Microstructural Evolution of Multi-Pass Caliber-Rolled Mg–Sn and Mg–Sn–Mn Alloys

Abstract

1. Introduction

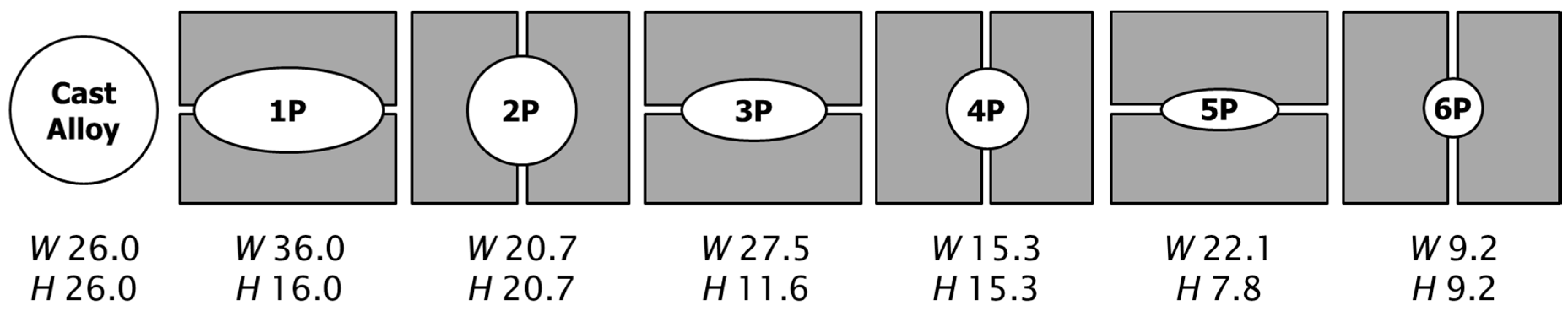

2. Materials and Methods

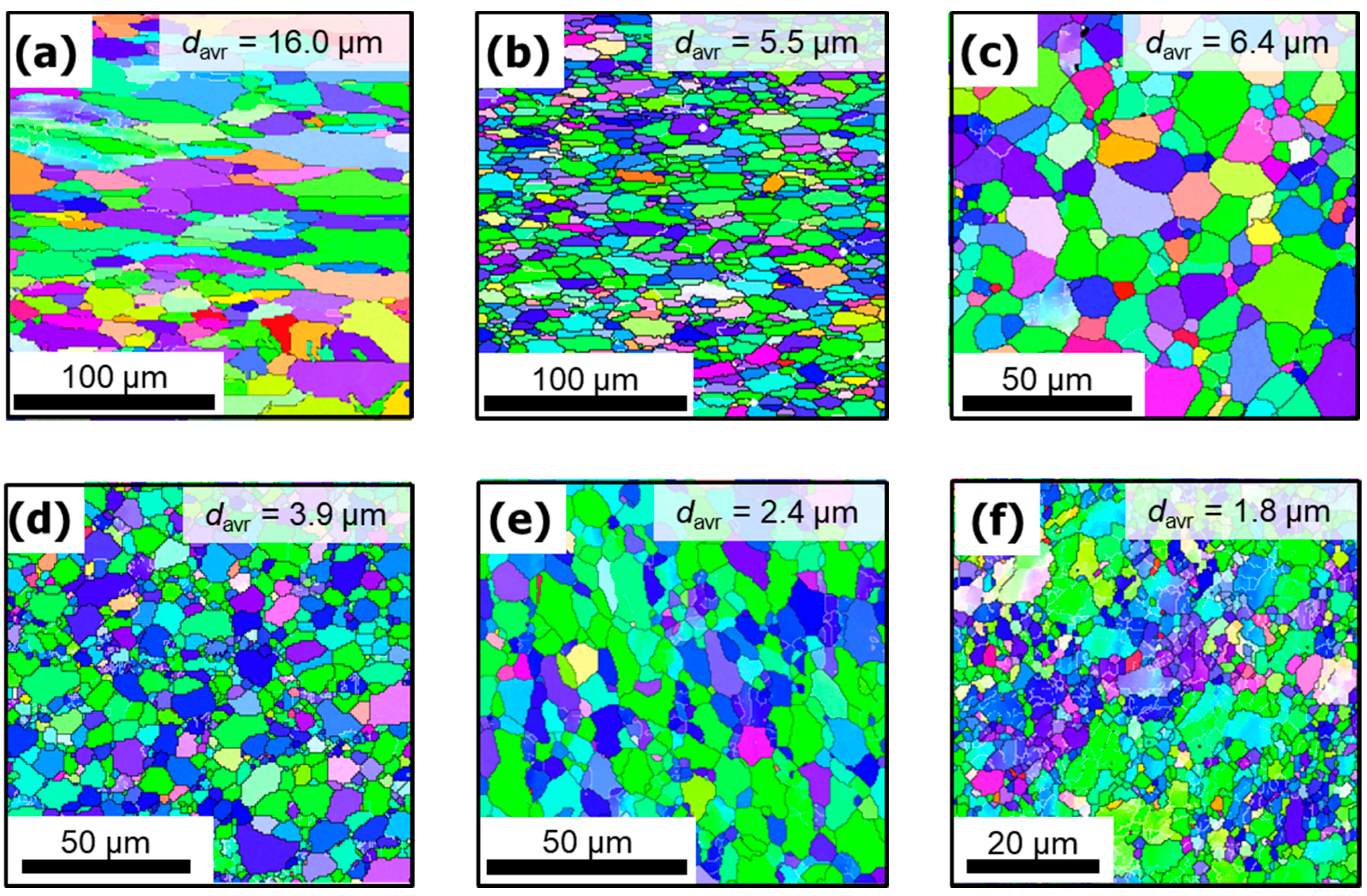

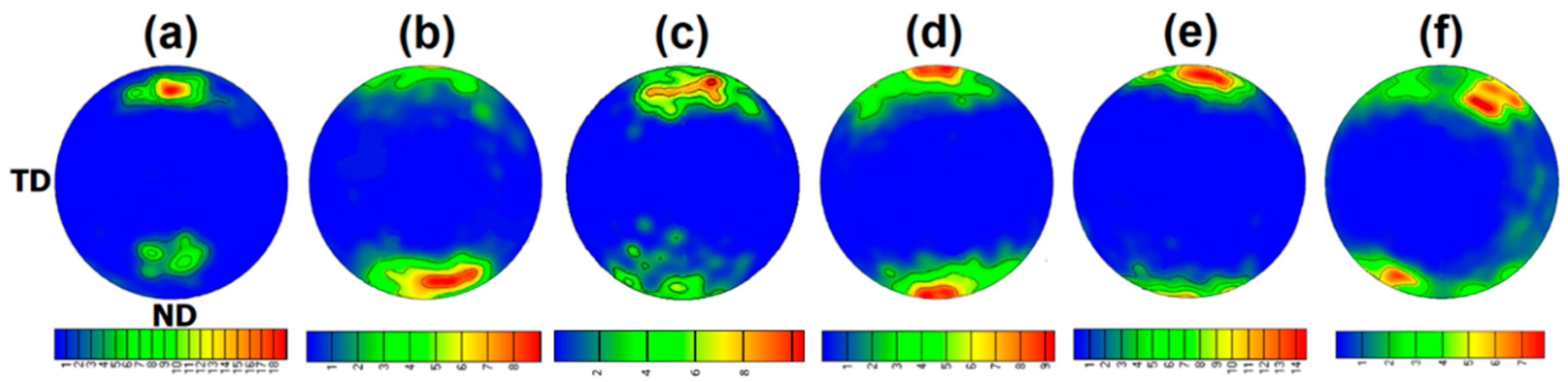

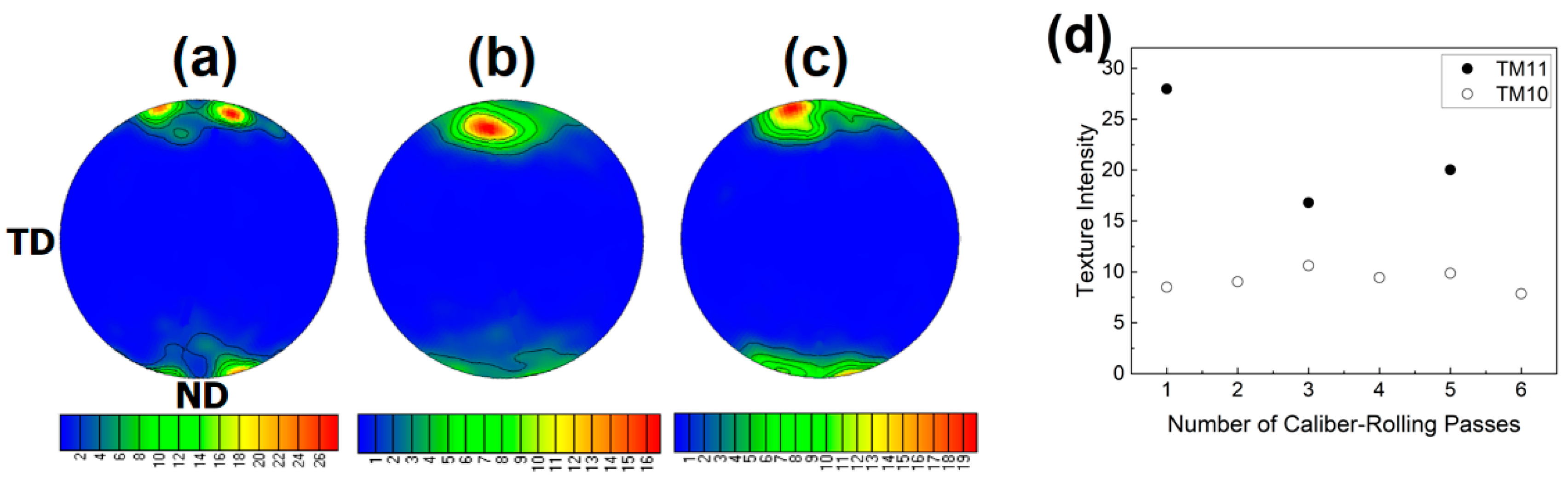

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Golrang, M.; Mobasheri, M.; Mirzadeh, H.; Emamy, M. Effect of Zn addition on the microstructure and mechanical properties of Mg-0.5Ca-0.5RE magnesium alloy. J. Alloys Compd. 2020, 815, 152380. [Google Scholar] [CrossRef]

- Kim, J.; Kawamura, Y. Influence of Rare Earth Elements on Microstructure and Mechanical Properties of Mg97Zn1Y1RE1 Alloys. Mater. Sci. Eng. A 2013, 573, 62–66. [Google Scholar] [CrossRef]

- Go, J.; Lee, J.U.; Moon, B.G.; Yoon, J.; Park, S.H. Improvement in Mechanical Properties of Rolled AZ31 Alloy Through Combined Addition of Ca and Gd. Met. Mater. Int. 2020. [Google Scholar] [CrossRef]

- Banijamali, S.M.; Palizdar, Y.; Najafi, S.; Sheikhani, A.; Nezhad, M.S.A.; Moghaddam, P.V.; Torkamani, H. Effect of Ce Addition on the Tribological Behavior of ZK60 Mg-Alloy. Met. Mater. Int. 2020, 1–11. [Google Scholar] [CrossRef]

- Lu, F.; Ma, A.; Jiang, J.; Chen, J.; Song, D.; Yuan, Y.; Chen, J.; Yang, D. Enhanced mechanical properties and rolling formability of fine-grained Mg–Gd–Zn–Zr alloy produced by equal-channel angular pressing. J. Alloys Compd. 2015, 643, 28–33. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, H.S.; Bae, J.H.; Yim, C.D.; You, B.S. Improving the mechanical properties of extruded Mg–3Al–1Zn alloy by cold pre-forging. Scr. Mater. 2013, 69, 250–253. [Google Scholar] [CrossRef]

- Lee, T.; Yamasaki, M.; Kawamura, Y.; Go, J.; Park, S.H. High-Strength AZ91 Alloy Fabricated by Rapidly Solidified Flaky Powder Metallurgy and Hot Extrusion. Met. Mater. Int. 2019, 25, 372–380. [Google Scholar] [CrossRef]

- Yu, H.; Park, S.H.; You, B.S. Development of extraordinary high-strength Mg-8Al-0.5Zn alloy via a low temperature and slow speed extrusion. Mater. Sci. Eng. A 2014, 610, 445–449. [Google Scholar] [CrossRef]

- Chang, S.Y.; Lee, S.W.; Kang, K.M.; Kamado, S.; Kojima, Y. Improvement of Mechanical Characteristics in Severely Plastic-deformed Mg Alloys. Mater. Trans. 2004, 45, 488–492. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse Temperature Dependence of Toughness in an Ultrafine Grain-Structure Steel. Science 2008, 320, 1057–1060. [Google Scholar] [CrossRef] [PubMed]

- Inoue, T.; Somekawa, H.; Mukai, T. Hardness Variation and Strain Distribution in Magnesium Alloy AZ31 Processed by Multi-pass Caliber Rolling. Adv. Eng. Mater. 2009, 11, 654–658. [Google Scholar] [CrossRef]

- Tripathi, A.; Murty, S.V.S.N.; Narayanan, P.R. Microstructure and texture evolution in AZ31 magnesium alloy during caliber rolling at different temperatures. J. Magnes. Alloys 2017, 5, 340–347. [Google Scholar] [CrossRef]

- Lee, J.H.; Kwak, B.J.; Kong, T.; Park, S.H.; Lee, T. Improved tensile properties of AZ31 Mg alloy subjected to various caliber-rolling strains. J. Magnes. Alloys 2019, 7, 381–387. [Google Scholar] [CrossRef]

- Kong, T.; Kwak, B.J.; Kim, J.; Lee, J.H.; Park, S.H.; Kim, J.H.; Moon, Y.H.; Yoon, H.S.; Lee, T. Tailoring strength-ductility balance of caliber-rolled AZ31 Mg alloy through subsequent annealing. J. Magnes. Alloys 2020, 8, 163–171. [Google Scholar] [CrossRef]

- Stefanik, A.; Szota, P.; Mróz, S.; Bajor, T.; Dyja, H. Properties of the AZ31 Magnesium Alloy Round Bars Obtained in Different Rolling Processes. Arch. Metall. Mater. 2015, 60, 3001–3006. [Google Scholar] [CrossRef]

- Lee, T.; Kwak, B.J.; Kong, T.; Lee, J.H.; Lee, S.W.; Park, S.H. Enhanced yield symmetry and strength-ductility balance of caliber-rolled Mg–6Zn-0.5Zr with ultrafine-grained structure and bulk dimension. J. Alloys Compd. 2019, 803, 434–441. [Google Scholar] [CrossRef]

- Kwak, B.J.; Park, S.H.; Moon, Y.H.; Lee, J.H.; Lee, T. Plastic anisotropy of multi-pass caliber-rolled Mg alloy with split texture distribution. Mater. Sci. Eng. A 2020, 788, 139496. [Google Scholar] [CrossRef]

- Somekawa, H.; Basha, D.A.; Singh, A. Change in dominant deformation mechanism of Mg alloy via grain boundary control. Mater. Sci. Eng. A 2019, 746, 162–166. [Google Scholar] [CrossRef]

- Liu, N.; Chen, L.; Fu, Y.; Zhang, Y.; Tan, T.; Yin, F.; Liang, C. Interfacial characteristic of multi-pass caliber-rolled Mg/Al compound castings. J. Mater. Process. Technol. 2019, 267, 196–204. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, P.; Yang, Y.; Gao, D.; Feng, P.; Gao, C.; Wu, H.; Liu, Y.; Bian, H.; Shuai, C. The microstructure, mechanical properties and degradation behavior of laser-melted MgSn alloys. J. Alloys Compd. 2016, 687, 109–114. [Google Scholar] [CrossRef]

- Liao, H.; Kim, J.; Liu, T.; Tang, A.; She, J.; Peng, P.; Pan, F. Effects of Mn addition on the microstructures, mechanical properties and work-hardening of Mg-1Sn alloy. Mater. Sci. Eng. A 2019, 754, 778–785. [Google Scholar] [CrossRef]

- Zhao, C.; Chen, X.; Pan, F.; Gao, S.; Zhao, D.; Liu, X. Effect of Sn content on strain hardening behavior of as-extruded Mg-Sn alloys. Mater. Sci. Eng. A 2018, 713, 244–252. [Google Scholar] [CrossRef]

- Yu, Z.; Tang, A.; Wang, Q.; Gao, Z.; He, J.; She, J.; Song, K.; Pan, F. High strength and superior ductility of an ultra-fine grained magnesium–manganese alloy. Mater. Sci. Eng. A 2015, 648, 202–207. [Google Scholar] [CrossRef]

- Lee, Y.; Choi, S.; Hodgson, P.D. Analytical model of pass-by-pass strain in rod (or bar) rolling and its applications to prediction of austenite grain size. Mater. Sci. Eng. A 2002, 336, 177–189. [Google Scholar] [CrossRef]

- Lee, T.; Park, K.-T.T.; Lee, D.J.; Jeong, J.; Oh, S.H.; Kim, H.S.; Park, C.H.; Lee, C.S. Microstructural evolution and strain-hardening behavior of multi-pass caliber-rolled Ti-13Nb-13Zr. Mater. Sci. Eng. A 2015, 648, 359–366. [Google Scholar] [CrossRef]

- Inoue, T.; Yin, F.; Kimura, Y. Strain distribution and microstructural evolution in multi-pass warm caliber rolling. Mater. Sci. Eng. A 2007, 466, 114–122. [Google Scholar] [CrossRef]

- Inoue, T. Optimum pass design of bar rolling for producing bulk ultrafine-grained steel by numerical simulation. Mater. Sci. Forum 2010, 654–656, 1561–1564. [Google Scholar] [CrossRef]

- Szota, P.; Mróz, S.; Stefanik, A.; Mola, R. Analysis of the AZ31 magnesium alloy bars rolling process in modified stretching passes. Mater. Sci. Eng. Technol. 2015, 46, 285–293. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.-G.; Lee, C.S. Activation mode dependent {1 0 -1 2} twinning characteristics in a polycrystalline magnesium alloy. Scr. Mater. 2010, 62, 202–205. [Google Scholar] [CrossRef]

- Kim, S.H.; Jo, W.K.; Hong, W.H.; Kim, W.; Yoon, J.; Park, S.H. Microstructural evolution of extruded AZ31 alloy with bimodal structure during compression. Mater. Sci. Eng. A 2017, 702, 1–9. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Liao, H.; Lee, J.H.; Moon, Y.H.; Yoon, H.S.; Kim, J.; Lee, T. Microstructural Evolution of Multi-Pass Caliber-Rolled Mg–Sn and Mg–Sn–Mn Alloys. Metals 2020, 10, 1203. https://doi.org/10.3390/met10091203

Yu J, Liao H, Lee JH, Moon YH, Yoon HS, Kim J, Lee T. Microstructural Evolution of Multi-Pass Caliber-Rolled Mg–Sn and Mg–Sn–Mn Alloys. Metals. 2020; 10(9):1203. https://doi.org/10.3390/met10091203

Chicago/Turabian StyleYu, Jinyeong, Hongxin Liao, Jeong Hun Lee, Young Hoon Moon, Hyun Sik Yoon, Jonghyun Kim, and Taekyung Lee. 2020. "Microstructural Evolution of Multi-Pass Caliber-Rolled Mg–Sn and Mg–Sn–Mn Alloys" Metals 10, no. 9: 1203. https://doi.org/10.3390/met10091203

APA StyleYu, J., Liao, H., Lee, J. H., Moon, Y. H., Yoon, H. S., Kim, J., & Lee, T. (2020). Microstructural Evolution of Multi-Pass Caliber-Rolled Mg–Sn and Mg–Sn–Mn Alloys. Metals, 10(9), 1203. https://doi.org/10.3390/met10091203