Microstructure Characterization of SAW and TIG Welded 25Cr2Ni2MoV Rotor Steel Metal

Abstract

1. Introduction

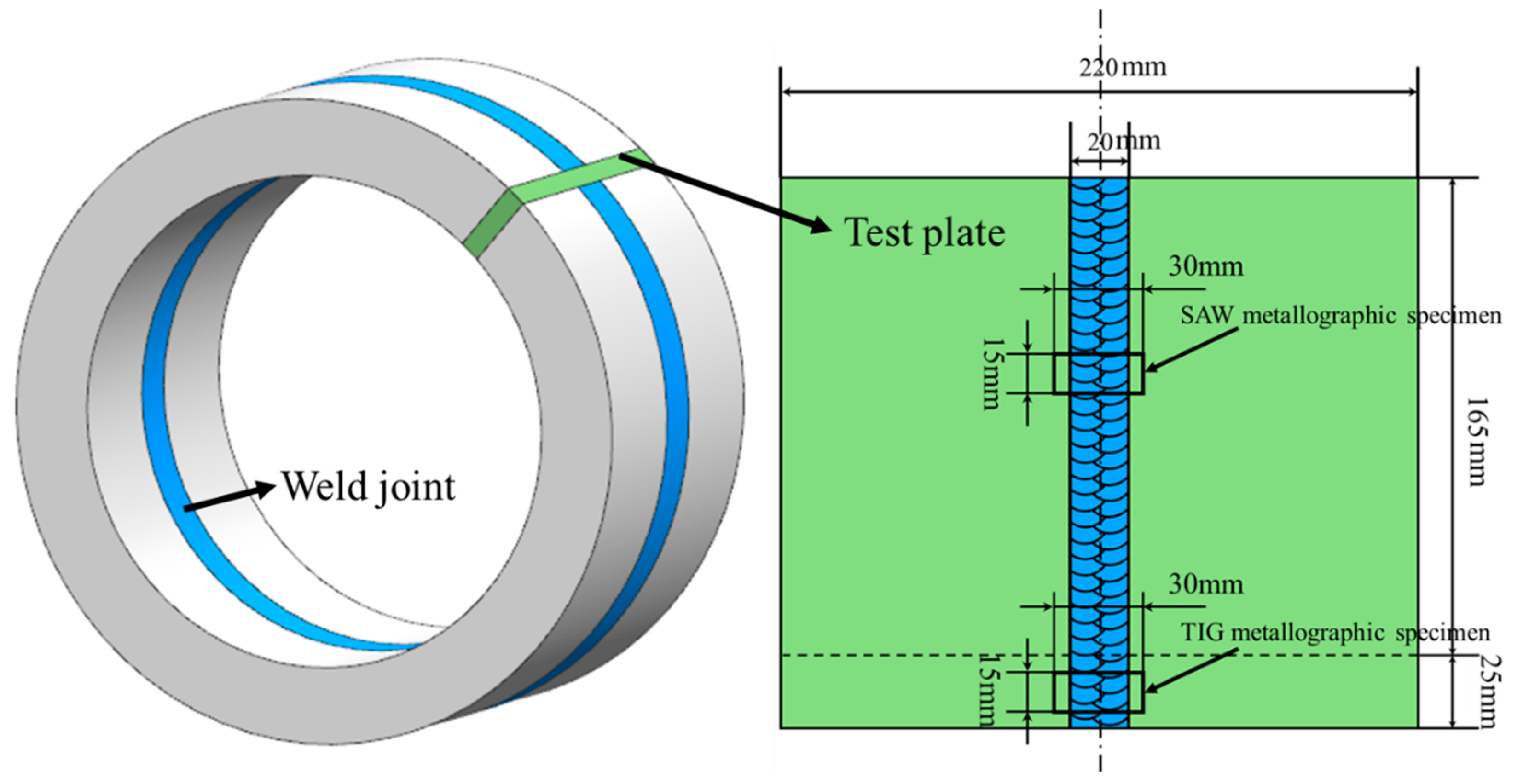

2. Materials and Methods

2.1. Materials and Welding

2.2. Microstructural Characterization

3. Results

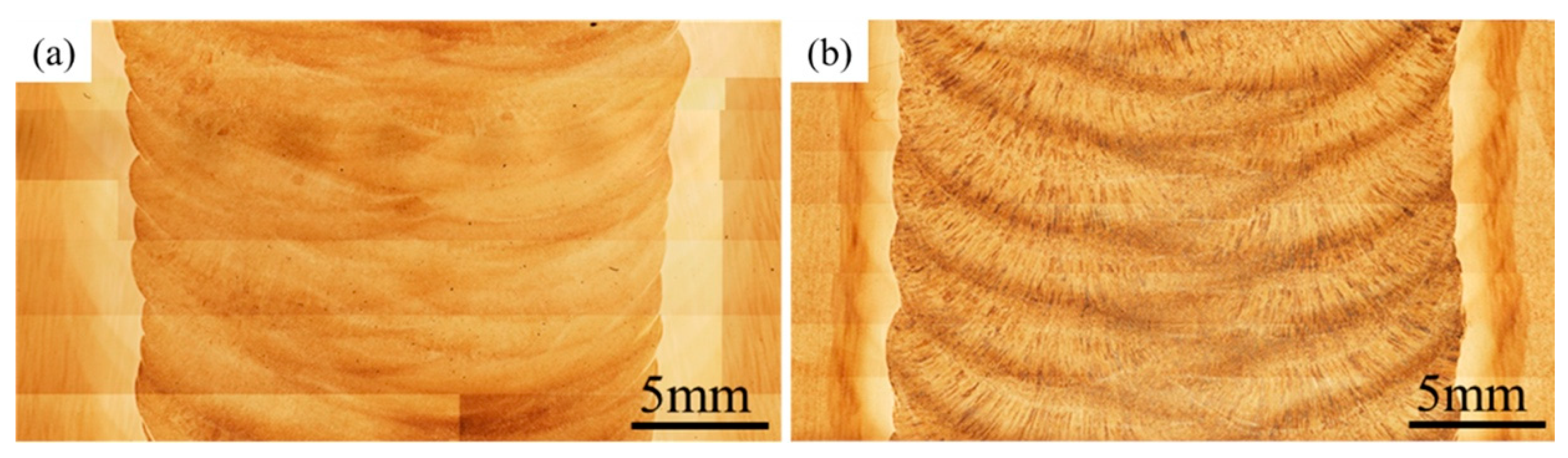

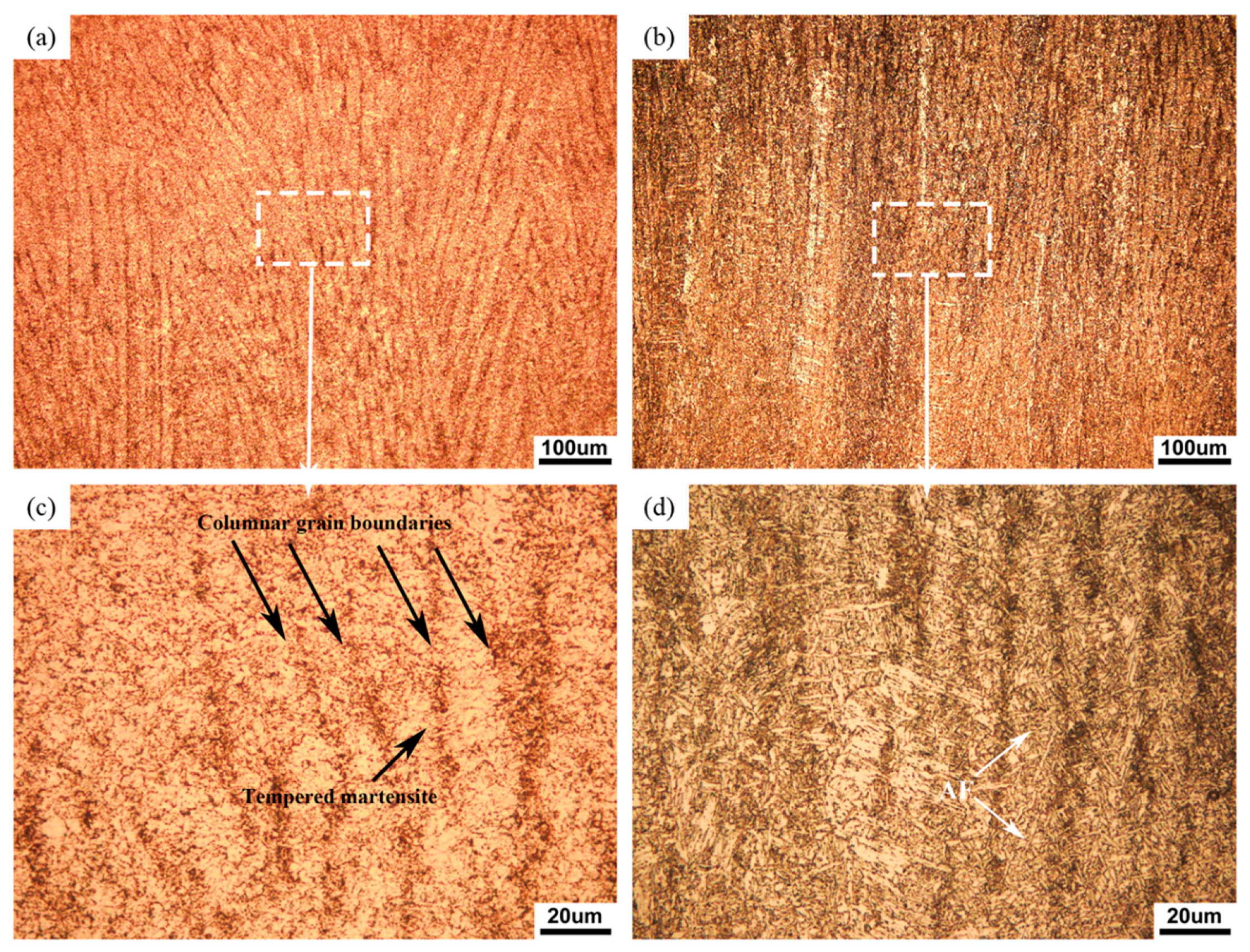

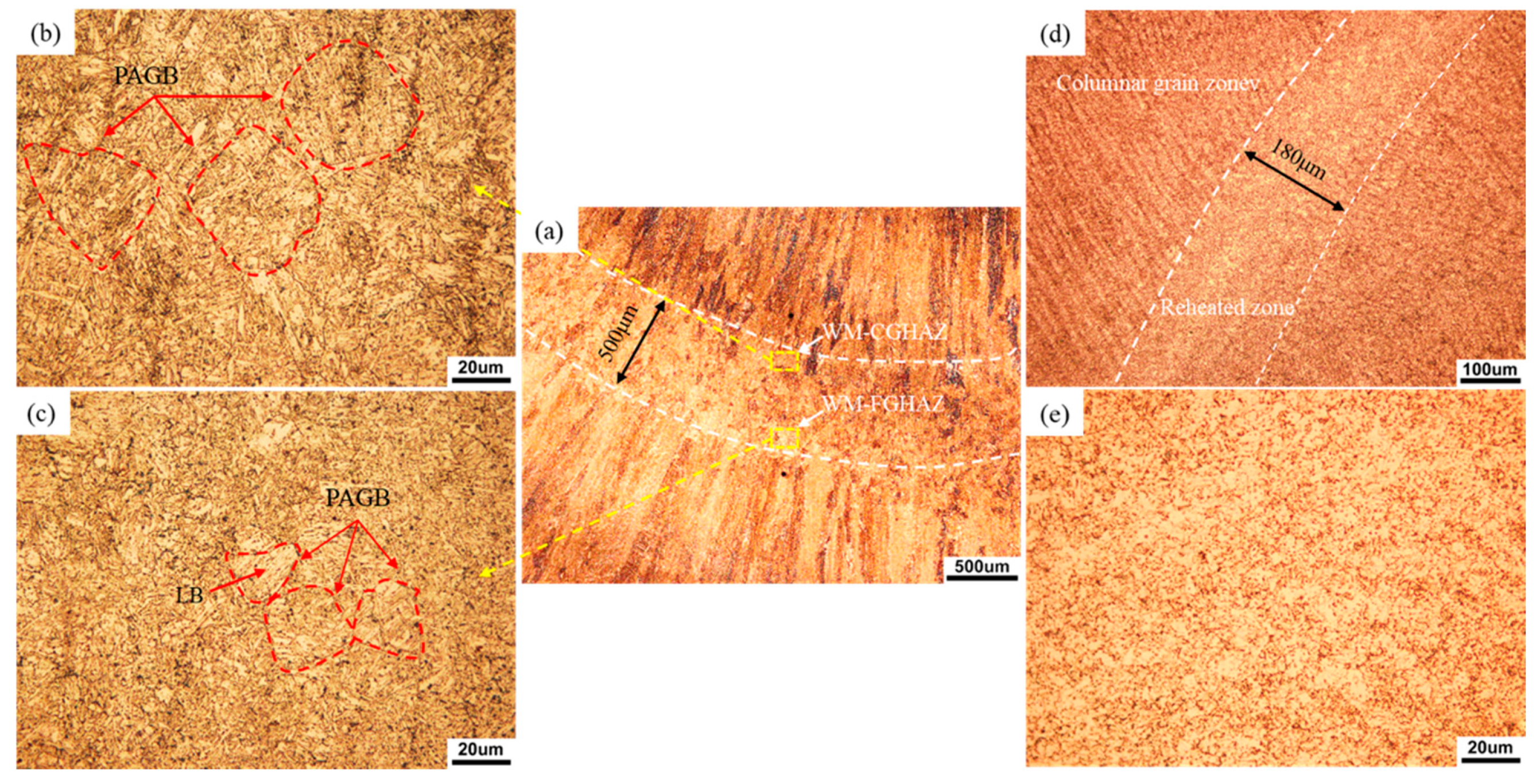

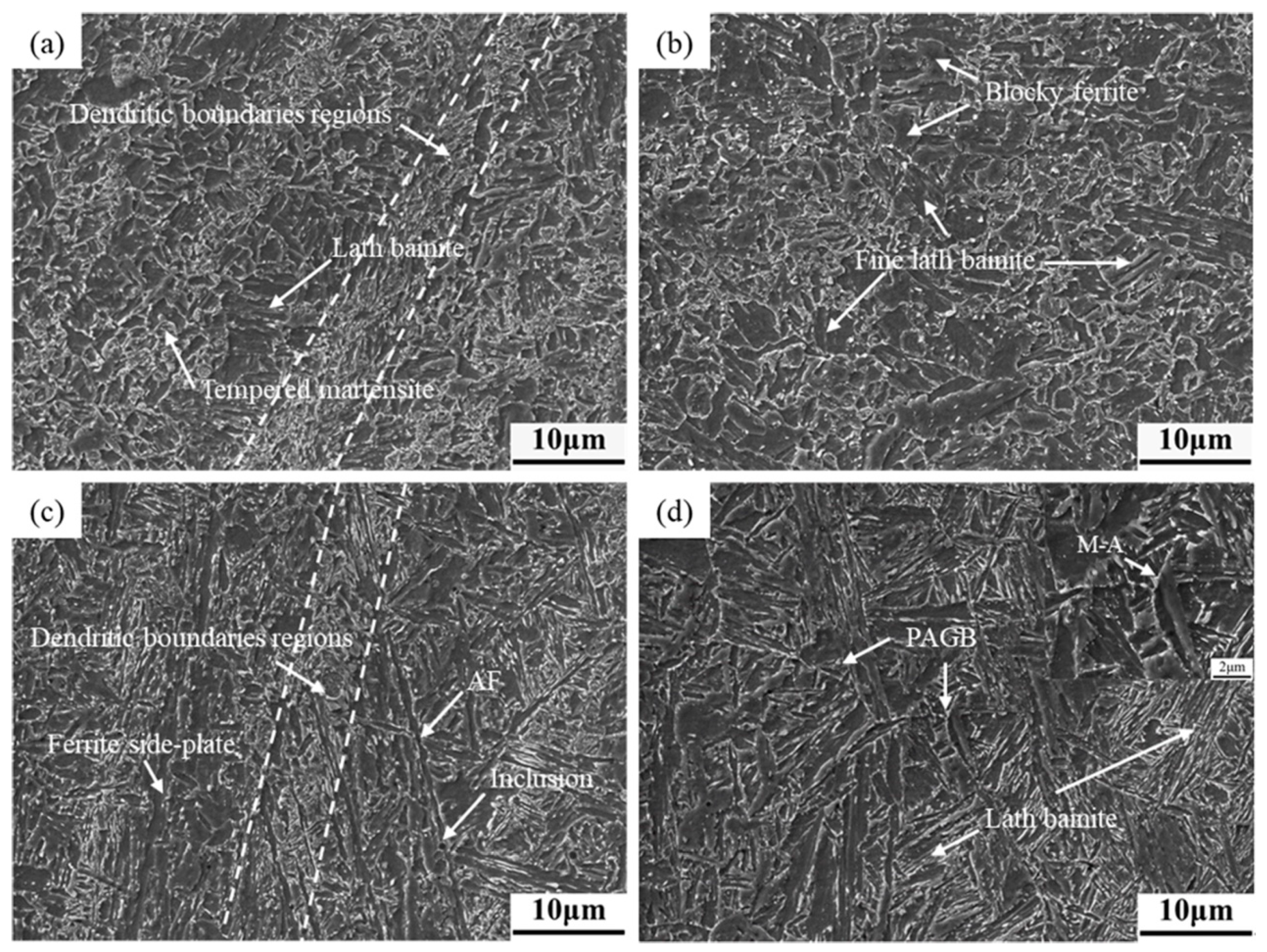

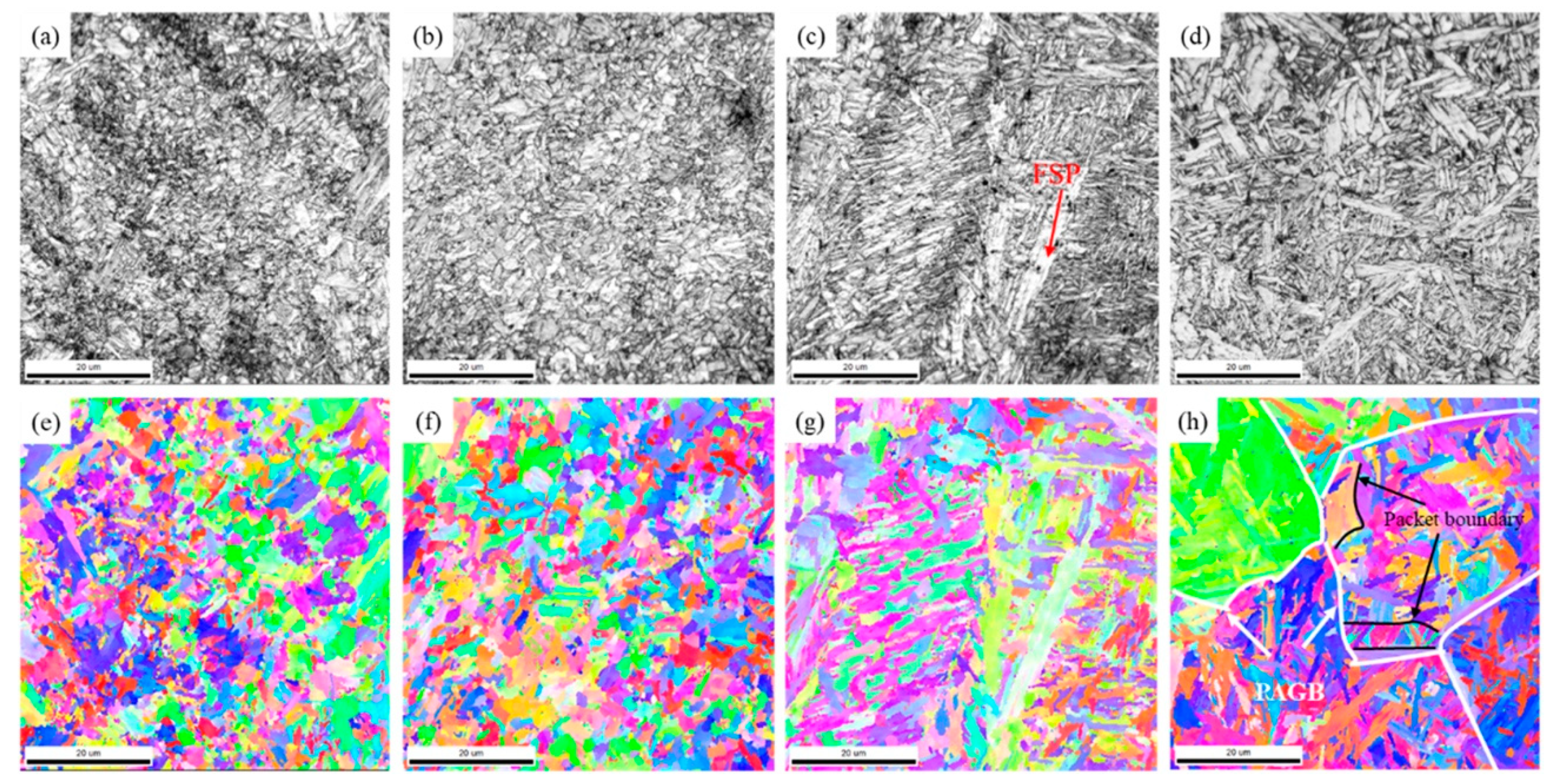

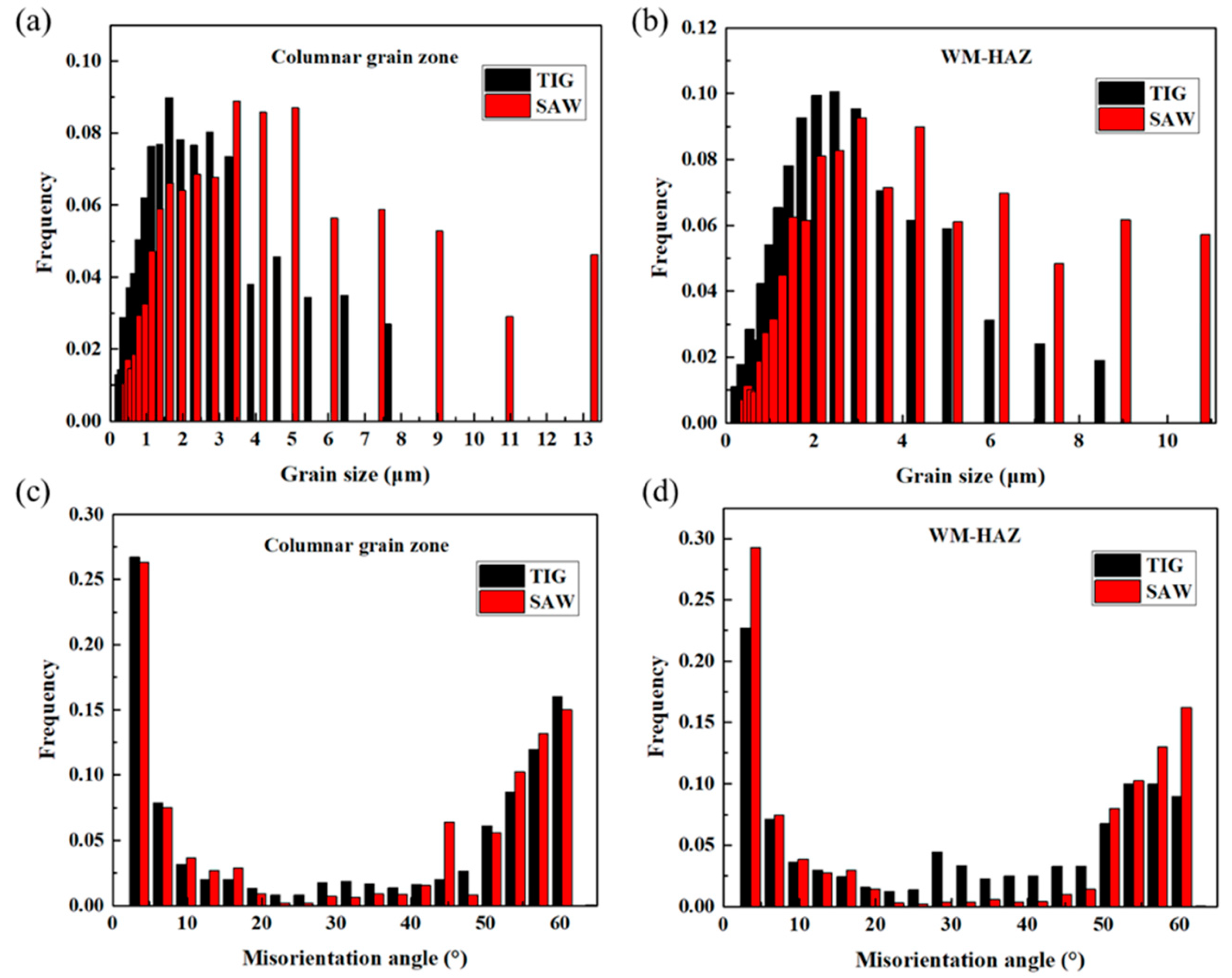

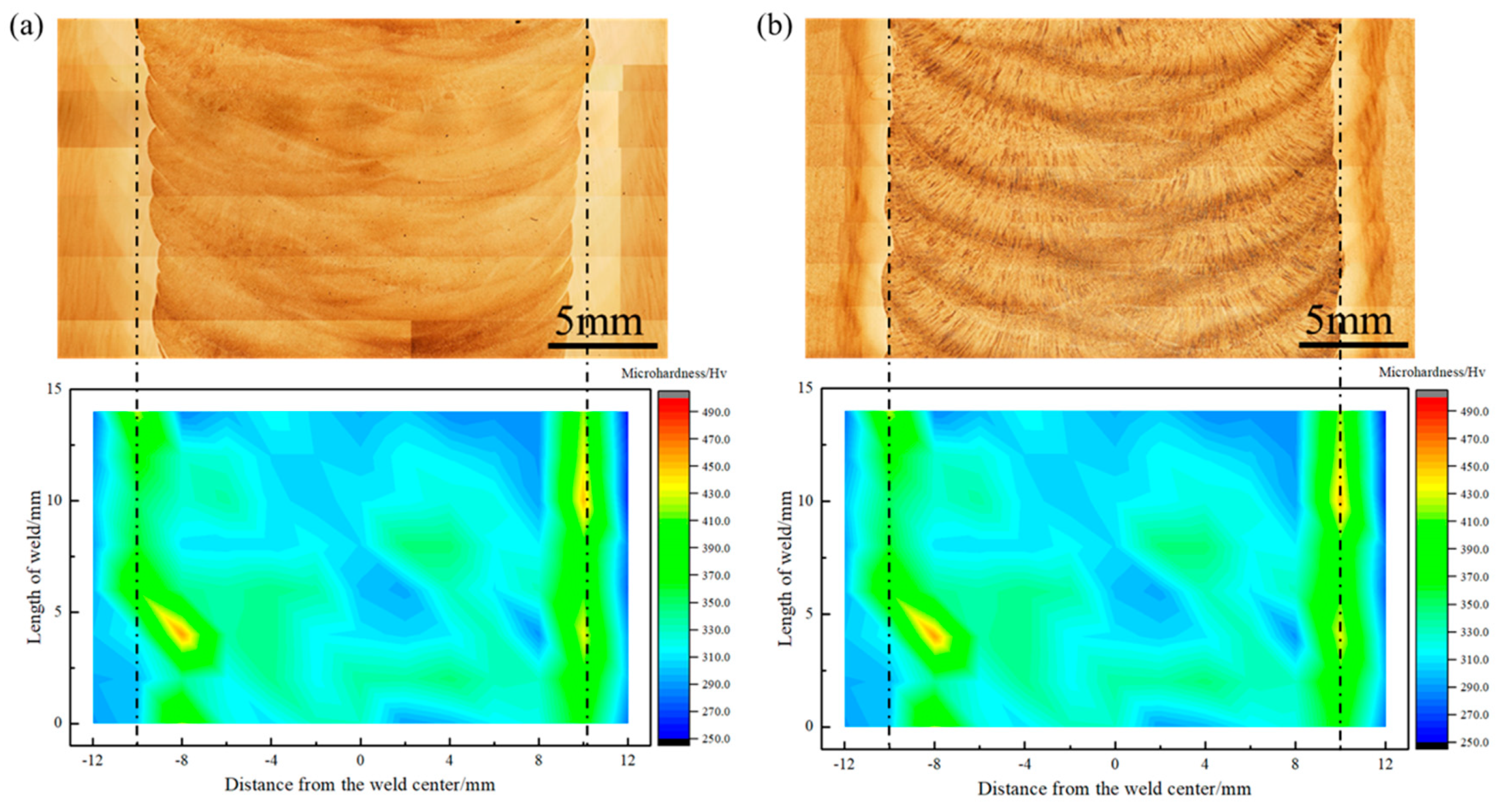

3.1. Columnar Grain and Reheated Zone Microstructures

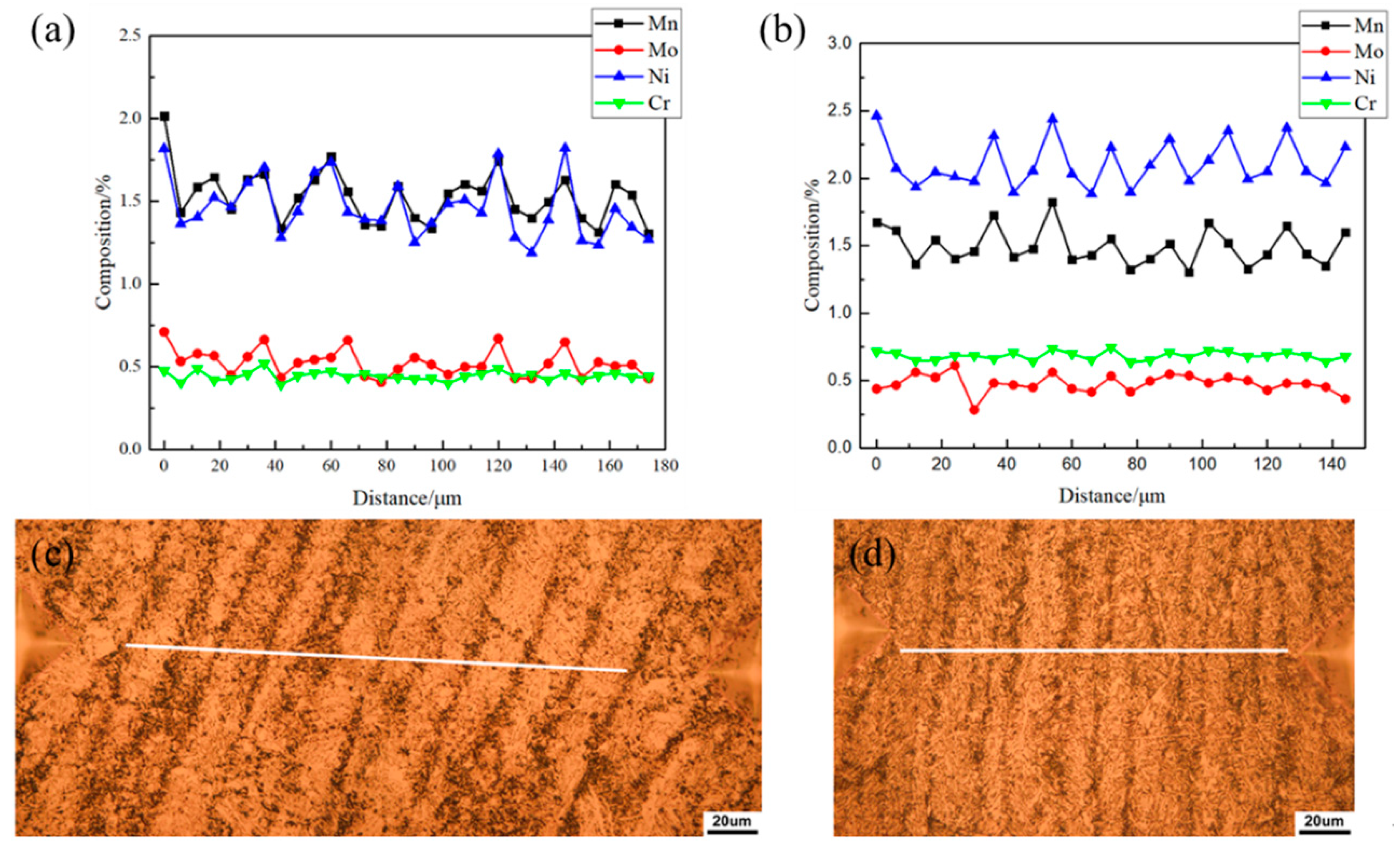

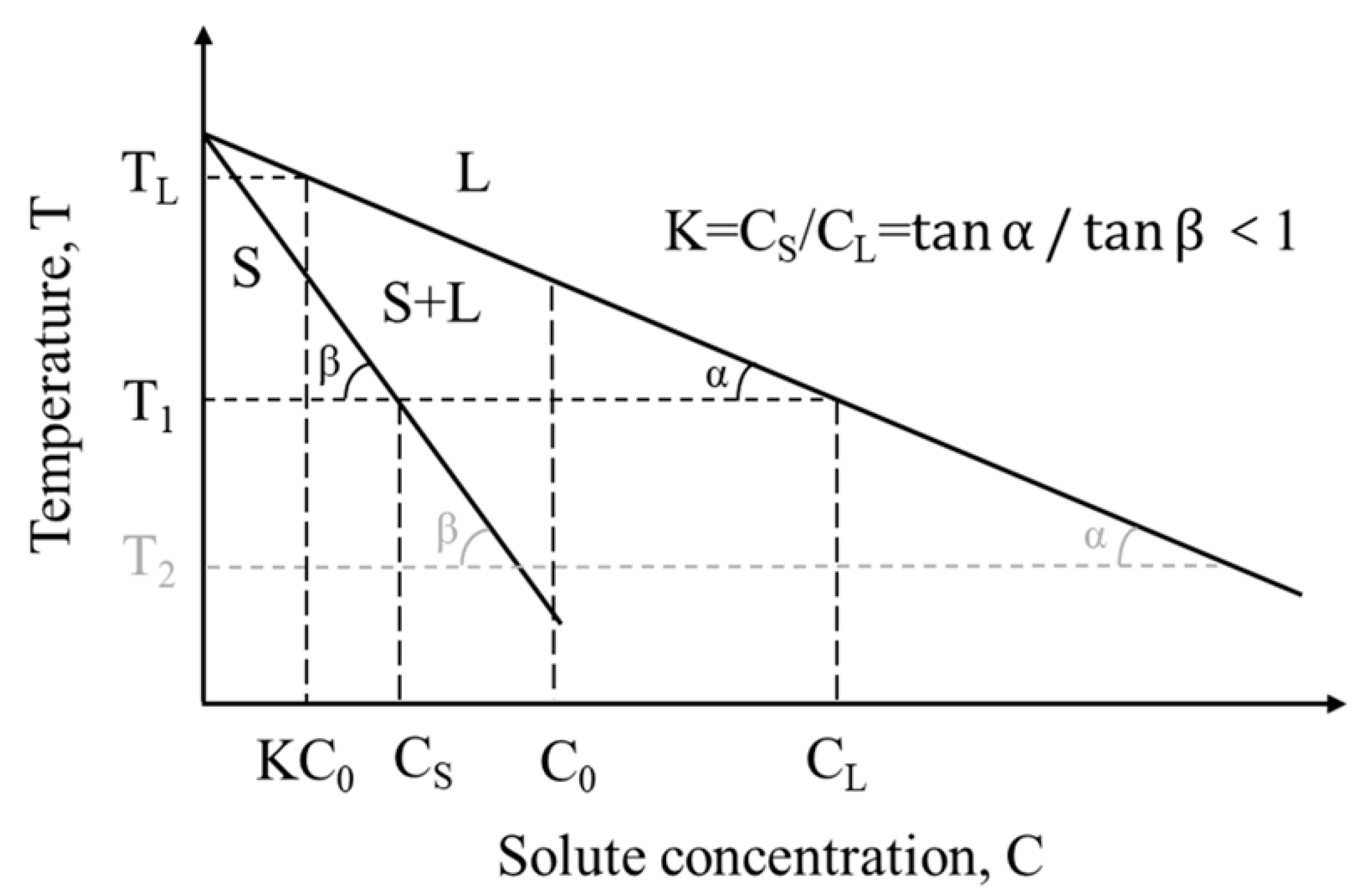

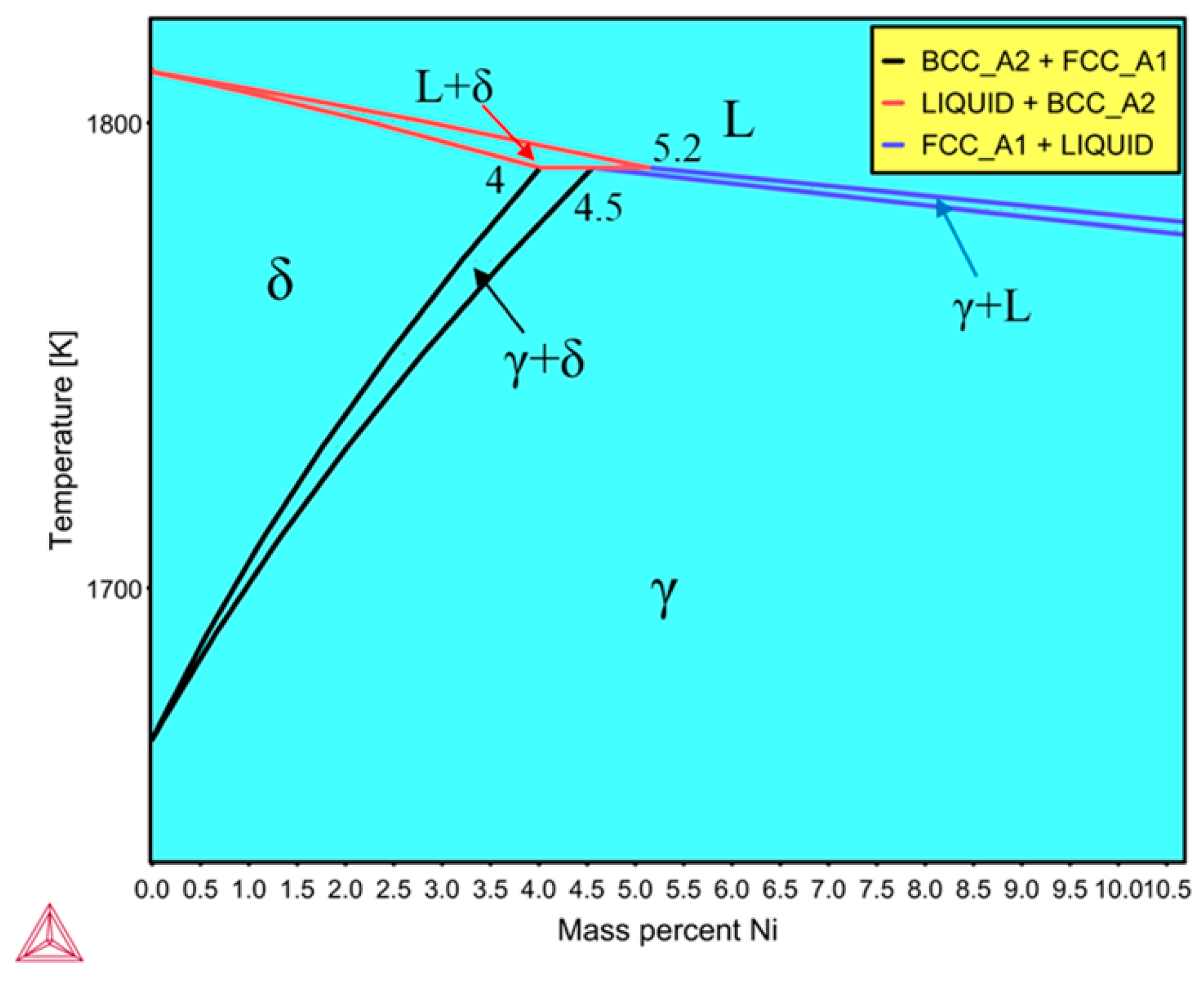

3.2. Micro-Segregation at Columnar Grain Boundary

4. Conclusions

- In TIG weld, the microstructure was composed of lath bainite, blocky ferrite and tempered martensite. In SAW weld metals, the microstructure consisted of acicular ferrite, lath bainite, ferrite side plate and tempered martensite.

- The grain size in columnar grain zone of TIG and SAW weld had a distinct discrepancy. The maximum effective grain sizes in TIG and SAW weld were 7.7 and 13.2 μm, respectively, which was attributed to the appearance of a coarse ferrite side plate in SAW weld.

- The widths of the reheated zone were 180 and 500μm in TIG and SAW weld, respectively. Higher heat input of SAW welding led to the reheated zone having a larger size and temperature gradient, which caused the formation of WM-CG and the WM-FG zone. The prior austenite grain sizes of WM-CG and the WM-FG zone were 39 and 21 μm, respectively. PAGB could not be distinguished in the reheated zone of TIG weld.

- During solidification, partial alloy elements, such as Ni and Mn, segregated at the dendritic boundaries. The contents of Ni and Mn at dendritic boundaries were 50% higher than those at dendritic core regions for SAW, and 30% higher for TIG. Ni and Mn segregation reduced the transformation temperature and resulted in martensite formation at room temperature in dendritic boundaries regions.

- The hardness of TIG and SAW weld has no obvious distinction. The hardness of TIG and SAW weld is 320 HV and 315 HV, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bandyopadhyay, N.; Briant, C.; Hall, E.J. Carbide precipitation, grain boundary segregation, and temper embrittlement in NiCrMoV rotor steels. Metall. Mater. Trans. A 1985, 16, 721–737. [Google Scholar] [CrossRef]

- Chen, R.K.; Gu, J.F.; Han, L.Z.; Pan, J.S. Novel process to refine grain size of NiCrMoV steel. Mater. Sci. Technol. Lond. 2013, 28, 773–777. [Google Scholar] [CrossRef]

- Liu, P.; Lu, F.; Liu, X.; Ji, H.; Gao, Y. Study on fatigue property and microstructure characteristics of welded nuclear power rotor with heavy section. J. Alloys Compd. 2014, 584, 430–437. [Google Scholar] [CrossRef]

- Liu, X.; Cai, Z.; Yang, S.; Feng, K.; Li, Z. Characterization on the Microstructure Evolution and Toughness of TIG Weld Metal of 25Cr2Ni2MoV Steel after Post Weld Heat Treatment. Metals 2018, 8, 160. [Google Scholar] [CrossRef]

- Bai, F.; Ding, H.; Tong, L.; Pan, L.; Wang, L. Microstructural Changes and Impact Toughness of Fill Pass in X80 Steel Weld Metal. Metals 2019, 9, 898. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Z.; Li, K.; Pan, J.; Liu, X.; Sun, L.; Wang, P. Investigation of local brittle zone in multipass welded joint of NiCrMoV steel with heavy section. J. Mater. Res. 2018, 33, 923–934. [Google Scholar] [CrossRef]

- Rathod, D.W.; Francis, J.A.; Roy, M.J.; Obasi, G.; Irvine, N.M. Thermal cycle-dependent metallurgical variations and their effects on the through-thickness mechanical properties in thick section narrow-gap welds. Mat. Sci. Eng. A-Struct. 2017, 707, 399–411. [Google Scholar] [CrossRef]

- Zhang, L.; Pittner, A.; Michael, T.; Rhode, M.; Kannengiesser, T. Effect of cooling rate on microstructure and properties of microalloyed HSLA steel weld metals. Sci. Technol. Weld. Join. 2015, 20, 371–377. [Google Scholar] [CrossRef]

- Wen, C.; Wang, Z.; Deng, X.; Wang, G.; Misra, R.D.K. Effect of Heat Input on the Microstructure and Mechanical Properties of Low Alloy Ultra-High Strength Structural Steel Welded Joint. Steel Res. Int. 2018, 89, 1700500. [Google Scholar] [CrossRef]

- Han, X.-L.; Wu, D.-Y.; Min, X.-L.; Wang, X.; Liao, B.; Xiao, F.-R. Influence of post-weld heat treatment on the microstructure, microhardness, and toughness of a weld metal for hot bend. Metals 2016, 6, 75. [Google Scholar] [CrossRef]

- Bose-Filho, W.W.; Carvalho, A.L.M.; Strangwood, M. Effects of alloying elements on the microstructure and inclusion formation in HSLA multipass welds. Mater. Charact. 2007, 58, 29–39. [Google Scholar] [CrossRef]

- Qi, X.; Di, H.; Sun, Q.; Wang, X.; Chen, X.; Gao, Y.; Liu, Z. A comparative analysis on microstructure and fracture mechanism of X100 pipeline steel CGHAZ between laser welding and arc welding. J. Mater. Eng. Perform. 2019, 28, 7006–7015. [Google Scholar] [CrossRef]

- Keehan, E.; Zachrisson, J.; Karlsson, L. Influence of cooling rate on microstructure and properties of high strength steel weld metal. Sci. Technol. Weld. Join. 2013, 15, 233–238. [Google Scholar] [CrossRef]

- Prijanovič, U.; Prijanovič Tonkovič, M.; Trdan, U.; Pleterski, M.; Jezeršek, M.; Klobčar, D. Remote fibre laser welding of advanced high strength martensitic steel. Metals 2020, 10, 533. [Google Scholar]

- Mao, G.; Cao, R.; Yang, J.; Jiang, Y.; Wang, S.; Guo, X.; Yuan, J.; Zhang, X.; Chen, J. Effect of nickel contents on the microstructure and mechanical properties for low-carbon bainitic weld metals. J. Mater. Eng. Perform. 2017, 26, 2057–2071. [Google Scholar] [CrossRef]

- Huang, G.; Wan, X.; Wu, K.; Zhao, H.; Misra, R. Effects of small Ni addition on the microstructure and toughness of coarse-grained heat-affected zone of high-strength low-alloy steel. Metals 2018, 8, 718. [Google Scholar] [CrossRef]

- Bhole, S.D.; Nemade, J.B.; Collins, L.; Liu, C. Effect of nickel and molybdenum additions on weld metal toughness in a submerged arc welded HSLA line-pipe steel. J. Mater. Process. Technol. 2006, 173, 92–100. [Google Scholar] [CrossRef]

- Kang, B.Y.; Kim, H.J.; Hwang, S.K. Effect of Mn and Ni on the variation of the microstructure and mechanical properties of low-carbon weld metals. ISIJ Int. 2000, 40, 1237–1245. [Google Scholar] [CrossRef]

- Wang, X.L.; Nan, Y.R.; Xie, Z.J.; Tsai, Y.T.; Yang, J.R.; Shang, C.J. Influence of welding pass on microstructure and toughness in the reheated zone of multi-pass weld metal of 550 MPa offshore engineering steel. Mat. Sci. Eng. A-Struct. 2017, 702, 196–205. [Google Scholar] [CrossRef]

- Kou, S.; Le, Y. The effect of quenching on the solidification structure and transformation behavior of stainless steel welds. Metall. Mater. Trans. A 1982, 13, 1141–1152. [Google Scholar] [CrossRef]

- Munitz, A. Microstructure of rapidly solidified laser molten AI-4.5 Wt Pct Cu Surfaces. Metall. Mater. Trans. B 1985, 16, 149–161. [Google Scholar] [CrossRef]

- Zhang, Z.; Farrar, R.A. Columnar grain development in C-Mn-Ni low-alloy weld metals and the influence of nickel. J. Mater. Sci. 1995, 30, 5581–5588. [Google Scholar] [CrossRef]

- Babu, S.S. The mechanism of acicular ferrite in weld deposits. Curr. Opin. Solid State Mater. Sci. 2004, 8, 267–278. [Google Scholar] [CrossRef]

- Wang, B.; Hu, J.; Hu, Y.; Pu, L. The effect of peak temperature on HAZ microstructure and toughness of V- and Nb-bearing microalloyed steels. Trans. Indian Inst. Met. 2019, 72, 1119–1127. [Google Scholar] [CrossRef]

- Yang, X.; Di, X.; Liu, X.; Wang, D.; Li, C. Effects of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels. Mater. Charact. 2019, 155, 109818. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M.; Field, D.P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar] [CrossRef]

- Gourgues, A.-F.; Flower, H.M.; Lindley, T.C. Electron backscattering diffraction study of acicular ferrite, bainite, and martensite steel microstructures. Mater. Sci. Technol.-Lond 2000, 16, 26–40. [Google Scholar] [CrossRef]

- Wen, C.; Deng, X.; Tian, Y.; Wang, Z.; Misra, R.D.K. Microstructural evolution and toughness of the various HAZs in 1300-MPa-grade ultrahigh-strength structural steel. J. Mater. Eng. Perform. 2019, 28, 1301–1311. [Google Scholar] [CrossRef]

- Morsdorf, L.; Jeannin, O.; Barbier, D.; Mitsuhara, M.; Raabe, D.; Tasan, C.C. Multiple mechanisms of lath martensite plasticity. Acta Mater. 2016, 121, 202–214. [Google Scholar] [CrossRef]

- Khodir, S.; Shibayanagi, T.; Takahashi, M.; Abdel-Aleem, H.; Ikeuchi, K. Microstructural evolution and mechanical properties of high strength 3–9% Ni-steel alloys weld metals produced by electron beam welding. Mater. Des. 2014, 60, 391–400. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2003; pp. 431–446. [Google Scholar]

- Keehan, E.; Karlsson, L.; Andrén, H.O.; Bhadeshia, H.K.D.H. Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: Part 2—Impact toughness gain resulting from manganese reductions. Sci. Technol. Weld. Join. 2013, 11, 9–18. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | Cr | Mo | Ni | V | Al | Cu | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| BM | 0.22 | 0.07 | 0.18 | 2.34 | 0.75 | 2.24 | 0.05 | 0.003 | / | / |

| TIG FM | 0.08 | 0.61 | 1.62 | 0.20 | 0.53 | 1.44 | 0.005 | 0.003 | 0.13 | 0.06 |

| SAW FM | 0.09 | 0.21 | 1.41 | 0.57 | 0.51 | 2.23 | / | / | 0.04 | / |

| Welding Method | Wire Diameter (mm) | Current (A) | Voltage (V) | Speed (mm/min) | Gas | Heat Input (KJ/cm) |

|---|---|---|---|---|---|---|

| TIG | 1 | 210 | 11.2 | 90 | Ar 99.999% | 13 |

| SAW | 3.2 | 420 | 29 | 420 | / | 26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, C.; Cai, Z.; Fan, M.; Liu, X.; Li, K.; Pan, J. Microstructure Characterization of SAW and TIG Welded 25Cr2Ni2MoV Rotor Steel Metal. Metals 2020, 10, 603. https://doi.org/10.3390/met10050603

Han C, Cai Z, Fan M, Liu X, Li K, Pan J. Microstructure Characterization of SAW and TIG Welded 25Cr2Ni2MoV Rotor Steel Metal. Metals. 2020; 10(5):603. https://doi.org/10.3390/met10050603

Chicago/Turabian StyleHan, Chaoyu, Zhipeng Cai, Manjie Fan, Xia Liu, Kejian Li, and Jiluan Pan. 2020. "Microstructure Characterization of SAW and TIG Welded 25Cr2Ni2MoV Rotor Steel Metal" Metals 10, no. 5: 603. https://doi.org/10.3390/met10050603

APA StyleHan, C., Cai, Z., Fan, M., Liu, X., Li, K., & Pan, J. (2020). Microstructure Characterization of SAW and TIG Welded 25Cr2Ni2MoV Rotor Steel Metal. Metals, 10(5), 603. https://doi.org/10.3390/met10050603