Interactions between Dislocations and Penta-Twins in Metallic Nanocrystals

Abstract

:1. Introduction

2. Experimental and Simulation Methods

2.1. In Situ TEM Nanofabrication and Nanomechanical Testing

2.2. Simulation Methods

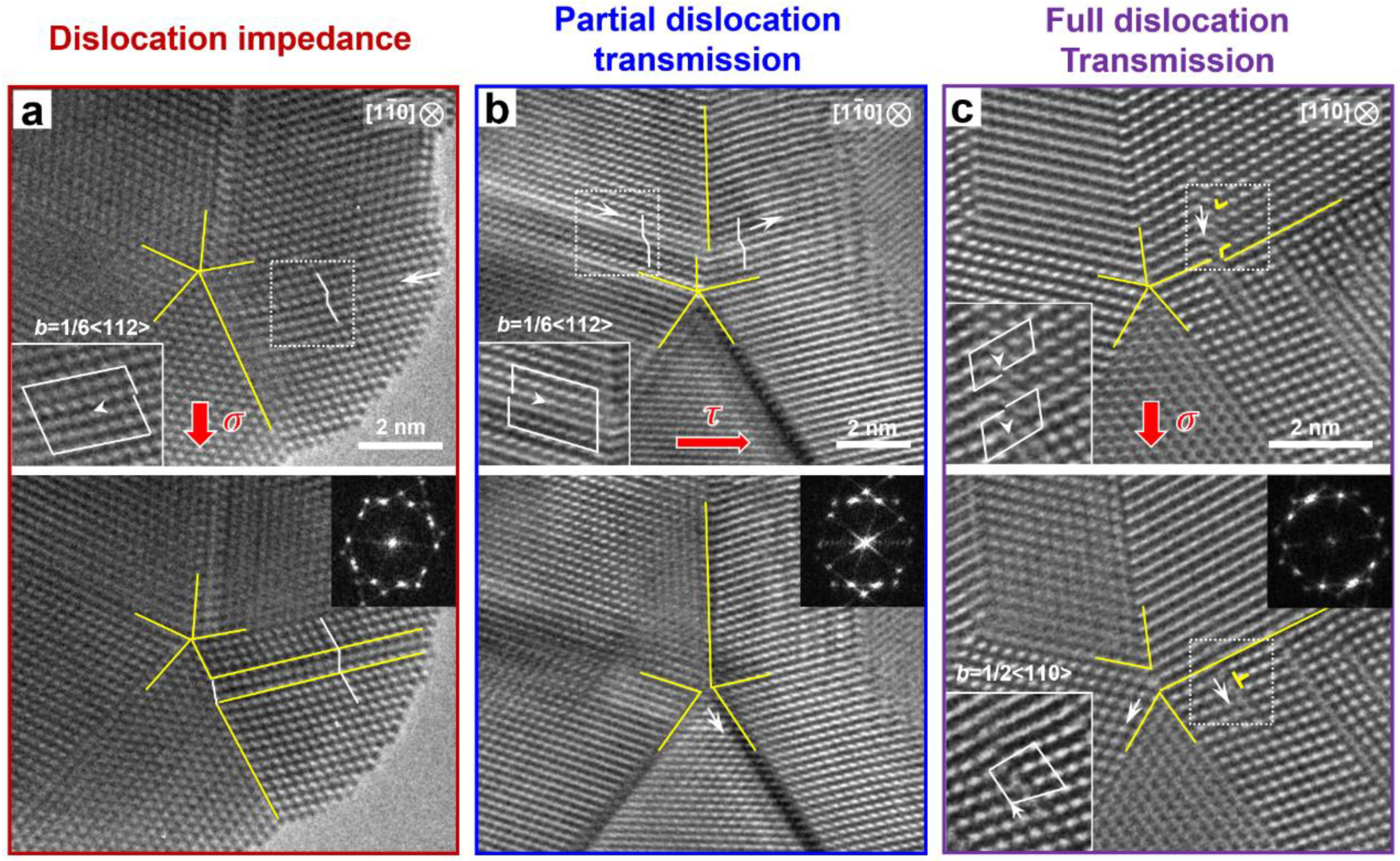

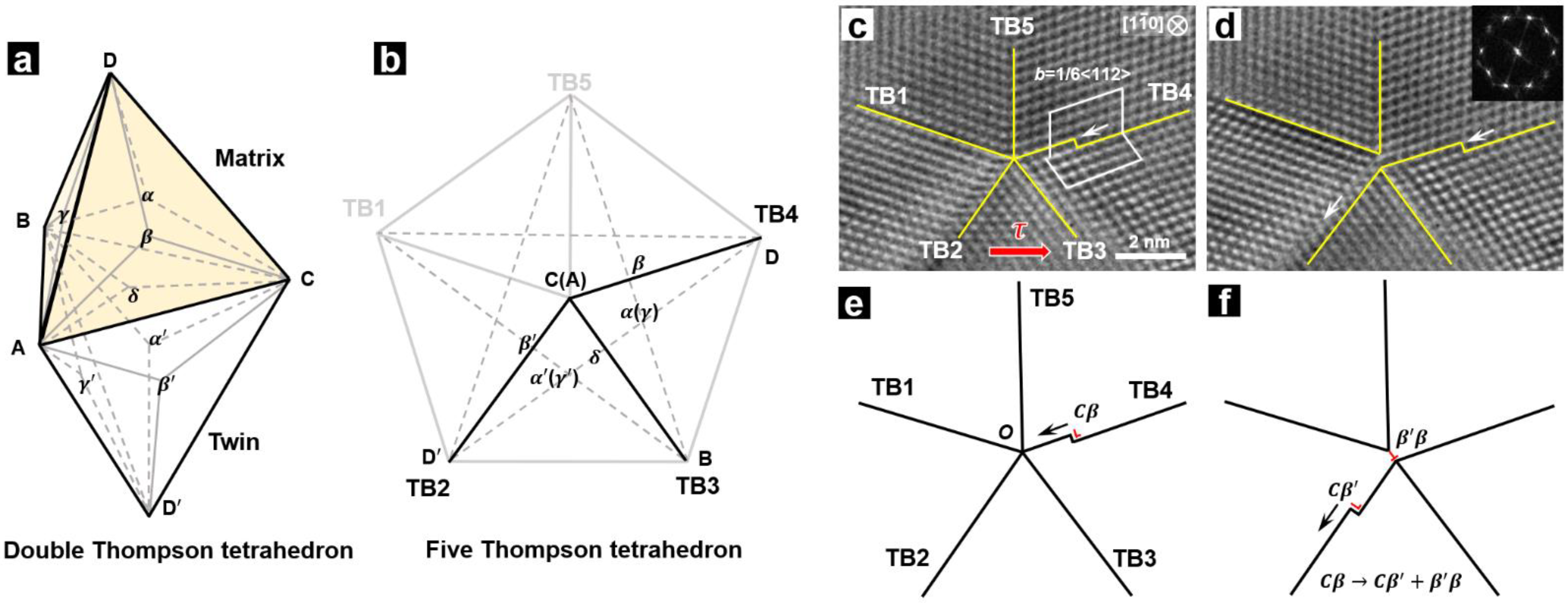

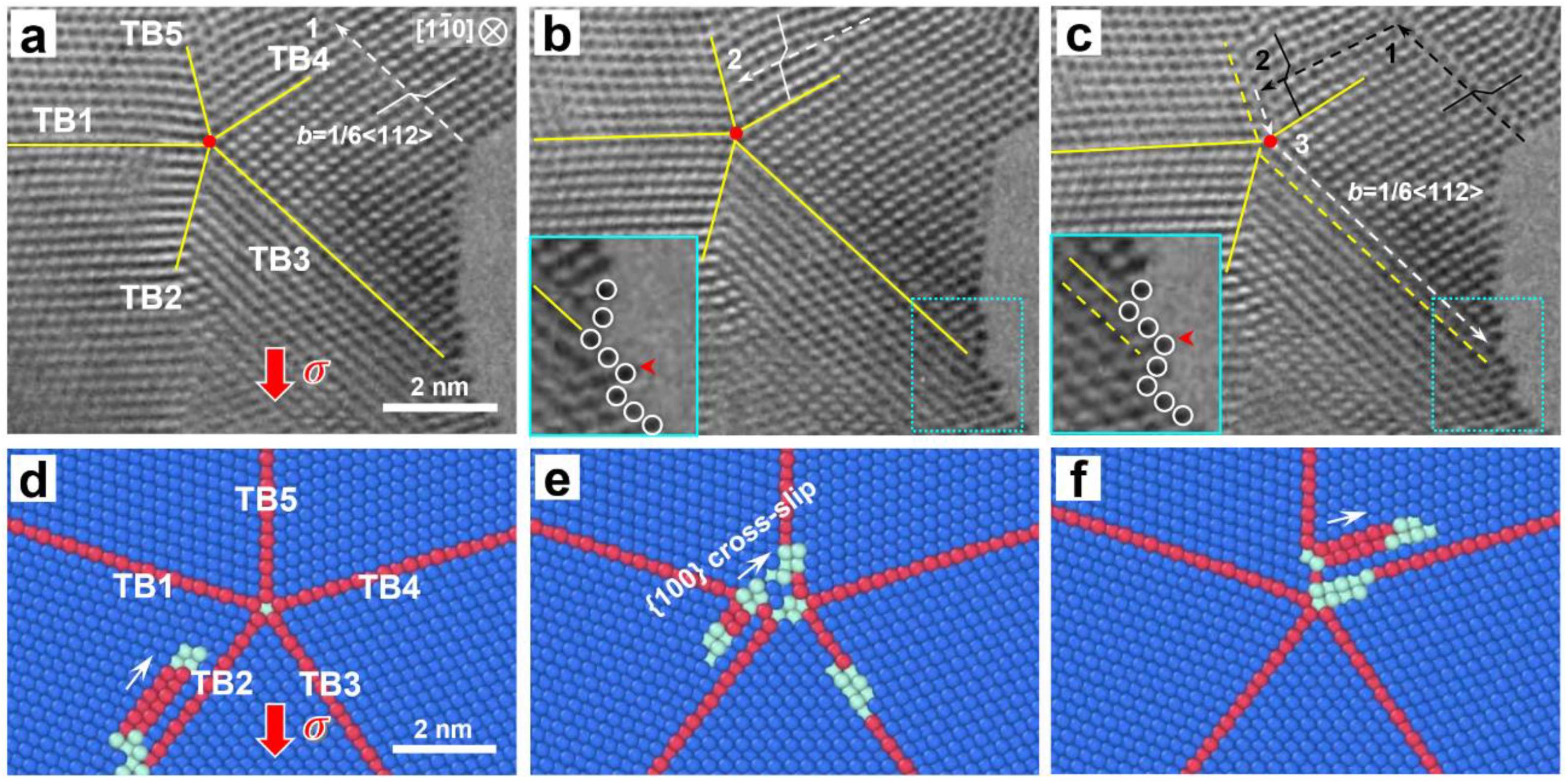

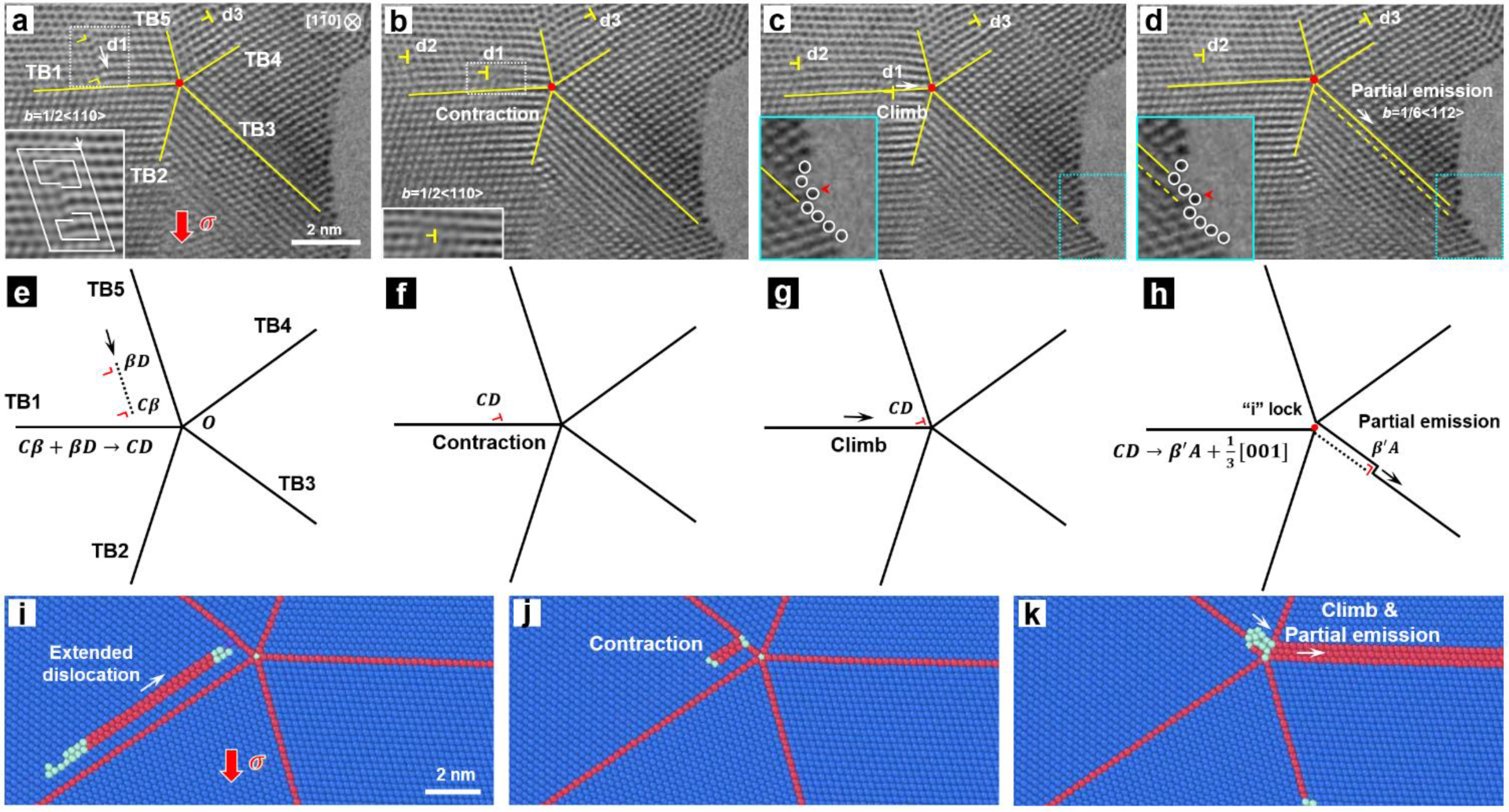

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, L.; Shen, Y.F.; Chen, X.H.; Qian, L.H.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the Maximum Strength in Nanotwinned Copper. Science 2009, 323, 607. [Google Scholar] [CrossRef]

- Jin, Z.H.; Gumbsch, P.; Albe, K.; Ma, E.; Lu, K.; Gleiter, H.; Hahn, H. Interactions between non-screw lattice dislocations and coherent twin boundaries in face-centered cubic metals. Acta Mater. 2008, 56, 1126–1135. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wu, X.L.; Liao, X.Z.; Narayan, J.; Kecskes, L.J.; Mathaudhu, S.N. Dislocation-twin interactions in nanocrystalline fcc metals. Acta Mater. 2011, 59, 812–821. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Cao, G.; Zhang, Z.; Sansoz, F. Size-dependent dislocation-twin interactions. Nanoscale 2019, 11, 12672–12679. [Google Scholar] [CrossRef]

- Zhao, S.; Zhu, Q.; Song, K.; Zhou, H.; Wang, J. Role of intersecting grain boundary on the deformation of twin-twin intersection. Scr. Mater. 2020, 188, 184–189. [Google Scholar] [CrossRef]

- Zhu, Q.; Kong, L.; Lu, H.; Huang, Q.; Chen, Y.; Liu, Y.; Yang, W.; Zhang, Z.; Sansoz, F.; Zhou, H.; et al. Revealing extreme twin-boundary shear deformability in metallic nanocrystals. Sci. Adv. 2021, 7, eabe4758. [Google Scholar] [CrossRef] [PubMed]

- Ni, S.; Wang, Y.B.; Liao, X.Z.; Figueiredo, R.B.; Li, H.Q.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. The effect of dislocation density on the interactions between dislocations and twin boundaries in nanocrystalline materials. Acta Mater. 2012, 60, 3181–3189. [Google Scholar] [CrossRef]

- Deng, Z.; Luo, J.; Yuan, W.; Xi, W. Formation and disintegration investigation of fivefold annealing twins in copper nanoparticles. Scr. Mater. 2019, 169, 42–45. [Google Scholar] [CrossRef]

- Song, M.; Zhou, G.; Lu, N.; Lee, J.; Nakouzi, E.; Wang, H.; Li, D. Oriented attachment induces fivefold twins by forming and decomposing high-energy grain boundaries. Science 2020, 367, 40–45. [Google Scholar] [CrossRef] [PubMed]

- Cheng, G.; Yin, S.; Li, C.; Chang, T.-H.; Richter, G.; Gao, H.; Zhu, Y. In-situ TEM study of dislocation interaction with twin boundary and retraction in twinned metallic nanowires. Acta Mater. 2020, 196, 304–312. [Google Scholar]

- Zhao, H.; Eggeman, A.S.; Race, C.P.; Derby, B. Geometrical constraints on the bending deformation of Penta-twinned silver nanowires. Acta Mater. 2020, 185, 110–118. [Google Scholar] [CrossRef]

- Parajuli, P.; Mendoza-Cruz, R.; Velazquez-Salazar, J.J.; Yacaman, M.J.; Ponce, A. Fivefold annealing twin in nanocrystalline Au/Pd film. Mater. Lett. 2019, 244, 88–91. [Google Scholar] [CrossRef]

- Niu, J.J.; Zhang, P.; Wang, R.H.; Zhang, J.Y.; Liu, G.; Zhang, G.J.; Sun, J. Formation of multiple twins and their strengthening effect in nanocrystalline Cu/Zr multilayer films. Mater. Sci. Eng. A 2012, 539, 68–73. [Google Scholar]

- Wang, B.; Idrissi, H.; Galceran, M.; Colla, M.S.; Turner, S.; Hui, S.; Raskin, J.P.; Pardoen, T.; Godet, S.; Schryvers, D. Advanced TEM investigation of the plasticity mechanisms in nanocrystalline freestanding palladium films with nanoscale twins. Int. J. Plast. 2012, 37, 140–156. [Google Scholar]

- Zahiri, A.H.; Chakraborty, P.; Wang, Y.; Cao, L. Strong strain hardening in ultrafast melt-quenched nanocrystalline Cu: The role of fivefold twins. J. Appl. Phys. 2019, 126, 075103. [Google Scholar] [CrossRef]

- Gao, Y.; Fu, Y.; Sun, W.; Sun, Y.; Wang, H.; Wang, F.; Zhao, J. Investigation on the mechanical behavior of fivefold twinned silver nanowires. Comput. Mater. Sci. 2012, 55, 322–328. [Google Scholar] [CrossRef]

- Wu, J.Y.; Nagao, S.; He, J.Y.; Zhang, Z.L. Role of Five-fold Twin Boundary on the Enhanced Mechanical Properties of fcc Fe Nanowires. Nano Lett. 2011, 11, 5264–5273. [Google Scholar] [CrossRef]

- Zhang, S.B. Mechanical behaviors of single crystalline and fivefold twinned Ag nanowires under compression. Comput. Mater. Sci. 2015, 98, 320–327. [Google Scholar] [CrossRef]

- Li, Q.; Xue, S.; Zhang, Y.; Sun, X.; Wang, H.; Zhang, X. Plastic anisotropy and tension-compression asymmetry in nanotwinned Al-Fe alloys: An in-situ micromechanical investigation. Int. J. Plast. 2020, 132, 102760. [Google Scholar]

- Yang, X.-S.; Zhai, H.-R.; Ruan, H.-H.; Shi, S.-Q.; Zhang, T.-Y. Multi-temperature indentation creep tests on nanotwinned copper. Int. J. Plast. 2018, 104, 68–79. [Google Scholar] [CrossRef]

- Qin, Q.; Yin, S.; Cheng, G.; Li, X.; Chang, T.-H.; Richter, G.; Zhu, Y.; Gao, H. Recoverable plasticity in penta-twinned metallic nanowires governed by dislocation nucleation and retraction. Nat. Commun. 2015, 6, 5983. [Google Scholar]

- Bernal, R.A.; Aghaei, A.; Lee, S.; Ryu, S.; Sohn, K.; Huang, J.; Cai, W.; Espinosa, H. Intrinsic Bauschinger effect and recoverable plasticity in pentatwinned silver nanowires tested in tension. Nano Lett. 2015, 15, 139–146. [Google Scholar]

- Wang, X.; Vara, M.; Luo, M.; Huang, H.; Ruditskiy, A.; Park, J.; Bao, S.; Liu, J.; Howe, J.; Chi, M.; et al. Pd@Pt Core–Shell Concave Decahedra: A Class of Catalysts for the Oxygen Reduction Reaction with Enhanced Activity and Durability. J. Am. Chem. Soc. 2015, 137, 15036–15042. [Google Scholar]

- Wu, J.; Qi, L.; You, H.; Gross, A.; Li, J.; Yang, H. Icosahedral Platinum Alloy Nanocrystals with Enhanced Electrocatalytic Activities. J. Am. Chem. Soc. 2012, 134, 11880–11883. [Google Scholar]

- An, X.H.; Lin, Q.Y.; Wu, S.D.; Zhang, Z.F.; Figueiredo, R.B.; Gao, N.; Langdon, T.G. Formation of fivefold deformation twins in an ultrafine-grained copper alloy processed by high-pressure torsion. Scr. Mater. 2011, 64, 249–252. [Google Scholar]

- Zhu, Y.T.; Liao, X.Z.; Valiev, R.Z. Formation mechanism of fivefold deformation twins in nanocrystalline face-centered-cubic metals. Appl. Phys. Lett. 2005, 86, 103112. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, S.; Huang, Q.; Zhu, Q.; Song, K.; Zhou, H.; Wang, J. A geometrical model for grain boundary migration mediated formation of multifold twins. Int. J. Plast. 2022, 148, 103128. [Google Scholar] [CrossRef]

- Huang, P.; Dai, G.Q.; Wang, F.; Xu, K.W.; Li, Y.H. Fivefold annealing twin in nanocrystalline Cu. Appl. Phys. Lett. 2009, 95, 203101. [Google Scholar] [CrossRef]

- Cao, Z.H.; Xu, L.J.; Sun, W.; Shi, J.; Wei, M.Z.; Pan, G.J.; Yang, X.B.; Zhao, J.W.; Meng, X.K. Size dependence and associated formation mechanism of multiple-fold annealing twins in nanocrystalline Cu. Acta Mater. 2015, 95, 312–323. [Google Scholar]

- Plimpton, S. Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Grochola, G.; Russo, S.P.; Snook, I.K. On fitting a gold embedded atom method potential using the force matching method. J. Chem. Phys. 2005, 123, 204719. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Zhou, Y.; Fichthorn, K.A. Internal Stress-Induced Orthorhombic Phase in 5-Fold-Twinned Noble Metal Nanowires. J. Phys. Chem. C 2014, 118, 18746–18755. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, C.; Zhang, H.; Zhang, S.; Liu, Z.; Legut, D.; Veprek, S.; Zhang, R. Designing ultrahard nanostructured diamond through internal defects and interface engineering at different length scales. Carbon 2020, 170, 394–402. [Google Scholar]

- Wang, J.; Li, N.; Anderoglu, O.; Zhang, X.; Misra, A.; Huang, J.Y.; Hirth, J.P. Detwinning mechanisms for growth twins in face-centered cubic metals. Acta Mater. 2010, 58, 2262–2270. [Google Scholar] [CrossRef]

- Ke, X.; Ye, J.; Pan, Z.; Geng, J.; Besser, M.F.; Qu, D.; Caro, A.; Marian, J.; Ott, R.T.; Wang, Y.M.; et al. Ideal maximum strengths and defect-induced softening in nanocrystalline-nanotwinned metals. Nat. Mater. 2019, 18, 1207–1214. [Google Scholar] [PubMed]

- Song, M.; Wu, Z.; Lu, N.; Li, D. Strain Relaxation-Induced Twin Interface Migration and Morphology Evolution of Silver Nanoparticles. Chem. Mater. 2019, 31, 842–850. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Q.; Zhao, S.; Zhou, H.; Wang, J. Penta-Twin Destruction by Coordinated Twin Boundary Deformation. Nano Lett. 2021, 21, 8378–8384. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Huang, Q.; Zhao, S.; Zhou, H.; Wang, J. Interactions between Dislocations and Penta-Twins in Metallic Nanocrystals. Metals 2021, 11, 1775. https://doi.org/10.3390/met11111775

Chen Y, Huang Q, Zhao S, Zhou H, Wang J. Interactions between Dislocations and Penta-Twins in Metallic Nanocrystals. Metals. 2021; 11(11):1775. https://doi.org/10.3390/met11111775

Chicago/Turabian StyleChen, Yingbin, Qishan Huang, Shuchun Zhao, Haofei Zhou, and Jiangwei Wang. 2021. "Interactions between Dislocations and Penta-Twins in Metallic Nanocrystals" Metals 11, no. 11: 1775. https://doi.org/10.3390/met11111775

APA StyleChen, Y., Huang, Q., Zhao, S., Zhou, H., & Wang, J. (2021). Interactions between Dislocations and Penta-Twins in Metallic Nanocrystals. Metals, 11(11), 1775. https://doi.org/10.3390/met11111775