Effect of Nb on the Microstructure and Mechanical Properties of Ti2Cu Intermetallic through the First-Principle Calculations and Experimental Investigation

Abstract

1. Introduction

2. Computational and Experimental Methods

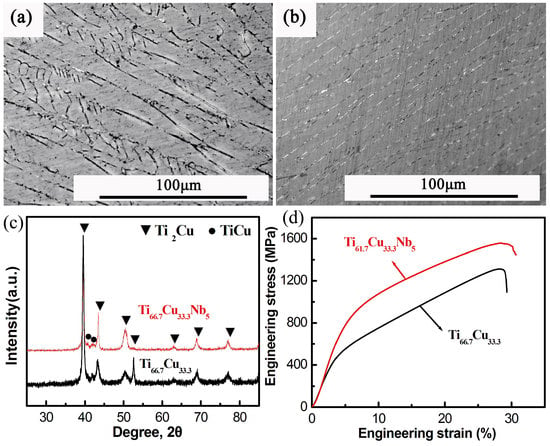

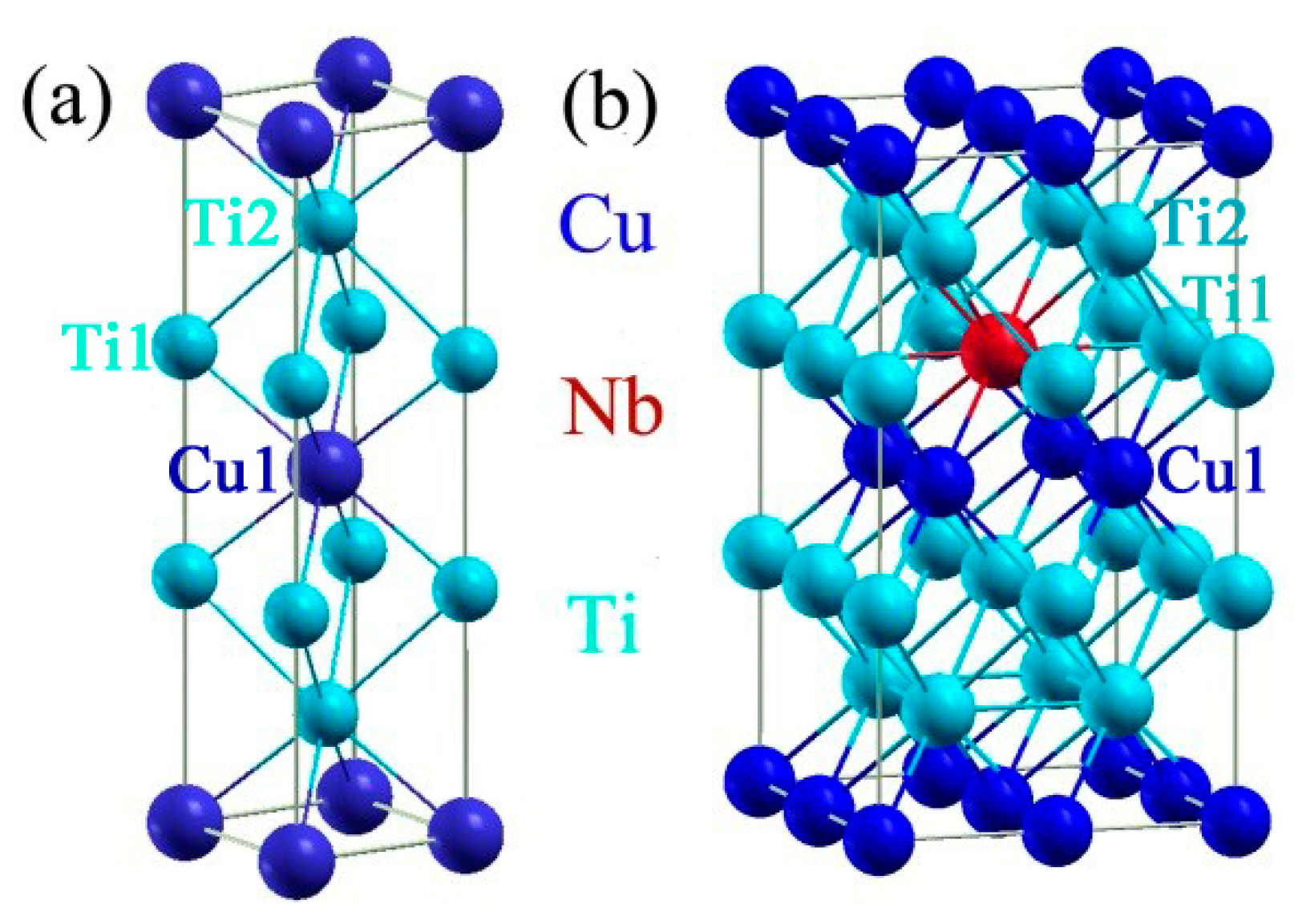

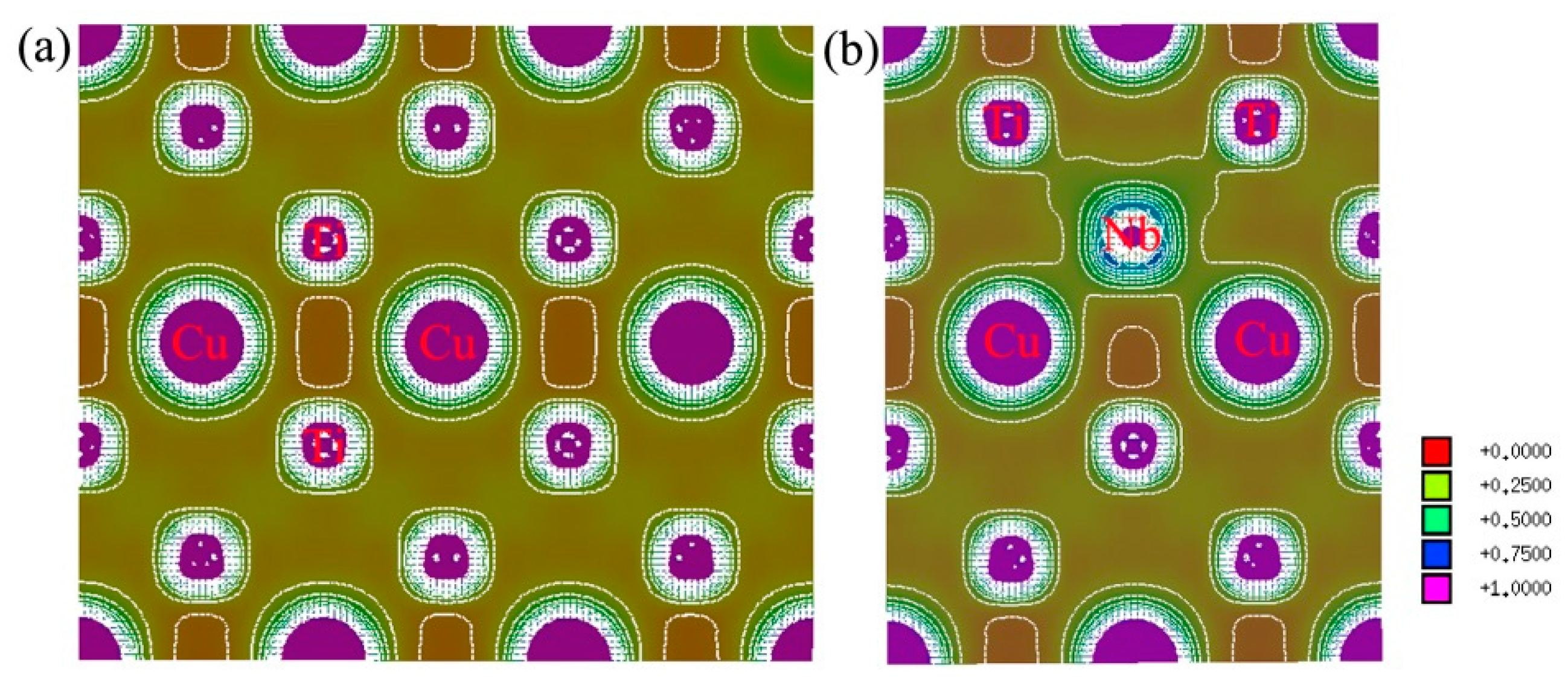

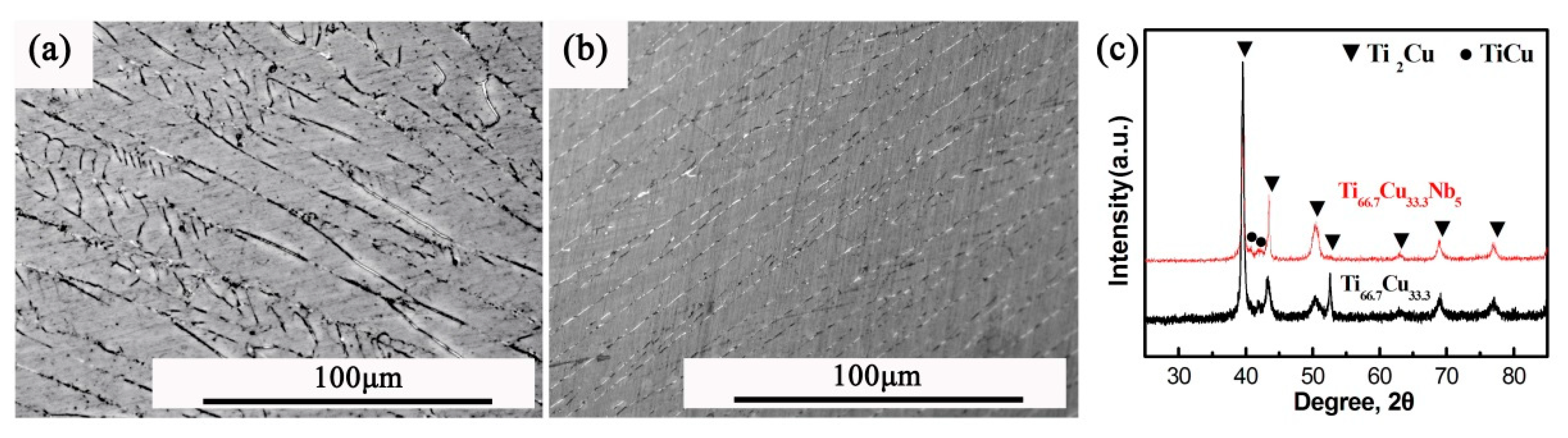

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ward-Close, C.M.; Minor, R.; Doorbar, P.J. Intermetallic-matrix composites—a review. Intermetallics 1996, 4, 217–229. [Google Scholar] [CrossRef]

- Liu, C.; George, E.P.; Maziasz, P.J.; Schneibel, J.H. Recent advances in B2 iron aluminide alloys: Deformation, fracture and alloy design. Mater. Sci. Eng. A 1998, 258, 84–98. [Google Scholar] [CrossRef]

- Stoloff, N.S.; Liu, C.T.; Deevi, S.C. Emerging applications of intermetallics. Intermetallics 2000, 8, 1313–1320. [Google Scholar] [CrossRef]

- Blaber, M.G.; Arnold, M.D.; Ford, M.J. A review of the optical properties of alloys and intermetallics for plasmonics. J. Phys. Condens. Matter 2010, 22, 143201. [Google Scholar] [CrossRef] [PubMed]

- Zamanzade, M.; Barnoush, A.; Motz, C. A review on the properties of iron aluminide intermetallics. Crystals 2016, 6, 10. [Google Scholar] [CrossRef]

- Wu, X. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Chen, G.; Peng, Y.B.; Zheng, G.; Qi, Z.X.; Wang, M.Z.; Yu, H.C.; Dong, C.L.; Liu, C.T. Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat. Mater. 2016, 15, 876–881. [Google Scholar] [CrossRef]

- Han, J.; Li, X.; Dippenaar, R.; Liss, K.D.; Kawasaki, M. Microscopic plastic response in a bulk nano-structured TiAl intermetallic compound processed by high-pressure torsion. Mater. Sci. Eng. A 2018, 714, 84–92. [Google Scholar] [CrossRef]

- He, Y.; Liu, Z.; Zhou, G.; Wang, H.; Bai, C.G.; Rodney, D.; Appel, F.; Xu, D.S.; Yang, R. Dislocation dipole-induced strengthening in intermetallic TiAl. Scripta Mater. 2018, 143, 98–102. [Google Scholar] [CrossRef]

- Wei, L.; Zhao, Z. Fabrication of the lamellar NiAl nanochannel by selective phase dissolution of NiAl–Cr (Mo) eutectic alloy. Corros Sci. 2018, 138, 142–145. [Google Scholar] [CrossRef]

- Wu, X.; Wang, C. Influence of alloying elements upon the theoretical tensile strength of Ni-based model superalloy: γ-Ni/γ′-Ni3Al multilayer. Comput. Mater. Sci. 2016, 119, 120–129. [Google Scholar] [CrossRef]

- Peng, J.; Fang, X.; Qu, Z.; Wang, J. Isothermal oxidation behavior of NiAl and NiAl-(Cr, Mo) eutectic alloys. Corros Sci. 2019, 151, 27–34. [Google Scholar] [CrossRef]

- Wang, Y.; Vecchio, K.S. Microstructure evolution in Fe-based-aluminide metallic–intermetallic laminate (MIL) composites. Mater. Sci. Eng. A 2016, 649, 325–337. [Google Scholar] [CrossRef]

- Zamanzade, M.; Hasemann, G.; Motz, C.; Krüger, M.; Barnoush, A. Vacancy effects on the mechanical behavior of B2-FeAl intermetallics. Mater. Sci. Eng. A 2018, 712, 88–96. [Google Scholar] [CrossRef]

- Siemiaszko, D.; Kuzia, J. The influence of large particles of iron powder on the microstructure and properties of FeAl intermetallic phase. Intermetallics 2019, 104, 16–23. [Google Scholar] [CrossRef]

- Aoki, K.; Izumi, O. Improvement in room temperature ductility of the L12 type intermetallic compound Ni3Al by boron addition. J. Jpn. Inst. Met. 1979, 43, 1190–1196. [Google Scholar] [CrossRef]

- Makamey, C.G.; Horton, J.A.; Liu, C.T. Effect on chromium on properties of Fe3Al. J. Mater. Res. 1989, 5, 1156–1163. [Google Scholar] [CrossRef]

- Liu, C.; George, E.P.; Oliver, W.C. Grain-boundary fracture and boron effect in Ni3Si alloys. Intermetallics 1996, 4, 77–83. [Google Scholar] [CrossRef]

- Hu, D. Effect on boron addition on the tensile ductility in lamellar TiAl alloys. Intermetallics 2002, 10, 851–858. [Google Scholar] [CrossRef]

- Cahn, R.W. Multiphase intermetallics, High-temperature Structural Materials; Cahn, R.W., Evans, A.G., McLean, M., Eds.; Springer: Dordrecht, The Netherlands, 1996; pp. 79–91. [Google Scholar]

- Chen, R.; Guo, J.; Yin, W.; Zhou, J. Superplasticity of a multiphase Ni-25Al-25Cr lntermetallic alloy. Scripta Mater. 1999, 40, 209–215. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Liu, X.; Vecchio, K.S. Microstructure evolution in pure Ni and Invar-based Metallic-Intermetallic Laminate (MIL) composites. Mater. Sci. Eng. A 2017, 682, 454–465. [Google Scholar] [CrossRef]

- Rohatgi, A.; Harach, D.J.; Vecchio, K.S.; Harvey, K.P. Resistance-curve and fracture behavior of Ti-Al3Ti metallic-intermetallic laminate (MIL) composites. Acta Mater. 2003, 51, 2933–2957. [Google Scholar] [CrossRef]

- Lu, Z.; Jiang, F.; Chang, Y.; Niu, Z.; Wang, Z.; Guo, C. Multi-phase intermetallic mixture structure effect on the ductility of Al3Ti alloy. Mater. Sci. Eng. A 2018, 721, 274–285. [Google Scholar] [CrossRef]

- Lu, Z.; Wei, N.; Li, P.; Guo, C.; Jiang, F. Microstructure and mechanical properties of intermetallic Al3Ti alloy with residual aluminum. Mater. Des. 2016, 110, 466–474. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, W.; Ma, H.; Yu, H.; Jiang, W. First-principles prediction of the physical properties of ThM2Al20 (M= Ti, V, Cr) intermetallics. Solid State Commun. 2018, 284–286, 75–83. [Google Scholar] [CrossRef]

- Yu, J.; Zhou, D.; Pu, C.; Tang, X.; Zhang, F. Prediction of stable Cu-Li binary intermetallics from first-principles calculations: Stoichiometries, crystal structures, and physical properties. J. Alloys. Compd. 2018, 766, 640–648. [Google Scholar] [CrossRef]

- Xing, H.; Dong, A.; Huang, J.; Zhang, J.; Sun, B. Revisiting intrinsic brittleness and deformation behavior of B2 NiAl intermetallic compound: A first-principles study. J Mater Sci Technol. 2018, 34, 620–626. [Google Scholar] [CrossRef]

- Blaha, P.; Schwarz, K.; Madsen, G.K.H.; Kvasnicka, D.; Luitz, J. WIEN2k; Vienna University of Technology: Vienna, Austria, 2001; ISBN 3-9501031-1-2. [Google Scholar]

- Eremenko, V.N.; Buyanov, Y.I.; Prima, S.B. Phase diagram of the system Ti-Cu. Sov. Powder. Metall. Met. Ceram. 1966, 5, 494–502. [Google Scholar] [CrossRef]

- Wu, Z.; Zhao, E.; Xiang, H.; Hao, X.; Liu, X.; Meng, J. Crystal structures and elastic properties of superhard IrN2 and IrN3 from first principles. Phys. Rev. B 2007, 76, 054115. [Google Scholar] [CrossRef]

- Chen, S.; Sun, Y.; Duan, Y.; Huang, B.; Peng, M. Phase stability, structural and elastic properties of C15-type Laves transition-metal compounds MCo2 from first-principles calculations. J Alloy Comp. 2015, 630, 202–208. [Google Scholar] [CrossRef]

- Pugh, S.F. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos.Mag. 1954, 45, 823–843. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, W.; Liu, Y.; Li, R.; Meng, F.; Song, J.; Qi, Y. A first principles investigation of W1-xMox (x=0-68.75 at.%) alloys: Structural, electronic, mechanical and thermal properties. J. Alloys Compd. 2020, 829, 154480. [Google Scholar] [CrossRef]

- Bader, R.F.W. Atom in Molecules: A Quantum Theory; Oxford University Pres: Oxford, UK, 1990; p. 155. [Google Scholar]

- Zhang, W.; Deevi, S.C.; Chen, G. On the origin of superior high strength of Ti–45Al–10Nb alloys. Intermetallics 2002, 10, 403–406. [Google Scholar] [CrossRef]

- Paul, J.D.H.; Appel, F.; Wagner, R. The compression behaviour of niobium alloyed γ-titanium alumindies. Acta Mater. 1998, 46, 1075–1085. [Google Scholar] [CrossRef]

| Alloy | a | b | c | c/a | u | dTi1-Ti1 /dNb-Ti1 | dTi1-Ti2 /dNb-Ti2 | dTi1-Cu1 /dNb-Cu1 |

|---|---|---|---|---|---|---|---|---|

| Ti2Cu | 2.936 | 2.936 | 10.770 | 3.6675 | 0.338 | 2.936/- | 2.809/- | 2.713/- |

| Experimental Values [30] | 2.943 | 2.943 | 10.784 | 3.6643 | 0.341 | - | - | - |

| Ti15Cu8Nb | 5.881 | 5.881 | 10.784 | - | - | -/2.941 | -/2.836 | -/2.743 |

| Alloy | C11 (GPa) | C12 (GPa) | C33 (GPa) | C44 (GPa) | C66 (GPa) | C13 (GPa) |

|---|---|---|---|---|---|---|

| Ti2Cu | 215 | 84 | 186 | 95 | 52 | 106 |

| Ti15Cu8Nb | 220 | 96 | 186 | 97 | 51 | 116 |

| Alloy | B (GPa) | G (GPa) | E (GPa) | B/G | ν |

|---|---|---|---|---|---|

| Ti2Cu | 134 | 66 | 149 | 2.03 | 0.288 |

| Ti15Cu8Nb | 142 | 64 | 167 | 2.22 | 0.304 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, J.; Yun, Y.; Wang, J.; Rui, J.; Wang, S.; Du, Y. Effect of Nb on the Microstructure and Mechanical Properties of Ti2Cu Intermetallic through the First-Principle Calculations and Experimental Investigation. Metals 2020, 10, 547. https://doi.org/10.3390/met10040547

Cheng J, Yun Y, Wang J, Rui J, Wang S, Du Y. Effect of Nb on the Microstructure and Mechanical Properties of Ti2Cu Intermetallic through the First-Principle Calculations and Experimental Investigation. Metals. 2020; 10(4):547. https://doi.org/10.3390/met10040547

Chicago/Turabian StyleCheng, Jialin, Yeling Yun, Jingjing Wang, Jiaxin Rui, Shun Wang, and Yulei Du. 2020. "Effect of Nb on the Microstructure and Mechanical Properties of Ti2Cu Intermetallic through the First-Principle Calculations and Experimental Investigation" Metals 10, no. 4: 547. https://doi.org/10.3390/met10040547

APA StyleCheng, J., Yun, Y., Wang, J., Rui, J., Wang, S., & Du, Y. (2020). Effect of Nb on the Microstructure and Mechanical Properties of Ti2Cu Intermetallic through the First-Principle Calculations and Experimental Investigation. Metals, 10(4), 547. https://doi.org/10.3390/met10040547