Study of the Effect of Multiple Tempering on the Impact Toughness of Forged S690 Structural Steel

Abstract

1. Introduction

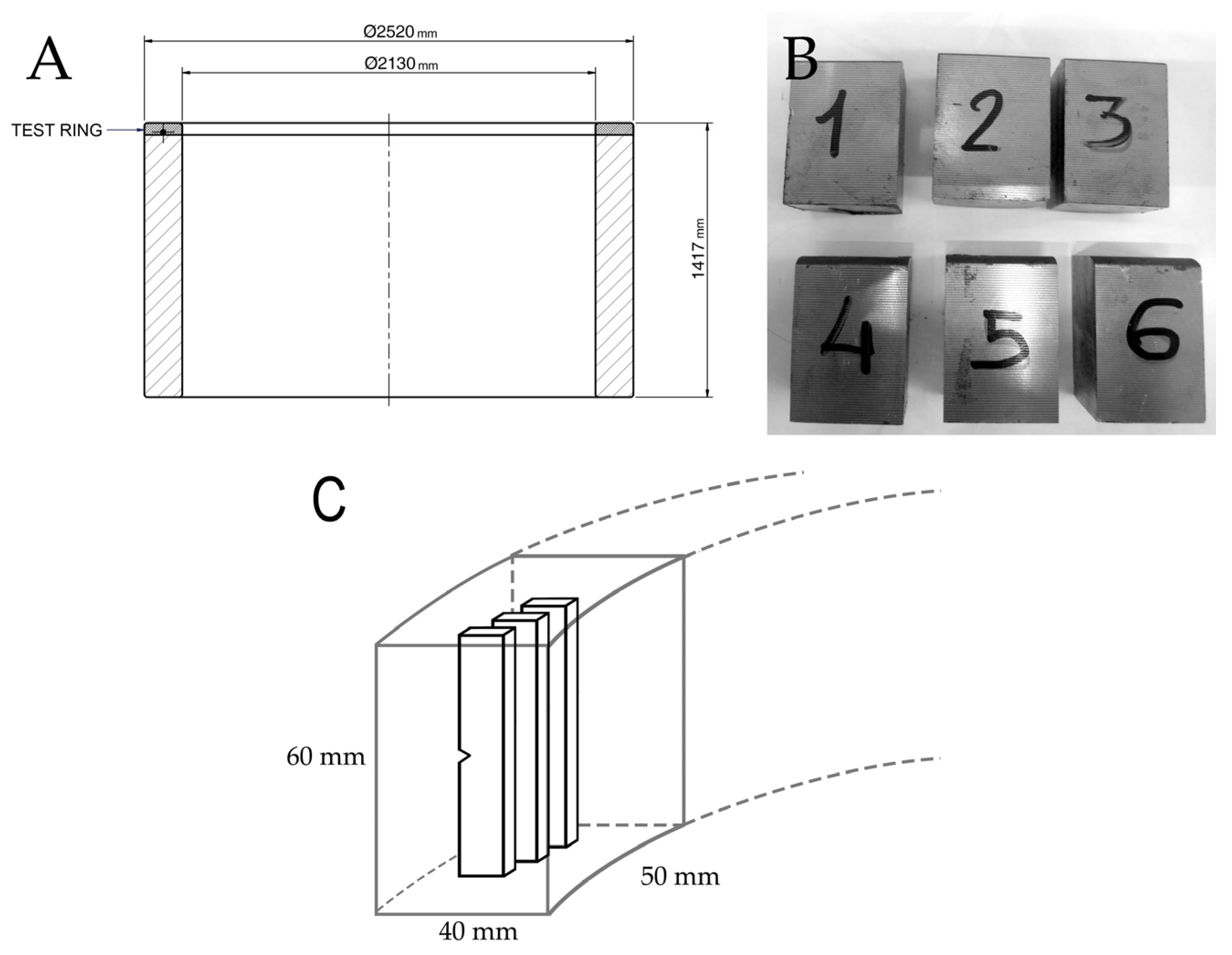

2. Materials and Methods

3. Results

3.1. Micro-Hardness and Impact Toughness Evaluation

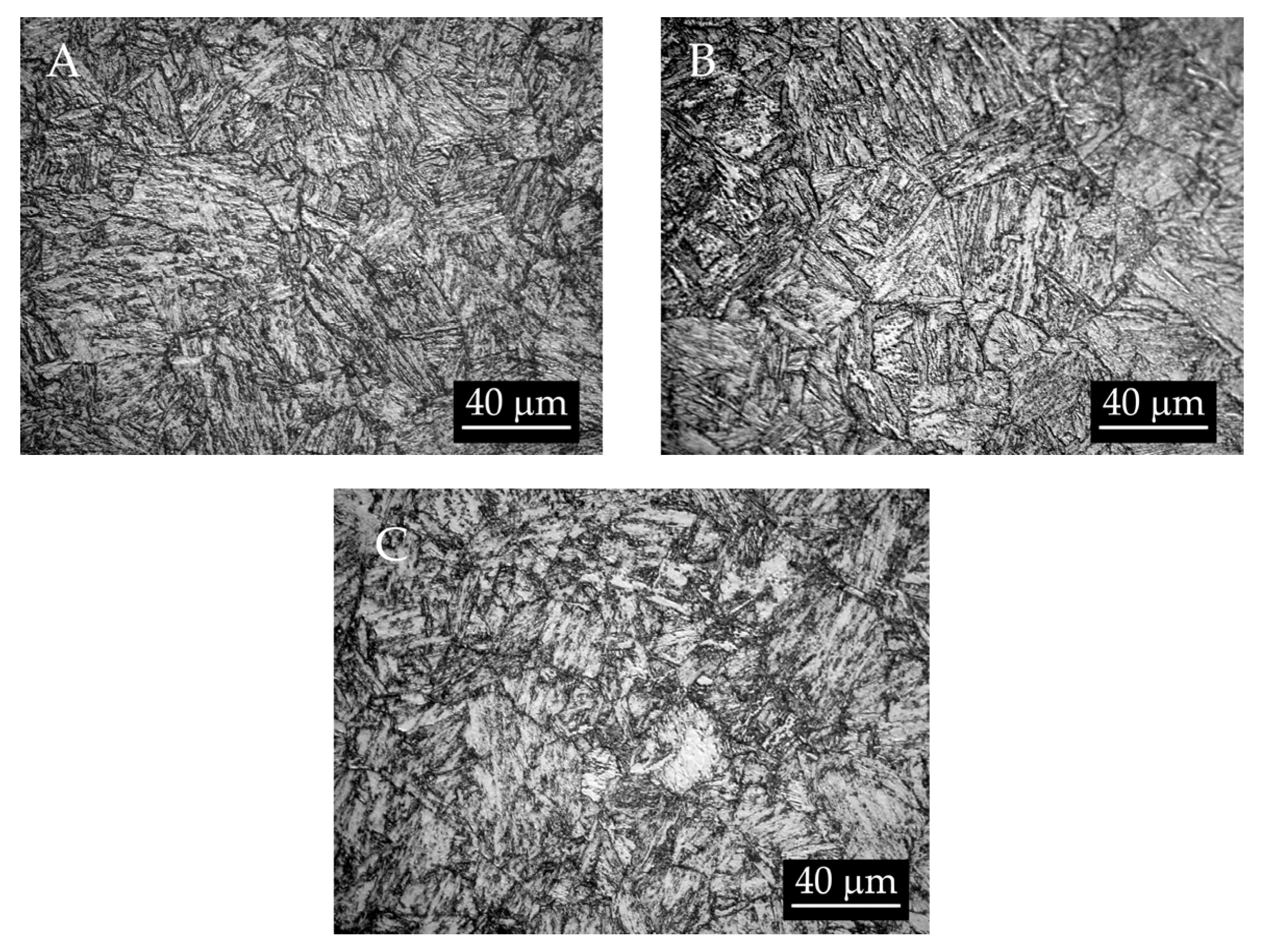

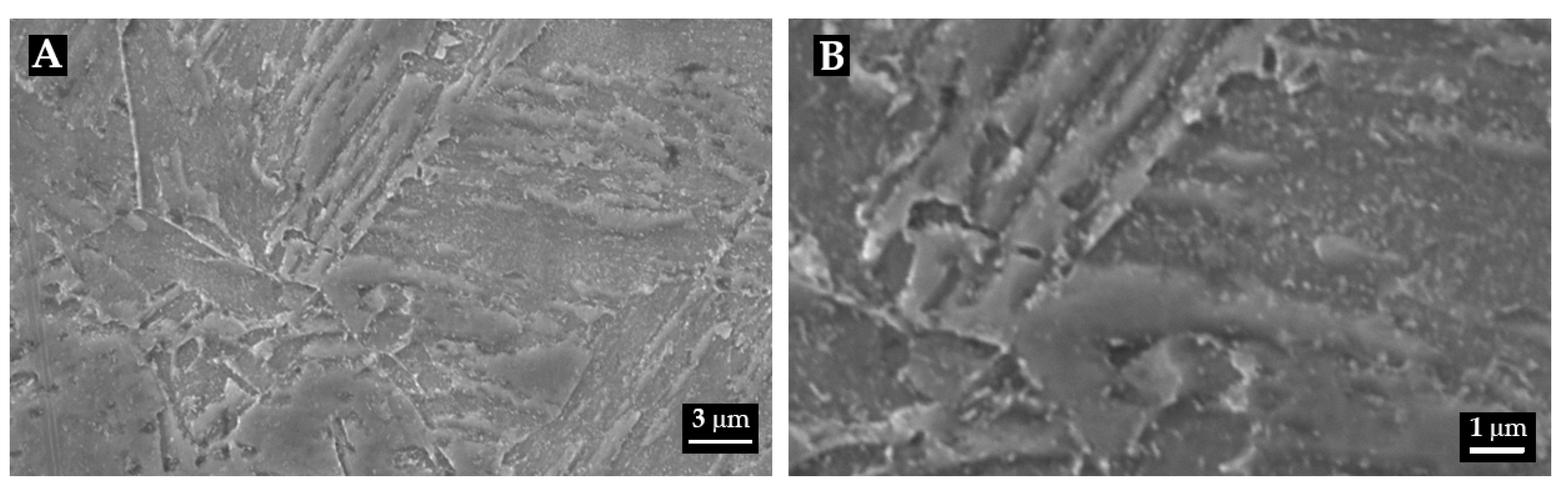

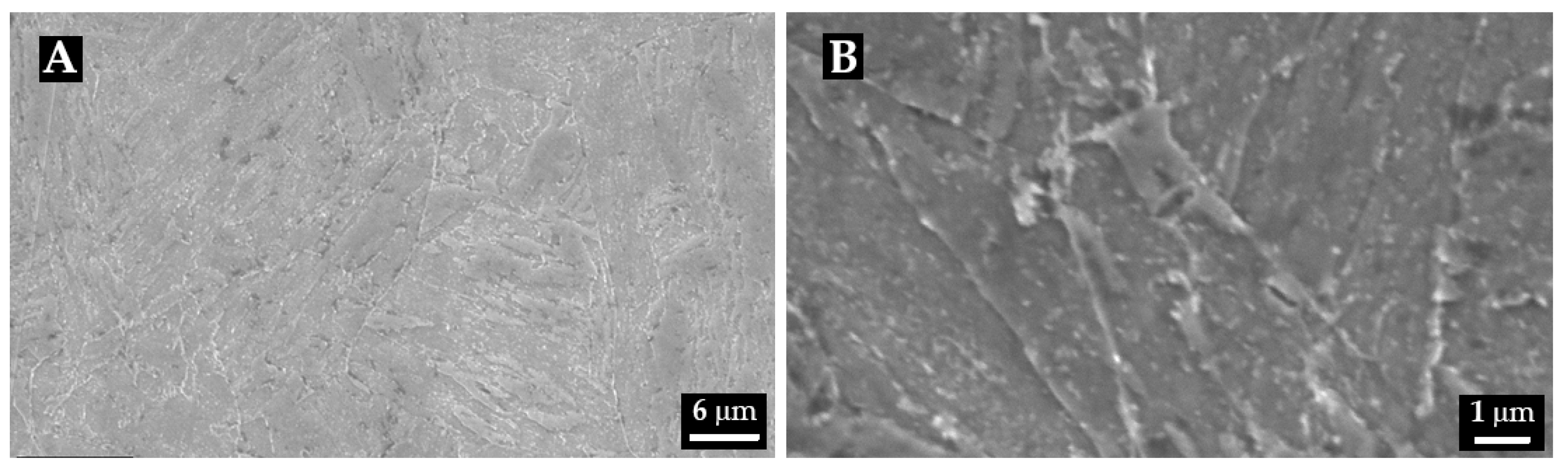

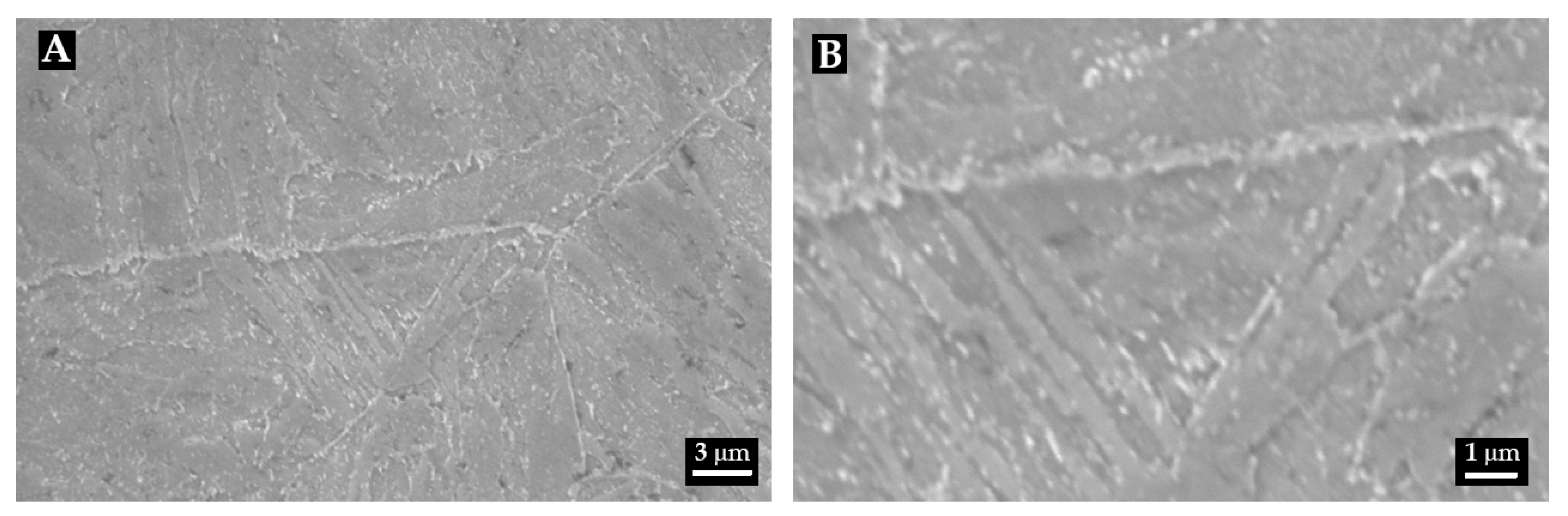

3.2. Microstructural Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qiang, X.; Bijlaard, F.; Kolstein, H. Dependence of mechanical properties of high strength steel S690 on elevated temperatures. Constr. Build. Mater. 2012, 30, 73–79. [Google Scholar] [CrossRef]

- De Jesus, A.M.P.; Matos, R.; Fontoura, B.F.C.; Rebelo, C.; Simões da Silva, L.; Veljkovic, M. A comparison of the fatigue behavior between S355 and S690 steel grades. J. Constr. Steel Res. 2012, 79, 140–150. [Google Scholar] [CrossRef]

- Di Schino, A.; Di Nunzio, P. Metallurgical aspects related to contact fatigue phenomena in steels for back-up rolls. Acta Metall. Slovaca 2017, 23, 62. [Google Scholar] [CrossRef]

- Di Schino, A.; Di Nunzio, P.E.; Lopez Turconi, G. Microstructure Evolution during Tempering of Martensite in a Medium-C Steel. Mater. Sci. Forum 2007, 558, 1435–1441. [Google Scholar] [CrossRef]

- Di Schino, A. Analysis of heat treatment effect on microstructural features evolution in a micro-alloyed martensitic steel. Acta Metall. Slovaca 2016, 22, 266. [Google Scholar] [CrossRef]

- Gennari, C.; Pezzato, L.; Piva, E.; Gobbo, R.; Calliari, I. Influence of small amount and different morphology of secondary phases on impact toughness of UNS S32205 Duplex Stainless Steel. Mater. Sci. Eng. A 2018, 729, 149–156. [Google Scholar] [CrossRef]

- Ćwiek, J.; Łabanowski, J.; Topolska, S. The effect of long-term service at elevated temperatures on structure and mechanical properties of Cr-Mo-V steel. Arch. Mater. Sci. Eng. 2011, 49, 33–39. [Google Scholar]

- Zielinski, M.A.; Dobrzanski, J.; Golanski, G. Estimation of the residual life of L17HMF cast steel elements after long-term service. J. Achiev. Mater. Manuf. Eng. 2009, 34, 137–144. [Google Scholar]

- Bhadeshia, H.K.D.H. Bainite in Steels; Woodhead Pub Ltd.: Cambridge, UK, 2001; Volume 32, ISBN 1861251122. [Google Scholar]

- Bhadeshia, H.K.D.H.; Honeycombe, R. Steels: Microstructure and Properties; Butterworths-Heinemann (Elsevier): Aalborg, Denmark, 2006; ISBN 9780750680844. [Google Scholar]

- Dépinoy, S.; Toffolon-Masclet, C.; Urvoy, S.; Roubaud, J.; Marini, B.; Roch, F.; Kozeschnik, E.; Gourgues-Lorenzon, A.F. Carbide Precipitation in 2.25 Cr-1 Mo Bainitic Steel: Effect of Heating and Isothermal Tempering Conditions. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2017. [Google Scholar] [CrossRef]

- Krawczyk, J.; Bała, P.; Pacyna, J. The effect of carbide precipitate morphology on fracture toughness in low-tempered steels containing Ni. J. Microsc. 2010. [Google Scholar] [CrossRef] [PubMed]

- Horn, R.M.; Ritchie, R.O. Mechanisms of tempered martensite embrittlement in low alloy steels. Metall. Trans. A 1978. [Google Scholar] [CrossRef]

- Yen, H.W.; Chiang, M.H.; Lin, Y.C.; Chen, D.; Huang, C.Y.; Lin, H.C. High-temperature tempered martensite embrittlement in quenched-and-tempered offshore steels. Metals 2017, 7, 253. [Google Scholar] [CrossRef]

- Abbasi, E.; Luo, Q.; Owens, D. Microstructural Characteristics and Mechanical Properties of Low-Alloy, Medium-Carbon Steels after Multiple Tempering. Acta Metall. Sin. 2019, 32, 74–88. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Monshi, A.; Monajatizadeh, H.; Idris, M.H.; Abdul Kadir, M.R.; Jafari, H. Effect of Multi-Step Tempering on Retained Austenite and Mechanical Properties of Low Alloy Steel. J. Iron Steel Res. Int. 2011, 18, 49–56. [Google Scholar] [CrossRef]

- Wang, J.; Kang, Y.; Yu, H.; Ge, W. Effect of Quenching Temperature on Microstructure and Mechanical Properties of Q1030 Steel. Mater. Sci. Appl. 2019, 10, 665–675. [Google Scholar] [CrossRef]

- Dong, D.; Li, H.; Shan, K.; Jia, X.; Li, L. Effects of Different Heat Treatment Process on Mechanical Properties and Microstructure of Q690 Steel Plate. IOP Conf. Ser. Mater. Sci. Eng. 2018, 394, 022017. [Google Scholar] [CrossRef]

- Qin, S.; Song, R.; Xiong, W.; Liu, Z.; Wang, Z.; Guo, K. Microstructure evolution and mechanical properties of grade E690 offshore platform steel. In HSLA Steels 2015, Microalloying 2015 & Offshore Engineering Steels 2015; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; Volume 2, pp. 1117–1123. ISBN 9781119223399. [Google Scholar]

- Takebayashi, S.; Ushioda, K.; Yoshinaga, N.; Ogata, S. Effect of carbide size distribution on the impact toughness of tempered martensitic steels with two different prior austenite grain sizes evaluated by instrumented charpy test. Mater. Trans. 2013. [Google Scholar] [CrossRef]

- Li, Z.; Jia, P.; Liu, Y.; Qi, H. Carbide Precipitation, Dissolution, and Coarsening in G18CrMo2–6 Steel. Metals 2019, 9, 916. [Google Scholar] [CrossRef]

- Dudova, N.; Mishnev, R.; Kaibyshev, R. Effect of tempering on microstructure and mechanical properties of boron containing 10%Cr steel. ISIJ Int. 2011. [Google Scholar] [CrossRef]

- Hao, X.; Gao, M.; Zhang, L.; Zhao, X.; Liu, K. Microstructure of annealed 12Cr13 stainless steel and its effect on the impact toughness. Jinshu Xuebao 2011. [Google Scholar] [CrossRef]

| C% | Mn% | Si% | Cr% | Ni% | Mo% | V% |

|---|---|---|---|---|---|---|

| 0.14 | 1.29 | 0.31 | 1.11 | 1.11 | 0.27 | 0.044 |

| Treatment | Micro-Hardness HV0.2 | Impact Toughness Room T (J) | Impact Toughness −22 °C (J) |

|---|---|---|---|

| Water Quenched (after austenitization 890 °C 4 h) | 400 ± 5 | - | - |

| Quenched and Tempered 590 °C 6 h | 276 ± 5 | 220 ± 10 | 48 ± 10 |

| Quenched and Tempered 590 °C 10 h | 275 ± 6 | 237 ± 9 | 60 ± 8 |

| Quenched and Tempered 590 °C 6 h + second tempering 590 °C 4 h | 272 ± 6 | 282 ± 9 | 128 ± 10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pezzato, L.; Gennari, C.; Chukin, D.; Toldo, M.; Sella, F.; Toniolo, M.; Zambon, A.; Brunelli, K.; Dabalà, M. Study of the Effect of Multiple Tempering on the Impact Toughness of Forged S690 Structural Steel. Metals 2020, 10, 507. https://doi.org/10.3390/met10040507

Pezzato L, Gennari C, Chukin D, Toldo M, Sella F, Toniolo M, Zambon A, Brunelli K, Dabalà M. Study of the Effect of Multiple Tempering on the Impact Toughness of Forged S690 Structural Steel. Metals. 2020; 10(4):507. https://doi.org/10.3390/met10040507

Chicago/Turabian StylePezzato, Luca, Claudio Gennari, Dmitry Chukin, Michele Toldo, Federico Sella, Mario Toniolo, Andrea Zambon, Katya Brunelli, and Manuele Dabalà. 2020. "Study of the Effect of Multiple Tempering on the Impact Toughness of Forged S690 Structural Steel" Metals 10, no. 4: 507. https://doi.org/10.3390/met10040507

APA StylePezzato, L., Gennari, C., Chukin, D., Toldo, M., Sella, F., Toniolo, M., Zambon, A., Brunelli, K., & Dabalà, M. (2020). Study of the Effect of Multiple Tempering on the Impact Toughness of Forged S690 Structural Steel. Metals, 10(4), 507. https://doi.org/10.3390/met10040507