Comparative Study on the Dry Sliding Friction Properties of In-Situ Micron and Submicron (Ti-V)C Reinforced Fe-Based Laser Cladding Layers

Abstract

1. Introduction

2. Experimental Materials and Methods

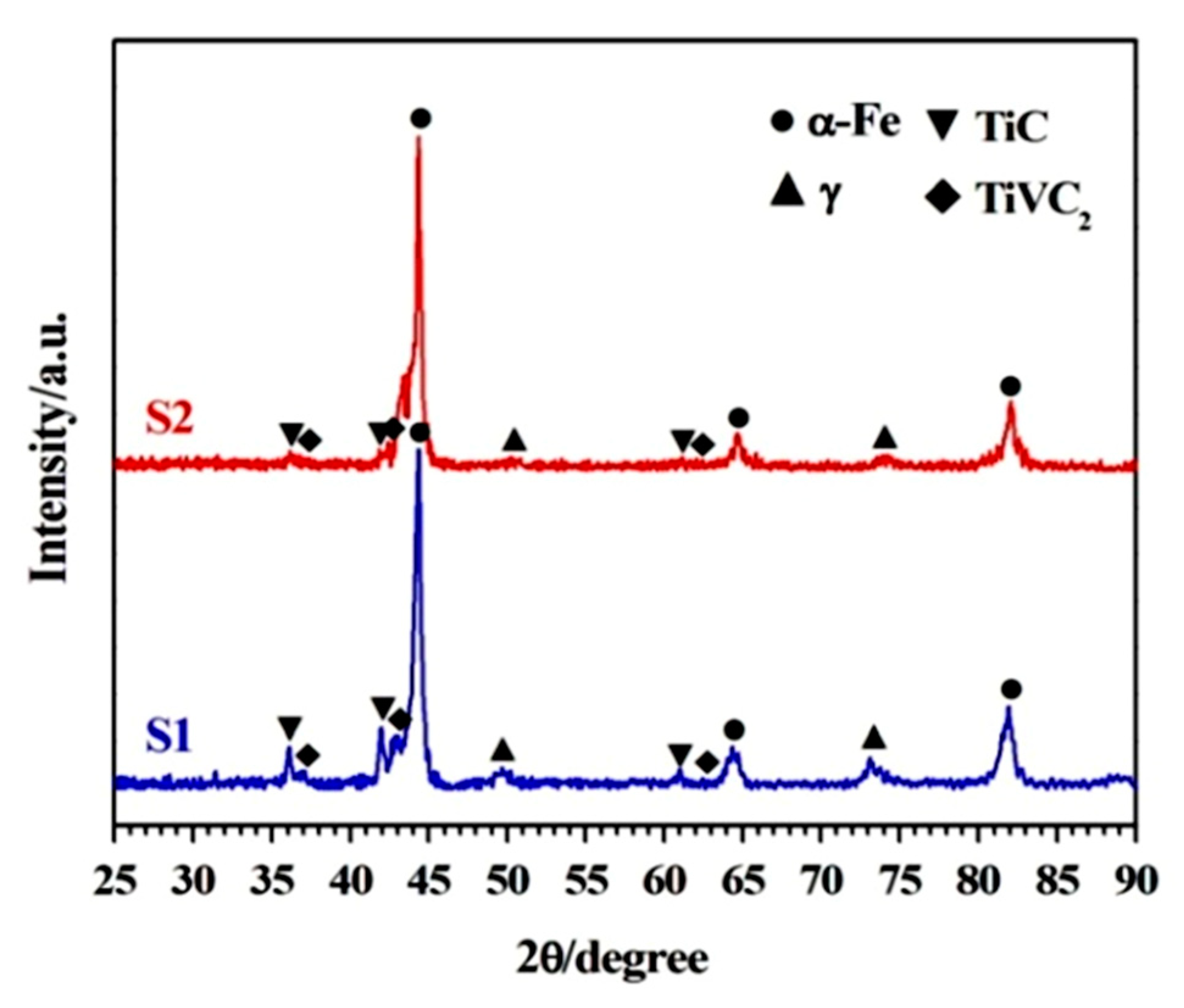

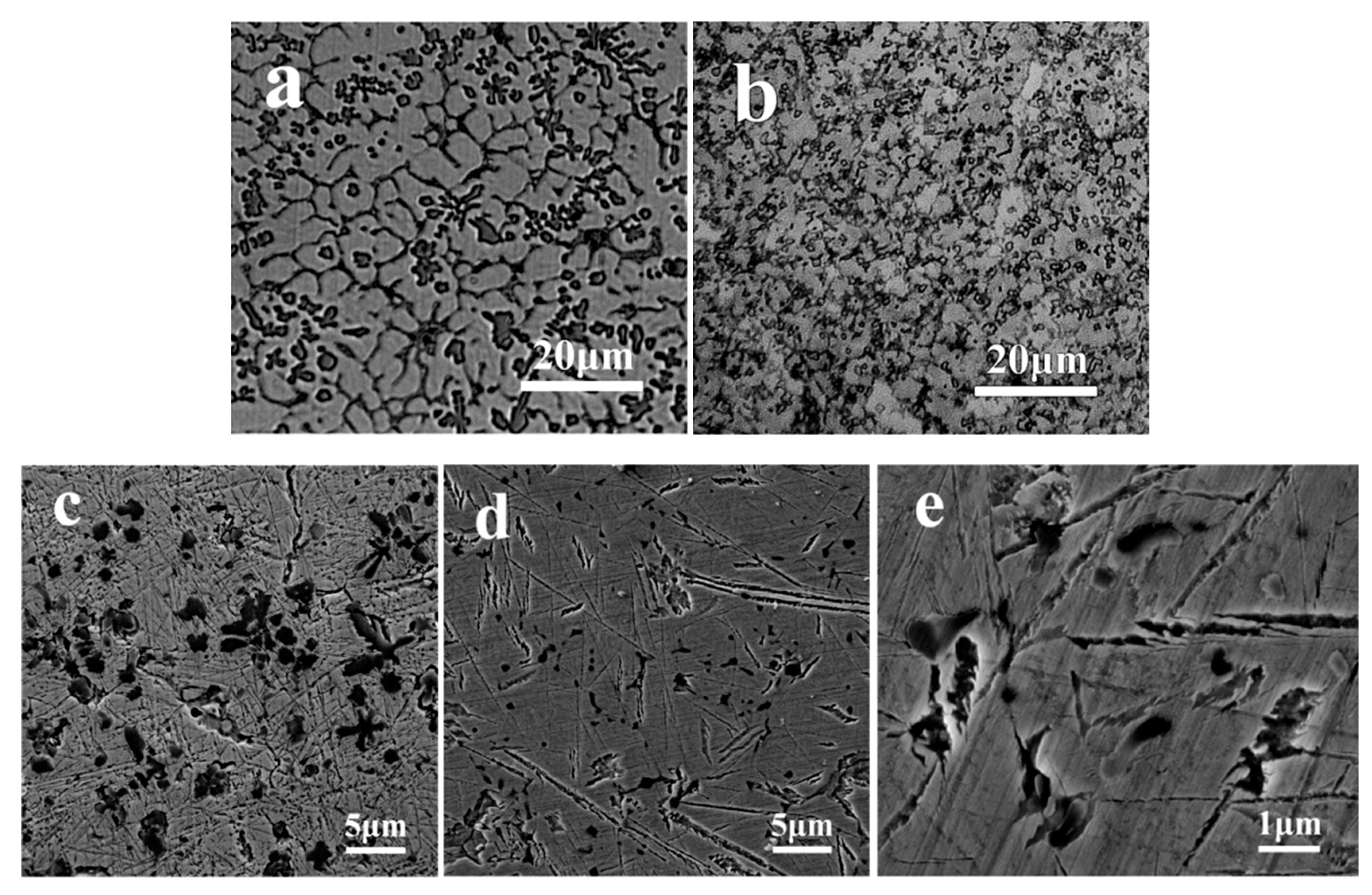

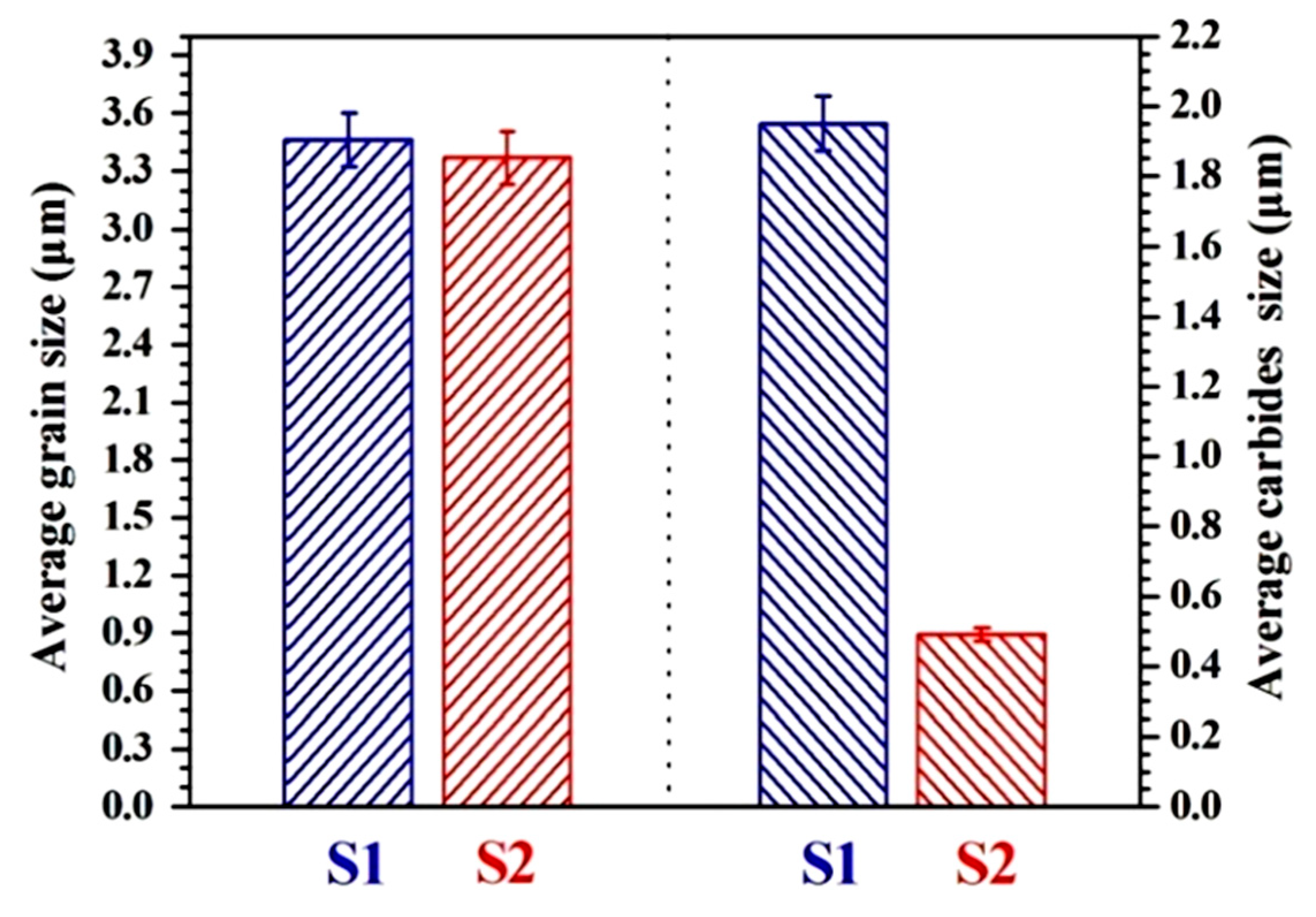

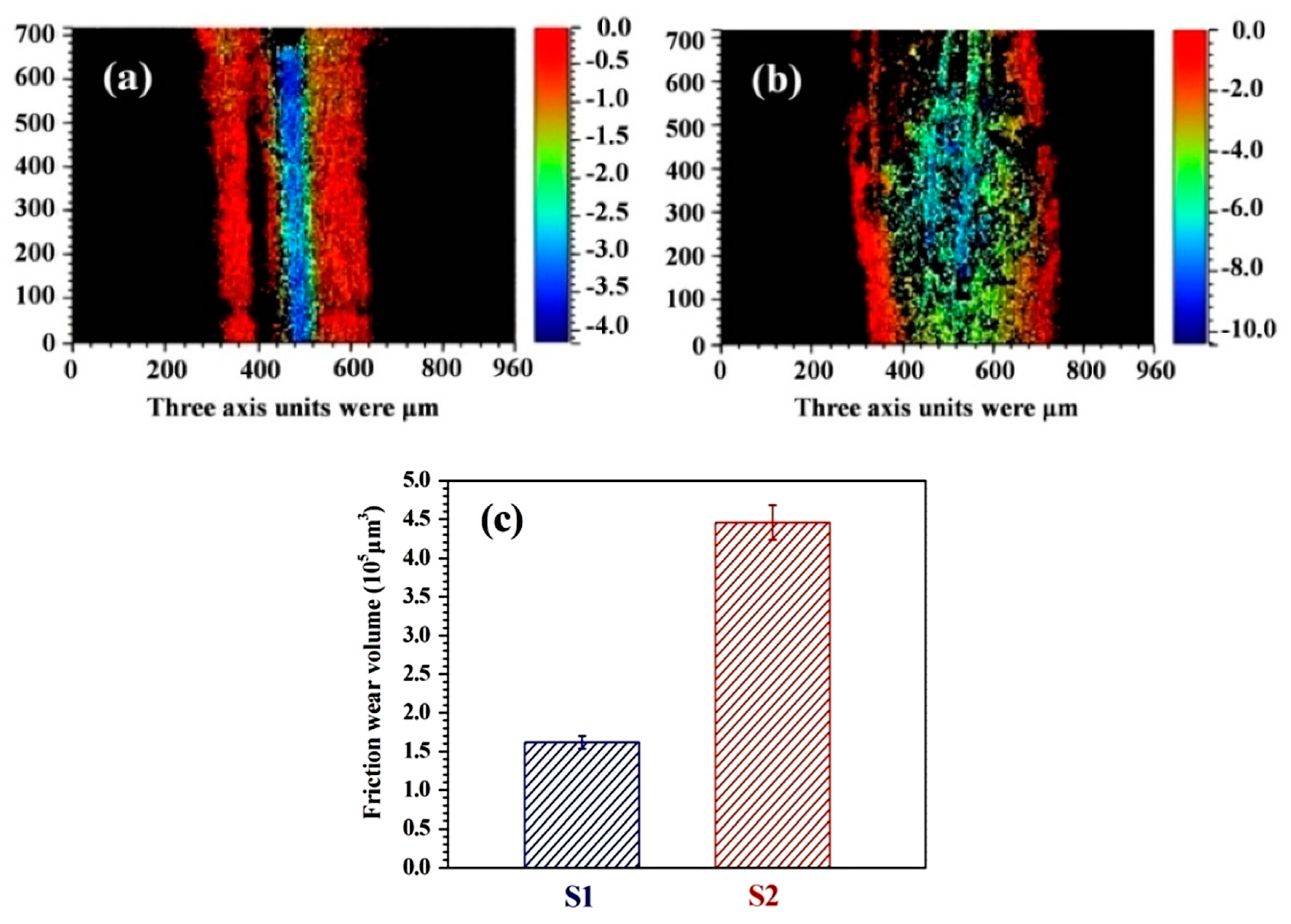

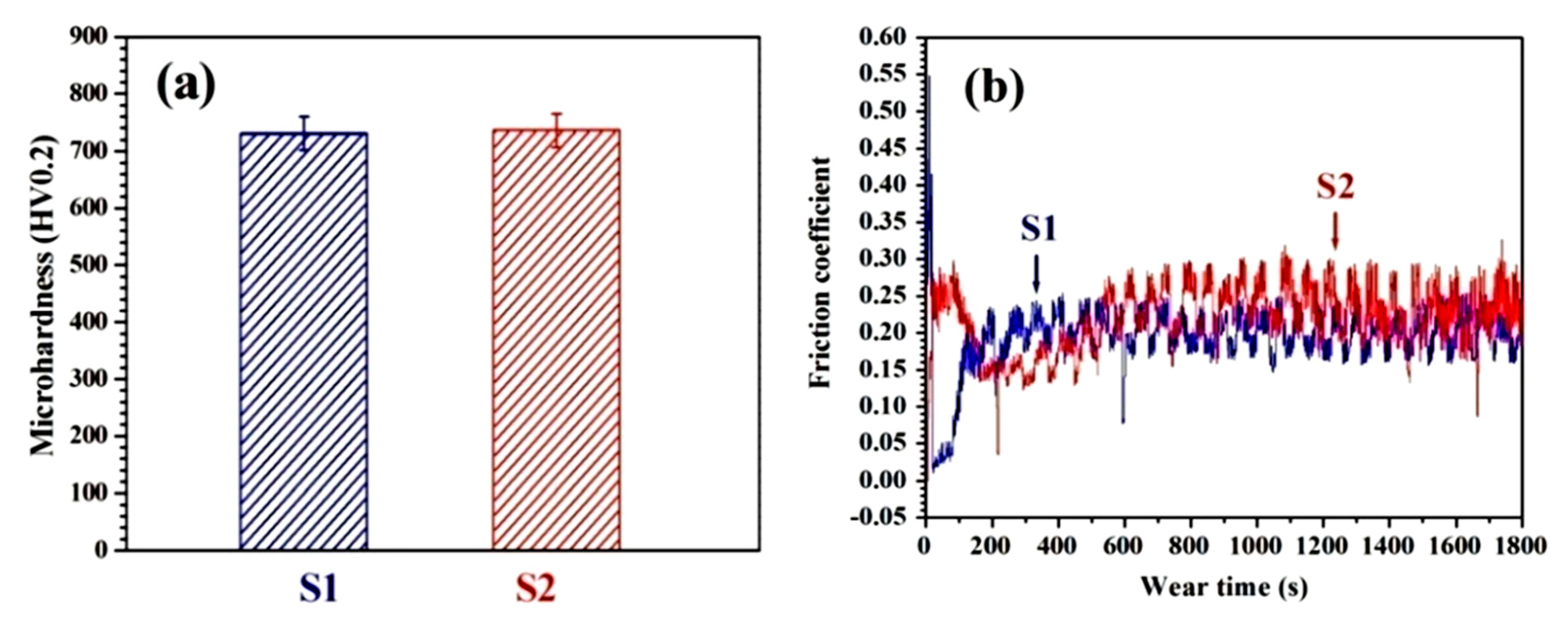

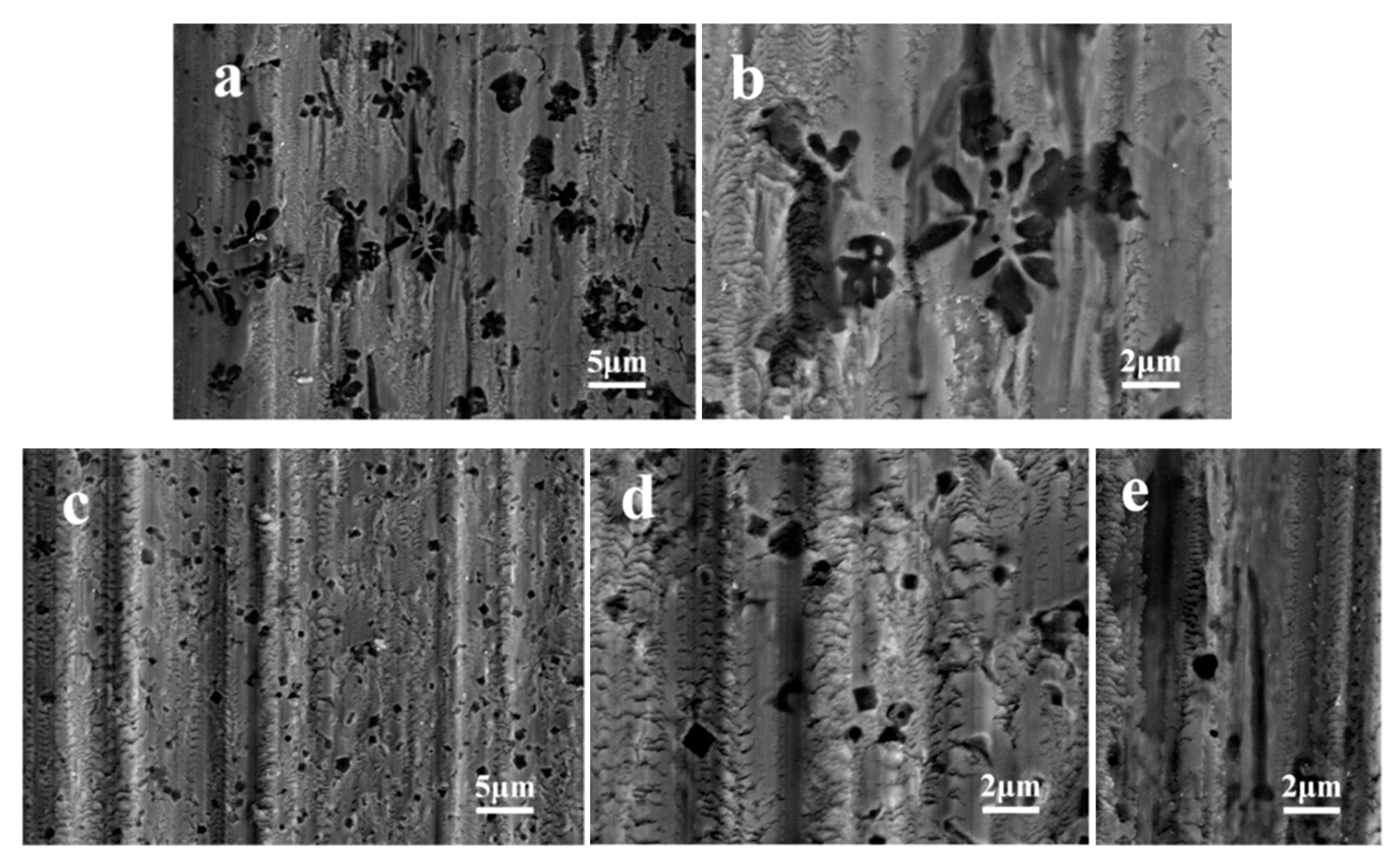

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, J.L.; Li, J.; Song, R.; Bai, L.L.; Shao, J.Z.; Qu, C.C. Effect of the scanning speed on microstructural evolution and wear behaviors of laser cladding NiCrBSi composite coatings. Opt. Laser Technol. 2015, 72, 86–99. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Y.; Shi, C.; Mao, D. Microscopic analysis and electrochemical behavior of Fe-based coating produced by laser cladding. Metals 2017, 7, 435. [Google Scholar] [CrossRef]

- Shu, D.; Cui, X.; Li, Z.; Sun, J.; Wang, J.; Chen, X.; Dai, S.; Si, W. Effect of the rare earth oxide CeO2 on the microstructure and properties of the nano-WC-reinforced Ni-based composite coating. Metals 2020, 10, 383. [Google Scholar] [CrossRef]

- Zhang, P.; Pang, Y.; Yu, M. Effects of WC particle types on the microstructures and properties of WC-reinforced Ni60 composite coatings produced by laser cladding. Metals 2019, 9, 583. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Z.; Zhao, S.; Wang, Y.; Chen, H.; Lin, X. Effect of a small addition of Ti on the Fe-based coating by laser cladding. Surf. Coat. Technol. 2016, 291, 423–429. [Google Scholar] [CrossRef]

- Ji, X.; Luo, C.; Sun, Y.; Zhao, J. Corrosive wear of multi-layer Fe-based coatings laser cladded from amorphous powders. Wear 2019, 438–439, 203113. [Google Scholar] [CrossRef]

- Li, Q.; Lei, Y.; Fu, H. Growth Characteristics and Reinforcing Behavior of In-situ NbCp in Laser Cladded Fe-based Composite Coating. J. Mater. Sci. Technol. 2015, 31, 766–772. [Google Scholar] [CrossRef]

- Li, Q.T.; Lei, Y.P.; Fu, H.G.; Wu, Z.W.; Lin, J. Microstructure and mechanical properties of in situ (Ti, Nb)Cp/Fe-based laser composite coating prepared with different heat inputs. Rare Met. 2018, 37, 852–858. [Google Scholar] [CrossRef]

- Zhang, H.; Chong, K.; Zhao, W.; Sun, Z. Laser cladding in-situ micro and sub-micro/nano Ti-V carbides reinforced Fe-based layers by optimizing initial alloy powders size. Mater. Lett. 2018, 220, 44–46. [Google Scholar] [CrossRef]

- Zhao, C.; Xing, X.; Guo, J.; Shi, Z.; Zhou, Y.; Ren, X.; Yang, Q. Micro-properties of (Nb,M)C carbide (M = V, Mo, W and Cr) and precipitation behavior of (Nb,V)C in carbide reinforced coating. J. Alloys Compd. 2019, 788, 852–860. [Google Scholar] [CrossRef]

- Zhou, S.; Xu, Y.; Liao, B.; Sun, Y.; Dai, X.; Yang, J.; Li, Z. Effect of laser remelting on microstructure and properties of WC reinforced Fe-based amorphous composite coatings by laser cladding. Opt. Laser Technol. 2018, 103, 8–16. [Google Scholar] [CrossRef]

- Fu, B.; Feng, K.; Li, Z. Study on the effect of Cu addition on the microstructure and properties of NiTi alloy fabricated by laser cladding. Mater. Lett. 2018, 220, 148–151. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L.; Dai, J.; Zhao, Z. Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J. Alloys Compd. 2017, 692, 989–996. [Google Scholar] [CrossRef]

- Tan, H.; Luo, Z.; Li, Y.; Yan, F.; Duan, R.; Huang, Y. Effect of strengthening particles on the dry sliding wear behavior of Al2O3-M7C3/Fe metal matrix composite coatings produced by laser cladding. Wear 2015, 324, 36–44. [Google Scholar] [CrossRef]

- Van Acker, K.; Vanhoyweghen, D.; Persoons, R.; Vangrunderbeek, J. Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings. Wear 2005, 258, 194–202. [Google Scholar] [CrossRef]

- Wang, H.; Gee, M.; Qiu, Q.; Zhang, H.; Liu, X.; Nie, H.; Song, X.; Nie, Z. Grain size effect on wear resistance of WC-Co cemented carbides under different tribological conditions. J. Mater. Sci. Technol. 2019, 35, 2435–2446. [Google Scholar] [CrossRef]

- Duan, X.; Gao, S.; Dong, Q.; Zhou, Y.; Xi, M.; Xian, X.; Wang, B. Reinforcement mechanism and wear resistance of Al2O3/Fe-Cr-Mo steel composite coating produced by laser cladding. Surf. Coat. Technol. 2016, 291, 230–238. [Google Scholar] [CrossRef]

- Kacher, J.; Landon, C.; Adams, B.L.; Fullwood, D. Bragg’s Law diffraction simulations for electron backscatter diffraction analysis. Ultramicroscopy 2009, 109, 1148–1156. [Google Scholar] [CrossRef] [PubMed]

- Mourlas, A.; Pavlidou, E.; Vourlias, G.; Rodríguez, J.; Psyllaki, P. Concentrated solar energy for in-situ elaboration of wear-resistant composite layers. Part I: TiC and chromium carbide surface enrichment of common steels. Surf. Coat. Technol. 2019, 377, 124882. [Google Scholar]

| Samples | Iron Powder | Ferrotitanium-Ferrovanadium Powder | Graphite Powder |

|---|---|---|---|

| S1 layer | 23–38 μm | 180–380 μm | 180–380 μm |

| S2 layer | 180–380 μm | 23–38 μm | 1.25–2.70 μm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, H.; Xiao, G.; Zhao, W.; Xu, H. Comparative Study on the Dry Sliding Friction Properties of In-Situ Micron and Submicron (Ti-V)C Reinforced Fe-Based Laser Cladding Layers. Metals 2020, 10, 742. https://doi.org/10.3390/met10060742

Liu Y, Zhang H, Xiao G, Zhao W, Xu H. Comparative Study on the Dry Sliding Friction Properties of In-Situ Micron and Submicron (Ti-V)C Reinforced Fe-Based Laser Cladding Layers. Metals. 2020; 10(6):742. https://doi.org/10.3390/met10060742

Chicago/Turabian StyleLiu, Yunpeng, Hui Zhang, Guangchun Xiao, Wei Zhao, and Hui Xu. 2020. "Comparative Study on the Dry Sliding Friction Properties of In-Situ Micron and Submicron (Ti-V)C Reinforced Fe-Based Laser Cladding Layers" Metals 10, no. 6: 742. https://doi.org/10.3390/met10060742

APA StyleLiu, Y., Zhang, H., Xiao, G., Zhao, W., & Xu, H. (2020). Comparative Study on the Dry Sliding Friction Properties of In-Situ Micron and Submicron (Ti-V)C Reinforced Fe-Based Laser Cladding Layers. Metals, 10(6), 742. https://doi.org/10.3390/met10060742