1. Introduction

During the continuous casting of steels, surface and internal cracks can be originated by the different thermal and mechanical stresses present [

1,

2,

3,

4]. The physical simulation of the most widely used process in steel production is important for product quality and savings, once it can help the improvement of the hot ductility, consequently reducing the incidence of cracks [

5,

6]. Many process parameters can influence the hot ductility of the steel, one of them being the time between the cooling and the deformation phases, referred to as the holding time. The aim of this work is to investigate the influence of the holding time on the ductility behavior of a low alloyed steel, bringing a new approach to the analysis of this parameter by evaluating the results from physical experiments alongside the computer simulations of precipitation kinetics.

The hot ductility of low alloyed steels usually presents its minimum in the temperature range of 700 °C to 1000 °C, which is also the usual range of the bending and straightening operation in the continuous casting process and the most critical for the formation of cracks [

2,

5,

7,

8]. This lower ductility is known to be caused by two main factors, the austenite–ferrite transformation, and the nucleation of precipitates, depending strongly on the alloying elements present [

6,

9,

10,

11]. Due to the lower strength of ferrite in comparison to austenite, the strain that concentrates in the ferrite films formed in the austenite grain boundaries initiate cracks as a result [

8,

10,

12]. In the context of the nucleation of precipitates, local hardening occurs, provoking stress concentration and promoting the initiation of cracks [

4,

12].

The procedure chosen in this work to physically simulate the industrial process is the hot tensile test, which is commonly used to determine the hot ductility curve for the material [

3,

5,

6,

9,

12]. The evaluation of this parameter has been done for many years by the determination of the reduction of area (RA) of the samples tested [

1,

2,

4,

5,

11].

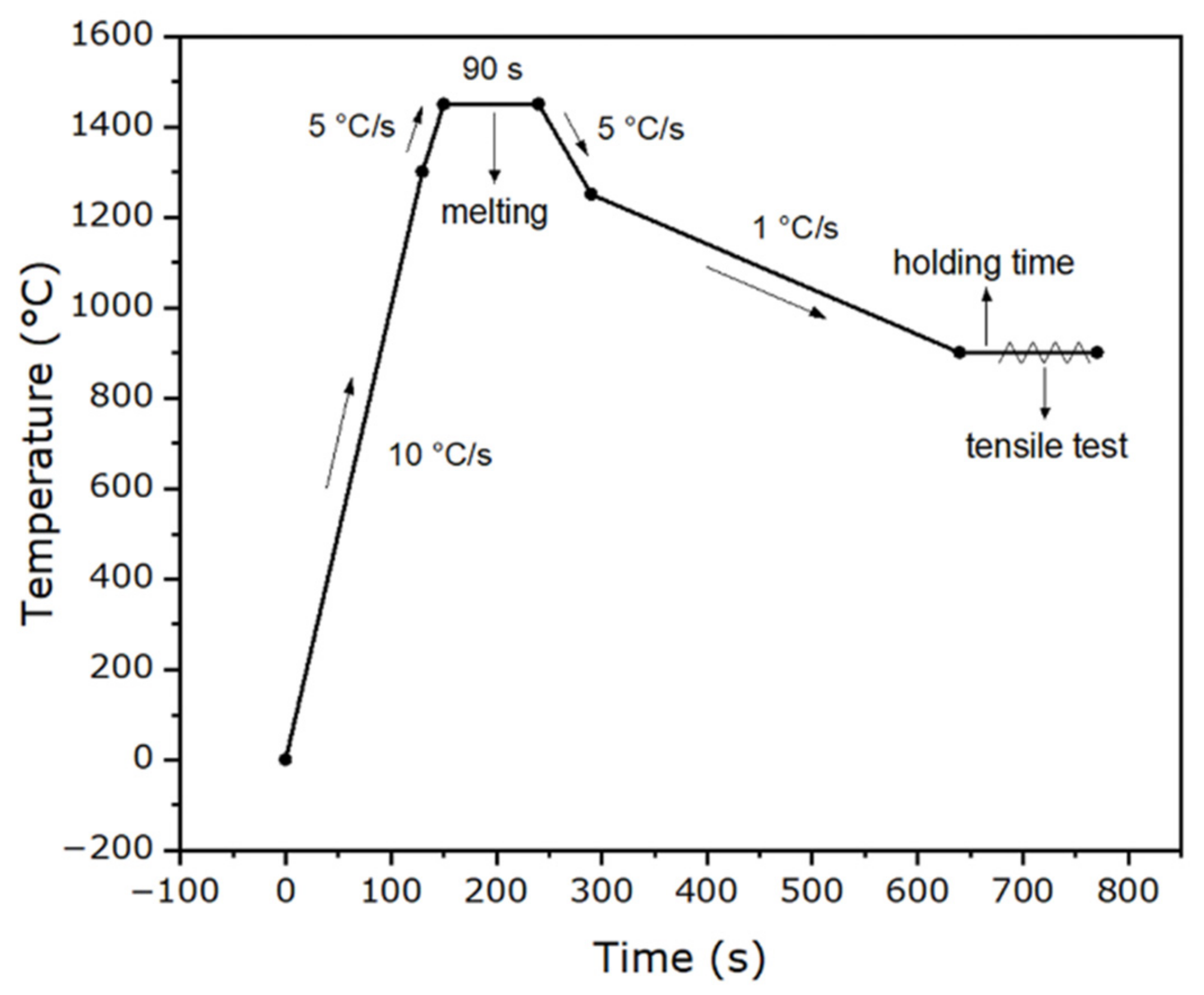

The thermal cycle used to represent the process usually consists of heating the steel well above the austenitization temperature to dissolve the alloying elements and obtain a microstructure that is most similar to the material when it is being cast. This aims to represent the beginning of the casting process, with the molten steel. However, many of the works found in the literature do not reach the melting point during the experiment, and only approximate to the real process [

3,

5,

8,

10,

13,

14,

15]. The in-situ melting of the samples during the investigation of the hot ductility is one of the important contributions offered by this work. After being heated to the higher temperature, samples are cooled at a selected cooling rate until the desired testing temperature is reached. On reaching this test temperature, the sample can go through an isothermal path for a determined time, the afore mentioned holding time, before the start of the tensile test.

The influence of the holding time on the hot ductility behavior of low alloyed steels has not been extensively explored, in contrast to other aspects of the processes such as cooling rate, strain rate, surface quality, and alloying elements. Moreover, the existing studies present diverse findings obtained by physical experiments, with no parallel simulations for comparison or confirmation.

Suzuki et al. [

16], observed that for a plain carbon steel, the increase in the holding time prior the hot tensile test between 1200 °C and 800 °C leads to an increase in the RA, which represents an improvement of the hot ductility.

Kang et al. [

14] also tested the hot ductility of low alloyed steels with different holding times, with the test temperatures selected as 900 °C and 1000 °C. The results showed that the sample with no special alloying element (Nb-free) was not influenced by the holding time, the one with Nb and Mn was slightly improved, and the other two with Nb contents of 0.031 and 0.062 wt% had their ductility significantly increased with the increase in the holding time.

Crowther and Mintz [

15] performed experiments with steels with higher (0.068 wt%) and lower (0.017 wt%) Al content and reported that when there was more Al, RA reduced at higher holding times. This change in the RA was not seen for the lower Al steel. The work also showed that the different holding times did not affect the grain size or peak stresses. Lastly, at higher and lower temperatures, the ductility curves converged for both no holding time and long holding times.

Ouchi and Matsumoto [

13] reported that the changes in holding time before the tensile test at temperatures lower than 1000 °C did not significantly influence the hot ductility, and that above this temperature, the changes were caused by more time for the coarsening and dissolution of the NbCN precipitates.

Zheng et al. [

17] carried out different analyses for the hot ductility of C-Mn steels, also testing various holding times at the tensile test temperature of 950 °C and strain rate of 22 s

−1. The reduction of area measured for each condition showed that there was no significant difference for low holding times (lower than 500 s). Only by holding for longer time periods could an improvement in the hot ductility of the steel be seen.

Balbi et al. [

18] tested samples with only one final quenching after annealing and samples with intermediate and final quenching. The tensile tests were done at room temperature and for both groups, the different holding times at the annealing temperature before the tests did not reflect in the different tensile properties.

Due to the contrasting results found in literature, with different test methods, results and no parallel thermokinetic simulations, gathering more information on the influence of this parameter on the hot ductility behavior of a low alloyed steel is deemed necessary. Hot tensile tests on in-situ melted samples and simulations to predict the behavior of precipitation were done at three different temperatures, with four different holding times, analyzing the macro and microscopic results to give a more complete understanding of the behavior observed.

Author Contributions

Conceptualization, M.G., C.H. and C.S.; methodology, M.G. and C.H.; validation, M.G. and C.H.; formal analysis M.G.; investigation, M.G.; resources, S.I. and J.S.; data curation, M.G and C.H.; writing—original draft preparation, M.G.; writing—review and editing, M.G, C.H., S.I., J.S. and C.S.; visualization, M.G. and C.H.; supervision, C.S.; project administration, M.G., C.H., S.I, J.S. and C.S.; funding acquisition, S.I, J.S. and C.S.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Austrian Research Promotion Agency, grant number 869295. The APC was funded by the quota granted to Christof Sommitsch, voucher number bc1c32e04035b455.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are openly available in FigShare at 10.6084/m9.figshare.13502061.

Acknowledgments

The authors gratefully acknowledge the funding support of K1-MET GmbH. The research program of the K1-MET competence center is supported by COMET (Competence Centre for Excellent Technologies), the Austrian program for competence centers. COMET is funded by the Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology, the Federal Ministry for Digital and Economic Affairs, the provinces of Upper Austria, Tyrol and Styria and by the Styrian Business Promotion Agency (SFG). Furthermore, we thank Upper Austrian Research for the continuous support. In addition, this research project is partially financed by the industrial partners Primetals Technologies Austria and voestalpine Stahl and the scientific partners Graz University of Technology and TU Wien.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Arikan, M.M. Hot ductility behavior of a peritectic steel during continuous casting. Metals 2015, 5, 986–999. [Google Scholar] [CrossRef]

- Caliskanoglu, O. Hot Ductility Investigations of Continuously Cast Steels. Ph.D. Thesis, Graz University of Technology, Graz, Austria, 2015. [Google Scholar]

- Schöbel, M.; Großeiber, S.; Jonke, J.; Wimpory, R.; Ilie, S.; Requena, G. Residual stress in continuously cast steel slabs. BHM 2013, 158, 475–476. [Google Scholar] [CrossRef]

- Mintz, B.; Yue, S.; Jonas, J.J. Hot ductility of steels and its relationship to the problem of transverse cracking during continuous casting. Int. Mater. Rev. 1991, 36, 187–220. [Google Scholar] [CrossRef]

- Huitron, R.M.P.; Lopez, P.E.R.; Vourinen, E.; Jentner, R.; Kärkkäinen, M.E. Converging criteria to characterize crack susceptibility in a micro-alloyed steel during continuous casting. Mater. Sci. Eng. A 2020, 772, 138691. [Google Scholar] [CrossRef]

- Louhenkilpi, S. Treatise on Process Metallurgy; Elsevier: Amsterdam, The Netherlands, 2014; Volume 3, pp. 373–434. [Google Scholar]

- Mintz, B.; Crowther, D.N. Hot ductility of steels and its relationship to the problem of transverse cracking in continuous casting. Int. Mater. Rev. 2010, 55, 168–196. [Google Scholar] [CrossRef]

- Lewis, J.; Jonas, J.J.; Mintz, B. The deformation induced ferrite during mechanical testing. ISIJ Int. 1998, 38, 300–309. [Google Scholar] [CrossRef]

- Hoflehner, C.; Ilie, S.; Six, J.; Beal, C.; Sommitsch, C. Influence of thermal history on the hot ductility of a continuously cast low alloy Cr-Mo steel. J. Mater. Eng. Perform. 2018, 26, 5124–5129. [Google Scholar] [CrossRef]

- Banks, K.M.; Tuling, A.; Mintz, B. Influence of thermal history on the hot ductility of steel and its relationship to the problem of cracking in continuous casting. Mater. Sci. Technol. 2012, 28, 536–542. [Google Scholar] [CrossRef]

- Bernhard, C.; Reiter, J.; Presslinger, H. A model for predicting the austenite grain size at the surface of continuously-cast slabs. Metall. Trans. B 2008, 39B, 885–895. [Google Scholar] [CrossRef]

- Beal, C.; Caliskanoglu, O.; Sommitsch, C.; Ilie, S.; Six, J.; Domankova, M. Influence of thermal history on the hot ductility of Ti-Nb microalloyed steels. Mater. Sci. Forum. 2016, 879, 199–204. [Google Scholar] [CrossRef]

- Ouchi, C.; Matsumoto, K. Hot ductility in Nb-bearing high-strength low-alloy steels. Trans. ISIJ 1982, 22, 181–189. [Google Scholar] [CrossRef]

- Kang, M.H.; Lee, J.S.; Koo, Y.M.; Kim, S.-J.; Heo, N.H. The mechanism of hot ductility loss and recovery in Nb-bearing low alloy steels. Metall. Trans. A 2014, 45A, 4302–4306. [Google Scholar] [CrossRef][Green Version]

- Crowther, D.N.; Mohamed, Z.; Mintz, B. The relative influence of dynamic and static precipitation on the hot ductility of microalloyed steels. Metall. Trans. A 1987, 18A, 1929–1939. [Google Scholar] [CrossRef]

- Suzuki, H.G.; Nishimura, S.; Yamaguchi, S. Characteristics of hot ductility in steels subjected to the melting and solidification. Trans. ISIJ. 1982, 22, 48–56. [Google Scholar] [CrossRef]

- Zheng, Z.; Yu, H.; Liu, Z.; Xu, T.; Devesh, R.; Misra, K. Mechanism of hot ductility loss in C-Mn steels based on nonequilibrium grain boundary segregation of impurities. J. Mater. Res. 2015, 30, 1701–1714. [Google Scholar] [CrossRef]

- Balbi, M.; Alvarez-Armas, I.; Armas, A. Effect of holding time at an intercritical temperature on the microstructure and tensile properties of a ferrite-martensite dual phase steel. Mater. Sci. Eng. A 2018, 733, 1–8. [Google Scholar] [CrossRef]

- Kozeschnik, E. MatCalc Version 6.02 (Database mc_fe_v2.060). Available online: http://matcalc.tuwien.ac.at/ (accessed on 14 September 2020).

- Lückl, M.; Wojcik, T.; Povoden-Karadeniz, E.; Zamberger, S.; Kozeschnik, E. Co-precipitation behavior of MnS and AlN in a low-carbon steel. Steel Res. Int. 2017, 89, 1700342. [Google Scholar] [CrossRef]

- Sun, W.P.; Militzer, M.; Jonas, J.J. Strain-induced nucleation of MnS in electrical steels. Metall. Trans. A 1992, 23A, 821–830. [Google Scholar] [CrossRef]

- Maehara, Y.; Nakai, K.; Yasumoto, K.; Mishima, T. Hot cracking of low alloy steels in simulated continuous casting direct rolling process. Trans. ISIJ 1988, 28, 1021–1027. [Google Scholar] [CrossRef]

- Carpenter, K.R.; Killmore, C.R.; Dippenaar, R. Influence of isothermal treatment on MnS and hot ductility in low carbon, low Mn steels. Metall. Trans. B 2013, 45, 372–380. [Google Scholar] [CrossRef]

- Lanjewar, H.A.; Tripathi, P.; Singhai, M.; Patra, P. Hot ductility and deformation behavior of C-Mn/Nb-microalloyed steel related to cracking during continuous casting. J. Mater. Eng. Perform. 2014, 23, 3600–3609. [Google Scholar] [CrossRef][Green Version]

- Li, J.; Cheng, G. Hot ductility of Cr15Mn7Ni4N austenitic stainless steel slab. J. Mater. Res. Technol. 2020, 9, 52–58. [Google Scholar] [CrossRef]

- Radis, R.; Kozeschnik, E. Kinetics of AlN precipitation in microalloyed steel. Modell. Simul. Mater. Sci. Eng. 2010, 18, 055003. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zhao, A. Precipitation of AlN and MnS in low carbon aluminium-killed steel. J. Iron Steel Res. Int. 2012, 19, 51–56. [Google Scholar] [CrossRef]

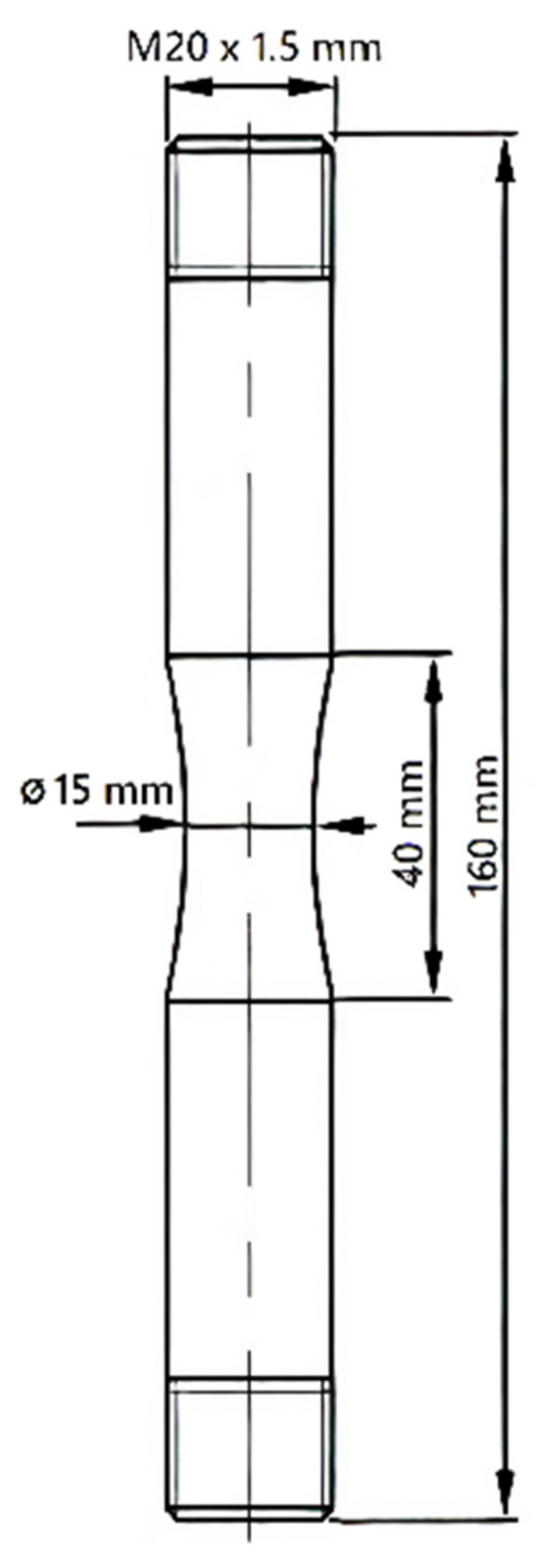

Figure 1.

Sample geometry in millimeters.

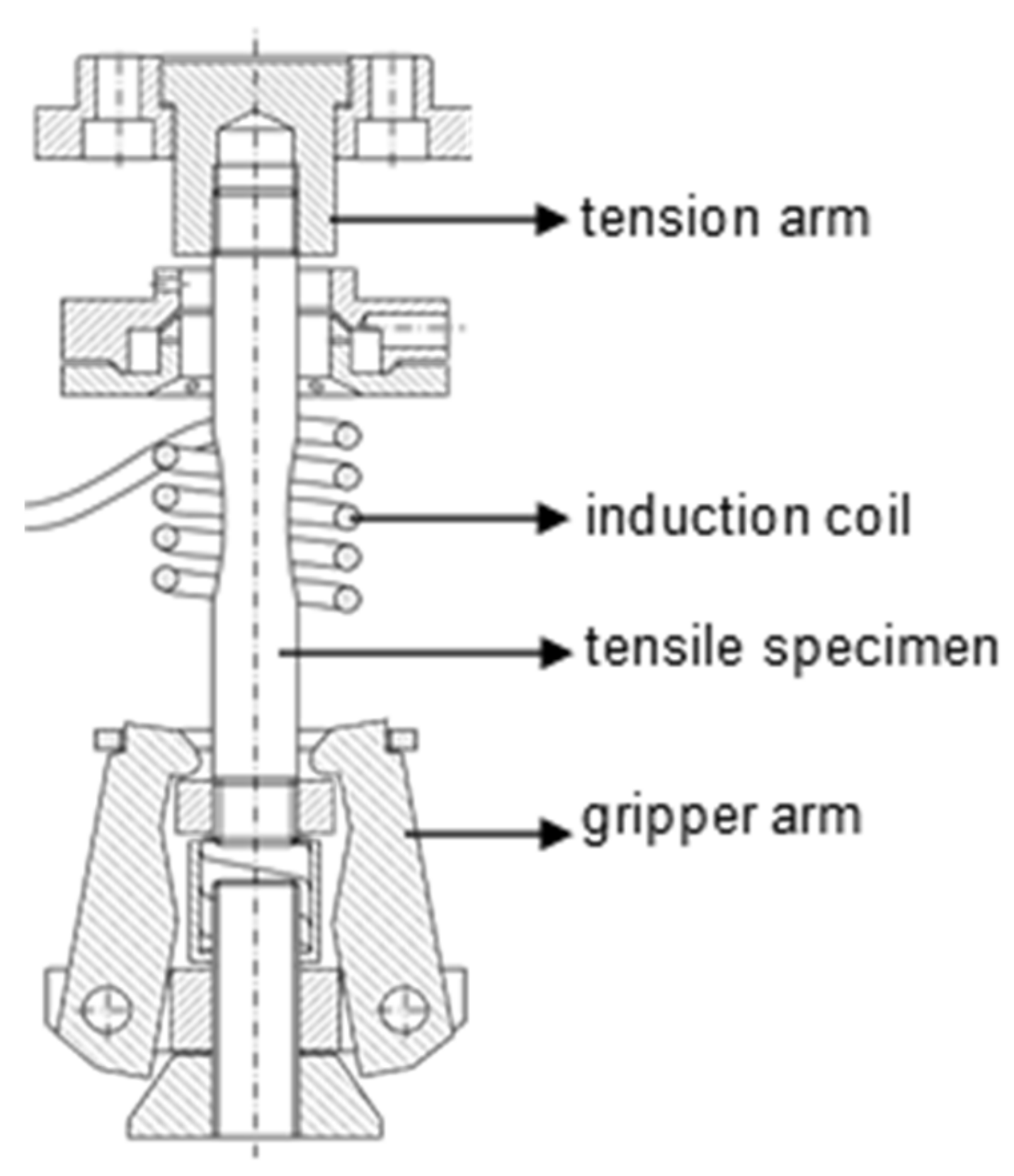

Figure 2.

Schematic thermomechanical simulator.

Figure 3.

Experimental thermal cycle.

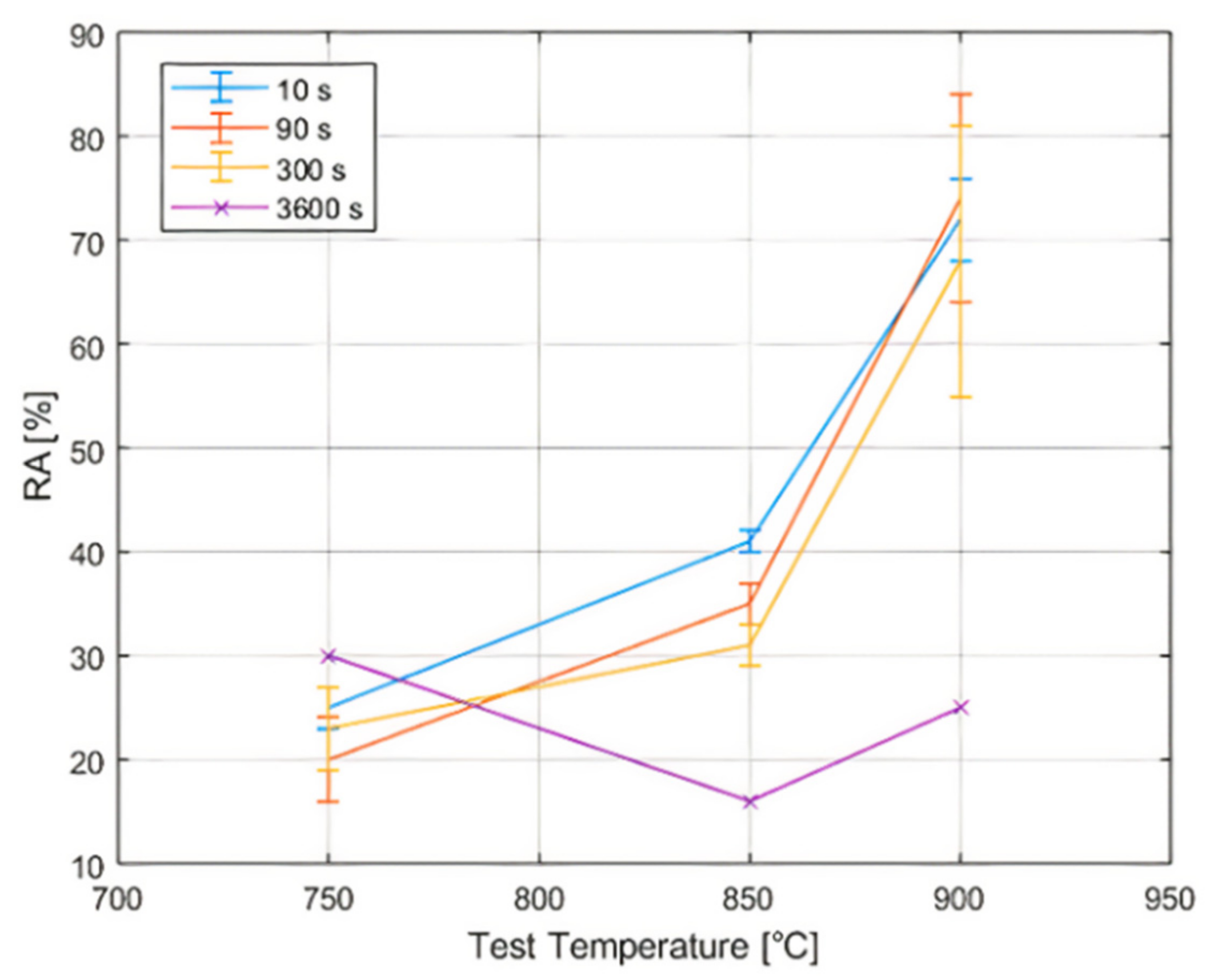

Figure 4.

Reduction of area at 750, 850, and 900 °C for the different holding times (10, 90, 300, and 3600 s).

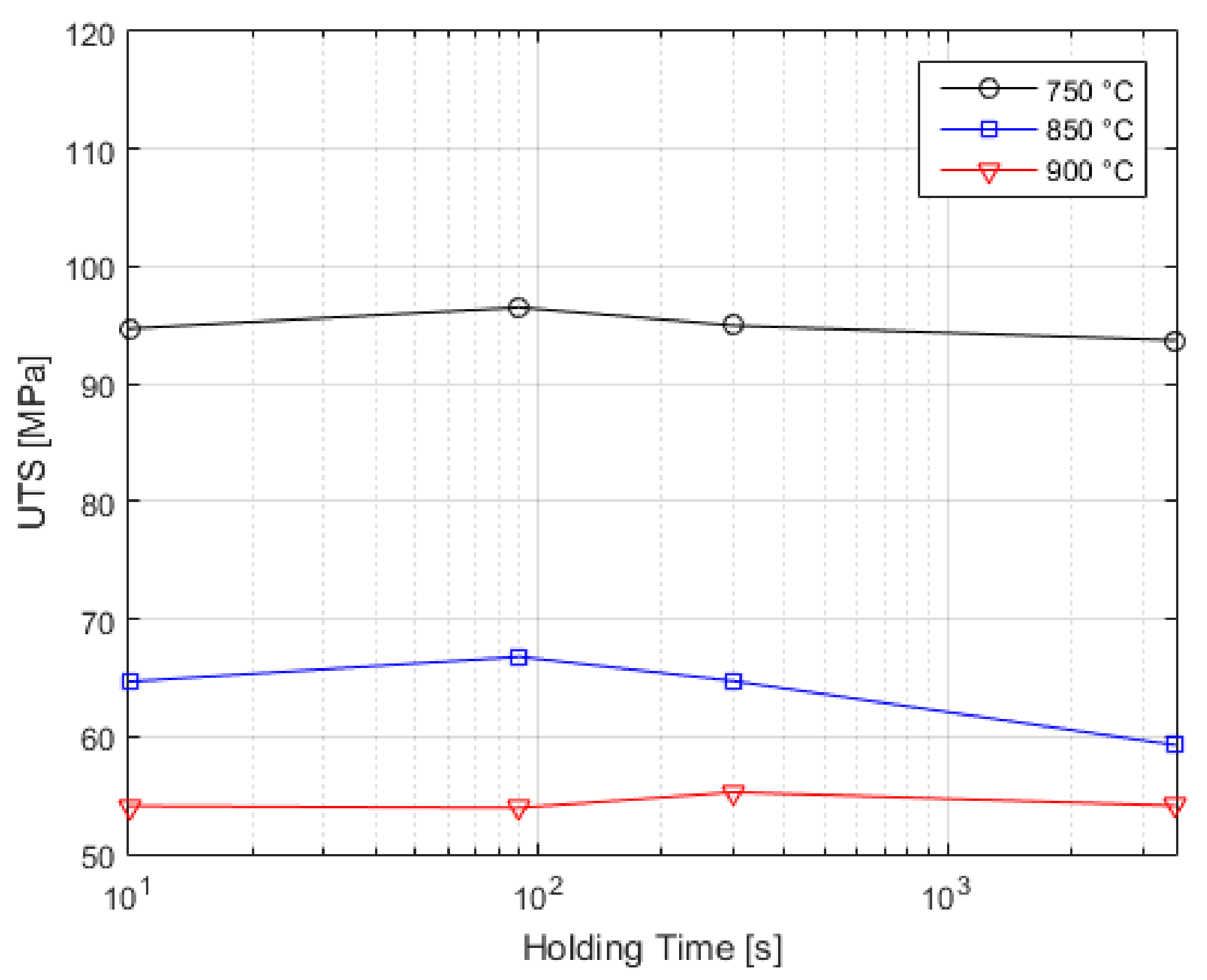

Figure 5.

Ultimate tensile strength for different holding times.

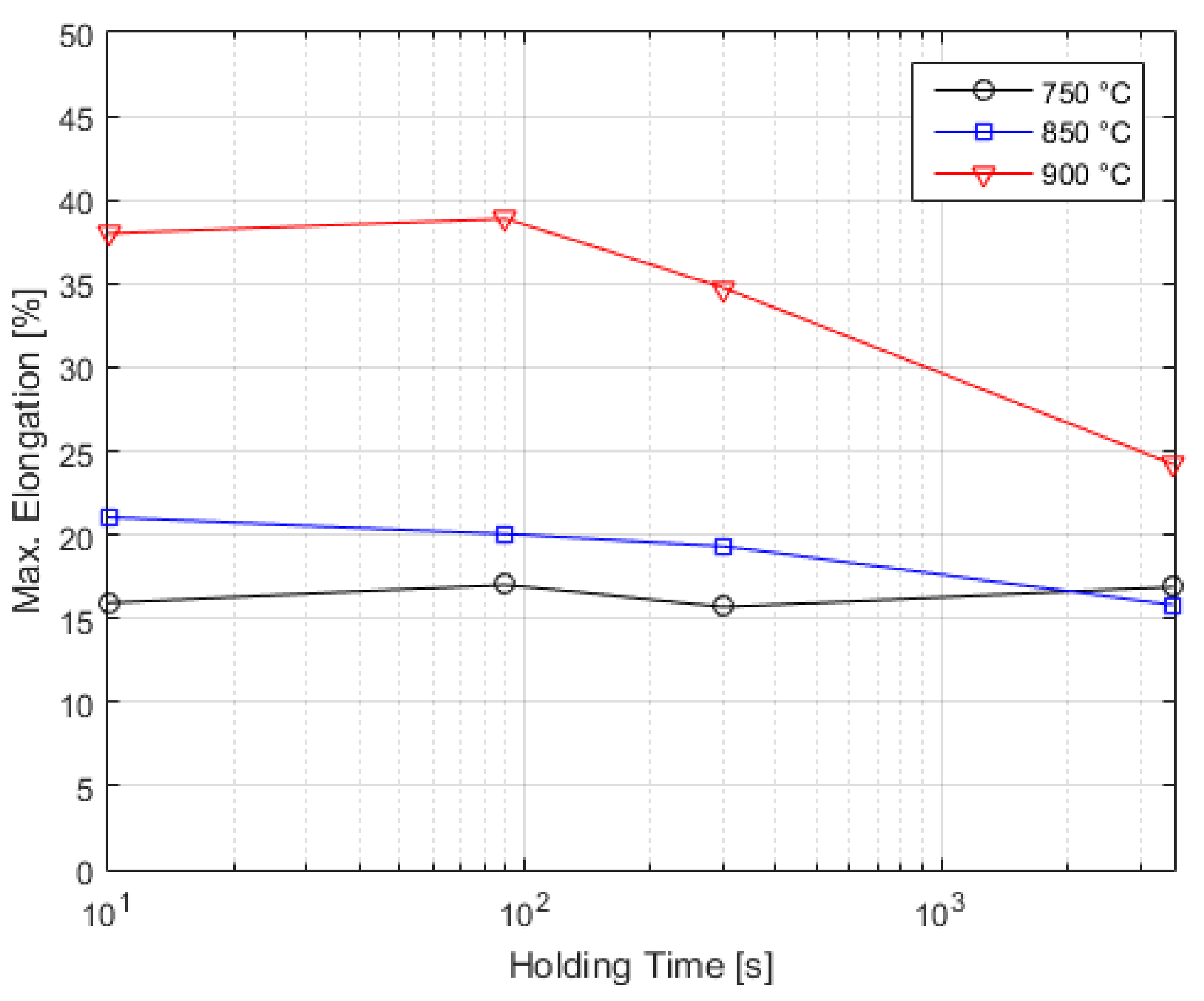

Figure 6.

Maximal elongation reached at each different temperature and holding time.

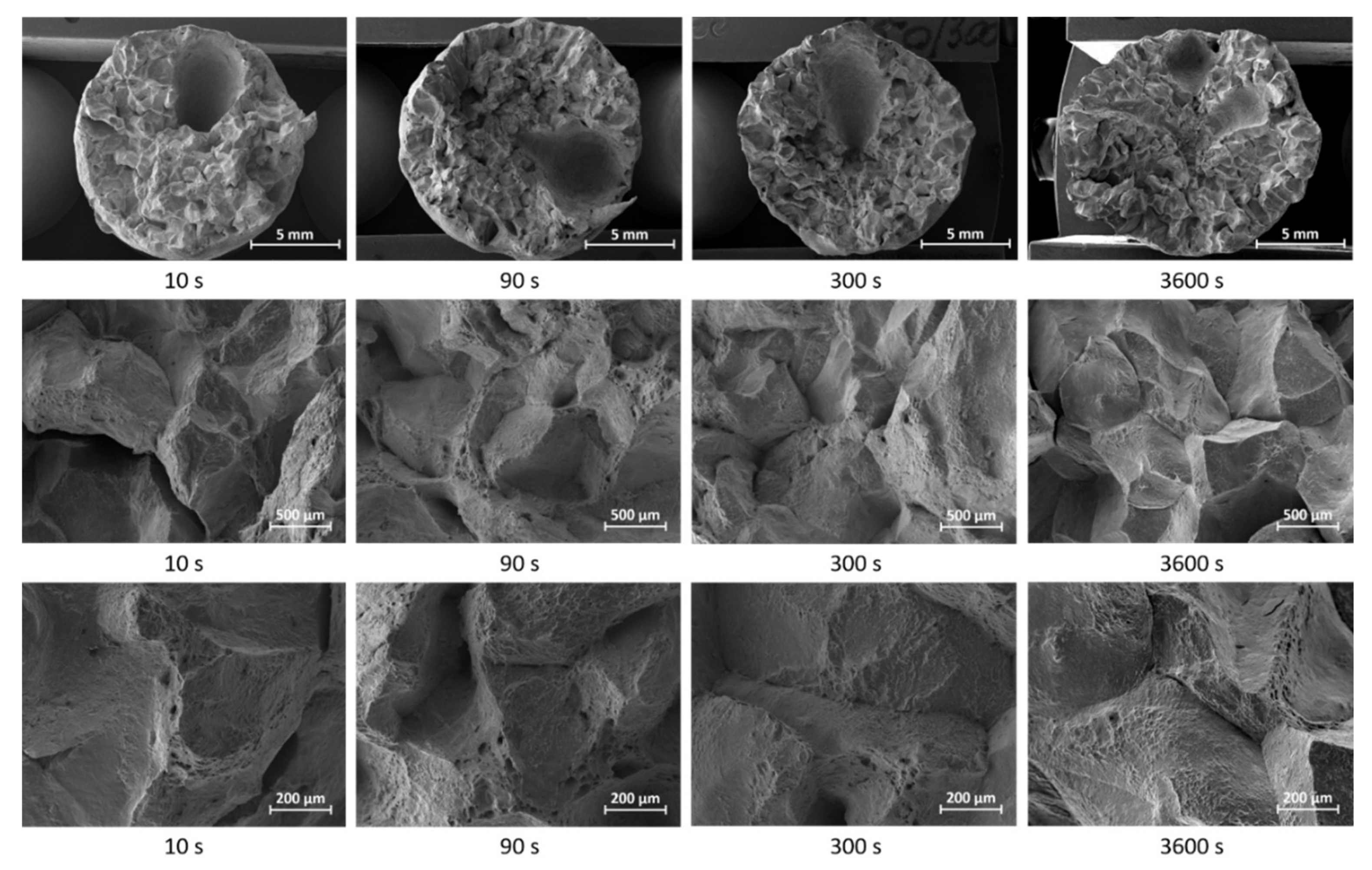

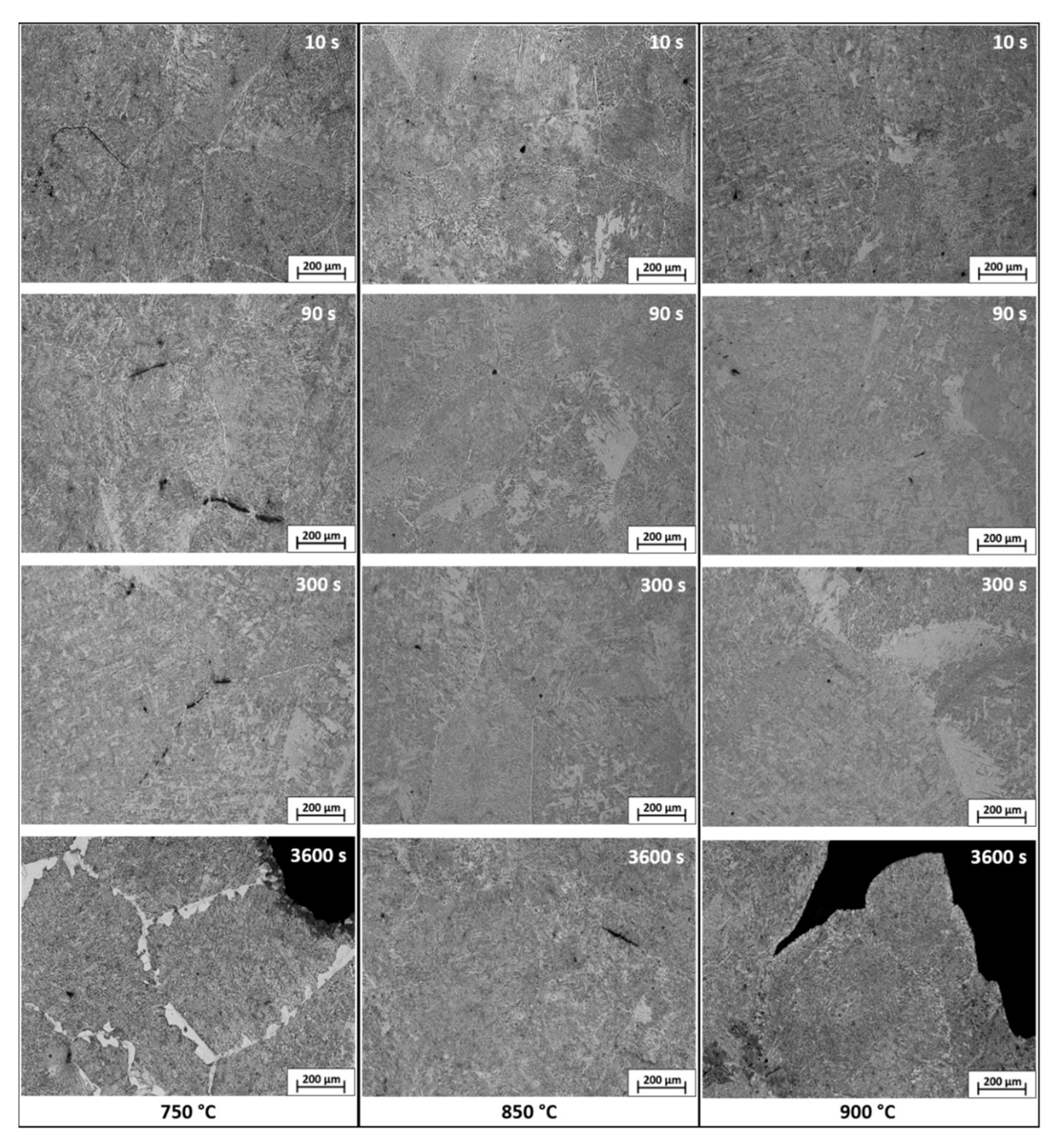

Figure 7.

SEM images with 15×, 100×, and 250× magnification for the samples tested at 750 °C and different holding times.

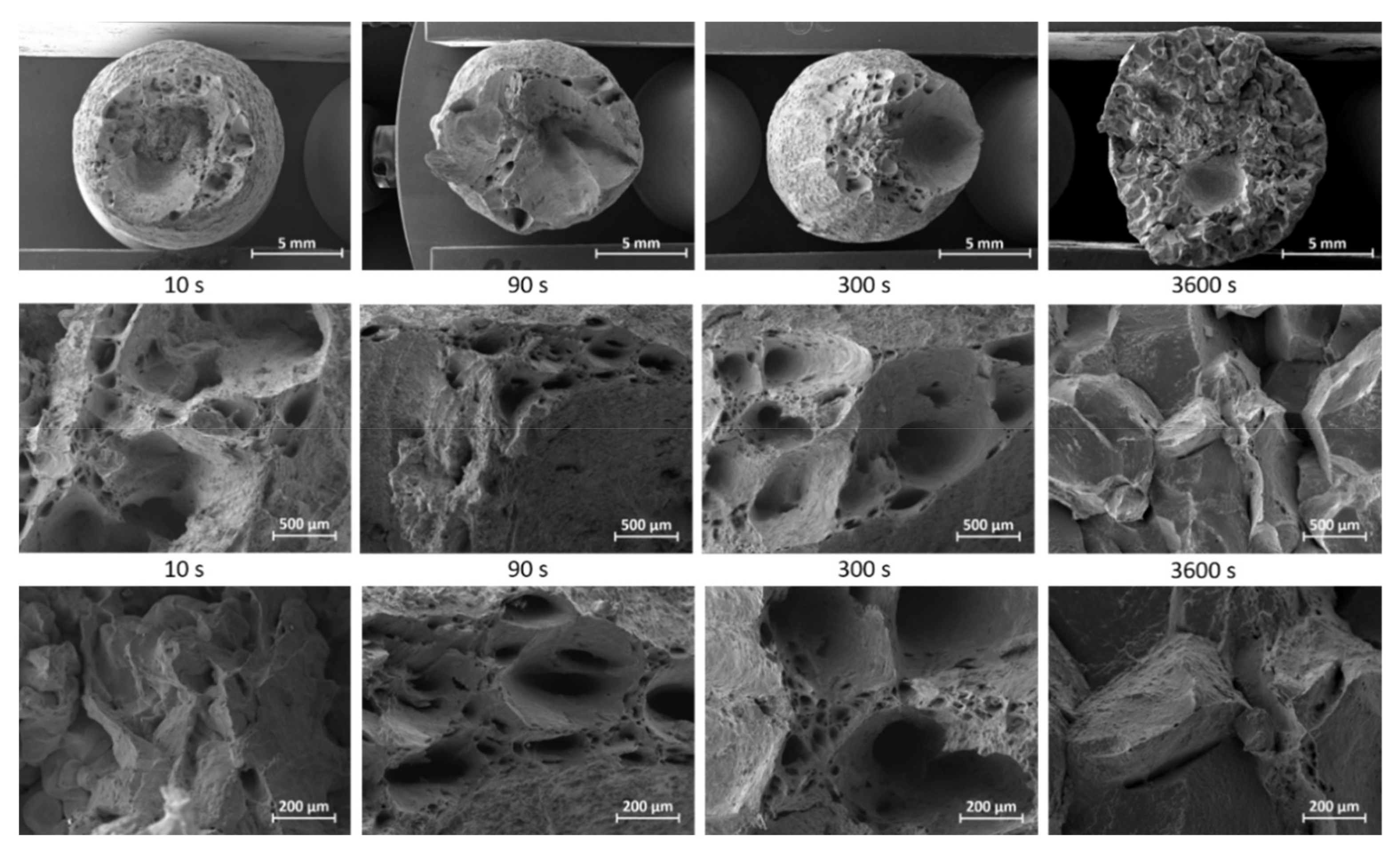

Figure 8.

SEM images with 15×, 100×, and 250× magnification for the samples tested at 850 °C and different holding times.

Figure 9.

SEM images with 15×, 100×, and 250× magnification for the samples tested at 900 °C and different holding times.

Figure 10.

LOM images with 100× magnification of samples etched with 3% Nital, tested at 750, 850, and 900 °C and with 10, 90, and 300 s of holding times.

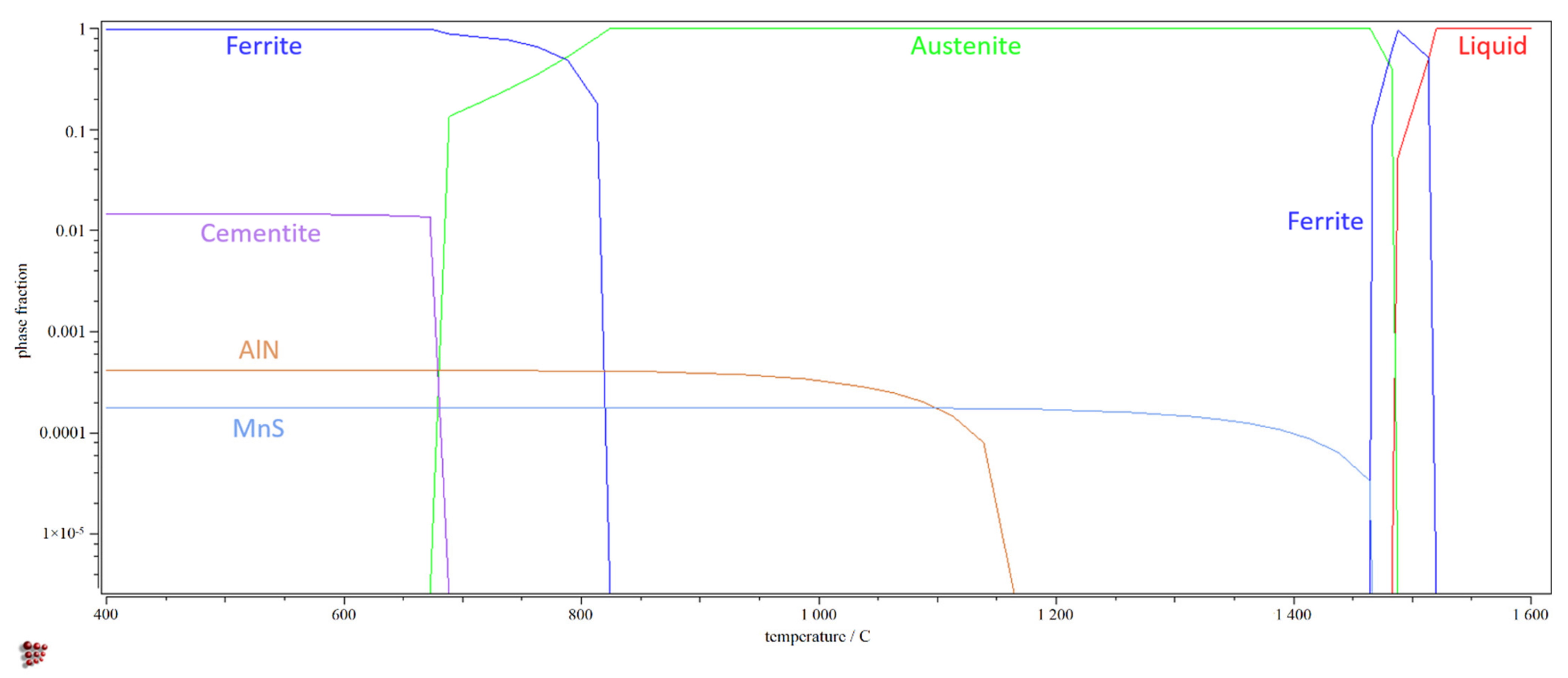

Figure 11.

Phase diagram at equilibrium.

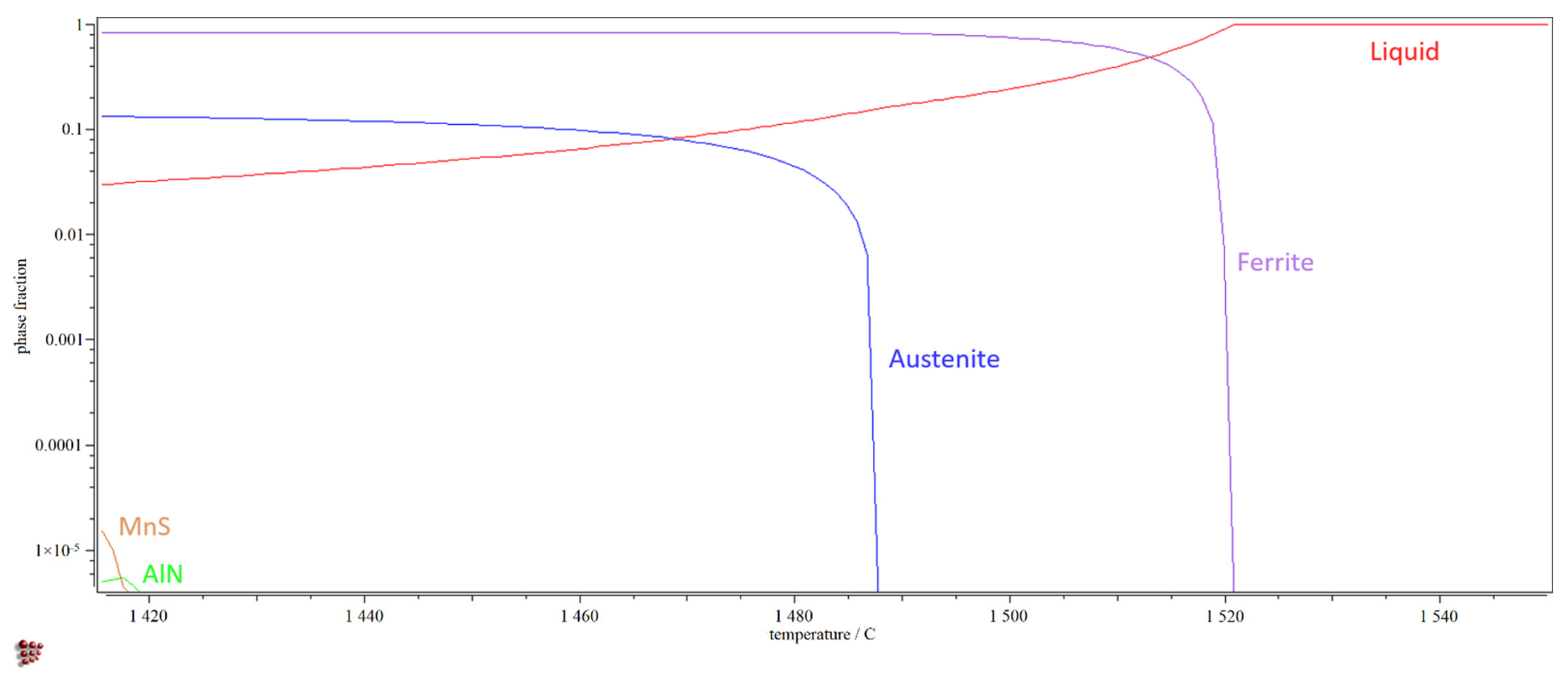

Figure 12.

Scheil–Gulliver equilibrium solidification simulation.

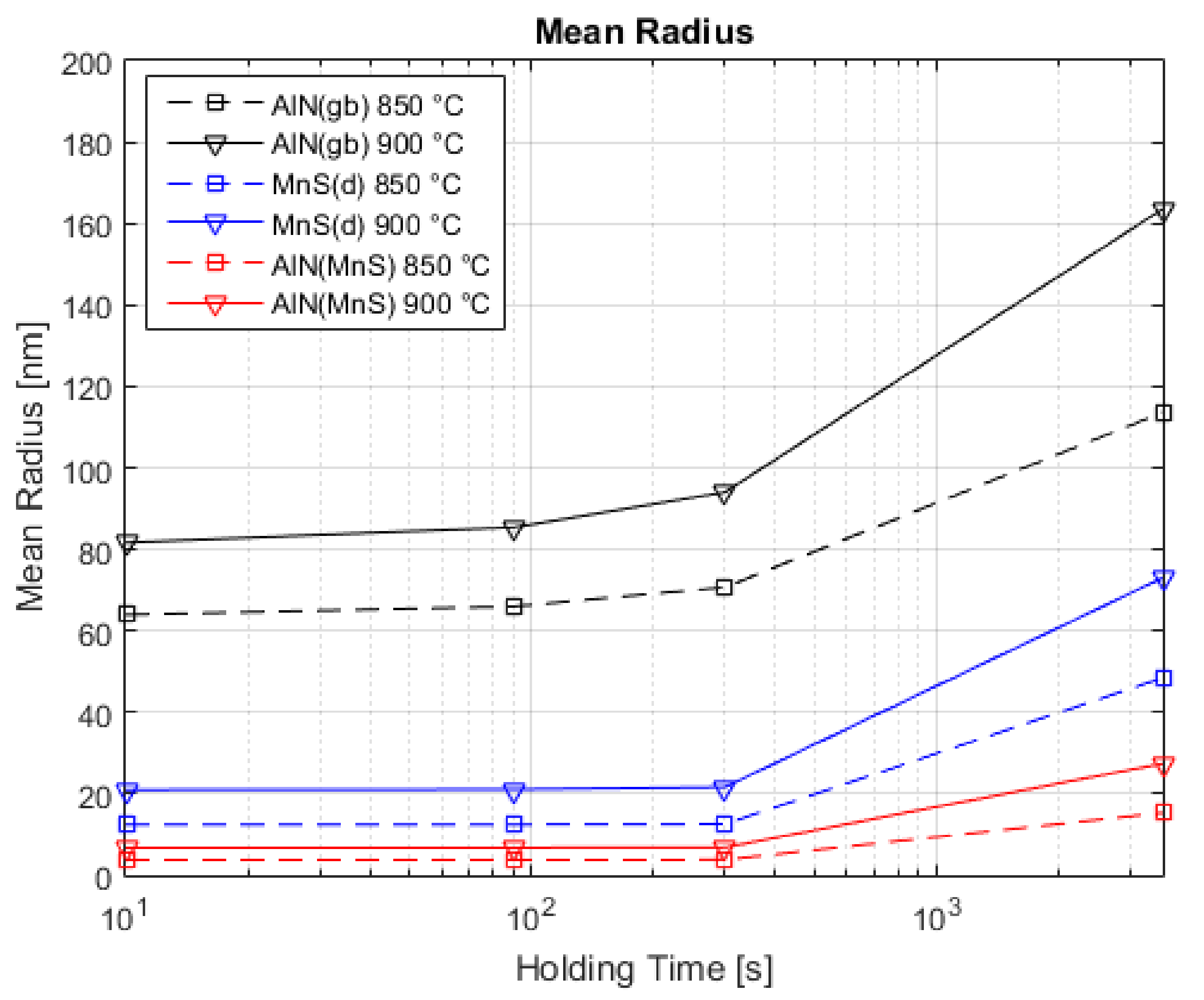

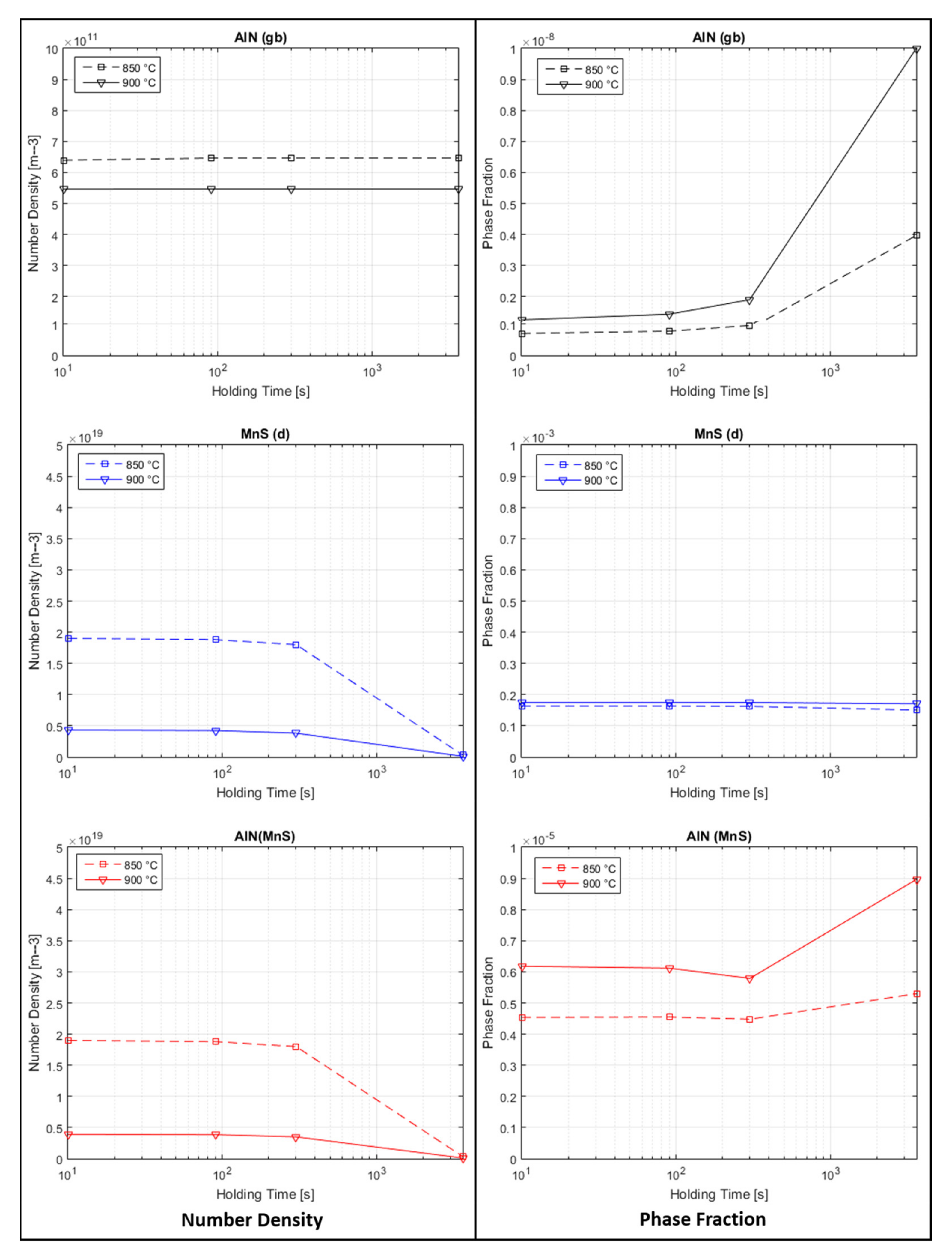

Figure 13.

Results of mean radius simulations for AlN at grain boundaries, MnS at dislocations, and AlN at MnS for different temperatures and holding times.

Figure 14.

Results of number density and phase fraction simulations for AlN at grain boundaries, MnS at dislocations, and AlN at MnS for different temperatures and holding times.

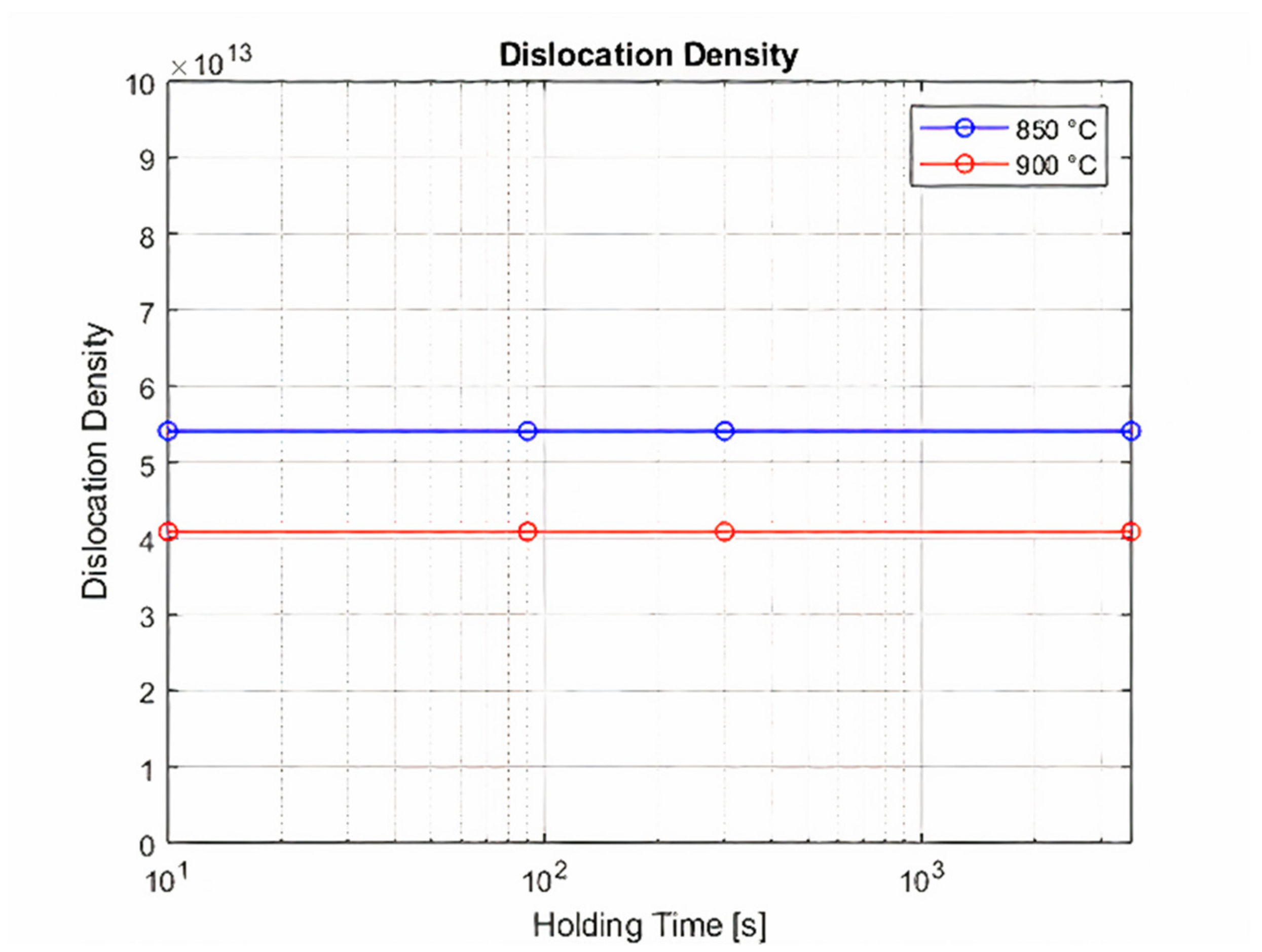

Figure 15.

Results of dislocation density simulations for different temperatures and holding times.

Table 1.

Chemical composition in wt%.

| C | Cr | Mn | Al | Nb | N | Ni | P | S | Ti | Fe |

|---|

| 0.079 | 0.280 | 1.670 | 0.051 | 0.003 | 0.0052 | 0.028 | 0.013 | 0.0051 | 0.0014 | balance |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).