Numerical Study on Cyclic Response of End-Plate Biaxial Moment Connection in Box Columns

Abstract

1. Introduction

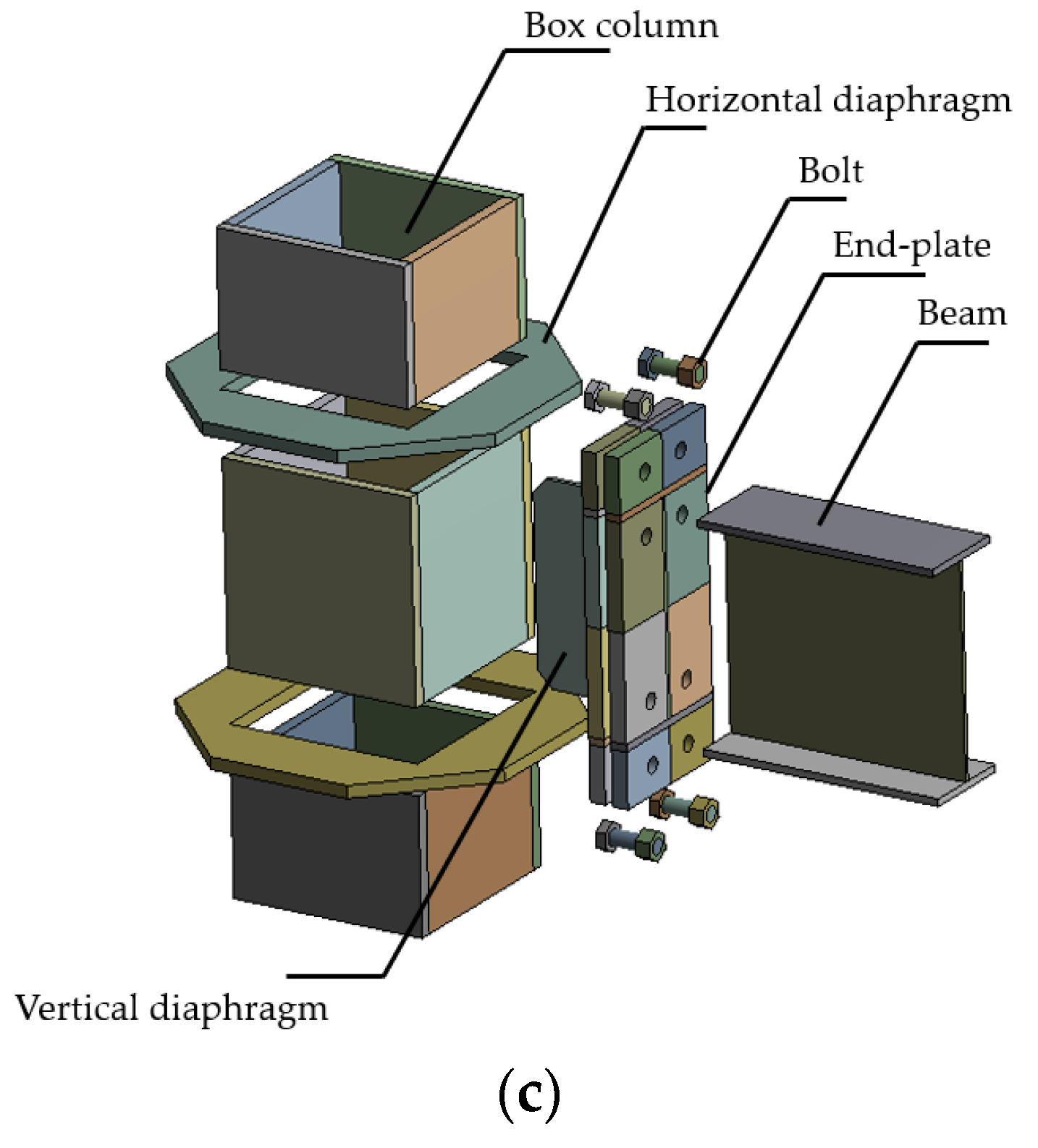

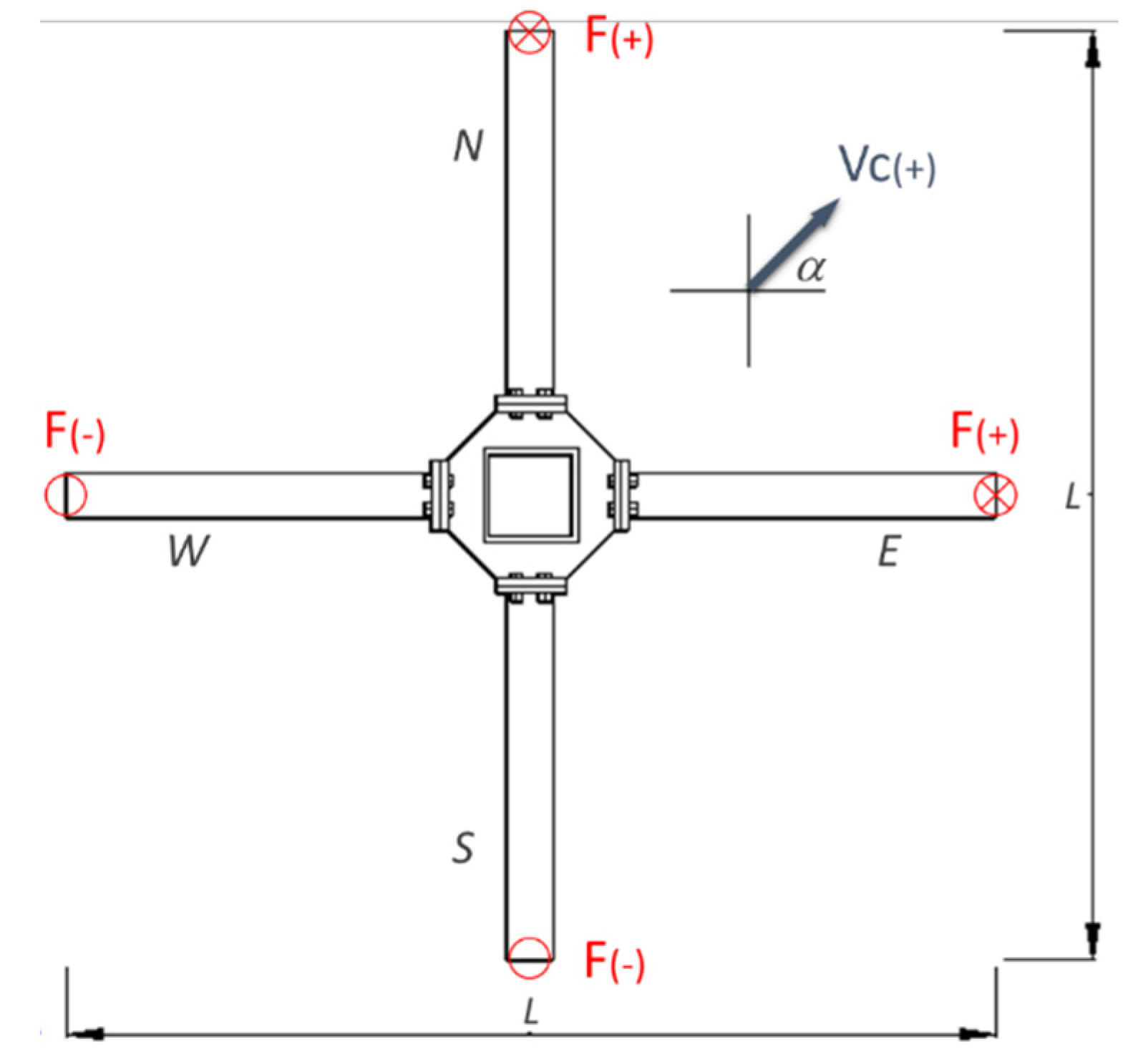

2. Description of Moment Connection

3. Finite Element Model

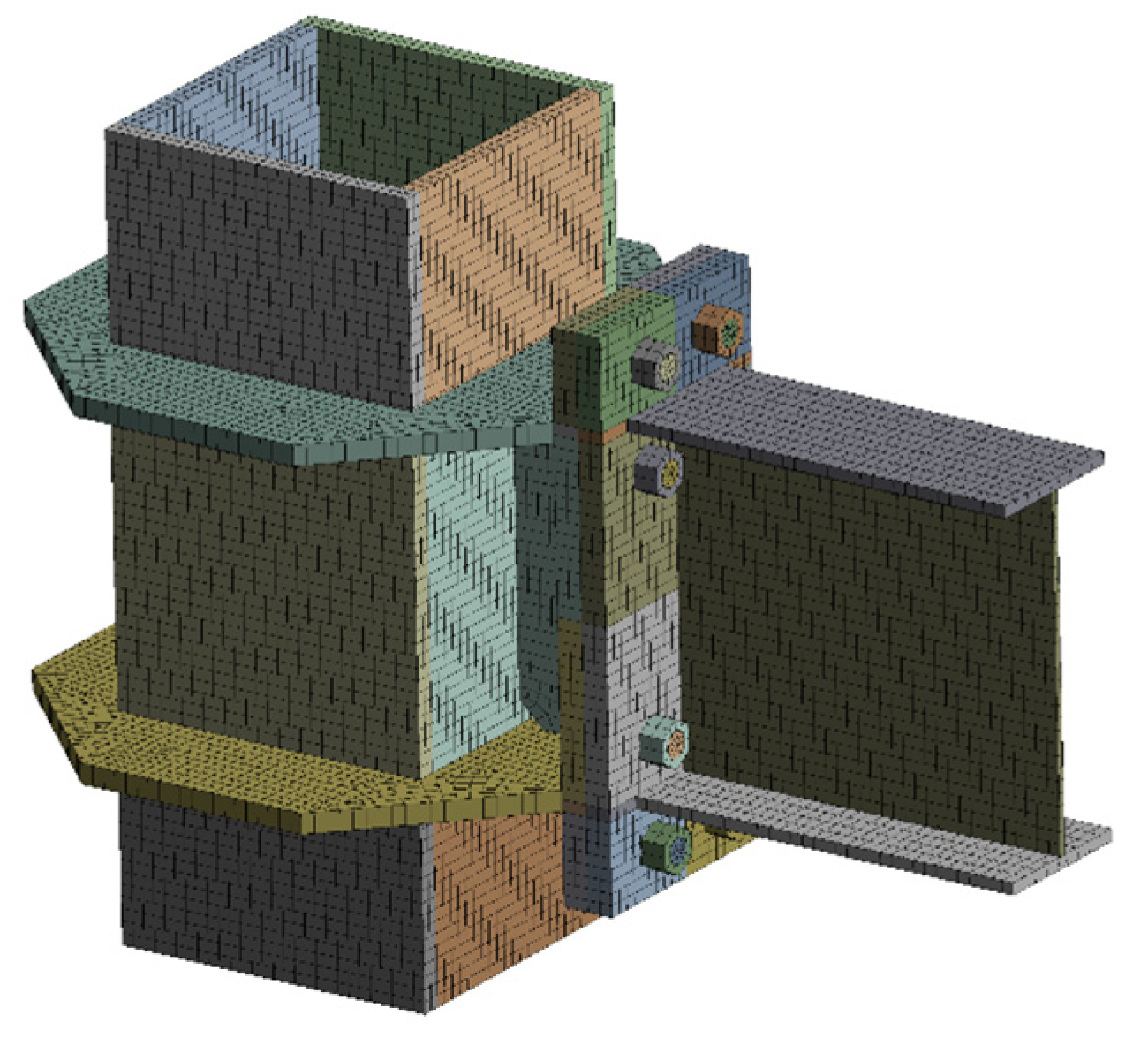

3.1. General Characteristics of the Numerical Model

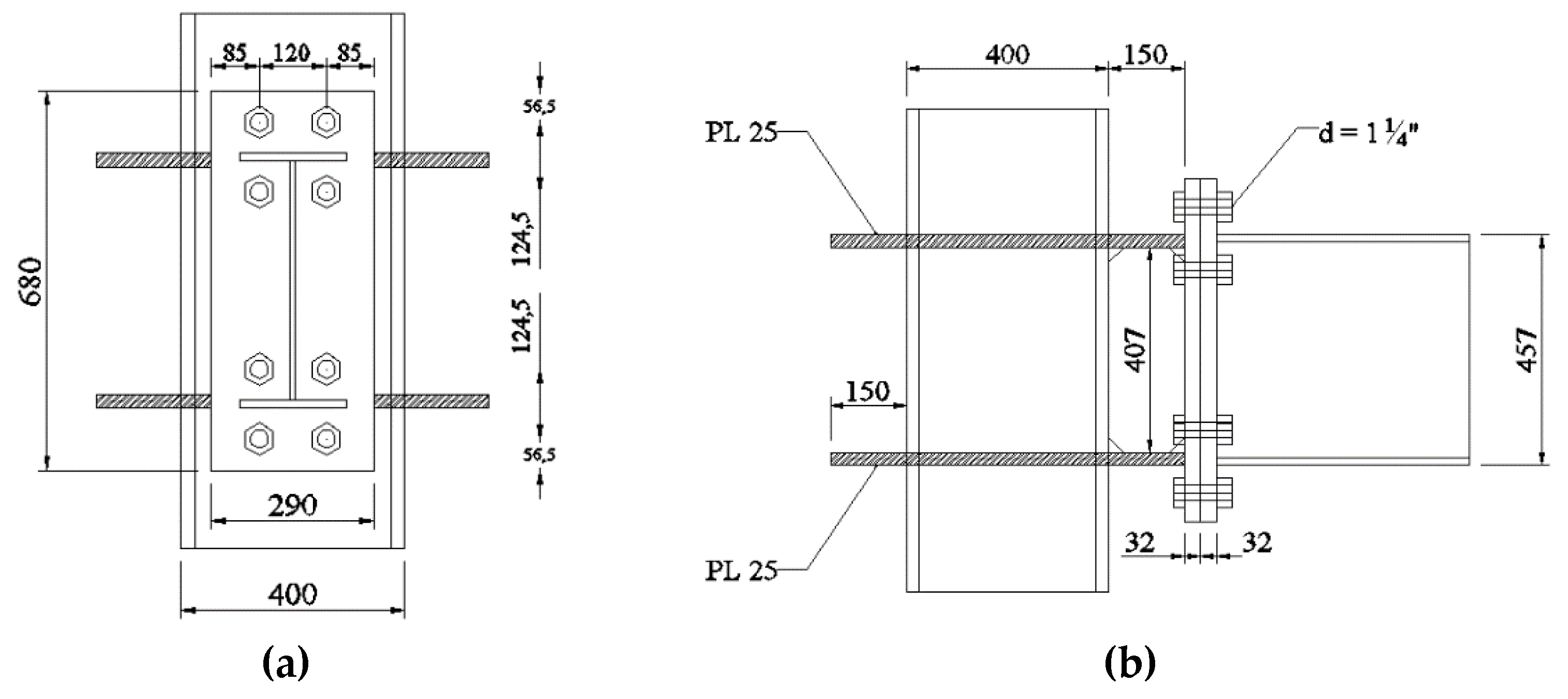

3.2. Element Type and Mesh

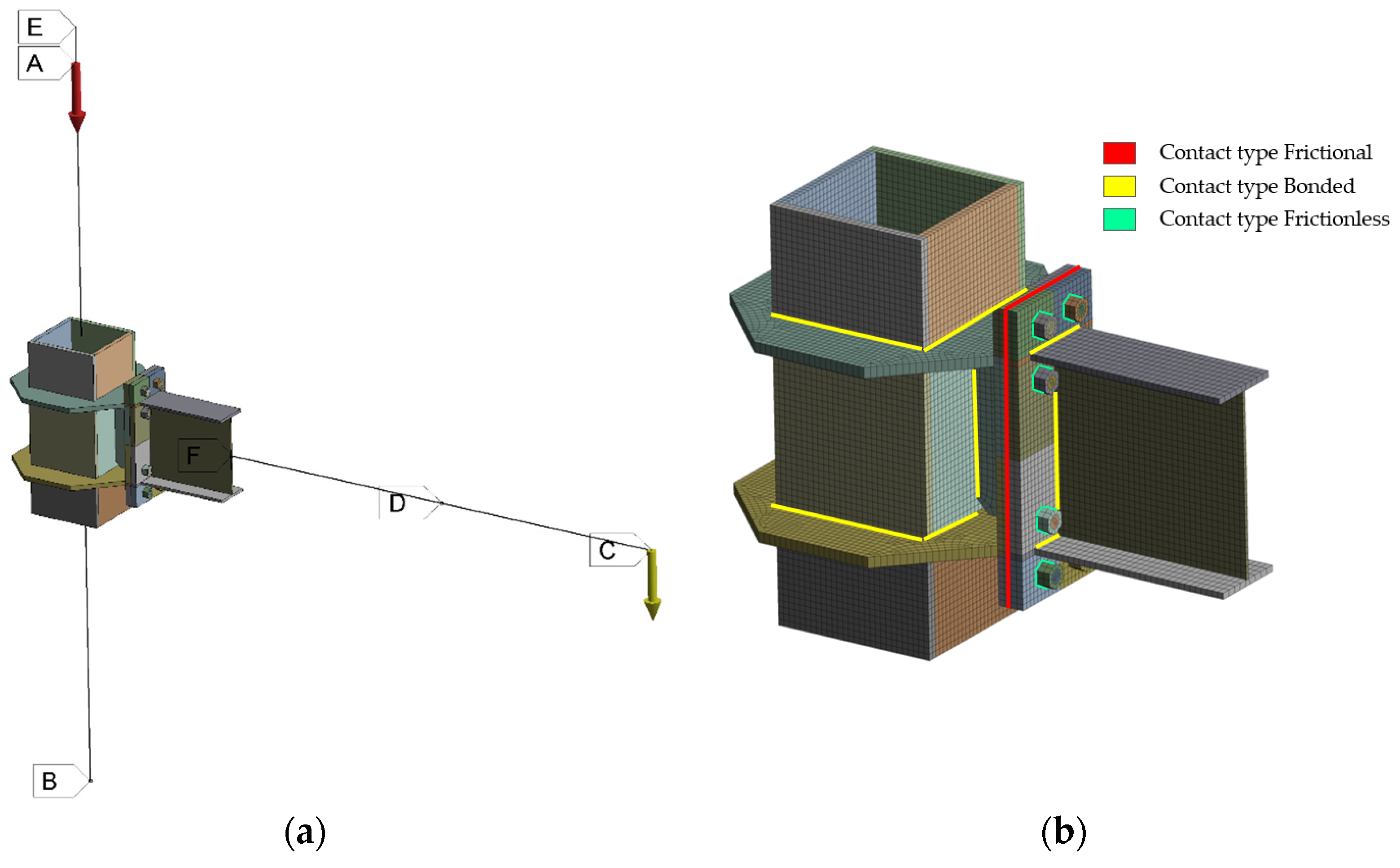

3.3. Boundary Conditions, Contacts and Loading

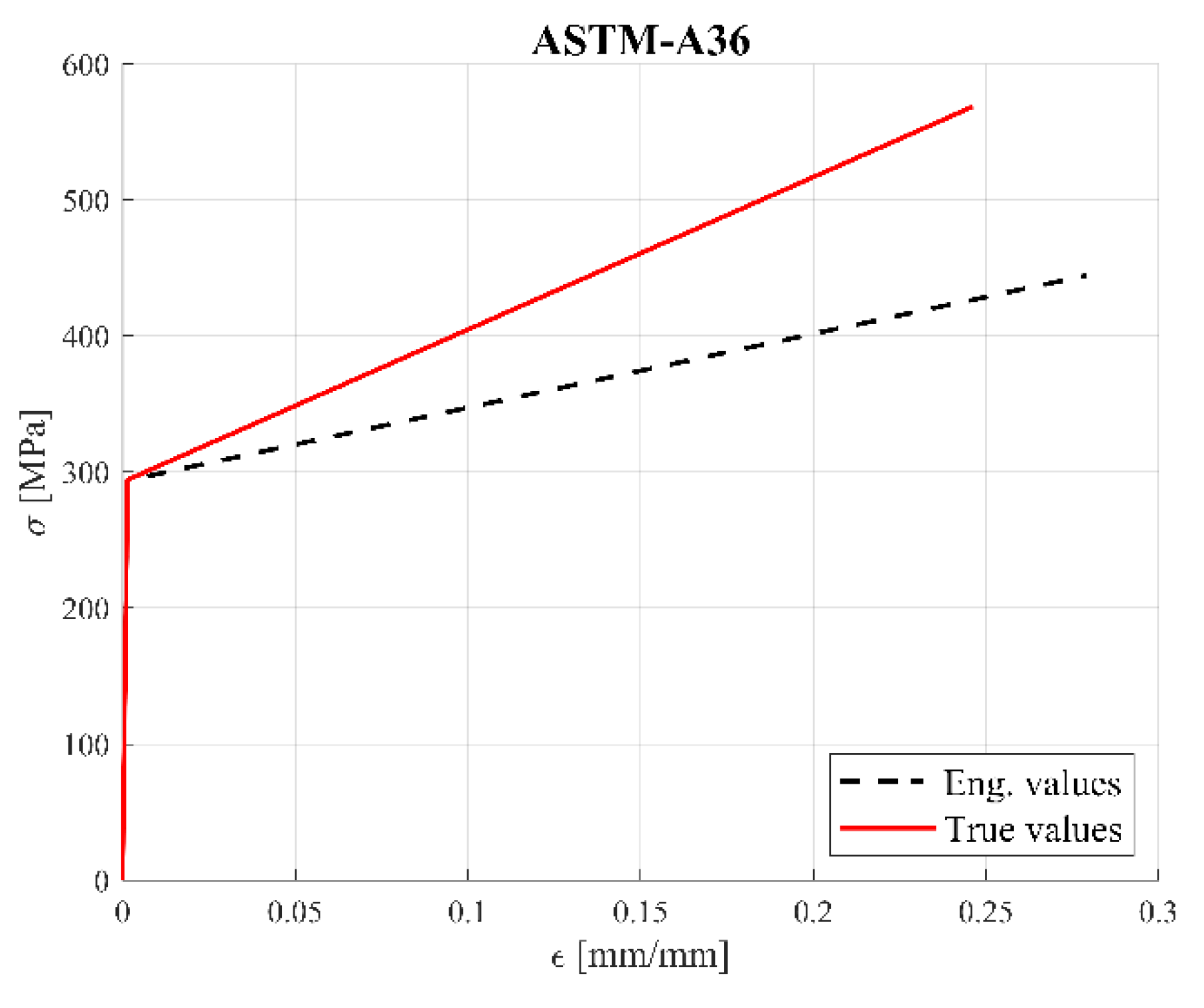

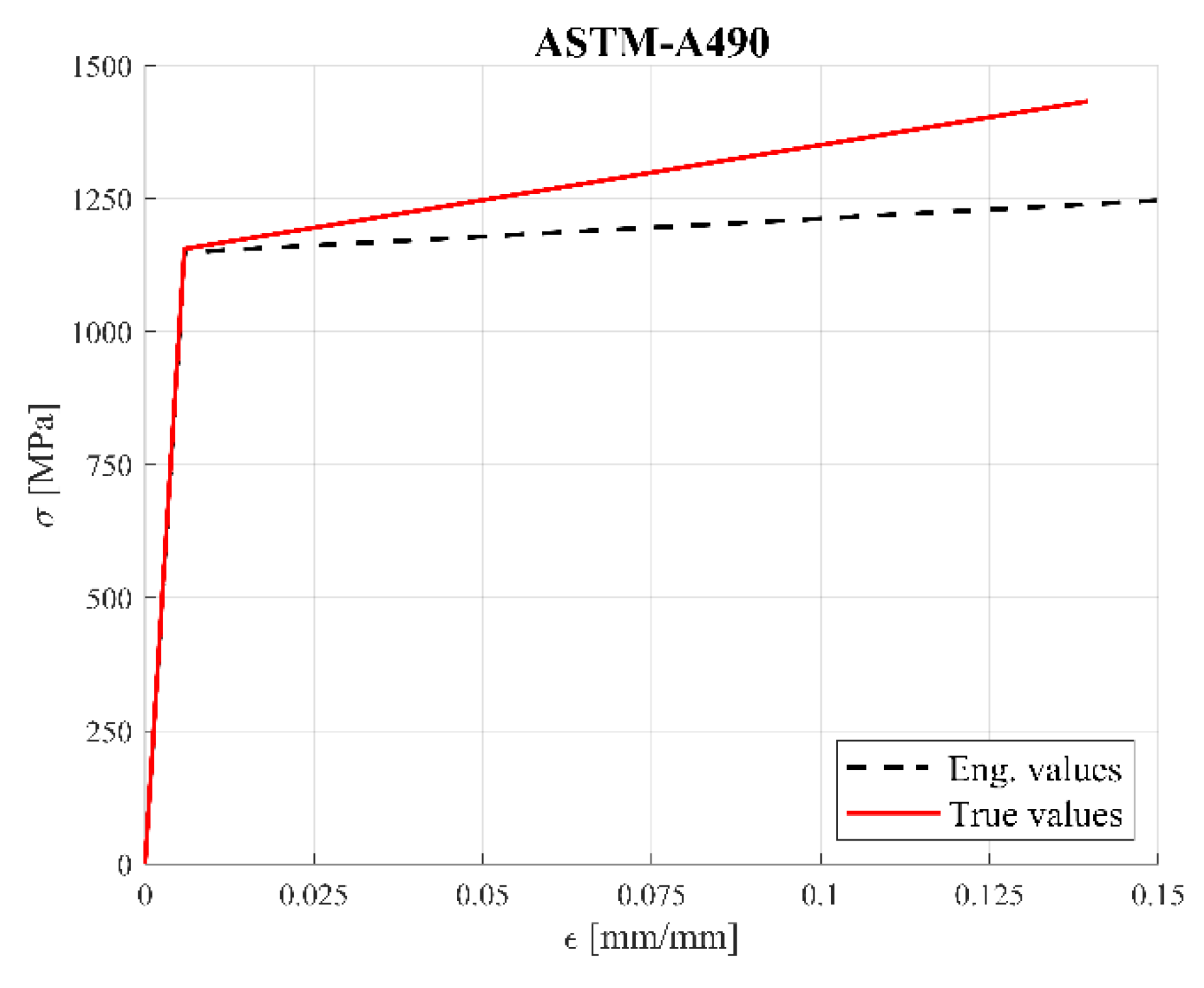

3.4. Material Modeling

4. Analysis Results

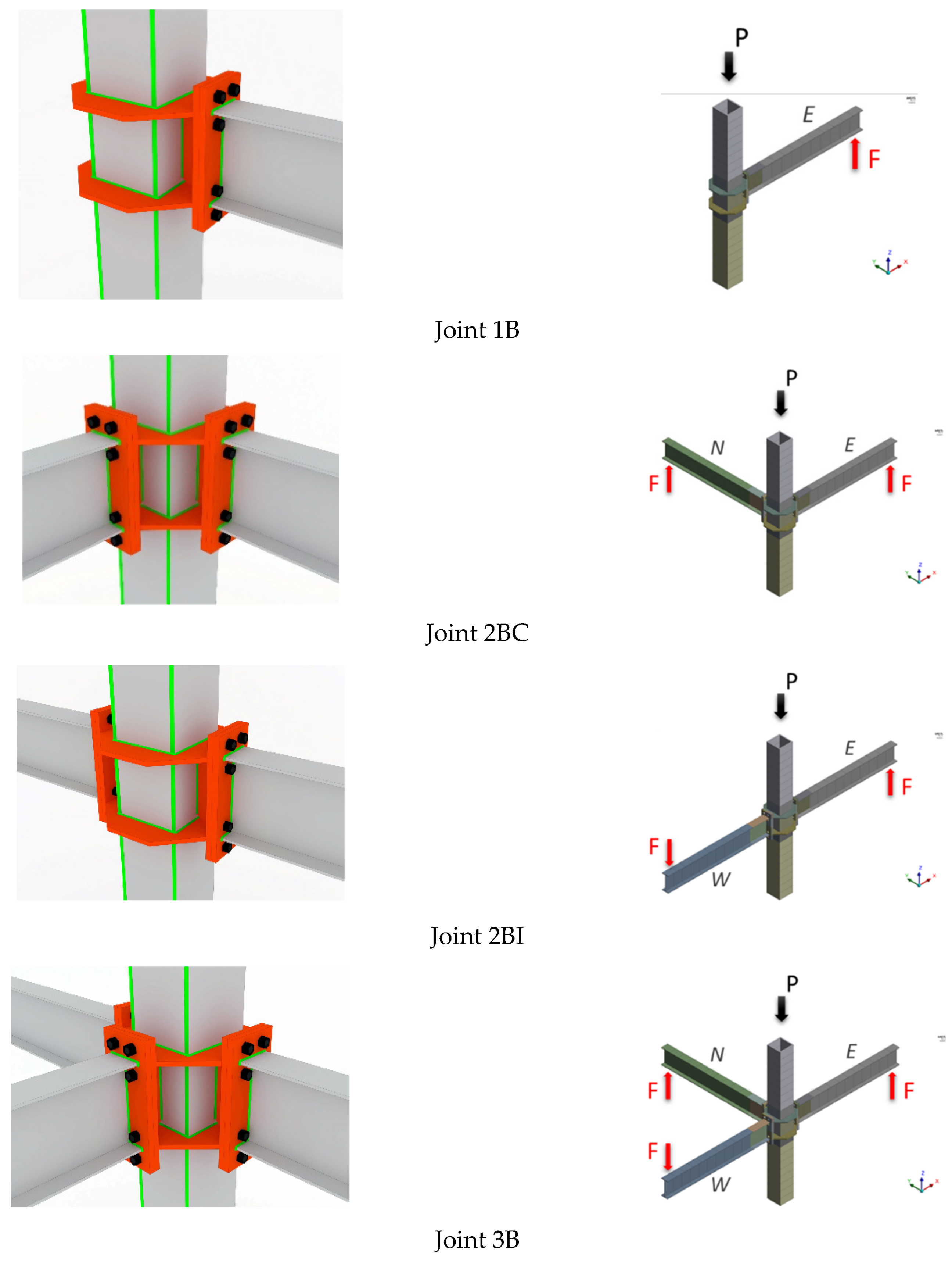

4.1. Seismic Performance for Different Joints

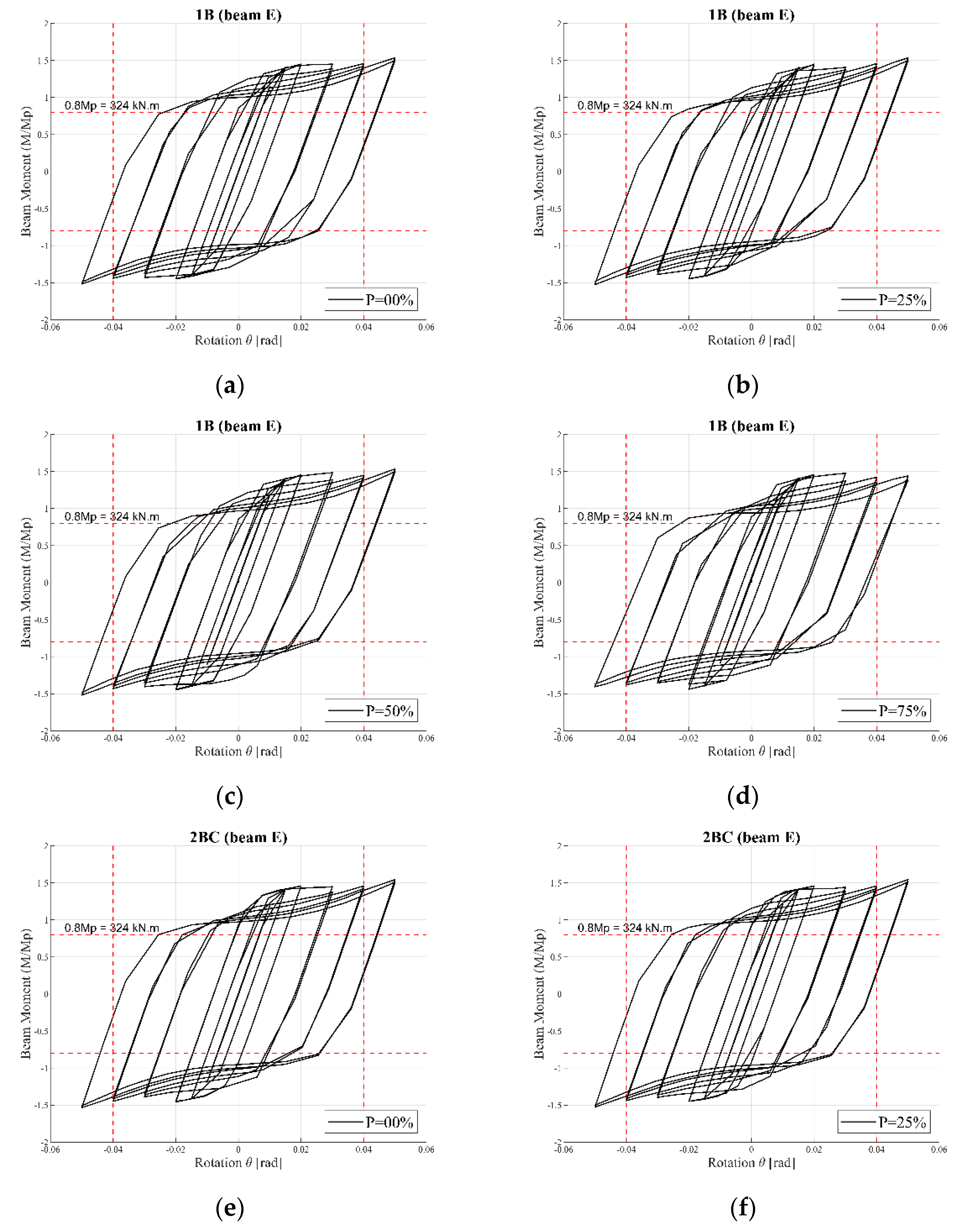

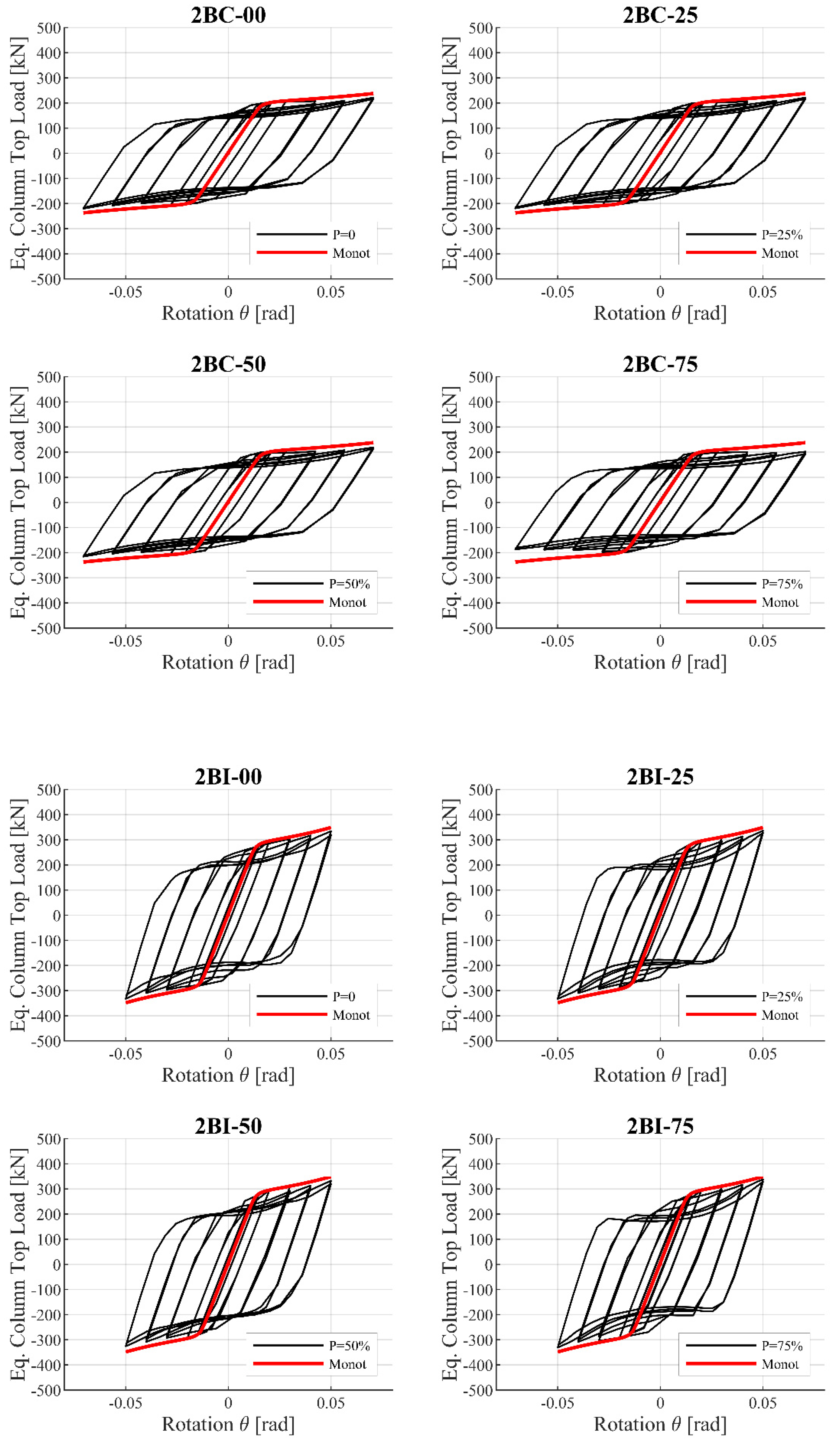

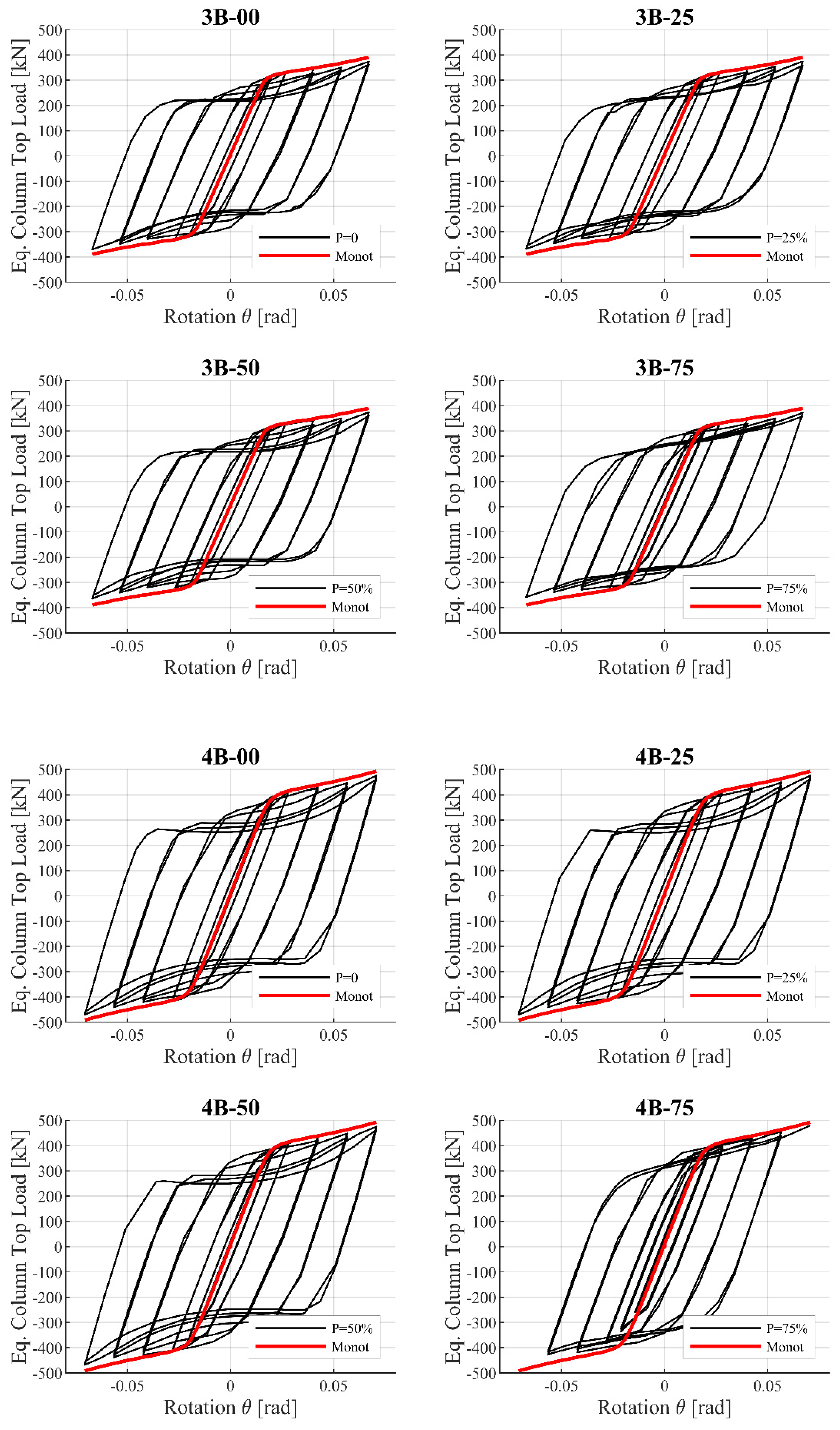

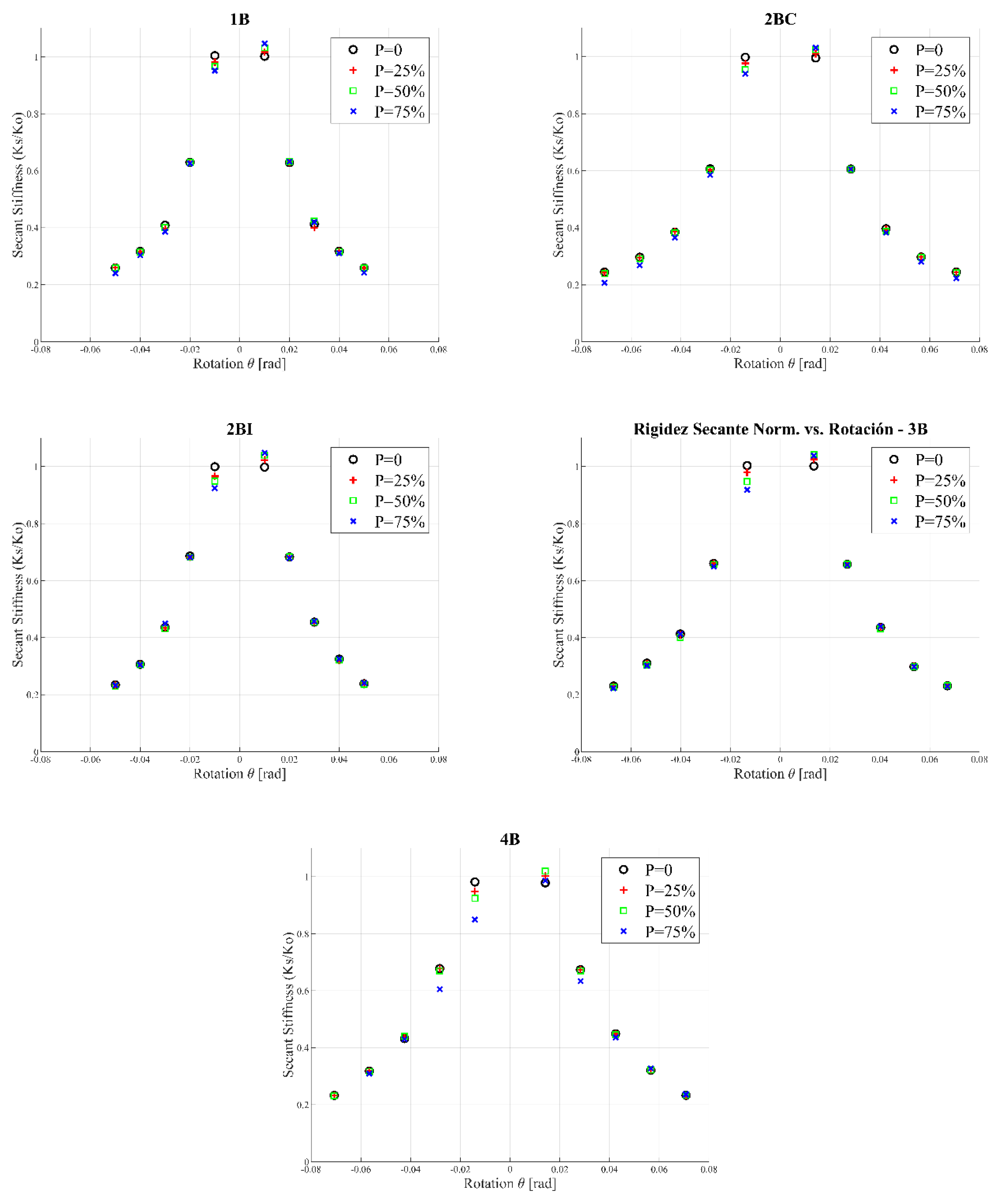

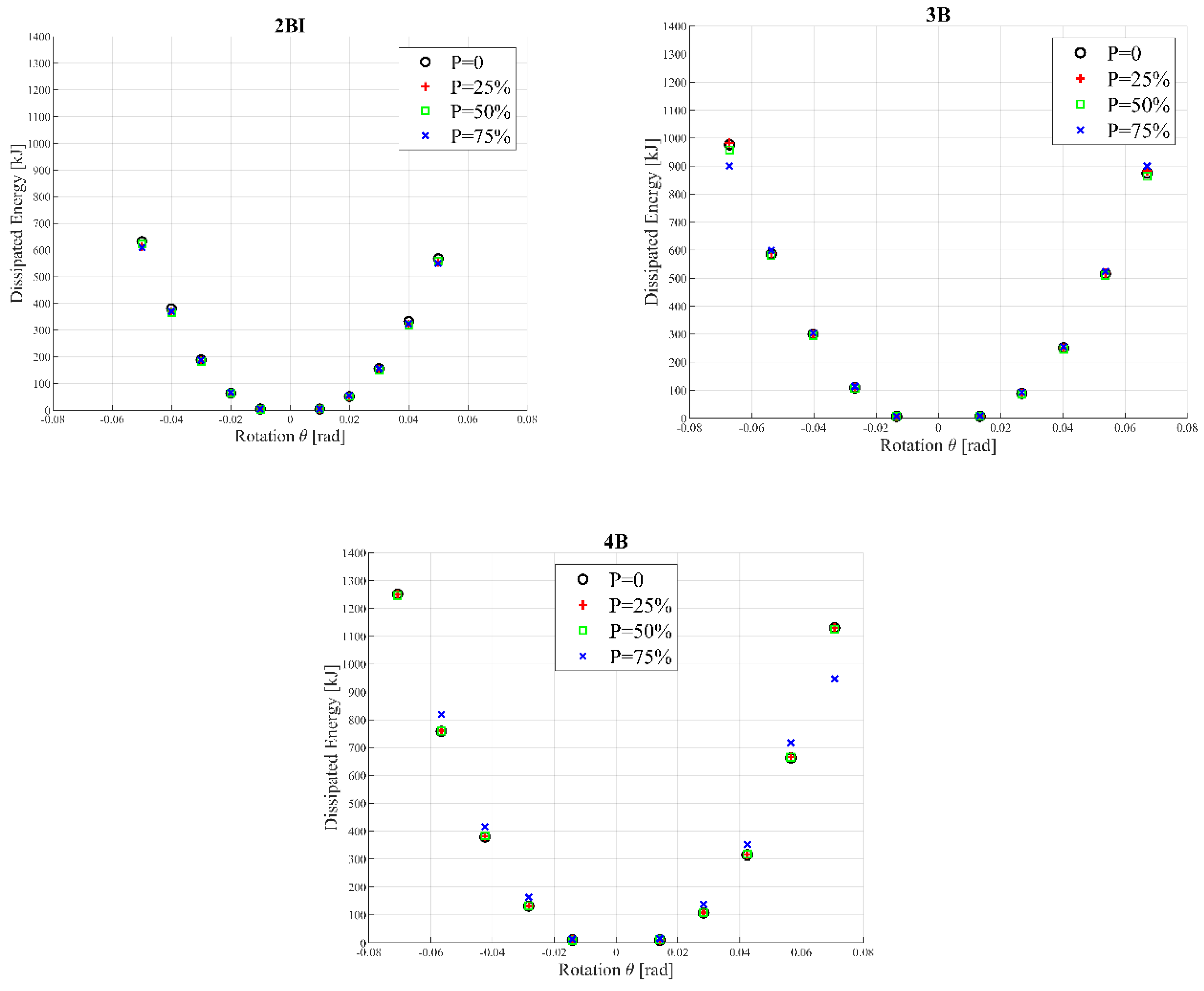

4.2. Hysteretic Behavior

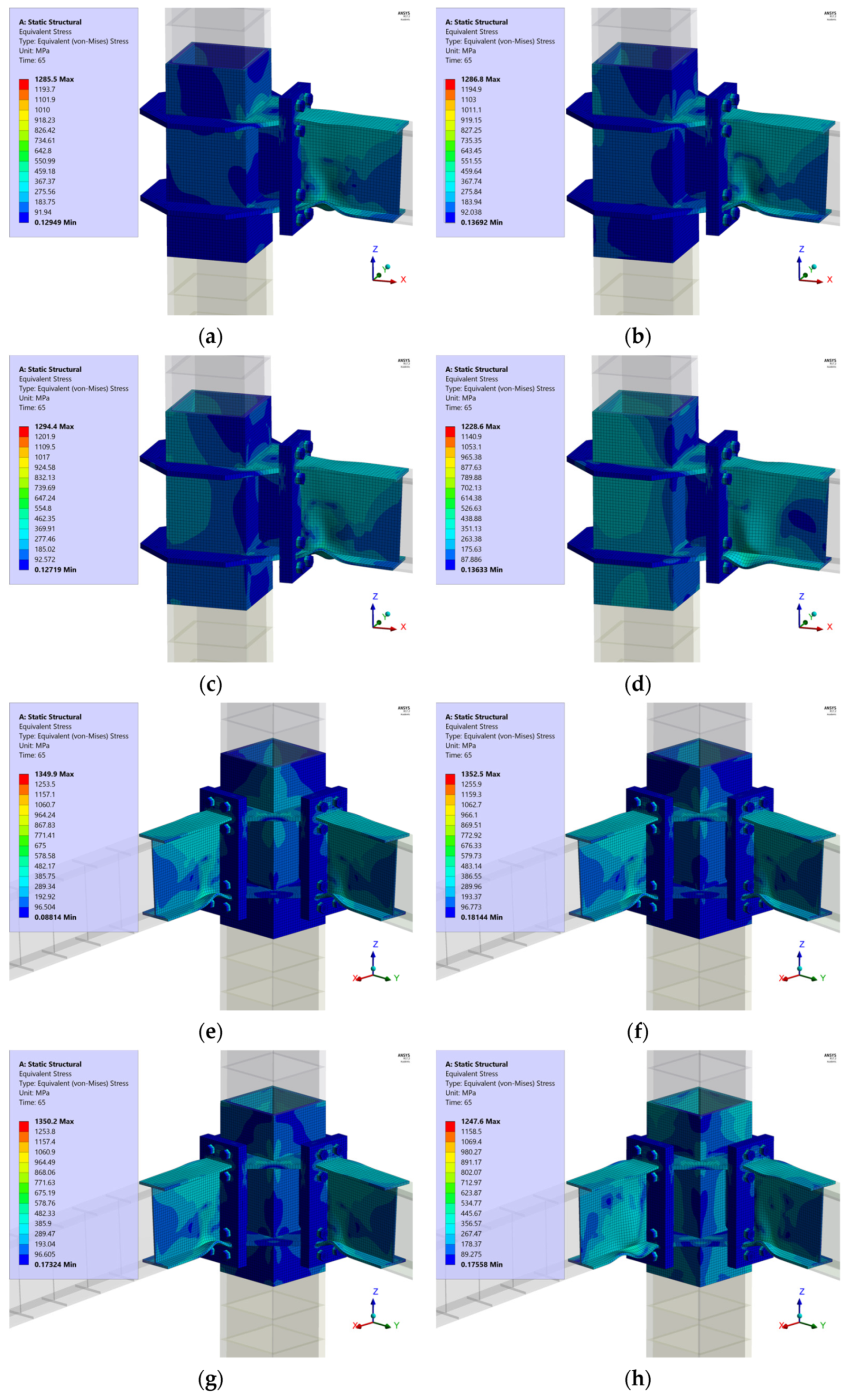

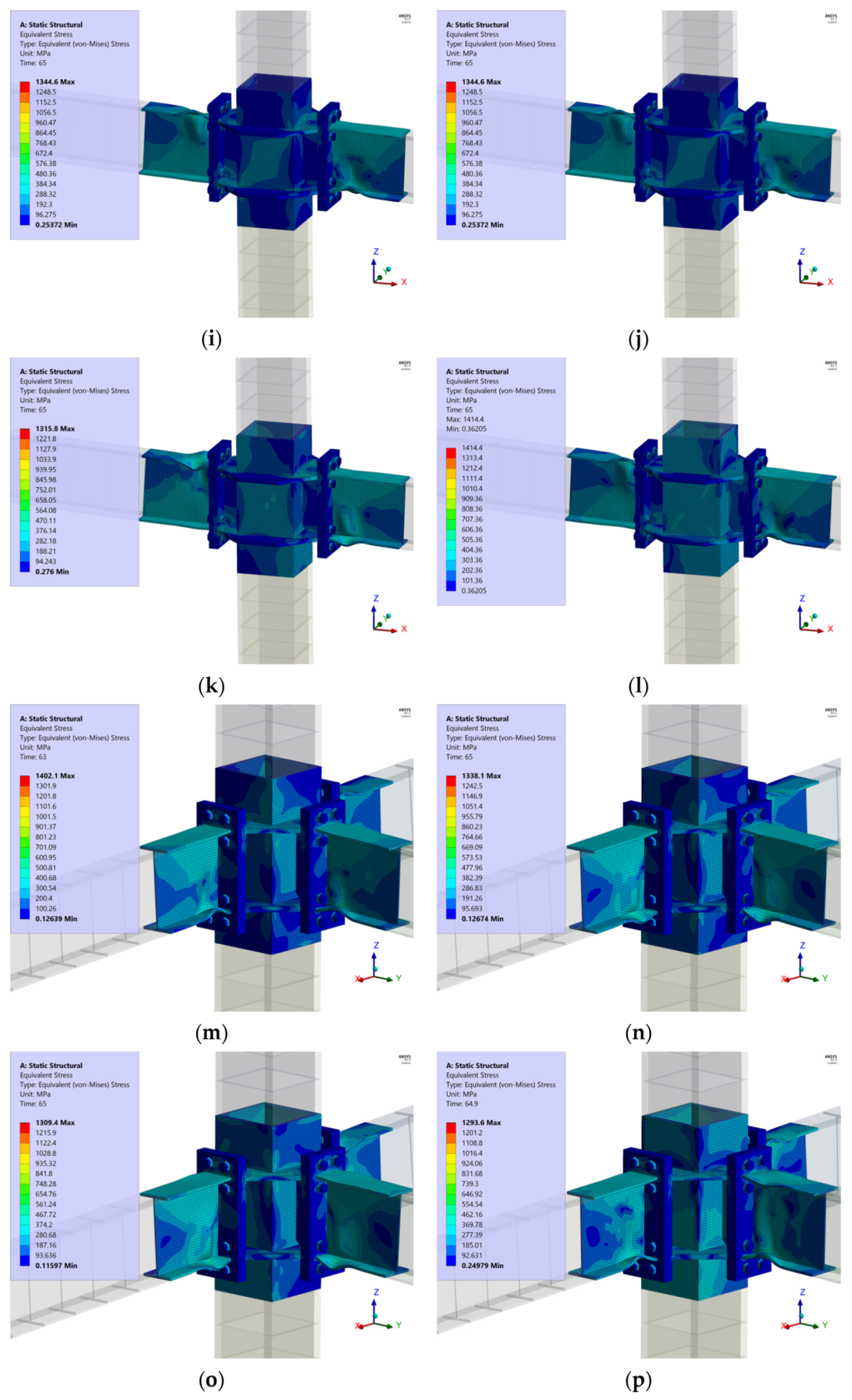

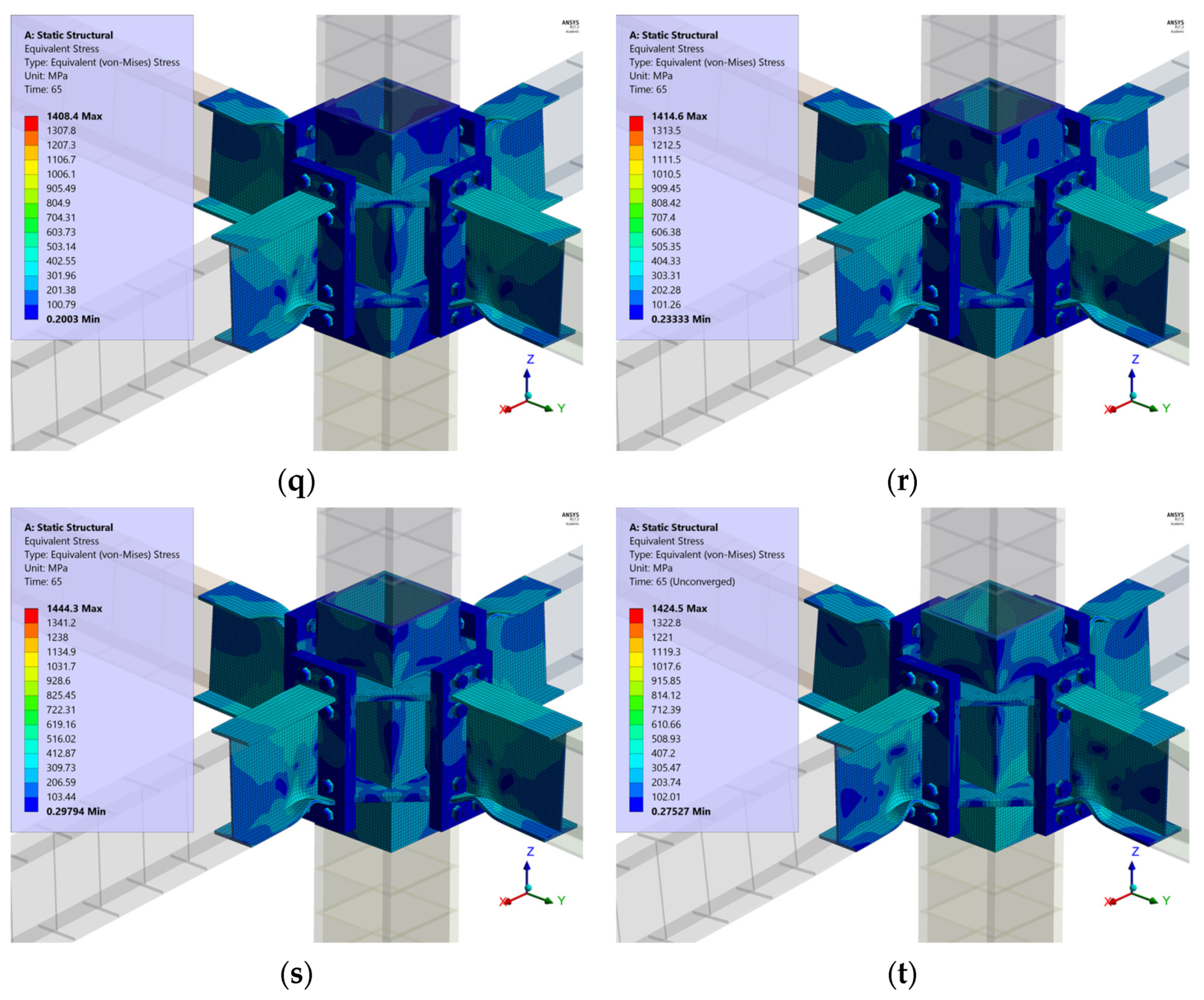

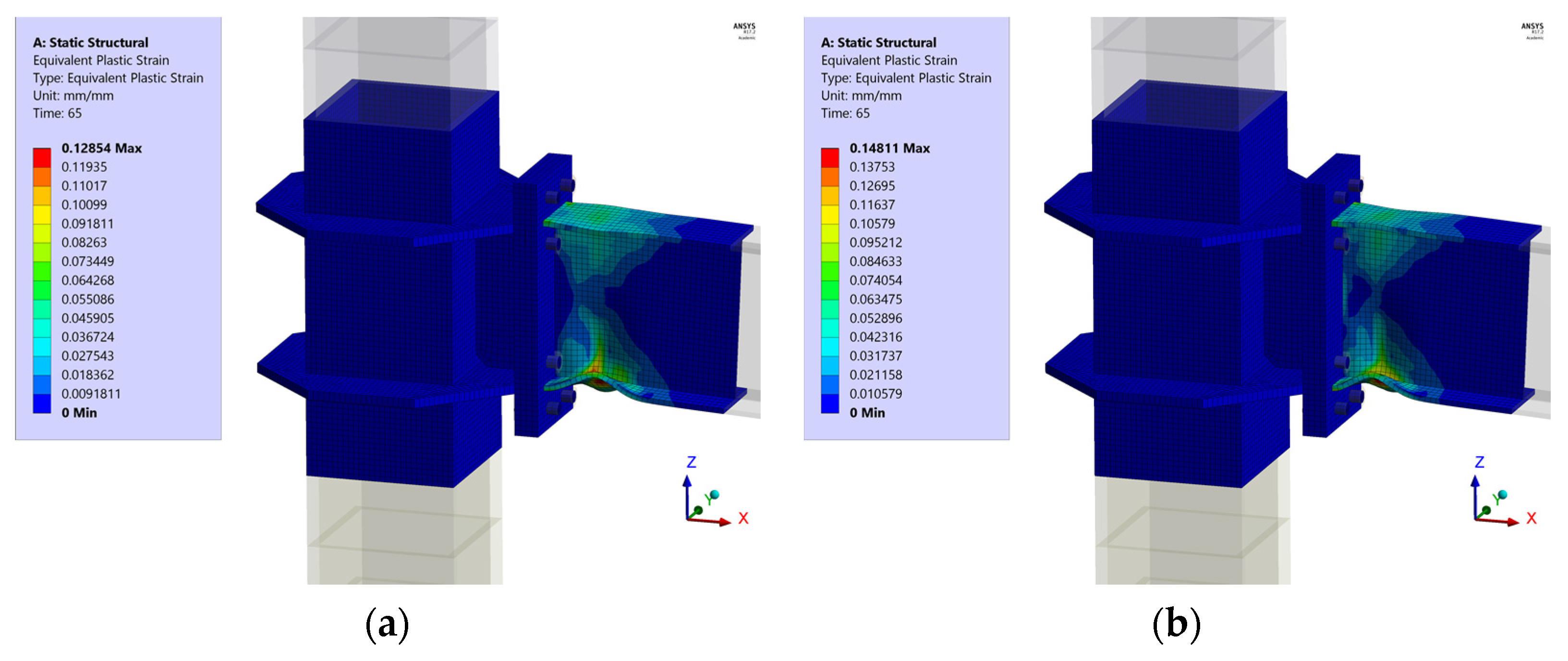

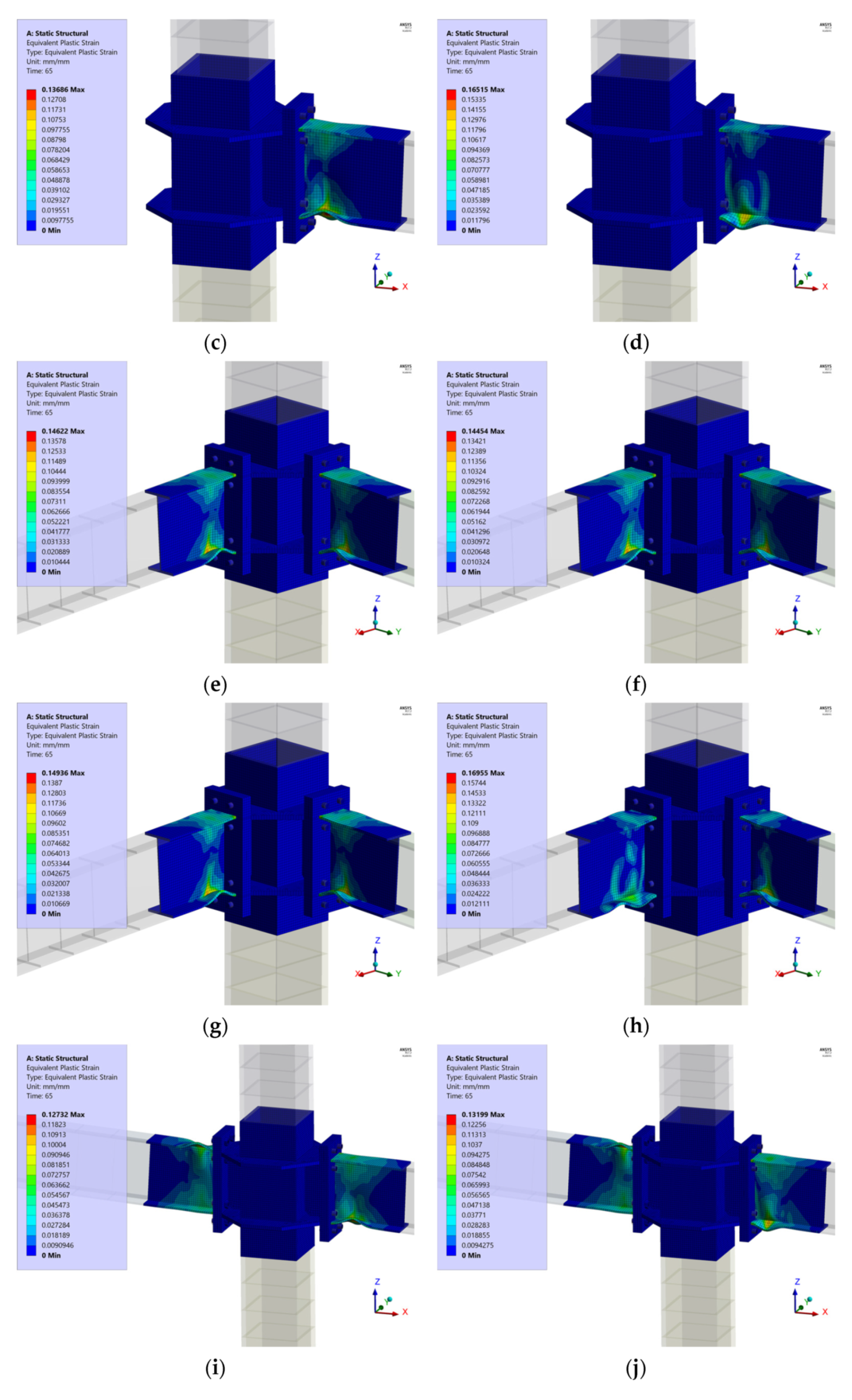

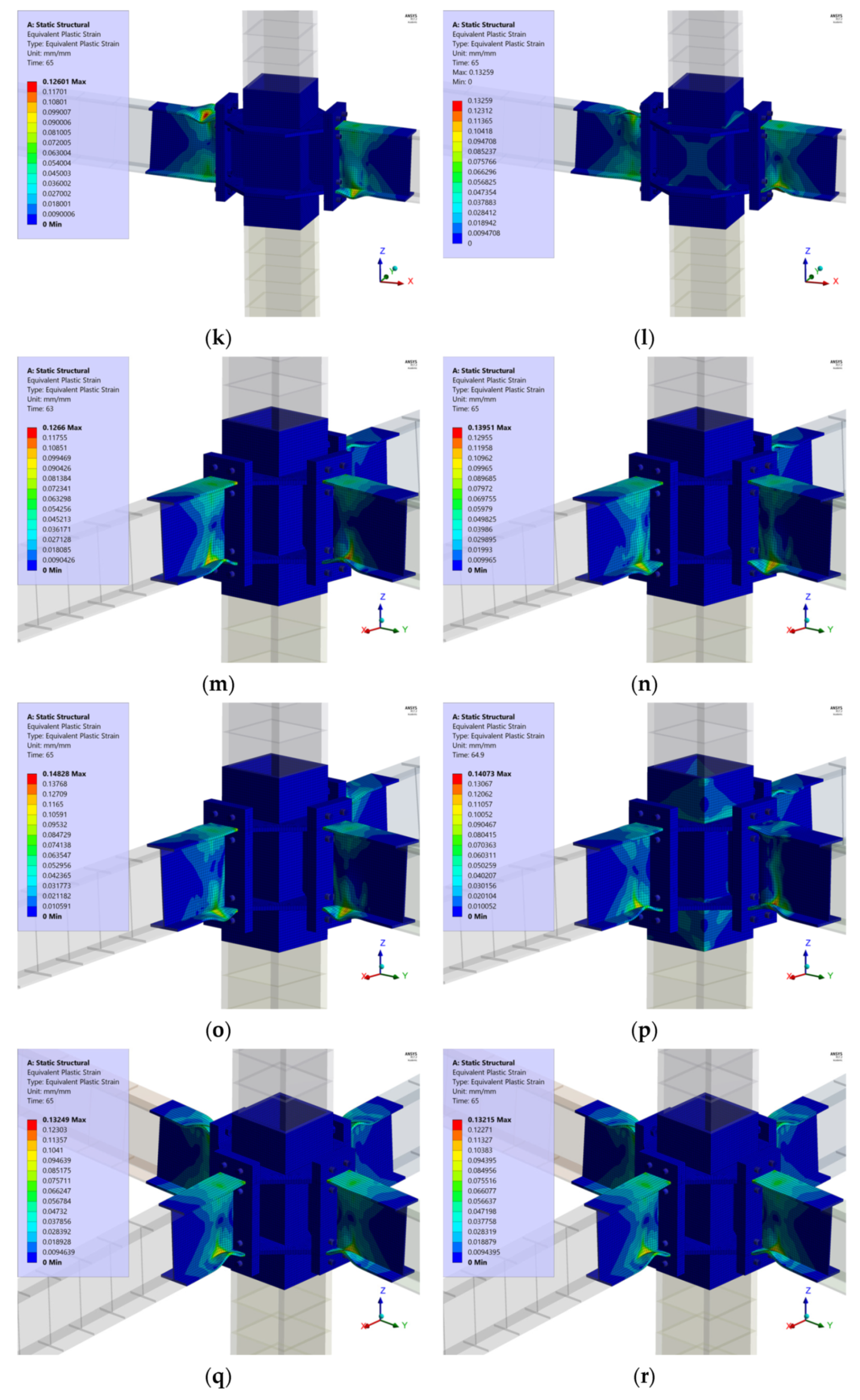

4.3. Failure Mechanism

5. Conclusions

- (1)

- The moment connection studied complies with the design philosophy, failure mechanisms and behavior established by Seismic Provisions. For all joint configurations a drift angle in excess of 0.04 (rad) and a flexural resistance greater than 0.8 Mp for all axial load levels is achieved.

- (2)

- The failure is concentrated in the beams of all joint configurations except in joints 3D and 2D for an axial load of 75% the column capacity, where a combined failure mechanism (plastic deformations in beam and column) is achieved, showing a good correlation with the strong column/weak beam criteria developed for the Contech® ConXL™ connection.

- (3)

- The elements outer diaphragm and vertical diaphragm, end-plate and bolts remain in elastic range while the beam reach the maximum inelastic incursion until 5% interstory drift. Additionally, the several components of connection around to panel zone avoid their distortion.

- (4)

- The equivalent damping and dissipated energy is similar for the five joint types, being greater in the 3D joints than the 2D joints. The global deformation in 3D joints is greater than 2D joints even with the same number of beams. Therefore, the response of joints may be underestimated if 3D effects are not considered.

- (5)

- The axial load level and bidirectional effect simultaneously affect the performance of joints as can be observed in the loss of energy dissipation. However, hysteretic loops without significant pinching are observed for all joint configurations.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| α | Angle from Vc |

| Δ | Equivalent column top displacement |

| F | Vertical load at the beam end |

| H | Distance between zero moment points |

| L | Distance between the loading points |

| Mp | Plastic moment of beam |

| Vc | Equivalent force in the top column |

| Vcx | Equivalent force in the top column in X direction |

| Vcx | Equivalent force in the top column in Y direction |

| W1 | Work performed by loads at beam end |

| W2 | Work performed by Vc force |

| δi | (i = 1,2,3,4) vertical displacement at the beam for east, west, north and south |

| εu | Ultimate deformation |

| εy | Yielding deformation |

| θ | Rotation angle due to moment of beam |

| σu | Ultimate stress |

| σy | Yielding stress |

References

- Wang, Y.Y. Lessons learned from the “5.12” Wenchuan earthquake: Evaluation of earthquake performance objectives and the importance of seismic conceptual design principles. Earthq. Eng. Eng. Vib. 2008, 7, 255–262. [Google Scholar] [CrossRef]

- Okazaki, T.; Lignos, D.; Midorikawa, M.; Ricles, J.; Love, J. Damage to Steel Buildings Observed After the 2011 Tohoku Earthquake. Earthq. Spectra 2013, 29, 219–243. [Google Scholar] [CrossRef]

- Eslami, M.; Namba, H.; Kodur, V.; Mhamid, M.; Morovat, M. Seismic behavior of composite beam connected to HSS column with large width-to-thickness ratio. Eng. Struct. 2019, 183, 423–442. [Google Scholar] [CrossRef]

- Sherman, D.R. Designing with structural tubing. Eng. J. Aisc 1996, 33, 101–109. [Google Scholar]

- FEMA-355D. State of the Art Report on Connection Performance; Federal Emergency Management Agency: Washington, DC, USA, 2000. [Google Scholar]

- ANSI/AISC 341-16. Seismic Provisions for Structural Steel Buildings; American Institute of Steel Construction: Chicago, IL, USA, 2016. [Google Scholar]

- ANSI/AISC 358-16. Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications; American Institute of Steel Construction: Chicago, IL, USA, 2016. [Google Scholar]

- ConXtech Inc. Test Report on ConXL Connection Assembly of Stanford Law School; ConXtech Inc.: Pleasanton, CA, 2009. [Google Scholar]

- Yang, C.; Yang, J.F.; Su, M.S.; Liu, C.Z. Numerical study on seismic behaviors of ConXL biaxial moment connection. J. Constr. Steel Res. 2016, 121, 185–201. [Google Scholar] [CrossRef]

- Nuñez, E.; Torres, R.; Herrera, R. Seismic performance of moment connections in steel moment frames with HSS columns. Steel Compos. Struct. 2017, 25, 271–286. [Google Scholar]

- Herrera, R.; Salas, C.; Beltran, J.; Nuñez, E. Experimental performance of double built-up T moment connections under cyclic loading. J. Constr. Steel Res. 2017, 138, 742–749. [Google Scholar] [CrossRef]

- Ataollahi, S.; Banan, M. Numerical cyclic behavior of T-RBS: A new steel moment connection. Steel Compos. Struct. 2016, 21, 1251–1264. [Google Scholar] [CrossRef]

- Ricles, J.M.; Peng, S.W.; Lu, L.W. Seismic Behavior of Composite Concrete Filled Steel Tube Column-Wide Flange Beam Moment Connections. J. Struct. Eng. 2004, 130, 223–232. [Google Scholar] [CrossRef]

- Herrera, R.; Ricles, J.; Sause, R. Seismic performance evaluation of a large-scale composite MRF using pseudodynamic testing. J. Struct. Eng. 2008, 134, 279–288. [Google Scholar] [CrossRef]

- Saleh, A.; Zahrai, S.; Mirghaderi, S. Experimental study on innovative tubular web RBS connections in steel MRFs with typical shallow beams. Struct. Eng. Mech. 2016, 57, 785–808. [Google Scholar] [CrossRef][Green Version]

- Erfani, S.; Ali Asnafi, A.; Gourdazi, A. Connection of I-beam to box-column by a short stub beam. J. Constr. Steel Res. 2016, 127, 136–150. [Google Scholar] [CrossRef]

- Čermelj, B.; Može, P.; Sinur, F. On the prediction of low-cycle fatigue in steel welded beam-to-column joints. J. Constr. Steel Res. 2016, 117, 49–63. [Google Scholar] [CrossRef]

- Esfandyary, R.; Razzaghi, M.; Eslami, A. A parametric investigation on the hysteretic behavior of CFT column to steel beam connections. Struct. Eng. Mech. 2015, 55, 205–228. [Google Scholar] [CrossRef]

- Faridmehr, I.; Osman, M.; Tahir, M.; Nejad, A.; Hodjati, R. Seismic and progressive collapse assessment of SidePlate moment connection system. Struct. Eng. Mech. 2015, 54, 35–54. [Google Scholar] [CrossRef]

- Fadden, M.; McCormick, J. HSS-to-HSS seismic moment connection performance and design. J. Constr. Steel Res. 2014, 101, 373–384. [Google Scholar] [CrossRef]

- Tahir, M.; Juki, I.; Ishak, M.; Plank, R. Performance of partial strength connection connected by thick plate between column flanges. Struct. Eng. Mech. 2014, 51, 215–228. [Google Scholar] [CrossRef]

- Gholami, M.; Deylami, A.; Tehranizadeh, M. Seismic performance of flange plate connections between steel beams and box columns. J. Constr. Steel Res. 2013, 84, 36–48. [Google Scholar] [CrossRef]

- Saneei, Z.; Ghassemieh, M.; Mazroi, A. WUF-W connection performance to box column subjected to uniaxial and biaxial loading. J. Constr. Steel Res. 2013, 88, 90–108. [Google Scholar] [CrossRef]

- ANSYS Multiphysics 17.2, ANSYS Inc.: Canonsburg, PA, USA, 2017.

- Moura, P.; Carvalho, H.; Figueiredo, L.; Aires, P.; Bártolo, R. Unitary model for the analysis of bolted connections using the finite element method. Eng. Fail. Anal. 2019, 104, 308–320. [Google Scholar]

- Díaz, C.; Victoria, M.; Martí, P.; Querin, O.M. FE model of beam-to-column extended end-plate joints. J. Constr. Steel Res. 2011, 67, 1578–1590. [Google Scholar] [CrossRef]

- Kim, T.S.; Kuwamura, H. Finite element modeling of bolted connections in thin-walled stainless steel plates under static shear. Thin-Walled Struct. 2007, 45, 407–421. [Google Scholar] [CrossRef]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering; Prentice-Hall: Englewood Cliffs, NJ, USA, 2007. [Google Scholar]

| No. | Group | Joint | Axial Load (P/Py) |

|---|---|---|---|

| 1 | 1 beam (1B) | 1B - 00 | 0 |

| 2 | 1B - 25 | 25% | |

| 3 | 1B - 50 | 50% | |

| 4 | 1B - 75 | 75% | |

| 5 | 2 beams - corner (2BC) | 2BC - 00 | 0 |

| 6 | 2BC - 25 | 25% | |

| 7 | 2BC - 50 | 50% | |

| 8 | 2BC - 75 | 75% | |

| 9 | 2 beams - interior (2BI) | 2BI - 00 | 0 |

| 10 | 2BI - 25 | 25% | |

| 11 | 2BI - 50 | 50% | |

| 12 | 2BI - 75 | 75% | |

| 13 | 3 beams (3B) | 3B - 00 | 0 |

| 14 | 3B - 25 | 25% | |

| 15 | 3B - 50 | 50% | |

| 16 | 3B - 75 | 75% | |

| 17 | 4 beams (4B) | 4B - 00 | 0 |

| 18 | 4B - 25 | 25% | |

| 19 | 4B - 50 | 50% | |

| 20 | 4B - 75 | 75% |

| No. | No. of cycles | Drift Angle (θ) (rad) |

|---|---|---|

| 1 | 6 | 0.00375 |

| 2 | 6 | 0.005 |

| 3 | 6 | 0.0075 |

| 4 | 4 | 0.01 |

| 5 | 2 | 0.015 |

| 6 | 2 | 0.02 |

| 7 | 2 | 0.03 |

| 8 | 2 | 0.04 |

| Elements Connection | Contact | Movement in Normal Direction | Movement in Tangential Direction |

|---|---|---|---|

| Column-Horizontal Stiffeners | Bonded | No separation | No slip |

| Column-Vertical Stiffeners | Bonded | No separation | No slip |

| Vertical Stiffeners-Horizontal Stiffeners | Bonded | No separation | No slip |

| End Plate-Horizontal Stiffeners | Bonded | No separation | No slip |

| End Plate-Vertical Stiffeners | Bonded | No separation | No slip |

| End Plate-End plate | Frictional | Separation allowed | Slip allowed |

| Beam-End plate, Bolt-Nut | Bonded | No separation | No slip |

| Bolt- End plate, Nut-End plate | Frictionless | Separation allowed | Slip allowed |

| Element | Designation | σy (MPa) | εy | σu (MPa) | εu |

|---|---|---|---|---|---|

| Bolts | ASTM-A-490 | 1156 | 0.00586 | 1433 | 0.14 |

| Beam | ASTM-A-36 | 293 | 0.001465 | 445 | 0.24 |

| Column | ASTM-A-36 | 293 | 0.001465 | 445 | 0.24 |

| Horizontal diaphragms | ASTM-A-36 | 293 | 0.001465 | 445 | 0.24 |

| Vertical diaphragms | ASTM-A-36 | 293 | 0.001465 | 445 | 0.24 |

| End-plate | ASTM-A-36 | 293 | 0.001465 | 445 | 0.24 |

| Joint | Maximum Load (kN) | Maximum Rotation (rad) | Initial Stiffness (kN/mm) | Dissipated Energy (kJ) | Maximum Equivalent Damping at 4% Drift Ratio (%) |

|---|---|---|---|---|---|

| 1B - 00 | 155.75 | 0.050 | 2.90 | 328.71 | 34.5 |

| 1B - 25 | 155.75 | 0.050 | 2.89 | 318.53 | 32.8 |

| 1B - 50 | 155.75 | 0.050 | 2.91 | 322.87 | 33.4 |

| 1B - 75 | 149.63 | 0.050 | 2.91 | 314.04 | 33.5 |

| 2BC - 00 | 221.50 | 0.071 | 3.02 | 666.78 | 32.8 |

| 2BC - 25 | 221.50 | 0.071 | 3.01 | 671.03 | 33.5 |

| 2BC - 50 | 219.03 | 0.071 | 2.99 | 658.58 | 32.8 |

| 2BC - 75 | 209.13 | 0.071 | 2.99 | 653.18 | 34.5 |

| 2BI - 00 | 334.25 | 0.050 | 5.25 | 662.04 | 32.2 |

| 2BI - 25 | 336.00 | 0.050 | 5.18 | 613.86 | 31 |

| 2BI - 50 | 332.50 | 0.050 | 5.27 | 623.54 | 30.5 |

| 2BI - 75 | 337.75 | 0.050 | 5.21 | 609.25 | 30.5 |

| 3B - 00 | 373.70 | 0.067 | 4.54 | 976.54 | 31 |

| 3B - 25 | 373.70 | 0.067 | 4.57 | 982.28 | 31.3 |

| 3B - 50 | 373.70 | 0.067 | 4.50 | 957.35 | 31.5 |

| 3B - 75 | 371.75 | 0.067 | 4.52 | 900.20 | 31.3 |

| 4B - 00 | 475.18 | 0.071 | 5.30 | 1251.40 | 30 |

| 4B - 25 | 475.18 | 0.071 | 5.26 | 1250.20 | 29.8 |

| 4B - 50 | 475.18 | 0.071 | 5.32 | 1247.00 | 29.5 |

| 4B - 75 | 480.13 | 0.071 | 5.23 | 947.20 | 30.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallegos, M.; Nuñez, E.; Herrera, R. Numerical Study on Cyclic Response of End-Plate Biaxial Moment Connection in Box Columns. Metals 2020, 10, 523. https://doi.org/10.3390/met10040523

Gallegos M, Nuñez E, Herrera R. Numerical Study on Cyclic Response of End-Plate Biaxial Moment Connection in Box Columns. Metals. 2020; 10(4):523. https://doi.org/10.3390/met10040523

Chicago/Turabian StyleGallegos, Marco, Eduardo Nuñez, and Ricardo Herrera. 2020. "Numerical Study on Cyclic Response of End-Plate Biaxial Moment Connection in Box Columns" Metals 10, no. 4: 523. https://doi.org/10.3390/met10040523

APA StyleGallegos, M., Nuñez, E., & Herrera, R. (2020). Numerical Study on Cyclic Response of End-Plate Biaxial Moment Connection in Box Columns. Metals, 10(4), 523. https://doi.org/10.3390/met10040523