Study of Residual Stresses and Microstructural Changes in Charpy Test Specimens Reconstituted by Various Welding Techniques

Abstract

1. Introduction

2. Materials and Methods

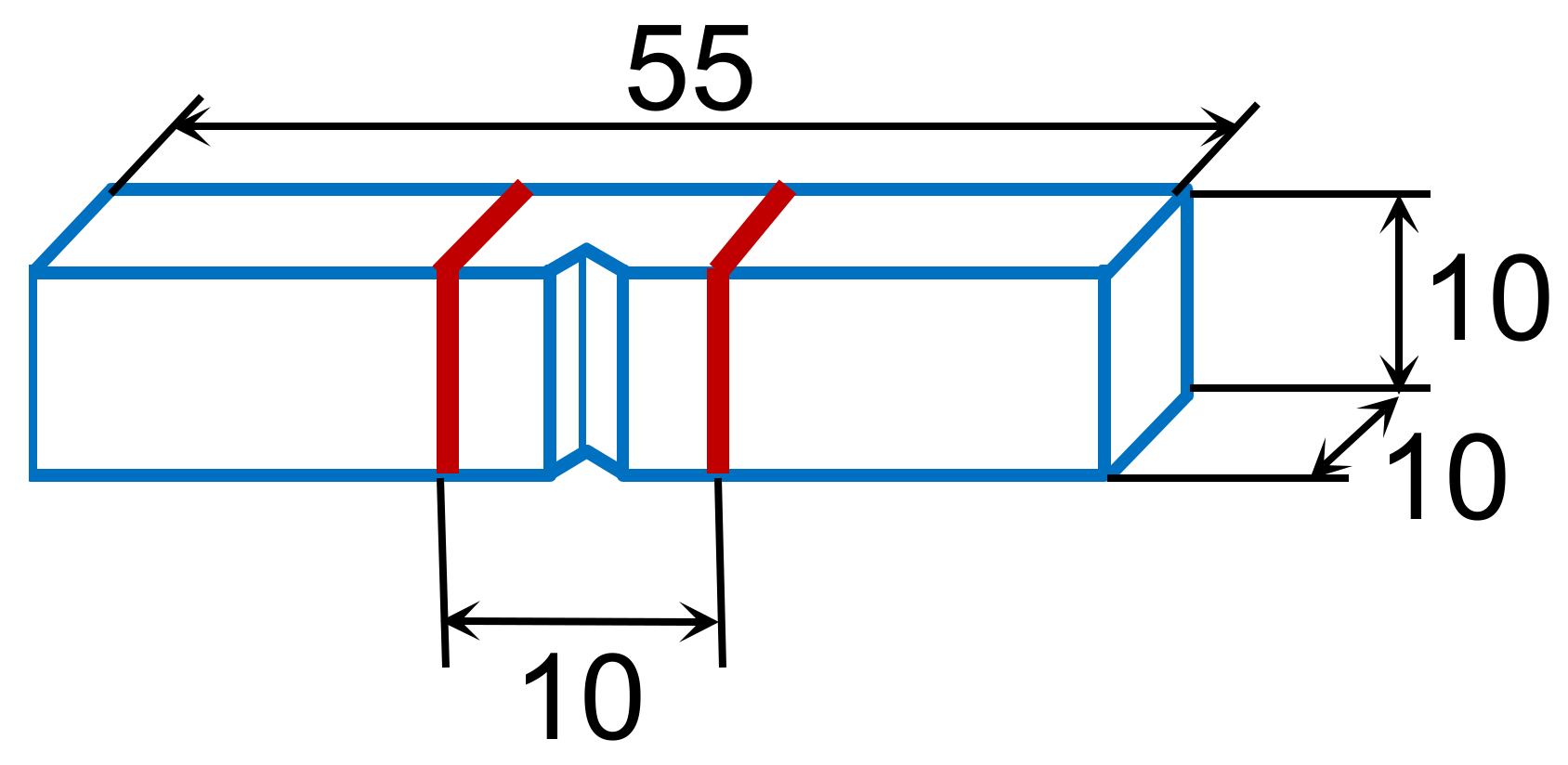

2.1. Welding Techniques for Surveillance Charpy-V Type Specimens Reconstitution

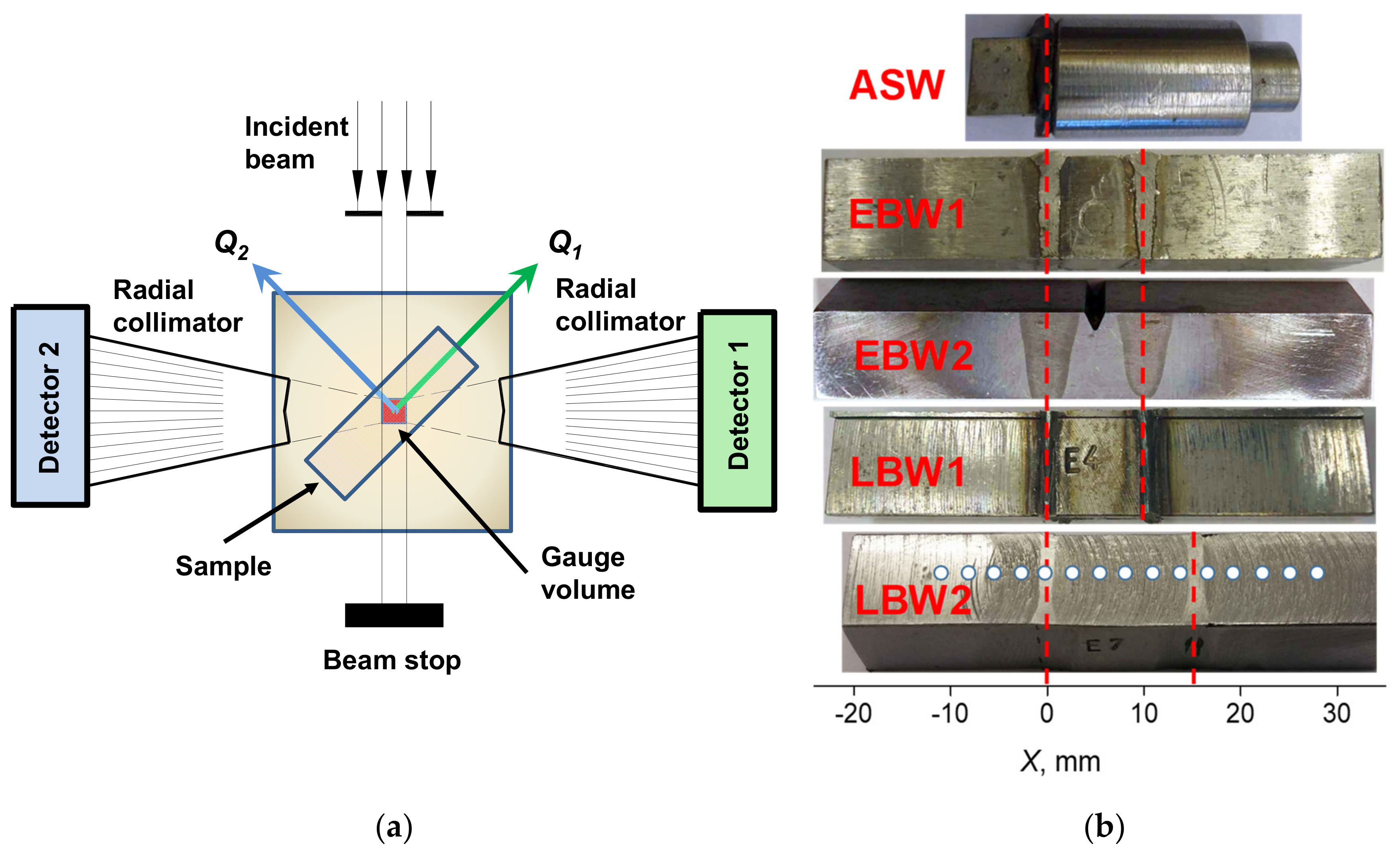

2.2. Residual Stresses Measurements by Neutron Diffraction

3. Results and Discussion

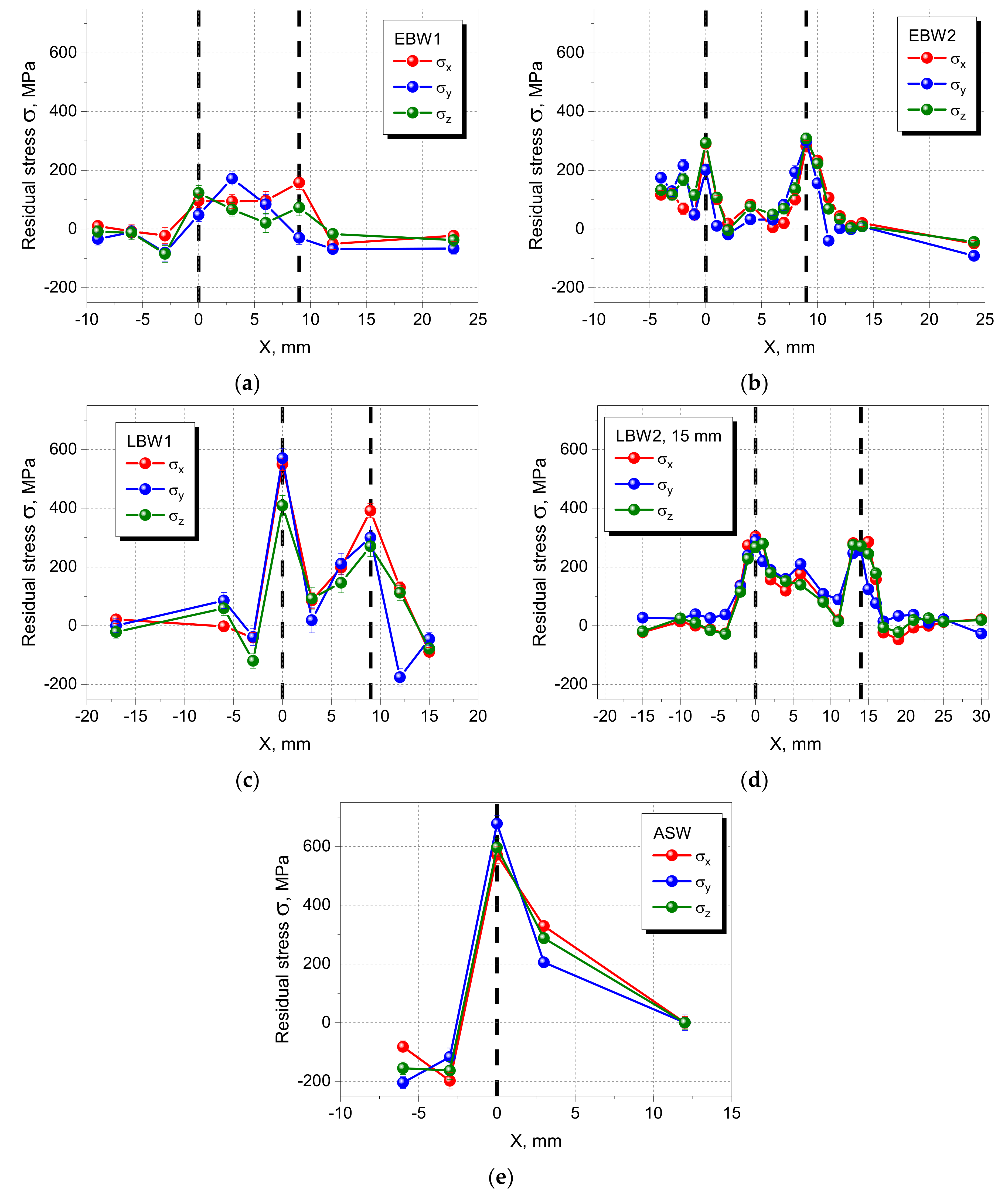

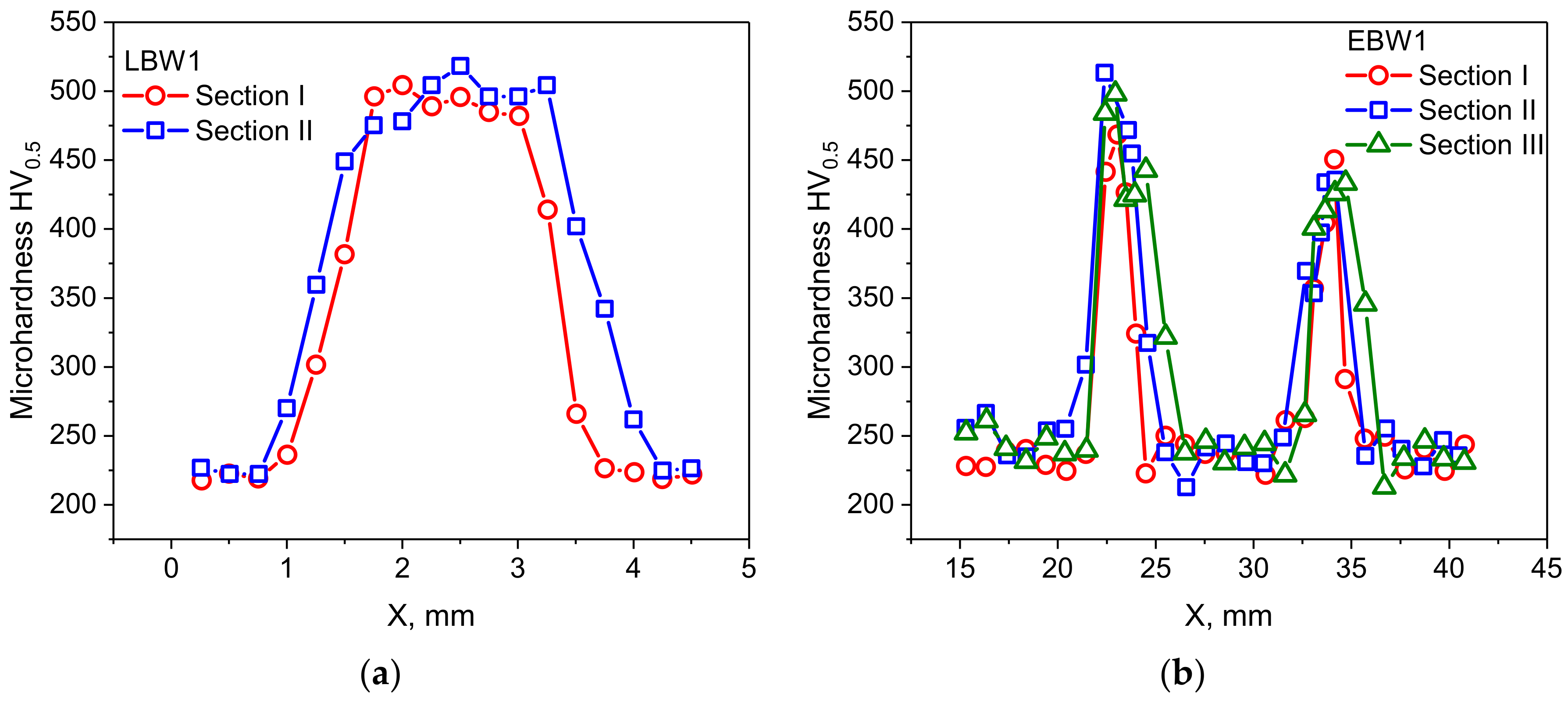

3.1. Residual Stresses Distributions in Reconstituted Charpy Specimens

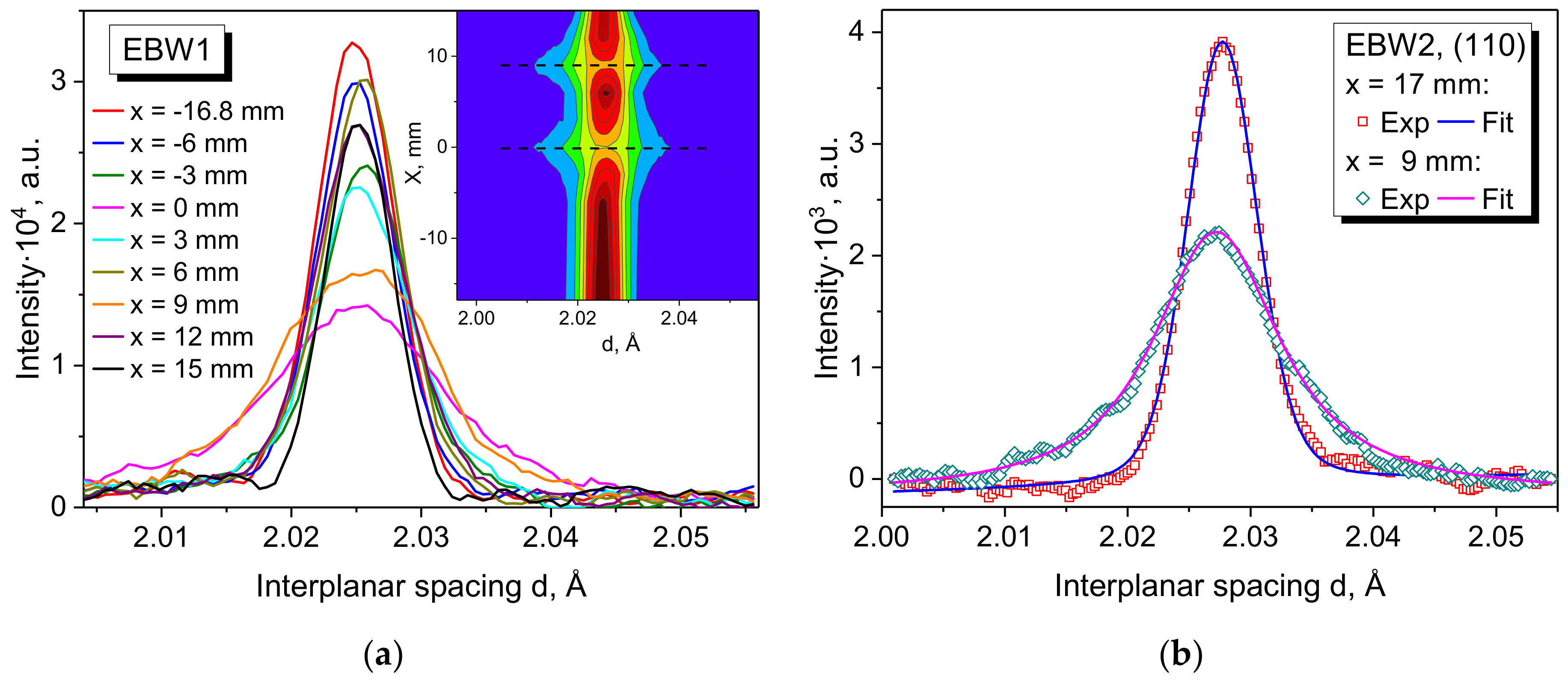

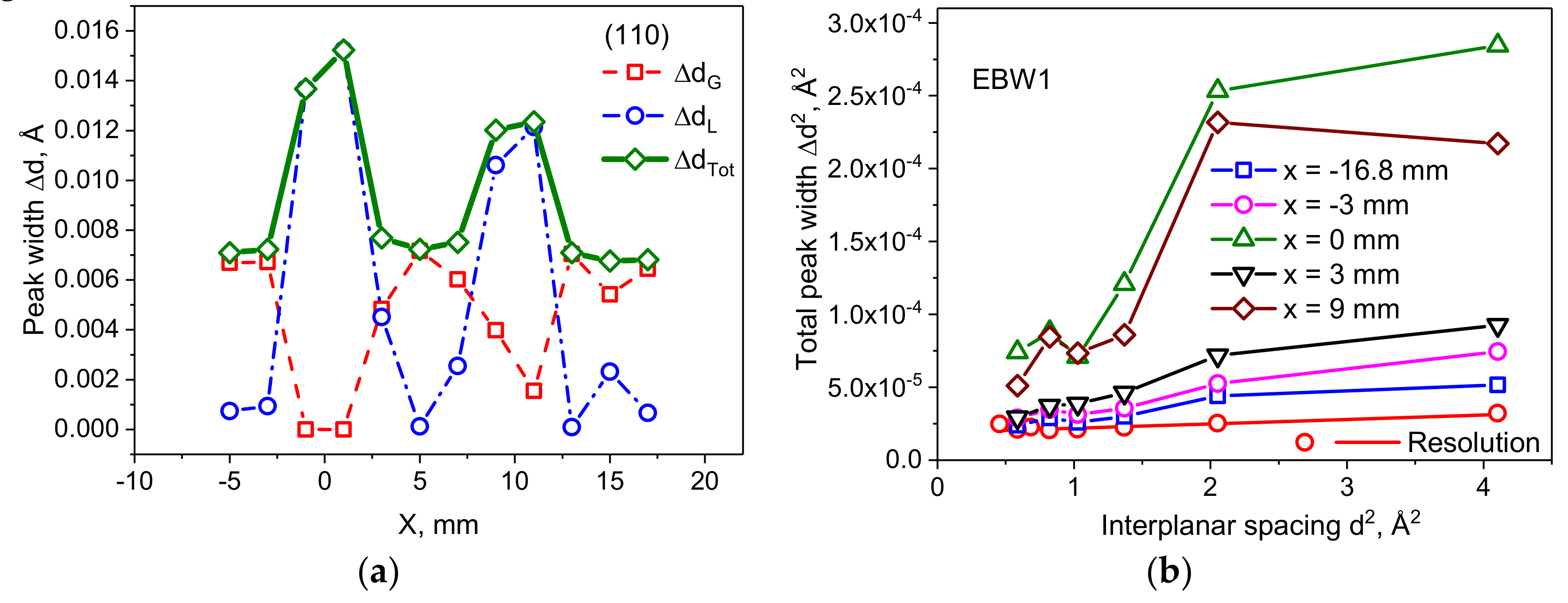

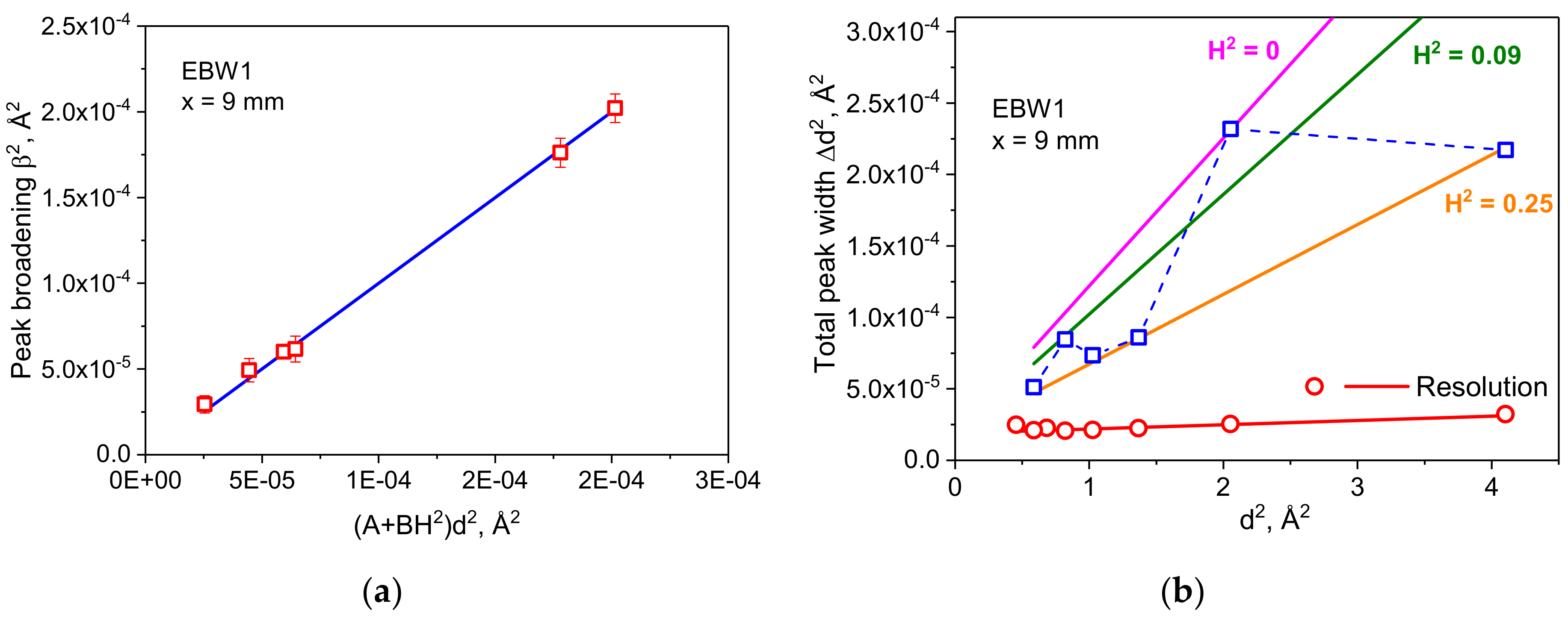

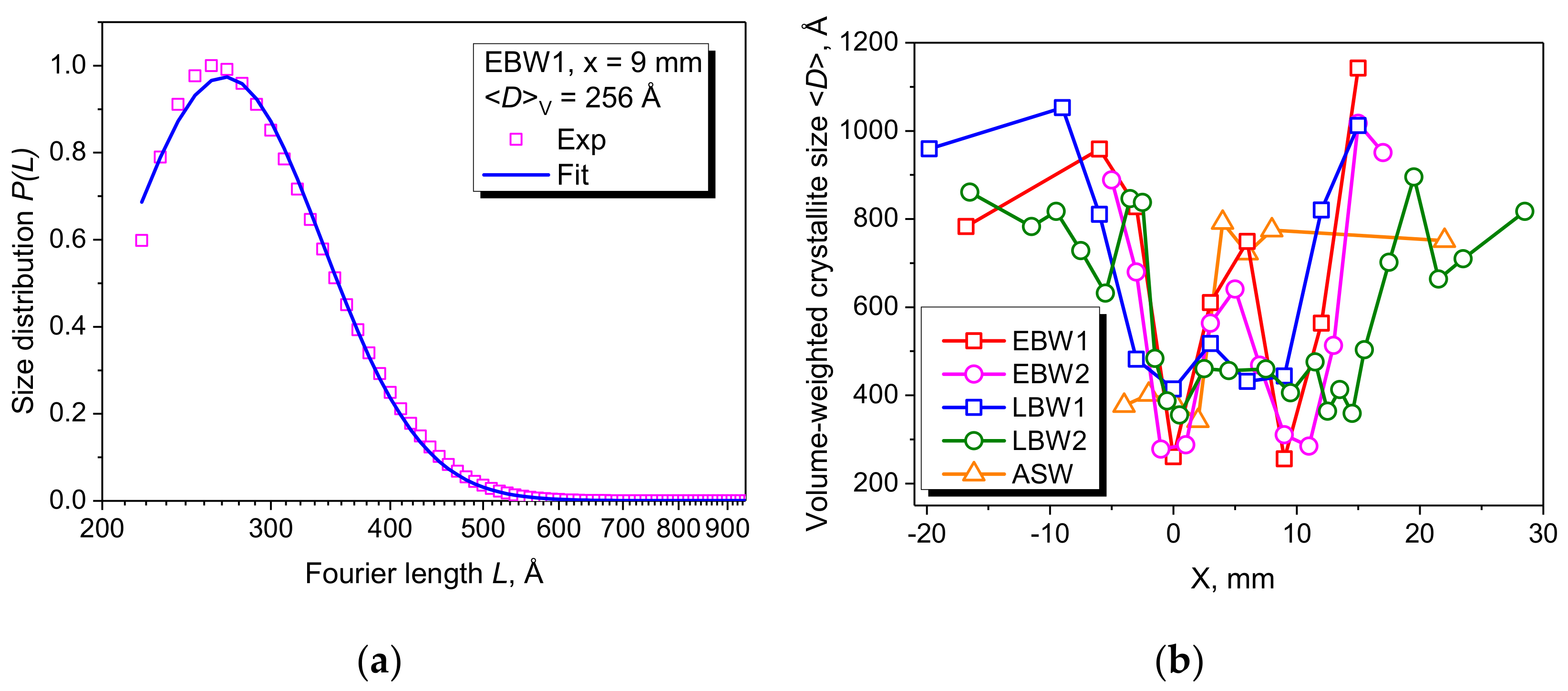

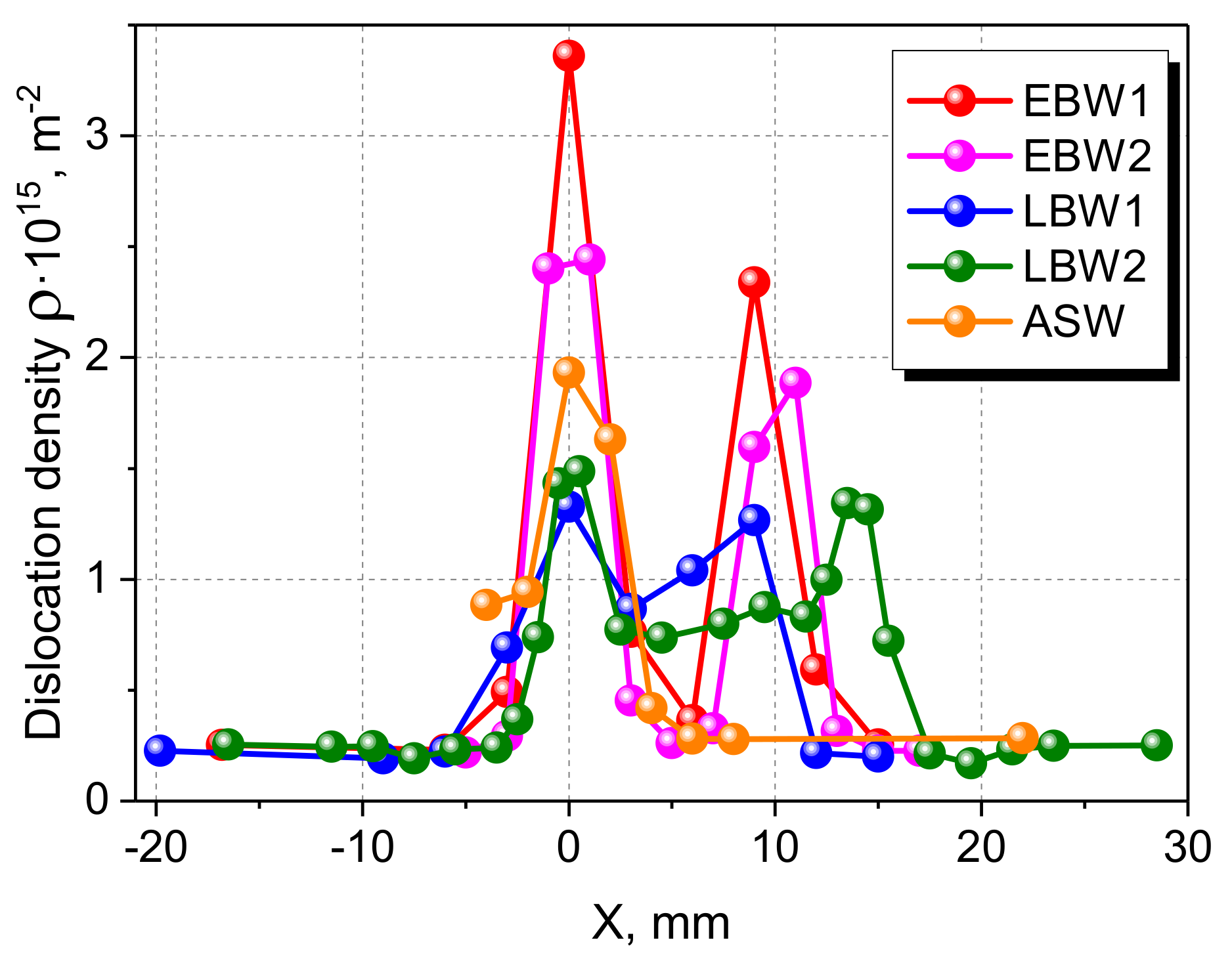

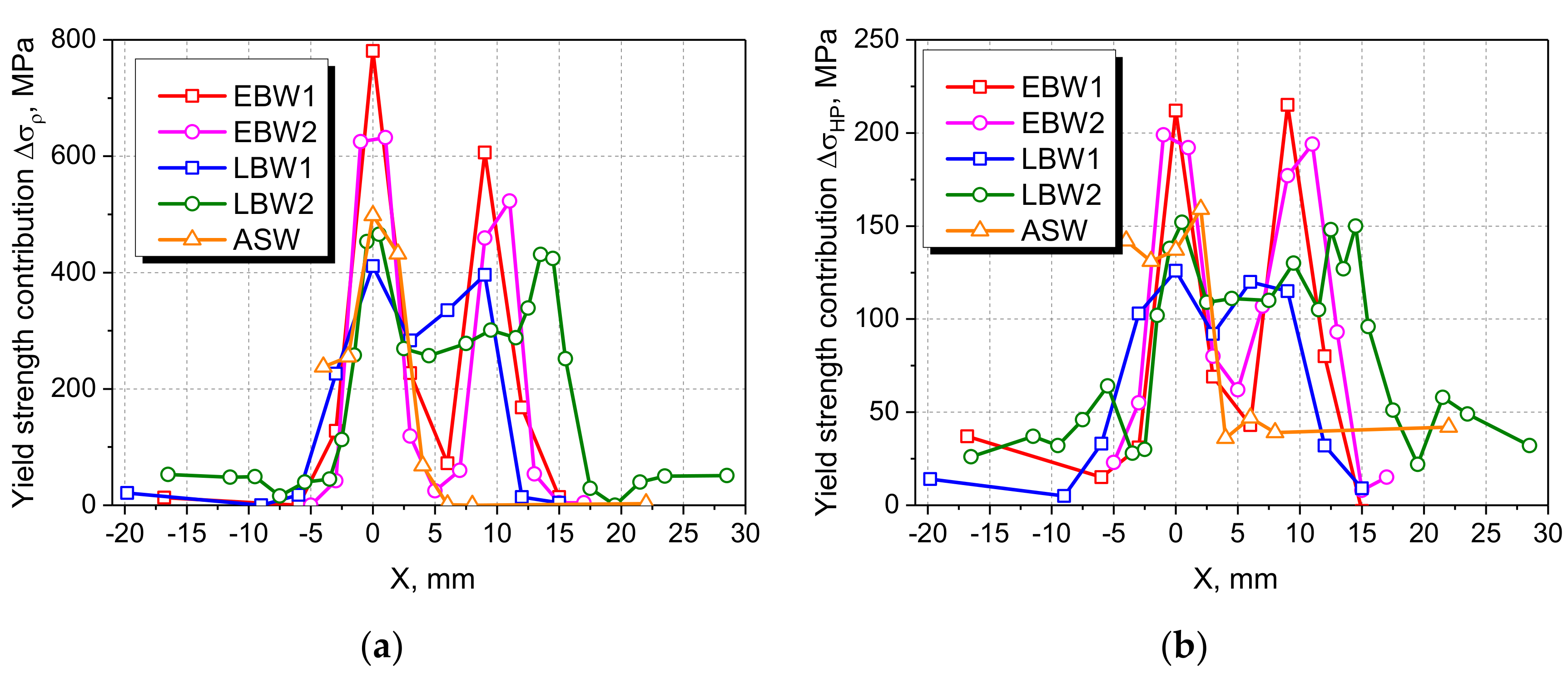

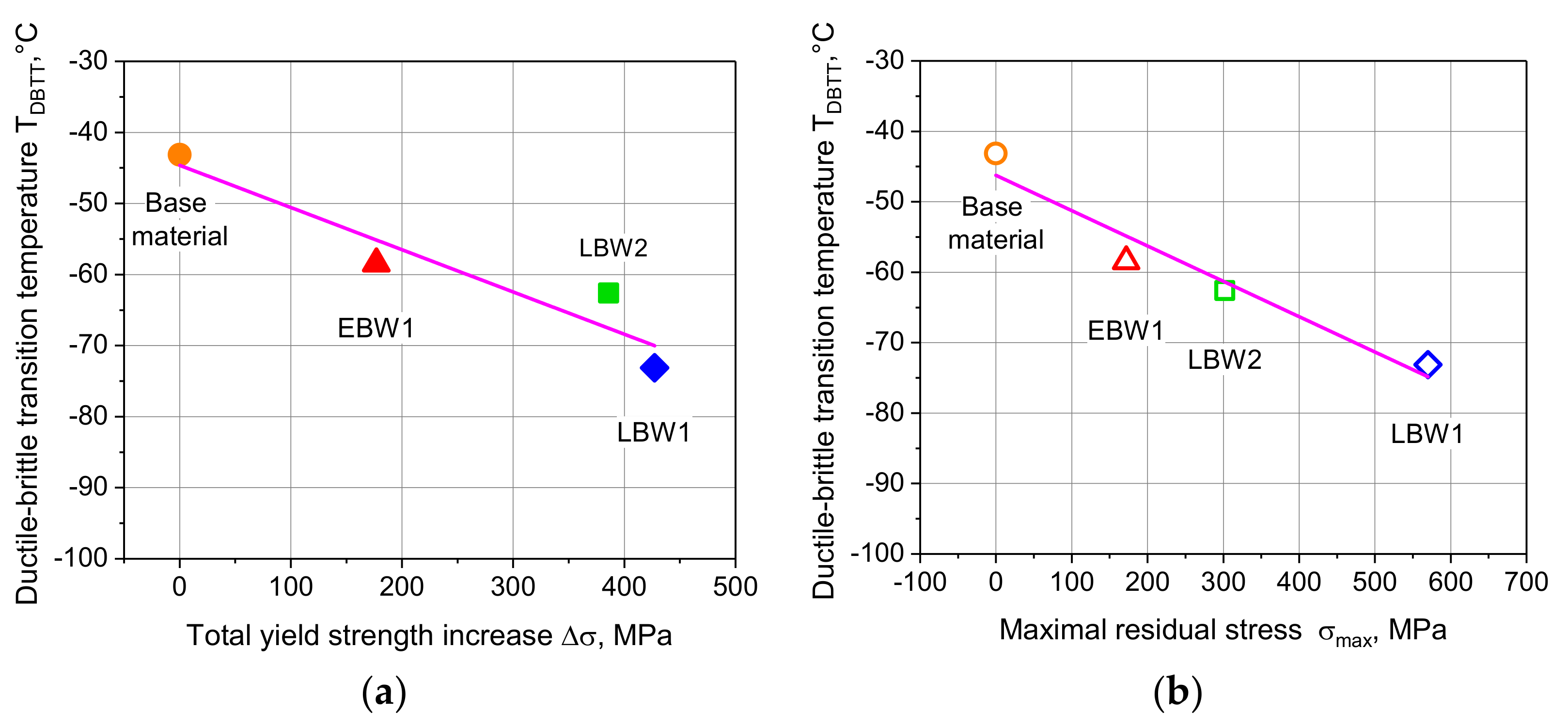

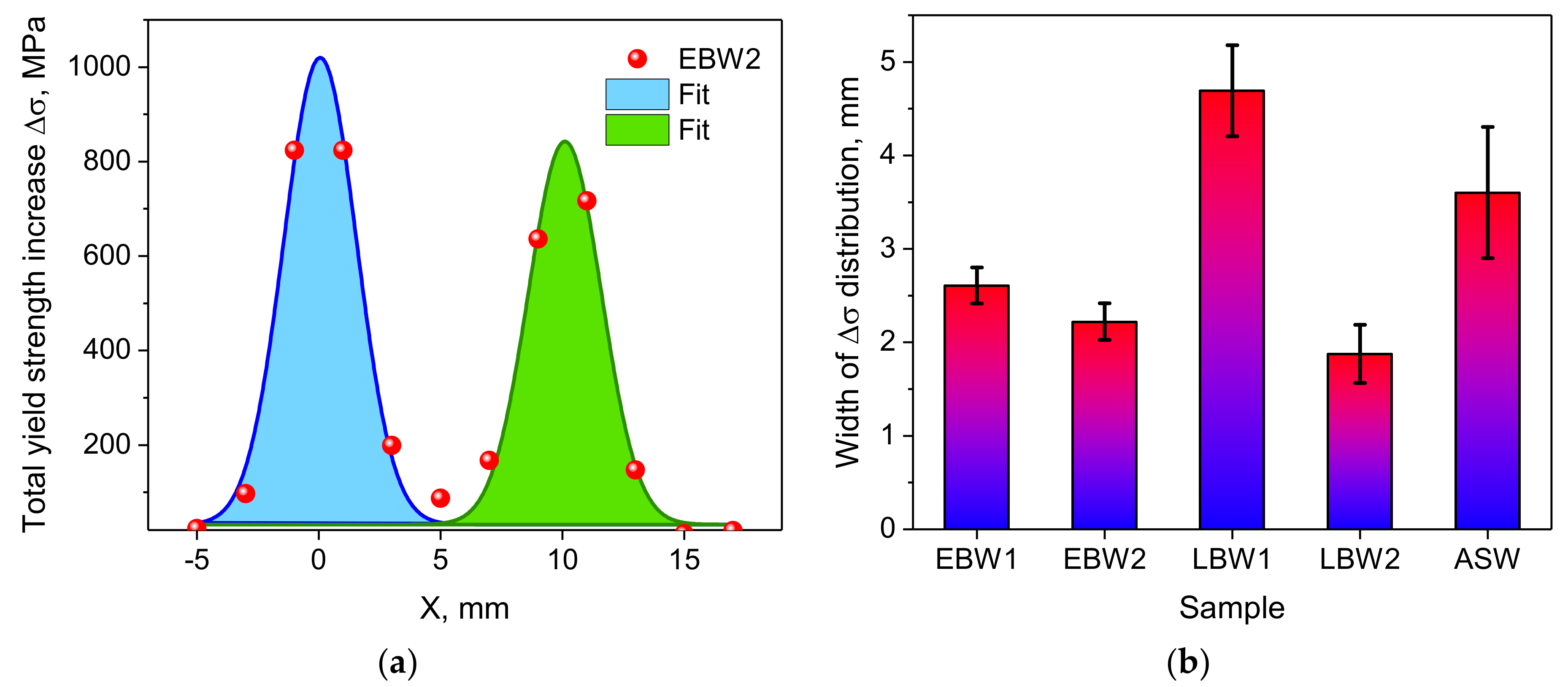

3.2. Diffraction Peak Broadening Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Van Walle, E. Mechanical Test Specimens, Reconstitution of. Encycl. Mater. Sci. Technol. 2001, 5265–5268. [Google Scholar] [CrossRef]

- Gutiérrez-Solana, F.; Cicero, S. The knowledge and its application: Materials Engineering and Structural Integrity. Brief review of the Spanish case and contributions from Prof. Elices. Eng. Fail. Anal. 2009, 16, 2705–2720. [Google Scholar] [CrossRef]

- De Backer, F.; Gutiérrez-Solana, F. Influence of the specimen configuration and the insert material on fracture toughness characterisation with reconstituted specimens. Nucl. Eng. Des. 1999, 188, 231–240. [Google Scholar] [CrossRef]

- Van Walle, E.; Scibetta, M.; Valo, M.J.; Viehrig, H.-W.; Richter, H.; Atkins, T.; Wootton, M.; Keim, E.; Debarberis, L.; Horsten, M. Reconstitution techniques qualification and evaluation to study ageing phenomena of nuclear pressure vessel materials (RESQUE). Nucl. Eng. Des. 2001, 209, 67–77. [Google Scholar] [CrossRef]

- Manahan, M.P.; Williams, J.; Martukanitz, R.P. Laser Weld Reconstitution of Conventional Charpy and Miniaturized Notch Test (MNT) Specimens. In Small Specimen Test Techniques Applied to Nuclear Reactor Vessel Thermal Annealing and Plant Life Extension; Corwin, W.R., Haggag, F., Server, W., Eds.; American Society for Testing and Materials: Philadelphia, PA, USA, 1993; pp. 62–76. [Google Scholar] [CrossRef]

- Petrov, P.I.; Scibetta, M.; Puzzolante, J.L.; van Walle, E. Reconstitution of Charpy-V Specimens with CO2-Laser Welding. In Small Specimen Test Techniques: Fourth Volume; ASTM STP 1418; Sokolov, M.A., Landes, J.D., Lucas, G.E., Eds.; American Society for Testing and Materials: West Conshohocken, PA, USA, 2002; pp. 464–476. [Google Scholar] [CrossRef]

- Goldak, J.; Akhlaghi, M. Computational Welding Mechanics; Springer: New York, NY, USA, 2005. [Google Scholar]

- Sepe, R.; Armentani, E.; Lamanna, G.; Caputo, F. Evaluation by FEM of the influence of the preheating and post-heating treatments on residual stresses in welding. Key Eng. Mater. 2015, 627, 93–96. [Google Scholar] [CrossRef]

- Sepe, R.; Laiso, M.; De Luca, A.; Caputo, F. Evaluation of residual stresses in butt welded joint of dissimilar material by FEM. Key Eng. Mater. 2017, 754, 268–271. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Noyan, I.C.; Cohen, J.B. Residual Stress–Measurement by Diffraction and Interpretation; Springer: Berlin, Germany, 1987. [Google Scholar]

- Javadi, Y.; Sadeghi, S.; Najafabadi, M.A. Taguchi optimization and ultrasonic measurement of residual stresses in the friction stir welding. Mater. Des. 2014, 55, 27–34. [Google Scholar] [CrossRef]

- Bokuchava, G.D.; Papushkin, I.V.; Tamonov, A.V.; Kruglov, A.A. Residual stress measurements by neutron diffraction at the IBR-2 pulsed reactor. Rom. J. Phys. 2016, 61, 491–505. [Google Scholar]

- Woo, W.; An, G.B.; Em, V.T.; De Wald, A.T.; Hill, M.R. Through-thickness distributions of residual stresses in an 80 mm thick weld using neutron diffraction and contour method. J. Mater. Sci. 2015, 50, 784–793. [Google Scholar] [CrossRef]

- Genchev, G.; Doynov, N.; Ossenbrink, R.; Michailov, V.; Bokuchava, G.; Petrov, P. Residual stresses formation in multi-pass weldment: A numerical and experimental study. J. Constr. Steel Res. 2017, 138, 633–641. [Google Scholar] [CrossRef]

- Sepe, R.; Wiebesiek, J.; Sonsino, C.M. Numerical and experimental validation of residual stresses of laser-welded joints and their influence on the fatigue behavior. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1126–1141. [Google Scholar] [CrossRef]

- Citarella, R.; Carlone, P.; Sepe, R.; Lepore, M. DBEM crack propagation in friction stir welded aluminum joints. Adv. Eng. Softw. 2016, 101, 50–59. [Google Scholar] [CrossRef]

- Bokuchava, G. Neutron Fourier Stress Diffractometer FSD at the IBR-2 pulsed reactor. Crystals 2018, 8, 318. [Google Scholar] [CrossRef]

- Bokuchava, G. Correlation RTOF diffractometry at long-pulse neutron source: I. Data acquisition in list-mode. Nucl. Instrum. Methods Phys. Res. A 2020, 964, 163770. [Google Scholar] [CrossRef]

- Balagurov, A.M.; Bokuchava, G.D.; Kuzmin, E.S.; Tamonov, A.V.; Zhuk, V.V. Neutron RTOF diffractometer FSD for residual stress investigation. Z. Krist. 2006, 23, 217–222. [Google Scholar] [CrossRef]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures. J. Appl. Cryst. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Mikula, P.; Vrána, M. Residual Stress Investigations of Electron Beam Welds on Samples Prepared by Reconstitution Method. Appl. Mech. Mater. 2014, 486, 147–150. [Google Scholar] [CrossRef]

- Radaj, D. Heat Effects of Welding: Temperature Field, Residual Stress, Distortion; Springer: Berlin/Heidelberg, Germany, 1992; Chapter 3; ISBN 978-3-642-48642-5. [Google Scholar] [CrossRef]

- Yang, Z.; Lee, Y. Effect of the welding residual stress redistribution on impact absorption energy. J. Weld. Join. 2015, 33, 72–79. [Google Scholar] [CrossRef][Green Version]

- Bokuchava, G.D.; Petrov, P.; Papushkin, I.V. Application of Neutron Stress Diffractometry for Studies of Residual Stresses and Microstrains in Reactor Pressure Vessel Surveillance Specimens Reconstituted by Beam Welding Methods, Journal of Surface Investigation. X-ray. Synchrotron Neutron Tech. 2016, 10, 1143–1153. [Google Scholar] [CrossRef]

- Bokuchava, G.D. Materials microstructure characterization using high resolution TOF neutron diffraction. Rom. J. Phys. 2016, 61, 903–925. [Google Scholar]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Warren, B.E.; Averbach, B.L. The Effect of Cold-Work Distortion on X-Ray Patterns. J. Appl. Crystallogr. 1950, 21, 595–599. [Google Scholar] [CrossRef]

- Bokuchava, G.D.; Papushkin, I.V.; Bobrovskii, V.I.; Kataeva, N.V. Evolution in the dislocation structure of austenitic 16Cr-15Ni-3Mo-1Ti steel depending on the degree of cold plastic deformation, Journal of Surface Investigation: X-ray. Synchrotron Neutron Tech. 2015, 9, 44–52. [Google Scholar] [CrossRef]

- Voronin, V.I.; Valiev, E.Z.; Berger, I.F.; Goschitskii, B.N.; Proskurnina, N.V.; Sagaradze, V.V.; Kataeva, N.F. Neutron diffraction analysis of Cr–Ni–Mo–Ti austenitic steel after cold plastic deformation and fast neutrons irradiation. J. Nucl. Mater. 2015, 459, 97–102. [Google Scholar] [CrossRef]

- HajyAkbarya, F.; Sietsma, J.; Böttger, A.J.; Santofimia, M.J. An improved X-ray diffraction analysis method to characterize dislocation density in lath martensitic structures. Mater. Sci. Eng. A 2015, 639, 208–218. [Google Scholar] [CrossRef]

- Huang, M.; Rivera-Díaz-del-Castillo, P.E.J.; Bouaziz, O.; van der Zwaag, S. Modelling strength and ductility of ultrafine grained BCC and FCC alloys using irreversible thermodynamics. Mater. Sci. Technol. 2009, 25, 833–839. [Google Scholar] [CrossRef]

- Delincé, M.; Bréchet, Y.; Embury, J.D.; Geers, M.G.D.; Jacques, P.J.; Pardoen, T. Structure-property optimization of ultrafine-grained dual-phase steels using a microstructure-based strain hardening model. Acta Mater. 2007, 55, 2337–2350. [Google Scholar] [CrossRef]

- Shibata, A.; Nagoshi, T.; Sone, M.; Morito, S.; Higo, Y. Evaluation of the block boundary and sub-block boundary strengths of ferrous lath martensite using a micro-bending test. Mater. Sci. Eng. A 2010, A527, 7538–7544. [Google Scholar] [CrossRef]

- Beleznai, R.; Szávai, S. Analysis of warm prestressing effect on fracture toughness of reactor pressure vessel steels. Strength Mater. 2010, 42, 120–123. [Google Scholar] [CrossRef]

- Szabó, P.J.; Field, D.P.; Jóni, B.; Horky, J.; Ungár, T. Bimodal Grain Size Distribution Enhances Strength and Ductility Simultaneously in a Low-Carbon Low-Alloy Steel. Metall. Mater. Trans. A 2015, 46, 1948–1957. [Google Scholar] [CrossRef]

| C | Si | P | S | Cr | Mn | Ni | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.18 | 0.35 | 0.012 | 0.013 | 0.32 | 0.58 | 0.72 | 0.61 | 0.1 | balance |

| Specimen | EBW1 | EBW2 | LBW1 | LBW2 | ASW | |

|---|---|---|---|---|---|---|

| Parameter | ||||||

| Voltage | 60 kV | 60 kV | - | - | 800 V | |

| Current | 50 mA | 75 mA | - | - | 25 A | |

| Beam power | - | - | 22 kW | 22 kW | - | |

| Welding speed | 10 mm/s | 10 mm/s | 33 mm/s | 67 mm/s | 18 mm/s | |

| Heat input | 300 J/mm | 450 J/mm | 660 J/mm | 330 J/mm | 896 J/mm | |

| Specimen | TDBTT, °C | σmax, MPa | Δσρ, MPa | ΔσHP, MPa | Δσ, MPa | Δσρ, MPa | ΔσHP, MPa | Δσ, MPa |

|---|---|---|---|---|---|---|---|---|

| Weld Seams Positions | Notch Position | |||||||

| Base material | −43.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| EBW1 | −58.5 | 172 | 781 | 212 | 993 | 126 | 51 | 177 |

| EBW2 | - | 308 | 632 | 199 | 831 | 23 | 63 | 86 |

| LBW1 | −73.1 | 570 | 411 | 126 | 537 | 317 | 111 | 428 |

| LBW2 | −62.3 | 302 | 466 | 152 | 618 | 276 | 110 | 386 |

| ASW | - | 678 | 498 | 137 | 635 | - | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bokuchava, G.; Petrov, P. Study of Residual Stresses and Microstructural Changes in Charpy Test Specimens Reconstituted by Various Welding Techniques. Metals 2020, 10, 632. https://doi.org/10.3390/met10050632

Bokuchava G, Petrov P. Study of Residual Stresses and Microstructural Changes in Charpy Test Specimens Reconstituted by Various Welding Techniques. Metals. 2020; 10(5):632. https://doi.org/10.3390/met10050632

Chicago/Turabian StyleBokuchava, Gizo, and Peter Petrov. 2020. "Study of Residual Stresses and Microstructural Changes in Charpy Test Specimens Reconstituted by Various Welding Techniques" Metals 10, no. 5: 632. https://doi.org/10.3390/met10050632

APA StyleBokuchava, G., & Petrov, P. (2020). Study of Residual Stresses and Microstructural Changes in Charpy Test Specimens Reconstituted by Various Welding Techniques. Metals, 10(5), 632. https://doi.org/10.3390/met10050632