The Effects of Inhomogeneous Elasticity and Dislocation on Thermodynamics and the Kinetics of the Spinodal Decomposition of a Fe-Cr System: A Phase-Field Study

Abstract

1. Introduction

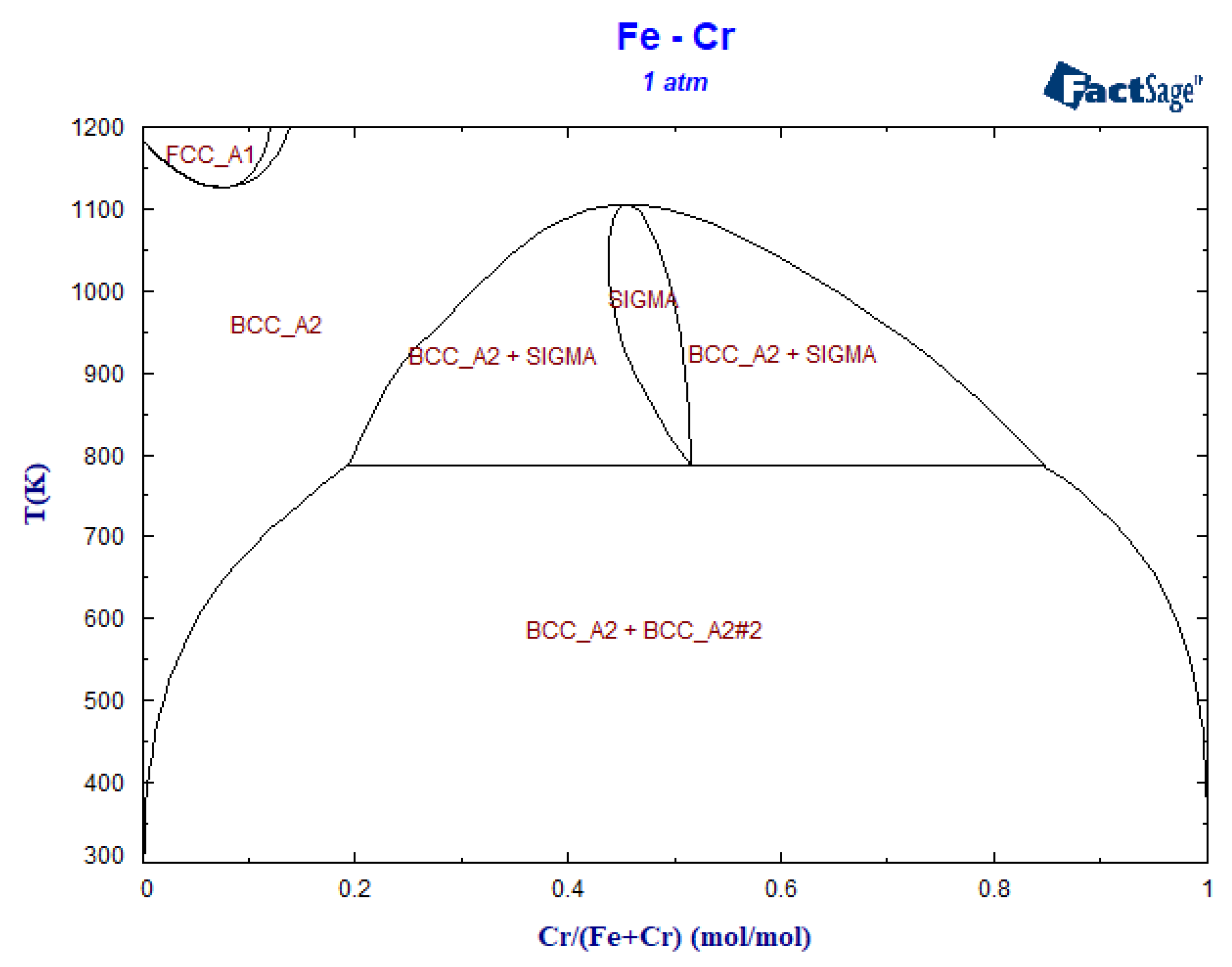

2. CALPHAD-Based Phase-Field Method

2.1. Cahn–Hilliard Equation

2.2. Free Energy of Fe-Cr System with Dislocation

2.3. Computational Details

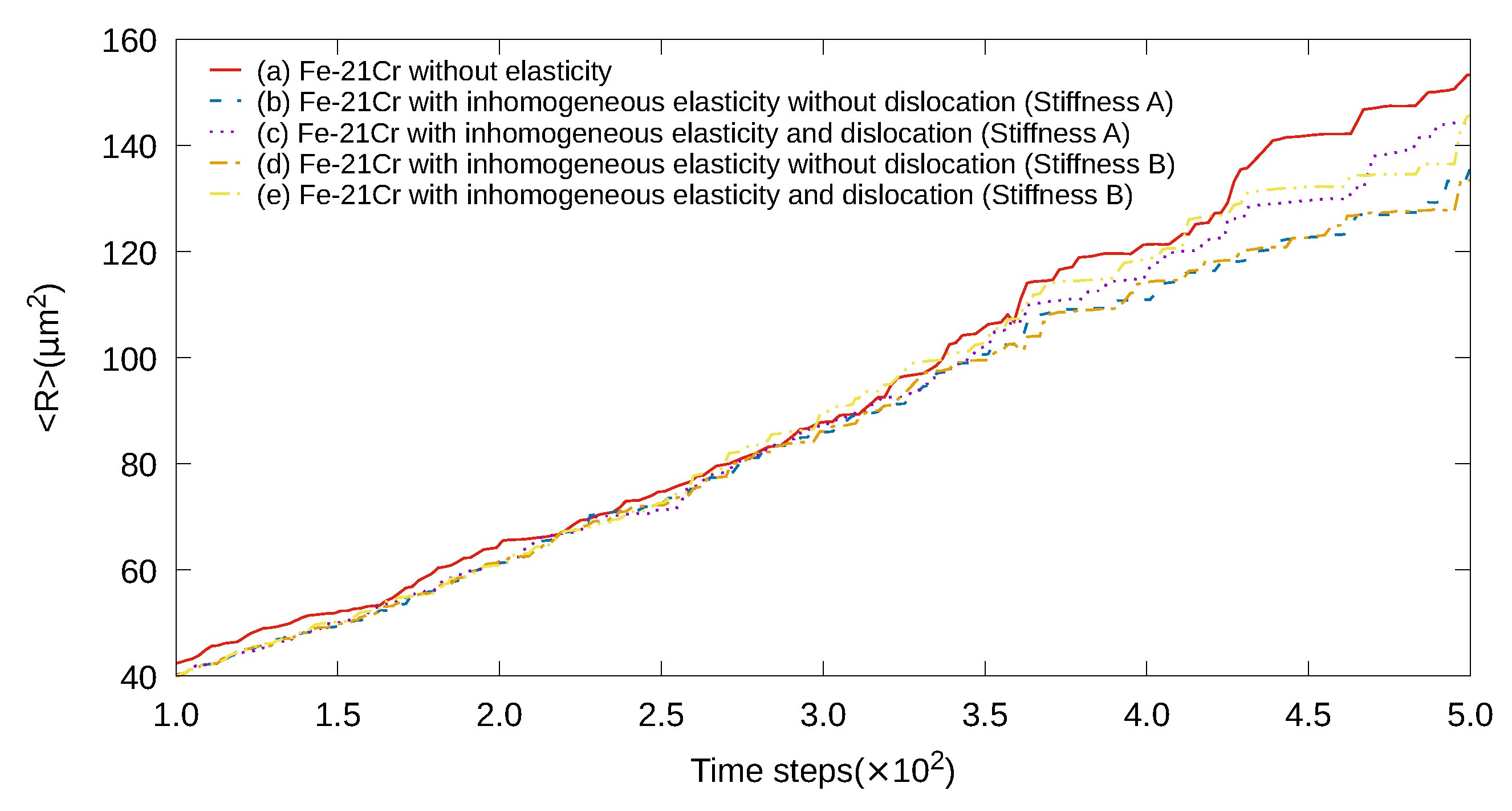

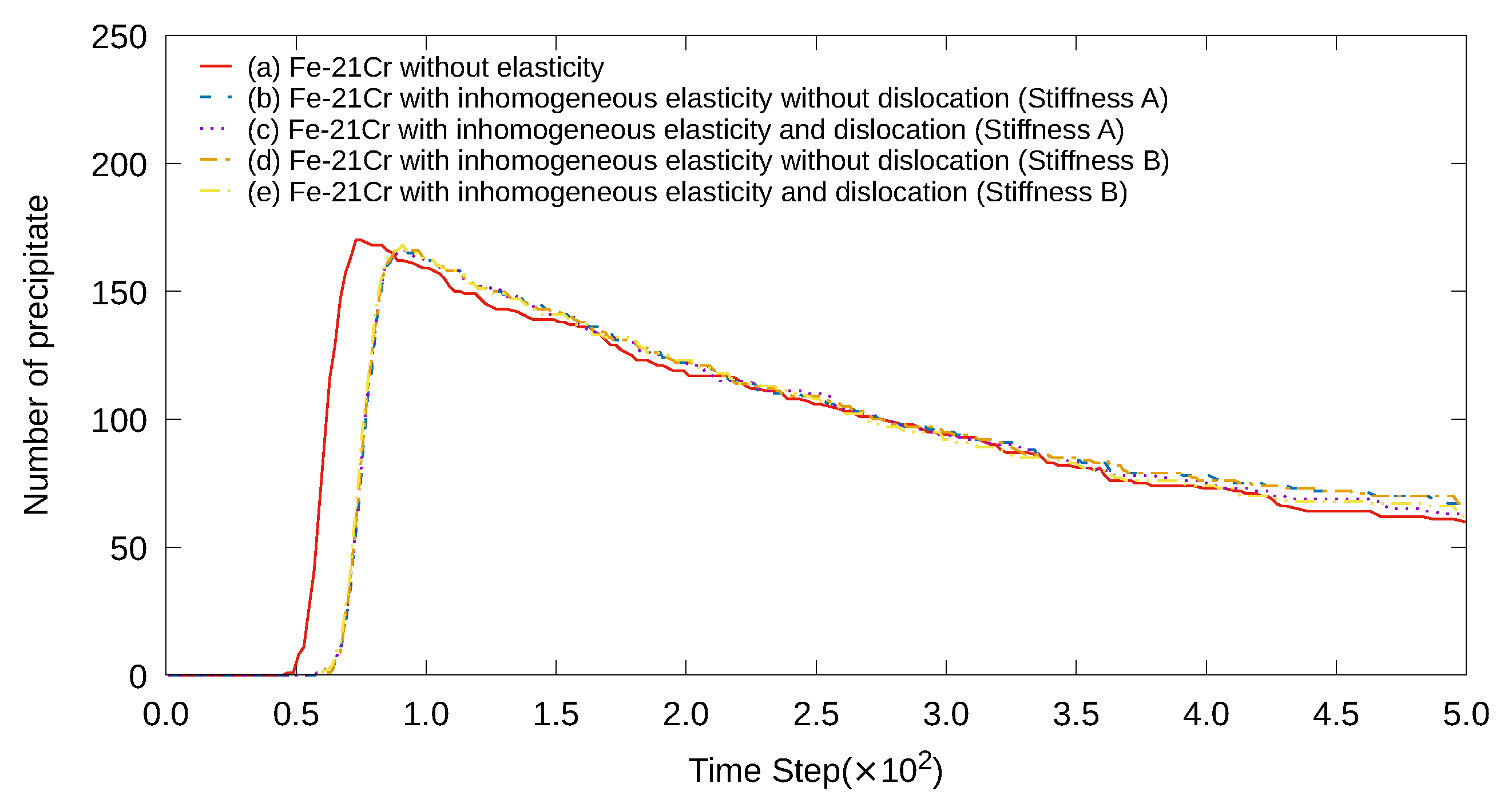

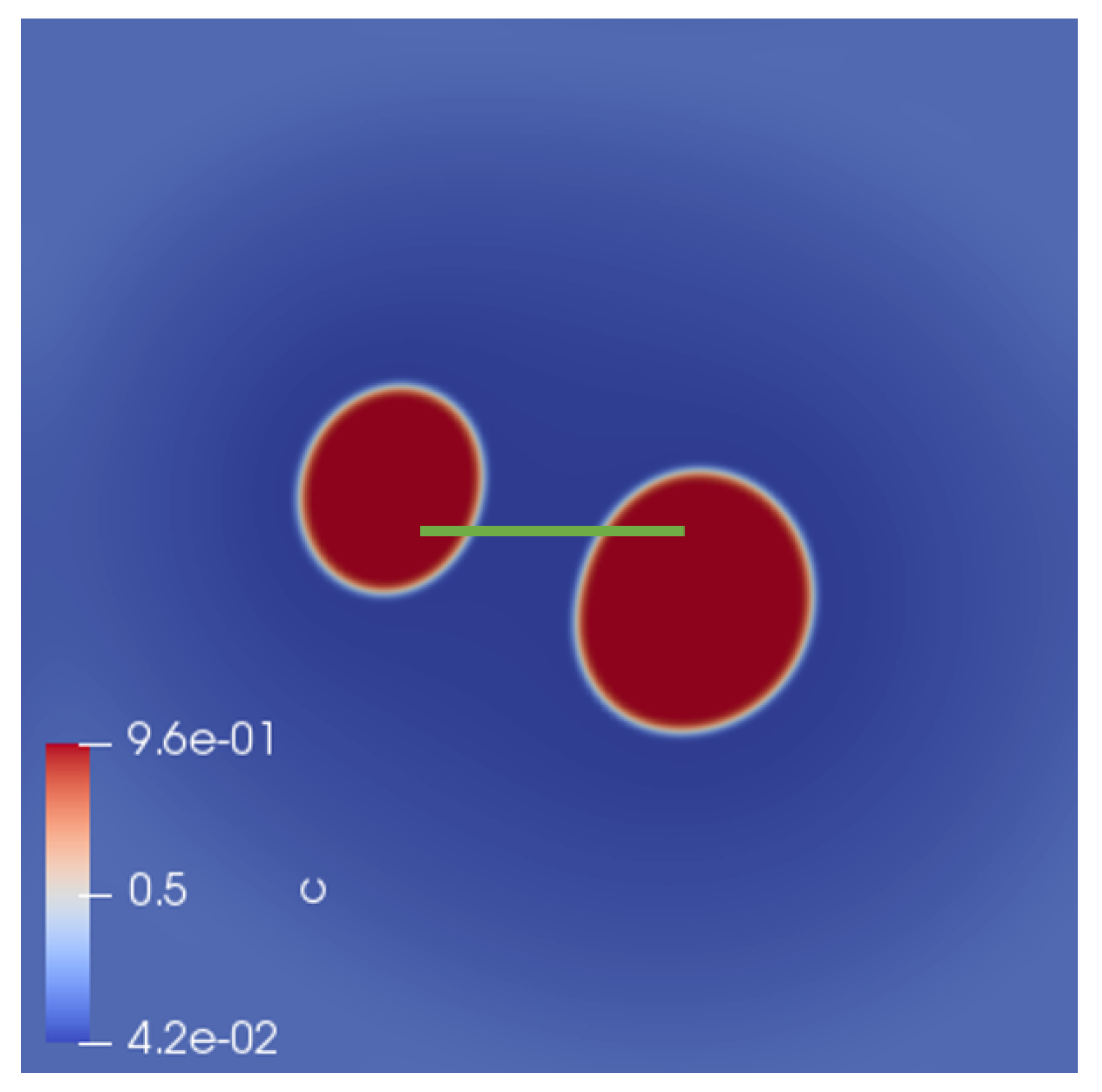

3. Results and Discussions

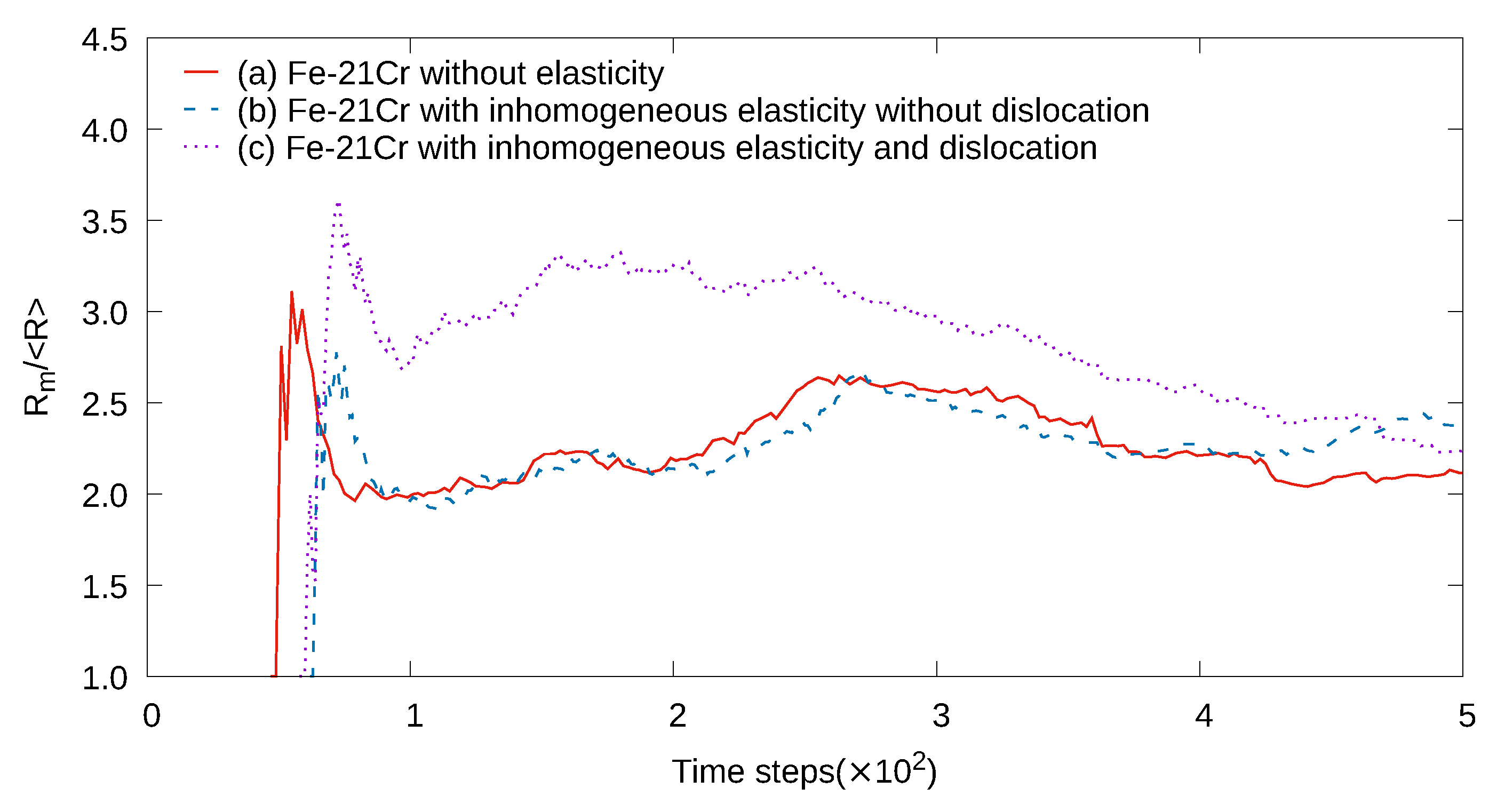

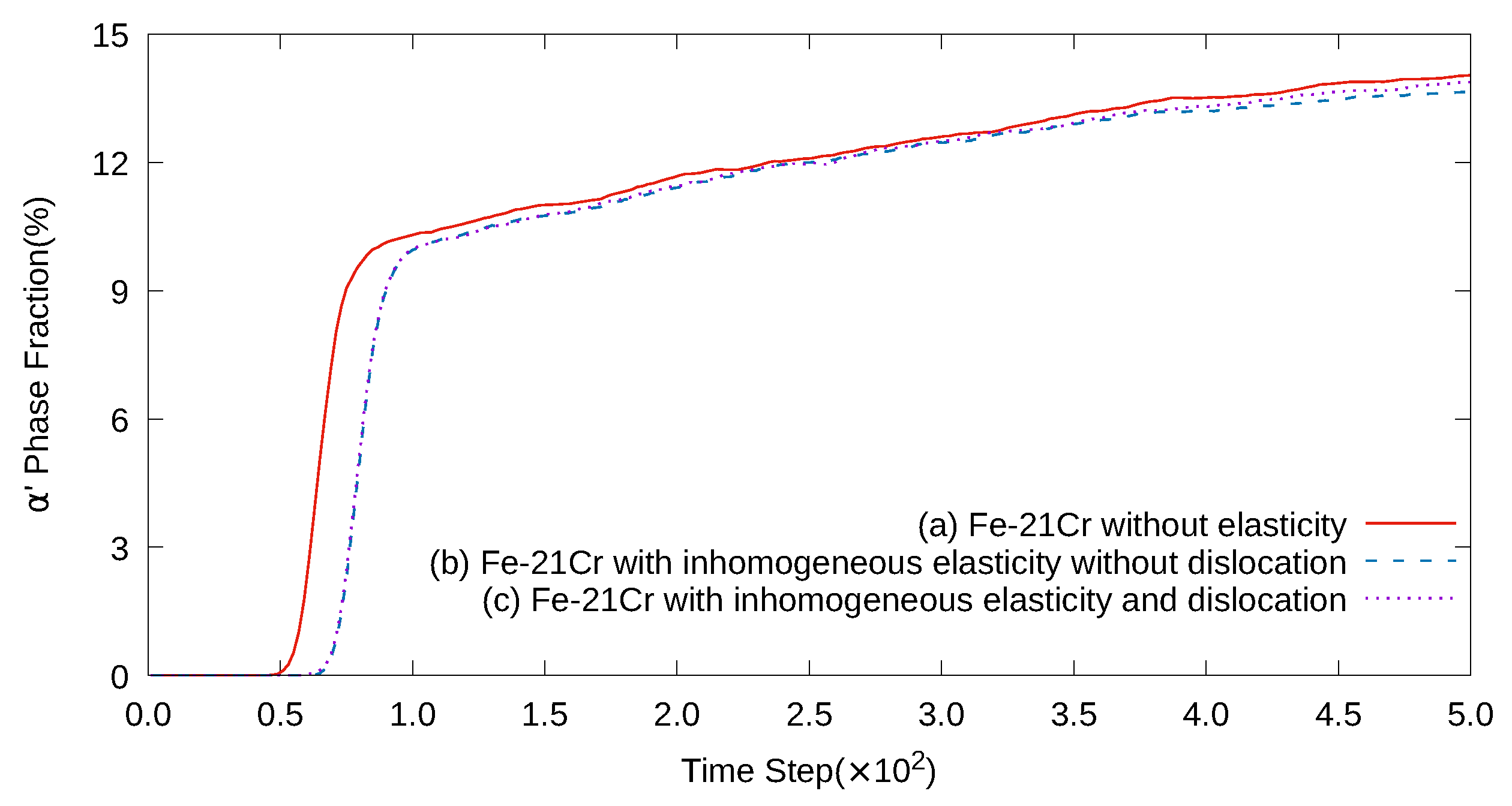

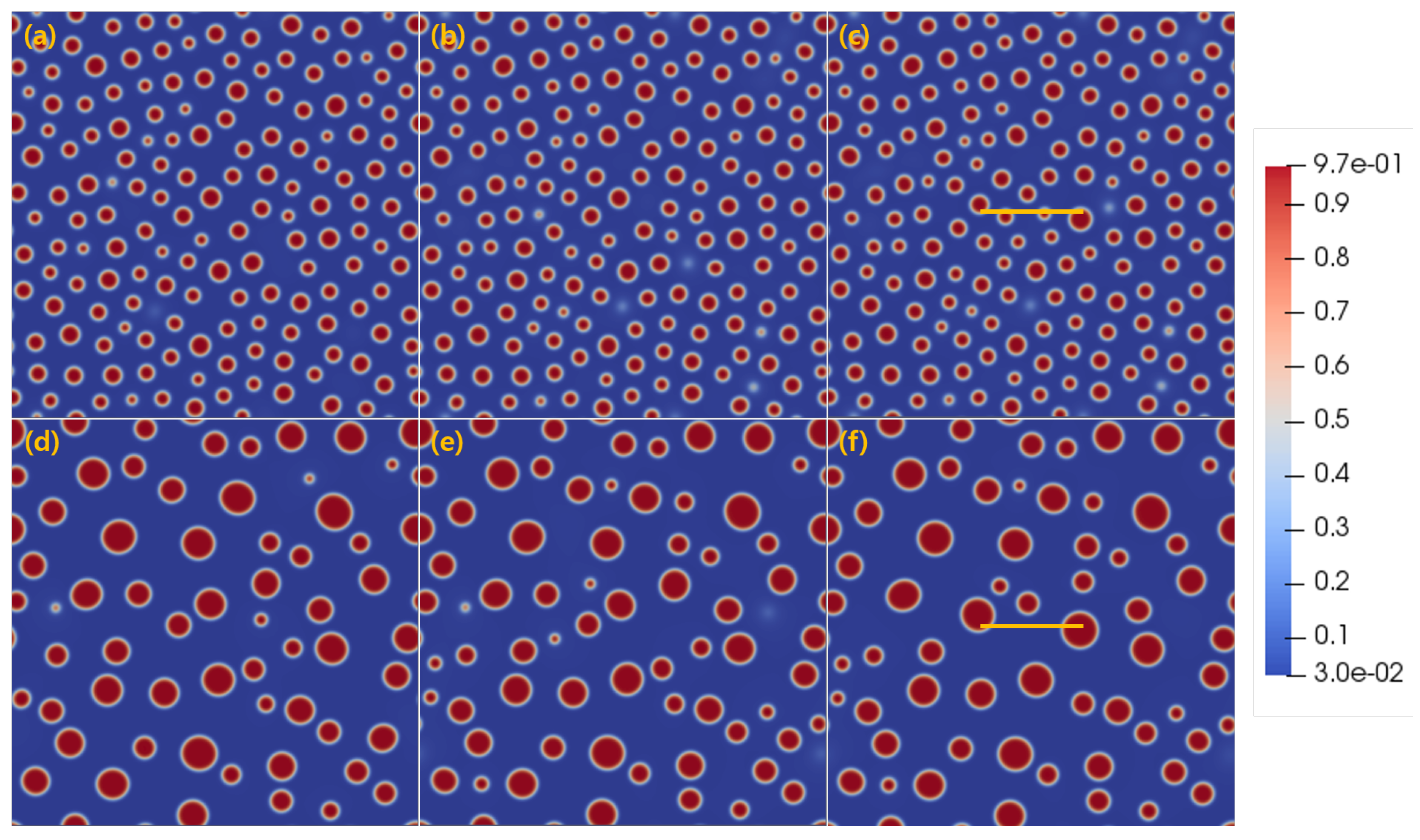

The Effect of Elasticity and Dislocation on Phase Precipitation Induced by the Spinodal Decomposition Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Grobner, P. The 885 F (475 C) embrittlement of ferritic stainless steels. Metall. Trans. 1973, 4, 251–260. [Google Scholar] [CrossRef]

- Chandra, D.; Schwartz, L. Mössbauer effect study of the 475‡ C decomposition of Fe-Cr. Metall. Trans. 1971, 2, 511–519. [Google Scholar] [CrossRef]

- Cieślak, J.; Dubiel, S. Nucleation and growth versus spinodal decomposition in Fe–Cr alloys: Mössbauer-effect modelling. J. Alloys Compd. 1998, 269, 208–218. [Google Scholar] [CrossRef]

- Solomon, H.; Levinson, L.M. Mössbauer effect study of ‘475 C embrittlement’of duplex and ferritic stainless steels. Acta Metall. 1978, 26, 429–442. [Google Scholar] [CrossRef]

- Miller, M.; Hyde, J.; Hetherington, M.; Cerezo, A.; Smith, G.; Elliott, C. Spinodal decomposition in Fe-Cr alloys: Experimental study at the atomic level and comparison with computer models—I. Introduction and methodology. Acta Metall. Mater. 1995, 43, 3385–3401. [Google Scholar] [CrossRef]

- Li, Y.S.; Li, S.X.; Zhang, T.Y. Effect of dislocations on spinodal decomposition in Fe–Cr alloys. J. Nucl. Mater. 2009, 395, 120–130. [Google Scholar] [CrossRef]

- Hedström, P.; Baghsheikhi, S.; Liu, P.; Odqvist, J. A phase-field and electron microscopy study of phase separation in Fe–Cr alloys. Mater. Sci. Eng. A 2012, 534, 552–556. [Google Scholar] [CrossRef]

- Cahn, J.W. On spinodal decomposition in cubic crystals. Acta Metall. 1962, 10, 179–183. [Google Scholar] [CrossRef]

- Eshelby, J. The continuum theory of lattice defects. In Solid State Physics; Elsevier: Amsterdam, The Netherlands, 1956; Volume 3, pp. 79–144. [Google Scholar]

- Zhu, L.; Li, Y.; Liu, C.; Chen, S.; Shi, S.; Jin, S. Effect of applied strain on phase separation of Fe–28 at.% Cr alloy: 3D phase-field simulation. Model. Simul. Mater. Sci. Eng. 2018, 26, 035015. [Google Scholar] [CrossRef]

- Lee, J.; Chang, K. Effect of magnetic ordering on the spinodal decomposition of the Fe-Cr system: A GPU-accelerated phase-field study. Comput. Mater. Sci. 2019, 169, 109088. [Google Scholar] [CrossRef]

- Dinsdale, A. SGTE data for pure elements. Calphad 1991, 15, 317–425. [Google Scholar] [CrossRef]

- Cahn, J.W.; Hilliard, J.E. Free energy of a nonuniform system. I. Interfacial free energy. J. Chem. Phys. 1958, 28, 258–267. [Google Scholar] [CrossRef]

- Cahn, J.W. On spinodal decomposition. Acta Metall. 1961, 9, 795–801. [Google Scholar] [CrossRef]

- Andersson, J.O.; Sundman, B. Thermodynamic properties of the Cr-Fe system. Calphad 1987, 11, 83–92. [Google Scholar] [CrossRef]

- Bale, C.W.; Chartrand, P.; Degterov, S.; Eriksson, G.; Hack, K.; Mahfoud, R.B.; Melançon, J.; Pelton, A.; Petersen, S. FactSage thermochemical software and databases. Calphad 2002, 26, 189–228. [Google Scholar] [CrossRef]

- Khachaturyan, A.G. Theory of Structural Transformations in Solids; Courier Corporation: Mineola, NY, USA, 2013. [Google Scholar]

- Newnham, R.E. Properties of Materials: Anisotropy, Symmetry, Structure; Oxford University Press on Demand: Oxford, UK, 2005. [Google Scholar]

- Adams, J.J.; Agosta, D.; Leisure, R.; Ledbetter, H. Elastic constants of monocrystal iron from 3 to 500 K. J. Appl. Phys. 2006, 100, 113530. [Google Scholar] [CrossRef]

- Bolef, D.T.; De Klerk, J. Anomalies in the elastic constants and thermal expansion of chromium single crystals. Phys. Rev. 1963, 129, 1063. [Google Scholar] [CrossRef]

- Biner, S.B. Programming Phase-Field Modeling; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Terentyev, D.; Bergner, F.; Osetsky, Y. Cr segregation on dislocation loops enhances hardening in ferritic Fe-Cr alloys. Acta Mater. 2013, 61, 1444–1453. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E.; Sherif, M. Phase Transformations in Metals and Alloys, (Revised Reprint); CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Kawasaki, K.; Enomoto, Y. Statistical theory of Ostwald ripening with elastic field interaction. Phys. Stat. Mech. Appl. 1988, 150, 463–498. [Google Scholar] [CrossRef]

- Li, Y.; Yan, Z.; Zhou, X. Kinetics of initial phase separation and coarsening of nanoscale phase in Fe–Cr alloys. J. Nucl. Mater. 2017, 497, 154–160. [Google Scholar] [CrossRef]

- Bachhav, M.; Odette, G.R.; Marquis, E.A. α′ precipitation in neutron-irradiated Fe-Cr alloys. Scr. Mater. 2014, 74, 48–51. [Google Scholar] [CrossRef]

- Porollo, S.; Dvoriashin, A.; Vorobyev, A.; Konobeev, Y.V. The microstructure and tensile properties of Fe–Cr alloys after neutron irradiation at 400 C to 5.5–7.1 dpa. J. Nucl. Mater. 1998, 256, 247–253. [Google Scholar] [CrossRef]

- Hyde, J.; Miller, M.; Hetherington, M.; Cerezo, A.; Smith, G.; Elliott, C. Spinodal decomposition in Fe-Cr alloys: Experimental study at the atomic level and comparison with computer models—II. Development of domain size and composition amplitude. Acta Metall. Mater. 1995, 43, 3403–3413. [Google Scholar] [CrossRef]

- Westraadt, J.; Olivier, E.; Neethling, J.; Hedström, P.; Odqvist, J.; Xu, X.; Steuwer, A. A high-resolution analytical scanning transmission electron microscopy study of the early stages of spinodal decomposition in binary Fe–Cr. Mater. Charact. 2015, 109, 216–221. [Google Scholar] [CrossRef]

- Zhou, J.; Odqvist, J.; Thuvander, M.; Hedström, P. Quantitative evaluation of spinodal decomposition in Fe-Cr by atom probe tomography and radial distribution function analysis. Microsc. Microanal. 2013, 19, 665–675. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, W.; Lee, J.; Chang, K. The Effects of Inhomogeneous Elasticity and Dislocation on Thermodynamics and the Kinetics of the Spinodal Decomposition of a Fe-Cr System: A Phase-Field Study. Metals 2020, 10, 1209. https://doi.org/10.3390/met10091209

Shin W, Lee J, Chang K. The Effects of Inhomogeneous Elasticity and Dislocation on Thermodynamics and the Kinetics of the Spinodal Decomposition of a Fe-Cr System: A Phase-Field Study. Metals. 2020; 10(9):1209. https://doi.org/10.3390/met10091209

Chicago/Turabian StyleShin, Wooseob, Jeonghwan Lee, and Kunok Chang. 2020. "The Effects of Inhomogeneous Elasticity and Dislocation on Thermodynamics and the Kinetics of the Spinodal Decomposition of a Fe-Cr System: A Phase-Field Study" Metals 10, no. 9: 1209. https://doi.org/10.3390/met10091209

APA StyleShin, W., Lee, J., & Chang, K. (2020). The Effects of Inhomogeneous Elasticity and Dislocation on Thermodynamics and the Kinetics of the Spinodal Decomposition of a Fe-Cr System: A Phase-Field Study. Metals, 10(9), 1209. https://doi.org/10.3390/met10091209