Revolution and Control of Fe-Al-(Mg, Ti)-O Oxide Inclusions in IF Steel during 260t BOF-RH-CC Process

Abstract

1. Introduction

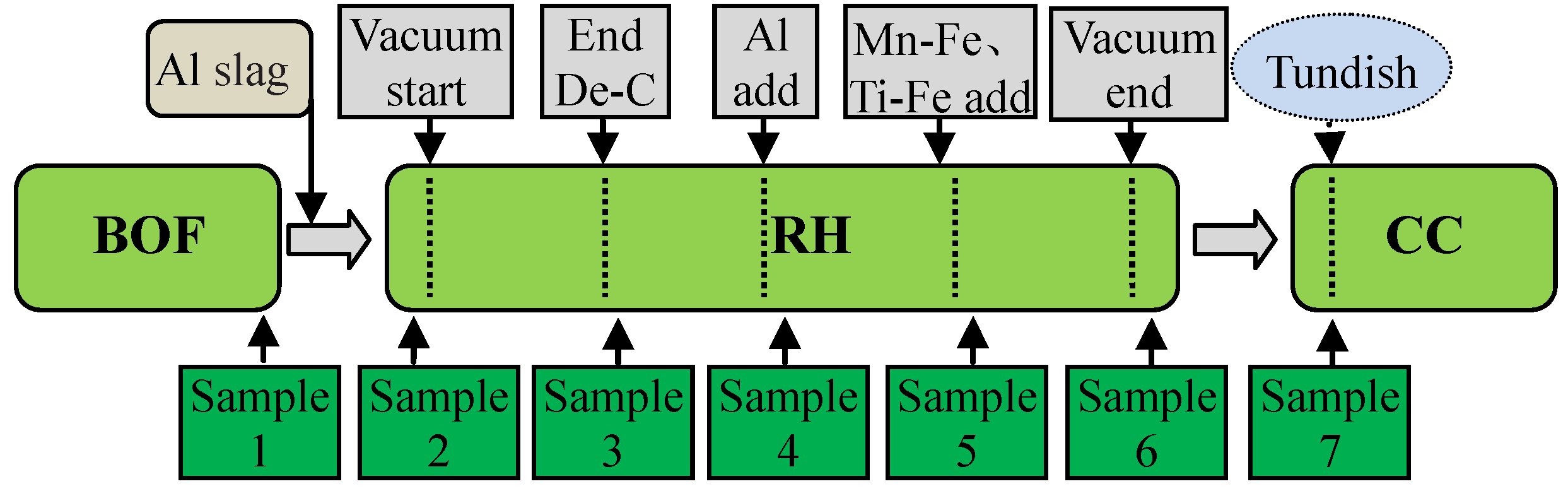

2. Materials and Methods

2.1. Materials

2.2. Mechanical Property Experiment

2.3. Methods of Chemical Analysis

3. Results and Discussion

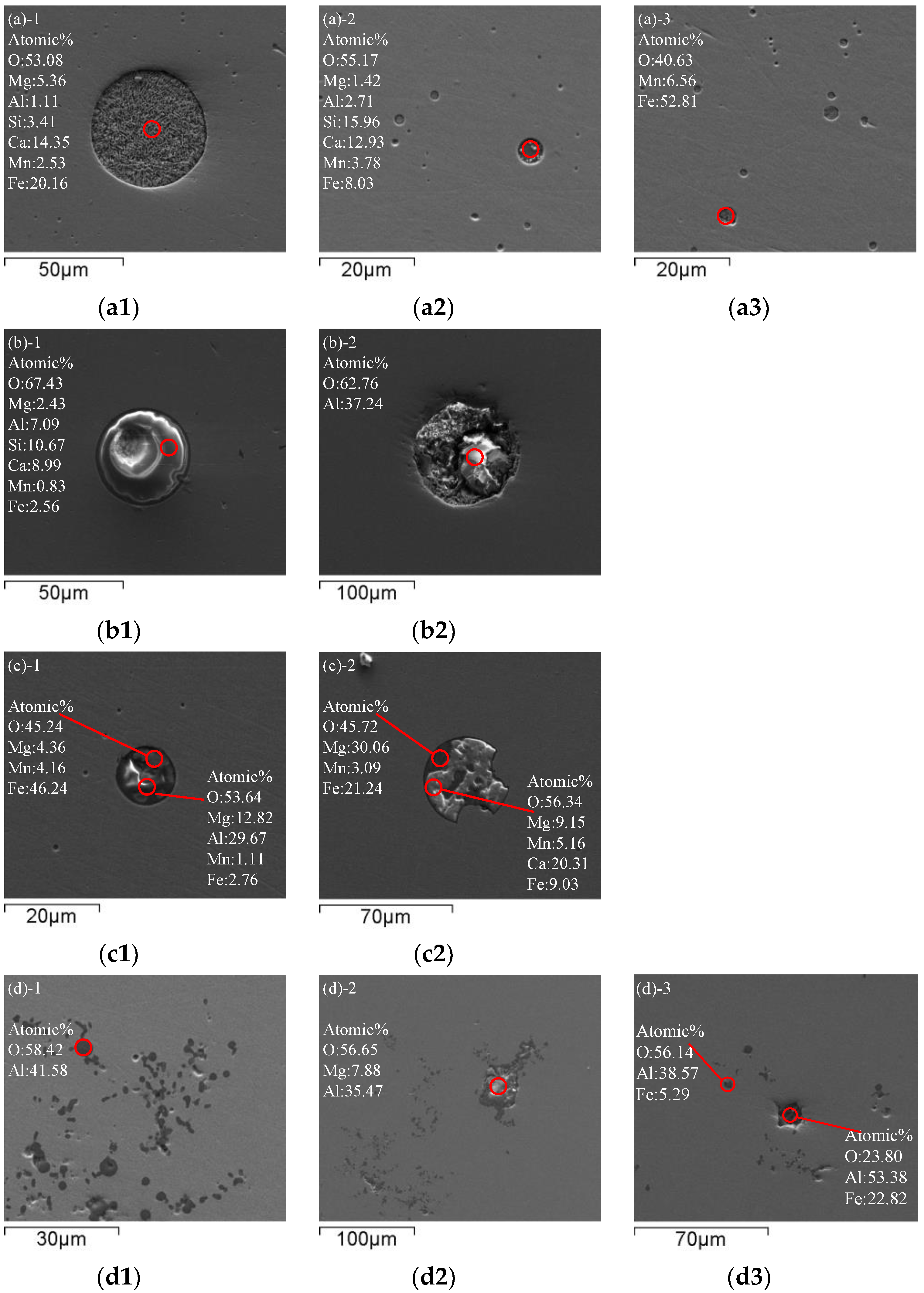

3.1. Morphology and Evolution of Typical Non-Metallic Inclusions in Molten Steel

3.2. Thermodynamics of Evolution and Control of Typical Oxide Inclusions during Refining

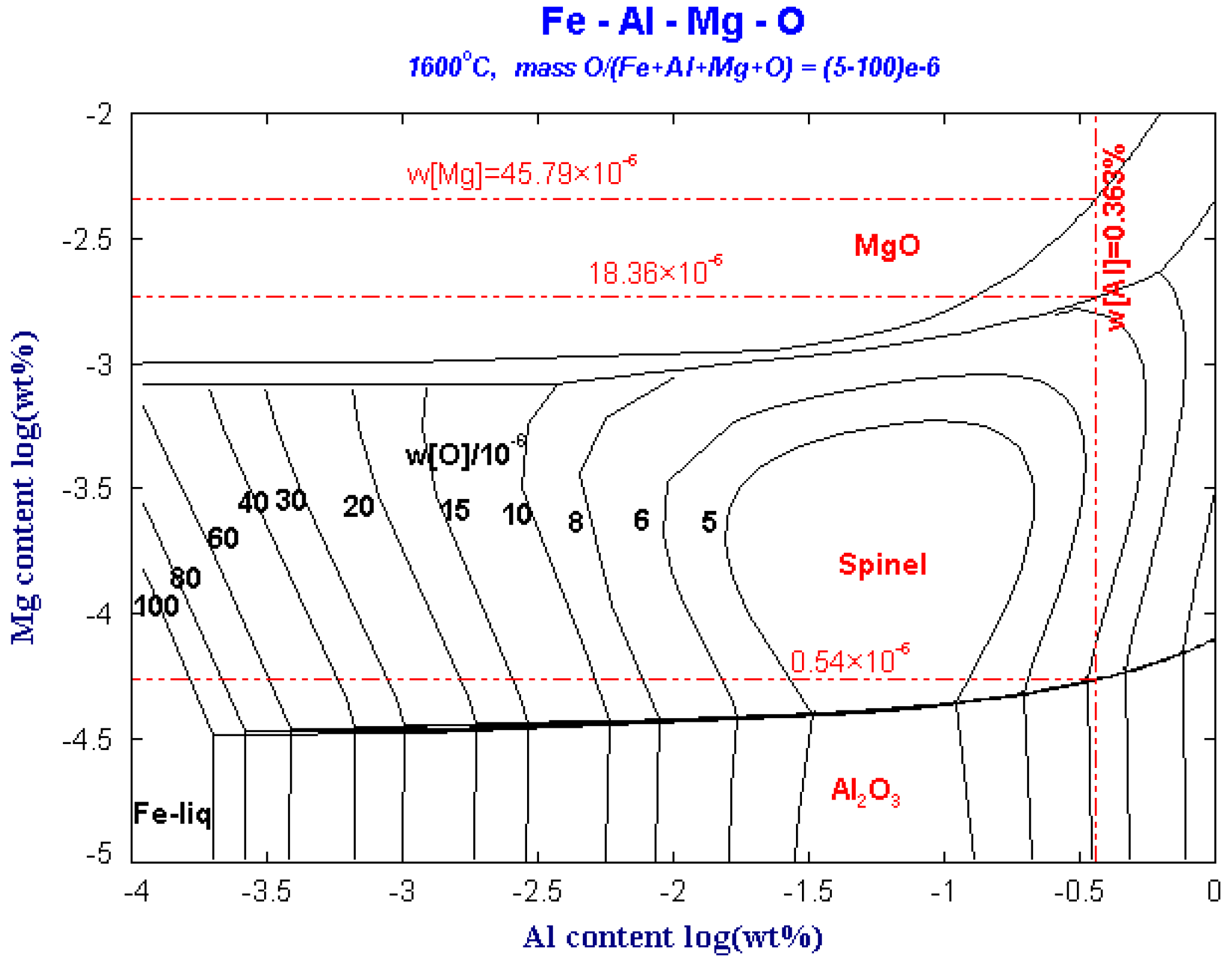

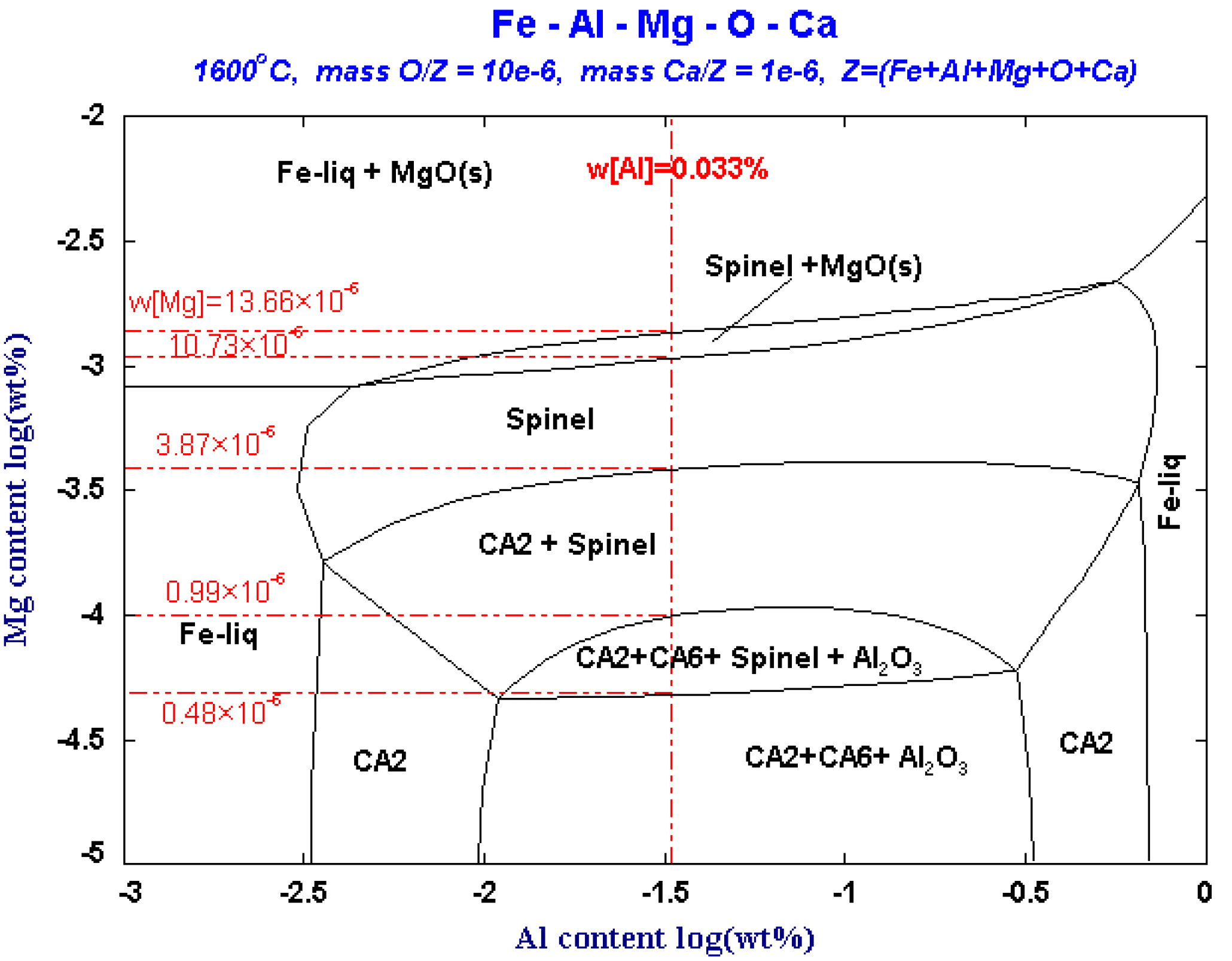

3.2.1. Typical Spinel Inclusions in Molten Steel before RH Refining

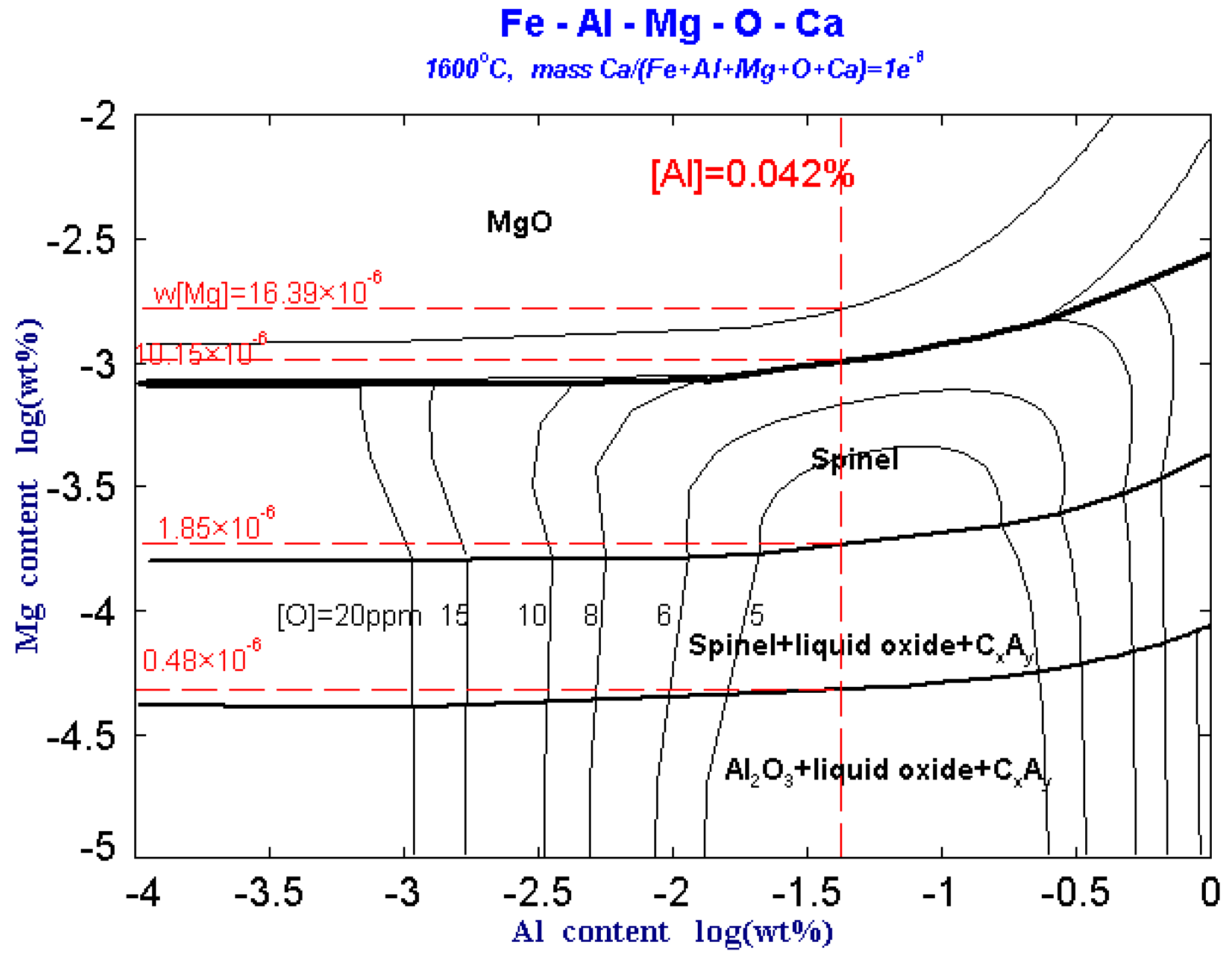

3.2.2. Typical Mg-Al Spinel Inclusions in Molten Steel after RH Refining

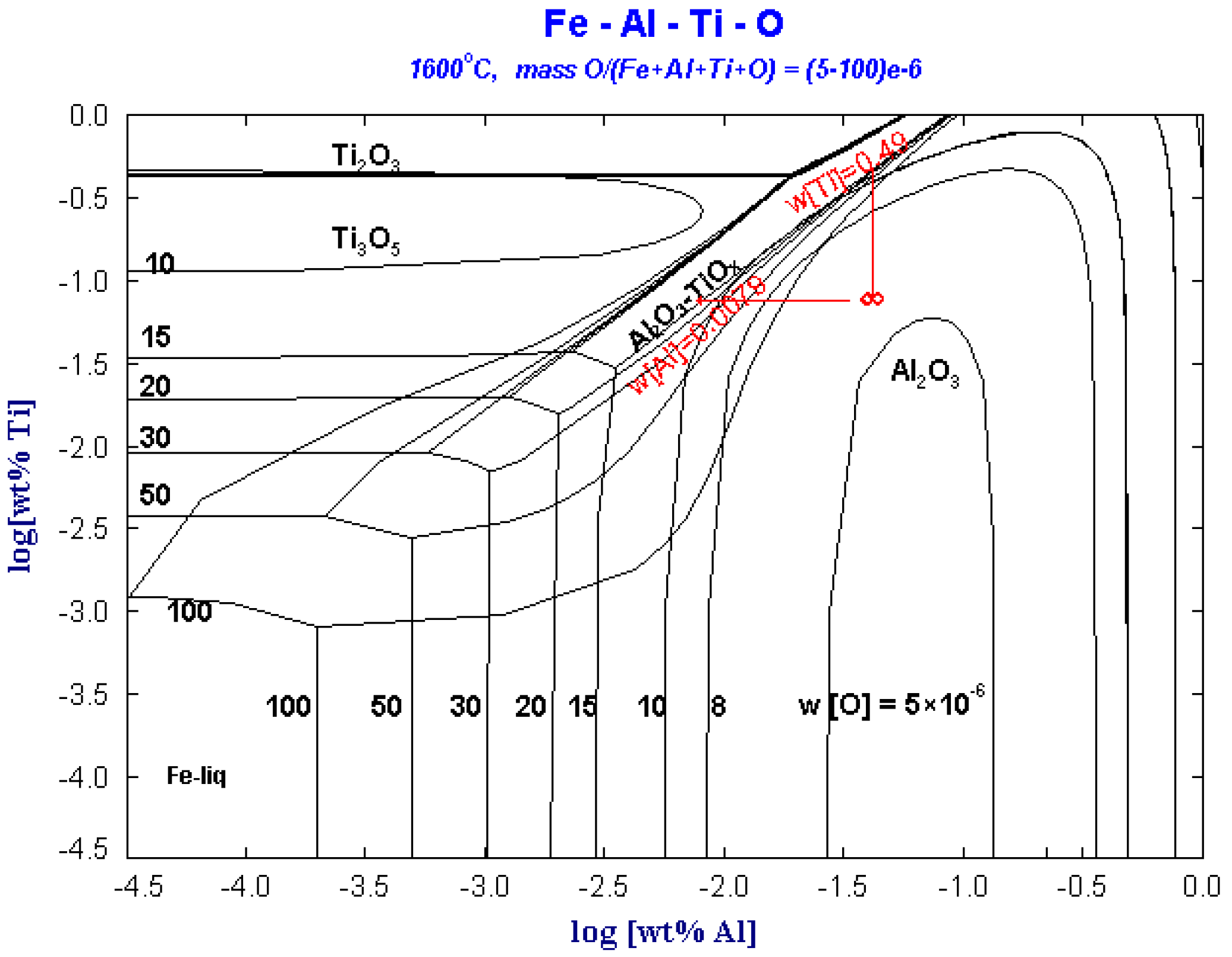

3.2.3. Typical Al-Ti Inclusions in Molten Steel after RH Refining

3.2.4. Typical Al-Mg Inclusions in Tundish Molten Steel

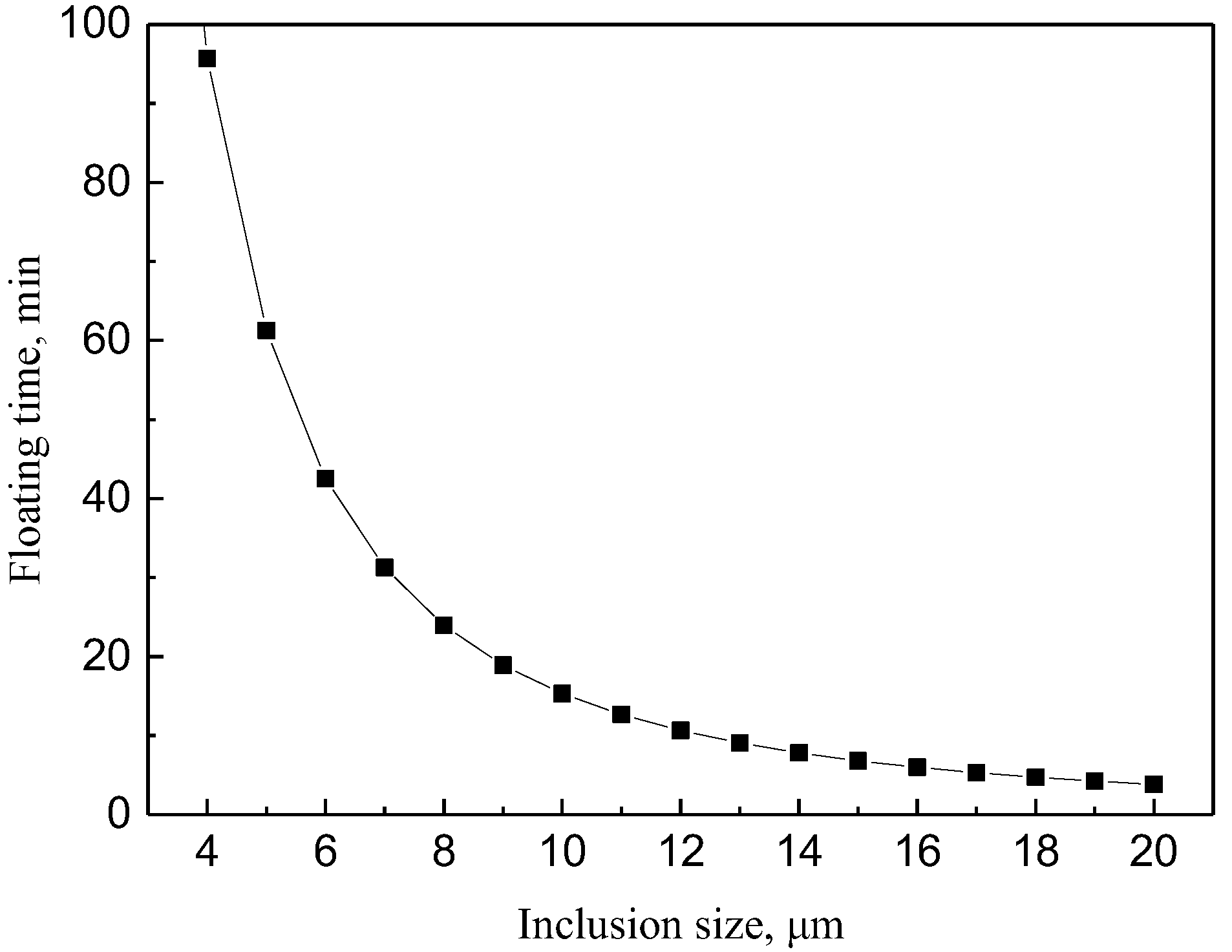

3.3. Change and Control of Inclusions during Refining and Holding Time

3.4. Mechanical Properties of IF Steel

4. Conclusions

- The IF steel inclusions in the BOF process are large sphere-like SiO2-CaO-FeO-MgO-MnO multi-phase composite inclusions below 50 μm and cluster spherical FeO-MnO inclusions below 5 μm. With the addition of Al-slag modifier and Al deoxidizer, a large amount of cluster-like or coral-like Al2O3 inclusions are formed. Moreover, MgO·Al2O3 spinel inclusions reduce gradually. Al2O3·TiOx inclusions begin to form after Ti addition, and Al2O3-type inclusions increase slightly. During the holding process, the inclusions are removed and the number of Al2O3 inclusions and Al2O3·TiOx inclusions in the steel is greatly reduced. In addition, Al2O3·TiOx inclusions are larger in size compared to Al2O3 inclusions. After the molten steel remains unstirred in the ladle during the holding process, most of the large-particle Al2O3 inclusions have been removed by floating. In the tundish, the inclusions of Al2O3·TiOx in the molten steel disappear, and only Al2O3 inclusions remain in the end. It is key to extend the holding time properly after RH to ensure the removal of Al2O3 inclusion.

- The predominance area diagram of Fe-Al-Mg-O system show that, when the Mg concentration in the molten steel before RH is (0.54–45.79) × 10−6, the MgAl2O4 spinel inclusions will exist in the molten steel. The type of inclusions is mainly affected by the [Mg] content, and it is difficult to suppress MgO·Al2O3 spinel formation by controlling the oxygen in the steel. When Ca content in steel is 1 × 10−6, Ca can modify part of the MgO·Al2O3 spinel inclusions during RH refining, and the amount of Mg required to form spinel is reduced to (0.48–16.39) × 10−6. With the increase of Mg content, the change path of inclusions in IF steel is that Al2O3 change to MgO·Al2O3, and finally change to MgO.

- Al2O3·TiOx will not be stable in the IF molten steel, except for three situations: (1) when the dissolved [O] in the molten steel is up to 15 × 10−6. (2) When the local Ti concentration in the molten steel is up to 0.49% during the titanium alloying adjusting process. (3) When the local Al concentration in the molten steel is as low as 0.0079%.

- In order to ensure the removal of 6–10 μm inclusions, the holding time is suitable for 19–42min.

- The yield strength Rp0.2, tensile strength Rm, elongation after fracture A80, tensile strain hardening index N90, and plastic strain ratio R90 of DC06 IF steel are 138.7 MPa, 304.7 MPa, 45.3%, 0.24, and 2.91, respectively. The mechanical properties of DC06 IF steel meet the requirements.

Author Contributions

Funding

Conflicts of Interest

References

- Tian, Y.; An, L.Q.; Jian, L.Z.; Mao, Y.; Guo, M.; Wang, P.; Li, Z.; Wen, T.G. Process analysis and practice of clean IF steel production. J. Iron Steel Res. Int. 2011, 18, 399–405. [Google Scholar]

- Yuan, P.; Li, H.B.; Chen, B.; Zhu, K.R.; Pei, X.W.; Jiang, J.R. Control technology of surface sliver defects for automobile steel sheets. J. Iron Steel Res. 2017, 29, 800–806. [Google Scholar]

- Sui, Y.F.; Sun, G.D.; Zhao, Y.; Wang, C.G.; Guo, M.; Zhang, M. Evolution of titaniferous inclusions in IF steelmaking. J. Univ. Sci. Technol. Beijing 2014, 36, 1174–1182. [Google Scholar]

- Wang, R.; Bao, Y.P.; Li, Y.H.; Li, T.Q.; Chen, D. Effect of slag composition on steel cleanliness in interstitial-free steel. J. Iron Steel Res. Int. 2017, 24, 579–585. [Google Scholar] [CrossRef]

- Shu, H.F.; Liu, L.; Liu, X.H.; Zhang, X.F. Investigation on variation of inclusions and total oxygen in IF steel after RH deoxidization. J. Iron Steel Res. Int. 2011, 18, 347–351. [Google Scholar]

- Qin, Y.M.; Wang, X.H.; Li, L.P.; Huang, F.X. Effect of Oxidizing Slag on Cleanliness of IF Steel during Ladle Holding Process. Steel Res. Int. 2015, 86, 1037–1045. [Google Scholar] [CrossRef]

- Yuan, P.; Zhang, J.; Liu, D.Z.; Li, H.B.; Zhu, K.R.; Chen, B. Formation mechanism and control technology of Al-Ti inclusions in ultra low carbon steel. Iron Steel 2018, 53, 24–30. [Google Scholar]

- Park, D.C.; Jung, I.H.; Rhee, P.C.H.; Lee, H.G. Reoxidation of Al-Ti containing steels by CaO-Al2O3-MgO-SiO2 slag. ISIJ Int. 2004, 44, 1669–1678. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, L.F.; Zhang, Y. Modeling reoxidation behavior of Al–Ti-containing steels by CaO–Al2O3–MgO–SiO2 slag. J. Iron Steel Res. Int. 2018, 25, 146–156. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, C.J. Modification mechanism of spinel inclusions in medium manganese steel with rare earth treatment. Metals 2019, 9, 804. [Google Scholar] [CrossRef]

- Wang, R.; Bao, Y.P.; Yan, Z.J.; Li, D.Z.; Kang, Y. Comparison between the surface defects caused by Al2O3 and TiN inclusions in interstitial-free steel auto sheets. Int. J. Miner. Metall. Mater. 2019, 26, 178–185. [Google Scholar] [CrossRef]

- Todoroki, H.; Mizuno, K. Effect of silica in slag on inclusion compositions in 304 stainless steel deoxidized with aluminum. ISIJ Int. 2004, 44, 1350–1357. [Google Scholar] [CrossRef]

- Yang, S.F.; Li, J.S.; Wang, Z.F.; Li, J.; Lin, L. Modification of MgO·Al2O3 spinel inclusions in Al-killed steel by Ca treatment. Int. J. Miner. Metall. Mater. 2011, 18, 18–23. [Google Scholar] [CrossRef]

- Shin, J.H.; Par, J.H. Modification of Inclusions in Molten Steel by Mg-Ca Transfer from Top Slag: Experimental Confirmation of the ‘Refractory-Slag-Metal-Inclusion (ReSMI)’ Multiphase Reaction Model. Metall. Mater. Trans. B 2017, 48, 1–6. [Google Scholar] [CrossRef]

- Cao, L.; Wang, G.C.; Yuan, X.H.; Jin, P.L.; Sridhar, S. Thermodynamics and agglomeration behavior on spinel inclusion in Al-deoxidized steel coupling with Mg treatment. Metals 2019, 9, 900. [Google Scholar] [CrossRef]

- Chu, Y.P.; Chen, Z.Y.; Liu, N.; Zhang, L.F. Formation and control of spinel inclusions in high-speed heavy rail steel. Iron steel 2020, 55, 38–46. [Google Scholar]

- Wang, Y.; Cui, H.; Wang, W.; Yang, H. Effect of RH circulation time and holding time on cleanliness of IF steel. J. Iron Steel Res. 2017, 29, 649–653. [Google Scholar]

| C | Si | Mn | P | S | Als | Ti | B | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.0020 | ≤0.010 | 0.08–0.14 | ≤0.012 | ≤0.009 | 0.020–0.050 | 0.065–0.075 | 0.0003–0.0008 | ≤0.003 |

| Process | Al | Als | Ca | Ti |

|---|---|---|---|---|

| Before RH | 0.472 | 0.363 | – | – |

| After RH | 0.044 | 0.042 | 0.0001 | 0.077 |

| Ladle holding | 0.036 | 0.033 | 0.0001 | 0.070 |

| Standard and Experiment | Yield Strength Rp0.2, MPa | Tensile Strength Rm, MPa | Elongation after Fracture A80, % | Tensile Strain Hardening Index N90 | Plastic Strain Ratio R90 |

|---|---|---|---|---|---|

| GB/T 5213-2019 | ≤170 | 260–330 | ≥42 | ≥0.22 | ≥2.1 |

| Experimental data | 138.7 | 304.7 | 45.3 | 0.24 | 2.91 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, R.; Li, R.; Cheng, D.; Liu, J.; Fang, Q.; Zhou, J.; Dong, W.; Zhang, H.; Ni, H. Revolution and Control of Fe-Al-(Mg, Ti)-O Oxide Inclusions in IF Steel during 260t BOF-RH-CC Process. Metals 2020, 10, 528. https://doi.org/10.3390/met10040528

Cheng R, Li R, Cheng D, Liu J, Fang Q, Zhou J, Dong W, Zhang H, Ni H. Revolution and Control of Fe-Al-(Mg, Ti)-O Oxide Inclusions in IF Steel during 260t BOF-RH-CC Process. Metals. 2020; 10(4):528. https://doi.org/10.3390/met10040528

Chicago/Turabian StyleCheng, Rijin, Renchun Li, Di Cheng, Junshan Liu, Qing Fang, Jian'an Zhou, Wenliang Dong, Hua Zhang, and Hongwei Ni. 2020. "Revolution and Control of Fe-Al-(Mg, Ti)-O Oxide Inclusions in IF Steel during 260t BOF-RH-CC Process" Metals 10, no. 4: 528. https://doi.org/10.3390/met10040528

APA StyleCheng, R., Li, R., Cheng, D., Liu, J., Fang, Q., Zhou, J., Dong, W., Zhang, H., & Ni, H. (2020). Revolution and Control of Fe-Al-(Mg, Ti)-O Oxide Inclusions in IF Steel during 260t BOF-RH-CC Process. Metals, 10(4), 528. https://doi.org/10.3390/met10040528