Numerical Analysis of Stress Distribution in Offshore Wind Turbine M72 Bolted Connections

Abstract

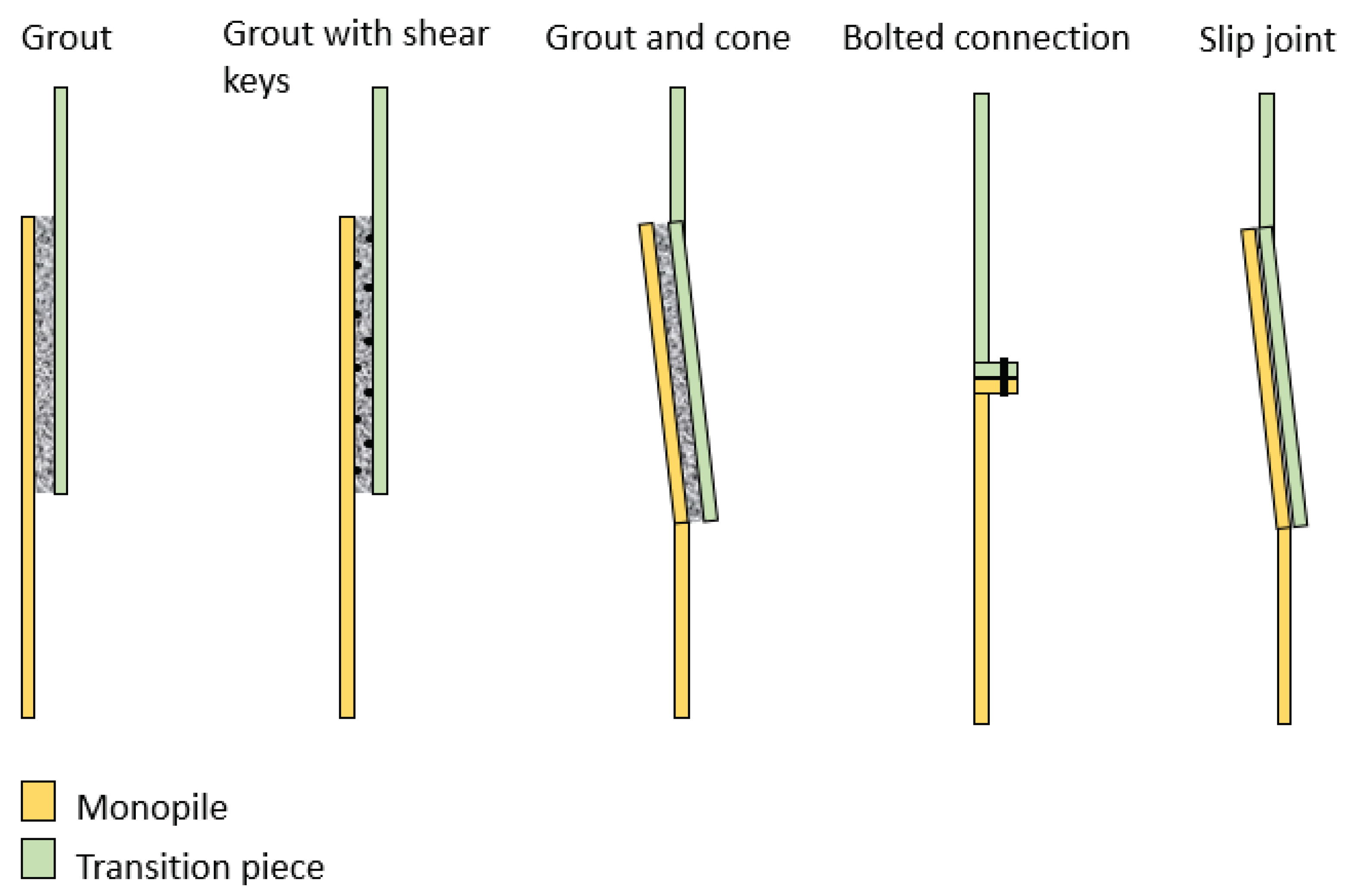

1. Introduction

2. Materials and Methodology

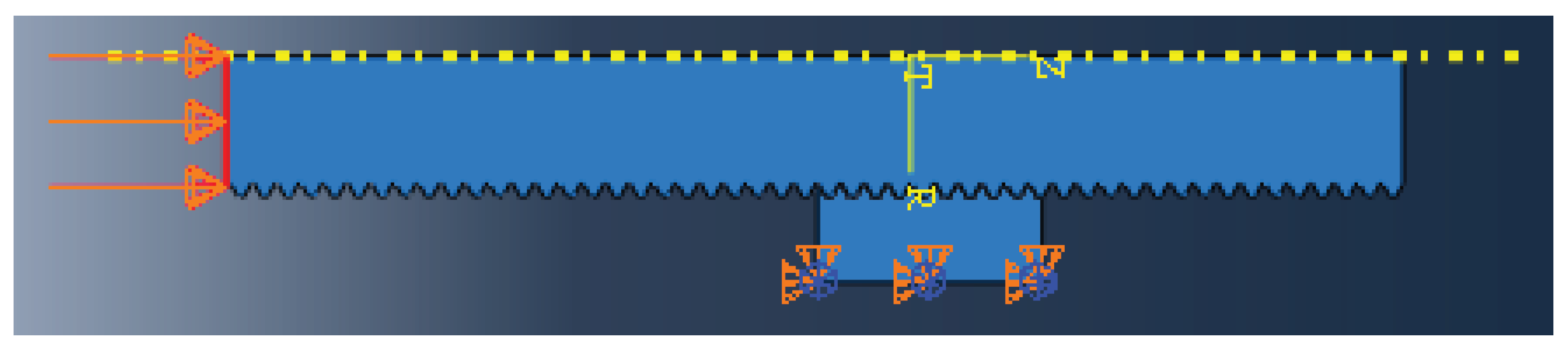

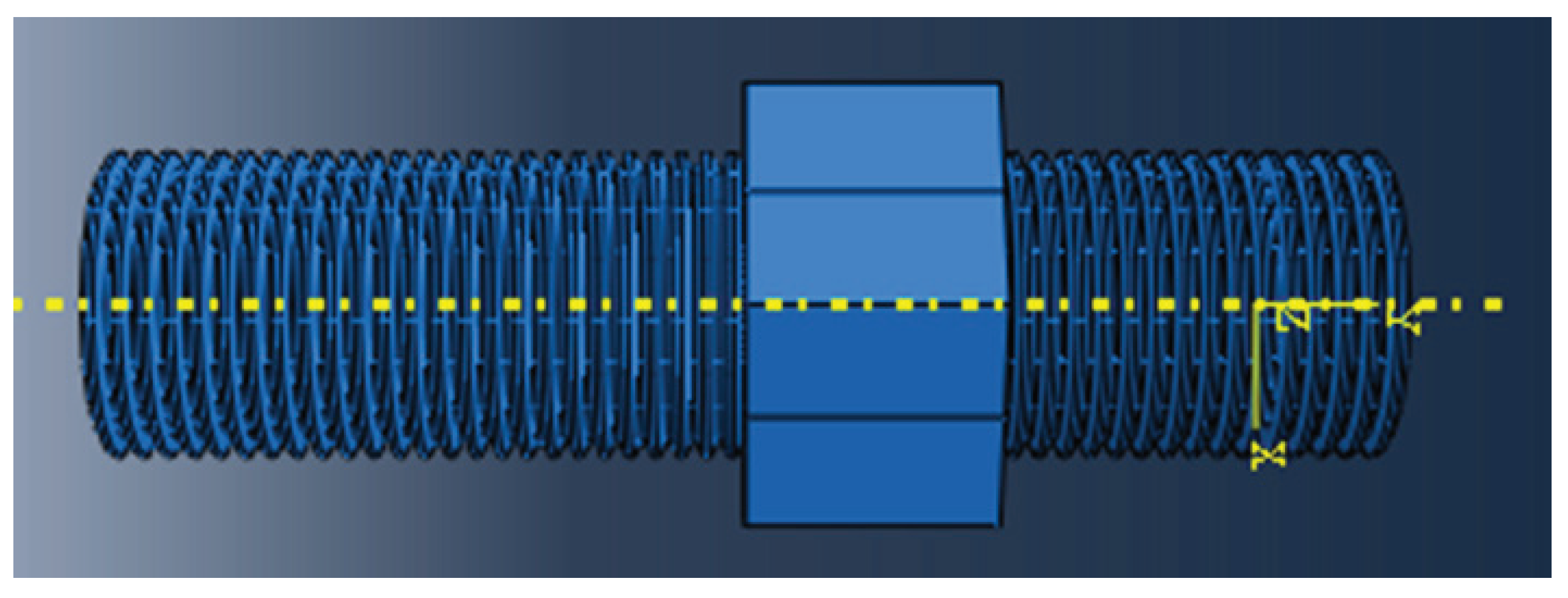

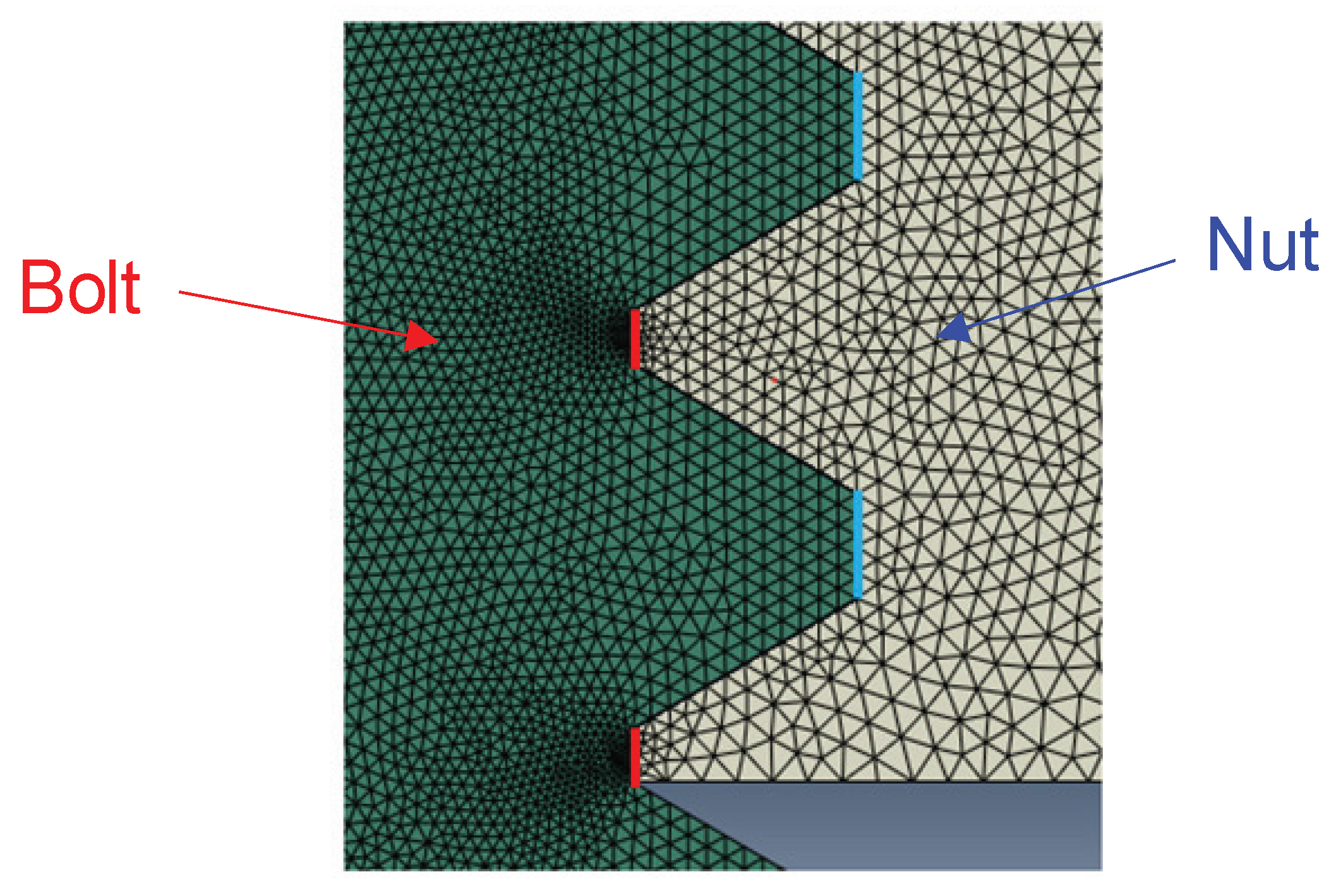

2.1. Axisymmetric and 3D Model Set-Up

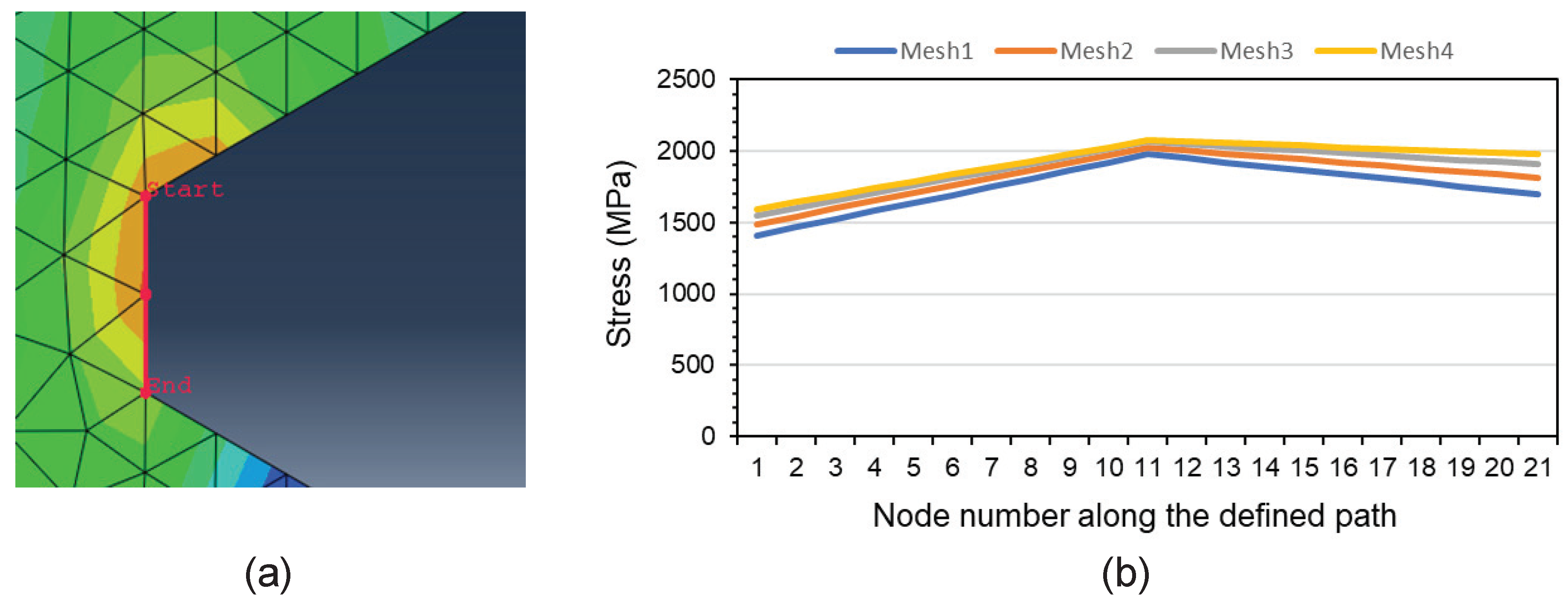

2.2. Mesh Convergence Analysis

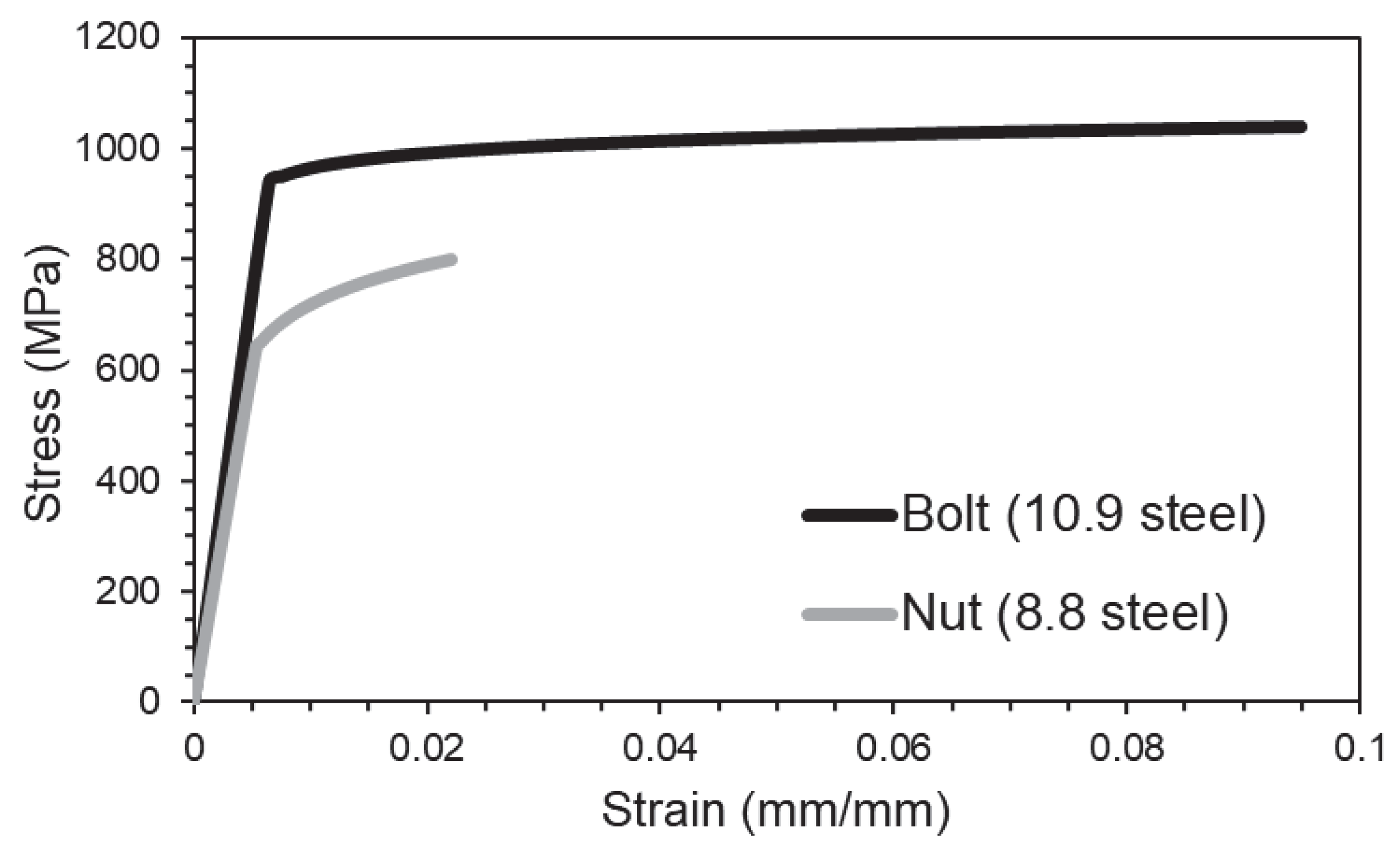

2.3. Axisymmetric and Elastic–Plastic Model

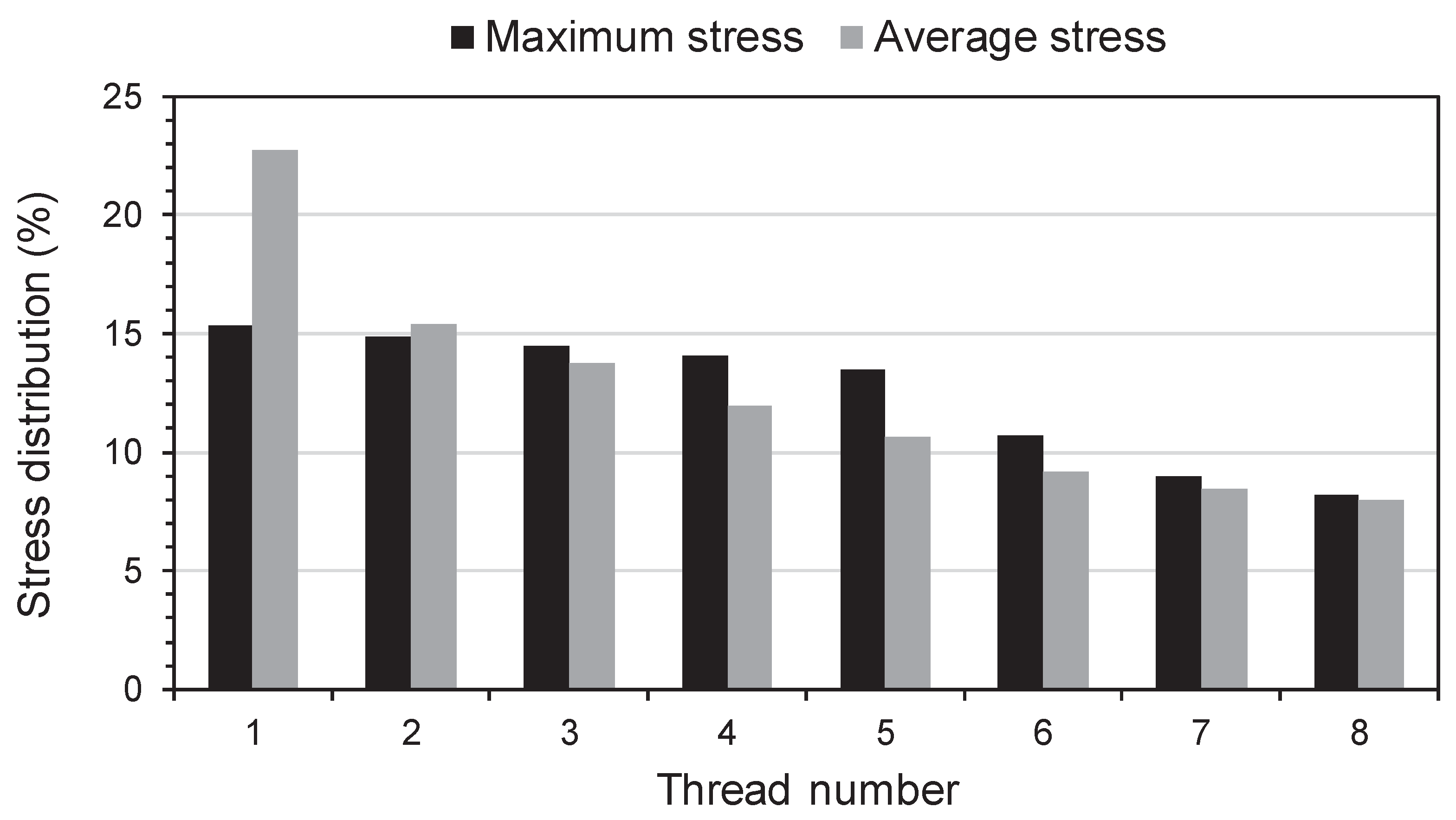

3. Stress Distribution Results in Bolted Connections

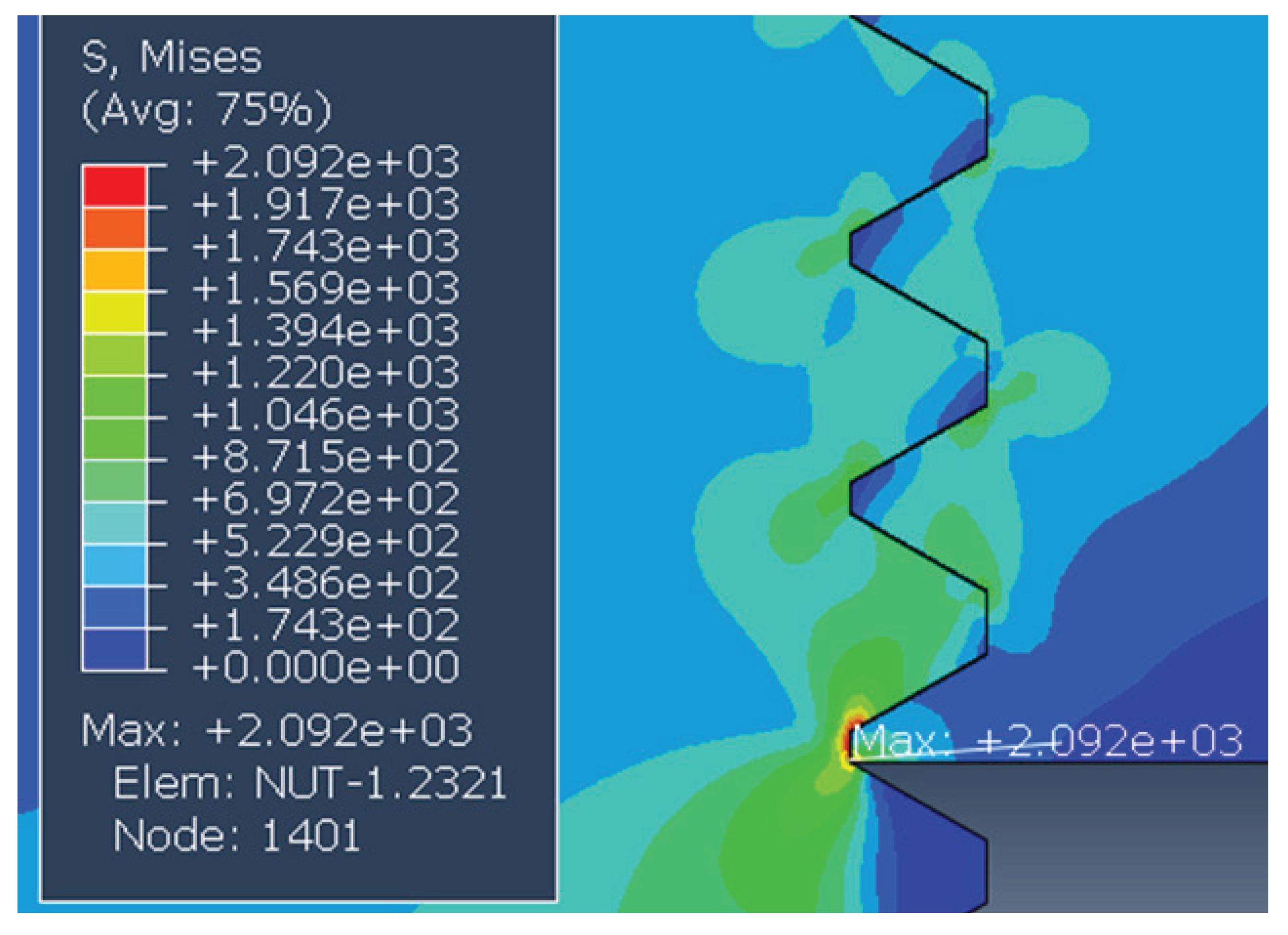

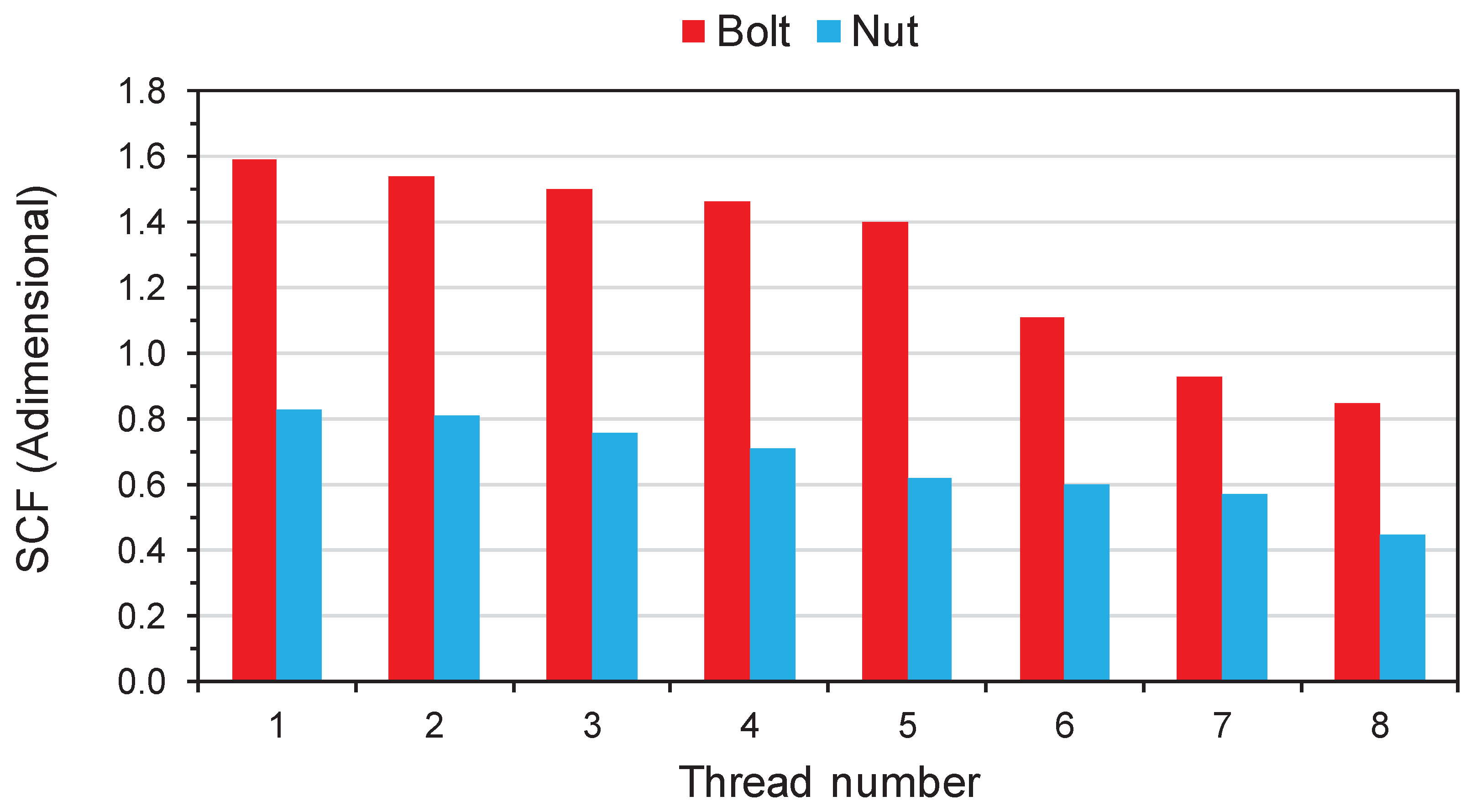

3.1. Stress Concentration Factor

- (1)

- Using the maximum von-Mises stress value at the root of the nut and bolt threads.

- (2)

- Using the average von-Mises stress value around the root of the nut and bolt threads.

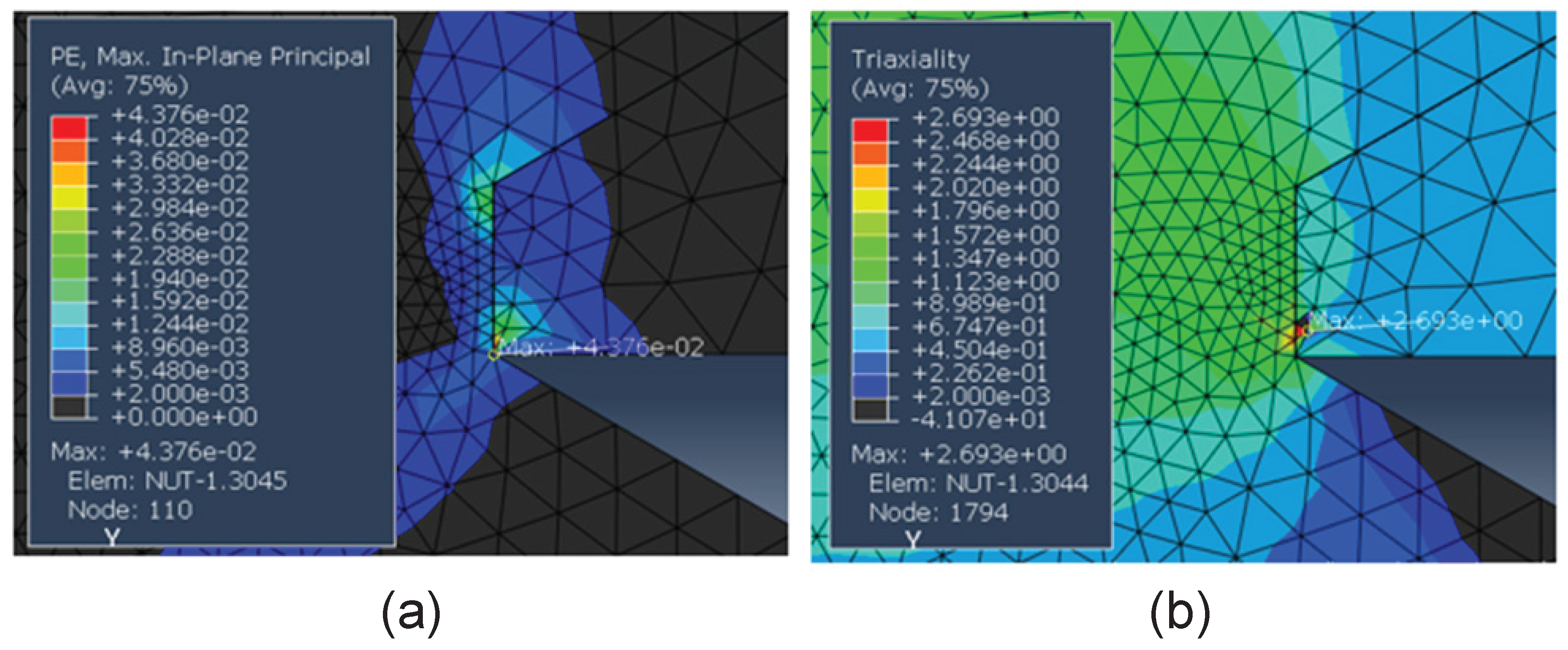

3.2. Analysis of Triaxiality around the First Engaged Thread

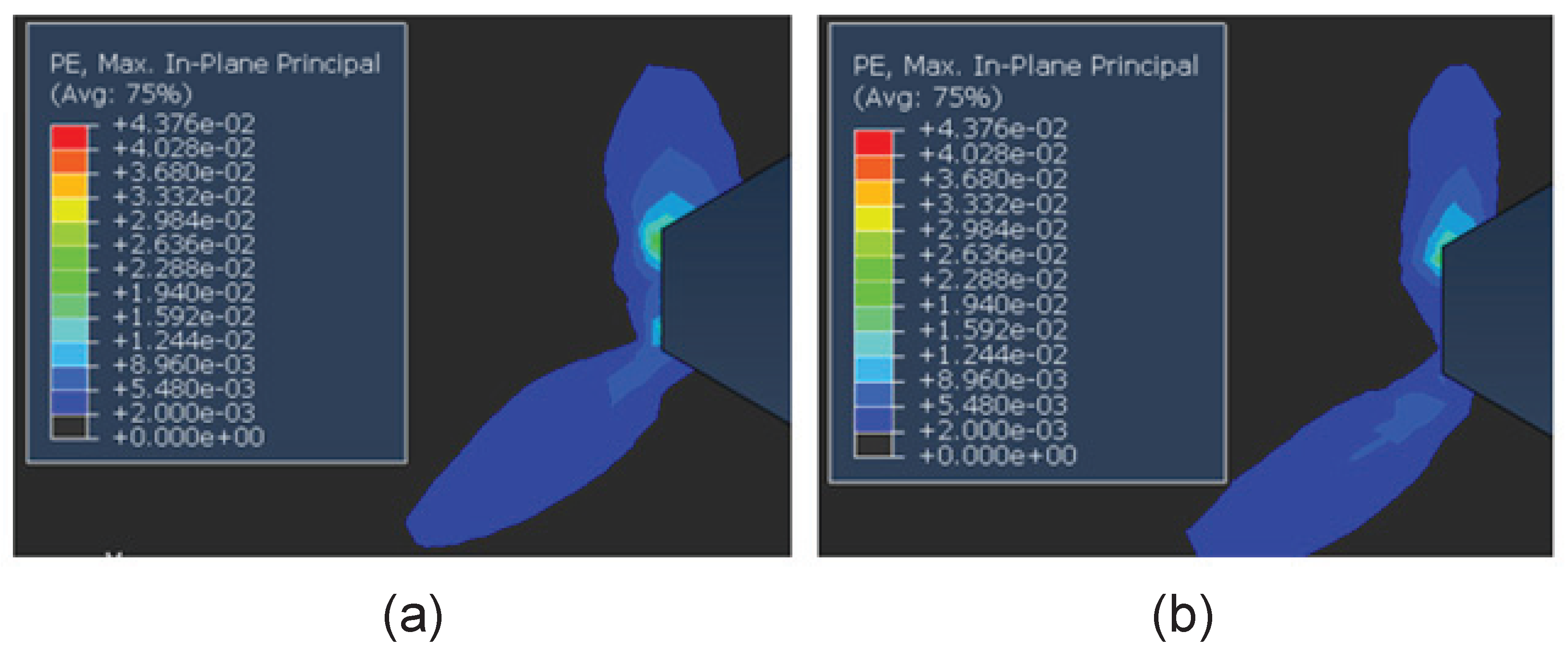

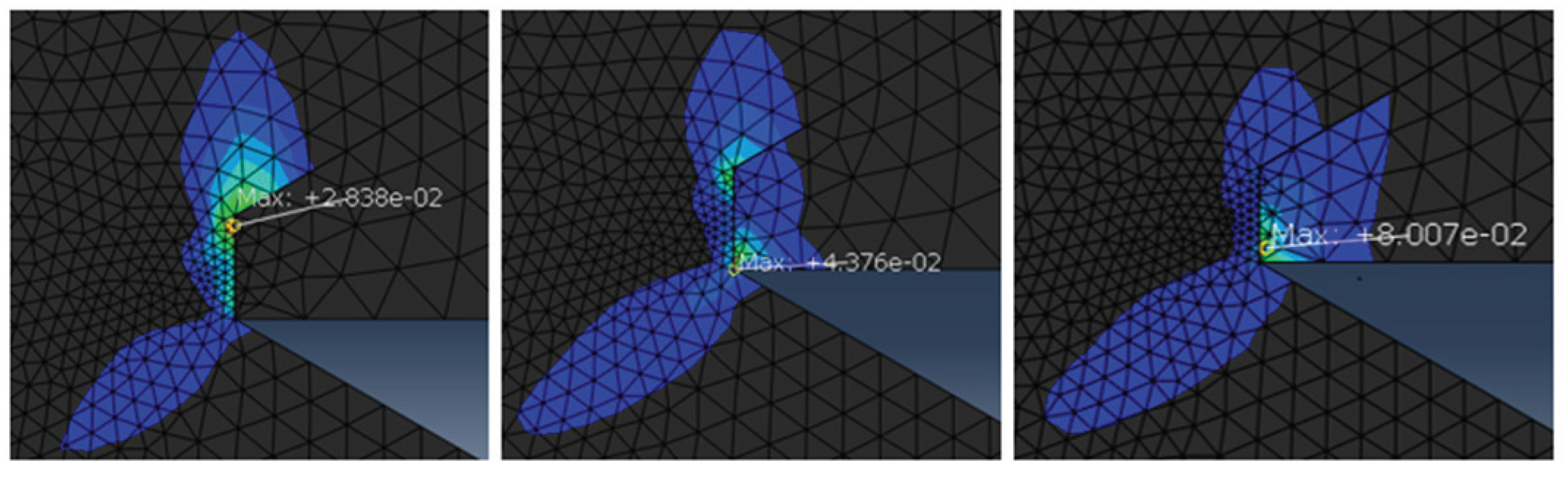

3.3. Rolling Effect on Strain Distribution

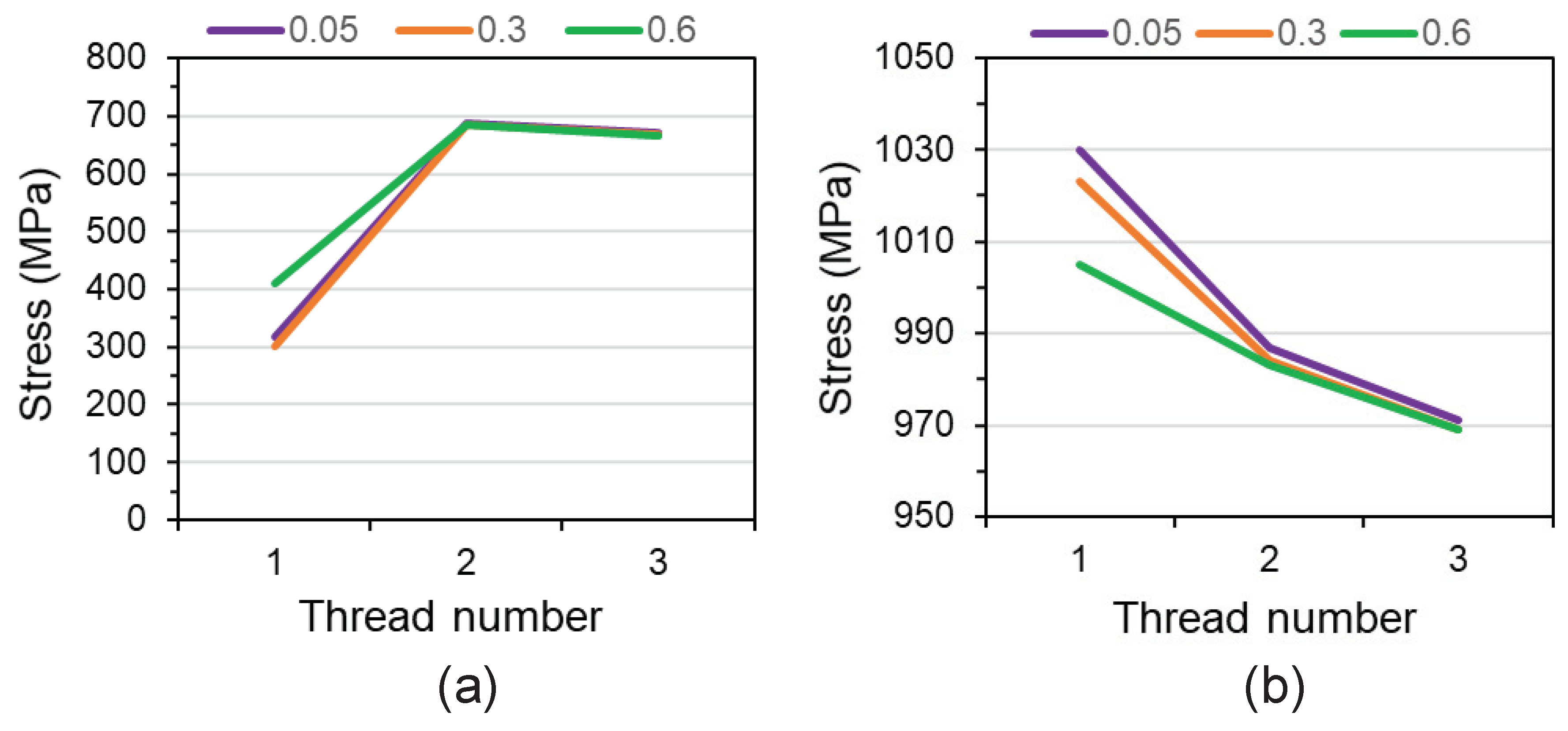

3.4. Influence of Lubricants on the Stress Distribution around the Threaded Connections

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mehmanparast, A.; Taylor, J.; Brennan, F.; Tavares, I. Experimental investigation of mechanical and fracture properties of offshore wind monopile weldments: SLIC interlaboratory test results. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2485–2501. [Google Scholar] [CrossRef]

- Mehmanparast, A.; Brennan, F.; Tavares, I. Fatigue crack growth rates for offshore wind monopile weldments in air and seawater: SLIC inter-laboratory test results. Mater. Des. 2017, 114, 494–504. [Google Scholar] [CrossRef]

- Gjersøe, N.F.; Hansen, N.-E.O.; Iversen, P. Long Term Behaviour of Lateral Dynamically Loaded Steel Grout Joints. In Proceedings of the The Twenty-first International Offshore and Polar Engineering Conference, Maui, HI, USA, 19–24 June 2011; International Society of Offshore and Polar Engineers: Maui, HI, USA, 2011; p. 7. [Google Scholar]

- Dallyn, P.; El-Hamalawi, A.; Palmeri, A.; Knight, R. Experimental testing of grouted connections for offshore substructures: A critical review. Structures 2015, 3, 90–108. [Google Scholar] [CrossRef]

- Lankhorst, S. ENECO: Update on the grouting issue of Princess Amalia Wind Farm. Available online: https://www.offshorewind.biz/2015/12/10/eneco-update-on-the-grouting-issue-of-princess-amalia-wind-farm (accessed on 21 May 2020).

- Tziavos, N. Experimental and Numerical Investigations on Grouted Connections for Monopile Offshore Wind Turbines. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2019. [Google Scholar]

- Lotsberg, I.; Serednicki, A.; Oerlemans, R.; Bertnes, H.; Lervik, A. Capacity of cylindrical shaped grouted connections with shear keys in off shore structures. Struct. Eng. 2013, 91, 42–48. [Google Scholar]

- Schaumann, P.; Lochte-Holtgreven, S.; Bechtel, A. Fatigue Design for Axially Loaded Grouted Connections of Offshore Wind Turbine Support Structures in Deeper Waters. In Earth and Space 2010: Engineering, Science, Construction, and Operations in Challenging Environments; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 2047–2054. [Google Scholar]

- The Supreme Court. MT Højgaard A/S (Respondent) v E. ON Climate & Renewables UK Robin Rigg East Limited and another (Appellants). Case ID: UKSC 2015/0115. August 2017. Available online: https://www.supremecourt.uk/cases/uksc-2015-0115.html (accessed on 21 May 2020).

- Van Gelder, B. Double Slip Joint—innovative foundation connection for offshore wind. In Proceedings of the WindEurope Conference, Hamburg, Germany, 27–29 September 2016. [Google Scholar]

- Grow, First Offshore Wind Turbine Using the Slip Joint Connection Successfully Installed. 2018. Available online: https://grow-offshorewind.nl/first-offshore-wind-turbine-using-the-slip-joint-connection-successfully-installed (accessed on 21 May 2020).

- Pavlović, M.; Heistermann, C.; Veljković, M.; Pak, D.; Feldmann, M.; Rebelo, C.; da Silva, L.S. Friction connection vs. ring flange connection in steel towers for wind converters. Eng. Struct. 2015, 98, 151–162. [Google Scholar] [CrossRef]

- Pavlović, M.; Heistermann, C.; Veljković, M.; Pak, D.; Feldmann, M.; Rebelo, C.; da Silva, L.S. Connections in towers for wind converters, part I: Evaluation of down-scaled experiments. J. Constr. Steel Res. 2015, 115, 445–457. [Google Scholar] [CrossRef]

- Pavlović, M.; Heistermann, C.; Veljković, M.; Pak, D.; Feldmann, M.; Rebelo, C.; da Silva, L.S. Connections in towers for wind converters, Part II: The friction connection behaviour. J. Constr. Steel Res. 2015, 115, 458–466. [Google Scholar] [CrossRef]

- Gollub, P.; Jensen, J.F.; Giese, D.; Güres, S. Flanged foundation connection of the offshore wind farm Amrumbank West-Concept, approval, design, tests and installation. Stahlbau 2014, 83, 522–528. [Google Scholar] [CrossRef]

- Braithwaite, J.; Mehmanparast, A. Analysis of tightening sequence effects on preload behaviour of offshore wind turbine M72 bolted connections. Energies 2019, 12, 4406. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI 2230 Blatt-1. Systematic Calculation of High Duty Bolted Joints—Joints with One Cylindrical Bolt; Oak Ridge National Lab: Oak Ridge, TN, USA, 2003. [Google Scholar]

- DASt-Guideline 021: Schraubenverbindungen aus Feuerverzinkten Garnituren M39 Bis 72; Deutscher Ausschuss für Stahlbau DASt, Stahlbau Verlags- und Service GmbH: Düsseldorf, Germany, 2013. (In German)

- Nord-Lock Group. Comparison of Common Bolt Tightening Methods. Available online: https://www.nord-lock.com/insights/knowledge/2014/comparison-of-common-bolt-tightening-methods (accessed on 21 May 2020).

- Metric Screw Thread-M Profile. An American National Standard. ASME B1.13M. 1995. Available online: https://www.asme.org/codes-standards/find-codes-standards/b1-13m-metric-screw-threads-m-profile (accessed on 21 May 2020).

- Kontolati, K.; Panagouli, O. Numerical Investigation of Weak Axis i Profile Connections; University of Thessaly: Volos, Greece, 2017. [Google Scholar]

- Liu, J.; Ouyang, H.; Ma, L.; Zhang, C.; Zhu, M. Numerical and theoretical studies of bolted joints under harmonic shear displacement. Lat. Am. J. Solids Struct. 2015, 12, 115–132. [Google Scholar] [CrossRef]

- Zhao, H. Stress concentration factors within bolt-nut connectors under elasto-plastic deformation. Int. J. Fatigue 1998, 20, 651–659. [Google Scholar] [CrossRef]

- Unglaub, J.; Jahns, H.; Thiele, K. Finite Element Analysis of Residual Stresses in Large Cold-Rolled Threads. In Proceedings of the XV International Conference on Computational Plasticity: fundamentals and applications (COMPLAS 2019), Barcelona, Spain, 3–5 September 2019. [Google Scholar]

| Material Type | E (GPa) | |||

|---|---|---|---|---|

| Nut (8.8 steel) | 640 | 800 | 0.022 | 210 |

| Bolt (10.9 steel) | 940 | 1040 | 0.095 | 210 |

| Friction Coefficient | Material | Lubricant |

|---|---|---|

| 0.04–0.01 | Black oxide coating, zinc laminated coating, electroplated coating, metallically bright | Solid lubricants, liquefied wax, wax dispersions |

| 0.20–0.35 | Austenitic steel, electroplated coatings, hot dip galvanized | Oil for the austenitic and none for the rest |

| >0.3 | Electroplated coatings, austenitic steel and Al, Mg alloys | None |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Redondo, R.; Mehmanparast, A. Numerical Analysis of Stress Distribution in Offshore Wind Turbine M72 Bolted Connections. Metals 2020, 10, 689. https://doi.org/10.3390/met10050689

Redondo R, Mehmanparast A. Numerical Analysis of Stress Distribution in Offshore Wind Turbine M72 Bolted Connections. Metals. 2020; 10(5):689. https://doi.org/10.3390/met10050689

Chicago/Turabian StyleRedondo, Raquel, and Ali Mehmanparast. 2020. "Numerical Analysis of Stress Distribution in Offshore Wind Turbine M72 Bolted Connections" Metals 10, no. 5: 689. https://doi.org/10.3390/met10050689

APA StyleRedondo, R., & Mehmanparast, A. (2020). Numerical Analysis of Stress Distribution in Offshore Wind Turbine M72 Bolted Connections. Metals, 10(5), 689. https://doi.org/10.3390/met10050689