Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility

Abstract

1. Introduction

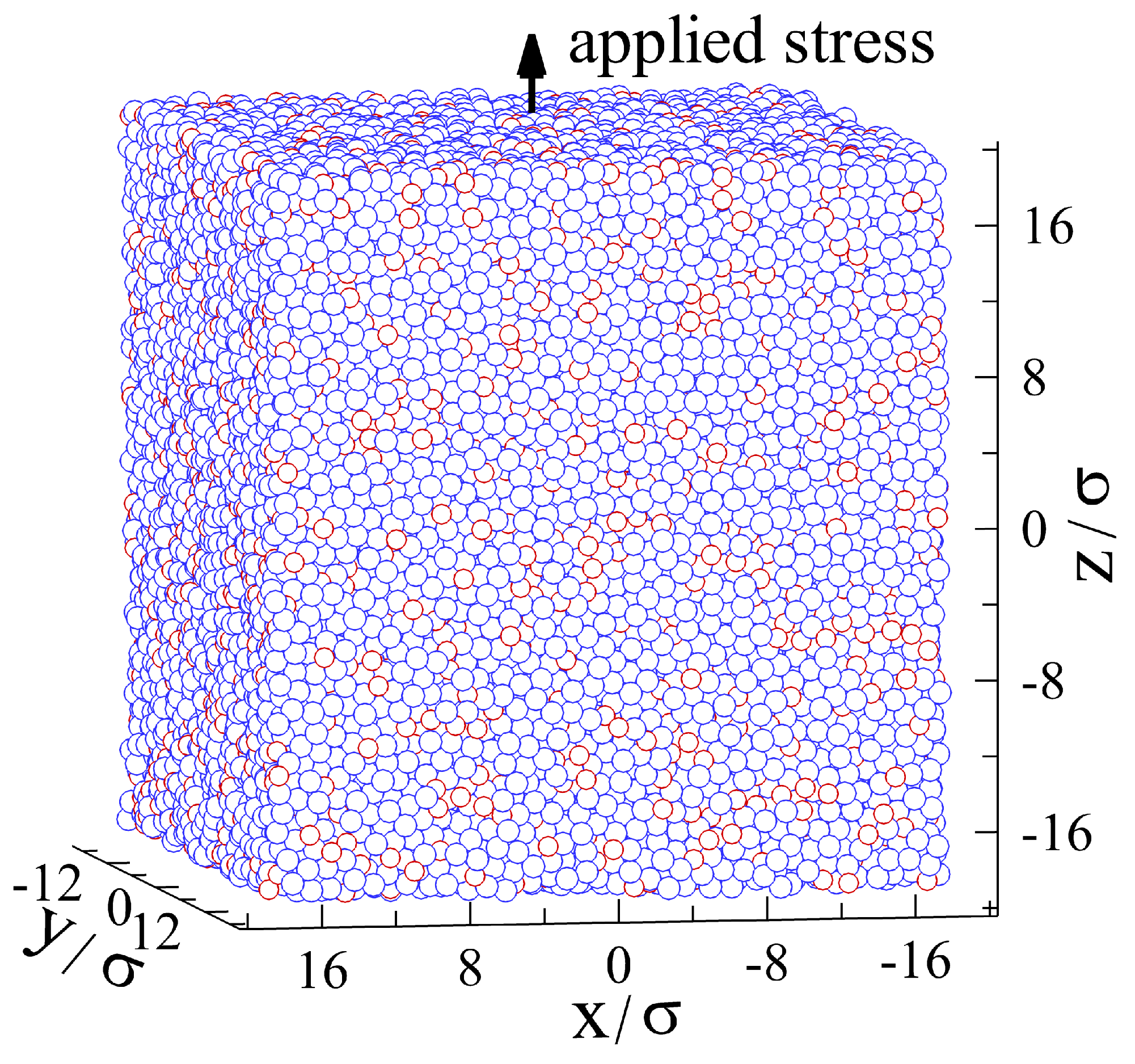

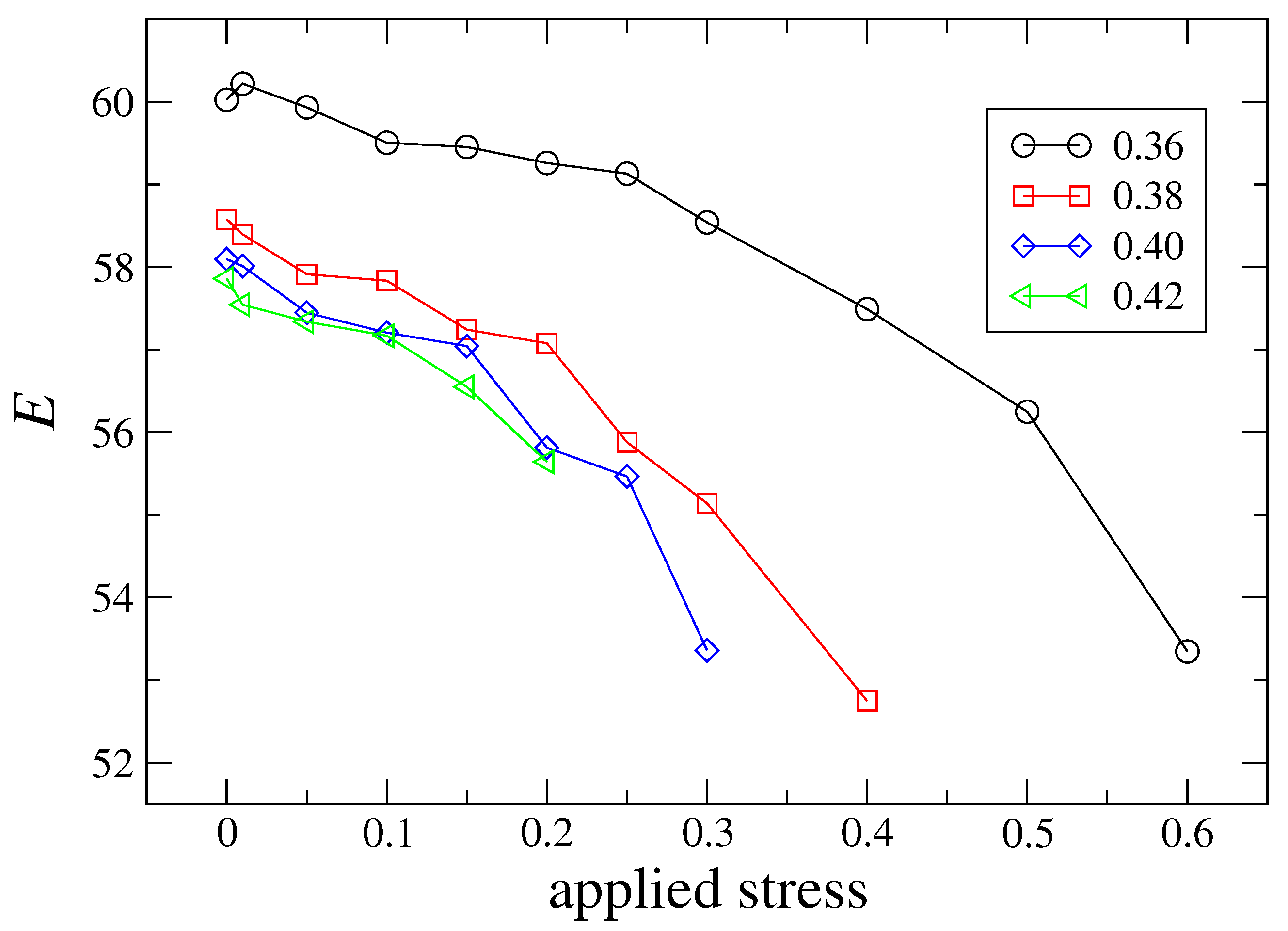

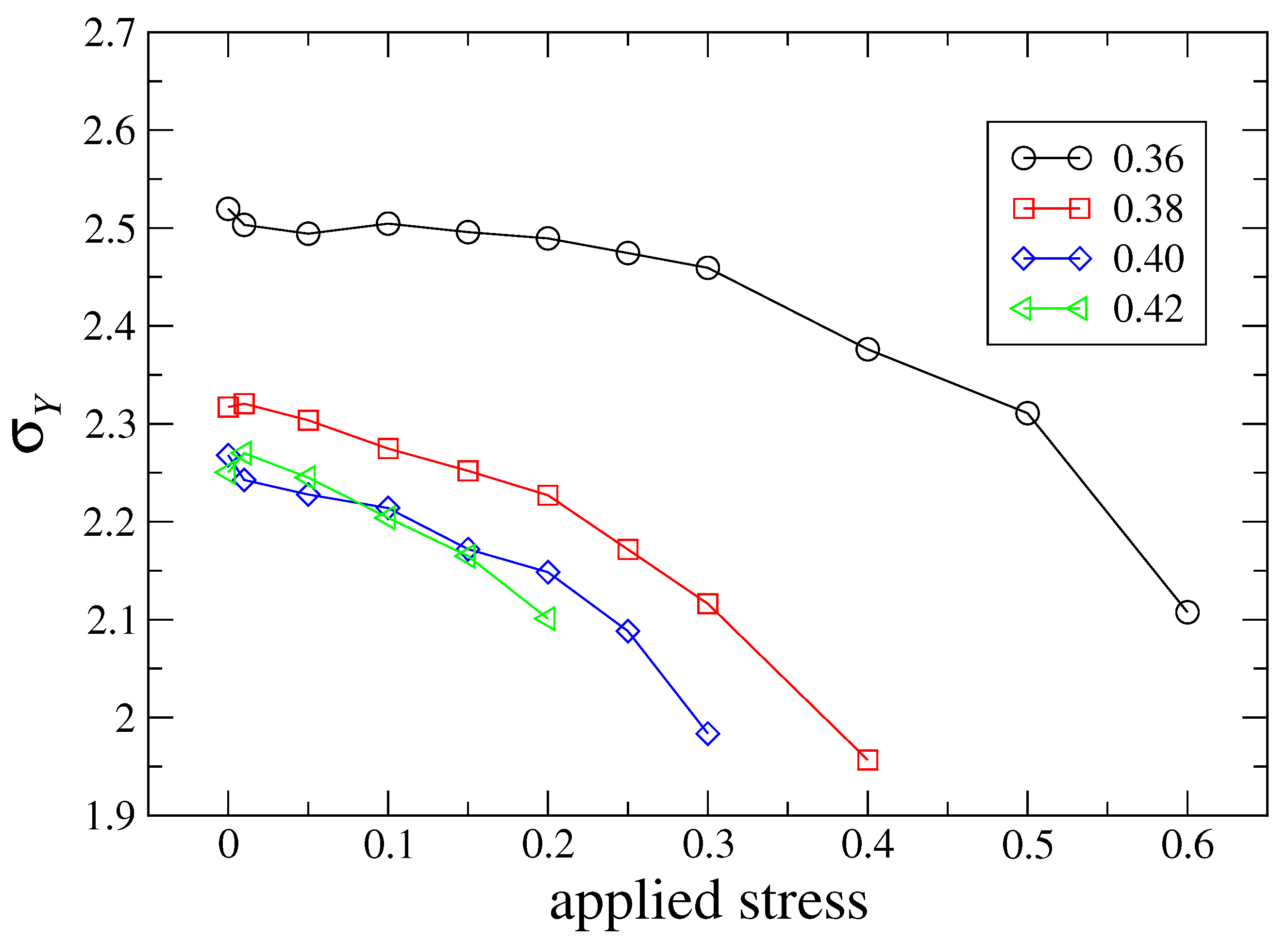

2. Molecular Dynamics Simulations

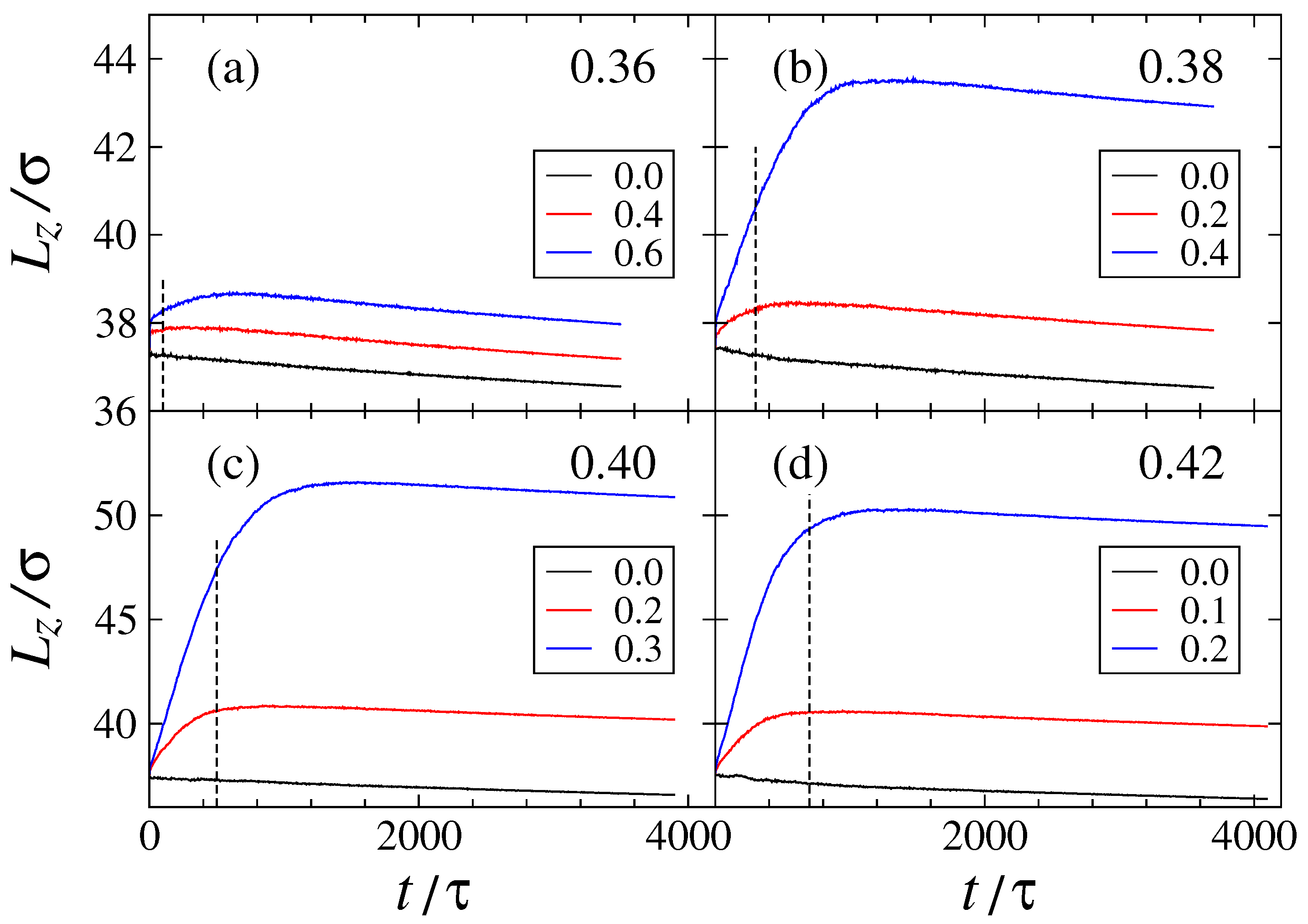

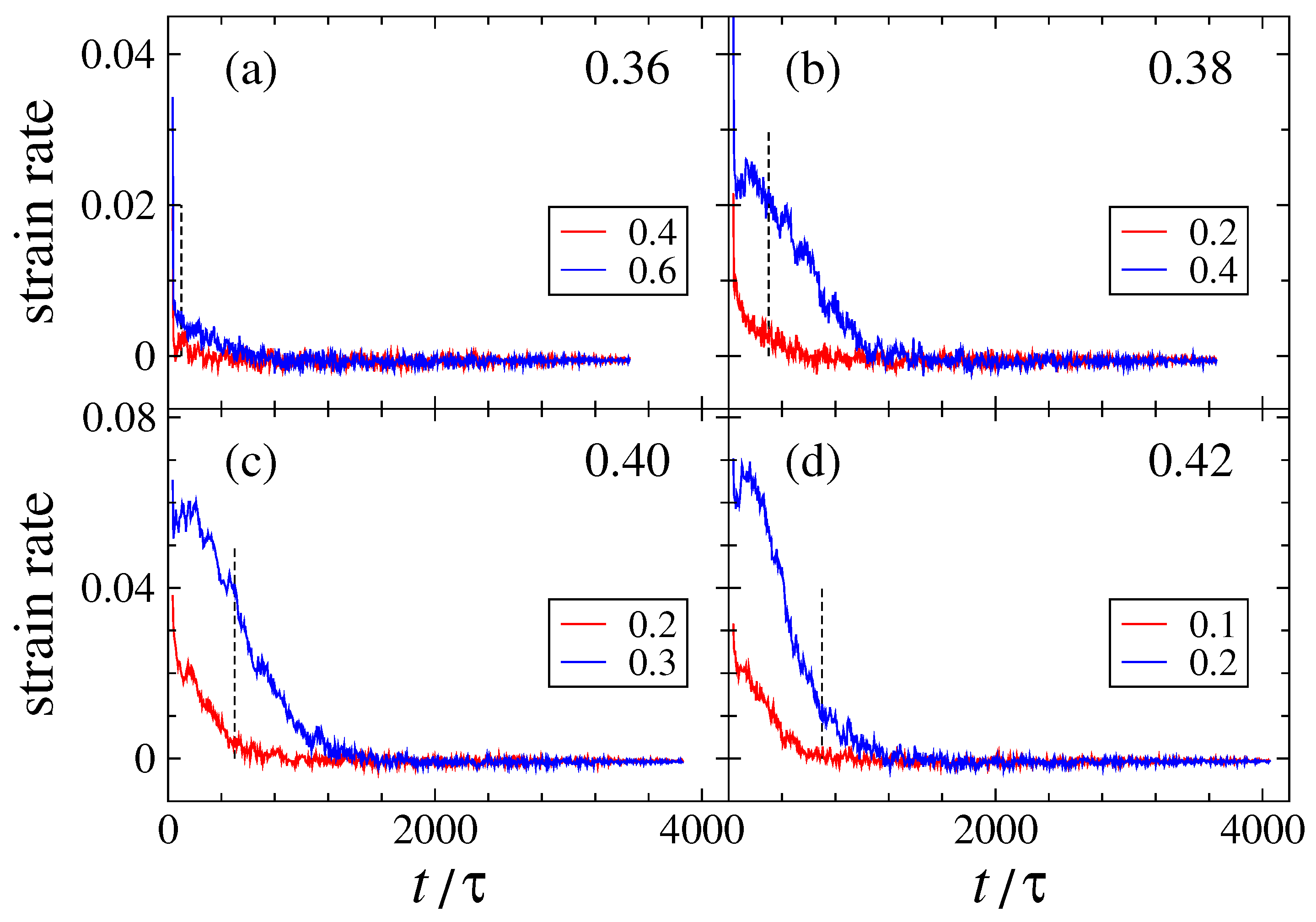

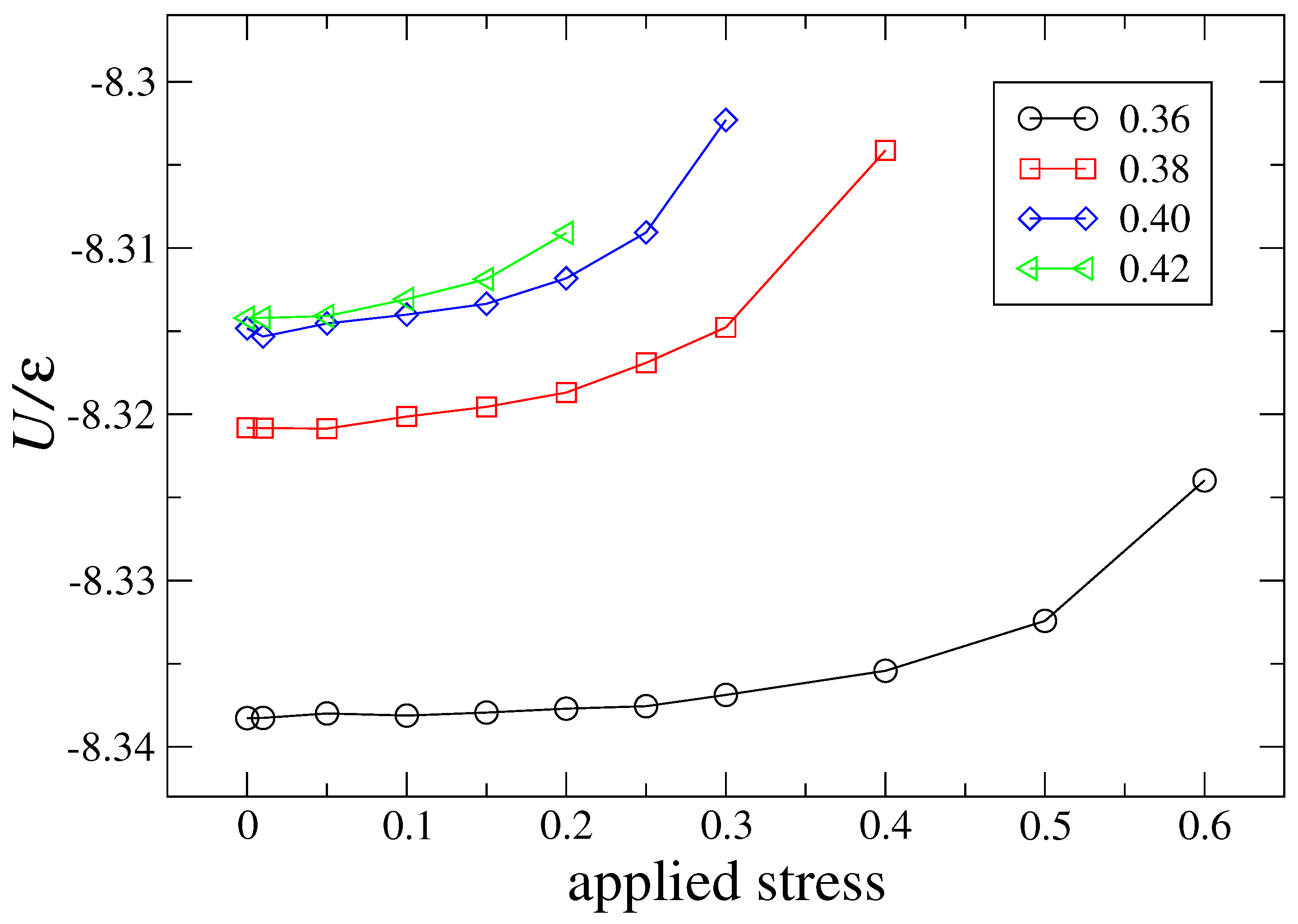

3. Results

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, M.M.; Nemati, A.; Rahman, Z.U.; Shah, U.H.; Asgar, H.; Haider, W. Recent advancements in bulk metallic glasses and their applications: A Review. Crit. Rev. Solid State Mater. Sci. 2018, 43, 233–268. [Google Scholar] [CrossRef]

- Li, H.F.; Zheng, Y.F. Recent advances in bulk metallic glasses for biomedical applications. Acta Biomater. 2016, 36, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Schuh, C.A.; Lund, A.C. Atomistic basis for the plastic yield criterion of metallic glass. Nat. Mater. 2003, 2, 449–452. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Cheng, Y.Q.; Ma, E. Correlating local structure with inhomogeneous elastic deformation in a metallic glass. Appl. Phys. Lett. 2012, 101, 121917. [Google Scholar] [CrossRef]

- Shang, B.S.; Li, M.Z.; Yao, Y.G.; Lu, Y.J.; Wang, W.H. Evolution of atomic rearrangements in deformation in metallic glasses. Phys. Rev. E 2014, 90, 042303. [Google Scholar] [CrossRef]

- Priezjev, N.V. The effect of thermal history on the atomic structure and mechanical properties of amorphous alloys. Comput. Mater. Sci. 2020, 174, 109477. [Google Scholar] [CrossRef]

- Priezjev, N.V. Spatiotemporal analysis of nonaffine displacements in disordered solids sheared across the yielding point. Metall. Mater. Trans. A 2020, 51, 3713. [Google Scholar] [CrossRef]

- Singh, M.; Ozawa, M.; Berthier, L. Brittle yielding of amorphous solids at finite shear rates. Phys. Rev. Mater. 2020, 4, 025603. [Google Scholar] [CrossRef]

- Sun, Y.; Concustell, A.; Greer, A.L. Thermomechanical processing of metallic glasses: Extending the range of the glassy state. Nat. Rev. Mater. 2016, 1, 16039. [Google Scholar] [CrossRef]

- Wakeda, M.; Saida, J.; Li, J.; Ogata, S. Controlled rejuvenation of amorphous metals with thermal processing. Sci. Rep. 2015, 5, 10545. [Google Scholar] [CrossRef]

- Kuchemann, S.; Derlet, P.M.; Liu, C.; Rosenthal, D.; Sparks, G.; Larson, W.S.; Maass, R. Energy storage in metallic glasses via flash annealing. Adv. Funct. Mater. 2018, 28, 1805385. [Google Scholar] [CrossRef]

- Priezjev, N.V. Atomistic modeling of heat treatment processes for tuning the mechanical properties of disordered solids. J. Non-Cryst. Solids 2019, 518, 128–133. [Google Scholar] [CrossRef]

- Wang, M.; Liu, H.; Li, J.; Jiang, Q.; Yang, W.; Tang, C. Thermal-pressure treatment for tuning the atomic structure of metallic glass Cu-Zr. J. Non-Cryst. Solids 2020, 535, 119963. [Google Scholar] [CrossRef]

- Magagnosc, D.J.; Kumar, G.; Schroers, J.; Felfer, P.; Cairney, J.M.; Gianola, D.S. Effect of ion irradiation on tensile ductility, strength and fictive temperature in metallic glass nanowires. Acta Mater. 2014, 74, 165–182. [Google Scholar] [CrossRef]

- Xue, P.; Pauly, S.; Gan, W.; Jiang, S.; Fan, H.; Ning, Z.; Huang, Y.; Sun, J. Enhanced tensile plasticity of a CuZr-based bulk metallic glass composite induced by ion irradiation. J. Mater. Sci. Technol. 2019, 35, 2221–2226. [Google Scholar] [CrossRef]

- Meng, F.; Tsuchiya, K.; Li, S.; Yokoyama, Y. Reversible transition of deformation mode by structural rejuvenation and relaxation in bulk metallic glass. Appl. Phys. Lett. 2012, 101, 121914. [Google Scholar] [CrossRef]

- Wang, Y.B.; Qu, D.D.; Wang, X.H.; Cao, Y.; Liao, X.Z.; Kawasaki, M.; Ringer, S.P.; Shan, Z.W.; Langdon, T.G.; Shen, J. Introducing a strain-hardening capability to improve the ductility of bulk metallic glasses via severe plastic deformation. Acta Mater. 2012, 60, 253–260. [Google Scholar] [CrossRef]

- Mear, F.O.; Vaughan, G.; Yavari, A.R.; Greer, A.L. Residual-stress distribution in shot-peened metallic-glass plate. Philos. Mag. Lett. 2008, 88, 757–766. [Google Scholar] [CrossRef]

- Gonzalez, S.; Fornell, J.; Pellicer, E.; Surinach, S.; Baro, M.D.; Greer, A.L.; Belzunce, F.J.; Sort, J. Influence of the shot-peening intensity on the structure and near-surface mechanical properties of Ti40Zr10Cu38Pd12 bulk metallic glass. Appl. Phys. Lett. 2013, 103, 211907. [Google Scholar] [CrossRef]

- Park, K.-W.; Lee, C.-M.; Wakeda, M.; Shibutani, Y.; Falk, M.L.; Lee, J.-C. Elastostatically induced structural disordering in amorphous alloys. Acta Mater. 2008, 56, 5440–5450. [Google Scholar] [CrossRef]

- Lee, C.-M.; Park, K.-W.; Lee, B.-J.; Shibutani, Y.; Lee, J.-C. Structural disordering of amorphous alloys: A molecular dynamics analysis. Scr. Mater. 2009, 61, 911–914. [Google Scholar] [CrossRef]

- Tong, Y.; Dmowski, W.; Yokoyama, Y.; Wang, G.; Liaw, P.K.; Egami, T. Recovering compressive plasticity of bulk metallic glasses by high-temperature creep. Scr. Mater. 2013, 69, 570–573. [Google Scholar] [CrossRef]

- Wang, Y.M.; Zhang, M.; Liu, L. Mechanical annealing in the homogeneous deformation of bulk metallic glass under elastostatic compression. Scr. Mater. 2015, 102, 67–70. [Google Scholar] [CrossRef]

- Zhao, L.Z.; Xue, R.J.; Li, Y.Z.; Wang, W.H.; Bai, H.Y. Revealing localized plastic flow in apparent elastic region before yielding in metallic glasses. J. Appl. Phys. 2015, 118, 244901. [Google Scholar] [CrossRef]

- Greer, A.L.; Sun, Y.H. Stored energy in metallic glasses due to strains within the elastic limit. Philos. Mag. 2016, 96, 1643–1663. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.M.; Li, F.X.; Jiang, S.Q.; Li, M.Z.; Liu, L. Mechanical relaxation-to-rejuvenation transition in a Zr-based bulk metallic glass. Sci. Rep. 2017, 7, 625. [Google Scholar] [CrossRef]

- Pan, J.; Wang, Y.X.; Guo, Q.; Zhang, D.; Greer, A.L.; Li, Y. Extreme rejuvenation and softening in a bulk metallic glass. Nat. Commun. 2018, 9, 560. [Google Scholar] [CrossRef]

- Priezjev, N.V. Aging and rejuvenation during elastostatic loading of amorphous alloys: A molecular dynamics simulation study. Comput. Mater. Sci. 2019, 168, 125–130. [Google Scholar] [CrossRef]

- Priezjev, N.V. Accelerated rejuvenation in metallic glasses subjected to elastostatic compression along alternating directions. J. Non-Cryst. Solids 2020, 120562. [Google Scholar] [CrossRef]

- Ketov, S.V.; Sun, Y.H.; Nachum, S.; Lu, Z.; Checchi, A.; Beraldin, A.R.; Bai, H.Y.; Wang, W.H.; Louzguine-Luzgin, D.V.; Carpenter, M.A.; et al. Rejuvenation of metallic glasses by non-affine thermal strain. Nature 2015, 524, 200–203. [Google Scholar] [CrossRef]

- Guo, W.; Saida, J.; Zhao, M.; Lu, S.; Wu, S. Rejuvenation of Zr-based bulk metallic glass matrix composite upon deep cryogenic cycling. Mater. Lett. 2019, 247, 135–138. [Google Scholar] [CrossRef]

- Priezjev, N.V. The effect of cryogenic thermal cycling on aging, rejuvenation, and mechanical properties of metallic glasses. J. Non-Cryst. Solids 2019, 503, 131–138. [Google Scholar] [CrossRef]

- Liu, Q.-L.; Priezjev, N.V. The influence of complex thermal treatment on mechanical properties of amorphous materials. Comput. Mater. Sci. 2019, 161, 93–98. [Google Scholar] [CrossRef]

- Priezjev, N.V. Potential energy states and mechanical properties of thermally cycled binary glasses. J. Mater. Res. 2019, 34, 2664–2671. [Google Scholar] [CrossRef]

- Samavatian, M.; Gholamipour, R.; Amadeh, A.A.; Mirdamadi, S. Correlation between plasticity and atomic structure evolution of a rejuvenated bulk metallic glass. Metall. Mater. Trans. A 2019, 50, 4743–4749. [Google Scholar] [CrossRef]

- Ketkaew, J.; Yamada, R.; Wang, H.; Kuldinow, D.; Schroers, B.S.; Dmowski, W.; Egami, T.; Schroers, J. The effect of thermal cycling on the fracture toughness of metallic glasses. Acta Mater. 2020, 184, 100. [Google Scholar] [CrossRef]

- Meylan, C.M.; Papparotto, F.; Nachum, S.; Orava, J.; Miglierini, M.; Basykh, V.; Ferenc, J.; Kulik, T.; Greer, A.L. Stimulation of shear-transformation zones in metallic glasses by cryogenic thermal cycling. J. Non-Cryst. Solids 2020, 584, 120299. [Google Scholar] [CrossRef]

- Du, Y.; Han, W.; Zhou, Q.; Xu, Y.; Zhai, H.; Bhardwaj, V.; Wang, H. Enhancing the plasticity of a Ti-based bulk metallic glass composite by cryogenic cycling treatments. J. Alloys Compd. 2020, 835, 155247. [Google Scholar] [CrossRef]

- Lacks, D.J.; Osborne, M.J. Energy landscape picture of overaging and rejuvenation in a sheared glass. Phys. Rev. Lett. 2004, 93, 255501. [Google Scholar] [CrossRef]

- Fiocco, D.; Foffi, G.; Sastry, S. Oscillatory athermal quasistatic deformation of a model glass. Phys. Rev. E 2013, 88, 020301(R). [Google Scholar] [CrossRef]

- Priezjev, N.V. Molecular dynamics simulations of the mechanical annealing process in metallic glasses: Effects of strain amplitude and temperature. J. Non-Cryst. Solids 2018, 479, 42–48. [Google Scholar] [CrossRef]

- Priezjev, N.V. Slow relaxation dynamics in binary glasses during stress-controlled, tension-compression cyclic loading. Comput. Mater. Sci. 2018, 153, 235–240. [Google Scholar] [CrossRef]

- Jana, P.K.; Priezjev, N.V. Structural relaxation in amorphous materials under cyclic tension-compression loading. J. Non-Cryst. Solids 2020, 540, 120098. [Google Scholar] [CrossRef]

- Priezjev, N.V. Accelerated relaxation in disordered solids under cyclic loading with alternating shear orientation. J. Non-Cryst. Solids 2019, 525, 119683. [Google Scholar] [CrossRef]

- Priezjev, N.V. Alternating shear orientation during cyclic loading facilitates yielding in amorphous materials. J. Mater. Eng. Perform. 2020, 29, 7328–7335. [Google Scholar] [CrossRef]

- Mota, R.; Lund, E.; Sohn, S.; Browne, D.; Schroers, J. Pulling metallic glasses ductile. Res. Sq. 2020. [Google Scholar] [CrossRef]

- Kob, W.; Andersen, H.C. Testing mode-coupling theory for a supercooled binary Lennard-Jones mixture: The van Hove correlation function. Phys. Rev. E 1995, 51, 4626–4641. [Google Scholar] [CrossRef]

- Weber, T.A.; Stillinger, F.H. Local order and structural transitions in amorphous metal-metalloid alloys. Phys. Rev. B 1985, 31, 1954–1963. [Google Scholar] [CrossRef]

- Plimpton, S.J. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon: Oxford, UK, 1987. [Google Scholar]

- Fan, M.; Wang, M.; Zhang, K.; Liu, Y.; Schroers, J.; Shattuck, M.D.; O’Hern, C.S. The effects of cooling rate on particle rearrangement statistics: Rapidly cooled glasses are more ductile and less reversible. Phys. Rev. E 2017, 95, 022611. [Google Scholar] [CrossRef]

- Vollmayr, K.; Kob, W.; Binder, K. How do the properties of a glass depend on the cooling rate? A computer simulation study of a Lennard-Jones system. J. Chem. Phys. 1996, 105, 4714–4728. [Google Scholar] [CrossRef]

- Utz, M.; Debenedetti, P.G.; Stillinger, F.H. Atomistic simulation of aging and rejuvenation in glasses. Phys. Rev. Lett. 2000, 84, 1471–1474. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Priezjev, N.V. Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility. Metals 2021, 11, 67. https://doi.org/10.3390/met11010067

Priezjev NV. Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility. Metals. 2021; 11(1):67. https://doi.org/10.3390/met11010067

Chicago/Turabian StylePriezjev, Nikolai V. 2021. "Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility" Metals 11, no. 1: 67. https://doi.org/10.3390/met11010067

APA StylePriezjev, N. V. (2021). Cooling under Applied Stress Rejuvenates Amorphous Alloys and Enhances Their Ductility. Metals, 11(1), 67. https://doi.org/10.3390/met11010067