Effect of Nb and Mo Additions in the Microstructure/Tensile Property Relationship in High Strength Quenched and Quenched and Tempered Boron Steels

Abstract

1. Introduction

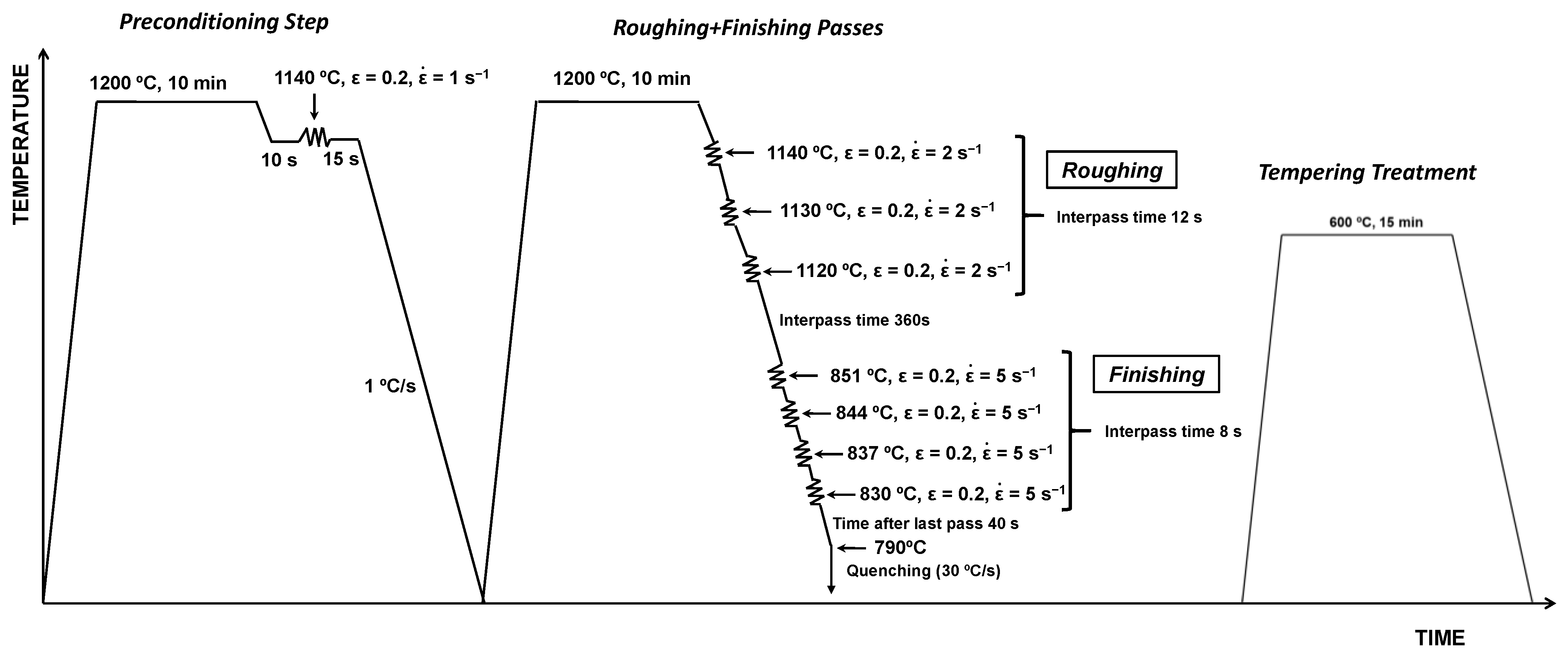

2. Materials and Methods

3. Results and Discussion

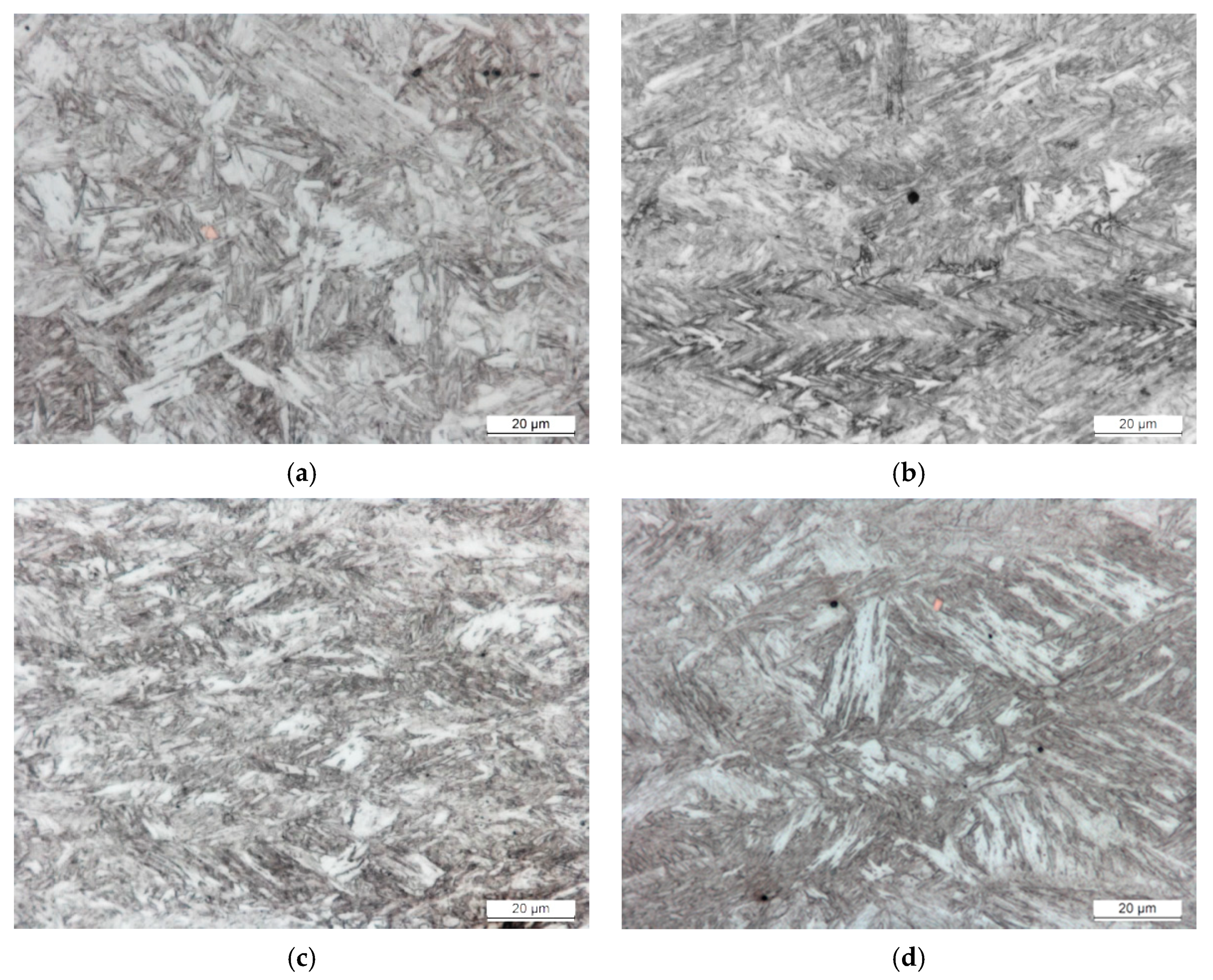

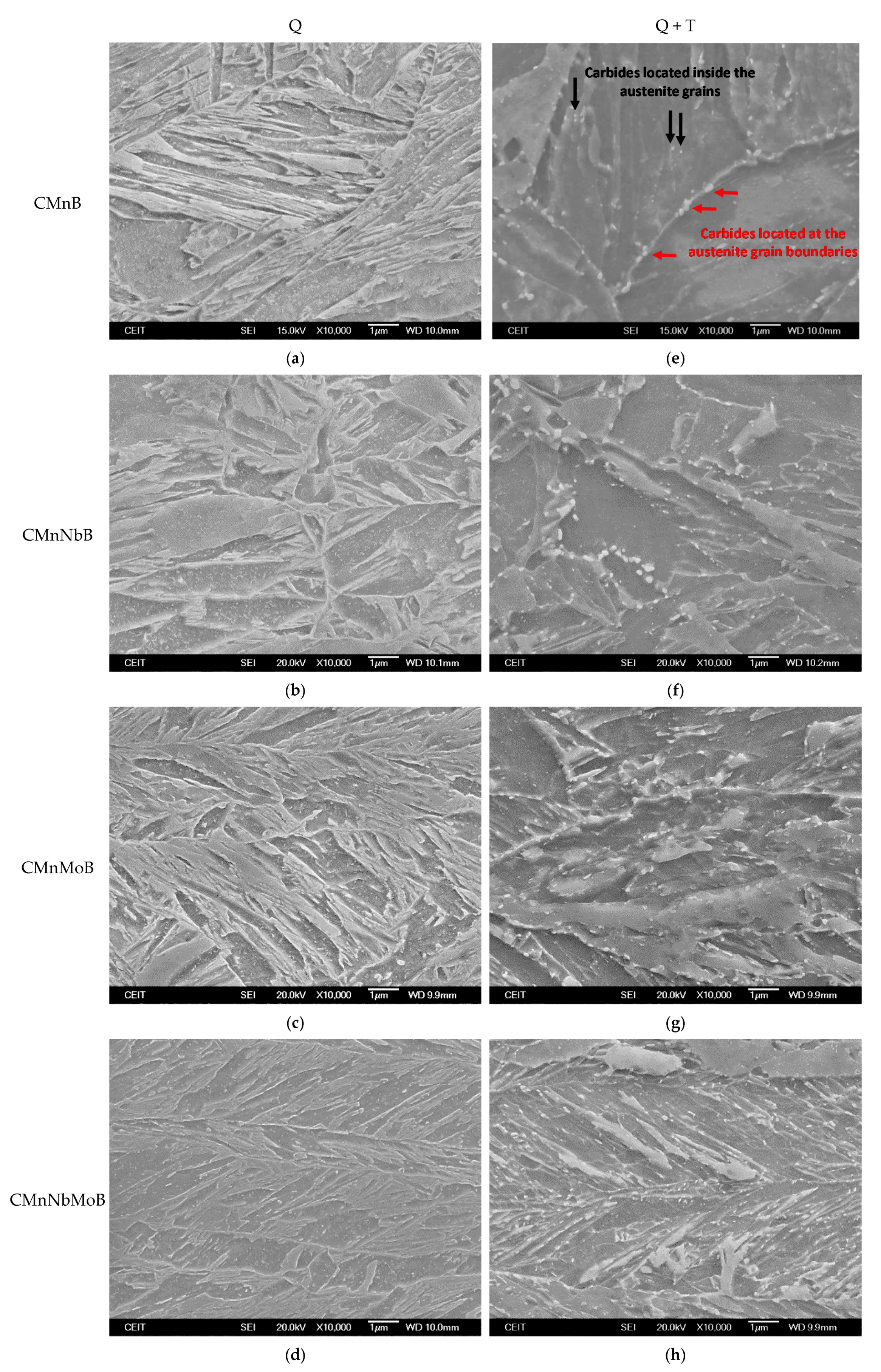

3.1. Microstructural Characterization

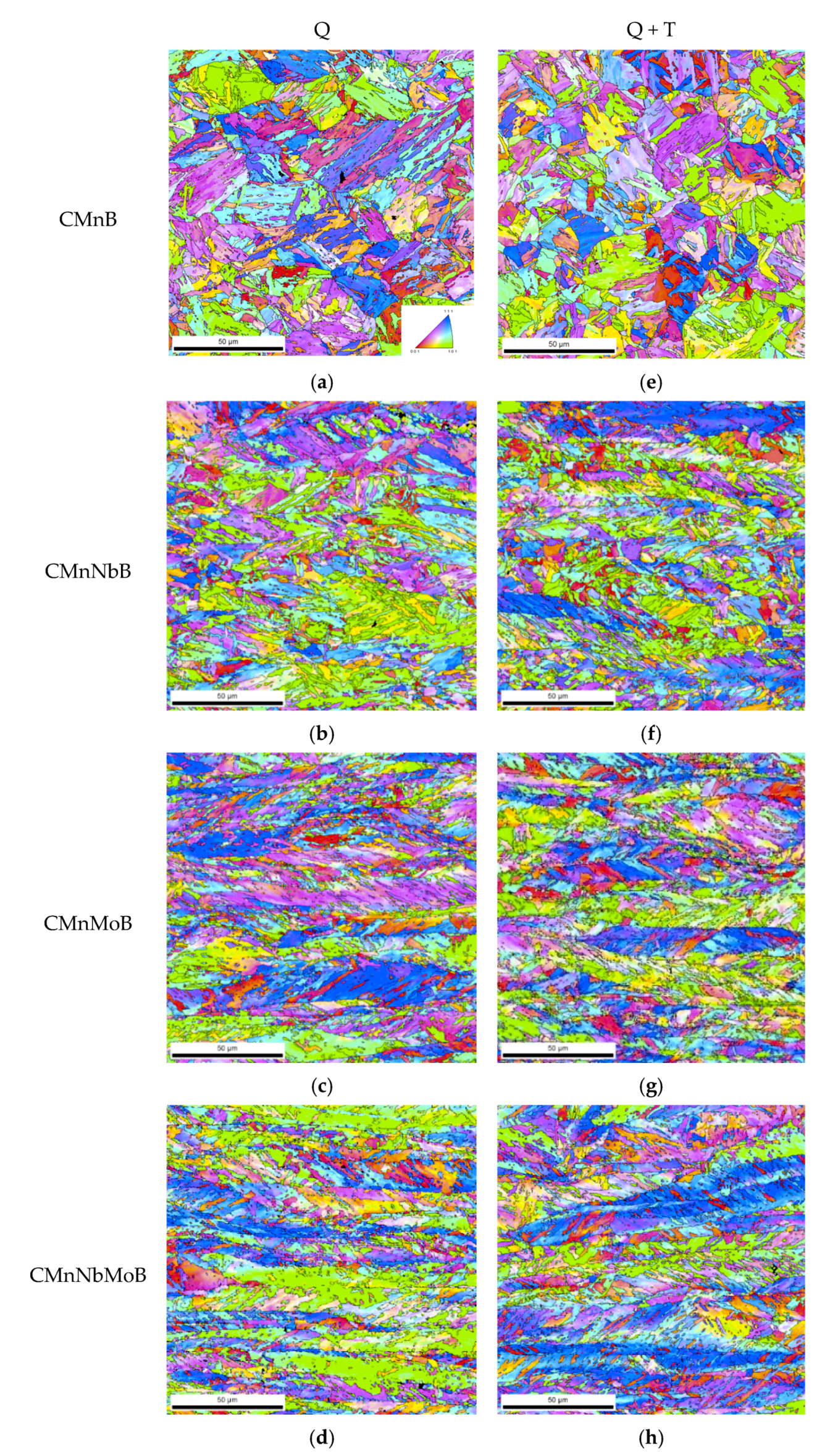

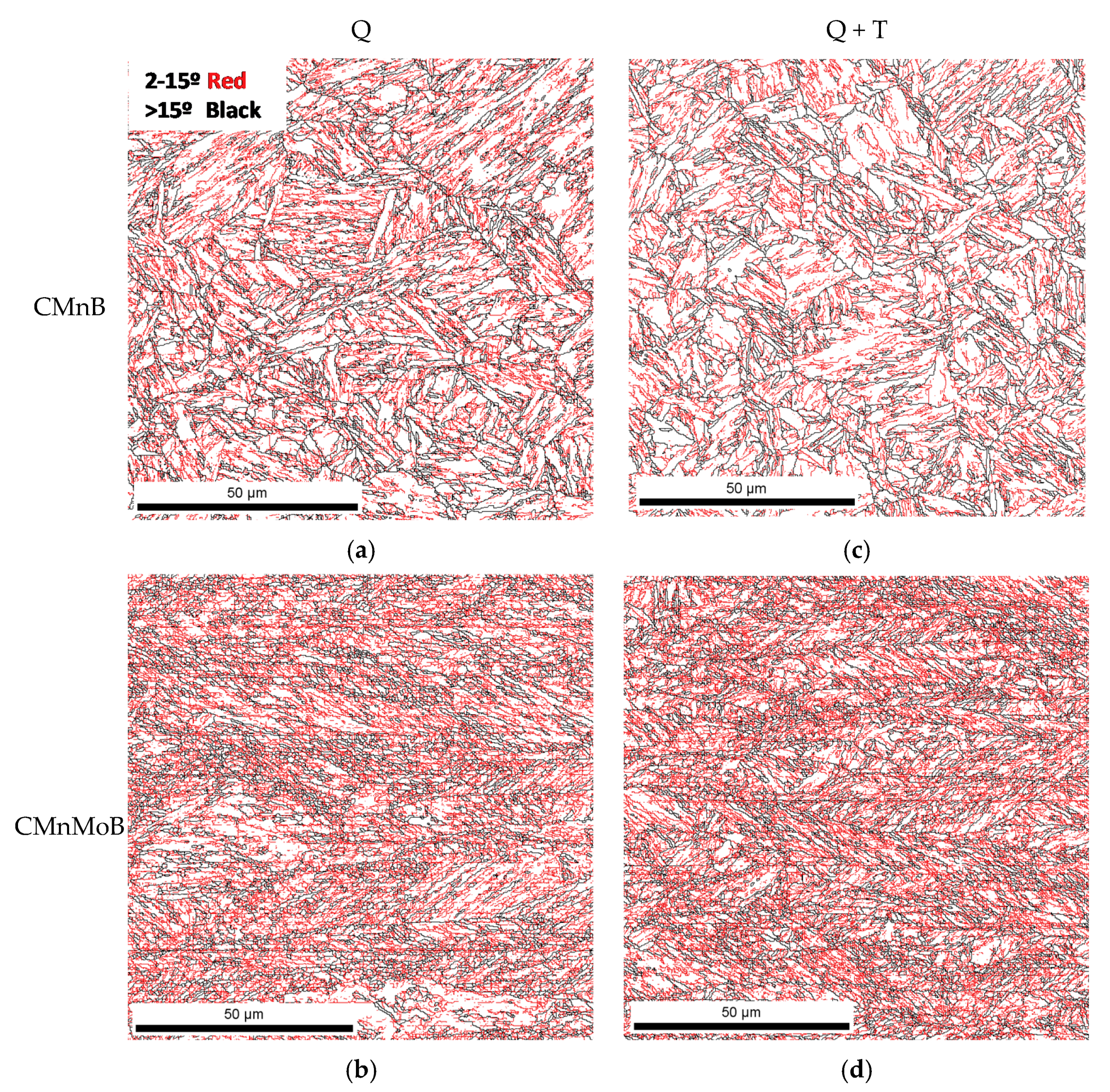

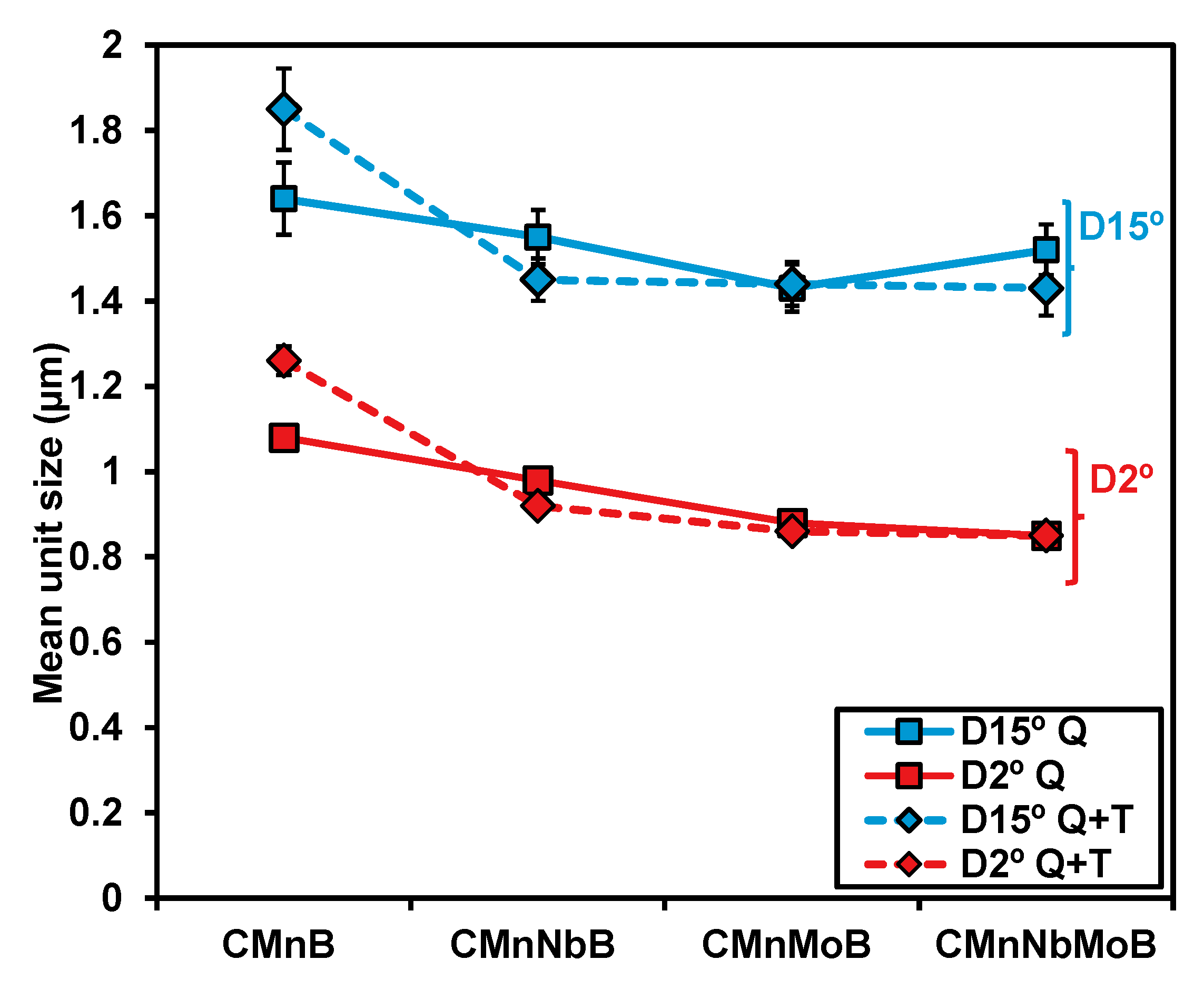

3.1.1. Quantification of Unit Sizes by Means of EBSD

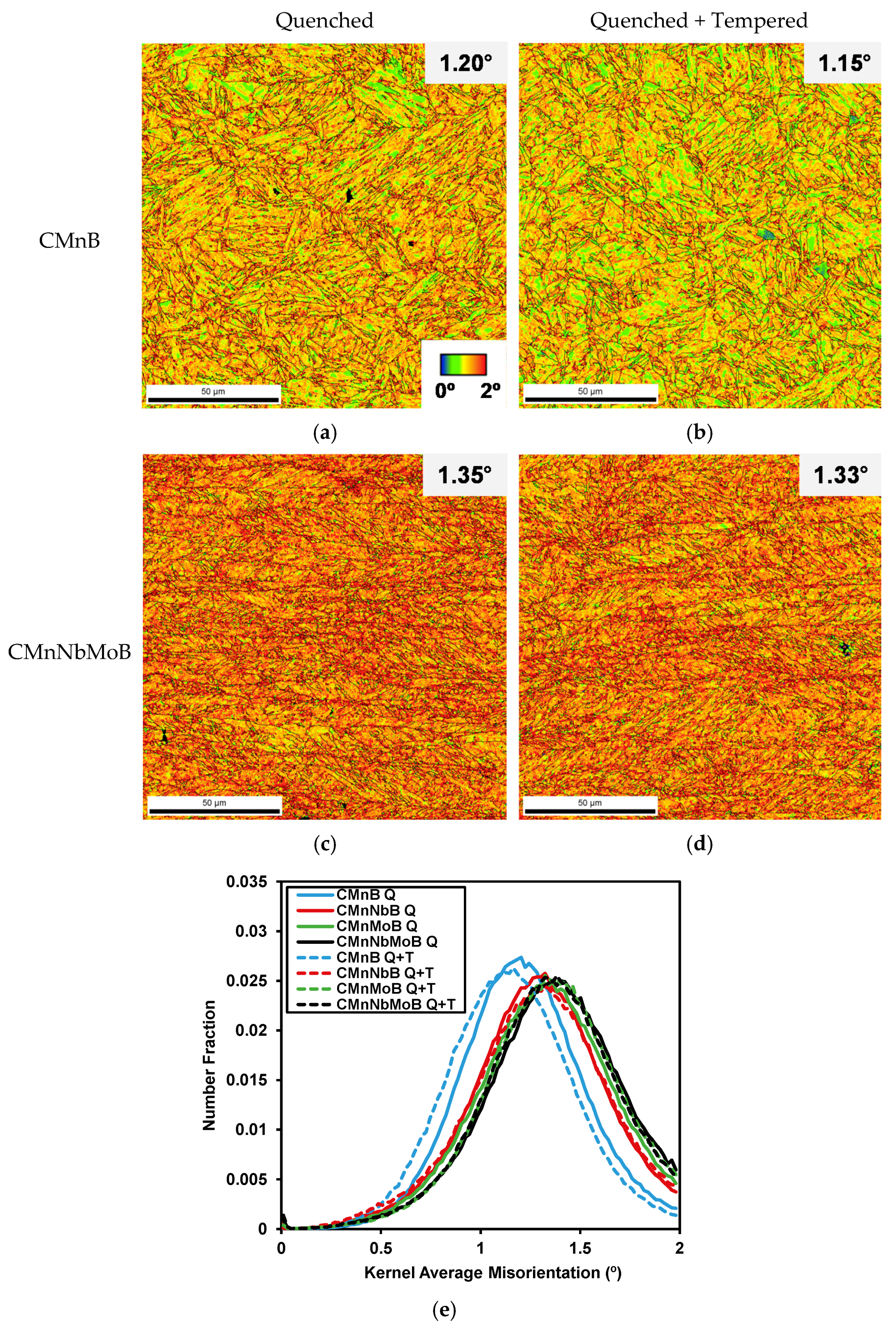

3.1.2. Dislocation Density Estimation Based on Kernel Average Misorientation

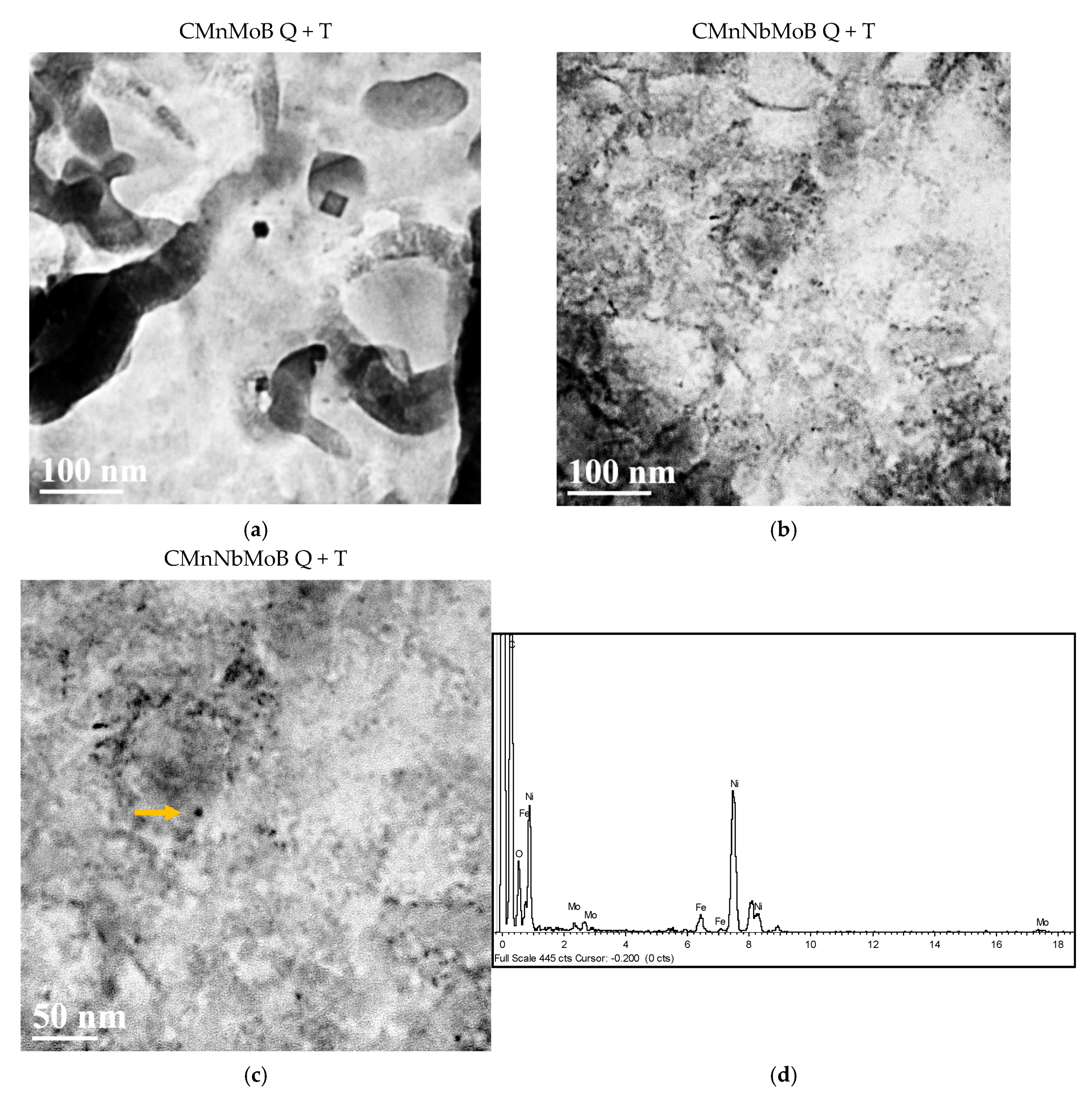

3.1.3. Fine Precipitation Analysis on Mo Containing Steels and Q + T State by TEM

3.2. Interaction between Microstructure and Tensile Properties

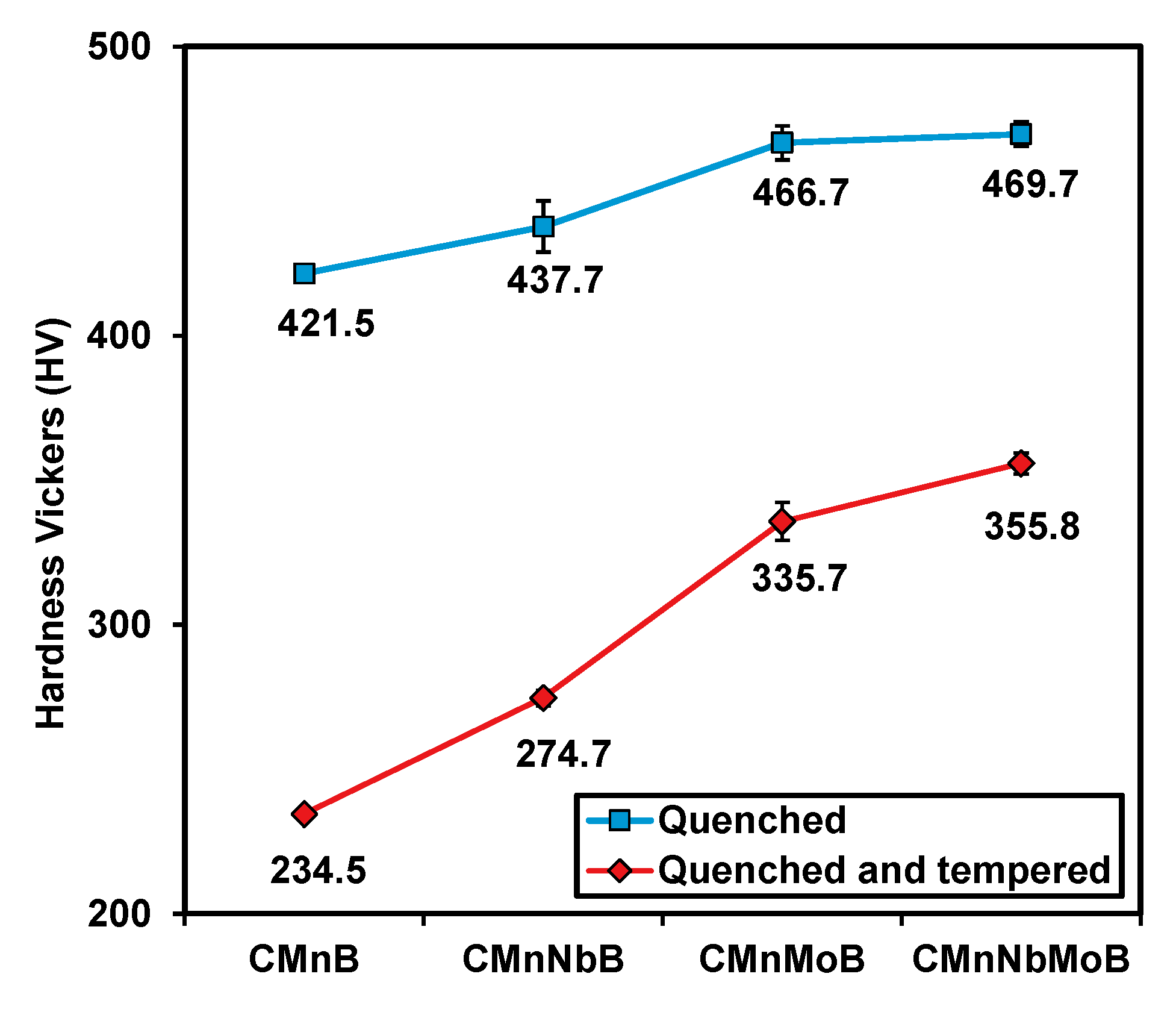

3.2.1. Hardness Measurements

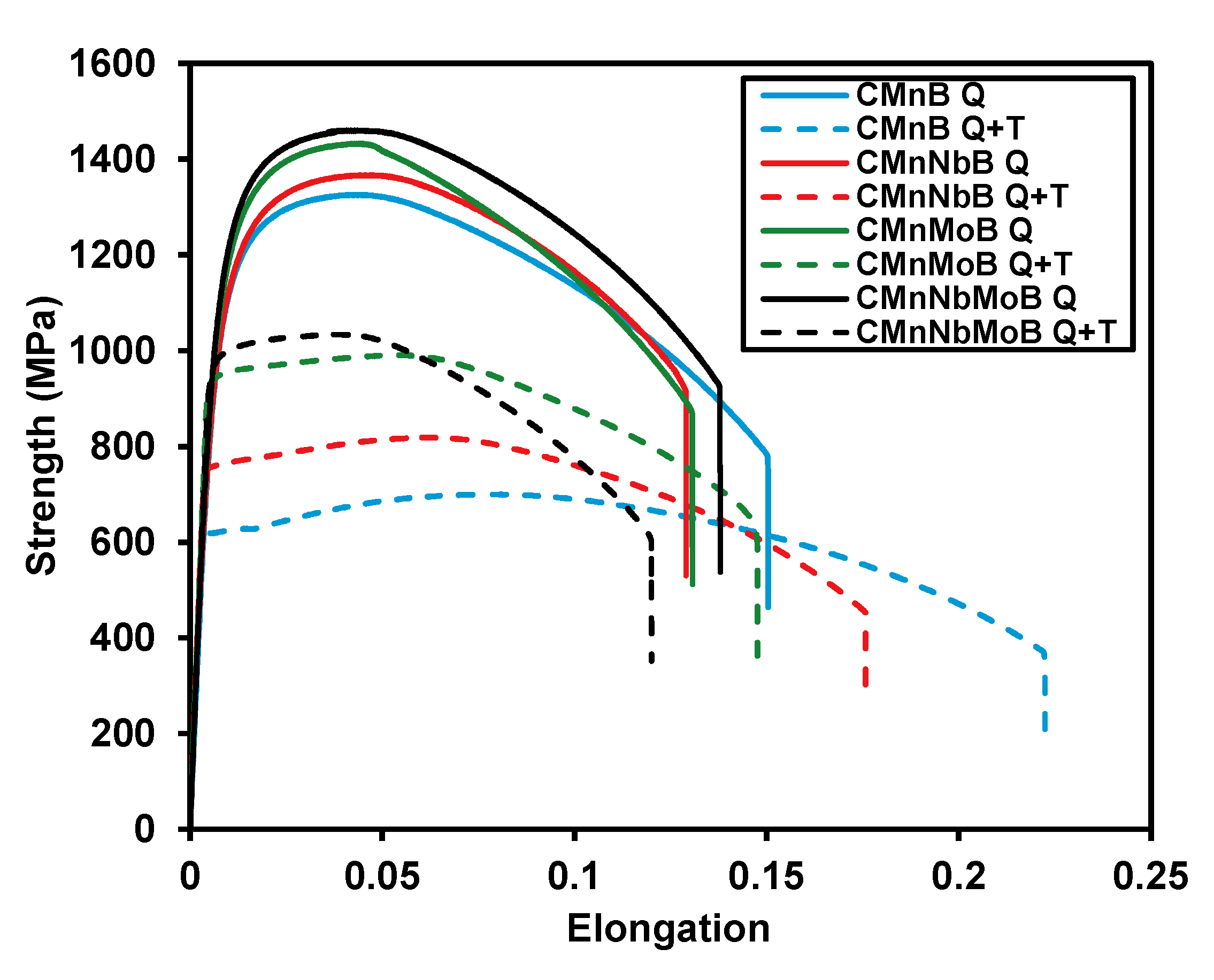

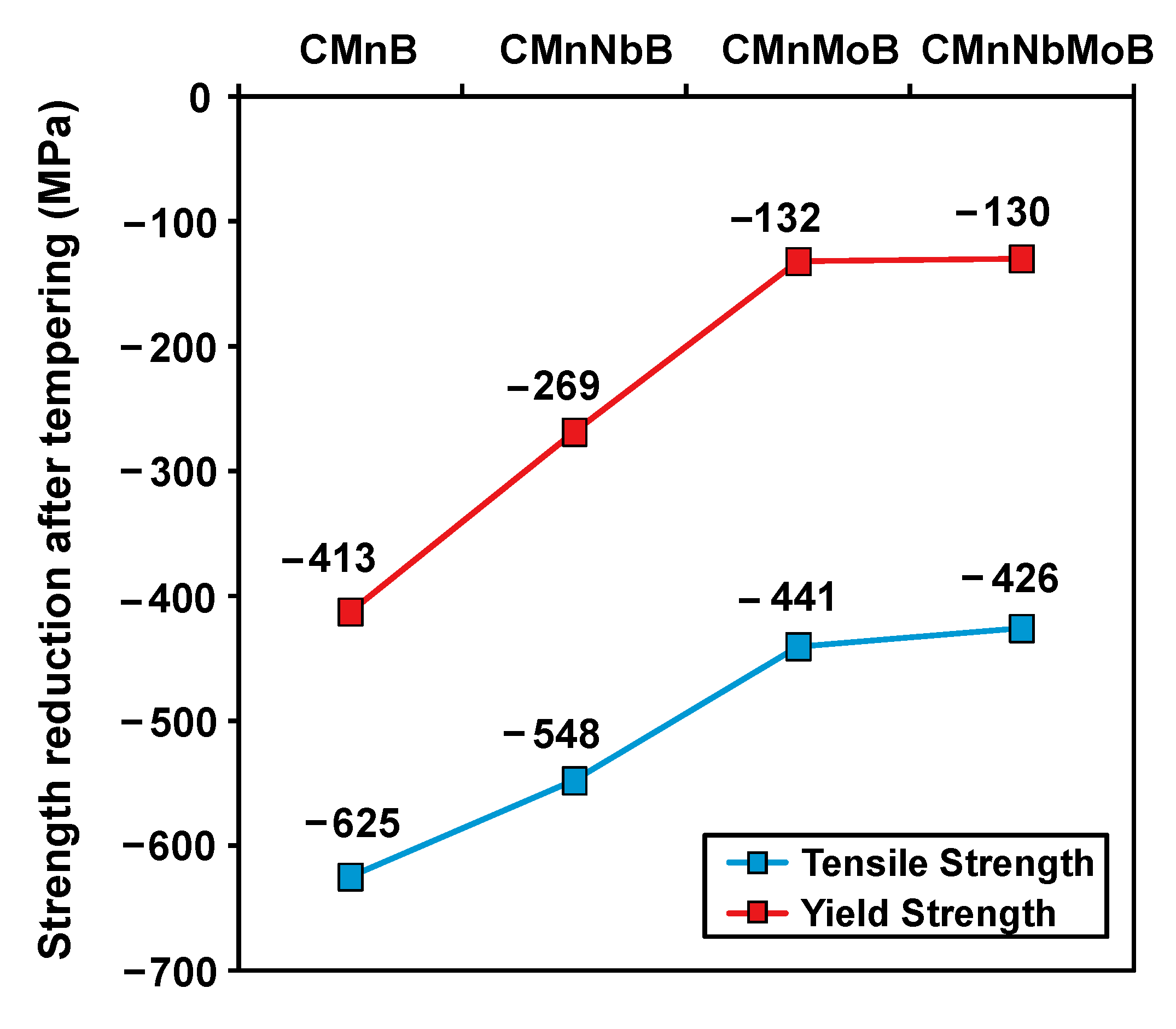

3.2.2. Tensile Properties

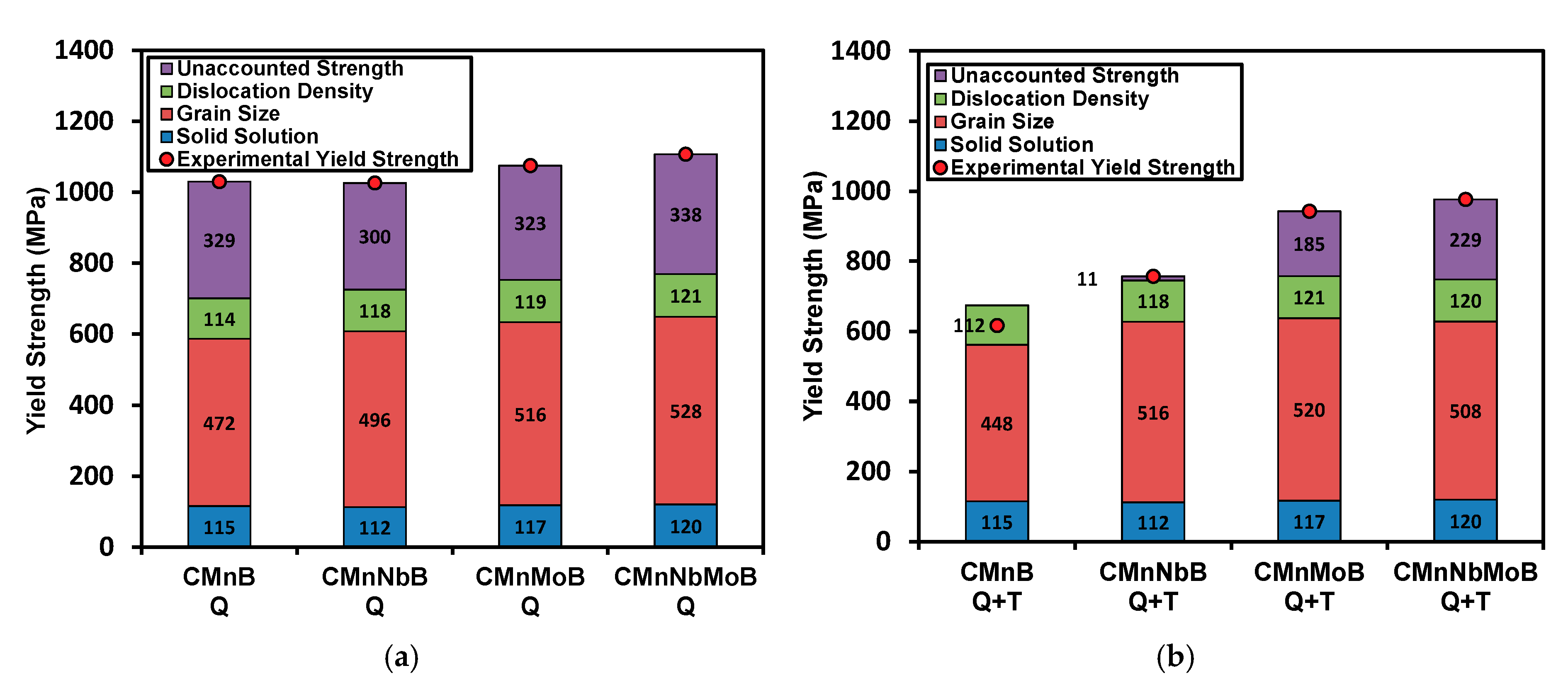

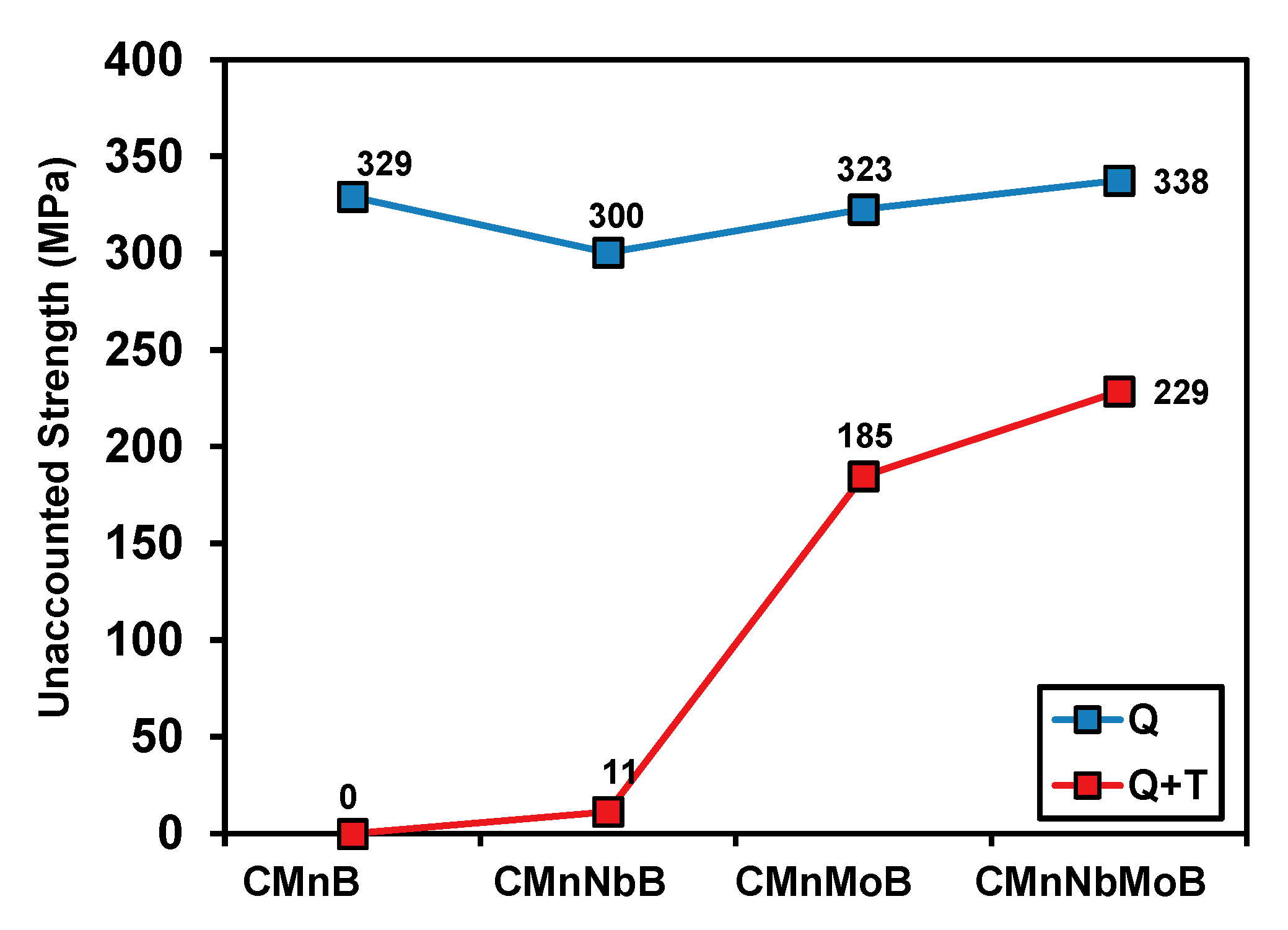

3.3. Estimation of the Contribution of Strengthening Mechanisms on Yield Strength

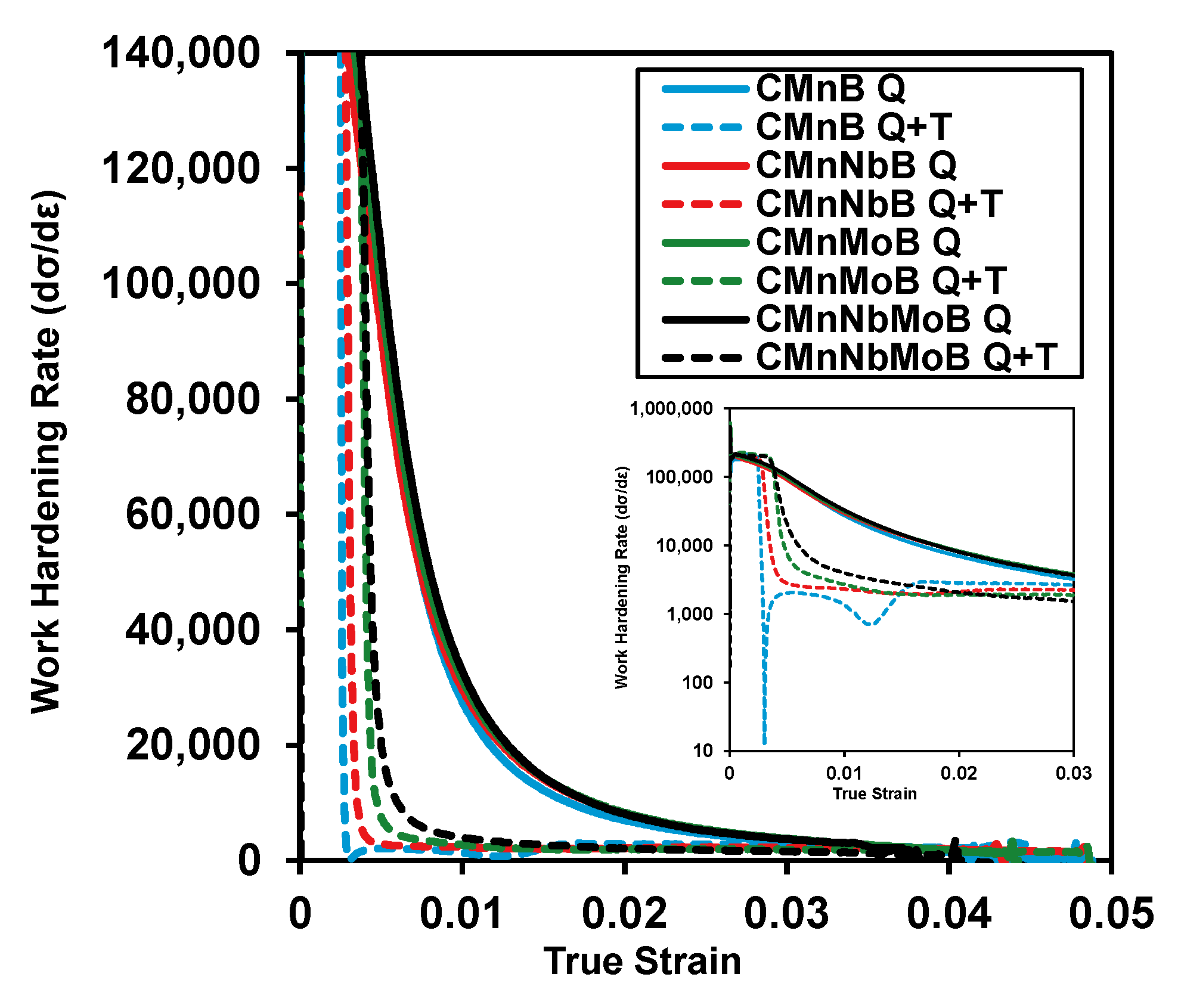

Effect of Composition and Tempering Treatment on Work Hardening Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Llewellyn, D.T. Nitrogen in Steels. Ironmak. Steelmak. 1993, 20, 338–343. [Google Scholar]

- Taylor, K.A. Grain-boundary segregation and precipitation of boron in 0.2 percent carbon steels. Met. Mater. Trans. A 1992, 23, 107–119. [Google Scholar] [CrossRef]

- Shigesato, G.; Fujishiro, T.; Hara, T. Grain Boundary Segregation Behavior of Boron in Low-Alloy Steel. Met. Mater. Trans. A 2014, 45, 1876–1882. [Google Scholar] [CrossRef]

- Li, Y.; Ponge, D.; Choi, P.; Raabe, D. Segregation of boron at prior austenite grain boundaries in a quenched martensitic steel studied by atom probe tomography. Scr. Mater. 2015, 96, 13–16. [Google Scholar] [CrossRef]

- Mohrbacher, H. Property Optimization in As-Quenched Martensitic Steel by Molybdenum and Niobium Alloying. Metals 2018, 8, 234. [Google Scholar] [CrossRef]

- Larrañaga-Otegui, A.; Pereda, B.; Jorge-Badiola, D.; Gutiérrez, I. Austenite Static Recrystallization Kinetics in Microalloyed B Steels. Met. Mater. Trans. A 2016, 47, 3150–3164. [Google Scholar] [CrossRef]

- He, X.; Djahazi, M.; Jonas, J.; Jackman, J. The non-equilibrium segregation of boron during the recrystalization of Nb-treated HSLA steels. Acta Met. Mater. 1991, 39, 2295–2308. [Google Scholar] [CrossRef]

- Hulka, K.; Kern, A.; Schriever, U. Application of Niobium in Quenched and Tempered High-Strength Steels. Mater. Sci. Forum 2005, 500–501, 519–526. [Google Scholar] [CrossRef]

- Miao, C.; Shang, C.; Zhang, G.; Subramanian, S. Recrystallization and strain accumulation behaviors of high Nb-bearing line pipe steel in plate and strip rolling. Mater. Sci. Eng. A 2010, 527, 4985–4992. [Google Scholar] [CrossRef]

- Hutchinson, C.; Zurob, H.; Sinclair, C.; Brechet, Y. The comparative effectiveness of Nb solute and NbC precipitates at impeding grain-boundary motion in Nb steels. Scr. Mater. 2008, 59, 635–637. [Google Scholar] [CrossRef]

- Isasti, N.; Jorge-Badiola, D.; Taheri, M.L.; Uranga, P. Microstructural and precipitation characterization in Nb-Mo microalloyed steels: Estimation of the contributions to the strength. Met. Mater. Int. 2014, 20, 807–817. [Google Scholar] [CrossRef]

- Larzabal, G.; Isasti, N.; Rodriguez-Ibabe, J.; Uranga, P. Evaluating Strengthening and Impact Toughness Mechanisms for Ferritic and Bainitic Microstructures in Nb, Nb-Mo and Ti-Mo Microalloyed Steels. Metals 2017, 7, 65. [Google Scholar] [CrossRef]

- Lee, W.-B.; Hong, S.-G.; Park, C.-G.; Park, S.-H. Carbide precipitation and high-temperature strength of hot-rolled high-strength, low-alloy steels containing Nb and Mo. Met. Mater. Trans. A 2002, 33, 1689–1698. [Google Scholar] [CrossRef]

- Togashi, F.; Nishizawa, T. Effect of Alloying Elements on the Mobility of Ferrite/Austenite Interface. J. Jpn. Inst. Met. 1976, 40, 12–21. [Google Scholar] [CrossRef]

- Coldren, A.P.; Eldis, G.T. Using CCT Diagrams to Optimize the Composition of an As-Rolled Dual-Phase Steel. JOM 1980, 32, 41–48. [Google Scholar] [CrossRef]

- Cizek, P.; Wynne, B.P.; Davies, C.H.J.; Hodgson, P.D. The Effect of Simulated Thermomechanical Processing on the Transformation Behavior and Microstructure of a Low-Carbon Mo-Nb Linepipe Steel. Met. Mater. Trans. A 2015, 46, 407–425. [Google Scholar] [CrossRef]

- Isasti, N.; Jorge-Badiola, D.; Taheri, M.L.; Lopez, B.; Uranga, P. Effect of Composition and Deformation on Coarse-Grained Austenite Transformation in Nb-Mo Microalloyed Steels. Met. Mater. Trans. A 2011, 42, 3729–3742. [Google Scholar] [CrossRef]

- Olasolo, M.; Uranga, P.; Rodriguez-Ibabe, J.; López, B. Effect of austenite microstructure and cooling rate on transformation characteristics in a low carbon Nb–V microalloyed steel. Mater. Sci. Eng. A 2011, 528, 2559–2569. [Google Scholar] [CrossRef]

- Kaijalainen, A.J.; Suikkanen, P.; Limnell, T.J.; Karjalainen, L.P.; Kömi, J.; Porter, D.A. Effect of austenite grain structure on the strength and toughness of direct-quenched martensite. J. Alloys Compd. 2013, 577, S642–S648. [Google Scholar] [CrossRef]

- Opiela, M.; Grzegorczyk, B. Thermo-mechanical Treatment of Forged Products of Ti-V-B Microalloyed Steel. In Proceedings of the Metal 2013, 22nd International Conference on Metallurgy and Materials, Brno, Czech Republic, 15–17 May 2013; Tanger Ltd.: Ostrava, Czechia, 2013; pp. 796–801. [Google Scholar]

- Siwecki, T. Improving Mechanical Properties on High-Strength Steel Plate by Optimizing the Direct Quenching Process. In Proceedings of the International Symposium on the Recent Developments in Plate Steels, Winter Park, CO, USA, 19–22 June 2011. [Google Scholar]

- Zurutuza, I.; Isasti, N.; Detemple, E.; Schwinn, V.; Mohrbacher, H.; Uranga, P. Effect of Thermomechanical Strategy and Mo-Nb-B Alloying Additions on High Strength Medium Carbon Q/Q&T Steels. In Proceedings of the Materials Science and Technology 2019 (MS&T19) Conference, Portland, OR, USA, 29 September–3 October 2019; pp. 1401–1408. [Google Scholar] [CrossRef]

- Uranga, P.; Gutiérrez, I.; López, B. Determination of recrystallization kinetics from plane strain compression tests. Mater. Sci. Eng. A 2013, 578, 174–180. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Zhou, T.; Babu, R.P.; Hou, Z.; Odqvist, J.; Hedström, P. Precipitation of multiple carbides in martensitic CrMoV steels—Experimental analysis and exploration of alloying strategy through thermodynamic calculations. Materialia 2020, 9, 100630. [Google Scholar] [CrossRef]

- Mohrbacher, H.; Senuma, T. Alloy Optimization for Reducing Delayed Fracture Sensitivity of 2000 MPa Press Hardening Steel. Metals 2020, 10, 853. [Google Scholar] [CrossRef]

- Seol, J.-B.; Na, S.-H.; Gault, B.; Kim, J.-E.; Han, J.-C.; Park, C.-G.; Raabe, D. Core-shell nanoparticle arrays double the strength of steel. Sci. Rep. 2017, 7, srep42547. [Google Scholar] [CrossRef]

- Yamasaki, S.; Bhadeshia, H.K.D.H. Modelling and characterisation of Mo2C precipitation and cementite dissolution during tempering of Fe–C–Mo martensitic steel. Mater. Sci. Technol. 2003, 19, 723–731. [Google Scholar] [CrossRef]

- Fujita, N.; Bhadeshia, H. Precipitation of molybdenum carbide in steel: Multicomponent diffusion and multicomponent capillary effects. Mater. Sci. Technol. 1999, 15, 627–634. [Google Scholar] [CrossRef]

- Pickering, F.B.; Gladman, T. Metallurgical Developments in Carbon Steels; Special Report No. 81; Iron and Steel Institute: London, UK, 1963. [Google Scholar]

- Iza-Mendia, A.; Gutiérrez, I. Generalization of the existing relations between microstructure and yield stress from ferrite–pearlite to high strength steels. Mater. Sci. Eng. A 2013, 561, 40–51. [Google Scholar] [CrossRef]

- Kubin, L.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef]

- Tomita, Y.; Okabayashi, K. Effect of microstructure on strength and toughness of heat-treated low alloy structural steels. Met. Mater. Trans. A 1986, 17, 1203–1209. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Shi, J.; Hui, W.; Dong, H. Effect of Microstructure Refinement on the Strength and Toughness of Low Alloy Martensitic Steel. J. Mater. Sci. Technol. 2007, 23, 659–664. [Google Scholar]

- Morito, S.; Ohba, T. Crystallographic Analysis of Characteristic Sizes of Lath Martensite Morphology. In Fundamentals of Martensite and Bainite toward Future Steels with High Performance; Furuhara, T., Tsuzaki, K., Eds.; ISIJ: Tokyo, Japan, 2007; pp. 57–62. [Google Scholar]

- Morris, J.J.W. On the Ductile-Brittle Transition in Lath Martensitic Steel. ISIJ Int. 2011, 51, 1569–1575. [Google Scholar] [CrossRef]

- Hannula, J.; Kömi, J.; Porter, D.A.; Somani, M.C.; Kaijalainen, A.; Suikkanen, P.; Yang, J.-R.; Tsai, S.-P. Effect of Boron on the Strength and Toughness of Direct-Quenched Low-Carbon Niobium Bearing Ultra-High-Strength Martensitic Steel. Met. Mater. Trans. A 2017, 48, 5344–5356. [Google Scholar] [CrossRef]

- Isasti, N.; Jorge-Badiola, D.; Taheri, M.L.; Uranga, P. Microstructural Features Controlling Mechanical Properties in Nb-Mo Microalloyed Steels. Part I: Yield Strength. Met. Mater. Trans. A 2014, 45, 4960–4971. [Google Scholar] [CrossRef]

- Hutchinson, B.; Hagström, J.; Karlsson, O.; Lindell, D.; Tornberg, M.; Lindberg, F.; Thuvander, M. Microstructures and hardness of as-quenched martensites (0.1–0.5%C). Acta Mater. 2011, 59, 5845–5858. [Google Scholar] [CrossRef]

- Mohrbacher, H.; Yang, J.-R.; Chen, Y.-W.; Rehrl, J.; Hebesberger, T. Metallurgical Effects of Niobium in Dual Phase Steel. Metals 2020, 10, 504. [Google Scholar] [CrossRef]

- Ashby, M.F. Physics of Strength and Plasticity; Argon, A.S., Ed.; MIT Press: Cambridge, MA, USA, 1969; p. 113. [Google Scholar]

- Larzabal, G.; Isasti, N.; Rodriguez-Ibabe, J.M.; Uranga, P. Precipitation Strengthening by Induction Treatment in High Strength Low Carbon Microalloyed Hot-Rolled Plates. Met. Mater. Trans. A 2018, 49, 946–961. [Google Scholar] [CrossRef]

- Huang, B.M.; Yang, J.-R.; Yen, H.W.; Hsu, C.H.; Huang, C.Y.; Mohrbacher, H. Secondary hardened bainite. Mater. Sci. Technol. 2014, 30, 1014–1023. [Google Scholar] [CrossRef]

- Xie, Z.; Ren, Y.; Zhou, W.; Yang, J.; Shang, C.; Misra, R. Stability of retained austenite in multi-phase microstructure during austempering and its effect on the ductility of a low carbon steel. Mater. Sci. Eng. A 2014, 603, 69–75. [Google Scholar] [CrossRef]

- Colla, V.; De Sanctis, M.; DiMatteo, A.; Lovicu, G.; Solina, A.; Valentini, R. Strain Hardening Behavior of Dual-Phase Steels. Met. Mater. Trans. A 2009, 40, 2557–2567. [Google Scholar] [CrossRef]

- Kamikawa, N.; Sato, K.; Miyamoto, G.; Murayama, M.; Sekido, N.; Tsuzaki, K.; Furuhara, T. Stress–strain behavior of ferrite and bainite with nano-precipitation in low carbon steels. Acta Mater. 2015, 83, 383–396. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Mo | Nb | B |

|---|---|---|---|---|---|---|

| CMnB | 0.15 | 0.32 | 1.05 | - | - | 0.0022 |

| CMnNbB | 0.16 | 0.29 | 1.05 | - | 0.026 | 0.0019 |

| CMnMoB | 0.16 | 0.28 | 1.07 | 0.5 | - | 0.0022 |

| CMnNbMoB | 0.16 | 0.31 | 1.07 | 0.5 | 0.026 | 0.0018 |

| Steel | Carbides Located at Prior Austenite Grain Boundaries | Carbides Located Inside Prior Austenite Grains | ||

|---|---|---|---|---|

| Carbide Size (nm) | Area Fraction (%) | Carbide Size (nm) | Area Fraction (%) | |

| CMnB | 113.6 ± 3.9 | 0.18 | 103.8 ± 4.3 | 0.33 |

| CMnNbB | 115.3 ± 3.9 | 0.16 | 105.9 ± 4.4 | 0.41 |

| CMnMoB | 91.4 ± 5.4 | 0.29 | 59.4 ± 3.1 | 0.91 |

| CMnNbMoB | 80.4 ± 3.8 | 0.31 | 66.8 ± 2.9 | 1.26 |

| Steel | Cycle | Yield Strength (MPa) | Tensile Strength (MPa) | YTR | Homogeneous Elongation | Total Elongation |

|---|---|---|---|---|---|---|

| CMnB | Q | 1030 | 1325 | 0.78 | 0.05 | 0.15 |

| Q + T | 617 | 700 | 0.88 | 0.08 | 0.22 | |

| CMnNbB | Q | 1026 | 1366 | 0.75 | 0.04 | 0.12 |

| Q + T | 757 | 818 | 0.93 | 0.07 | 0.17 | |

| CMnMoB | Q | 1075 | 1432 | 0.75 | 0.04 | 0.13 |

| Q + T | 943 | 991 | 0.95 | 0.06 | 0.15 | |

| CMnNbMoB | Q | 1107 | 1460 | 0.76 | 0.04 | 0.14 |

| Q + T | 977 | 1034 | 0.95 | 0.03 | 0.12 |

| Solid Solution | [30] | |

| Grain Size | [31] | |

| Dislocation Density | , | [24,32] |

| Steel | Cycle | Solid Solution (MPa) | Grain Size (MPa) | Dislocation Density (MPa) | Unaccounted Strength (MPa) |

|---|---|---|---|---|---|

| CMnB | Q | 115 | 472 | 114 | 329 |

| Q + T | 115 | 448 | 112 | 0 | |

| CMnNbB | Q | 112 | 496 | 118 | 300 |

| Q + T | 112 | 516 | 118 | 11 | |

| CMnMoB | Q | 117 | 516 | 119 | 323 |

| Q + T | 117 | 520 | 121 | 185 | |

| CMnNbMoB | Q | 120 | 528 | 121 | 338 |

| Q + T | 120 | 508 | 120 | 229 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zurutuza, I.; Isasti, N.; Detemple, E.; Schwinn, V.; Mohrbacher, H.; Uranga, P. Effect of Nb and Mo Additions in the Microstructure/Tensile Property Relationship in High Strength Quenched and Quenched and Tempered Boron Steels. Metals 2021, 11, 29. https://doi.org/10.3390/met11010029

Zurutuza I, Isasti N, Detemple E, Schwinn V, Mohrbacher H, Uranga P. Effect of Nb and Mo Additions in the Microstructure/Tensile Property Relationship in High Strength Quenched and Quenched and Tempered Boron Steels. Metals. 2021; 11(1):29. https://doi.org/10.3390/met11010029

Chicago/Turabian StyleZurutuza, Irati, Nerea Isasti, Eric Detemple, Volker Schwinn, Hardy Mohrbacher, and Pello Uranga. 2021. "Effect of Nb and Mo Additions in the Microstructure/Tensile Property Relationship in High Strength Quenched and Quenched and Tempered Boron Steels" Metals 11, no. 1: 29. https://doi.org/10.3390/met11010029

APA StyleZurutuza, I., Isasti, N., Detemple, E., Schwinn, V., Mohrbacher, H., & Uranga, P. (2021). Effect of Nb and Mo Additions in the Microstructure/Tensile Property Relationship in High Strength Quenched and Quenched and Tempered Boron Steels. Metals, 11(1), 29. https://doi.org/10.3390/met11010029