Abstract

Changes of unsteady multiphase fluid flow patterns of liquid steel during electric arc furnace-ladle tapping operations, with simultaneous argon bottom injection, are simulated using interfacial tracking computing techniques. The impinging steel jet interacts with the argon bubbling plume, suffering mutual bending effects, and imparting non-symmetric flows of liquid steel during the whole ladle filling time. At low bath levels, radial recirculating flows are generated and at high bath levels, these flows are substituted by vertical long flows generated by the permanent interaction between the impinging jet and the argon plume. Turbulence intensity increases as the bath level rises. Low bath levels are suitable for pre-melting and preheating ferroalloy particles. High bath levels of steel in the ladle, close to total ladle filling, are the most suitable conditions for thermal and chemical homogenizations. Argon gas forms an intermittent blanket over the air–liquid steel mix due to its higher density than air during the whole ladle filling time.

1. Introduction

Steel tapping is the most important operation of the steelmaking process. An optimum tapping must include features such as a compact steel jet from the eccentric bottom tapping (EBT) system, an optimum timing of fluxes and alloying additions, suitable sizes of ferroalloys and steel temperature, and minimization of slag carry over into the ladle. A successful tapping yields maximum efficiency of deoxidants and alloying elements, low pickups of nitrogen and oxygen from the surrounding air and fast slag formation, making the ladle ready for its transport to the ladle furnace. Once in this unit, steel is refined, its final chemistry is adjusted, and the floatation of inclusions is carried out using gentle argon stirring conditions. Any misstep in this operation will have a charge in the process like longer refining times with larger energy consumptions, higher consumptions of deoxidants and, eventually, dirtier steel. Fluid flow dynamics of steel during tapping had been analyzed by Guthrie et al. [1] and Tanaka et al. [2] using water and numerical (one-phase flow) models and reported the velocity fields and trajectories of particles during the ladle filling. According with these authors, buoyant additions, such as aluminum and Fe-Si, are hardly affected by the flow pattern of steel since buoyancy force is so large that the dynamic behavior of these particles does not change, even when compared with conditions of particles in a stagnant liquid. The reverse is true for denser particles, whose trajectories are strongly influenced by fluid flow dynamics having, consequently, better alloying efficiencies. The penetration of either, dense or light additions is improved when they are injected close or in the plunging steel jet. Rodriguez et al. [3] reported mathematical simulations of velocity fields through a multiphase numerical model. These authors reported trajectories of particles of ferroalloys such as Fe-Si, Fe-Nb, Al and Fe-Mn defining the optimum locations and bath height to maximize their residence time in the melt. Berg et al. [4] reported computed fluid dynamics (CFD) simulations of fluid flow and alloy dissolution during steel tapping. Further efforts in the direction to model physically plunging steel jets using water jets including the dragging effects of air on the flow have been reported by Hammad [5] using Particle Image Velocimetry (PIV) measurements and Iguchi et al. [6] employing Laser Doppler Velocimetry (LDV) measurements. They found that two-phase flow dynamics are overly sensitive to ambient perturbations, such as free surface instability and external vibrations. On the other hand, LDV measurements were not possible in the developing region of the two-phase flow.

The characteristic of all those works is that none of them reported the multiphase interaction of the impinging steel jet with the simultaneous bottom argon injection to provide additional pneumatic stirring to the bath for enhancing alloy dissolution and chemical and thermal homogenizations. Hence, the focus of the present work is to study the influence of the simultaneous actions of the impinging jet of steel and the bubbling plume of argon on the fluid dynamics of liquid in steel during the ladle filling time. The velocity fields under these conditions will be employed to study the trajectories and dynamic of melting of alloying particles during steel tapping in future works.

2. The Mathematical Model

2.1. Model Assumptions

This model is elaborated under the following assumptions:

- The system is considered isothermal and then, there is no need to solve the equation for energy transport. The temperature of the system is 1620 °C. Argon stirring proved to be effective to decrease large temperature gradients of liquid steel existing after a relatively long stand still time of the ladle, in just only three seconds [7,8] of stirring. Therefore, with the combined effect of the impinging jet and the argon stirring, the temperature gradients are negligible.

- The previous assumption involves, implicitly, that the buoyancy forces are negligible compared with the inertial forces. The validity of this assumption is based on the work of Berg et al. [4] who previously simulated the flow patterns under non-isothermal and non-isothermal conditions without finding any signifying differences of the flow patterns of steel.

- The physical properties of the steel, argon and air were evaluated at the film temperature (average between room and liquid steel temperatures).

- As a first approach to deal with this complex flow, the effects of additions such as ferro-alloys and fluxes on the flow patterns are not considered. Therefore, only the gaseous and liquid phases are involved in these simulations.

- According to Iron thermodynamics [9] the solubility of air and argon in liquid steel is negligible implying that there is not mass transfer among the phases.

- The impinging jet of steel has a compact structure. This assumption is reasonable if the EBT system is clean of debris, this is true specifically when the sleeve is new.

- Strictly speaking, air and argon form a gaseous phase. However, since the densities are different, in this work both gases are considered as different phases by using a jumping boundary condition at the argon-air interphases. This trick will allow for tracking the segregation of argon inside and outside the bath.

The physical properties for each gas and liquid steel employed in the model are reported in Table 1 and the specific conditions of the tapping process are summarized in Table 2.

Table 1.

Physical properties of the phase in the tapping operations.

Table 2.

Tapping conditions of liquid steel from furnace to ladle.

2.2. Dynamics of the Multiphase Flow

In the study of dynamics of multiphase flows, it is very important to track the interfaces related with their location in the 3D domain and their evolution with time. Hence, to simulate the dynamics of the multiphase flow during steel tapping the volume of fluid (VOF) model, which is one of the most effective for this purpose, is employed in the present work. In this model, the volume fraction of one of the fluids is defined by the volume averaged [10,11] of the phase indicator

according to,

The phase indicator must fulfill the next constraints:

At any interface, the gradient of this indicator is defined by,

where is the unit external vector pointing toward the bulk of phase q,

is Dirac’s delta function, the coordinates in the bulk phase are

are the coordinates of the interfaces. The model employs only one set of continuity and momentum transfer equations according to,

Differential Equations (4) and (5) are solved simultaneously for the respective partial differential equations for the balances of the turbulent kinetic energy, k, and its dissipation rate, ε, embedded in the model of turbulence k-ε [12,13]. The k-ε model is solved in the bulk of phase q and at the interfaces, jump boundary conditions are applied. At the interface, jump-boundary conditions for momentum transfer are expressed as:

The velocity um is a kind of representative velocity for all phases involved in the system or what may be called the velocity of the mixture of phases. The velocity field, um, is employed to solve the advection equation for the transport of the volume fractions of each phase as is explained below.

The evolution of the volume fraction function in time and space is determined by a scalar advection equation for the

phases (as the sum of all volume fractions should be equal to one):

The explicit discretized expression for solving the advection Equation (7) is given as:

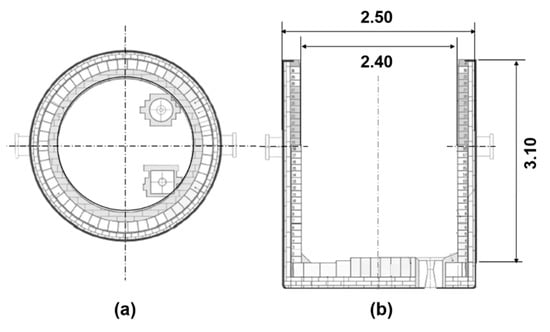

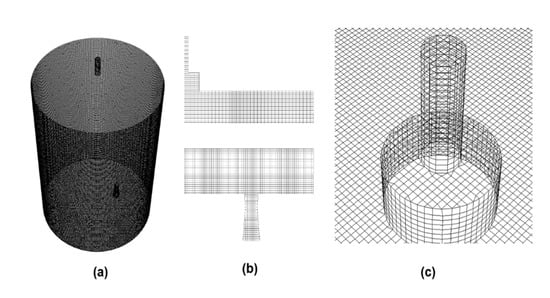

The drawback of the VOF model is just to solve the system of Equation (9) for the advection of the volume fractions preserving the conservation of mass. The difficulties arise because the conventional differencing schemes for the convection term, which guarantee the volume fraction field obeying the physical bounds on zero and unity, smear the step profile of the interface over several mesh cells due to numerical diffusion. This is particularly a severe problem when using an upwind scheme. To overcome this condition, the second upwind discretization scheme [14,15] was applied to discretize Equation (9). In addition to using the 2nd upwind discretization, a piecewise linear interface construction method was applied to reconstruct the interfaces as proposed by Youngs [16]. The geometric features of ladle are shown in Figure 1. An inlet velocity boundary condition was applied for the argon gas. The computation mesh consisted of 3,344,679, hexahedral cells with maximum aspect ratio of 12.99 and maximum ortho-skewness of 0.631 and a minimum orthogonal quality of 0.153. The method of gradient [15] was used for the interpolation of the flow variables between the centers of the computational cells and their respective faces. Figure 2 shows the computational mesh employed for the solution of the system of partial differential equations.

Figure 1.

Geometry of the ladle furnace (m). (a) Top view, (b) Frontal view.

Figure 2.

Computational mesh employed to solve the equations of the mathematical model through the finite volume scheme. (a) At the wall, (b) Center plane top and bottom side, (c) At inlet of steel.

2.3. Boundary Conditions

At all solid surfaces, in the bottom and wall of the ladle and in the internal wall of the EBT sleeve, a no-slip condition of velocity was applied. The logarithm law function [17] was applied to relate the step velocity gradients in the boundary layer with the outer velocities. A velocity profile obeying the 1/7 law [18] implemented as a user defined function was applied inside the sleeve of the EBT. From the tip of the EBT to the top of the bath, height h, the velocity of the melt was calculated as , where vt is the velocity profile at the tip. Each vector was later modified by adding

and the resulting profile is employed as an input of velocity in the melt surface. On the bath surface a pressure boundary condition was applied equal to 101,000 Pa. At the ladle bottom, in the argon plug, a velocity boundary condition was applied.

2.4. Method of Solution

The segregated-finite volume method was employed to solve each one of the equations of momentum and the respective equations of the turbulent kinetic energy and its dissipation rate embedded in the k-ε model of turbulence under unsteady state conditions using the commercial software ANSYS Fluent® version 17 [15]. The PISO [19] algorithm was applied, in the segregated scheme for linking the pressure-velocity coupling. The extrapolation of the variables in the center of a cell to its surface, to calculate the fluxes, was carried out using the gradient of each variable evaluated at the cell centroid. The numerical convergence was attained when the sum of the residuals for the flow variables was less than 10−4.

3. Results and Discussion

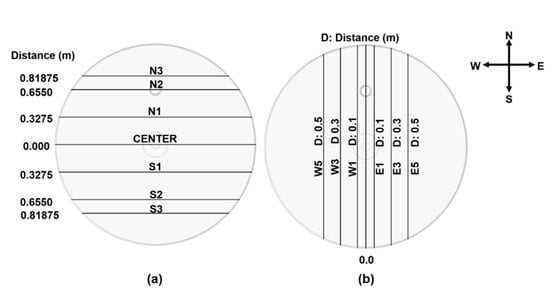

To describe the flow patterns, different vertical planes were selected as is indicated in Figure 3a,b located in sectors north (N) where the argon plug is located, south (S) in the lower side and west (W) and east (E) sides. The velocity fields in the vertical planes examined here are located at both sides of the plane of symmetry, in the side or sector of the porous bottom (N) and in the opposite side (S), as is indicated from the top views of Figure 3a. Some perpendicular planes to the N-S sector, in the W-E sector were also examined, as is indicated in Figure 3b.

Figure 3.

(a) Planes examined in the mathematical model in the North and South sectors. (b) Planes in the East and West sectors. Numbers in the planes indicate their distances from the plane of symmetry of Center plane.

Figure 4 show the velocity fields in the Central plane (these fields in the center of symmetry are the same as in the views from the N and S sectors at different steel levels of 16, 30, 50, and 80 tons in the ladle. The interface between steel and air is delineated by the region where the jet splashes.

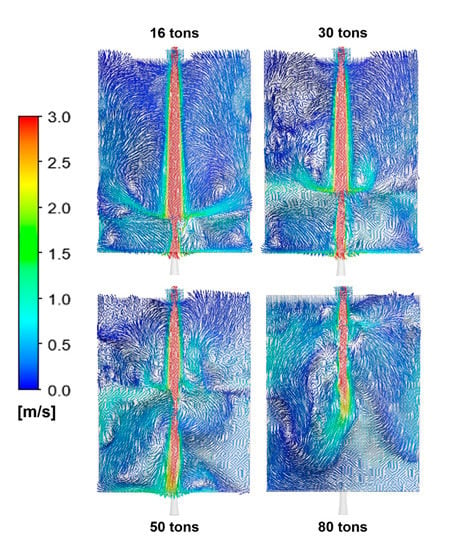

Figure 4.

Velocity profiles in the symmetry-impinging planes (Central plane) at different bath levels in the ladle with simultaneous argon bottom stirring.

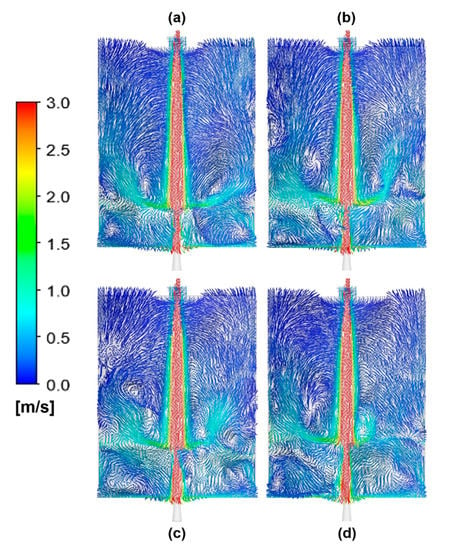

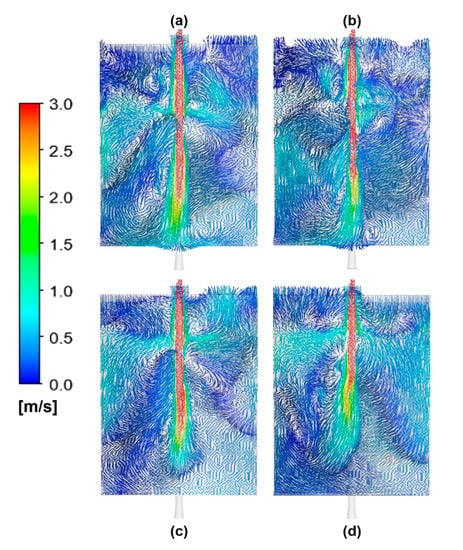

A dragging boundary-layer of air is produced on the surface of the falling liquid jet of steel due to the high momentum transferred from the liquid phase to the surrounding air. These volumes of dragged air are partially entrained in the melt increasing, eventually, the pickups of oxygen and nitrogen in the actual melting shop. The impinging jet losses momentum and as the bath level increases, the penetration in the bath is shallower. At low bath levels, the column of argon bubbles has small effects on the velocity patterns and increasing the liquid volume leads to a biasing or bending of the impinging jet due to the ascending motion of the argon-liquid steel (two-phase) plume. At medium and high levels of liquid (50 and 80 tons) the momentum transfer between the impinging jet and the plume promote turbulent vertical-recirculating flows. However, low velocity regions are generated in the corners between the body and the bottom of the ladle. Figure 5a–d show the changes of flow patterns at low steel levels (the time difference between each image is 10 s) and Figure 6a–d show the corresponding velocity fields at high steel levels under unsteady state conditions in the same plane of symmetry or the central plane (the time difference between each image is 20 s). In the first case, the flow is characterized by small rotating flows in the ladle corners due to the small bath height. At high steel levels, the impinging jet inside the let oscillates due to the intermittent effect of the plume, inducing larger recirculations along the bath height and leaving unsteady regions of low velocity.

Figure 5.

(a–d) Unsteady fields of velocity in the central plane during ladle filling from 16 to 30 tons. Each figure shows a time step of 10 s.

Figure 6.

(a–d) Unsteady fields of velocity in the central plane during ladle filling from 50 to 80 tons. Each figure shows a time step of 20 s.

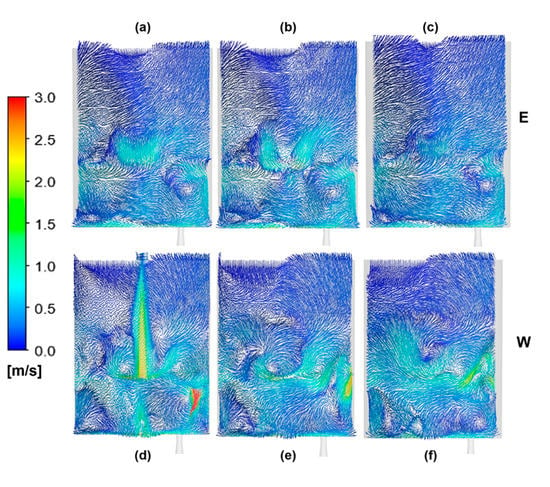

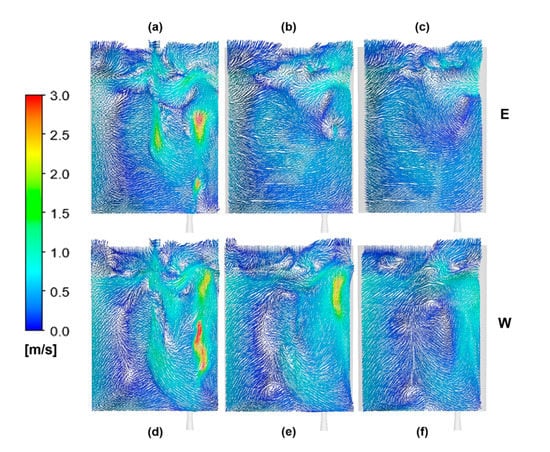

Sectors W and E yield asymmetric flows as is seen in Figure 7 and Figure 8 for the vertical planes E1, E3, E5, and W1, W3, and W5 and bath levels of 30 and 80 tons, respectively.

Figure 7.

Velocity fields in planes East and West sectors at a bath level of 30 tons. (a–c), correspond to the East sector, respectively. (d–f), correspond to the West sector, respectively.

Figure 8.

Velocity fields in planes East and West sectors at a bath level of 80 tons. (a–c), correspond to the East sector, respectively. (d–f), correspond to the West sector, respectively.

The jet is slightly biased toward the plane W1, for a bath level of 30 tons, Figure 7, as can be seen by comparing this flow field with the opposite plane E1. The argon plume is pushed by the stream of steel formed after the impacting of the entry jet with the ladle bottom and part of the biased region of this plume can be seen in the bottom of the right side of plane W1. Comparing planes E3-W3 and E5-W5, it becomes evident that planes W contain velocities slightly larger than those contained in planes E emphasizing that this result comes from the interaction between the jet of steel and the argon plume. When the steel level is at its maximum (80 tons), the flow patterns in sectors W and E suffer radical changes since the bath height can hold larger turbulent fluid flow eddies. The proximity of the impinging jet of steel to planes W1 and E1 together with the combined effect of the argon plume provides highly turbulent flows and it is, probably, the best condition for alloy melting, dissolution, and dispersion processes of the ferroalloys. When the ferroalloys are added at lower bath levels, like that shown in Figure 7, the turbulence is considerably smaller and at this stage heating process, steel shell formation on the surface of these particles can be expected with poor or even without mixing and homogenization. As the bath level increases during the ladle filling, the steel shell (surrounding the ferroalloy particle) remelting processes and ferroalloy particle melting proceeds until reaching the stage of high mixing and chemical homogenization. However, it is a fact that the trajectories and residence times of particles of ferroalloys are considerably dependent of their ratio of densities with respect of the density of liquid steel, the bath height and position in the ladle where they are added [1,2,3,4]. As the intuitiveness would indicate, high levels of turbulence are helpful to melt, dissolve and homogenize the alloying elements in liquid steel. Hence, a flow variable useful to quantify the turbulence level, at macroscopic levels, is the turbulent viscosity calculated through the fields of the turbulent kinetic energy and its dissipation rate {12} as,

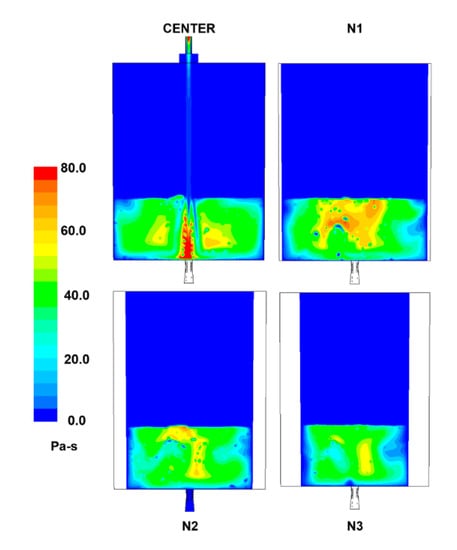

Figure 9 shows the turbulent viscosity contours for planes Central, N1, N2 (corresponds to the plane where the argon plug is located), and N3, respectively, at a bath level of 30 tons. Figure 10 shows the turbulent viscosity contours for planes S1, S2, and S3.

Figure 9.

Fields of Turbulent viscosity (Pa-s) in planes of the North sector at a bath level of 30 tons.

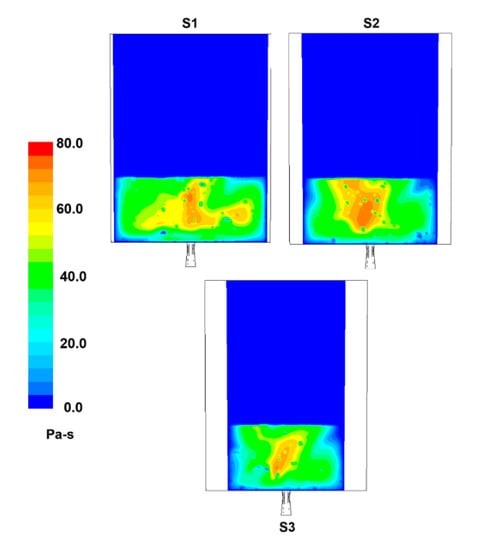

Figure 10.

Fields of Turbulent viscosity (Pa-s) in planes of the South sector at a bath level of 30 tons.

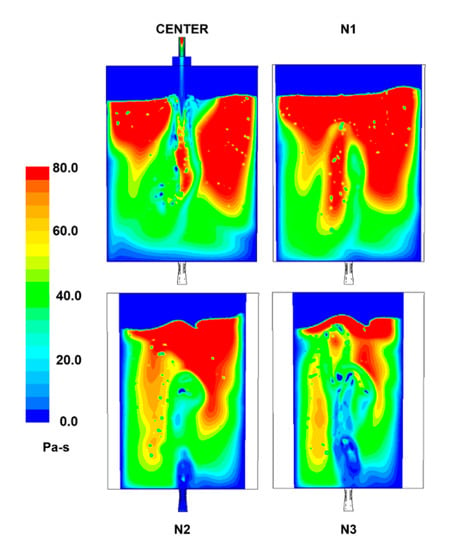

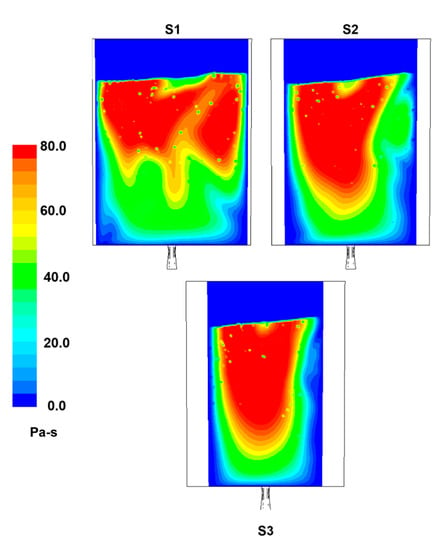

The viscosity pattern in central plane, reports high levels of turbulence in the immersed liquid jet and its surroundings. Planes N1 and S1 have, apparently similar levels of turbulence. Observing the turbulence viscosity fields in planes N2 and S2 it is seen that the turbulence level is slightly higher in plane S2 which is just the counterpart of plane N2 where the argon plug is located. The reason for this result is due to deviation of the argon plume by the flows of liquid steel streams generated by the impinging jet impacting on the ladle bottom. Due to this very reason, the turbulence level in the plane S3 is slightly higher than in the plane N3. The overall level of turbulence at this bath level of 30 tons has essentially intermediate levels between 30 and 60 Pa-s, which corresponds to relatively short length eddies dominated by the short bath level. When the bath level increases up to 80 tons, a considerable fraction of the volume of liquid in the ladle reaches the highest levels of turbulence of 80 Pa-s. Indeed, Figure 11 and Figure 12 show the turbulent viscosity in planes center plane, N1, N2, and N3 in the first figure and in the planes S1, S2, and S3 in the second figure. The levels of turbulence, interpreted through the turbulent viscosity, are similar in the pairs of planes N1/S1. However, comparing the pairs of planes N2/S2 and N3/S3 it results evident that the volumes of liquid with the highest level of turbulence are in the South sector. As mentioned before, the asymmetric flows between sectors N and S come from the interaction between the impinging jet with the argon plume. In a broad view, comparing Figure 11 and Figure 12 with Figure 9 and Figure 10, it is again corroborated that, in the large bath levels, the turbulence is larger, and these are the conditions appropriated for thermal and chemical homogenization of the bath.

Figure 11.

Fields of Turbulent viscosity (Pa-s) in planes of the North sector at a bath level of 80 tons.

Figure 12.

Fields of Turbulent viscosity (Pa-s) in planes of the South sector at a bath level of 80 tons.

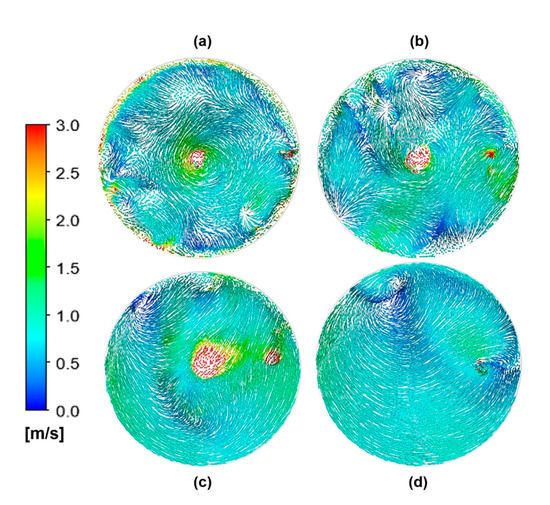

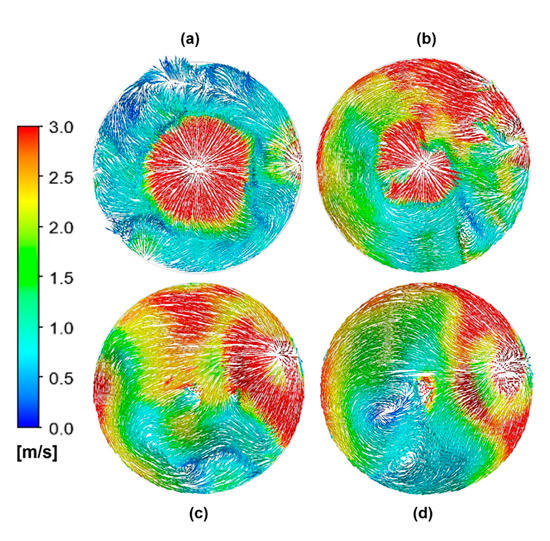

Other important views of the flow patterns in steel tapping correspond to the regions close to the ladle bottom. Figure 13a–d, show the velocity fields in a horizontal plane at a level of 0.20 m from ladle bottom at the bath levels of 16, 30, 50 and 80 tons, respectively. At low bath levels, the flow patterns consist of recirculating flows around the impinging jet together with radial and vortexing flows, with medium and small magnitudes of velocities in regions approaching to ladle wall. At high bath levels, the impinging jet together with the argon plume induce rotating and peripherical flows. Figure 14a–d show the velocity fields in a plane located 0.1 m below the bath surface at bath levels of 16, 30, 50 and 80 tons, respectively. At the lowest bath level, there are large and small radial flows around the proximities of the impinging jet and the argon plume, respectively. At a level of 30 tons, the impinging jet maintains a radial flow around its entry region while the bending effect of the argon plume induces a rotating-peripherical flow. At higher bath levels such as 50 and 80 tons, and at this later plane in particular, the argon plume forms radial flows influencing mostly the flow pattern. There are also vortexing flows in regions which are close to the ladle wall.

Figure 13.

Velocity fields in a horizontal plane located 0.20 m from the ladle bottom at different bath levels: (a) 16 tons, (b) 30 tons, (c) 50 tons and (d) 80 tons.

Figure 14.

Velocity fields in a horizontal plane located 0.10 m from the bath surface at different bath levels: (a) 16 tons, (b) 30 tons, (c) 50 tons and (d) 80 tons.

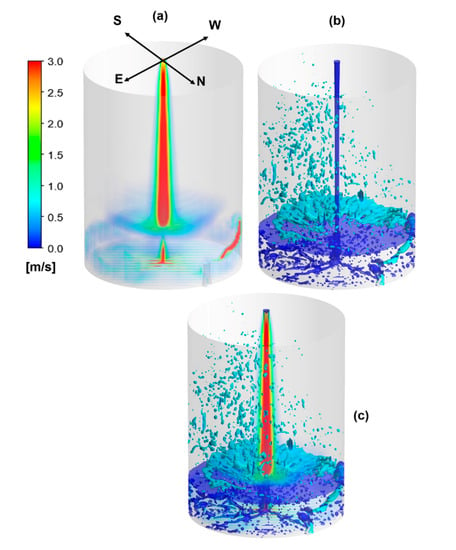

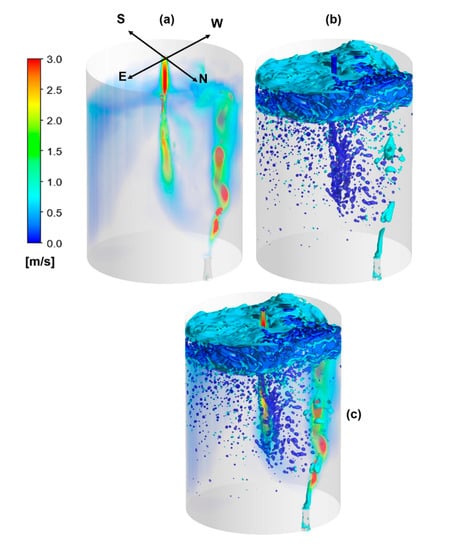

Overviews of the interface argon–air, velocity of interfaces, and a 3D view of the velocity field for a bath level of 16 tons are shown in Figure 15a–c, respectively. The difference of density between argon and air (which is denser than air) leads to the formation of a blanket layer on the bath surface over a mixture of steel and air which is dragged and entrained inside the bath by the liquid jet. In these figures is seen that the streams of liquid steel formed by the impact of the impinging jet on the ladle bottom biases and bends the argon plume. Figure 16a–c are the corresponding overviews at the level of 80 tons for interface argon–air, velocity of interfaces, and a 3D view of the velocity field, respectively. The argon, from the plume, ascends through the bath height and once reaching the bath surface, a thick blanket of this gas is accumulated on the opposite side of the ladle. A small portion of the argon accumulated on the bath surface is entrained together with the atmospheric air by the impinging jet, dragging both gases inside the bath. The interaction between the impinging jet and the argon plume results in a permanent bending of the entry jet with a biased plume. This effect results in the generation of high turbulence, particularly in the South sector of the ladle, opposite to the North sector where the argon plug is located. The level of turbulence related with the height of the bath and the specific position for the addition of ferroalloys have effects with the speed of melting and mixing kinetics of the alloy elements.

Figure 15.

(a) 3D view of the velocity field (b) Dynamics of Interfaces air-argon, (c) 3D view of the velocity with interface air-argon. Bath level of 36 tons.

Figure 16.

(a) 3D view of the velocity field (b) Dynamics of Interfaces air-argon, (c) 3D view of the velocity with interface air-argon. Bath level of 80 tons.

Finally, regarding the validity of these simulations, it is suitable at this point to reinforce the findings presented here. The argon plume dynamics in a bottom stirred ladle was studied using a water model [20]. The velocities of the water in the spout of the plume were measured using ultrasound techniques. Later, the velocity of the plume was simulated, in a water model of the same ladle, through two multiphase mathematical models; the VOF model and the population balance model (PBM) supported by the Eulerian–Eulerian two-phase model. This later model predicted the upper and lower bounds of velocity along the plume height corresponding to the liquid and gas phases, respectively. The VOF model, which provides a single velocity of the two-phase flow in the plume, predicted ups and downs of velocity which corresponded very closely to the bounds predicted by the PBM-Euler model (Figure 5b of reference [20]). Both models matched the measurements of velocity. Therefore, the agreement of mathematical predictions of the VOF model with the PBM–Euler model and the experimental measurements of velocity validate that this model is fully applicable to an actual ladle under the assumptions explained above.

4. Conclusions

The velocity fields of liquid steel during tapping operations considering the simultaneous effects of the imping jet and the argon plume from the ladle bottom were simulated using the multiphase Volume of Fluid model and from the results the following conclusions are drawn:

- At low liquid steel levels in the ladle, the flow turbulence is smaller than at high steel levels. A tall bath allows larger recirculations of the flow, enhancing the transport of kinetic energy, enhancing the turbulence of the system.

- The eccentric position of the argon plug in the ladle bottom and the impinging jet interact in such a way that the melt streams formed after impacting the ladle bottom bend the argon plume inducing asymmetric flows throughout all the liquid volume at any bath level.

- The bending effect of the imping jet and the resultant deviation of the argon plume remain during the full time of the ladle filling operation. Besides the unsteadiness of the velocity fields of this complex flow is a clear indication of the existing potential for particle melting and thermal and chemical mixing during steel tapping.

- The argon bubbles travel all the plume height in the plume and when it reaches the bath surface, this gas is dragged to the opposite side to where the plug is located forming a thick blanket of this gas covering a superficial mixture of steel and air. Due to the higher density of argon than air, it is concluded that this blanket decreases the direct contact between air and steel during the ladle filling operation.

- Part of the argon, forming the blanket, is dragged inside the bath bulk by the impinging jet. These results encourage further simulations aimed at the optimization of the steel tapping operation, which is not a trivial issue.

Author Contributions

Conceptualization: R.D.M.; Methodology: R.D.M. and A.N.-B.; Software: J.R.-Á., J.G.-G. and A.N.-B.; Formal analysis: R.D.M. and A.N.-B.; Investigation: R.D.M.; Supervision: R.D.M. and K.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Consejo Nacional de Ciencia y Tecnología (CoNaCyT), SNI and University of Toronto.

Acknowledgments

The authors give the thanks to the institutions IPN, University of Toronto, SNI and CoNaCyT for their support to the Process Engineering Groups.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Cμ | Constant in the turbulence model |

| H | radius of curvature |

| I k | Identity matrix |

| k | kinetic energy |

| t | time |

| u | velocity |

| V | Volume |

| α | volume fraction |

| ε | dissipation rate of kinetic energy |

| μ | viscosity |

| ρ | density |

| σ | surface tension |

| T | strain stress |

| Χ | phase indicator |

| q | phase |

| m | mixture |

| n | normal |

| I | interface |

References

- Guthrie, R.I.L.; Clift, R.; Henein, H. Contacting problems associated with aluminum and ferro-alloy additions in steelmaking-hydrodynamic aspects. Met. Mater. Trans. B 1975, 6, 321–329. [Google Scholar] [CrossRef]

- Tanaka, M.; Mazumdar, D.; Guthrie, R.I.L. Motions of alloying additions during furnace tapping in steelmaking processing operations. Met. Mater. Trans. B 1993, 24, 639–648. [Google Scholar] [CrossRef]

- Rodríguez-Ávila, J.; Morales, R.D.; Nájera-Bastida, A. Numerical Study of multiphase Flow dynamics of plugging jets in liquid steel and trajectories of ferroalloy additions in a ladle during tapping operations. ISIJ Int. 2012, 52, 814–822. [Google Scholar] [CrossRef]

- Berg, H.; Laux, H.; Johansen, S.T. Flow pattern and alloy dissolution during tapping of steel furnaces. Ironmak. Steelmak. 1999, 26, 127–139. [Google Scholar] [CrossRef]

- Milanovic, I.; Hammad, K.J. PIV Study of the Near-Field Region of a Turbulent Round Jet. In Proceedings of the ASME 2010 3rd Joint US-European Fluids Engineersing Summer Meeting and 8th International Conference on Nanochannels, Microchannels and Minichannels, Montreal, QC, Canada, 1–5 August 2010. [Google Scholar]

- Iguchi, M.; Okita, K.; Yamamoto, F. Workshop on multicomponent and multiphase flow dynamics. Int. J. Multiph. Flows 1998, 24, 523–537. [Google Scholar] [CrossRef]

- Dávila, O.; García-Demedices, L.; Morales, R.D. Mathematical simulation of fluid dynamics during steel draining operations from a ladle. Met. Mater. Trans. B 2006, 37, 71–87. [Google Scholar] [CrossRef]

- Grip, C.E.; Jonsson, L.; Jonsson, P.; Jonsson, K.O. Numerical prediction and experimental verification of thermal stratification during holding in pilot plant and production ladles. ISIJ Int. 1999, 39, 715–721. [Google Scholar] [CrossRef]

- Darken, L.S.; Gurry, R.W.; Bever, M.B. Physical Chemistry of Metals; McGraw-Hill Books: New York, NY, USA, 1953; pp. 372–395. [Google Scholar]

- Jakobsen, H.A. Chemical Reactor Modelling; Springer: New York, NY, USA, 2014; pp. 300–389. [Google Scholar]

- Yeoh, G.H. Computational Techniques for Multiphase-Flows; Butterworth-Heinemann: Oxford, UK, 2010; pp. 215–232. [Google Scholar]

- Wilcox, D.C. Turbulence Modeling for CFD; DCW Industries: La Cañada, CA, USA, 2000; pp. 103–104. [Google Scholar]

- Tennekes, H.; Lumley, J.L. A First Course in Turbulence; MIT Press Journals: Cambridge, MA, USA, 1972; pp. 27–30. [Google Scholar]

- Ferziger, J.H.; Peric, M. Computational Methods for Fluid Dynamics; Springer: New York, NY, USA, 2002; pp. 72–74. [Google Scholar]

- ANSYS, Inc. Available online: www.ansys.com (accessed on 10 April 2019).

- Youngs, D.L. Numerical Methods for Fluid Dynamics; Morton, K.W., Baines, M.J., Eds.; Academic Press: London, UK, 1982; pp. 273–385. [Google Scholar]

- Chung, T.J. Computational Fluid Dynamics; Cambridge University Press: London, UK, 2002; pp. 218–220. [Google Scholar]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena; Wiley International: Hoboken, NJ, USA, 1960; p. 153. [Google Scholar]

- Issa, R.I. Solution of the implicitly discretized fluid flow equations by operator-splitting. Comp. Phys. 1986, 62, 40–65. [Google Scholar] [CrossRef]

- Morales, R.D.; Calderón-Hurtado, F.A.; Chattopadhyay, K.; Guarneros, S.J.G. Physical and Mathematical Modeling of Flow Structures of Liquid Steel in Ladle Stirring Operations. Met. Mater. Trans. A 2020, 51, 628–648. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).