Microstructures and Tribological Properties of TiC Reinforced FeCoNiCuAl High-Entropy Alloy at Normal and Elevated Temperature

Abstract

1. Introduction

2. Experimental

3. Results

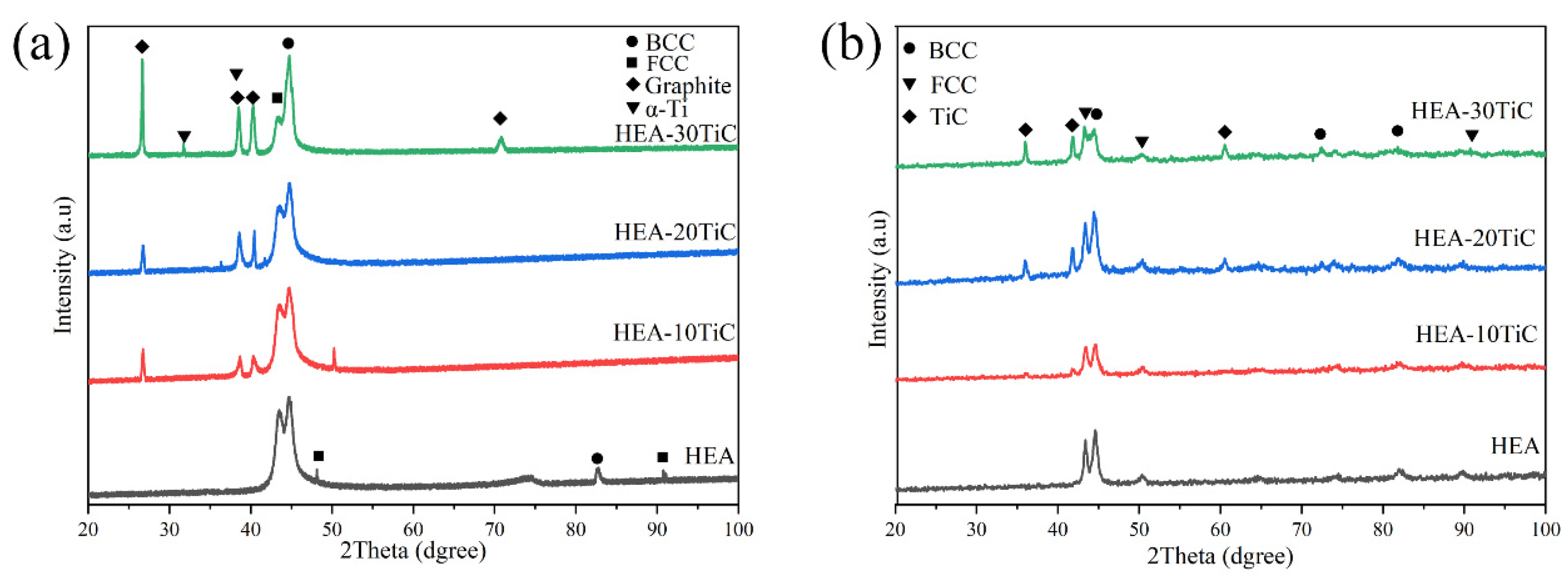

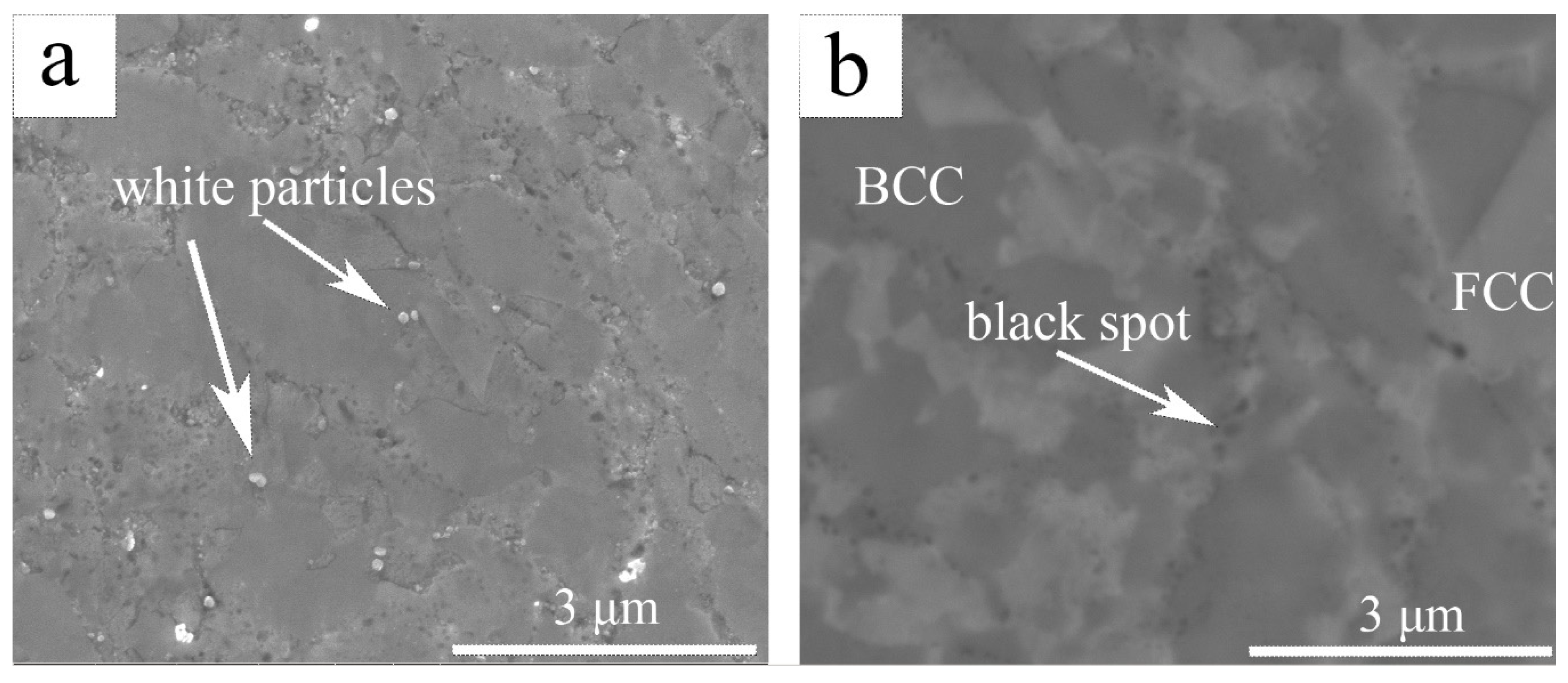

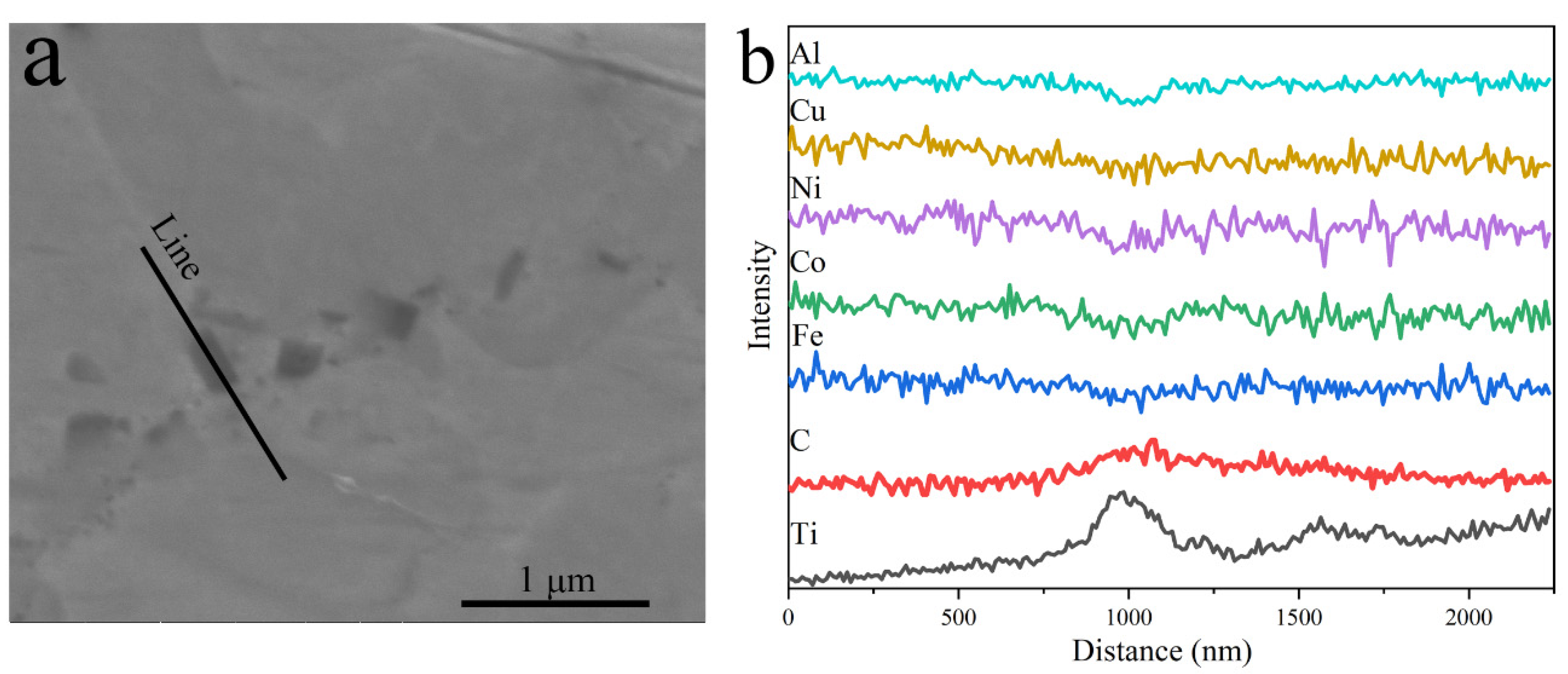

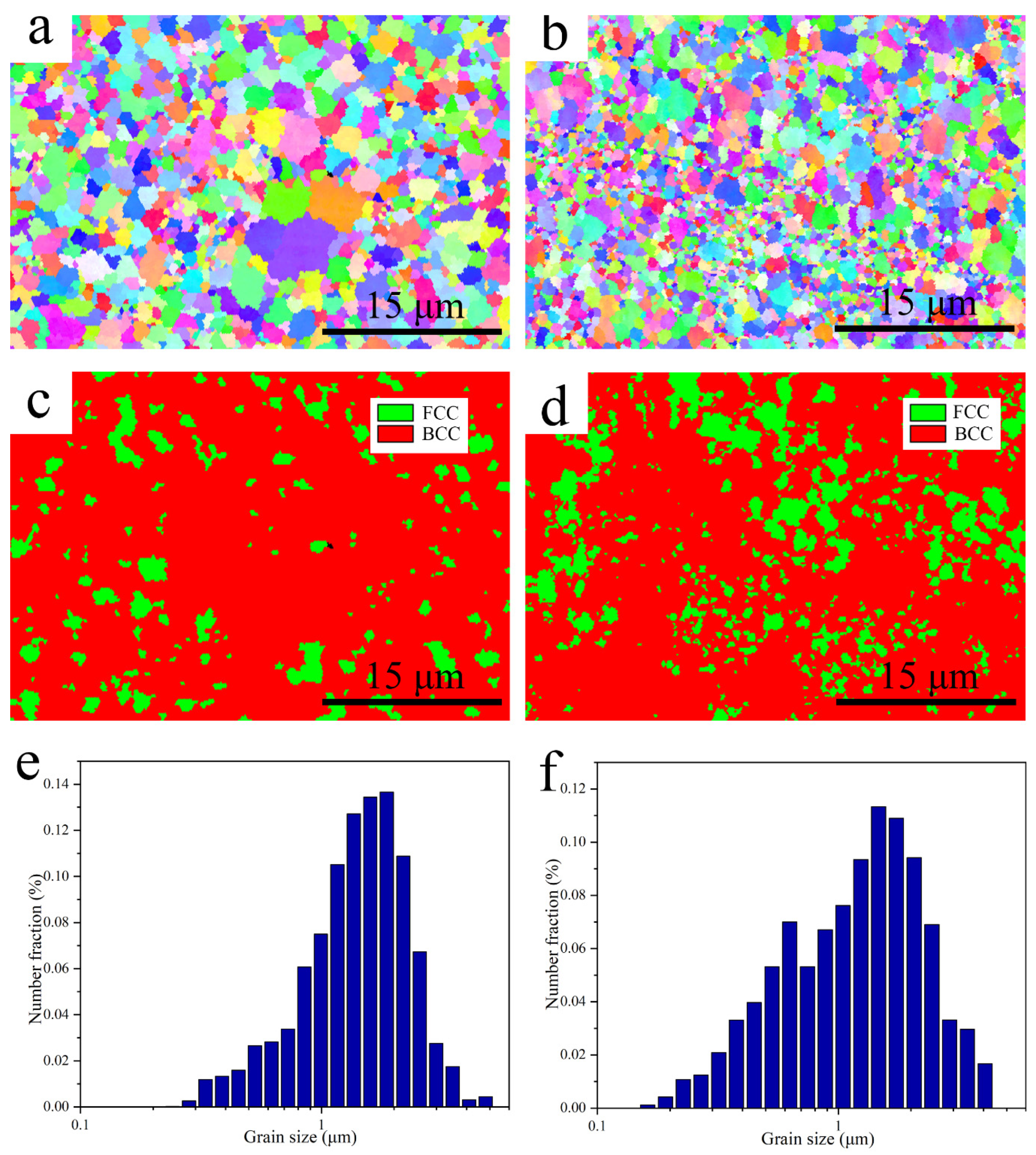

3.1. Microstructures

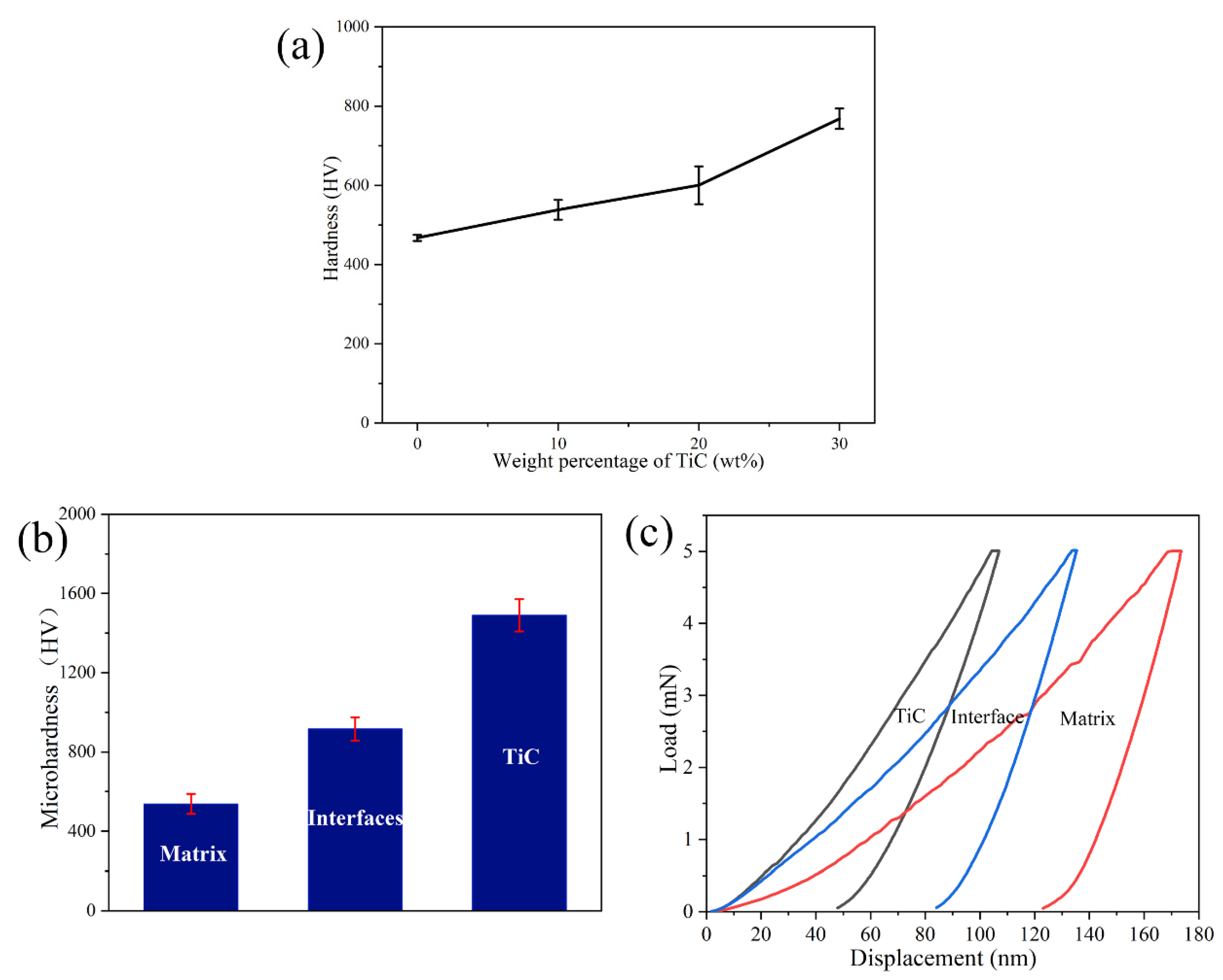

3.2. Hardness

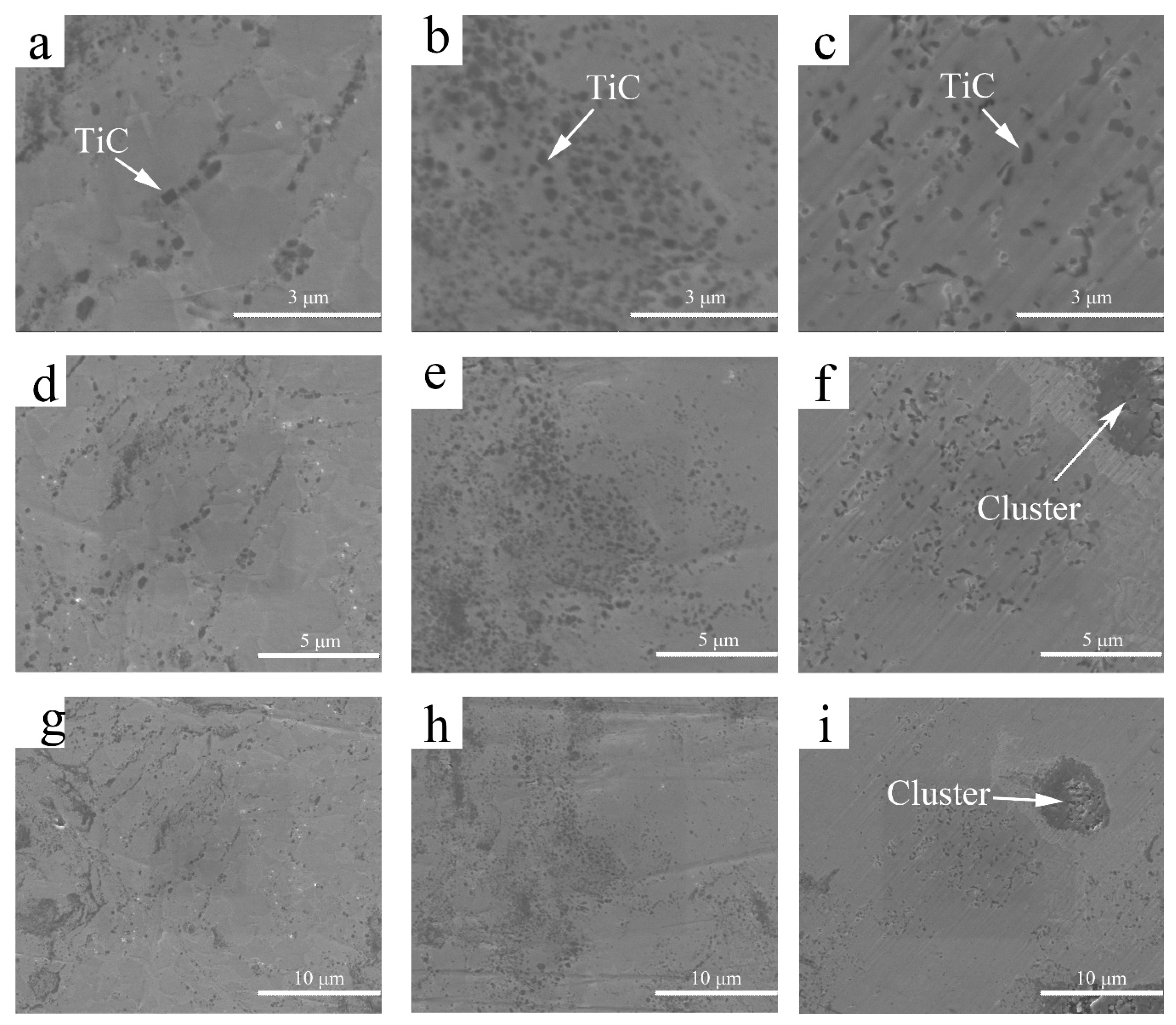

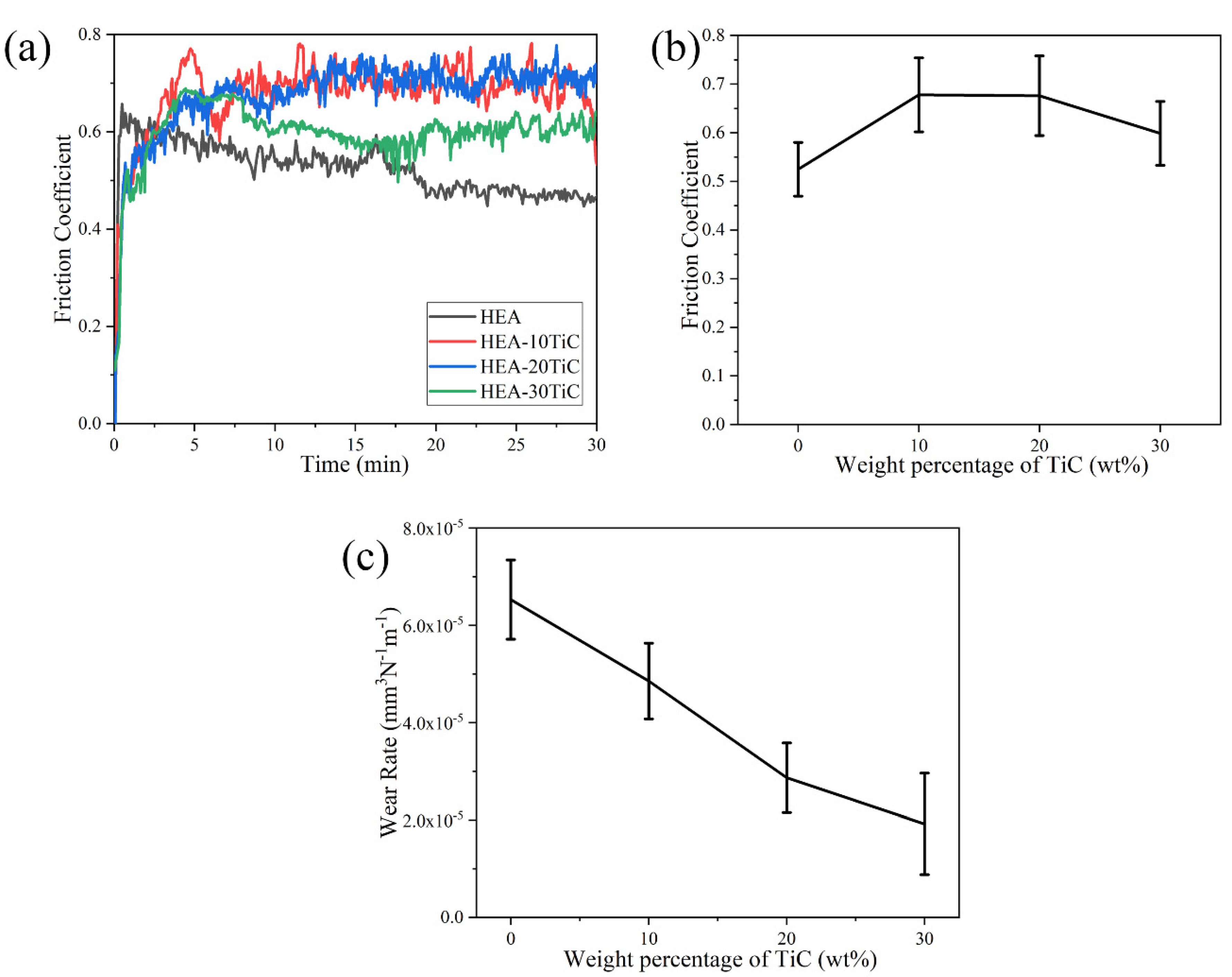

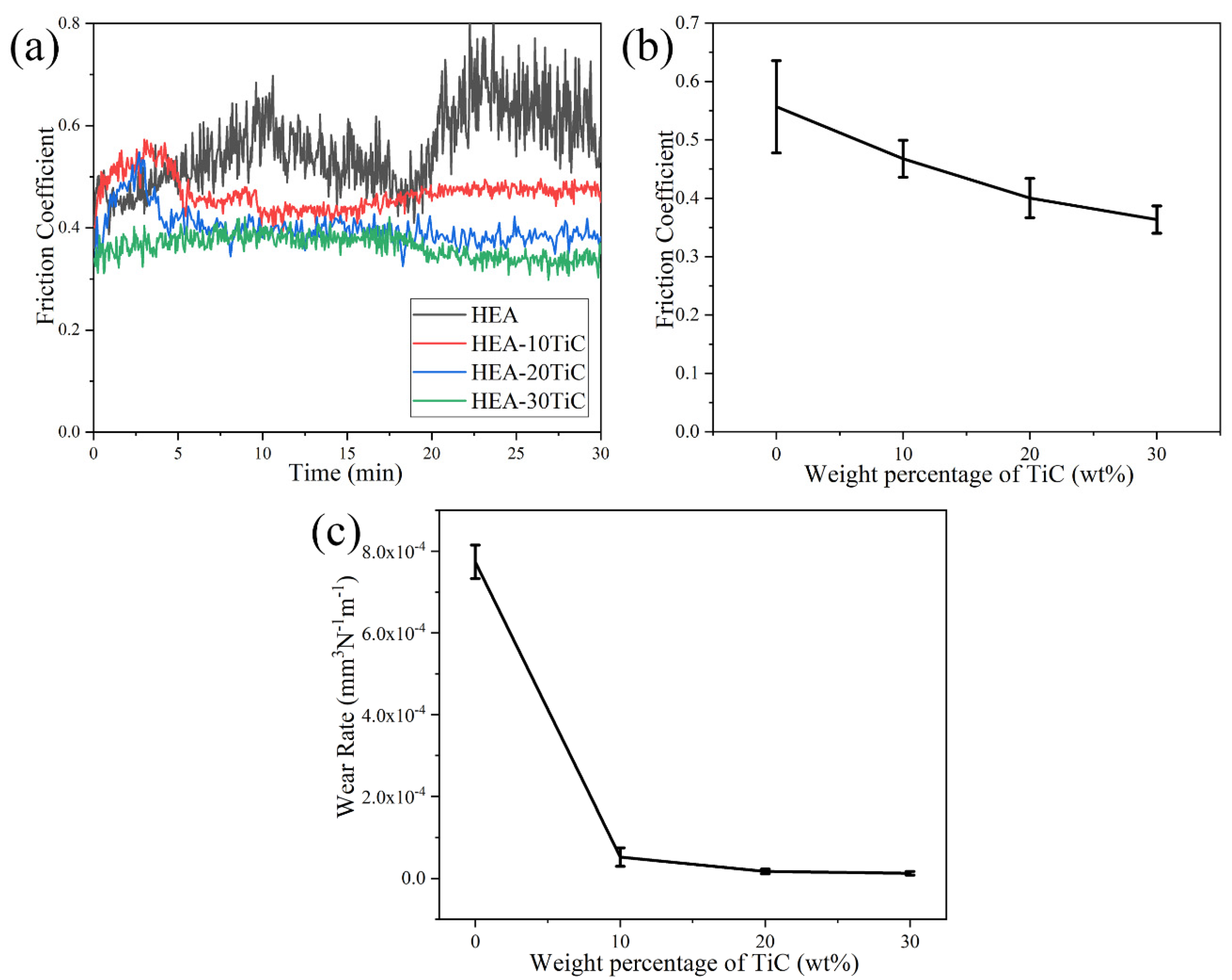

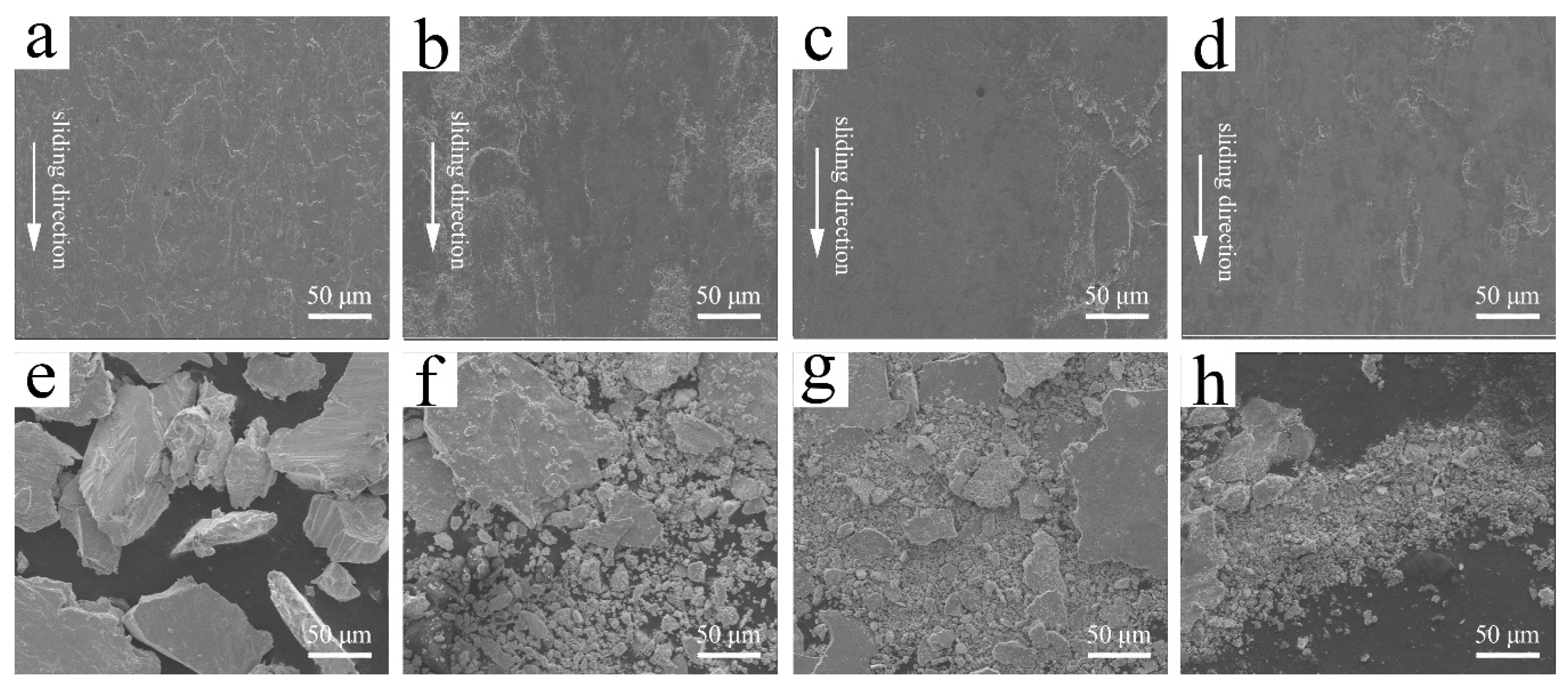

3.3. Friction and Wear Properties, Worn Surface, and Debris

4. Discussion

4.1. Microstructures

4.2. Wear Behavior

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W. Nanostructured high-entropy alloys with multiple principal elements. Nov. Alloy Des. Concepts Outcomes 2004, 6, 299–303. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Liu, B.; Wang, J.; Liu, Y.; Fang, Q.; Wu, Y.; Chen, S.; Liu, C.T. Microstructure and mechanical properties of equimolar FeCoCrNi high entropy alloy prepared via powder extrusion. Intermetallics 2016, 75, 25–30. [Google Scholar] [CrossRef]

- Poletti, M.G.; Fiore, G.; Gili, F.; Mangherini, D.; Battezzati, L. Development of a new high entropy alloy for wear resistance: FeCoCrNiW 0.3 and FeCoCrNiW 0.3 + 5 at.% of C. Mater. Des. 2017, 115, 247–254. [Google Scholar] [CrossRef]

- Butler, T.M.; Weaver, M.L. Oxidation behavior of arc melted AlCoCrFeNi multi-component high-entropy alloys. J. Alloys Compd. 2016, 674, 229–244. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Feng, T.; Zhang, Y.; Sha, G.; Lewandowski, J.J.; Liaw, P.K.; Zhang, Y. High-entropy Al 0.3 CoCrFeNi alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 2017, 123, 285–294. [Google Scholar] [CrossRef]

- Li, Q.H.; Yue, T.M.; Guo, Z.N.; Lin, X. Microstructure and corrosion properties of AlCoCrFeNi high entropy alloy coatings deposited on AISI 1045 steel by the electrospark process. Metall. Mater. Trans. A 2012, 44, 1767–1778. [Google Scholar] [CrossRef]

- Beyramali Kivy, M.; Asle Zaeem, M.; Lekakh, S. Investigating phase formations in cast AlFeCoNiCu high entropy alloys by combination of computational modeling and experiments. Mater. Des. 2017, 127, 224–232. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Xue, H.D.; Chen, Z.Y.; Hu, Z.Y.; He, J.C. Effect of annealing treatment on microstructures and mechanical properties of FeCoNiCuAl high entropy alloys. Mater. Sci. Eng. A 2013, 572, 30–35. [Google Scholar] [CrossRef]

- Verma, A.; Tarate, P.; Abhyankar, A.C.; Mohape, M.R.; Gowtam, D.S.; Deshmukh, V.P.; Shanmugasundaram, T. High temperature wear in CoCrFeNiCux high entropy alloys: The role of Cu. Scr. Mater. 2019, 161, 28–31. [Google Scholar] [CrossRef]

- Mao, C.; Zhou, F.; Hu, Y.; Cai, P.; Jiang, Y.; Bi, Z.; Peng, G. Tribological behavior of cBN-WC-10Co composites for dry reciprocating sliding wear. Ceram. Int. 2019, 45, 6447–6458. [Google Scholar] [CrossRef]

- Mao, C.; Lu, J.; Zhao, Z.; Yin, L.; Hu, Y.; Bi, Z. Simulation and experiment of cutting characteristics for single cBN-WC-10Co fiber. Precis. Eng. 2018, 52, 170–182. [Google Scholar] [CrossRef]

- Zhou, R.; Chen, G.; Liu, B.; Wang, J.; Han, L.; Liu, Y. Microstructures and wear behaviour of (FeCoCrNi) 1-x (WC) x high entropy alloy composites. Int. J. Refract. Met. Hard Mater. 2018, 75, 56–62. [Google Scholar] [CrossRef]

- Rogal, Ł.; Kalita, D.; Tarasek, A.; Bobrowski, P.; Czerwinski, F. Effect of SiC nano-particles on microstructure and mechanical properties of the CoCrFeMnNi high entropy alloy. J. Alloys Compd. 2017, 708, 344–352. [Google Scholar] [CrossRef]

- Dobeš, F.; Hadraba, H.; Chlup, Z.; Dlouhý, A.; Vilémová, M.; Matějíček, J. Compressive creep behavior of an oxide-dispersion-strengthened CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2018, 732, 99–104. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, X.; Wang, H. Fabrication of TiC particulate reinforced magnesium matrix composites. Scr. Mater. 2003, 48, 713–717. [Google Scholar] [CrossRef]

- Yim, D.; Sathiyamoorthi, P.; Hong, S.-J.; Kim, H.S. Fabrication and mechanical properties of TiC reinforced CoCrFeMnNi high-entropy alloy composite by water atomization and spark plasma sintering. J. Alloys Compd. 2018. [Google Scholar] [CrossRef]

- Du, X.; Gao, T.; Liu, G.; Liu, X. In situ synthesizing SiC particles and its strengthening effect on an Al–Si–Cu–Ni–Mg piston alloy. J. Alloys Compd. 2017, 695, 1–8. [Google Scholar] [CrossRef]

- Shu, D.; Li, Z.; Zhang, K.; Yao, C.; Li, D.; Dai, Z. In situ synthesized high volume fraction WC reinforced Ni-based coating by laser cladding. Mater. Lett. 2017, 195, 178–181. [Google Scholar] [CrossRef]

- Zhao, N.; Xu, Y.; Fu, Y. Mechanical properties of one-step in situ synthesized NbC-Fe composite coating. Surf. Coat. Technol. 2017, 309, 1105–1110. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, D.; Liang, X.; Chen, Y. Evolution of microstructure and mechanical properties of in situ synthesized TiC–TiB2/CoCrCuFeNi high entropy alloy coatings. Surf. Coat. Technol. 2015, 281, 109–116. [Google Scholar] [CrossRef]

- Guo, N.N.; Wang, L.; Luo, L.S.; Li, X.Z.; Chen, R.R.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Microstructure and mechanical properties of in-situ MC-carbide particulates-reinforced refractory high-entropy Mo0.5NbHf0.5ZrTi matrix alloy composite. Intermetallics 2016, 69, 74–77. [Google Scholar] [CrossRef]

- Moravcik, I.; Cizek, J.; Gavendova, P.; Sheikh, S.; Guo, S.; Dlouhy, I. Effect of heat treatment on microstructure and mechanical properties of spark plasma sintered AlCoCrFeNiTi0.5 high entropy alloy. Mater. Lett. 2016, 174, 53–56. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Lampke, T. Enhanced wear behaviour of spark plasma sintered AlCoCrFeNiTi high-entropy alloy composites. Materials 2018, 11, 2225. [Google Scholar] [CrossRef] [PubMed]

- Sakkaki, M.; Sadegh Moghanlou, F.; Vajdi, M.; Shahedi Asl, M.; Mohammadi, M.; Shokouhimehr, M. Numerical simulation of heat transfer during spark plasma sintering of zirconium diboride. Ceram. Int. 2020, 46, 4998–5007. [Google Scholar] [CrossRef]

- Ko, Y.G.; Shin, D.H.; Park, K.-T.; Lee, C.S. An analysis of the strain hardening behavior of ultra-fine grain pure titanium. Scr. Mater. 2006, 54, 1785–1789. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Fang, Q.; Liu, B.; Wu, Y.; Chen, S. Preparation of superfine-grained high entropy alloy by spark plasma sintering gas atomized powder. Intermetallics 2016, 68, 16–22. [Google Scholar] [CrossRef]

- Fan, Q.C.; Li, B.S.; Zhang, Y. The microstructure and properties of (FeCrNiCo)AlxCuy high-entropy alloys and their TiC-reinforced composites. Mater. Sci. Eng. A 2014, 598, 244–250. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, H.; Li, J.; Huang, J.; Xie, Z. Influence of aluminum content on the microstructure and properties of the in-situ TiC reinforced AlxFeCoNiCu high entropy alloy matrix composites. Mater. Sci. Eng. A 2019, 743, 540–545. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, H.; Li, J.; Huang, J.; Xie, Z. High entropy alloy FeCoNiCu matrix composites reinforced with in-situ TiC particles and graphite whiskers. Mater. Chem. Phys. 2018. [Google Scholar] [CrossRef]

- Rogal, Ł.; Kalita, D.; Litynska-Dobrzynska, L. CoCrFeMnNi high entropy alloy matrix nanocomposite with addition of Al2O3. Intermetallics 2017, 86, 104–109. [Google Scholar] [CrossRef]

- An, Q.; Wang, J.; Liu, Y.; Liu, B.; Guo, W.; Fang, Q.; Nie, Y. Effects of C and Mo on microstructures and mechanical properties of dual-phase high entropy alloys. Intermetallics 2019, 110. [Google Scholar] [CrossRef]

- Zhou, R.; Li, M.; Wu, H.; Liu, B.; Liu, Y. Effect of multi-component carbides on the mechanical behavior of a multi-element alloy. Mater. Sci. Eng. A 2019, 758, 99–102. [Google Scholar] [CrossRef]

- Inoue, A.T.A.A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Peng, Y.B.; Zhang, W.; Mei, X.L.; Wang, H.J.; Zhang, M.Y.; Wang, L.; Li, X.F.; Hu, Y. Microstructures and mechanical properties of FeCoCrNi-Mo high entropy alloys prepared by spark plasma sintering and vacuum hot-pressed sintering. Mater. Today Commun. 2020. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Basu, J.; Kashyap, S.; Pradeep, K.G.; Kottada, R.S. Thermal stability and grain boundary strengthening in ultrafine-grained CoCrFeNi high entropy alloy composite. Mater. Des. 2017, 134, 426–433. [Google Scholar] [CrossRef]

- Murty, B.S.; Ranganathan, S.J.M.R. Novel materials synthesis by mechanical alloying/milling. Int. Mater. Rev. 1998, 43, 101–141. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Wen, L.H.; Kou, H.C.; Li, J.S.; Chang, H.; Xue, X.Y.; Zhou, L. Effect of aging temperature on microstructure and properties of AlCoCrCuFeNi high-entropy alloy. Intermetallics 2009, 17, 266–269. [Google Scholar] [CrossRef]

- Wu, J.-M.; Lin, S.-J.; Yeh, J.-W.; Chen, S.-K.; Huang, Y.-S.; Chen, H.-C. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 2006, 261, 513–519. [Google Scholar] [CrossRef]

- Moravcikova-Gouvea, L.; Moravcik, I.; Omasta, M.; Vesely, J.; Cizek, J.; Minarik, P.; Cupera, J.; Zadera, A.; Jan, V.; Dlouhy, I. High-strength Al0.2Co1.5CrFeNi1.5Ti high-entropy alloy produced by powder metallurgy and casting: A comparison of microstructures, mechanical and tribological properties. Mater. Charact. 2020, 159, 752–757. [Google Scholar] [CrossRef]

- Yu, Y.; He, F.; Qiao, Z.; Wang, Z.; Liu, W.; Yang, J. Effects of temperature and microstructure on the triblogical properties of CoCrFeNiNbx eutectic high entropy alloys. J. Alloys Compd. 2019, 775, 1376–1385. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Liu, W.J.; Chen, Z.Y.; Xue, H.D.; He, J.C. Effect of elemental interaction on microstructure and mechanical properties of FeCoNiCuAl alloys. Mater. Sci. Eng. A 2012, 556, 395–399. [Google Scholar] [CrossRef]

- Zhuang, Y. Effect of Co element on microstructure and mechanical properties of FeCoXNiCuAl alloys.pdf. Acta Metallurgica Sinica 2012. [Google Scholar] [CrossRef]

- Kao, Y.-F.; Chen, T.-J.; Chen, S.-K.; Yeh, J.-W. Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloys Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Du, B.; Wang, X.; Zou, Z. Microstructure and tribological behavior of laser in situ synthesized TiC-reinforced Fe-based composite coatings. Tribol. Lett. 2011, 43, 295–301. [Google Scholar] [CrossRef]

- Zhou, Z.; Shan, Q.; Jiang, Y.; Li, Z.; Zhang, Z. Effect of nanoscale V2C precipitates on the three-body abrasive wear behavior of high-Mn austenitic steel. Wear 2019, 436–437. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Stott, F.H. High-temperature sliding wear of metals. Tribol. Int. 2002, 35, 489–495. [Google Scholar] [CrossRef]

| Fe | Co | Ni | Cu | Al | Ti | |

|---|---|---|---|---|---|---|

| C | −50 | −42 | −39 | −33 | −36 | −109 |

| Chemical Composition | Fe | Co | Ni | Cu | Al | Ti | C |

|---|---|---|---|---|---|---|---|

| FCC | 26.7 | 21.4 | 17.0 | 27.0 | 7.3 | - | - |

| BCC | 23.2 | 24.0 | 25.0 | 7.8 | 19.7 | - | - |

| TiC | 5.1 | 5.3 | 5.3 | 2.2 | 3.3 | 53.3 | 25.6 |

| Chemical Composition | Fe | Co | Ni | Cu | Al | Ti | C | O |

|---|---|---|---|---|---|---|---|---|

| TiC00 | 21.3 | 22.0 | 21.2 | 11.0 | 19.6 | - | - | 4.9 |

| TiC10 | 16.1 | 13.5 | 12.3 | 17.9 | 12.5 | 8.5 | 12.7 | 6.6 |

| TiC20 | 15.5 | 15.3 | 14.8 | 8.8 | 13.7 | 14.4 | 10.7 | 7.0 |

| TiC30 | 10.7 | 10.3 | 9.8 | 9.2 | 8.6 | 24.0 | 15.9 | 11.4 |

| Chemical Composition | Fe | Co | Ni | Cu | Al | Ti | C | O |

|---|---|---|---|---|---|---|---|---|

| TiC00 | 9.9 | 10.9 | 11.4 | 14.6 | 25.2 | - | - | 28.0 |

| TiC10 | 2.6 | 3.5 | 4.1 | 15.5 | 5.4 | 3.4 | 4.8 | 60.6 |

| TiC20 | 1.5 | 3.7 | 3.4 | 13.0 | 3.9 | 6.8 | 3.0 | 64.7 |

| TiC30 | 1.0 | 2.2 | 3.0 | 15.8 | 3.8 | 9.8 | 4.1 | 60.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, T.; Wu, H.; Zhou, R.; Zhang, N.; Yin, Y.; Liang, L.; Liu, Y.; Li, J.; Shan, Q.; Li, Q.; et al. Microstructures and Tribological Properties of TiC Reinforced FeCoNiCuAl High-Entropy Alloy at Normal and Elevated Temperature. Metals 2020, 10, 387. https://doi.org/10.3390/met10030387

Zhu T, Wu H, Zhou R, Zhang N, Yin Y, Liang L, Liu Y, Li J, Shan Q, Li Q, et al. Microstructures and Tribological Properties of TiC Reinforced FeCoNiCuAl High-Entropy Alloy at Normal and Elevated Temperature. Metals. 2020; 10(3):387. https://doi.org/10.3390/met10030387

Chicago/Turabian StyleZhu, Tie, Hong Wu, Rui Zhou, Ningyi Zhang, Yong Yin, Luxin Liang, Yong Liu, Jia Li, Quan Shan, Qingxiang Li, and et al. 2020. "Microstructures and Tribological Properties of TiC Reinforced FeCoNiCuAl High-Entropy Alloy at Normal and Elevated Temperature" Metals 10, no. 3: 387. https://doi.org/10.3390/met10030387

APA StyleZhu, T., Wu, H., Zhou, R., Zhang, N., Yin, Y., Liang, L., Liu, Y., Li, J., Shan, Q., Li, Q., & Huang, W. (2020). Microstructures and Tribological Properties of TiC Reinforced FeCoNiCuAl High-Entropy Alloy at Normal and Elevated Temperature. Metals, 10(3), 387. https://doi.org/10.3390/met10030387