Mechanical Characterization of Graphene Nanoplatelets-Reinforced Mg-3Sn Alloy Synthesized by Powder Metallurgy

Abstract

1. Introduction

2. Materials and Methods

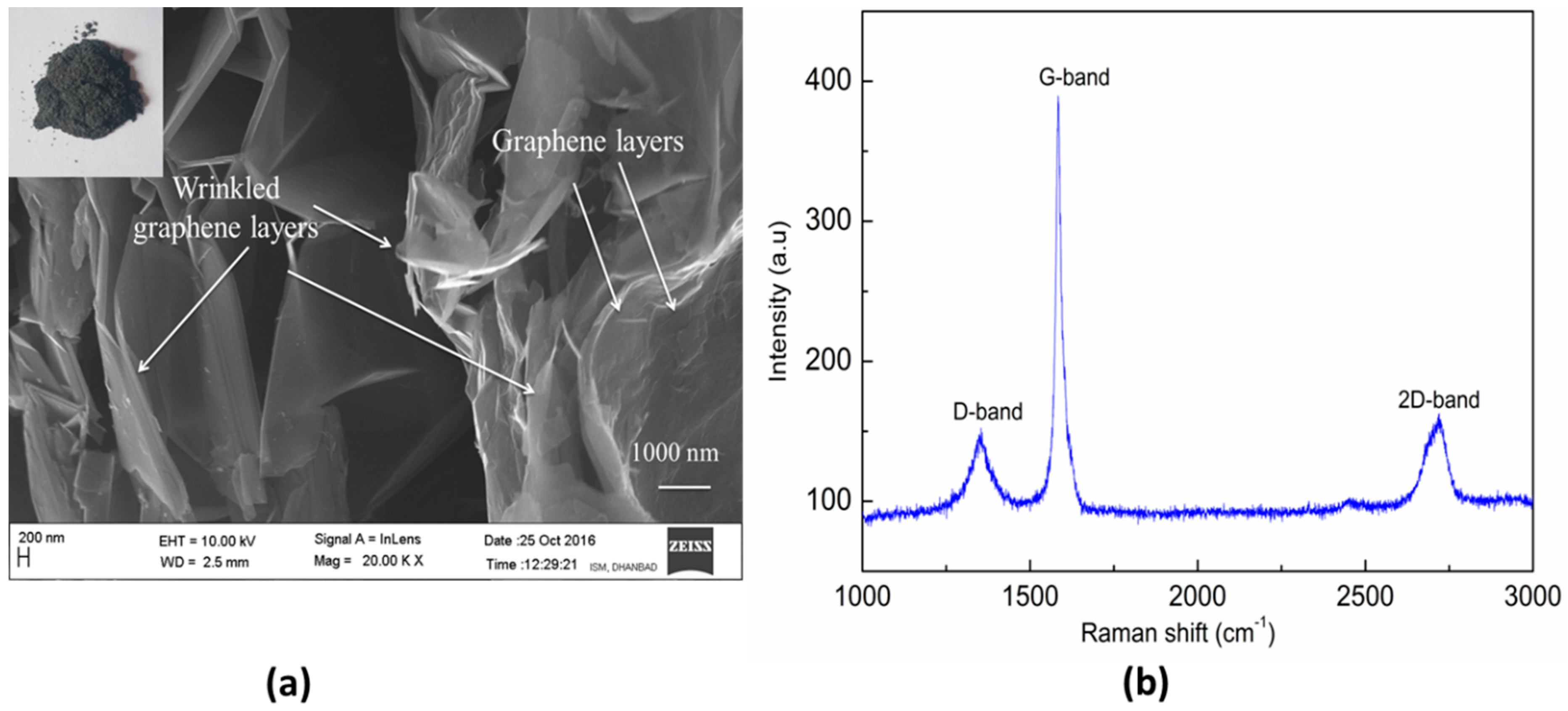

2.1. Materials

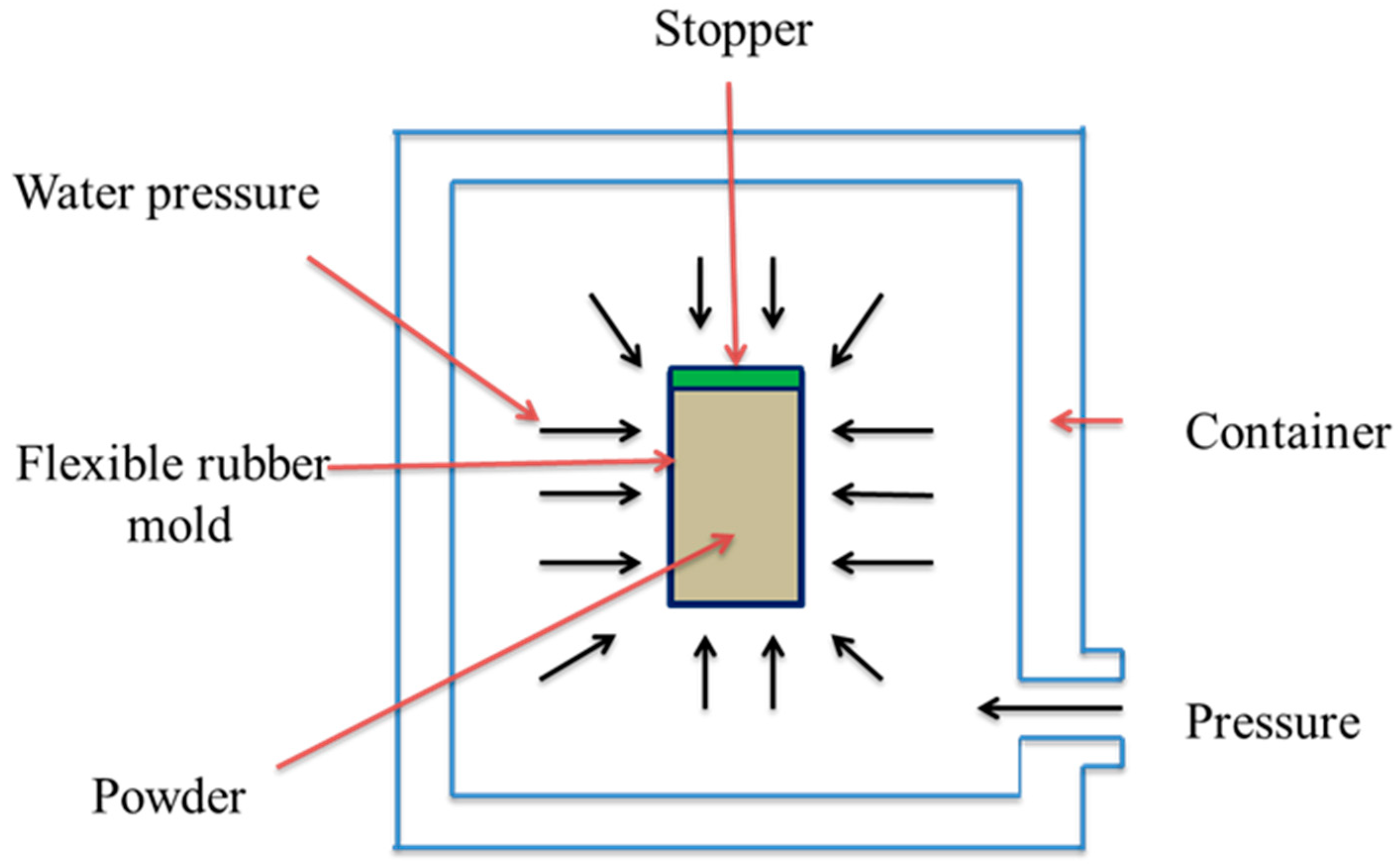

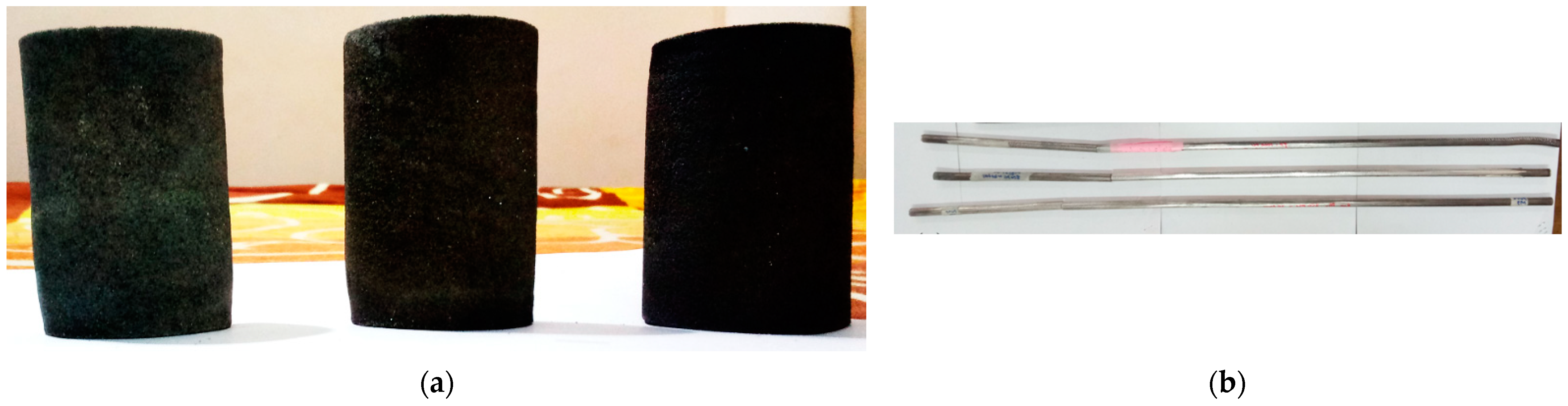

2.2. Synthesis

2.3. X-ray Diffraction Analysis

2.4. Density and Porosity Measurement

2.5. Microhardness Test

2.6. Microstructural Characterization

2.7. Tensile Test

2.8. Compression Test

3. Results

3.1. Density Measurement

3.2. XRD Analysis

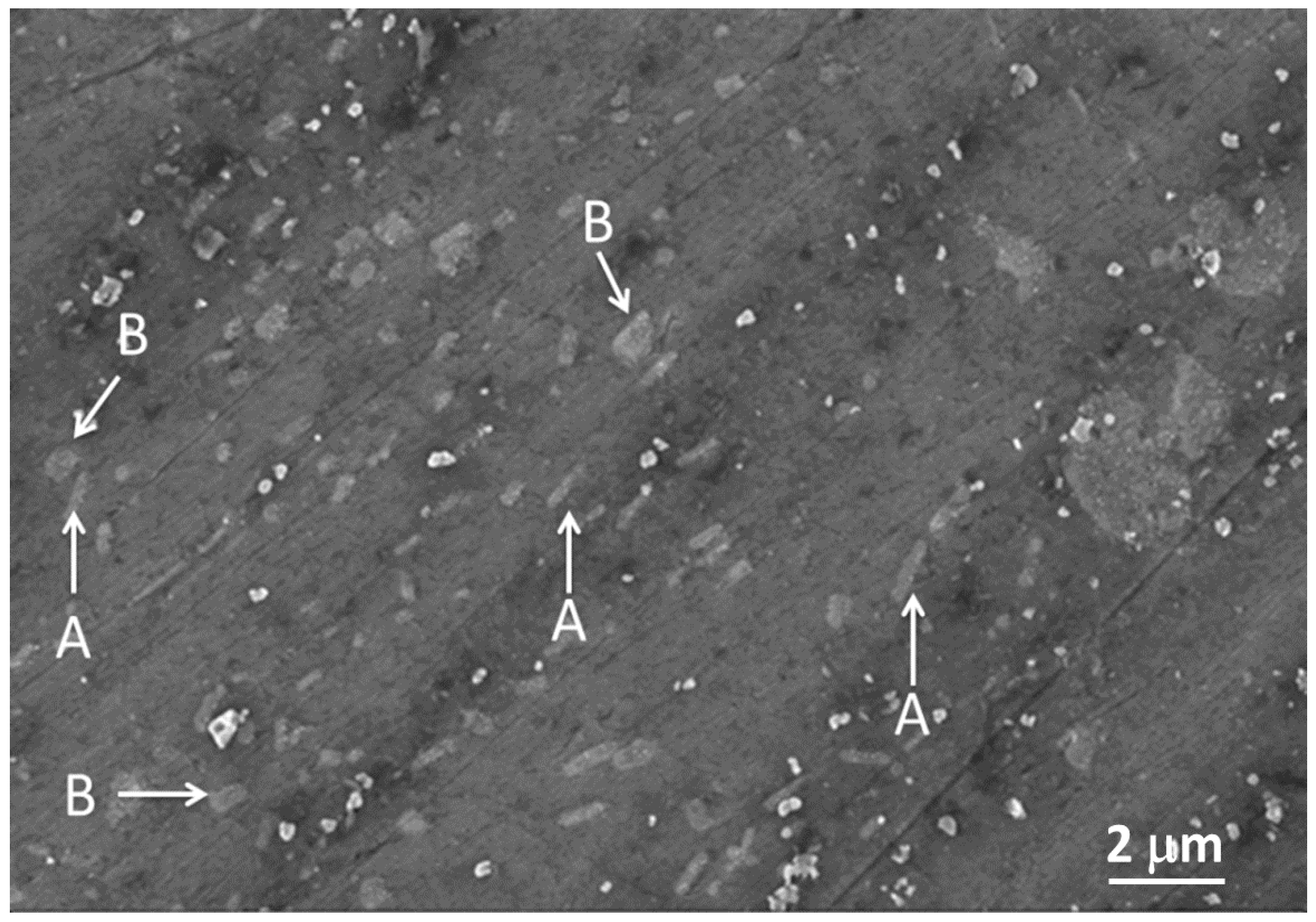

3.3. Microstructural Analysis

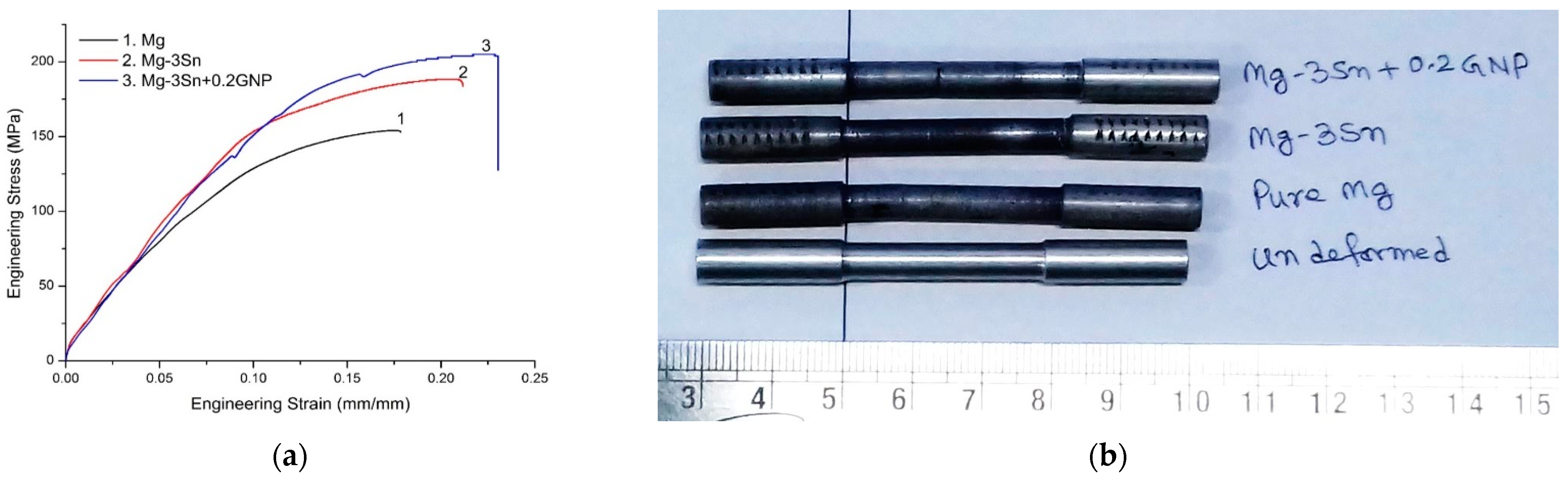

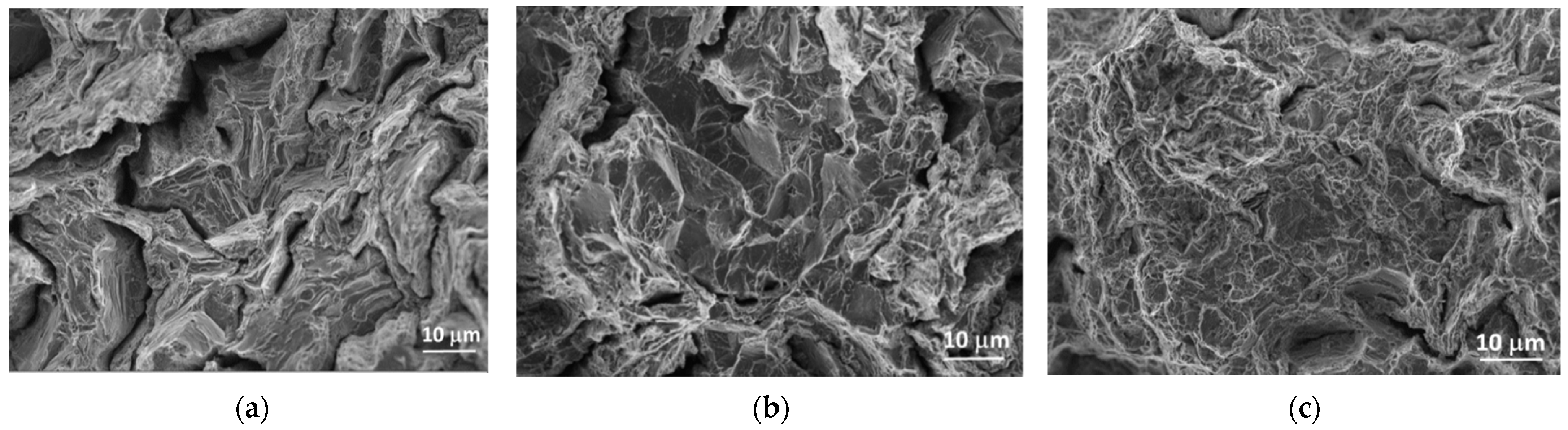

3.4. Microhardness and Tensile Properties

4. Discussion

4.1. Density Analysis

4.2. XRD Results Analysis

4.3. Microhardness and Tensile Properties Analysis

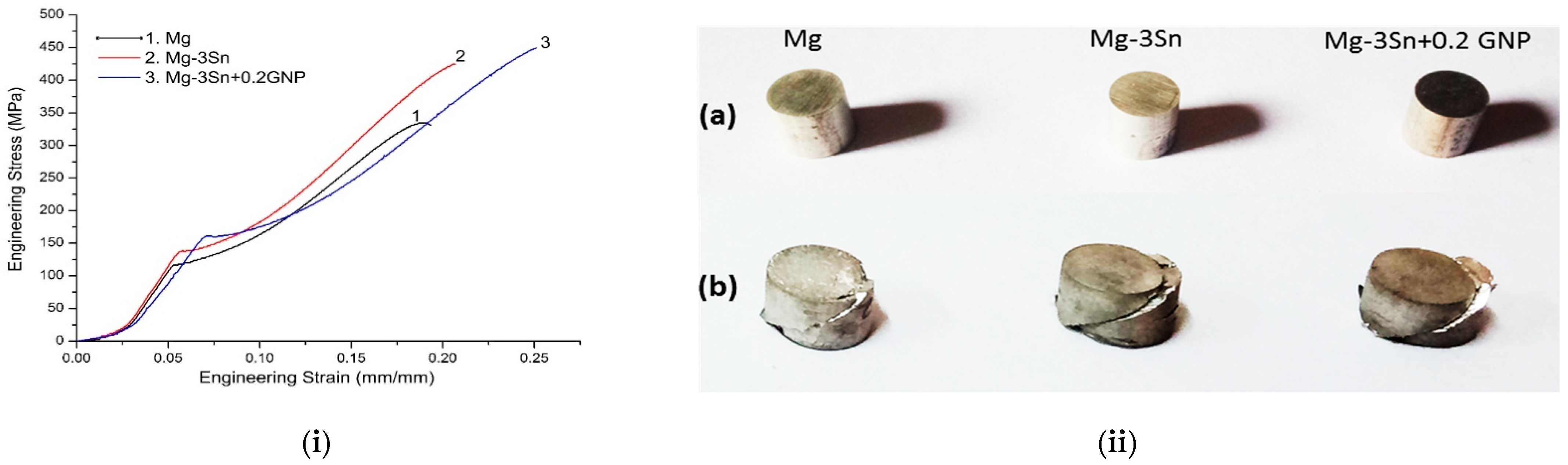

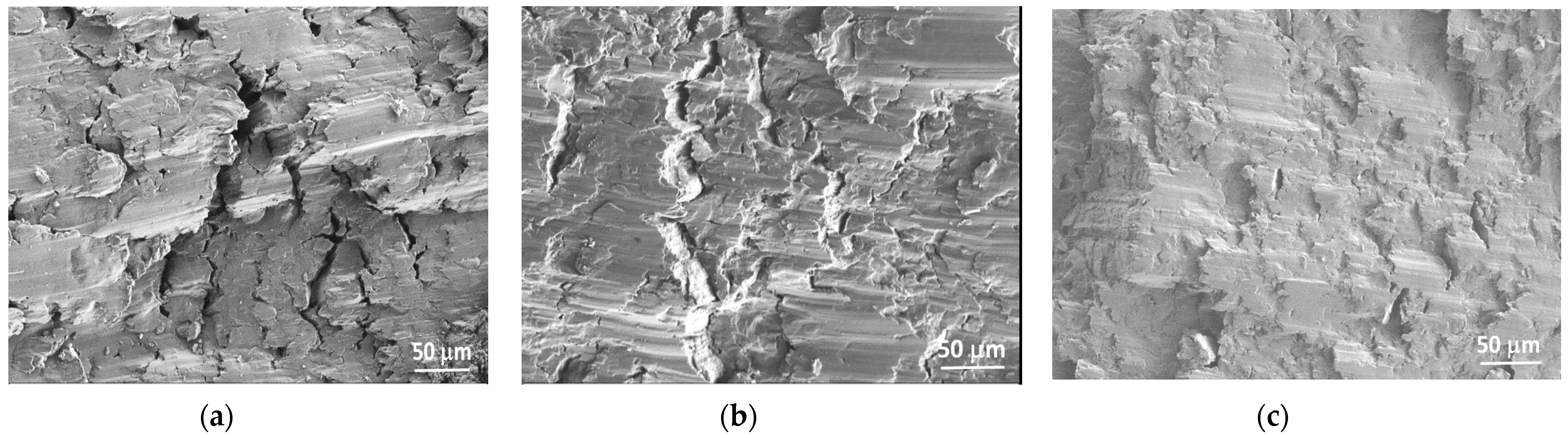

4.4. Compressive Properties Analysis

5. Conclusions

- The microhardness of the Mg-3Sn alloy was improved by 22.4% with respect to that of pure Mg. The microhardness of the Mg-3Sn + 0.2 GNP was improved by 42.4 and 7.8% with respect to those of pure Mg and the Mg-3Sn alloy, respectively. This can be attributed to obstruction in dislocation movement in the presence of harder intermetallic Mg2Sn phase and GNP.

- The ultimate tensile strength of the Mg-3Sn alloy was improved by 22.5% with respect to that of pure Mg. The ultimate tensile strength of Mg-3Sn + 0.2 GNP was improved by 33.5 and 9% with respect to those of pure Mg and the Mg-3Sn alloy, respectively. The percentage failure strain of the nanocomposite was improved by 21.8 and 19% with respect to those of pure Mg and Mg-3Sn alloy.

- The ultimate compressive strength of the Mg-3Sn alloy was improved by 20% with respect to that of pure Mg. The ultimate compressive strength of Mg-3Sn + 0.2 GNP was improved by 32.9 and 10.7% with respect to those of pure Mg and the Mg-3Sn alloy, respectively without compromising failure strain. No significant changes were observed in the ductility.

- After the addition of 0.2% GNP in the Mg-3Sn alloy, the improvement in the tensile strength (+16.6 MPa) of the Mg-3Sn + 0.2 GNP alloy-nanocomposite was lower than that of the compressive strength (+43.7 MPa). However, the nanocomposite possessed good value of ultimate tensile strength of 201 MPa and ultimate compressive strength of 453 MPa. This improvement in the properties can be ascribed to CTE mismatch, elastic modulus mismatch, load transfer mechanism, and Orowan strengthening.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kainer, K.U. (Ed.) Magnesium Alloys and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Xu, W.; Birbilis, N.; Sha, G.; Wang, Y.; Daniels, J.E.; Xiao, Y.; Ferry, M. A high-specific-strength and corrosion-resistant magnesium alloy. Nat. Mater. 2015, 14, 1229–1235. [Google Scholar] [CrossRef] [PubMed]

- Mallick, A.; Vedantam, S.; Li, L. Grain size dependent tensile behavior of Mg–3% Al alloy at elevated temperatures. Mater. Sci. Eng. A 2009, 515, 14–18. [Google Scholar] [CrossRef]

- Zhang, X.; Lihua, L.; Naiheng, M.; Haowei, W. Mechanical properties and damping capacity of magnesium matrix composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2011–2016. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Gupta, M. Selective laser melting of magnesium and magnesium alloy powders: A review. Metals 2017, 7, 2. [Google Scholar] [CrossRef]

- Wong, W.L.E.; Gupta, M. High performance lightweight magnesium nano composites for engineering and biomedical applications. Nano World J. 2016, 2, 78–83. [Google Scholar]

- Ferguson, J.B.; Jaberi, F.S.; Kim, C.S.; Rohatgi, P.K.; Cho, K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater. Sci. Eng. A 2012, 558, 193–204. [Google Scholar] [CrossRef]

- Kraus, T.; Fischerauer, S.F.; Hanzi, A.C.; Uggowitzer, P.J.; Loffler, J.F.; Weinberg, A.M. Magnesium alloys for temporary implants in osteosynthesis: In vivo studies of their degradation and interaction with bone. Acta Biomater. 2012, 8, 1230–1238. [Google Scholar] [CrossRef]

- Kirkland, N.T.; Birbilis, N. Magnesium Biomaterials: Design, Testing, and Best Practice; Springer International Publishing: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Yang, Z.; Li, J.P.; Zhang, J.X.; Lorimer, G.W.; Robson, J.A.M.S.E.L. Review on research and development of magnesium alloys. Acta Met. Sin. 2009, 21, 313–328. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Dieringa, H. Processing of magnesium-based metal matrix nanocomposites by ultrasound-assisted particle dispersion: A review. Metals 2018, 8, 431. [Google Scholar] [CrossRef]

- Mendis, C.L.; Hono, K. 4-Understanding precipitation processes in magnesium alloys. Fundam. Magnes. Alloy Metall. 2013, 125–151. [Google Scholar] [CrossRef]

- Seetharaman, S.; Blawert, C.; Ng, B.M.; Wong, W.L.E.; Goh, C.S.; Hort, N.; Gupta, M. Effect of erbium modification on the microstructure, mechanical and corrosion characteristics of binary Mg–Al alloys. J. Alloys Compd. 2015, 648, 759–770. [Google Scholar] [CrossRef]

- Avedesian, M.M.; Baker, H. (Eds.) ASM Specialty Handbook: Magnesium and Magnesium Alloys; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- Chen, J.H.; Shen, Y.C.; Chao, C.G.; Liu, T.F. Wear Behavior and Microstructure of Mg-Sn Alloy Processed by Equal Channel Angular Extrusion. Materials 2017, 10, 1315. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Chen, Y.; Tang, T.; Wei, S.; Niu, G. The microstructure, tensile properties, and creep behavior of as-cast Mg–(1–10)% Sn alloys. J. Alloys Compd. 2007, 440, 122–126. [Google Scholar] [CrossRef]

- Huang, Y.; Dieringa, H.; Kainer, K.U.; Hort, N. Effects of Sn segregation and precipitates on creep response of Mg-Sn alloys. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 308–315. [Google Scholar] [CrossRef]

- Kang, D.H.; Park, S.S.; Kim, N.J. Development of creep resistant die cast Mg–Sn–Al–Si alloy. Mater. Sci. Eng. A 2005, 413, 555–560. [Google Scholar] [CrossRef]

- Bowles, A.L.; Dieringa, H.; Blawert, C.; Hort, N.; Kainer, K.U. Investigations in the Magnesium-Tin system. In Materials Science Forum; Trans Tech Publications Ltd.: Zurich, Switzerland, 2005; Volume 488, pp. 135–138. [Google Scholar]

- Huang, Y.; Dieringa, H.; Kainer, K.U.; Hort, N. Understanding effects of microstructural inhomogeneity on creep response–New approaches to improve the creep resistance in magnesium alloys. J. Magnes. Alloys 2014, 2, 124–132. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Meenashisundaram, G.K.; Gupta, M. Enhancing the tensile and ignition response of monolithic magnesium by reinforcing with silica nanoparticulates. J. Mater. Res. 2017, 32, 2169–2178. [Google Scholar] [CrossRef]

- Kujur, M.S.; Mallick, A.; Manakari, V.; Parande, G.; Tun, K.S.; Gupta, M. Significantly enhancing the ignition/compression/damping response of monolithic magnesium by addition of Sm2O3 nanoparticles. Metals 2017, 7, 357. [Google Scholar] [CrossRef]

- Tekumalla, S.; Nandigam, Y.; Bibhanshu, N.; Rajashekara, S.; Yang, C.; Satyam, S.; Gupta, M. A strong and deformable in-situ magnesium nanocomposite igniting above 1000 C. Sci. Rep. 2018, 8, 7308. [Google Scholar] [CrossRef]

- Ferkel, H.; Mordike, B.L. Magnesium strengthened by SiC nanoparticles. Mater. Sci. Eng. A 2001, 298, 193–199. [Google Scholar] [CrossRef]

- Labib, F.; Mahmudi, R.; Ghasemi, H.M. Impression creep behavior of extruded Mg–SiCp composites. Mater. Sci. Eng. A 2015, 640, 91–97. [Google Scholar] [CrossRef]

- Kumar, H.; Chaudhari, G.P. Creep behavior of AS41 alloy matrix nano-composites. Mater. Sci. Eng. A 2014, 607, 435–444. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced metal matrix nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Kumar, P.; Mallick, A.; Kujur, M.S.; Tun, K.S.; Gupta, M. Effects of graphene nanoplatelets on the tribological, mechanical, and thermal properties of Mg-3Al alloy nanocomposites. Int. J. Mat. Res. 2019, 110, 534–542. [Google Scholar] [CrossRef]

- Hu, Z.; Tong, G.; Lin, D.; Chen, C.; Guo, H.; Xu, J.; Zhou, L. Graphene-reinforced metal matrix nanocomposites–a review. Mater. Sci. Technol. 2016, 32, 930–953. [Google Scholar] [CrossRef]

- Xiang, S.; Wang, X.; Gupta, M.; Wu, K.; Hu, X.; Zheng, M. Graphene nanoplatelets induced heterogeneous bimodal structural magnesium matrix composites with enhanced mechanical properties. Sci. Rep. 2016, 6, 38824. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Hu, H.; Asif, M.; Hussain, S.; She, J. Enhanced tensile properties of magnesium composites reinforced with graphene nanoplatelets. Mater. Sci. Eng. A 2015, 630, 36–44. [Google Scholar] [CrossRef]

- Kumar, P.; Mallick, A.; Kujur, M.S.; Tun, K.S.; Shabadi, R.; Gupta, M. Strength of Mg–3% Al alloy in presence of graphene nano-platelets as reinforcement. Mater. Sci. Technol. 2018, 34, 1086–1095. [Google Scholar] [CrossRef]

- Kumar, P.; Mallick, A.; Kujur, M.S.; Tun, K.S.; Gupta, M. Synthesis and analysis of Mg–3% Al alloy nanocomposites reinforced by RGO. Mater. Manuf. Process. 2020, 35, 1650–1660. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M.; Tang, A. Powder metallurgy of Mg–1% Al–1% Sn alloy reinforced with low content of graphene nanoplatelets (GNPs). J. Ind. Eng. Chem. 2014, 20, 4250–4255. [Google Scholar] [CrossRef]

- Munir, K.; Wen, C.; Li, Y. Graphene nanoplatelets-reinforced magnesium metal matrix nanocomposites with superior mechanical and corrosion performance for biomedical applications. J. Magnes. Alloys 2020, 8, 269–290. [Google Scholar] [CrossRef]

- Ratcliffe, R.T. The measurement of small density changes in solids. Br. J. Appl. Phys. 1965, 16, 1193. [Google Scholar] [CrossRef]

- Thenambika, V.; Jayalakshmi, S.; Singh, A.; Nidhi, J.K. Impression creep behaviour of extruded Mg-Sn alloy. Int. J. Veh. Struct. Syst. 2016, 8, 174–178. [Google Scholar] [CrossRef]

- Pekguleryuz, M.O.; Kainer, K.U.; Kaya, A.A. Fundamentals of Magnesium Alloy Metallurgy; Woodhead Publishing Ltd.: Cambridge, UK, 2013. [Google Scholar]

- Peng, Y.; Deng, K. Study on the mechanical properties of the novel Sn–Bi/Graphene nanocomposite by finite element simulation. J. Alloys Compd. 2015, 625, 44–51. [Google Scholar] [CrossRef]

- Gupta, M.; Sharon, N.M.L. Magnesium, Magnesium Alloys, and Magnesium Composites; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ahmad, I.; Islam, M.; Subhani, T.; Zhu, Y. Toughness enhancement in graphene nanoplatelet/SiC reinforced Al2O3 ceramic hybrid nanocomposites. Nanotechnology 2016, 27, 425704. [Google Scholar] [CrossRef]

- Johanes, M.; Tekumalla, S.; Gupta, M. Fe3O4 nanoparticle-reinforced magnesium nanocomposites processed via disintegrated melt deposition and turning-induced deformation techniques. Metals 2019, 9, 1225. [Google Scholar] [CrossRef]

- Ceschini, L.; Dahle, A.; Gupta, M.; Jarfors, A.E.W.; Jayalakshmi, S.; Morri, A.; Rotundo, F.; Toschi, S.; Singh, R.A. Aluminum and Magnesium Metal Matrix Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Ogurtani, T.O.; Dogukan, S.; Buke, G.C. Wrinkling of graphene because of the thermal expansion mismatch between graphene and copper. Surf. Interface Anal. 2018, 50, 547–551. [Google Scholar] [CrossRef]

- Saba, F.; Zhang, F.; Liu, S.; Lie, T. Reinforcement size dependence of mechanical properties and strengthening mechanisms in diamond reinforced titanium metal matrix composites. Compos. Part B Eng. 2019, 167, 7–19. [Google Scholar] [CrossRef]

- Tun, K.S. Development and Characterization of New Magnesium Based Nanocomposites. Ph.D. Thesis, National University of Singapore, Singapore, 2009. [Google Scholar]

- Sankaranarayanan, S.; Nayak, U.P.; Sabat, R.K.; Suwas, S.; Almajid, A.; Gupta, M. Nano-ZnO particle addition to monolithic magnesium for enhanced tensile and compressive response. J. Alloys Compd. 2014, 615, 211–219. [Google Scholar] [CrossRef]

- Kujur, M.S.; Manakari, V.; Parande, G.; Tun, K.S.; Mallick, A.; Gupta, M. Enhancement of thermal, mechanical, ignition and damping response of magnesium using nano-ceria particles. Ceram. Int. 2018, 44, 15035–15043. [Google Scholar] [CrossRef]

| Material | Theoretical Density | Experimental Density | Porosity (%) |

|---|---|---|---|

| Mg | 1.740 | 1.707 ± 0.0040 | 1.90 |

| Mg-3Sn | 1.781 | 1.766 ± 0.0028 | 0.84 |

| Mg-3Sn + 0.2 GNP | 1.782 | 1.765 ± 0.0017 | 0.95 |

| Material | Vicker’s Hardness (HV) | 0.2% Offset Yield Strength (Nmm−2) | Ultimate Tensile Strength (Nmm−2) | Failure Strain (%) |

|---|---|---|---|---|

| Mg | 38 ± 4 | 82 ± 3 | 151 ± 3 | 17.9 ± 0.7 |

| Mg-3Sn | 50 ± 4 | 132 ± 11 | 185 ± 10 | 21.3 ± 2.2 |

| Mg-3Sn + 0.2 GNP | 54 ± 3 | 136 ± 21 | 201 ± 7 | 21.8 ± 1.6 |

| Material | 0.2% Offset Yield Strength (Nmm−2) | Ultimate Compressive Strength (Nmm−2) | Failure Strain (%) |

|---|---|---|---|

| Mg | 115 ± 8 | 341 ± 11 | 23.3 ± 0.8 |

| Mg-3Sn | 138 ± 14 | 409 ± 24 | 24.6 ± 1.5 |

| Mg-3Sn + 0.2 GNP | 159 ± 9 | 453 ± 19 | 25 ± 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, P.; Skotnicova, K.; Mallick, A.; Gupta, M.; Cegan, T.; Jurica, J. Mechanical Characterization of Graphene Nanoplatelets-Reinforced Mg-3Sn Alloy Synthesized by Powder Metallurgy. Metals 2021, 11, 62. https://doi.org/10.3390/met11010062

Kumar P, Skotnicova K, Mallick A, Gupta M, Cegan T, Jurica J. Mechanical Characterization of Graphene Nanoplatelets-Reinforced Mg-3Sn Alloy Synthesized by Powder Metallurgy. Metals. 2021; 11(1):62. https://doi.org/10.3390/met11010062

Chicago/Turabian StyleKumar, Pravir, Katerina Skotnicova, Ashis Mallick, Manoj Gupta, Tomas Cegan, and Jan Jurica. 2021. "Mechanical Characterization of Graphene Nanoplatelets-Reinforced Mg-3Sn Alloy Synthesized by Powder Metallurgy" Metals 11, no. 1: 62. https://doi.org/10.3390/met11010062

APA StyleKumar, P., Skotnicova, K., Mallick, A., Gupta, M., Cegan, T., & Jurica, J. (2021). Mechanical Characterization of Graphene Nanoplatelets-Reinforced Mg-3Sn Alloy Synthesized by Powder Metallurgy. Metals, 11(1), 62. https://doi.org/10.3390/met11010062