Comparative Study of Droplet Transfer Modes on Appearance, Microstructure, and Mechanical Properties of Weld during Pulsed GMAW

Abstract

1. Introduction

2. Experimental Procedures and Equipment

2.1. Welding and High-Speed Camera System

2.2. Materials and Welding Parameters

2.3. Appearance and Microstructure Characterization

2.4. Mechanical Testing

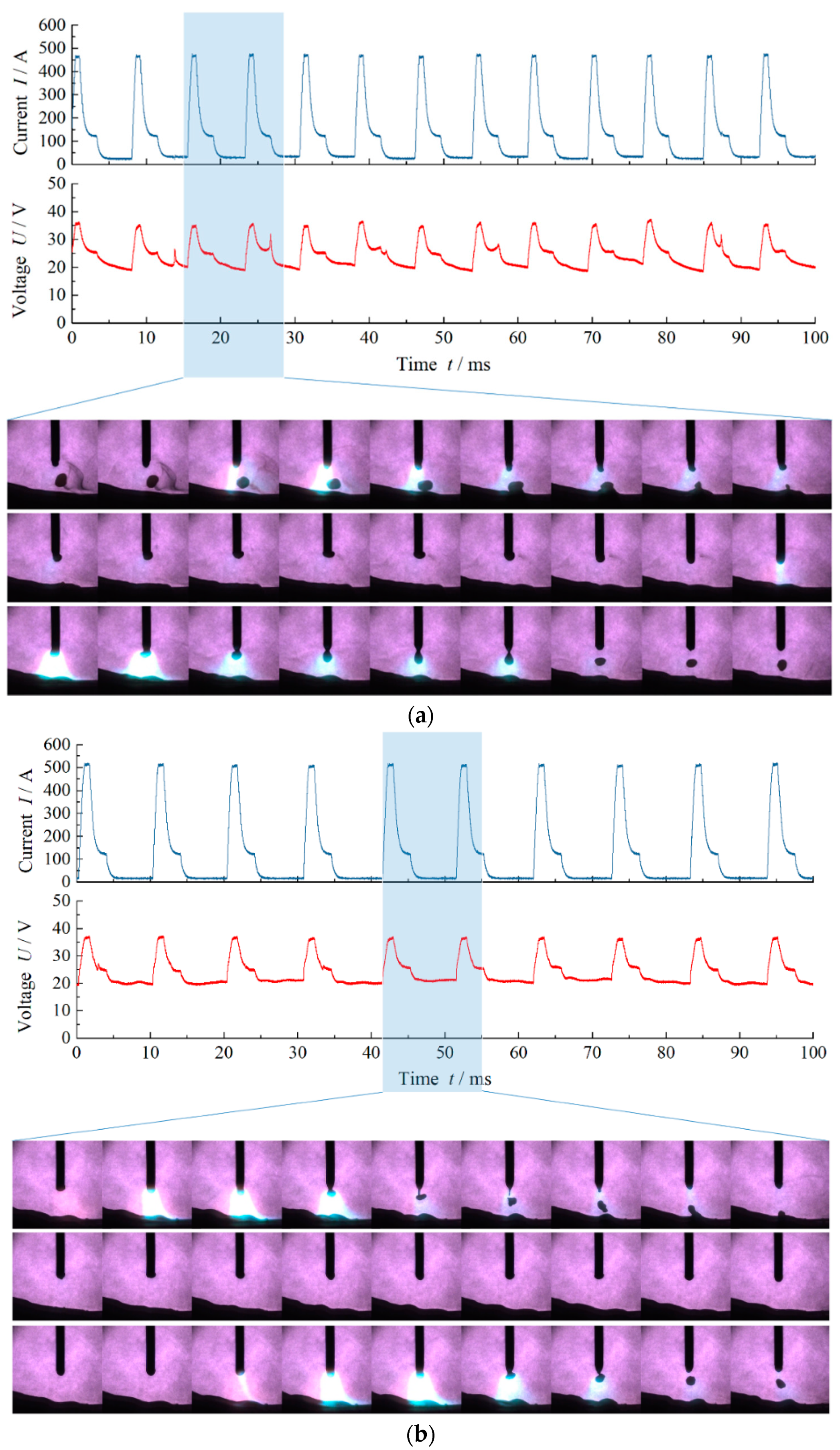

3. Results and Discussion

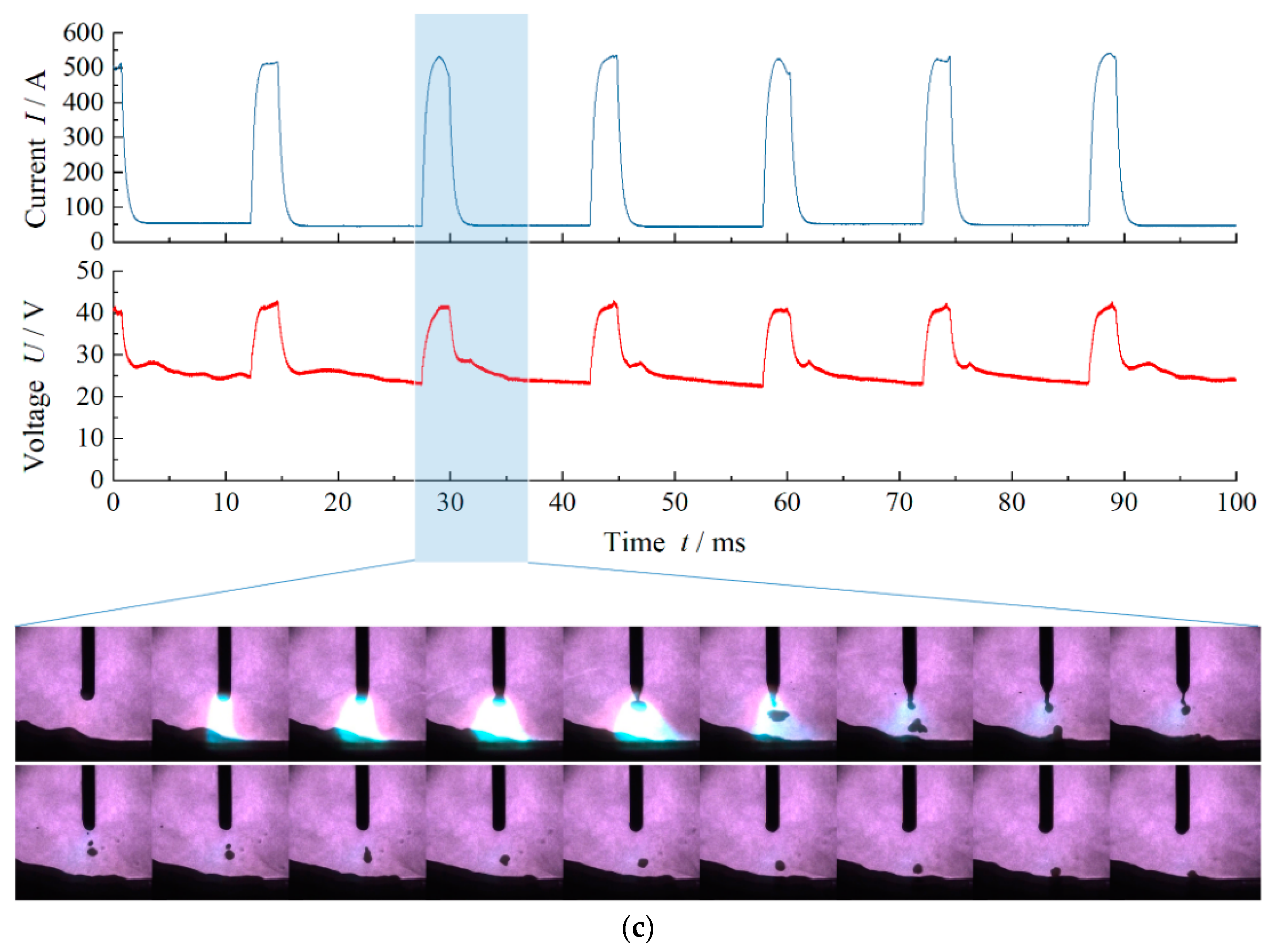

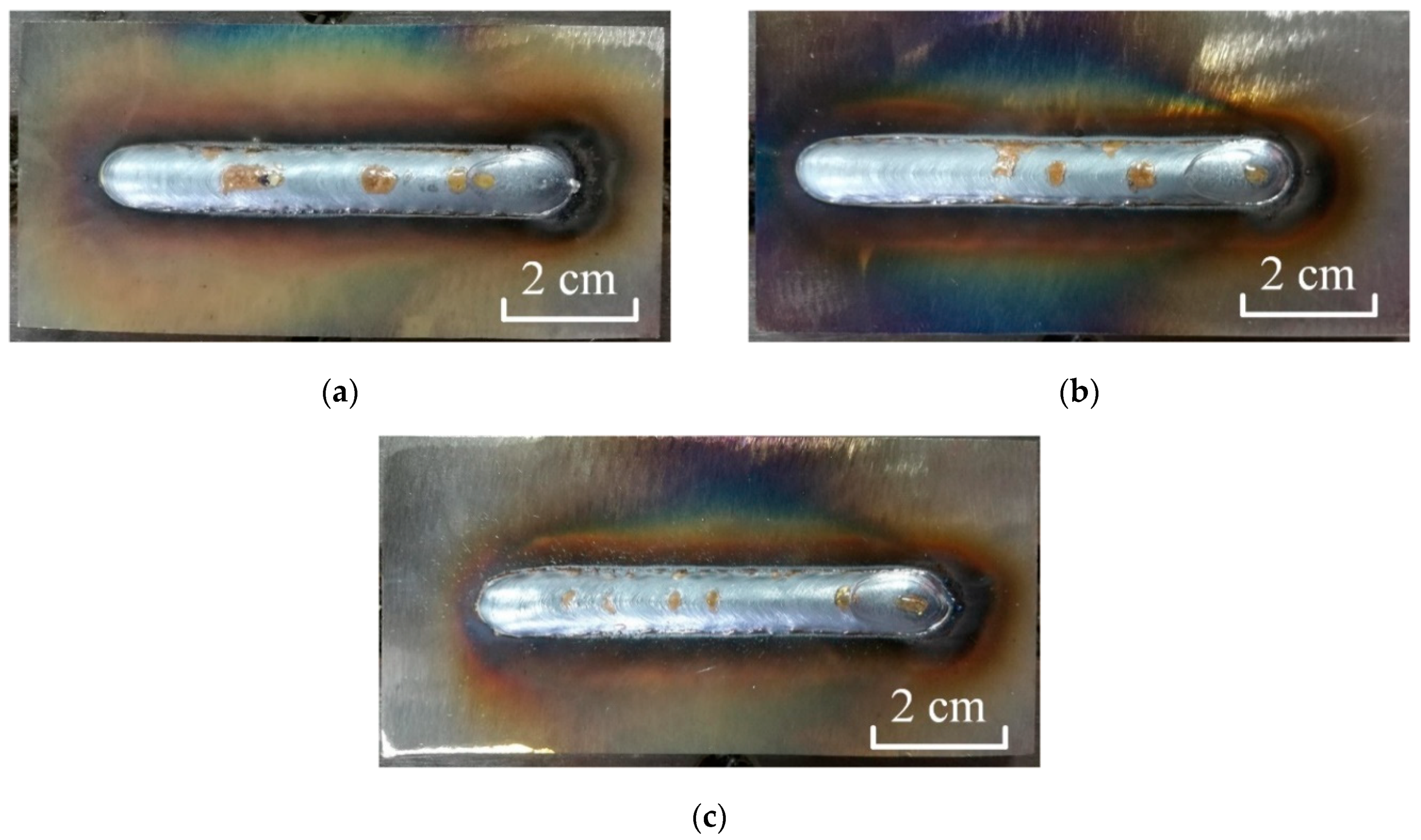

3.1. The Appearance of Weld Bead

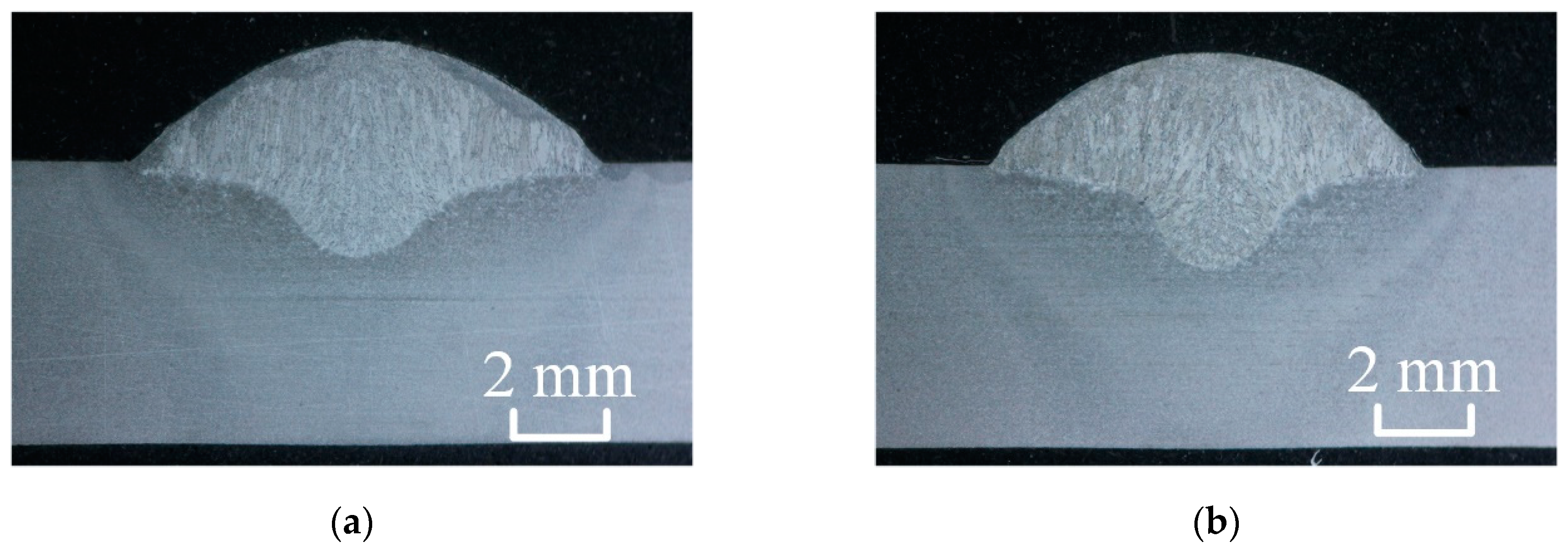

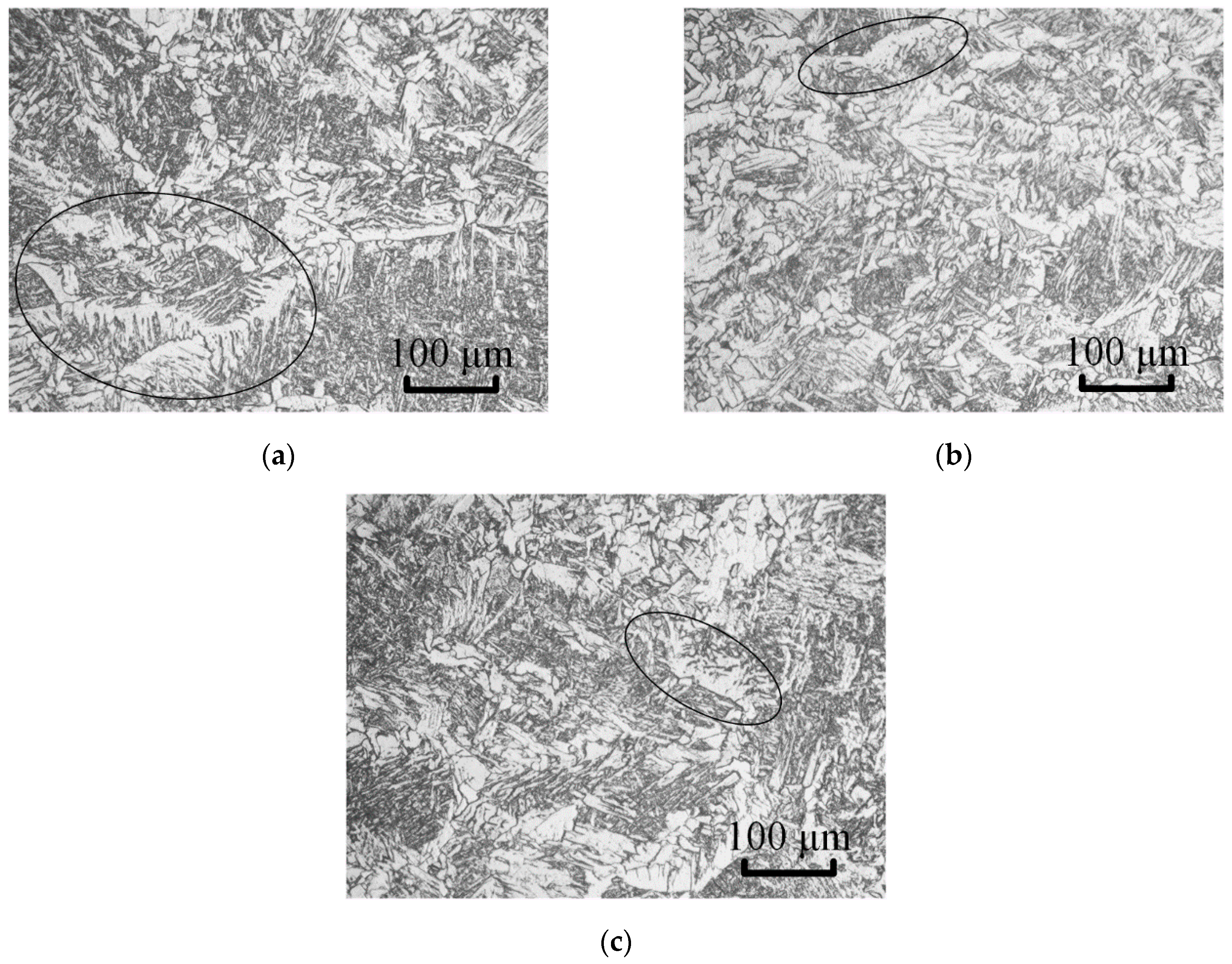

3.2. Microstructure Analysis of Weld

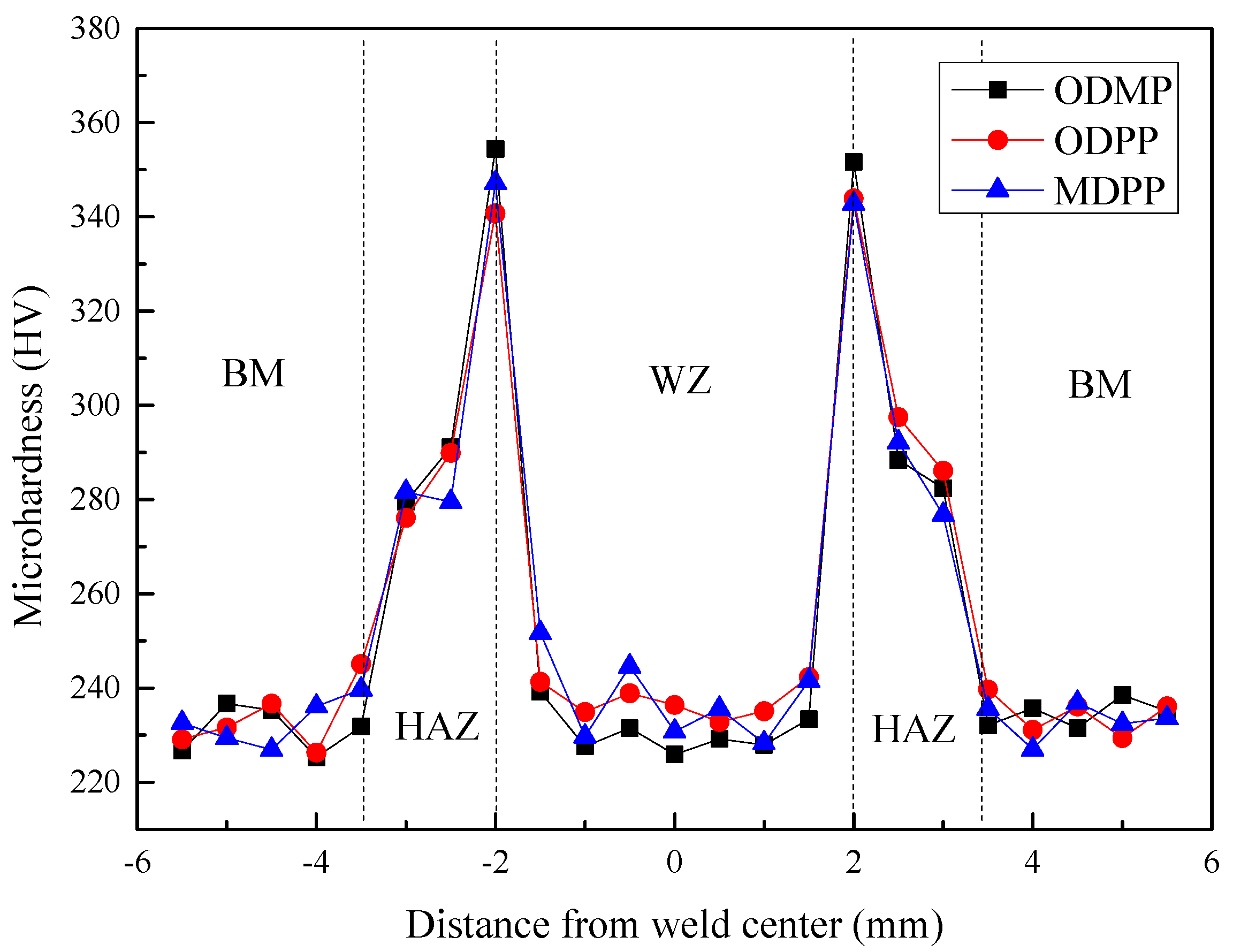

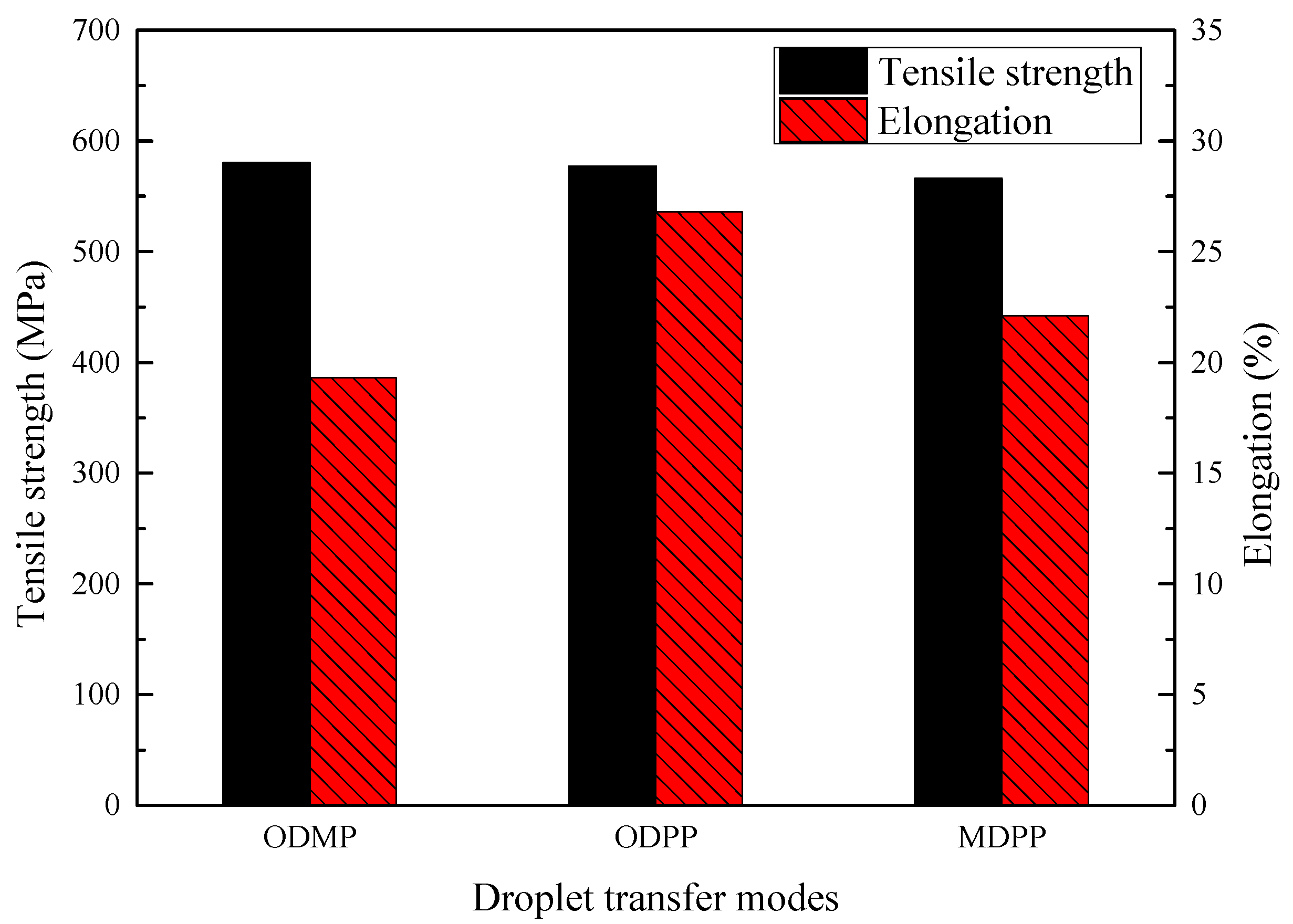

3.3. Microhardness and Tensile Properties of Welded Joint

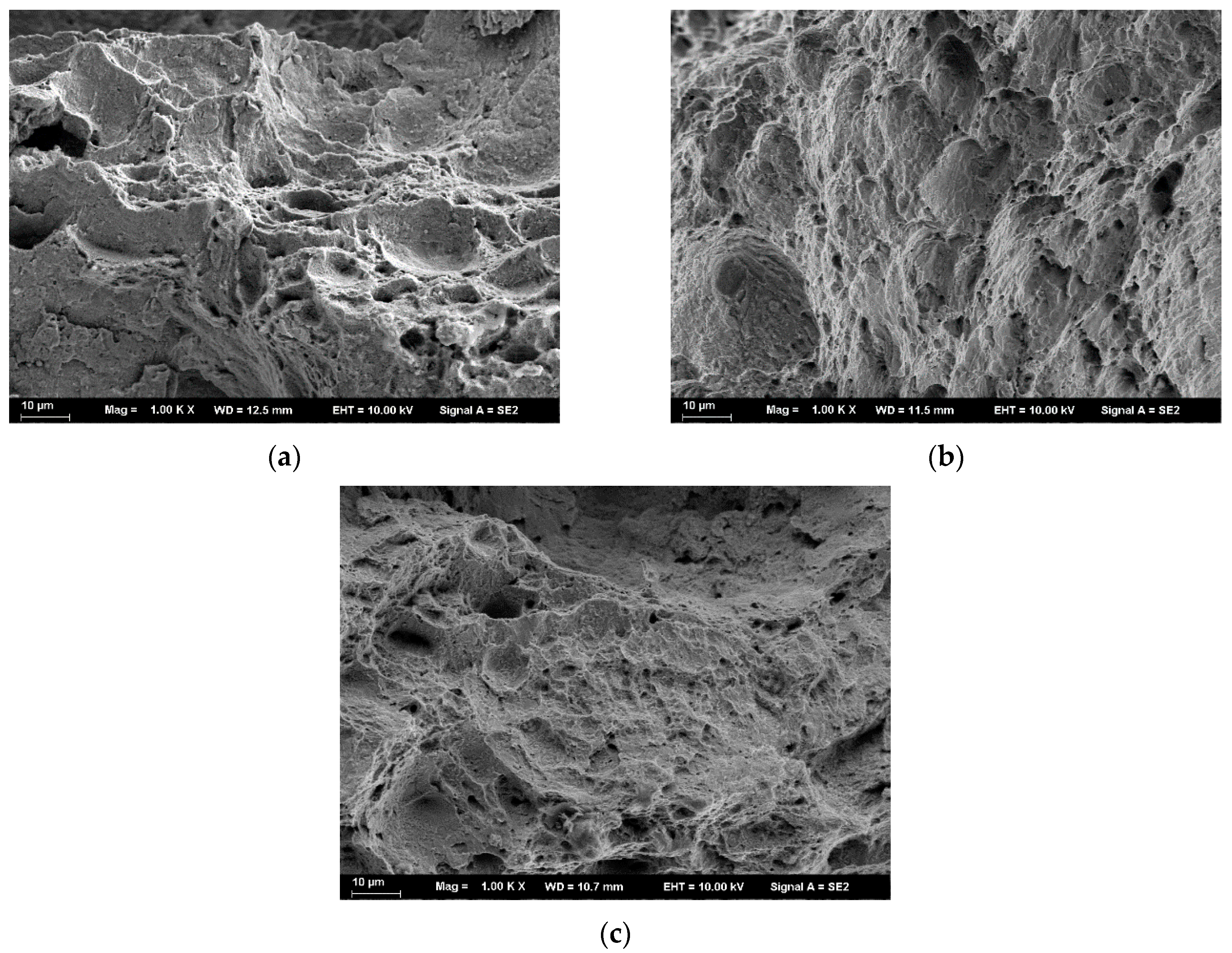

3.4. Impact Characteristics and Fractography

4. Conclusions

- (1)

- At the same wire feeding speed and arc length, the average current was similar in ODPP and MDPP conditions. However, the average current in the ODMP condition was about 15 A larger than the former two, contributing to the higher heat input. Therefore, the proeutectoid ferrite and ferrite side plate were more and coarser in the ODMP condition. Besides, the microstructure of weld metal in the ODPP condition exhibited more uniform distribution compared with MDPP.

- (2)

- Compared with ODMP and MDPP, the smooth, straight, and bright weld bead could be found during the ODPP welding process. A deeper penetration was gained in the ODPP condition, which was about 10% deeper than that in ODMP and MDPP conditions. Besides, the amount of fume covered on the steel plate after welding in the ODPP condition was less, which could save time in cleaning the surface of the workpiece and improve production efficiency.

- (3)

- The effect of droplet transfer modes on the tensile strength was little. The longest elongation of the welded joint was found in the ODPP condition, which was 7.5% longer than the shortest one (ODMP condition). The lowest impact energy was found in the weld zone with ODMP droplet transfer. The decease of elongation and impact toughness might result from the coarsen microstructure, like the proeutectoid ferrite and ferrite side plate.

Author Contributions

Funding

Conflicts of Interest

References

- Chiocca, A.; Frendo, F.; Bertini, L. Evaluation of Heat Sources for the Simulation of the Temperature Distribution in Gas Metal Arc Welded Joints. Metals 2019, 9, 1142. [Google Scholar] [CrossRef]

- Cai, X.; Dong, B.; Lin, S.; Murphy, A.B.; Fan, C.; Yang, C. Heat Source Characteristics of Ternary-Gas-Shielded Tandem Narrow-Gap GMAW. Materials 2019, 12, 1397. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Su, C.; Wang, Y.; Siddiquee, A.N.; Sergey, K.; Jayalakshmi, S.; Singh, R.A. Cold Metal Transfer (CMT) Based Wire and Arc Additive Manufacture (WAAM) System. J. Surf. Ingestig. 2018, 12, 1278–1284. [Google Scholar] [CrossRef]

- Yao, P.; Zhou, K.; Lin, H.; Xu, Z.; Yue, S. Exploration of Weld Bead Forming Rule during Double-Pulsed GMAW Process Based on Grey Relational Analysis. Materials 2019, 12, 3662. [Google Scholar] [CrossRef] [PubMed]

- Yao, P.; Zhou, K.; Huang, S. Process and Parameter Optimization of the Double-Pulsed GMAW Process. Metals 2019, 9, 1009. [Google Scholar] [CrossRef]

- Wang, L.; Xue, J. Perspective on Double Pulsed Gas Metal Arc Welding. Appl. Sci. 2017, 7, 894. [Google Scholar] [CrossRef]

- Makles, K.; Winczek, J.; Gucwa, M. Advanced Output Characteristics of Welding Power Source for Pulsed GMAW. In Advances in Manufacturing Engineering and Materials. Lecture Notes in Mechanical Engineering; Hloch, S., Klichová, D., Krolczyk, G., Chattopadhyaya, S., Ruppenthalová, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 307–314. [Google Scholar]

- Wang, Q.; Qi, B.; Cong, B.; Yang, M. Output characteristic and arc length control of pulsed gas metal arc welding process. J. Manuf. Process. 2017, 29, 427–437. [Google Scholar] [CrossRef]

- Xu, Y.; Lv, N.; Fang, G.; Du, S.; Zhao, W.; Ye, Z.; Chen, S. Welding seam tracking in robotic gas metal arc welding. J. Mater. Process. Technol. 2017, 248, 18–30. [Google Scholar] [CrossRef]

- Xu, Y.; Fang, G.; Lv, N.; Chen, S.; Zou, J.J. Computer vision technology for seam tracking in robotic GTAW and GMAW. Robot. Comput.-Integr. Manuf. 2015, 32, 25–36. [Google Scholar] [CrossRef]

- Kozakov, R.; Gött, G.; Schöpp, H.; Uhrlandt, D.; Schnick, M.; Häßler, M.; Füssel, U.; Rose, S. Spatial structure of the arc in a pulsed GMAW process. J. Phys. D Appl. Phys. 2013, 46, 224001. [Google Scholar] [CrossRef]

- Chen, C.; Fan, C.; Cai, X.; Lin, S.; Yang, C. Analysis of droplet transfer, weld formation and microstructure in Al-Cu alloy bead welding joint with pulsed ultrasonic-GMAW method. J. Mater. Process. Technol. 2019, 271, 144–151. [Google Scholar] [CrossRef]

- Dos Santos, E.B.F.; Pistor, R.; Gerlich, A.P. Pulse profile and metal transfer in pulsed gas metal arc welding: Droplet formation, detachment and velocity. Sci. Technol. Weld. Join. 2017, 22, 627–641. [Google Scholar] [CrossRef]

- Hertel, M.; Rose, S.; Füssel, U. Numerical simulation of arc and droplet transfer in pulsed GMAW of mild steel in argon. Weld. World 2016, 60, 1055–1061. [Google Scholar] [CrossRef]

- Konovalov, S.; Chen, X.; Sarychev, V.; Nevskii, S.; Gromov, V.; Trtica, M. Mathematical Modeling of the Concentrated Energy Flow Effect on Metallic Materials. Metals 2016, 7, 4. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, G.J.; Zhang, W.J.; Zhang, Y.M. Active Metal Transfer Control by Utilizing Enhanced Droplet Oscillation Part 1: Experimental Study. Weld. J. 2014, 93, 282s–291s. [Google Scholar]

- Xiao, J.; Zhang, G.J.; Zhang, W.J.; Zhang, Y.M. Active Metal Transfer Control by Utilizing Enhanced Droplet Oscillation Part II: Modeling and Analysis. Weld. J. 2014, 93, 321s–330s. [Google Scholar]

- Pal, K.; Pal, S.K. Effect of Pulse Parameters on Weld Quality in Pulsed Gas Metal Arc Welding: A Review. J. Mater. Eng. Perform. 2011, 20, 918–931. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Goyal, V.K.; Dhiman, H.K.; Kumar, M. Thermal and metal transfer behaviours in pulsed current gas metal arc weld deposition of Al–Mg alloy. Sci. Technol. Weld. Join. 2006, 11, 232–242. [Google Scholar] [CrossRef]

- Wu, C.S.; Chen, M.A.; Lu, Y.F. Effect of current waveforms on metal transfer in pulsed gas metal arc welding. Meas. Sci. Technol. 2005, 16, 2459–2465. [Google Scholar] [CrossRef]

- Rajasekaran, S. Weld Bead Characteristics in Pulsed GMA Welding of AI-Mg Alloys. Weld. J. 1999, 78, 397s–407s. [Google Scholar]

- Rajasekaran, S.; Kulkarni, S.D.; Mallya, U.D.; Chaturvedi, R.C. Droplet detachment and plate fusion characteristics in pulsed current gas metal arc welding. Weld. J. 1998, 77, 254s–269s. [Google Scholar]

- Zhai, P.; Xue, S.; Chen, T.; Wang, J.; Tao, Y. An Image-Processing Method for Extracting Kinematic Characteristics of Droplets during Pulsed GMAW. Appl. Sci. 2019, 9, 5481. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Dorn, L.; Devakumaran, K.; Hofmann, F. Pulsed Current Gas Metal Arc Welding under Different Shielding and Pulse Parameters; Part 1: Arc Characteristics. ISIJ Int. 2009, 49, 251–260. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Dorn, L.; Devakumaran, K.; Hofmann, F. Pulsed Current Gas Metal Arc Welding under Different Shielding and Pulse Parameters; Part 2: Behaviour of Metal Transfer. ISIJ Int. 2009, 49, 261–269. [Google Scholar] [CrossRef][Green Version]

- Mirzaei, M.; Arabi Jeshvaghani, R.; Yazdipour, A.; Zangeneh-Madar, K. Study of welding velocity and pulse frequency on microstructure and mechanical properties of pulsed gas metal arc welded high strength low alloy steel. Mater. Des. 2013, 51, 709–713. [Google Scholar] [CrossRef]

- Xue, J.; Xu, M.; Huang, W.; Zhang, Z.; Wu, W.; Jin, L. Stability and Heat Input Controllability of Two Different Modulations for Double-Pulse MIG Welding. Appl. Sci. 2019, 9, 127. [Google Scholar] [CrossRef]

- Shome, M.; Gupta, O.P.; Mohanty, O.N. Effect of simulated thermal cycles on the microstructure of the heat-affected zone in HSLA-80 and HSLA-100 steel plates. Metall. Mater. Trans. A 2004, 35, 985–996. [Google Scholar] [CrossRef]

- Suresh, M.V.; Vamsi Krishna, B.; Venugopal, P.; Prasad Rao, K. Effect of pulse frequency in gas tungsten arc welding of powder metallurgical preforms. Sci. Technol. Weld. Join. 2004, 9, 362–368. [Google Scholar] [CrossRef]

- Wei, L.; Nelson, T.W. Influence of heat input on post weld microstructure and mechanical properties of friction stir welded HSLA-65 steel. Mater. Sci. Eng. A 2012, 556, 51–59. [Google Scholar] [CrossRef]

- Kurşun, T. Effect of the Gmaw and the Gmaw-P Welding Processes on Microstructure, Hardness, Tensile and Impact Strength of Aisi 1030 Steel Joints Fabricated by ASP316L Austenitic Stainless Steel Filler Metal. Arch. Metall. Mater. 2011, 56, 955–963. [Google Scholar] [CrossRef]

- Lippold, J.C. Welding metallurgy and weldability; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

| Materials | Chemical Composition (wt.%) | ||||||

|---|---|---|---|---|---|---|---|

| C | Mn | Si | S | P | Cu | Fe | |

| Q345 | 0.16 | 1.35 | 0.29 | 0.015 | 0.016 | 0.11 | Bal. |

| ER50-6 | 0.09 | 1.57 | 0.91 | 0.015 | 0.013 | 0.23 | Bal. |

| Materials | Mechanical Properties | |||

|---|---|---|---|---|

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Impact Energy (J) | |

| Q345 | ≥345 | 470–630 | ≥29 | ≥34 (20 °C) |

| ER50-6 | ≥400 | ≥490 | ≥22 | ≥27 (−30 °C) |

| Test | Droplet Transfer Modes | Pulse Frequency f/Hz | Average Current Ia/A | Average Voltage Ua/V | Heat Input Q/(J/mm) |

|---|---|---|---|---|---|

| 1 | ODMP 1 | 129 | 128 | 24.4 | 625 |

| 2 | ODPP 2 | 96 | 113 | 23.8 | 538 |

| 3 | MDPP 3 | 68 | 115 | 23.1 | 531 |

| Droplet Transfer Modes | Bead Width (mm) | Bead Height (mm) | Penetration (mm) |

|---|---|---|---|

| ODMP | 9.98 | 2.59 | 2.03 |

| ODPP | 9.28 | 2.44 | 2.22 |

| MDPP | 9.95 | 2.59 | 2.04 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, P.; Xue, S.; Wang, J.; Tao, Y.; Chen, W.; Chen, T.; Ji, S. Comparative Study of Droplet Transfer Modes on Appearance, Microstructure, and Mechanical Properties of Weld during Pulsed GMAW. Metals 2020, 10, 611. https://doi.org/10.3390/met10050611

Zhai P, Xue S, Wang J, Tao Y, Chen W, Chen T, Ji S. Comparative Study of Droplet Transfer Modes on Appearance, Microstructure, and Mechanical Properties of Weld during Pulsed GMAW. Metals. 2020; 10(5):611. https://doi.org/10.3390/met10050611

Chicago/Turabian StyleZhai, Peizhuo, Songbai Xue, Jianhao Wang, Yu Tao, Weizhong Chen, Tao Chen, and Shilei Ji. 2020. "Comparative Study of Droplet Transfer Modes on Appearance, Microstructure, and Mechanical Properties of Weld during Pulsed GMAW" Metals 10, no. 5: 611. https://doi.org/10.3390/met10050611

APA StyleZhai, P., Xue, S., Wang, J., Tao, Y., Chen, W., Chen, T., & Ji, S. (2020). Comparative Study of Droplet Transfer Modes on Appearance, Microstructure, and Mechanical Properties of Weld during Pulsed GMAW. Metals, 10(5), 611. https://doi.org/10.3390/met10050611