Study on Grinding and Deformation Fracture Control of Cold Rolled Titanium Strip

Abstract

1. Introduction

2. Materials and Methods

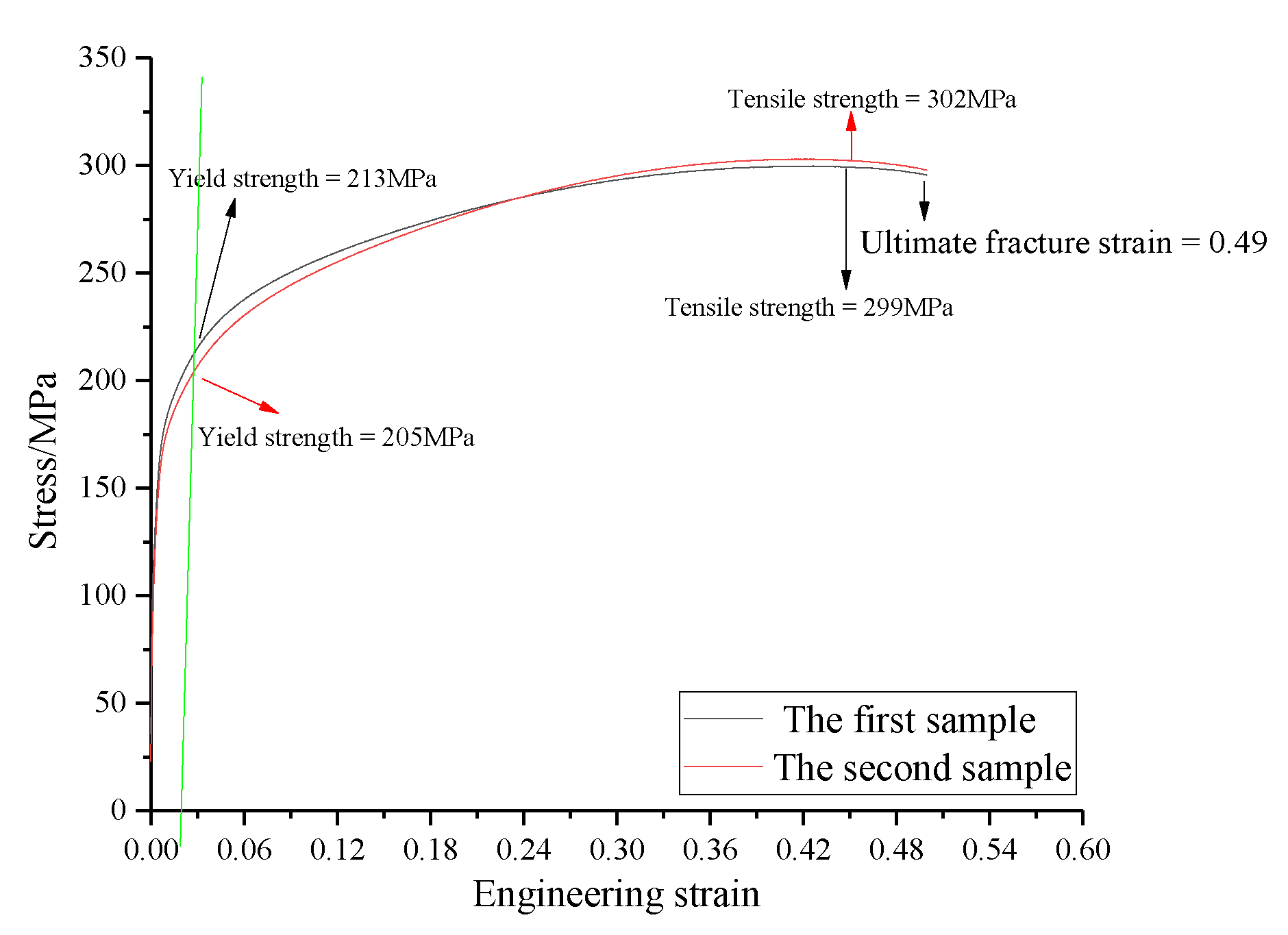

2.1. Cold Rolling and Physical Parameters

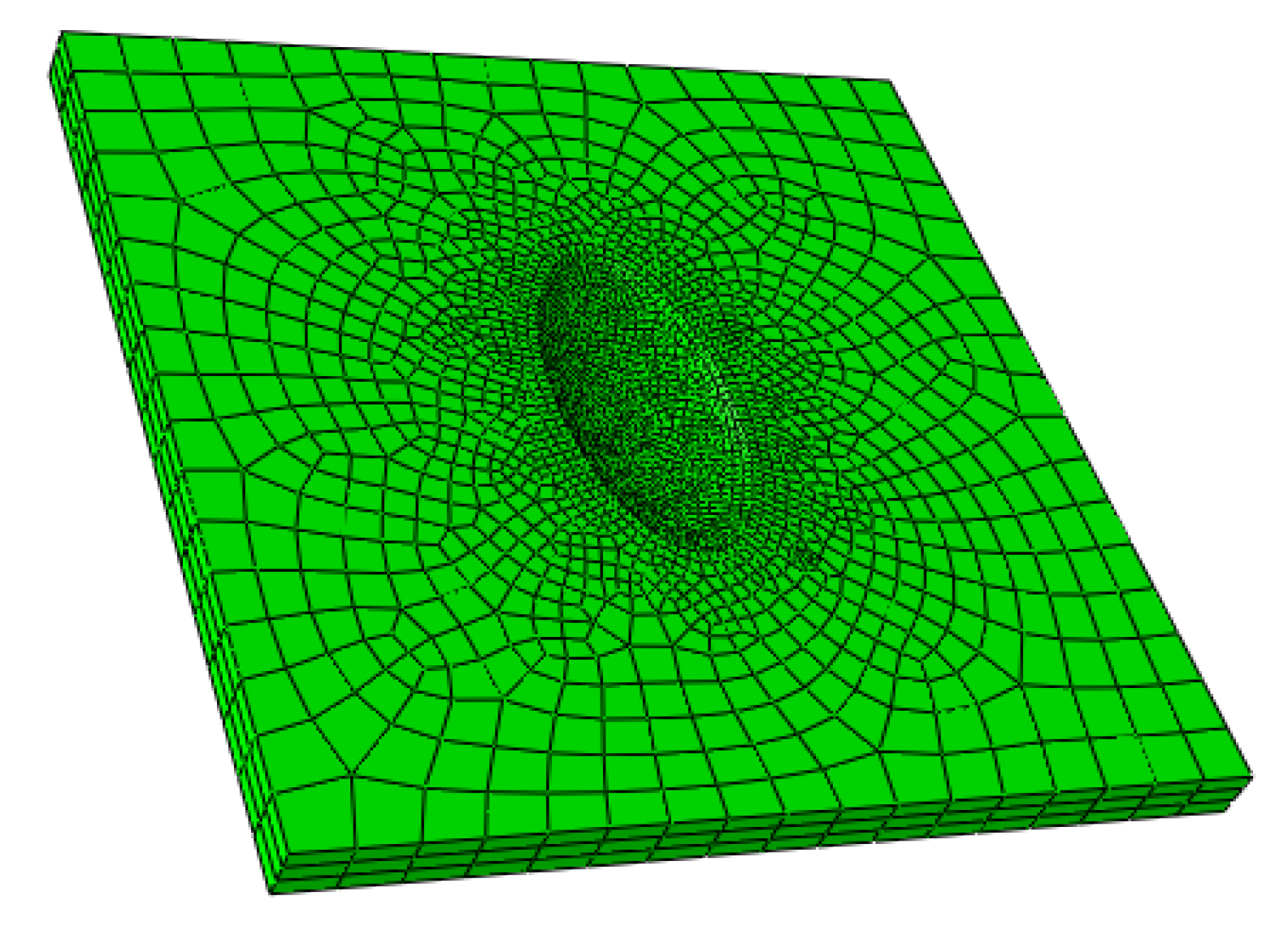

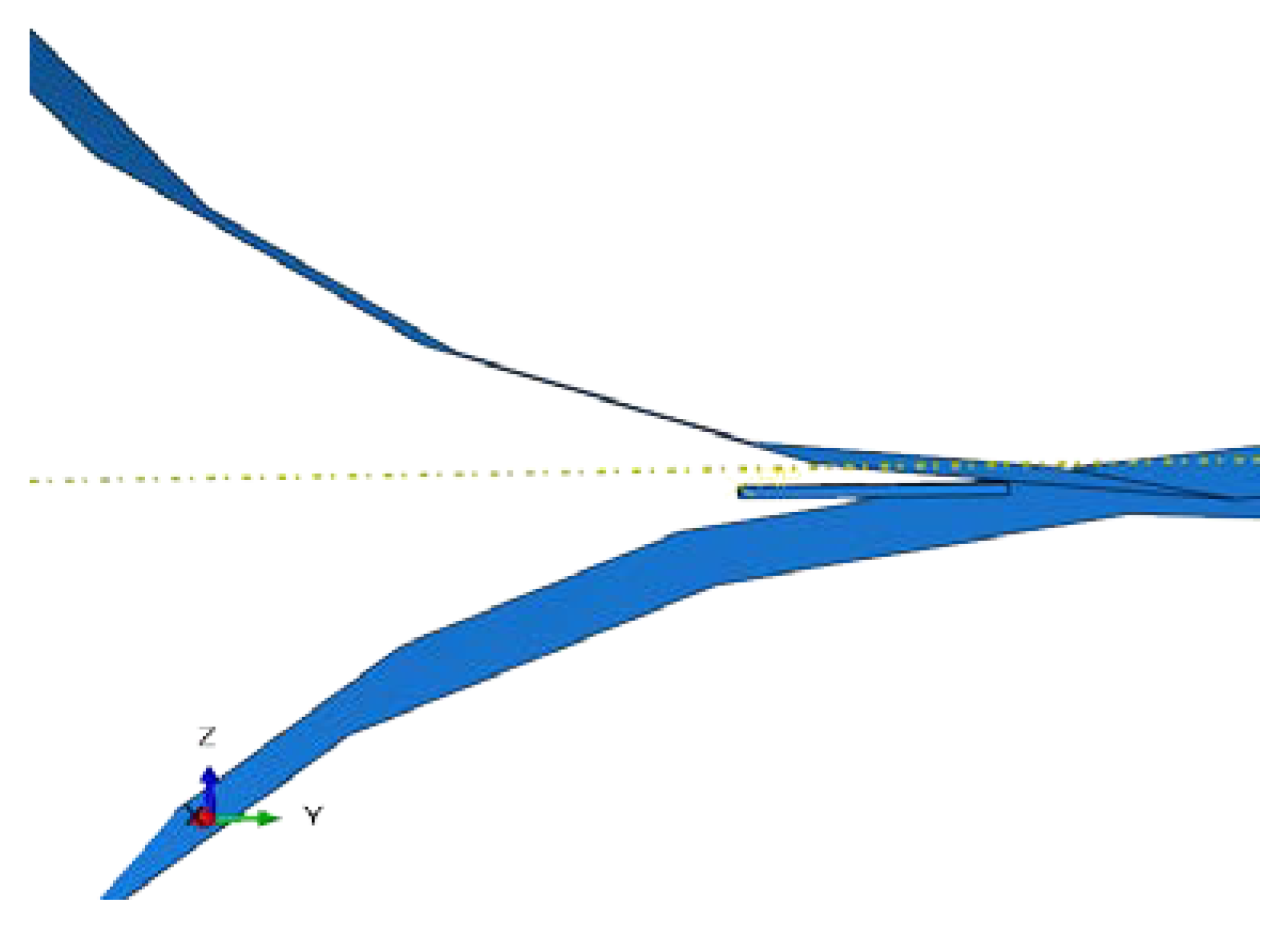

2.2. Mesh Generation and Geometric Model

2.3. Boundary and Initial Conditions

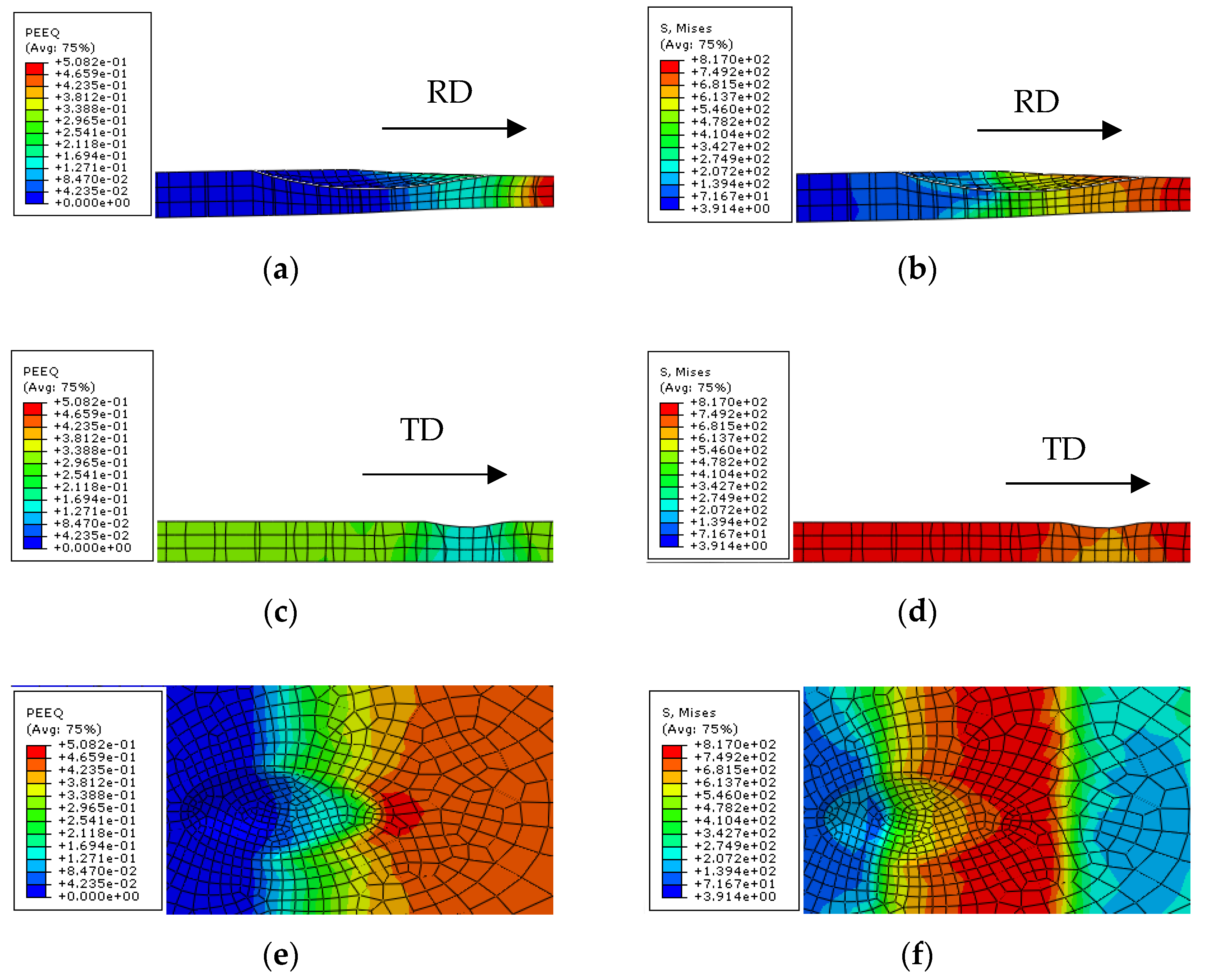

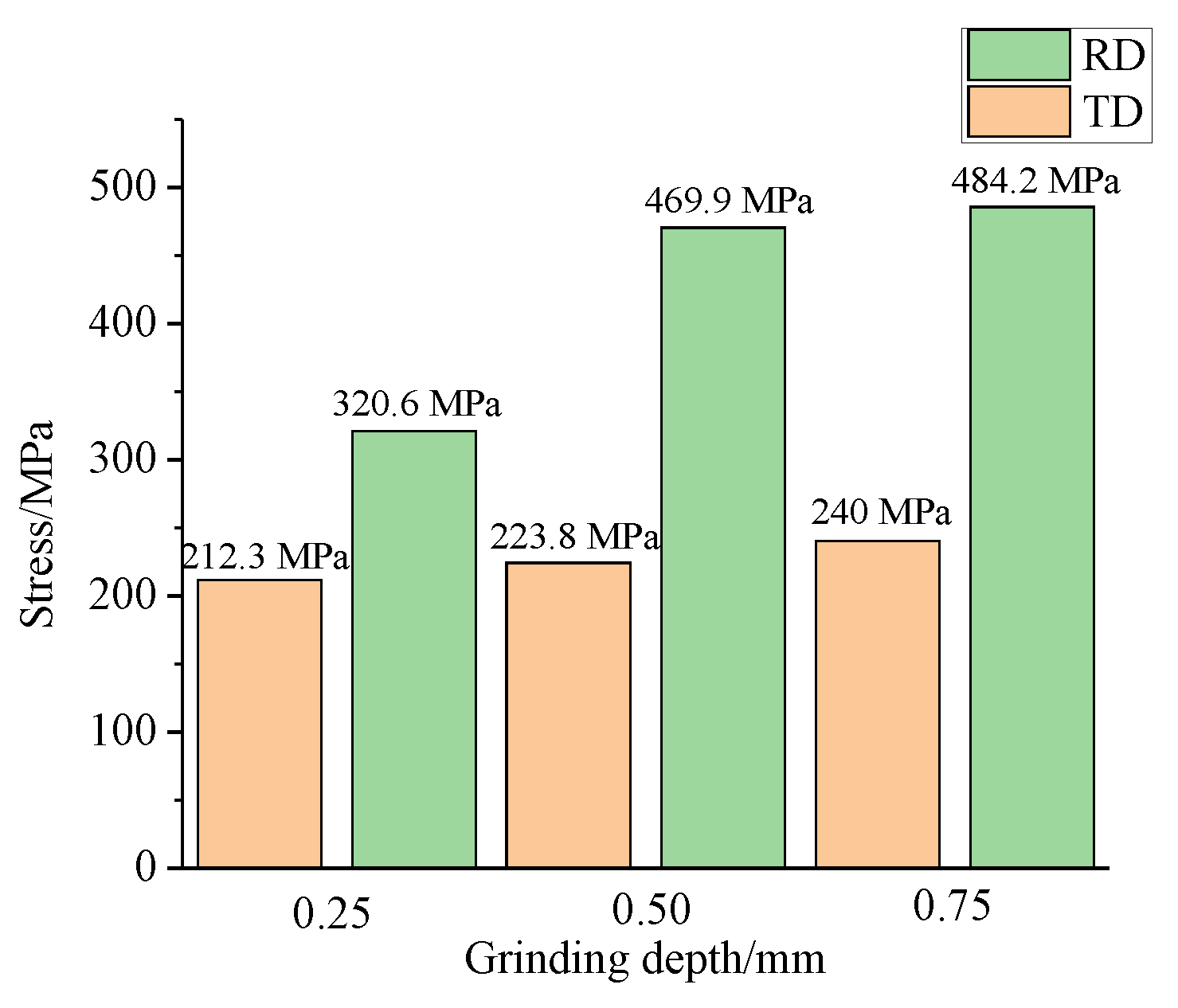

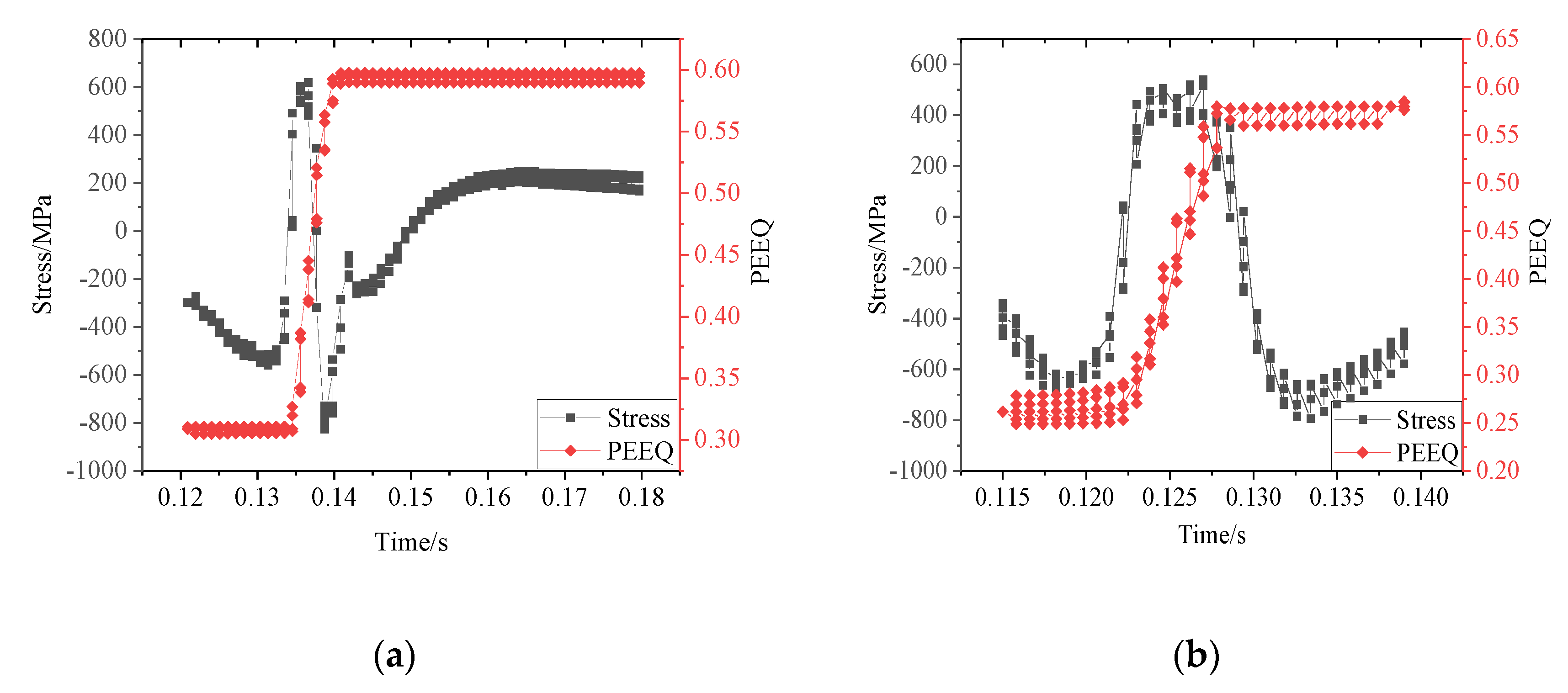

3. Results

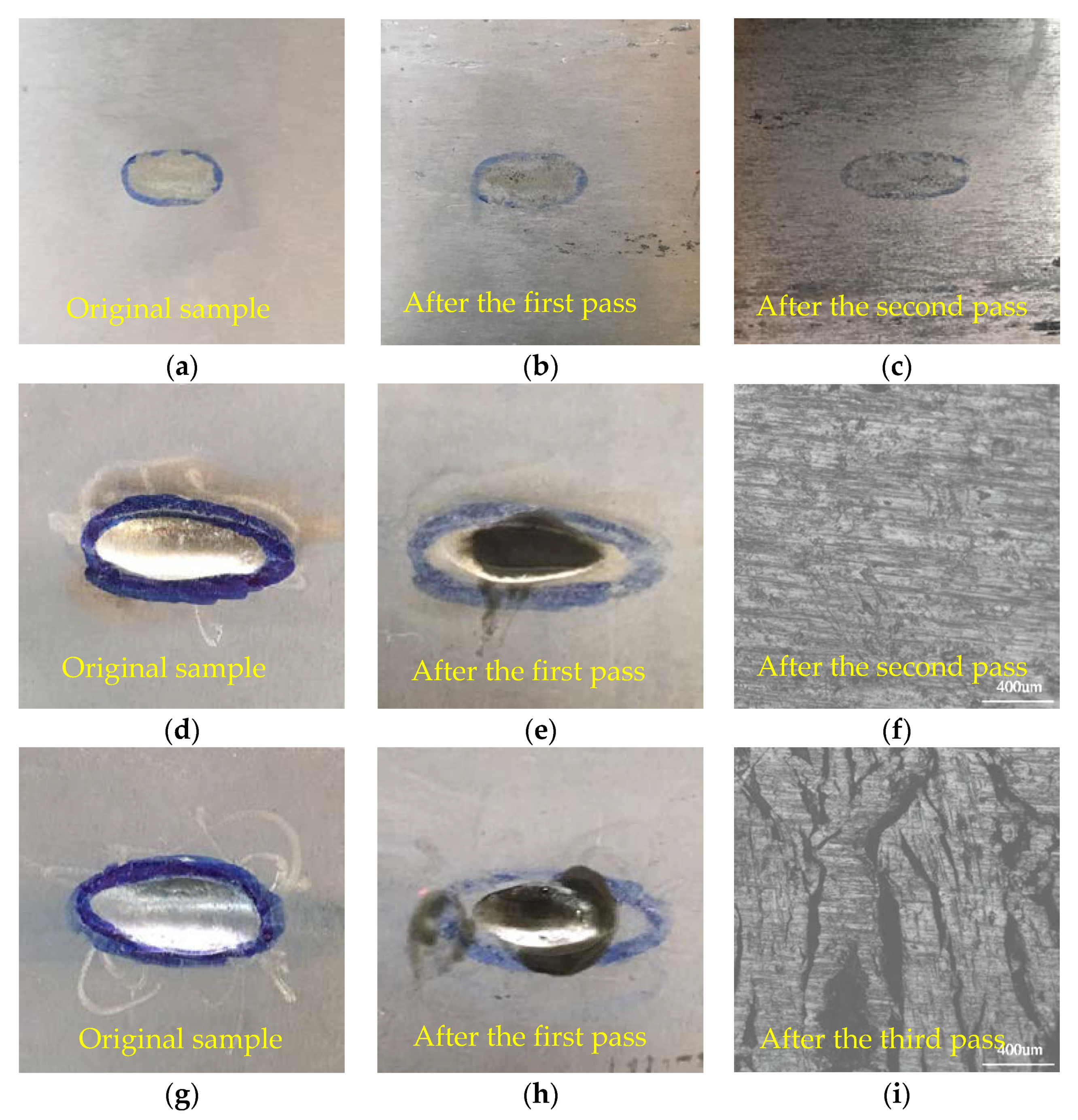

4. Cold-Rolling Test Verification

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hubert, C.; Dubar, L.; Dubar, M.; Dubois, A. Finite Element simulation of the edge-trimming/cold rolling sequence: Analysis of edge cracking. J. Mater. Process. Technol. 2012, 212, 1049–1060. [Google Scholar] [CrossRef]

- Lin, D.; Wang, L.; Meng, F.Q.; Cui, J.Z.; Le, Q.C. Effects of second phases on fracture behavior of Mg-10Gd-3Y-0.6Zr alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 421–425. [Google Scholar] [CrossRef]

- Kwon, H.C.; Lee, H.W.; Kim, H.Y.; Lm, Y.T.; Park, H.D.; Lee, D.L. Surface wrinkle defect of carbon steel in the hot bar rolling process. J. Mater. Process. Technol. 2009, 209, 4476–4483. [Google Scholar] [CrossRef]

- Zhao, J.W.; Huo, M.S.; Ma, X.G.; Jia, F.H.; Jiang, Z.Y. Study on edge cracking of copper foils in micro rolling. Mater. Sci. Eng. A 2019, 747, 53–62. [Google Scholar] [CrossRef]

- Zhou, Y.; Mo, J.L.; Cai, Z.B.; Deng, C.G.; Peng, J.F.; Zhu, M.H. Third-body and crack behavior in white etching layer induced by sliding–rolling friction. Tribol. Int. 2019, 140, 105882. [Google Scholar] [CrossRef]

- Chen, G.; Ren, C.Z.; Lu, L.P.; Ke, Z.H.; Qin, X.D.; Ge, X. Determination of ductile damage behaviors of high strain rate compression deformation for Ti-6Al-4V alloy using experimental numerical combined approach. Eng. Fract. Mech. 2018, 222, 499–520. [Google Scholar] [CrossRef]

- Wang, L.N.; Shi, Y.D.; Zhang, Y.L.; Bai, Y.; Lei, S. Ductile-to-brittle fracture of CP titanium with torsion deformation. Mater. Lett. 2018, 217, 263–266. [Google Scholar] [CrossRef]

- Yang, C.P.; Dong, H.B.; Hua, Z.H. Micro-mechanism of central damage formation during cross wedge rolling. J. Mater. Process. Technol. 2018, 252, 322–332. [Google Scholar] [CrossRef]

- Katani, S.; Madadi, F.; Atapour, M.; Rad, S.Z. Micromechanical modelling of damage behavior of Ti–6Al–4V. Mater. Des. 2013, 49, 1016–1021. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Analysis of the cup-cone fracture in a round tensile bar. Acta Metall. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Li, J.; Su, C.Y.; Lu, L.; Zhang, p.; Chang, L.; Miao, X.T.; Zhou, B.B.; He, X.H.; Zhou, C.Y. Investigation on fatigue crack growth behavior for commercial pure titanium at different crack tip plastic deformed levels. Theor. Appl. Fract. Mech. 2019, 100, 1–13. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zeng, W.D.; Zhao, Y.Q. Influence of Deformation Parameters on Fracture Mechanism of Ti40 Titanium Alloy. Rare Metal Mater. Eng. 2017, 46, 1207–1213. [Google Scholar]

- Briffod, F.; Bleuset, A.; Shiraiwa, T.; Enoki, M. Effect of crystallographic orientation and geometrical compatibility on fatigue crack initiation and propagation in rolled Ti-6Al-4V alloy. Acta Mater. 2019, 177, 56–67. [Google Scholar] [CrossRef]

- Ahmed, S.; Ahsan, Q.; Kurny, A.S.W. Effect of rolling on tensile and fracture of Al-4.5Cu-3.4Fe cast composite. J. Mater. Technol. 2007, 182, 215–219. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Zhou, Z.J.; Zhong, M.; Tan, J. Effect of hot rolling on the microstructure and fracture behavior of a bulk fine-grained W–Y2O3 alloy. Mater. Sci. Eng. A 2015, 646, 19–24. [Google Scholar] [CrossRef]

- Turczyn, S. The effect of the roll-gap shape factor on internal defects in rolling. J. Mater. Process. Technol. 1996, 60, 275–282. [Google Scholar] [CrossRef]

- Nioi, M.; Pinna, C.; Celotto, S.; Swart, E.; Farrugia, D.; Husain, Z.; Ghadbeigi, H. Finite element modelling of surface defect evolution during hot rolling of Silicon steel. J. Mater. Process. Technol. 2019, 268, 181–191. [Google Scholar] [CrossRef]

- Lemaitre, J. A continuous damage mechanics model for ductile fracture. J. Eng. Mater. Technol. Trans. ASME 1985, 107, 83–89. [Google Scholar] [CrossRef]

- Soyarslan, C.; Tekkaya, A.E. Prevention of internal cracks in forward extrusion by means of counter pressure: A numerical treatise. Steel Res. Int. 2009, 80, 671–679. [Google Scholar]

- Mashayekhi, M.; Torabian, N.; Poursina, M. Continuum damage mechanics analysis of strip tearing in a tandem cold rolling process. Simul. Model. Pract. Theory 2011, 19, 612–625. [Google Scholar] [CrossRef]

- Yan, Y.X.; Sun, Q.; Chen, J.J.; Pan, H.L. The initiation and propagation of edge cracks of silicon steel during tandem cold rolling process based on the Gurson–Tvergaard–Needleman damage model. J. Mater. Process. Technol. 2013, 213, 598–605. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, J.J.; Li, X.X.; Pan, H.L. Parametric Study of Edge Crack of Silicon Steel Strip in Cold Rolling based on a Shear Modified GTN Damage Model. Procedia Mater. Sci. 2014, 3, 1632–1637. [Google Scholar] [CrossRef][Green Version]

- Sun, Q.; Zan, D.Q.; Chen, J.J.; Pan, H.L. Analysis of edge crack behavior of steel sheet in multi-pass cold rolling based on a shear modified GTN damage model. Theor. Appl. Fract. Mech. 2015, 80, 259–266. [Google Scholar] [CrossRef]

- Dwivedi, S.; Rana, R.S.; Rana, A.; Rajpurohit, S.; Purohit, R. Investigation of damage in small deformation in hot rolling process using FEM. Mater. Today Proc. 2017, 4, 2360–2372. [Google Scholar] [CrossRef]

- Zhang, D.F.; Dai, Q.W.; Fang, L.; Xu, X.X. Prediction of edge cracks and plastic-damage analysis of Mg alloy sheet in rolling. Trans. Nonferrous Met. Soc. China 2011, 21, 1112–1117. [Google Scholar] [CrossRef]

- Xing, J.Z.; Li, J. ANSYS modeling method and mesh generation. China Water Transp. 2006, 9, 116–118. [Google Scholar]

| CP-Ti Strip | Roll | ||||

|---|---|---|---|---|---|

| Density (kg·m−3) | Elastic Modulus (MPa) | Poisson ratio | Size (m) | Length (m) | Diameter (m) |

| 4510 | 108,544 | 0.3 | 0.05 × 0.05 × 0.003 | 1.25 | 0.5 |

| σ | ε | σ | ε | σ | ε | σ | ε |

|---|---|---|---|---|---|---|---|

| 323 | 0 | 324 | 0 | 400 | 0 | 430 | 0 |

| 430 | 0.07 | 452 | 0.07 | 524 | 0.07 | 586 | 0.07 |

| 501 | 0.16 | 524 | 0.16 | 605 | 0.16 | 687 | 0.16 |

| 564 | 0.26 | 596 | 0.25 | 702 | 0.26 | 744 | 0.26 |

| 612 | 0.35 | 622 | 0.35 | 726 | 0.36 | 802 | 0.35 |

| 670 | 0.45 | 684 | 0.45 | 761 | 0.45 | 816 | 0.45 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Yu, W.; Dong, E.; Zhang, Z.; Shi, J.; Gong, G. Study on Grinding and Deformation Fracture Control of Cold Rolled Titanium Strip. Metals 2020, 10, 323. https://doi.org/10.3390/met10030323

Zhang J, Yu W, Dong E, Zhang Z, Shi J, Gong G. Study on Grinding and Deformation Fracture Control of Cold Rolled Titanium Strip. Metals. 2020; 10(3):323. https://doi.org/10.3390/met10030323

Chicago/Turabian StyleZhang, Jiaming, Wei Yu, Entao Dong, Zeyu Zhang, Jiaxin Shi, and Gaoxiang Gong. 2020. "Study on Grinding and Deformation Fracture Control of Cold Rolled Titanium Strip" Metals 10, no. 3: 323. https://doi.org/10.3390/met10030323

APA StyleZhang, J., Yu, W., Dong, E., Zhang, Z., Shi, J., & Gong, G. (2020). Study on Grinding and Deformation Fracture Control of Cold Rolled Titanium Strip. Metals, 10(3), 323. https://doi.org/10.3390/met10030323