balandin, G.F.; Kogan, M.G. Ultrasonic Welding; Mashgiz: Moscow, Russia, 1962. (In Russian) [Google Scholar]

- Mitskevich, A.M. Ultrasonic welding of metals. In Physical Foundations of Ultrasonic Technology; Rosenberg, L.D., Ed.; Plenum Press: New York, NY, USA, 1973; Volume 1, Part 2; pp. 101–238. [Google Scholar]

- Kumar, S.; Wu, C.S.; Padhy, G.K.; Ding, W. Application of ultrasonic vibrations in welding and metal processing: A status review. J. Manuf. Processes. 2017, 26, 295–322. [Google Scholar] [CrossRef]

- Graff, K.F. Ultrasonic metal welding. In New Developments in Advanced Welding; Ahmed, T., Ed.; Woodhead: Cambridge, UK, 2005; pp. 241–269. [Google Scholar]

- Matheny, M.P.; Graff, K.F. Ultrasonic welding of metals. In Power Ultrasonics-Applications of High-Intensity Ultrasound; Gallego-Juárez, J.A., Graff, K.F., Eds.; Woodhead: Cambridge, UK, 2015; pp. 259–293. [Google Scholar]

- Willrich, H.O. Application of ultrasonic waves. Weld. J. 1950, 18, 61–66. [Google Scholar]

- White, D. Ultrasonic Object Consolidation. U.S. Patent 6,519,500, 23 March 2000. [Google Scholar]

- Shimizu, S.; Fujii, H.T.; Sato, Y.S.; Kokawa, H.; Sriraman, M.R.; Babu, S.S. Mechanism of weld formation during very-high-power ultrasonic additive manufacturing of Al alloy 6061. Acta Mater. 2014, 74, 234–243. [Google Scholar] [CrossRef]

- Sriraman, M.R.; Babu, S.S.; Short, M. Bonding characteristics during very high power ultrasonic additive manufacturing of copper. Scr. Mater. 2010, 62, 560–563. [Google Scholar] [CrossRef]

- Hopkins, C.D.; Dapino, M.J.; Fernandez, S.A. Statistical characterization of ultrasonic additive manufacturing Ti/Al composites. J. Eng. Mater. Technol. 2010, 132, 041006. [Google Scholar] [CrossRef]

- Wolcott, P.J.; Sridharan, N.; Babu, S.S.; Miriyev, A.; Frage, N.; Dapino, M.J. Characterisation of Al–Ti dissimilar material joints fabricated using ultrasonic additive manufacturing. Sci. Technol. Weld. Join. 2016, 21, 114–123. [Google Scholar] [CrossRef]

- Levy, A.; Miriyev, A.; Sridharan, N.; Han, T.; Tuval, E.; Babu, S.S.; Dapino, M.J.; Frage, N. Ultrasonic additive manufacturing of steel: Method, post-processing treatments and properties. J. Mater. Process. Tech. 2018, 256, 183–189. [Google Scholar] [CrossRef]

- Li, D.; Soar, R.C. Characterization of process for embedding SiC fibers in al 6061 o matrix through ultrasonic consolidation. J. Eng. Mater. Technol. 2009, 131, 021016. [Google Scholar] [CrossRef]

- Chen, X.; Hehr, A.; Dapino, M.J.; Anderson, P.M. Deformation mechanisms in NiTi-Al composites fabricated by ultrasonic additive manufacturing. Shap. Mem. Superelasticity 2015, 1, 294–309. [Google Scholar] [CrossRef]

- Nazarov, A.A.; Mulyukov, R.R. Nanostructured materuials. In Nanoscience, Engineering and Technology Handbook; Lyshevski, S., Brenner, D., Iafrate, J., Goddard, W., Eds.; CRC Press: Boca Raton, FL, USA, 2002; pp. 22-1–22-41. [Google Scholar]

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Galieva, E.; Valitov, V.; Lutfullin, R.; Bikmukhametova, A. Low-temperature superplasticity of the Ni-based EK61 superalloy and application of this effect to obtain solid phase joints. Def. Diff. Forum. 2018, 385, 150–154. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Progr. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Mulyukov, R.R.; Imayev, R.M.; Nazarov, A.A. Production, properties and application prospects of bulk nanostructured materials. J. Mater. Sci. 2008, 43, 7257–7263. [Google Scholar] [CrossRef]

- Imayev, R.M.; Nazarov, A.A.; Mulyukov, R.R.; Khasanova, G.F. The principles of producing an ultrafine-grained structure in large-section billets. Lett. Mater. 2014, 4, 295–301. [Google Scholar] [CrossRef][Green Version]

- Valiakhmetov, O.R.; Galeyev, R.M.; Ivan’ko, V.A.; Imayev, R.M.; Inozemtsev, A.A.; Koksharov, N.L.; Kruglov, A.A.; Lutfullin, R.Y.; Mulyukov, R.R.; Nazarov, A.A.; et al. The use of nanostructured materials and nanotechnologies for the elaboration of hollow structures. Nanotechnol. Russ. 2010, 5, 108–122. [Google Scholar] [CrossRef]

- Shayakhmetova, E.R.; Nazarov, A.A.; Samigullina, A.A.; Zhilyaev, A.P. Ultrasonic welding of ultrafine grained nickel. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1008, 012009. [Google Scholar] [CrossRef]

- Parkhimovich, N.Y.; Yusupova, N.R.; Nazarov, A.A. Strength of copper joints obtained by ultrasonic welding using copper intermediate layers in different structure states. Lett. Mater. 2020, 10, 322–327. [Google Scholar] [CrossRef]

- Contactless Vibrometer. Available online: https://cavitation.bsuir.by/en/non-contact-vibrometer (accessed on 1 November 2021).

- Humphreys, F. Review Grain and subgrain characterisation by electron backscatter diffraction. J. Mat. Sci. 2001, 36, 3833–3854. [Google Scholar] [CrossRef]

- Danilenko, V.N.; Mironov, S.; Belyakov, A.N.; Zhilyev, A.P. Application of EBSD analysis of physical materials (review). Factory Laboratory. Diagn. Mater. 2012, 2, 28–46. (In Russian) [Google Scholar]

- Lewis, W.J.; Antonevich, J.N.; Monroe, R.E.; Rieppel, P.J. Fundamental studies on the mechanism of ultrasonic welding. Mater. Sci. 1959. Available online: https://www.semanticscholar.org/paper/PROGRESS-REPORT-ON-RESEARCH-AND-DEVELOPMENT-OF-FOR-Lewis-Antonevich/19e4ceb12b374cb20b6ef0551b564f30fcf1e26a (accessed on 1 November 2021).

- Devine, J.; Welding, U. Mechanical Properties. In ASM Handbook; Welding, Brazing, and Soldering 1994; ASM International: Materials Park, OH, USA, 1994; Volume 6, pp. 907–909. [Google Scholar]

- Su, Z.; Zhu, Z.; Zhang, Y.; Zhang, H.; Xiao, Q. Recrystallization behavior of a pure Cu connection interface with ultrasonic welding. Metals 2021, 11, 61. [Google Scholar] [CrossRef]

- Ni, Z.L.; Ye, F.X. Dissimilar joining of aluminum to copper using ultrasonic welding. Mater. Manuf. Process. 2016, 31, 2091–2100. [Google Scholar] [CrossRef]

- Park, D.S.; Kim, J.H.; Seo, J.S. Ultrasonic Welding of Ni Thin Sheet. Int. J. Min. Metall. Mech. Eng. 2013, 1, 168–172. [Google Scholar]

- Zhilyaev, A.P.; Lee, S.; Nurislamova, G.V.; Valiev, R.Z.; Langdon, T.G. Microhardness and microstructural evolution in pure nickel during high-pressure torsion. Scripta Mater. 2001, 44, 2753–2758. [Google Scholar] [CrossRef]

- Ghosh, P.; Renk, O.; Pippan, R. Microtexture analysis of restoration mechanisms during high pressure torsion of pure nickel. Mater. Sci. Eng. A 2017, 684, 101–109. [Google Scholar] [CrossRef]

- Wolcott, P.J.; Dapino, M.J. Fatigue Characterization of Ultrasonic Additive Manufactured Aluminum 3003; Department of Mechanical and Aerospace Engnieering, The Ohio State University: Columbus, OH, USA, 2012. [Google Scholar]

- Patel, V.; Bhole, S.D.; Chen, D. Ultrasonic spot welded AZ31 magnesium alloy: Microstructure, texture, and lap shear strength. Mater. Sci. Eng. A 2013, 569, 78–85. [Google Scholar] [CrossRef]

- Peng, H.; Chen, D.L.; Bai, X.F.; She, X.W.; Li, D.; Jiang, X.Q. Ultrasonic spot welding of magnesium-to-aluminum alloys with a copper interlayer: Microstructural evolution and tensile properties. J. Manuf. Process. 2019, 37, 91–100. [Google Scholar] [CrossRef]

- Haddadi, F.; Tsivoulas, D. Grain structure, texture and mechanical property evolution of automotive aluminium sheet during high power ultrasonic welding. Mater. Charact. 2016, 118, 340–351. [Google Scholar] [CrossRef]

- Yang, J.; Cao, B.; Lu, Q. The effect of welding energy on the microstructural and mechanical properties of ultrasonic-welded copper joints. Materials 2017, 10, 193. [Google Scholar] [CrossRef]

- Fujii, H.T.; Sriraman, M.R.; Babu, S.S. Quantitative evaluation of bulk and interface microstructures in Al-3003 alloy builds made by very high power ultrasonic additive manufacturing. Metall. Mater. Trans. 2011, 42, 4045–4055. [Google Scholar] [CrossRef]

- Janaki Ram, G.D.; Yang, Y.; Nylander, C.; Aydelotte, B.; Stucker, B.E.; Adams, B.L. Interface Microstructures and Bond Formation in Ultrasonic Consolidation. In Proceedings of the 2007 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 5 September 2007; pp. 266–283. [Google Scholar] [CrossRef]

- Korznikov, A.V.; Korznikova, G.F.; Myshlyaev, M.M.; Valiev, R.Z.; Salimonenko, D.; Dimitrov, O. Evolution of nanocrystalline Ni structure during heating. Phys. Met. Metall. 1997, 84, 413–417. [Google Scholar]

- Zhilyaev, A.P.; Nurislamova, G.V.; Valiev, R.Z.; Baró, M.D.; Langdon, T.G. Thermal stability and microstructural evolution in ultrafine-grained nickel after equal-channel angular pressing (ECAP). Metall. Mater. Trans. 2002, 33, 1865–1868. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Nurislamova, G.V.; Suriñach, S.; Baró, M.D.; Langdon, T.G. Calorimetric measurements of grain growth in ultrafine-grained nickel. Mater. Phys. Mech. 2002, 5, 23–30. [Google Scholar]

- Chen, Y.C.; Bakavos, D.; Gholinia, A.; Prangnell, P. HAZ development and accelerated post-weld natural ageing in ultrasonic spot welding aluminium 6111-T4 automotive sheet. Acta Mater. 2012, 60, 2816–2828. [Google Scholar] [CrossRef]

- Lutfullin, R.Y.; Mukhametrakhimov, M.K. Effect of initial structure on the mechanical properties of specimens of titanium alloy VT6 joined in the superplastic state. Met. Sci. Heat Treat. 2006, 48, 54–56. [Google Scholar] [CrossRef]

- Drozdov, A.A.; Povarova, K.B.; Valitov, V.A.; Galieva, E.V.; Arginbaeva, E.G.; Bazyleva, O.A.; Bulakhtina, M.A.; Raevskikh, A.N. Effect of the Temperature of Pressure Welding of a Wrought EP975 Nickel Alloy and a Single-Crystal Intermetallic VKNA-25 Alloy on the Structure and Properties of the Welded Joints. Rus. Metall. 2020, 7, 752–759. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shayakhmetova, E.R.; Murzinova, M.A.; Nazarov, A.A. Ultrasonic Welding of Nickel with Coarse and Ultrafine Grained Structures. Metals 2021, 11, 1800. https://doi.org/10.3390/met11111800

Shayakhmetova ER, Murzinova MA, Nazarov AA. Ultrasonic Welding of Nickel with Coarse and Ultrafine Grained Structures. Metals. 2021; 11(11):1800. https://doi.org/10.3390/met11111800

Chicago/Turabian StyleShayakhmetova, Elvina R., Mariya A. Murzinova, and Ayrat A. Nazarov. 2021. "Ultrasonic Welding of Nickel with Coarse and Ultrafine Grained Structures" Metals 11, no. 11: 1800. https://doi.org/10.3390/met11111800

APA StyleShayakhmetova, E. R., Murzinova, M. A., & Nazarov, A. A. (2021). Ultrasonic Welding of Nickel with Coarse and Ultrafine Grained Structures. Metals, 11(11), 1800. https://doi.org/10.3390/met11111800