3.3. Fatigue Behavior Parametric Analylsis

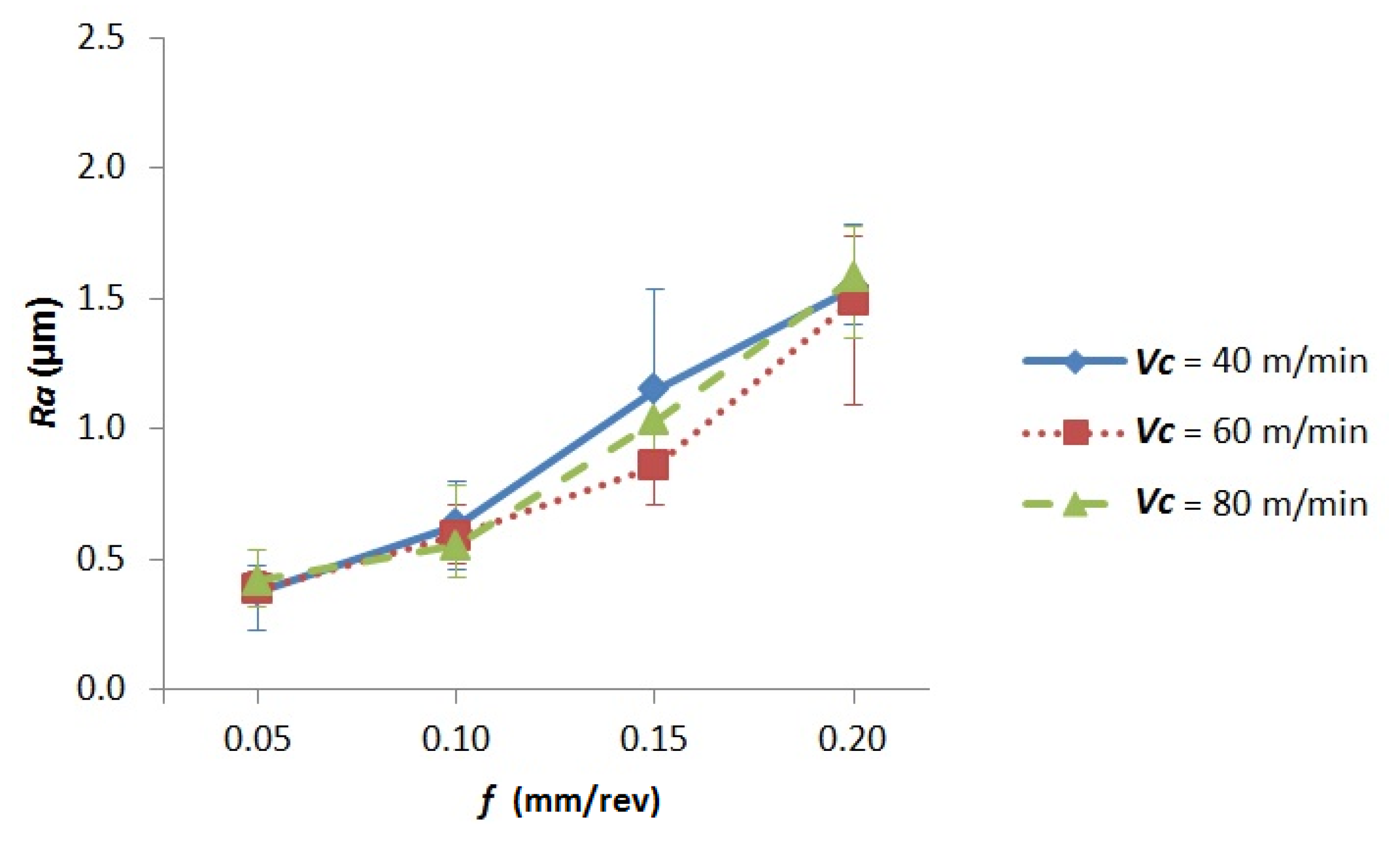

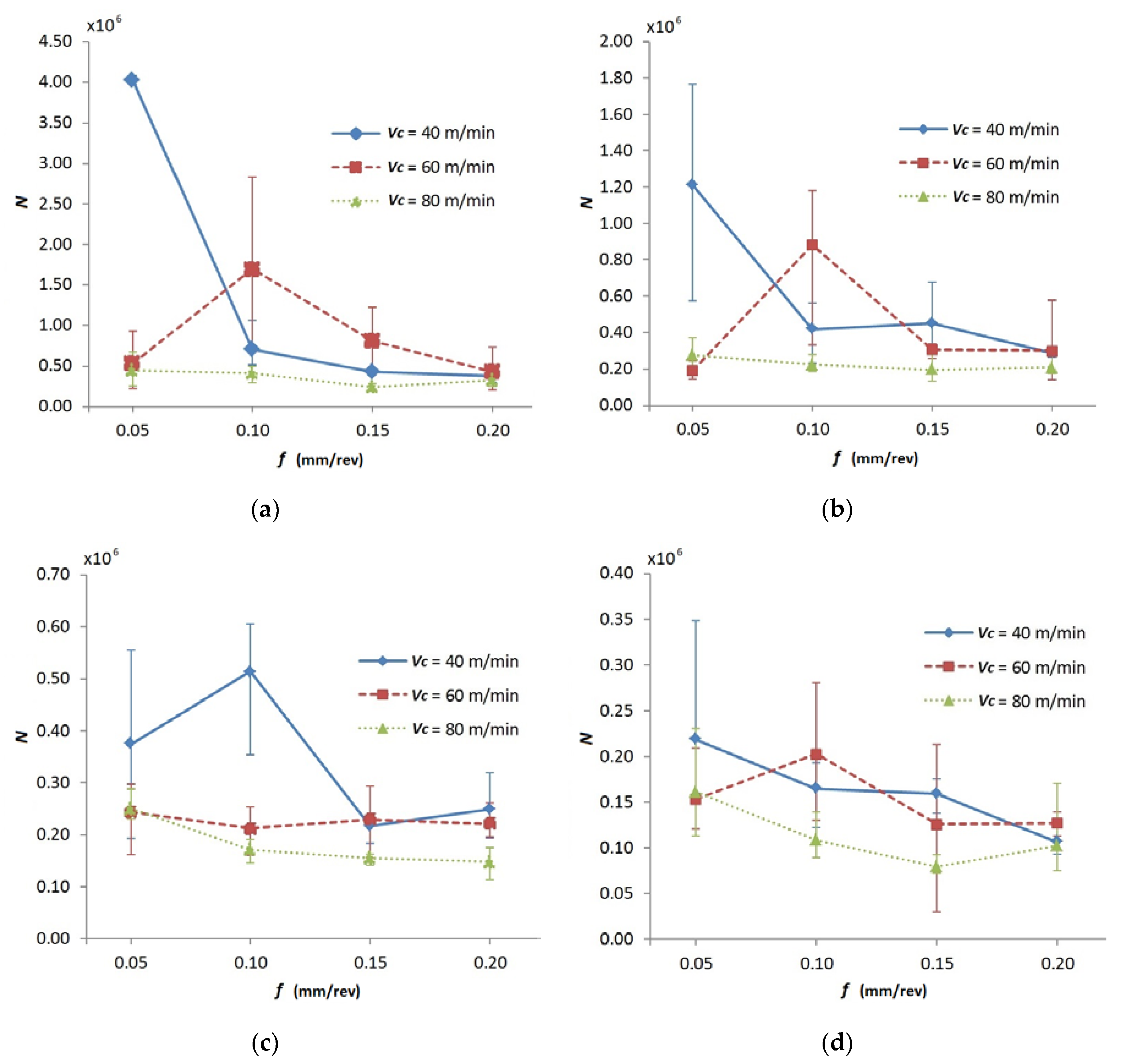

Figure 9 shows the evolution of

N as a function of

vc and

f, for each applied load. Regarding

f, a general trend to decrease

N with

f was observed, regardless of

vc. This trend was more evident within the low range of load applied (244.40 and 257.24 MPa). Therefore, the surface topography was especially relevant in the crack initiation of fatigue failure at lower stresses and, as a result,

f becomes more regardless. At higher stresses, this influence became lower and, therefore, surface roughness became less relevant. At high loads, other factors may be more prominent, such as the geometrical deviations, residual stresses or microstructure, which are more influenced by the cutting speed [

56]. Notwithstanding, some singularities in this trend are observed for the low range of

f applied (0.05–0.01 mm/rev), for

vc = 40 and 60 m/min, where a reduction of

N was observed for some of the loads studied. This can be explained taking into account that the highest dispersion occurs for these

vc values. Under these cutting conditions, the distance between the real and expected fracture section was also the highest.

With regard to

vc, a general trend to decrease

N with

vc was observed, regardless of

f. Only for

vc = 60 m/min this trend was the opposite within the low range of

f (0.05–0.10 mm/rev) and

S (244.40 and 257.24 MPa). In addition, the worst results were obtained when the highest

f and

vc were combined. Furthermore, in

Figure 9c, for

vc = 40 m/min and

f = 0.10 mm/rev, the increase of

N could be explained because the distance between the expected fracture section and the real one was higher, reducing the equivalent stress and increasing

N.

Additionally, the increase of

S (in connection with the load increase) gave rise to a reduction of

N in the whole range of the cutting parameters values, as expected. However, the effect of the applied cutting parameters in the machining process should not be neglected. For each tested value of

S,

vc and

f have modified the fatigue behavior of the turned parts. In general, they have negatively affected the fatigue behavior, reducing

N. On one hand, an

f increment results in higher

Ra values, which makes easier the crack initiation. On the other hand, a

vc increase gives rise to a microhardness reduction, an increment of geometrical deviations (due to higher vibrations) and an increase of tensile stresses [

36,

55,

56], which results in

N reductions. Those effects are enhanced when both cutting parameters (

f and

vc) increase simultaneously.

These experimental results suggest the possibility of obtaining an equation that relates fatigue life not only with the stress (or the load) but also with the cutting parameters.

First, the relation

S-

N (Basquin’s equation) has been obtained for each cutting parameters combination. For this marginal equation the cutting speed and feed have remained constant. A potential relation, as shown in Equation (2), is usually used [

39]. This equation allows obtaining a relation between

S and

N.

In Equation (2), C and α are constant. This type of potential equations can be fit from the experimental data using a linear regression (log-log).

Table 5 shows the results for these constants, according to ISO 12107:2012 [

57]. These parametric relationships show, in general terms, a reasonable fit (R

2 = 0.7–0.8) for most cutting parameters combinations, taking into account the usual dispersion of fatigue test results.

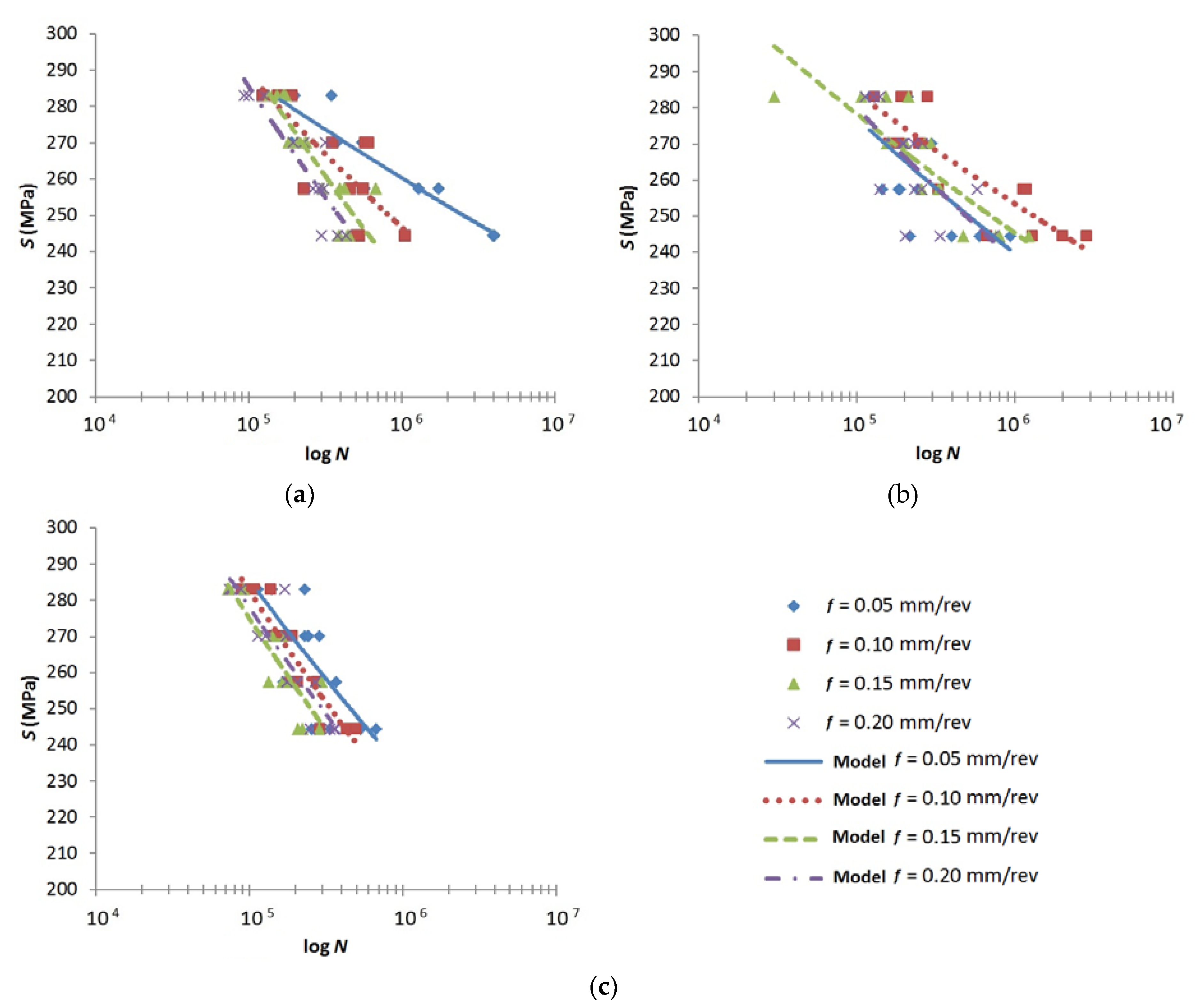

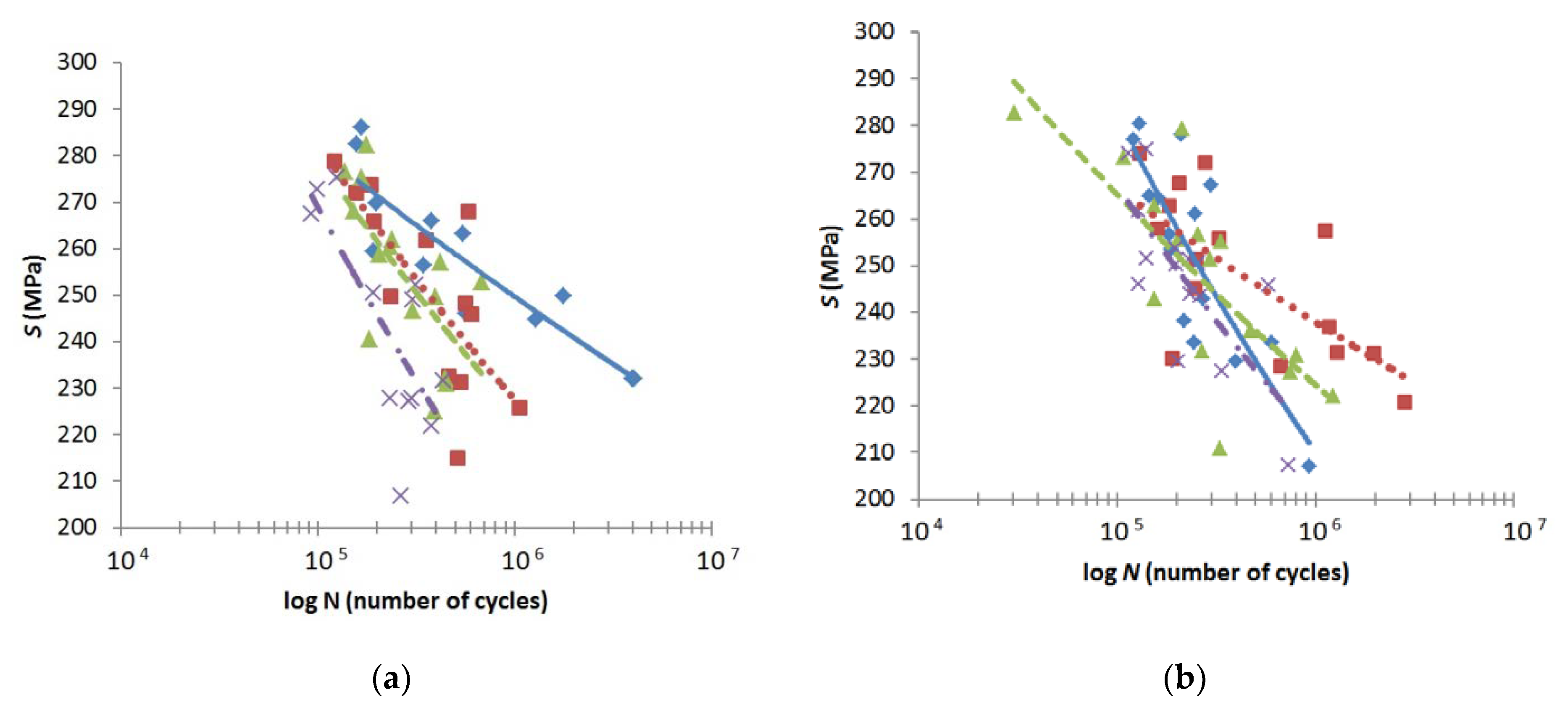

For an easier understanding, results are shown as

S-log N (Wöhler curve) for each cutting parameter combination considered (

Figure 10).

On one hand, for

vc = 40 m/min (

Figure 10a), the results revealed a clear influence of

f in the

S-N relation, where an increase of

f tended to reduce the

N values, regardless of

S. This fact is more noticeable for the lowest

S (244.40 MPa), where the highest difference for

N was obtained. In this regard, higher differences in the fatigue life (

N) were observed for low

f values (0.05–0.10 mm/rev) whereas these differences were lower for higher values (0.15–0.20 mm/rev). These differences became less relevant when

S increased and

N tended to converge to the highest

S (282.91 MPa). In that point,

N exhibited less sensitivity to change with

f. This fact was in good agreement with that mentioned above. For lower

S values, the surface conditions took more relevance. Higher

f resulted in higher

Ra (worse surface quality), which makes easier microcrack generation and nucleation [

59]. However, crack initiation occurred faster for higher values of

S and surface topography became less relevant.

On the other hand, for

vc = 60 m/min (

Figure 10b), a lower

f influence on the

S-N relation was observed. In general, as with

vc = 40 m/min, a higher

f influence could be observed at low

S values (244.40 MPa), tending to converge at higher

S values (282.91 MPa). Notwithstanding, the worst results were obtained for

f = 0.05 mm/rev. Hence,

f became less predominant and

vc took more relevance. In addition, although the dispersion was greater for

vc = 60 m/min, it is within the common dispersion for fatigue tests. Similar studies carried out on the cutting parameters influence on the microhardness and microstructure of the machined surface (which affect fatigue behavior) coincide in obtaining a greater dispersion in the results for

vc = 60 m/min [

55]. The authors explain this behavior due to a combined effect of mechanical effects (feed) and thermal effects (cutting speed) that influences on surface microhardness and microstructure and, therefore, on fatigue behavior.

Finally, for

vc = 80 m/min (

Figure 10c), the proposed equations and the experimental results, seemed to remain parallel along the whole

S range. Additionally, in this case, the worst results were obtained for

f = 0.15 mm/rev.

Considering that

vc had a very low influence on

Ra, everything seemed to indicate that other variables (not only micro-geometrical deviations) took parts in the

S-N evolution, especially for higher values of

vc (60–80 m/min). As previously mentioned, different research establishes that fatigue behavior is related with other surface conditions, as residual stresses, microstructure and surface microhardness [

36,

38], which are more influenced by

vc. This fact is relevant enough because, traditionally, Wöhler curves are corrected only as a function of the micro-geometrical surface deviations [

59] and, hence, the effect of

vc is usually neglected.

Since experimental data have revealed the influence of both cutting parameters on the fatigue life of the specimens, it is reasonable to modify the

S-N relation as a function of

vc and

f. In the present work, obtaining a relationship of the studied output variable (fatigue behavior) as a function of the input variables (load and cutting parameters) may be interesting. Therefore, a new equation is proposed as an adaptation of the Basquin’s equation that may be useful from an industrial point of view. Initially, different marginal equations (

vc constant) that relate

N with

S and

f have been developed, Equation (3).

In Equation (3), C, x and y are constants.

Table 6 shows the results for these constants. The exponent for

f (

y) shows higher value for

vc = 40 m/min, which highlights the

f greater influence on

N at low cutting speeds. At higher cutting speed,

y takes a lower value, the

f influence being practically negligible for

vc = 60 m/min. These results were in good agreement with the experimental data. In addition, the equations show a reasonable fit, considering the usual dispersion in the fatigue test results, due to the synergistic action of different factors, such as surface roughness, geometric deviations, residual stresses, surface microstructure changes or vibrations [

39,

60].

Finally, potential parametric relationships,

N = g(

S,vc,f), have been proposed, which includes the effect of

vc, as follows (Equation (4)).

In Equation (4), C, x, y and z are constants.

Table 7 shows the results for these constants. It is observed that

z shows higher value than

y (more than double). Therefore, the equation reveals that

vc has higher relevance than

f in the fatigue life (

N). In addition, both exponents are negative and, therefore,

vc and

f tend to reduce the fatigue life of the specimens.

The results from

Table 7 revealed that Equation (4) has shown a reasonable fit (R

2 = 0.71) within a wide range of cutting speed, regardless of

f, taking into account the normal dispersion of fatigue tests. For

vc = 40 m/min, this equation allows one to get a good approximation for

N, as it could be observed for the marginal equations from

Table 6 (R

2 = 0.79), being higher for

vc = 80 m/min (R

2 = 0.91).

However, for

vc = 60 m/min, the equation fit shows a lower value (R

2 = 0.63). For this cutting speed the dispersion of experimental results was greater but, as previously commented, within the common dispersion for fatigue tests. In fact, for this

vc value (60 m/min), the combination of the thermal and mechanical effect (cutting speed and feed, respectively) gave rise to singularities in the microhardness and microstructure of the machined surface (which affect fatigue behavior) [

55]. Regardless of the fit value, this equation allows for explaining the relative importance of each cutting parameter on

N.

As previously mentioned, this relation indicates that surface roughness was not the only variable that affected fatigue behavior, but other variables, such as residual stresses, microhardness and surface microstructure, should be considered. Furthermore, this equation highlights the importance of the cutting parameters (vc, f), especially when high vc and f values are combined.

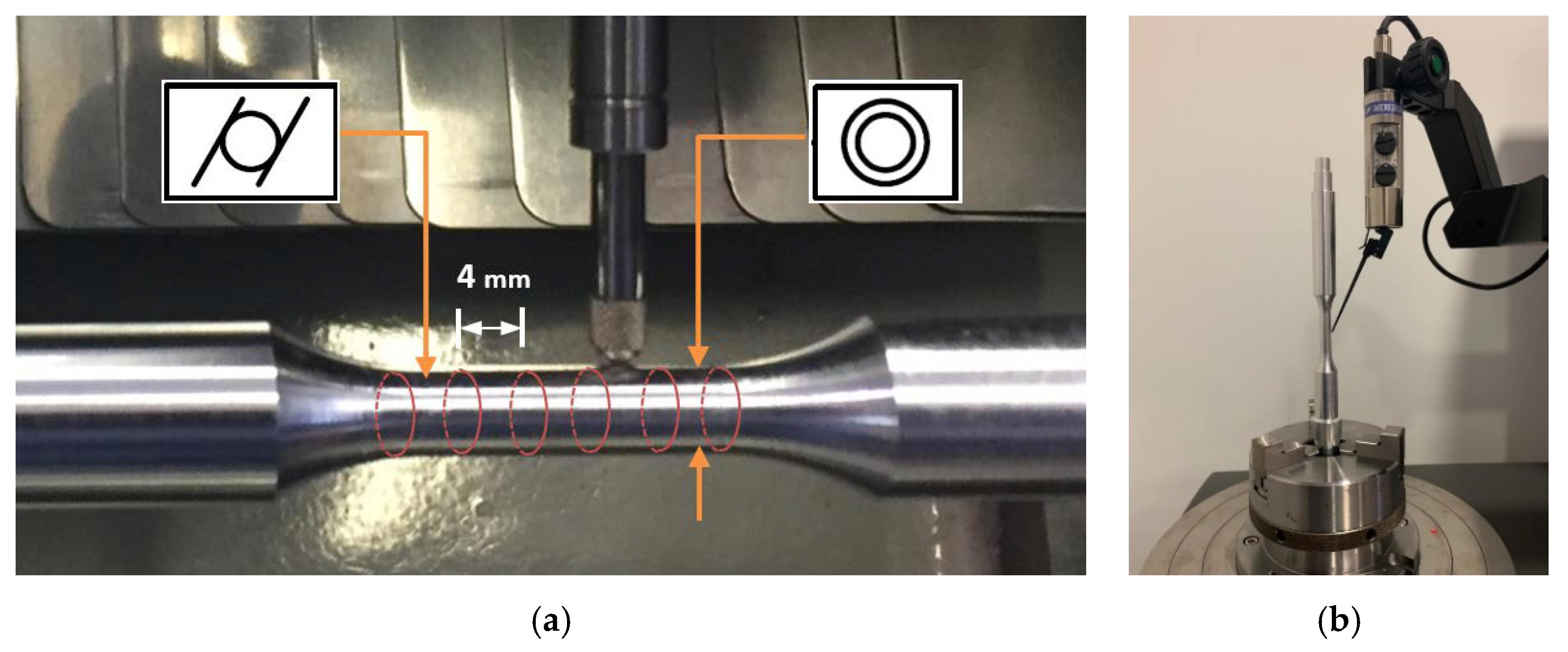

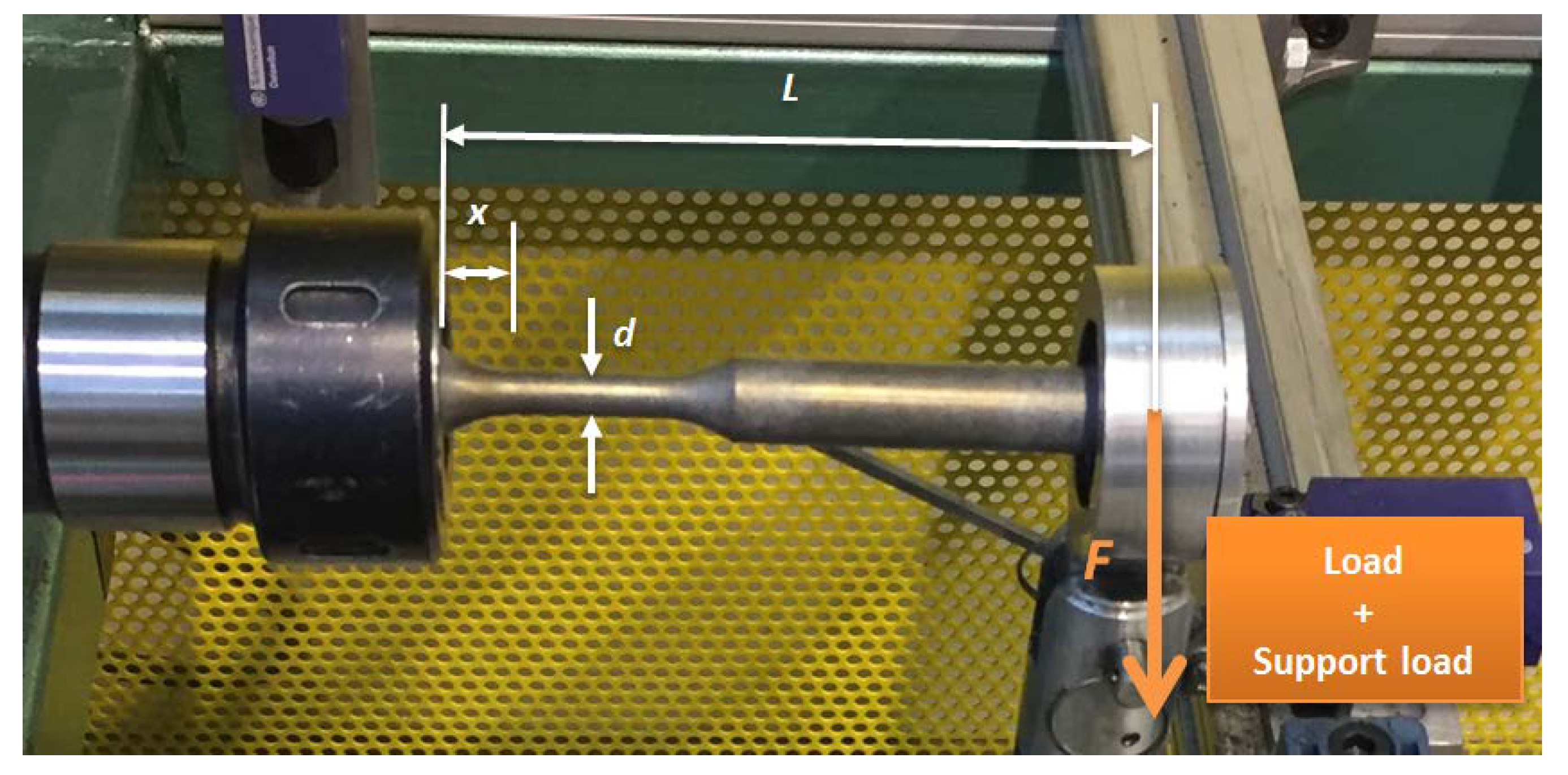

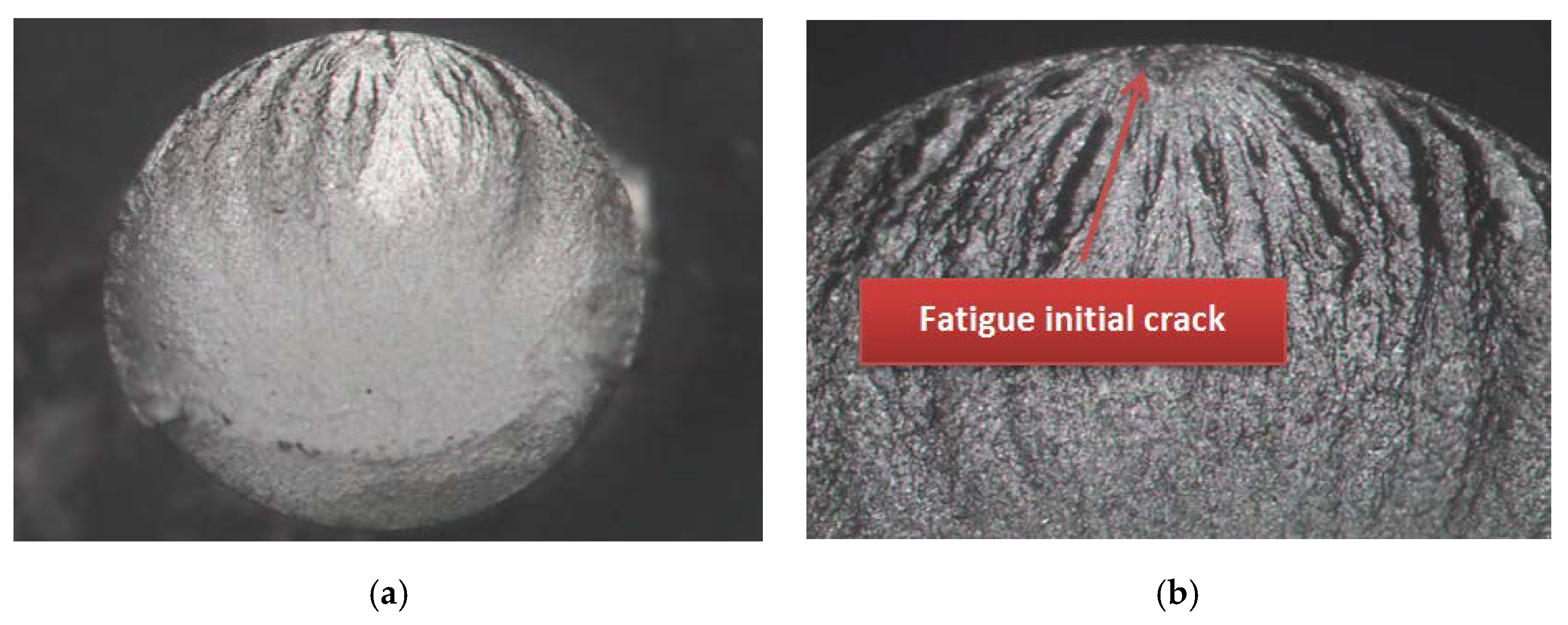

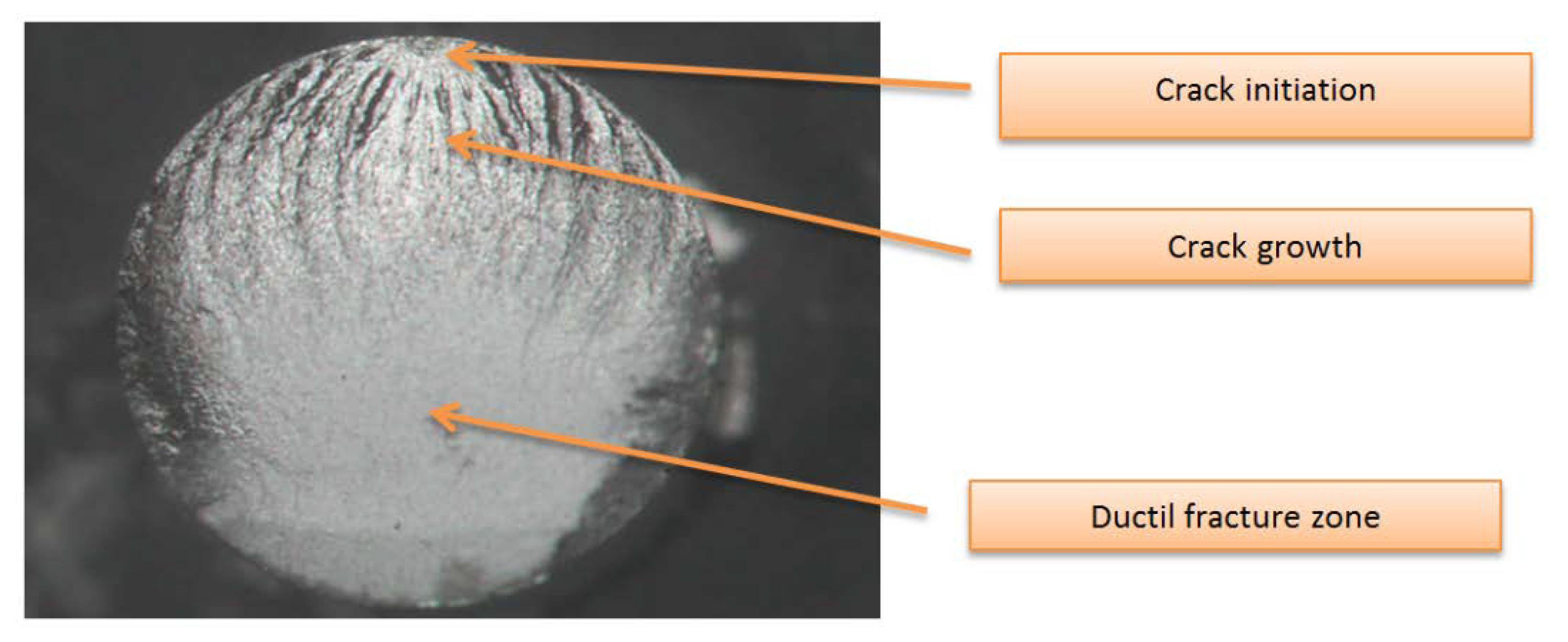

3.4. Effect of the Real Fracture Section Position on Fatigue Behaviour

ISO 1143:2010 standard demands strong requirements for geometrical tolerances of the rotating bar bending specimen, in order to minimize their effect in fatigue behavior. In this regard, the standard establishes maximum geometrical deviations values for roughness (

Ra < 0.32 μm), concentricity (

CON < 15 μm) and cylindricity (

CYL < 20 μm). In addition, due to economic reasons, industrial machining operations use cutting conditions that can result in higher geometrical deviations. Therefore, both micro and macro-geometrical deviations influence should be considered in the fatigue behavior analysis. In order to do this, concentricity and cylindricity were measured before the fatigue tests.

Table 8 shows the average values for the micro and macro-geometrical deviations.

As it can be observed in

Table 8,

Ra values were higher than the standard requirements in the whole range of cutting parameters tested. Similar behavior could be observed in

CYL, except for low

f (0.05 mm/rev) and

vc (40 and 60 m/min). On the other hand,

CON seemed to be lower than standard requirements, except for the highest value of

vc (80 m/min). Hence, these macro-geometrical deviations may be an important factor to consider, mainly in the high range of the applied cutting parameters values. These high values for the macro-geometrical deviations may result in the specimen fracture in a different area from that expected (maximum stress),

Figure 11.

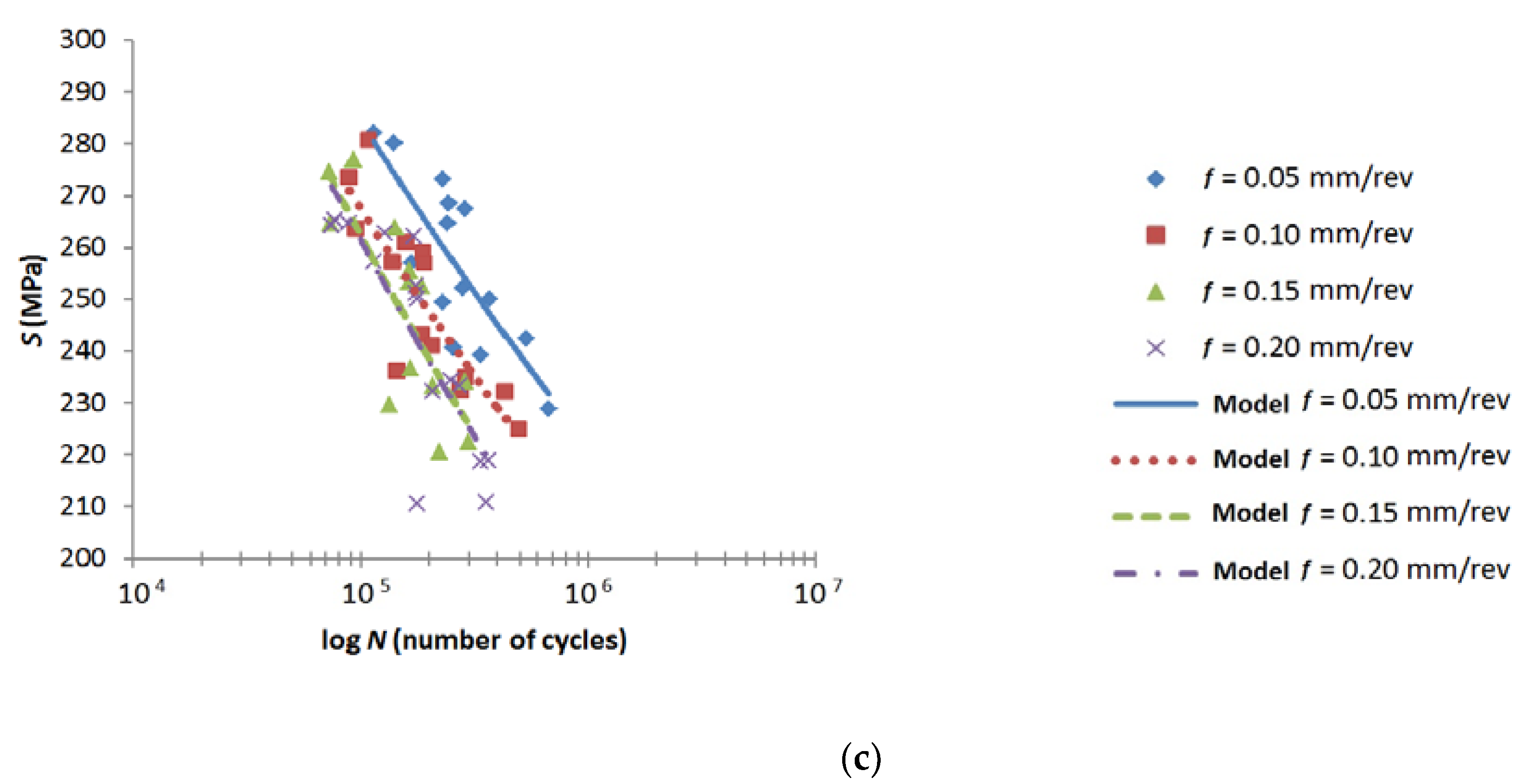

Hence, in this work, as a novelty, different stress values were calculated (Equation (1)), as a function of the real position where a fracture occurs. These stress values were related to the number of cycles (

N), giving rise to new experimental Wöhler curves,

Figure 12.

As a result, new potential relationships were developed.

Table 9 shows the values of the constants for the new

S-N potential equation, as a function of

f and

vc, according to Equation (2). These relations show a worse fit than the previous one (

Table 5) due to higher dispersion in the experimental data, typical of fatigue behavior tests. The influence of the cutting parameters on the position of the fracture section, mainly at high

f and

vc, should not be disregarded and their effect should be included in the equation.

Considering these results, a new parametric relationship was proposed, according to Equation (3).

Table 10 shows the values of C, x and y.

Compared to the previously obtained marginal equations, these new relations exhibited higher f dependence. The exponent for f (y) was higher in the whole range of the tested cutting speeds. Even, this influence was significant for vc = 60 m/min, whereas it was negligible for the previous one. In addition, the difference with S exponent (x) was lower. Hence, these equations fit better to reality and revealed higher influence of micro-geometrical deviations on fatigue behavior. Although the equations fit were slightly lower than the previous one, they show a reasonable fit, mainly for 40 and 80 m/min.

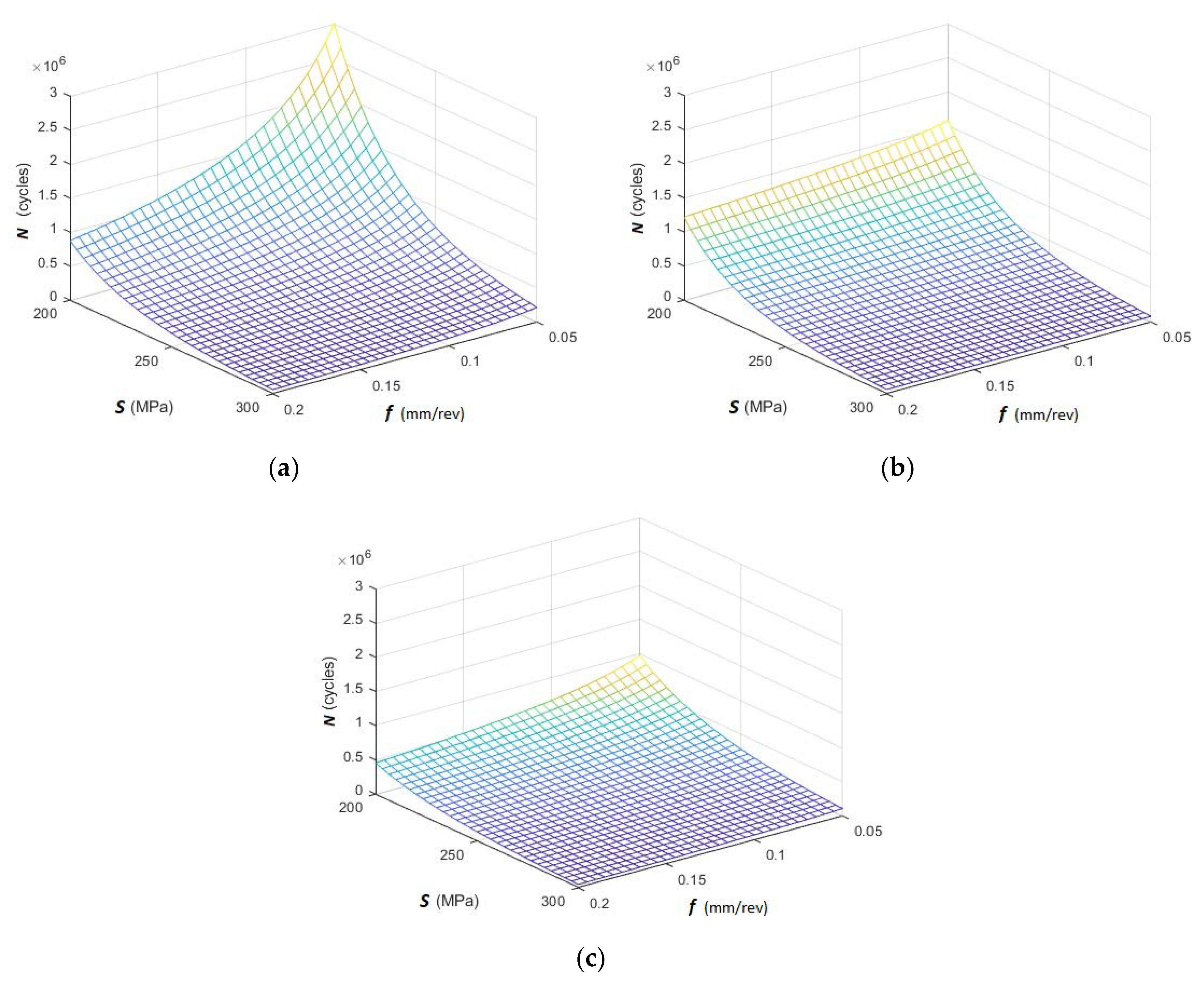

Figure 13 plots the parametrical potential equations exposed in

Table 10. As previously commented, these relations show stronger dependence on

S. Notwithstanding, the

f influence on

N was more noticeable at lower

S (200 MPa), especially for low

vc (40 m/min), whereas

f exhibited lower influence at higher

S.

Additionally,

Figure 13 shows the

vc influence on fatigue life (

N). This influence was more noticeable in the low range of

S (200–250 MPa), and became less important above 250 MPa, regardless of

f. As previously commented, this influence might be explained by considering that surface conditions take special importance in microcrack initiation at low

S values, being these surface conditions were related to the cutting parameters (mainly

f). On the other hand, at higher values of

S, surface conditions are less important, because microcrack initiation and nucleation quickly happen.

Finally, a potential parametric equation

N = g (

S,vc,f) was proposed, which includes the effect of

vc, as follows, according to Equation (4).

Table 11 shows the results obtained for C, x, y and z.

First, compared to the equation from

Table 7,

S influence was reduced and the influence of the cutting parameters (

vc,

f) in fatigue behavior became more relevant, especially for

f. This higher influence may be explained in part by the effect of macro-geometrical deviations on fatigue life. An

f increase results in

CON and

CYL increments [

56], regardless of

Ra. Therefore, the influence of micro-geometrical deviations (and hence of

f) on fatigue behavior is relevant, but the effect of

f and

vc on macro-geometrical deviations and these on fatigue behavior should not be neglected.

In addition, these new parameters for Equation (4) (

Table 11) present the next advantages regarding the original coefficients (

Table 7). On one hand, a better approximation to the roughness effect on

N (

vc = 60 m/min and

f = 0.05 mm/rev,

vc = 80 m/min and

f = 0.15 mm/rev), showing the expected evolution of

N as a function of

f (close related with

Ra). On the other hand, for

vc = 60 and 80 m/min, at high

S values, the cutting parameters influence was less significant, presenting

N = g(

S,vc,f) a greater convergence, as shown in

Figure 12b,c.

This equation allows predicting fatigue life as a function of the stress in the real fracture section (Wöhler curves) and corrects this value as a function of the input variables to the manufacturing process (cutting parameters,

vc and

f). The results from

Table 11 show that, for the real fracture section position, also Equation (4) has shown a reasonable fit (R

2 = 0.67). For

vc = 40 and 80 m/min, the corrected equation provides a good approximation for

N (R

2 = 0.73 and 0.90 respectively,

Table 10). Additionally, the equation fit for

vc = 60 m/min was the lowest (R

2 = 0.57) and the dispersion of experimental results greater, within the common values for fatigue tests.